Patents

Literature

1389results about How to "Quick repair" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

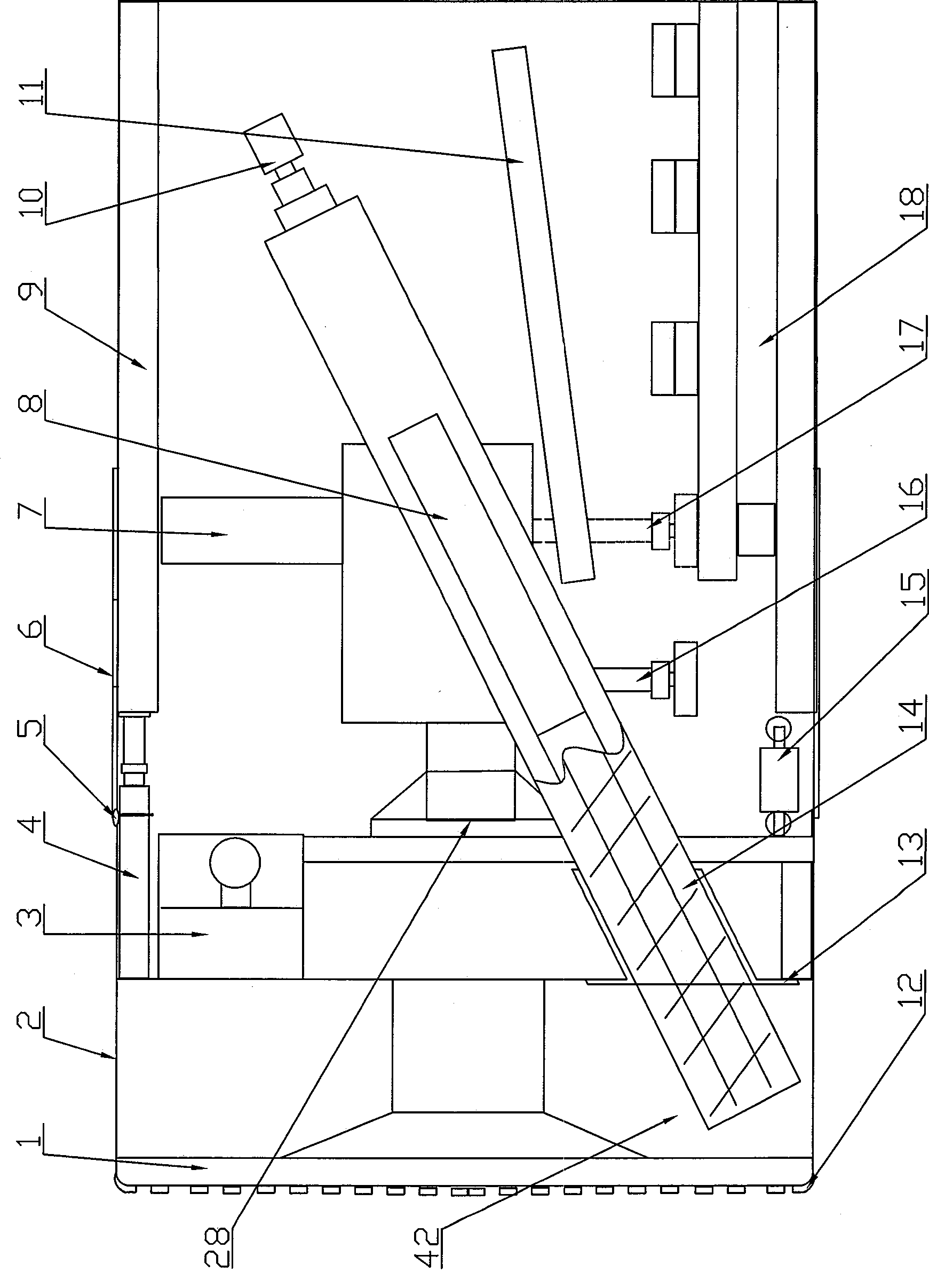

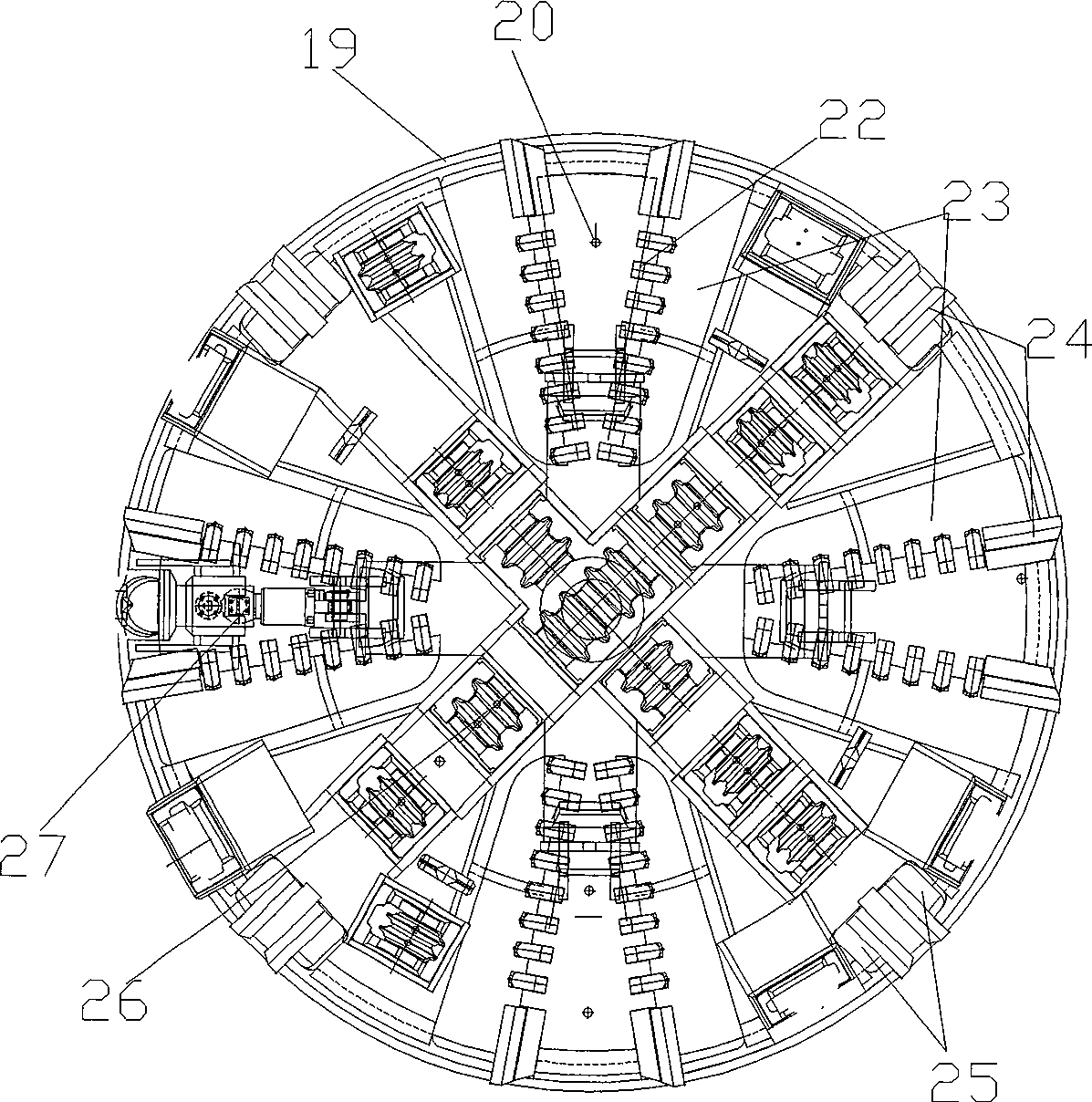

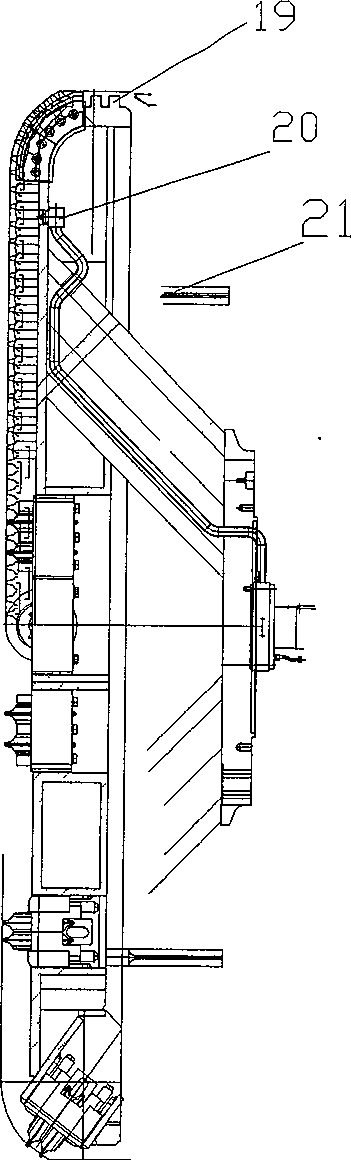

Composite shield structure suitable for bad ground construction

The invention provides a compound tunnel shield suitable for construction of complex formation, relating to an architectural construction machinery. The compound tunnel shield comprises a compound cutter head suitable for construction of soft soil formation, hard rock formation, formation with uneven hardness and compound formation with both soft soil and hard rock; 3 excavation modes adopting an open mode, a local atmospheric pressure mode or an excavated surface stabilization mode of an earth pressure balance mode according to different geological characteristics of the geology, and a ground conditioning system; the cutter head is respectively provided with a soft soil layer construction tool and a hard rock layer construction tool, cutters are changed to adapt to different formations in the process of the construction thereof; addition agent is injected into the cutter head surface, a soil chamber or a screw conveyer and the addition agent and muck are mixed by rotary stirring of the cutter head, the soil chamber or the screw conveyer to adapt to different formations through ground conditioning. The invention solves the problem of safe construction of the tunnel shield in soft soil, decomposed rock, formations with uneven hardness, sand layer and sand gravel formation, etc.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +1

