High-strength bus duct and manufacturing method thereof

A bus duct, high-strength technology, applied in the field of bus duct, can solve the problems of ground fault, easy to cause accidents, reduced current carrying capacity, etc., achieve good insulation performance and fire resistance, avoid accidents, and facilitate heat dissipation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

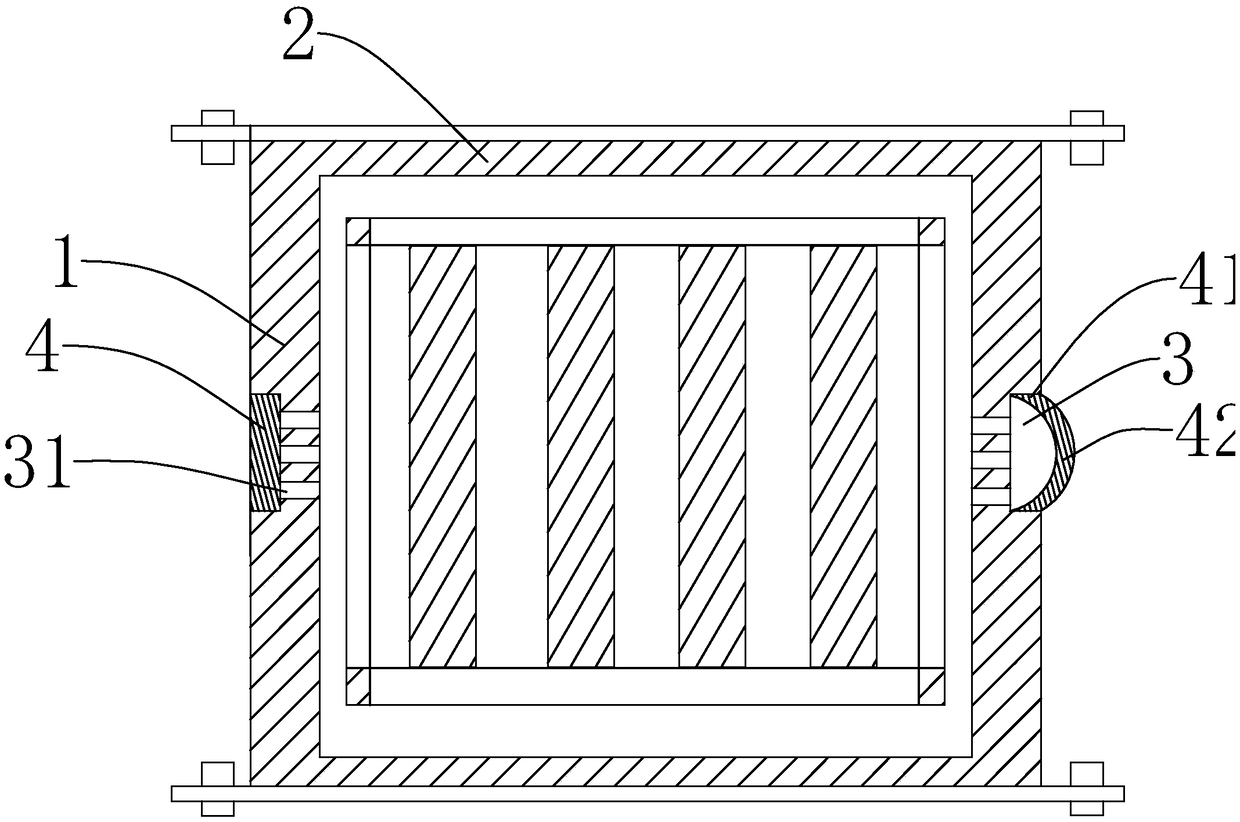

[0024] A high-strength bus duct and its preparation method provided by this embodiment, the structure is as follows figure 1 shown.

[0025] The high-strength busway includes a shell composed of a side plate 1 and a cover plate 2. A number of grooves 3 are opened on the outside of the side plate 1, and a bimetallic sheet 4 is arranged in the groove 3. The bimetallic sheet 4 includes a deformed part 42 and the connecting part 41 located at both ends, the connecting part 41 is hinged with the side wall of the groove 3, and the bimetal sheet 4 is a composite material composed of two or more metals or other materials with suitable properties. The thermal expansion coefficients of the component layers are different. When the temperature changes, the deformation of the active layer is greater than that of the passive layer, so that the whole of the bimetal sheet 4 will bend to the side of the passive layer, and the curvature of the composite material will change. produce deformatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com