Plant fiber reinforced alkali slag cementing material and preparation method thereof

A plant fiber and cementitious material technology, applied in solid waste management, sustainable waste treatment, climate sustainability, etc., can solve the problems of polluting the environment, occupying space, and the brittleness of alkali slag cementitious materials, and achieves low self-weight. , Improve ductility, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

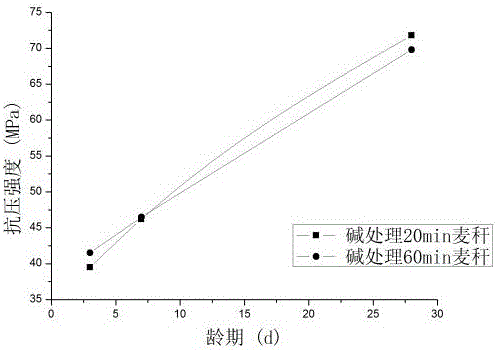

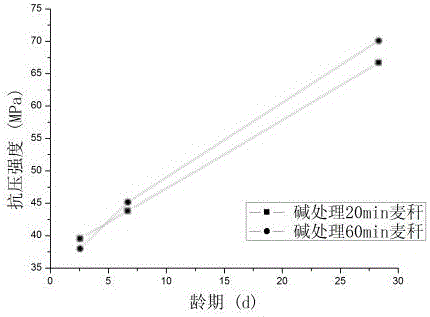

[0042] A kind of plant fiber reinforced alkali slag cementitious material and preparation method thereof, firstly, the treatment mode of plant fiber is alkali treatment, and described alkali treatment is to use the sodium hydroxide solution that mass fraction is 10% to soak plant fiber 20min or 60min, Then pass clear water once, and the treated plant fibers are placed in the shade to dry naturally, and the final moisture content can be used at 15%, and the plant fibers are respectively mixed into the alkali slag cementitious material.

Embodiment 2

[0044] According to the plant fiber reinforced alkali slag cementitious material and the preparation method thereof described in Example 1, the plant fibers include wheat straw, rice stalk, and corn stalk, and the alkali treatment is carried out for 20 minutes, and the wheat straw, rice stalk Stalk, corn stalk plant fiber moisture content is 16.8%, 14.8%, 17.4%, carry out described alkali treatment 60min, described wheat straw, rice stalk, corn stalk plant fiber moisture content are 14.2%, 15.1%, 14.4% .

Embodiment 3

[0046] According to the plant fiber reinforced alkali slag cementitious material and preparation method thereof described in embodiment 1, the described alkali slag cementitious material comprises the slag that the parts by weight are 1, the water glass that the parts by weight are 0.22, and the parts by weight are 0.05 sodium hydroxide, the water of 0.2 parts by weight;

[0047] Pour the weighed sodium hydroxide particles into the water glass and stir evenly with a glass stirring rod until the sodium hydroxide is completely dissolved and no white flocs are suspended in the solution, then place the prepared water glass in a cool, dry and ventilated place. Stand still for 1.5h to release the heat generated by dissolving sodium hydroxide until the temperature of the solution drops to normal temperature;

[0048] Put the weighed slag and plant fiber into the mixing pot, pour in the prepared water glass, then use the mixer to stir at a low speed for about 1 minute, slowly pour in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com