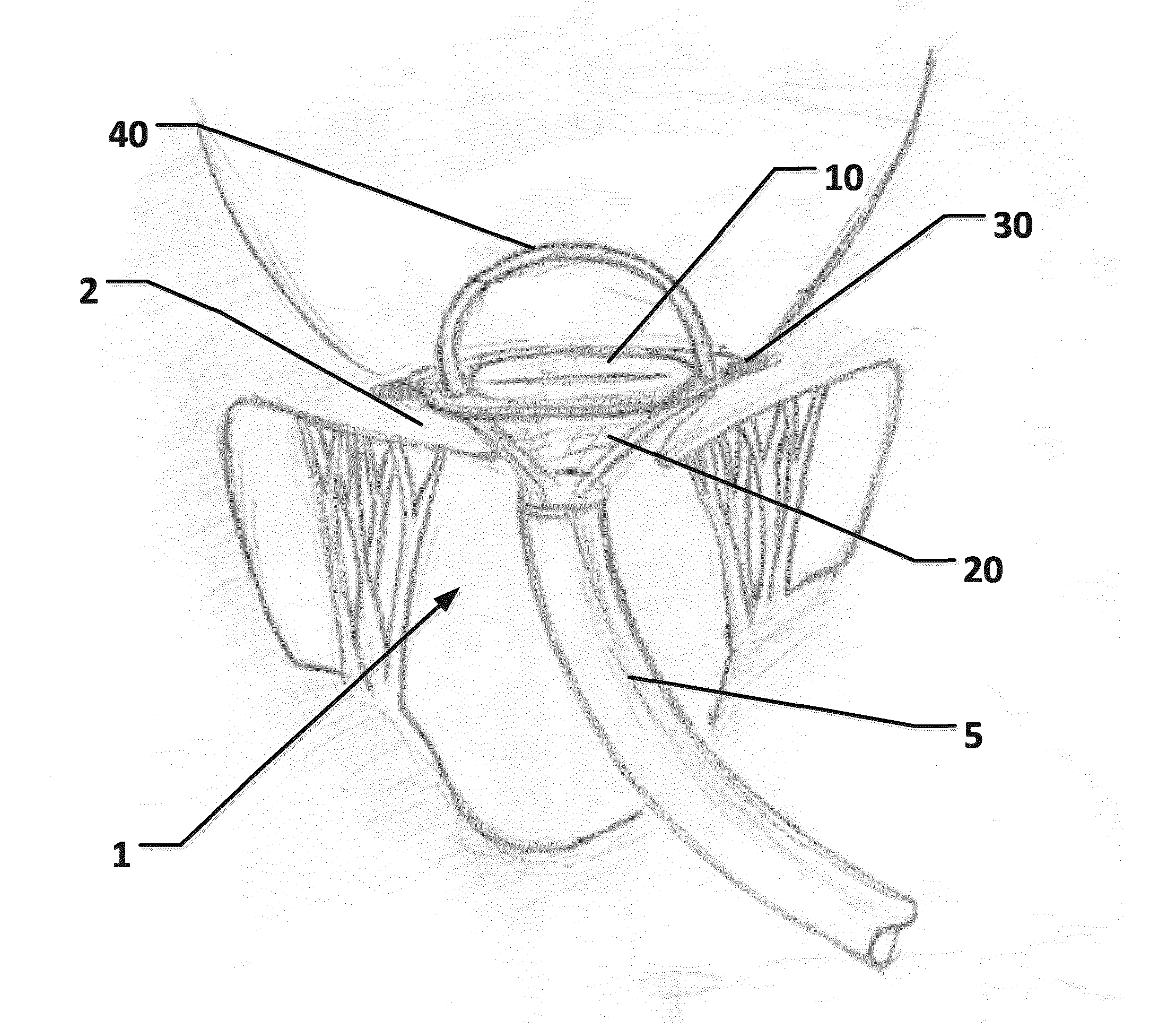

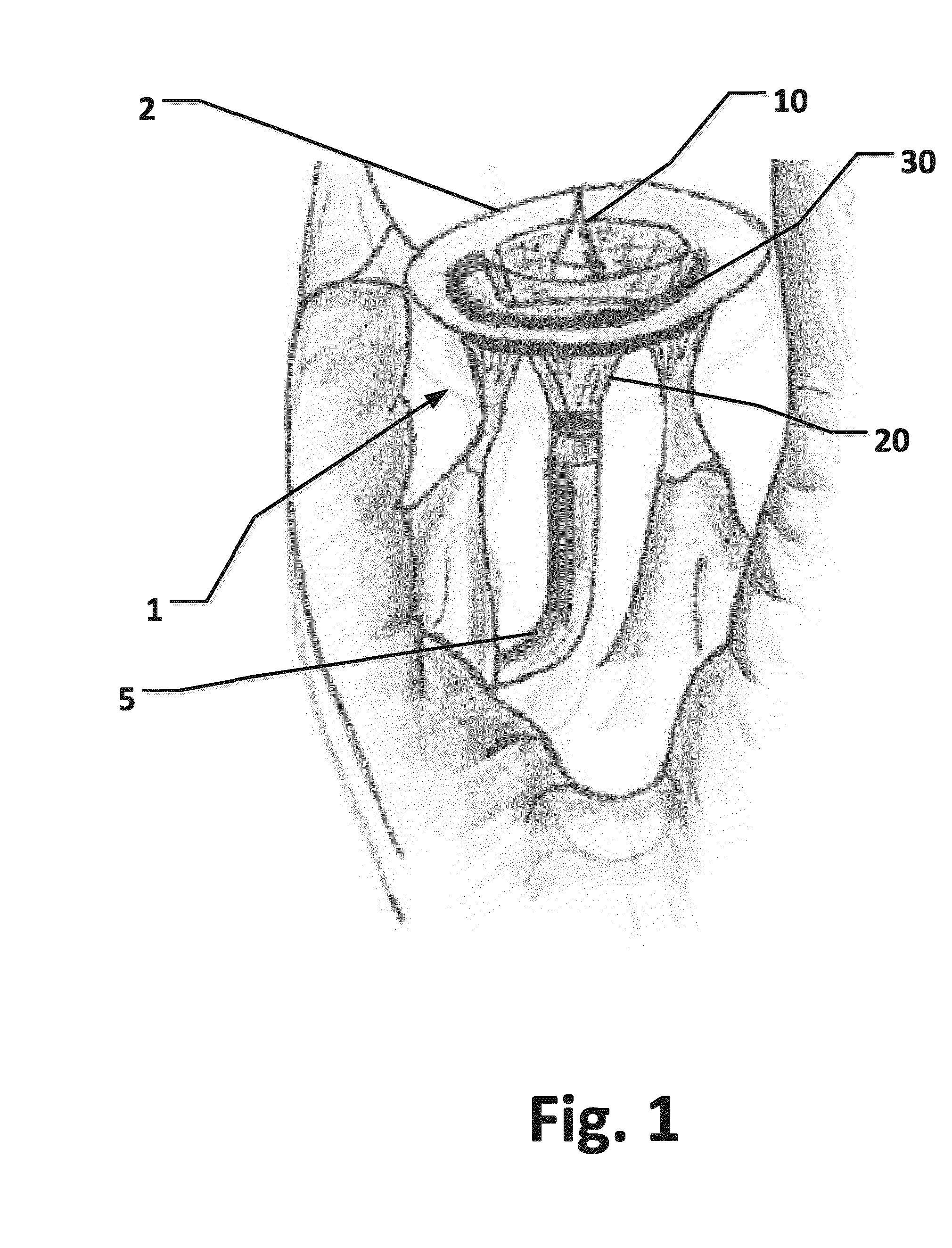

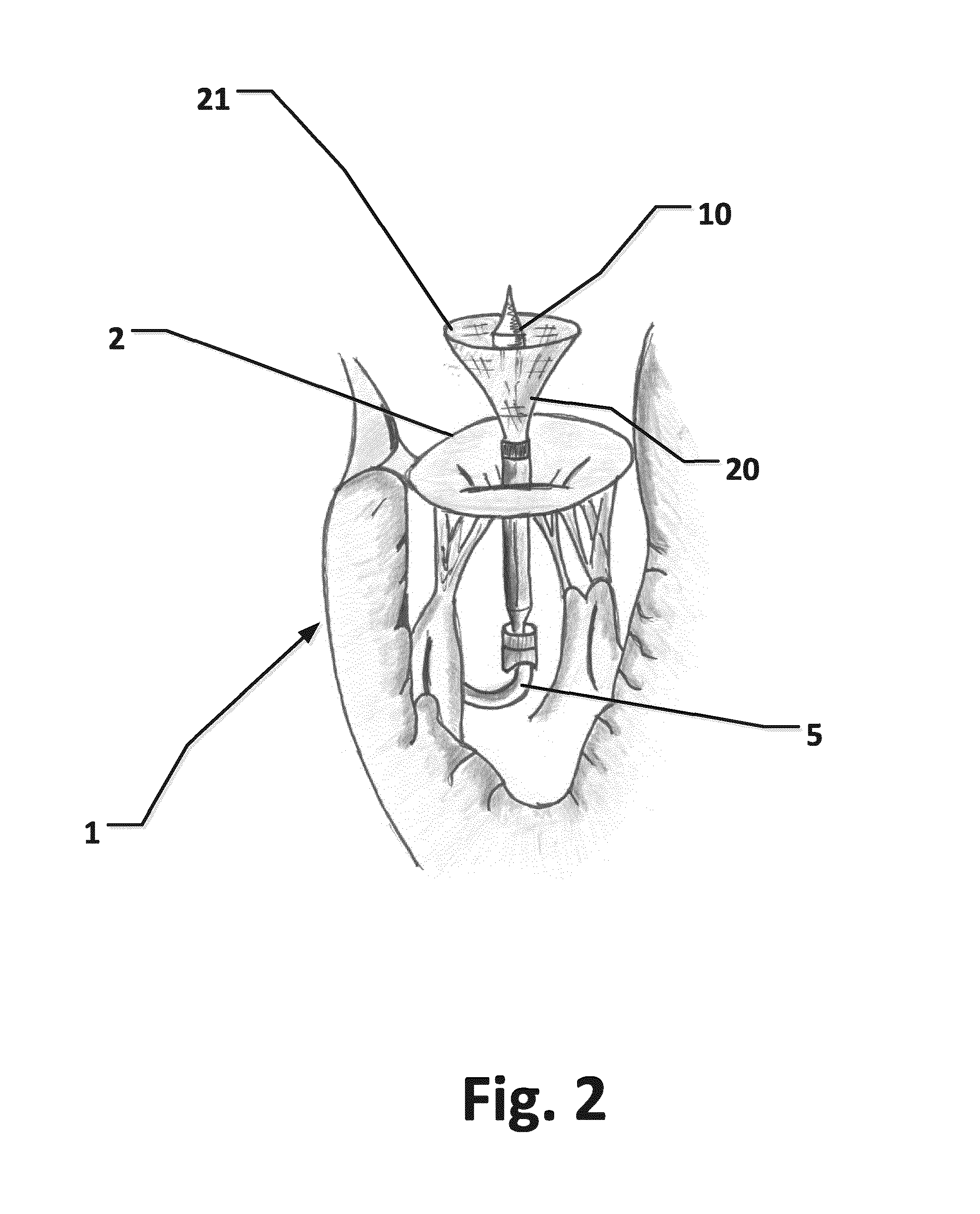

A System For Cardiac Valve Repair

ActiveUS20150351908A1Quick repairEasy orientationAnnuloplasty ringsSurgeryCommissureMitral valve flow

A medical system for repairing a mitral valve comprising a catheter (5) with a temporary valve (10), a commissure locator device (20), wherein the commissure locator device and the temporary valve are connected, and an annuloplasty implant (30).

Owner:HVR CARDIO OY

Geopolymer gel material for rush repairs and rush constructions

ActiveCN101628791AGood mechanical propertiesEasy constructionSolid waste managementCement productionSlagMetakaolin

The invention provides a geopolymer gel material for rush repairs and rush constructions, which is prepared by adding water to 13-17 percent by weight of exciting agent and 82-87 percent by weight of slag containing aluminosilicate. The slag comprises one or the combination of more of blast furnace slag, steel slag, coal ash and coal gangue, and the exciting agent comprises the following components in percentage by weight: 35-75 percent of SiO2, 0-55 percent of Na2O, 0-65 percent of K2O, 0-1 percent of CaO and 0-1 percent of SO3. The geopolymer gel material which has the characteristic of quick setting and hardening is prepared by using the industrial waste slag as a main raw material and matching the exciting agent, and the geopolymer gel material has excellent mechanical property and controllable setting time and can replace gel materials such as fast setting and hardening cement, and the like in the processes of rush repairs and rush constructions. The industrial solid wastes such as the blast furnace slag, the steel slag, the coal ash, the coal gangue, and the like containing the aluminosilicate series are used as main raw materials, metakaolin is not added and the raw materials do not need to be calcined, thus the invention has low energy consumption, less pollution, simple process, low cost, environmental protection and energy saving.

