Modified phenol-formaldehyde resin and applications thereof in anticorrosion coating

A phenolic resin, anti-corrosion coating technology, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., to achieve the effect of high bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

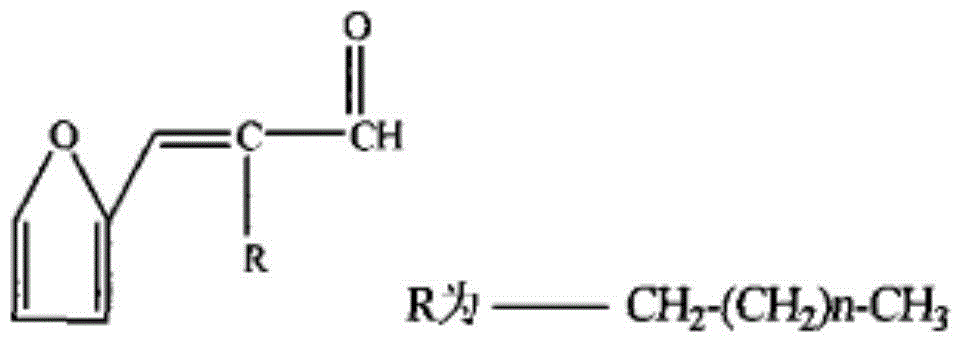

[0026] A, a, preparation of β-furan acrolein

[0027] Inject N into the mouth of the flask 2 For about 10 minutes, adjust the temperature of the water bath to 40°C, slowly add 20ml of furfural dropwise into the syringe and start the mixer to stir evenly. React for 3 hours, filter and wash with deionized water until neutral, and dry over anhydrous magnesium sulfate to obtain a reddish-brown oily transparent liquid, which is 3-furyl 2-ethylacrolein.

[0028] The prepared 3-furyl-2-ethyl-acrolein has a molecular weight of 150g / mol, a density of 1.079g / cm3, and a boiling range of 208-210°C.

[0029] B. Synthesis of modified phenolic resin

[0030] Equipped with reflux condenser, stirrer, thermometer and N 2 Add 37.6g of phenol and 0.3g of sodium hydroxide catalyst into the four-necked flask with gas inlet, heat to 150°C, and drop 30.0g of 3-furyl-2-ethyl-acrolein into the reaction system at a speed of 5 seconds / drop During the reaction, keep the temperature for 2 hours. After ...

Embodiment 2

[0037] A. Preparation of α, β-furan acrolein

[0038] Take 31ml of n-valeraldehyde in a four-neck flask, install a condensing device, and feed N into one mouth of the flask. 2 For about 10 minutes, adjust the temperature of the water bath to 45°C, add 2.0g of sodium hydroxide and slowly add 20ml of furfural dropwise, and start the mixer to stir evenly. React for 3 hours, filter and wash with deionized water until neutral, and dry over anhydrous magnesium sulfate to obtain a reddish-brown oily transparent liquid, which is 3-furyl-2-propylacrolein.

[0039] The prepared 3-furyl-2-propyl-acrolein has a molecular weight of 164g / mol, a density of 1.021g / cm3, and a boiling range of

[0040] 224~226℃.

[0041] B. Synthesis of modified phenolic resin

[0042] Equipped with reflux condenser, stirrer, thermometer and N 2 Add 28.2g of phenol and 0.7g of sodium carbonate catalyst into the four-necked flask with gas inlet, heat to 150°C, and drop 32.8g of 3-furyl-2-propyl-acrolein into...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com