Owner:深圳市航天新材科技有限公司

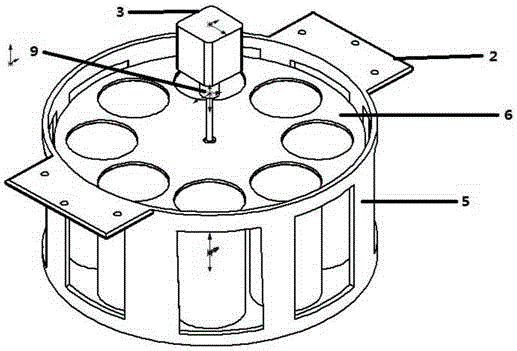

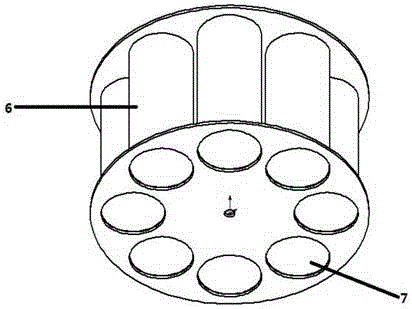

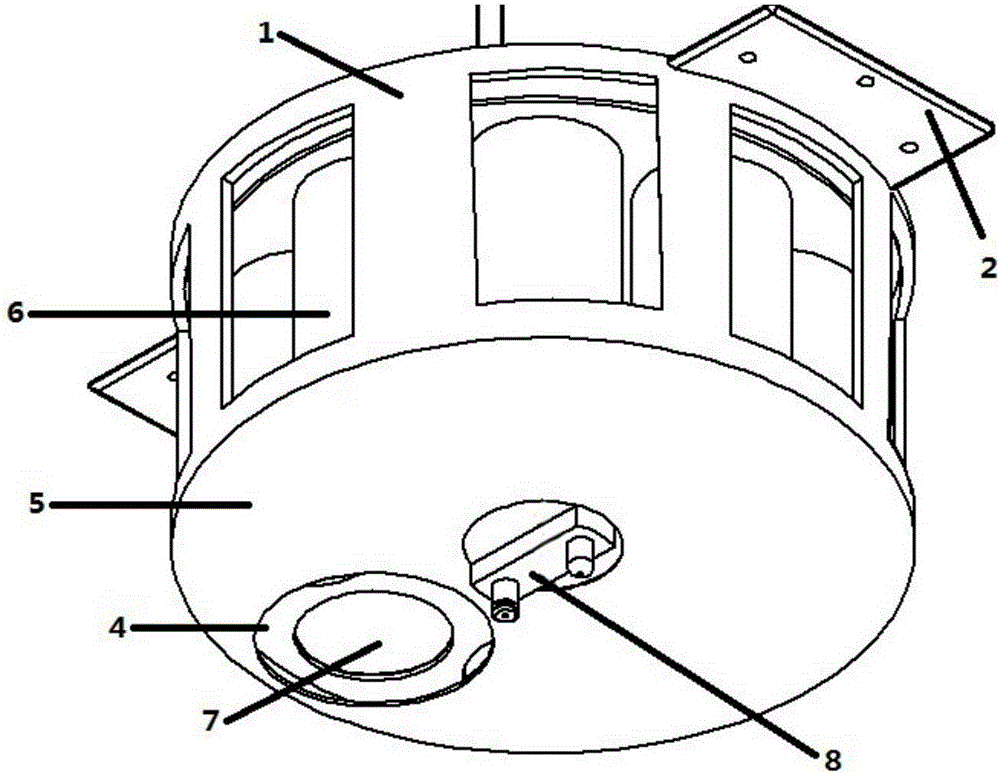

Dropping device for rotor craft

The invention discloses a dropping device for a rotor craft. The dropping device for the rotor craft comprises a dropping bin body, a fixed support, a motor and a dropping hole. The dropping bin body comprises a shell and an inner rotary table. A sighting device composed of a camera and a laser generator is mounted on the shell. The shell is cylindrical on the whole. The fixed support is mounted on a craft underframe. The shell is kept relatively static during working, and the shell and the inner rotary table are kept concentric. The dropping hole with the diameter being slightly larger than that of a carrying hole of the inner rotary table is distributed in the lower portion of the shell. The laser generator is mounted in the middle of the circle center of the lower bottom surface of the cylindrical shell. The dropping device for the rotor craft is small in size, low in manufacturing cost, capable of being dismounted and mounted conveniently and rapidly, convenient to maintain, capable of carrying a large number of articles, good in safety and stability and capable of achieving accurate air dropping; a large number of dropping devices can be prepared in actual use, unmanned aerial vehicle can move back and forth repeatedly, efficiency is improved, and cost is reduced.

Owner:BEIJING UNIV OF POSTS & TELECOMM

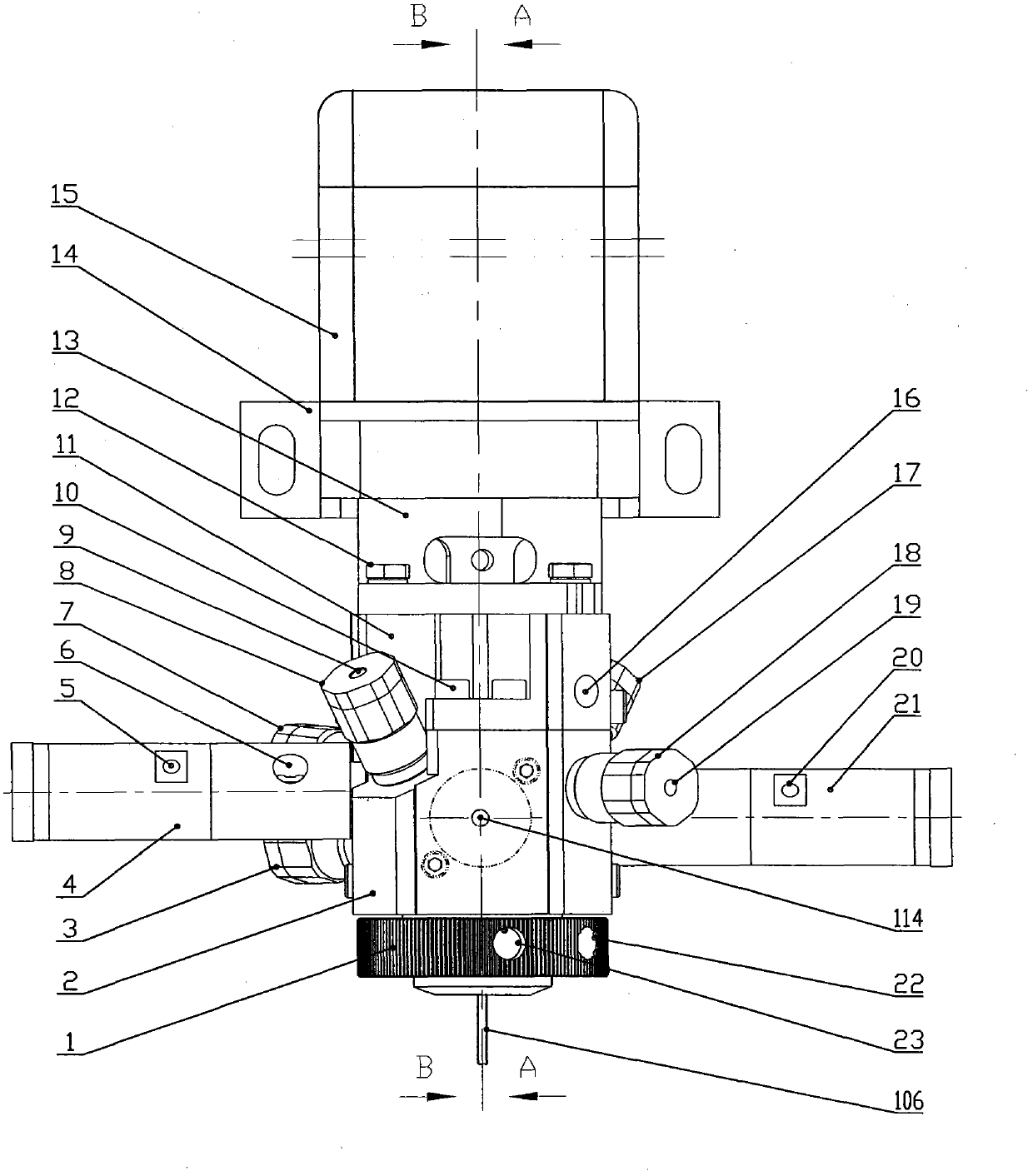

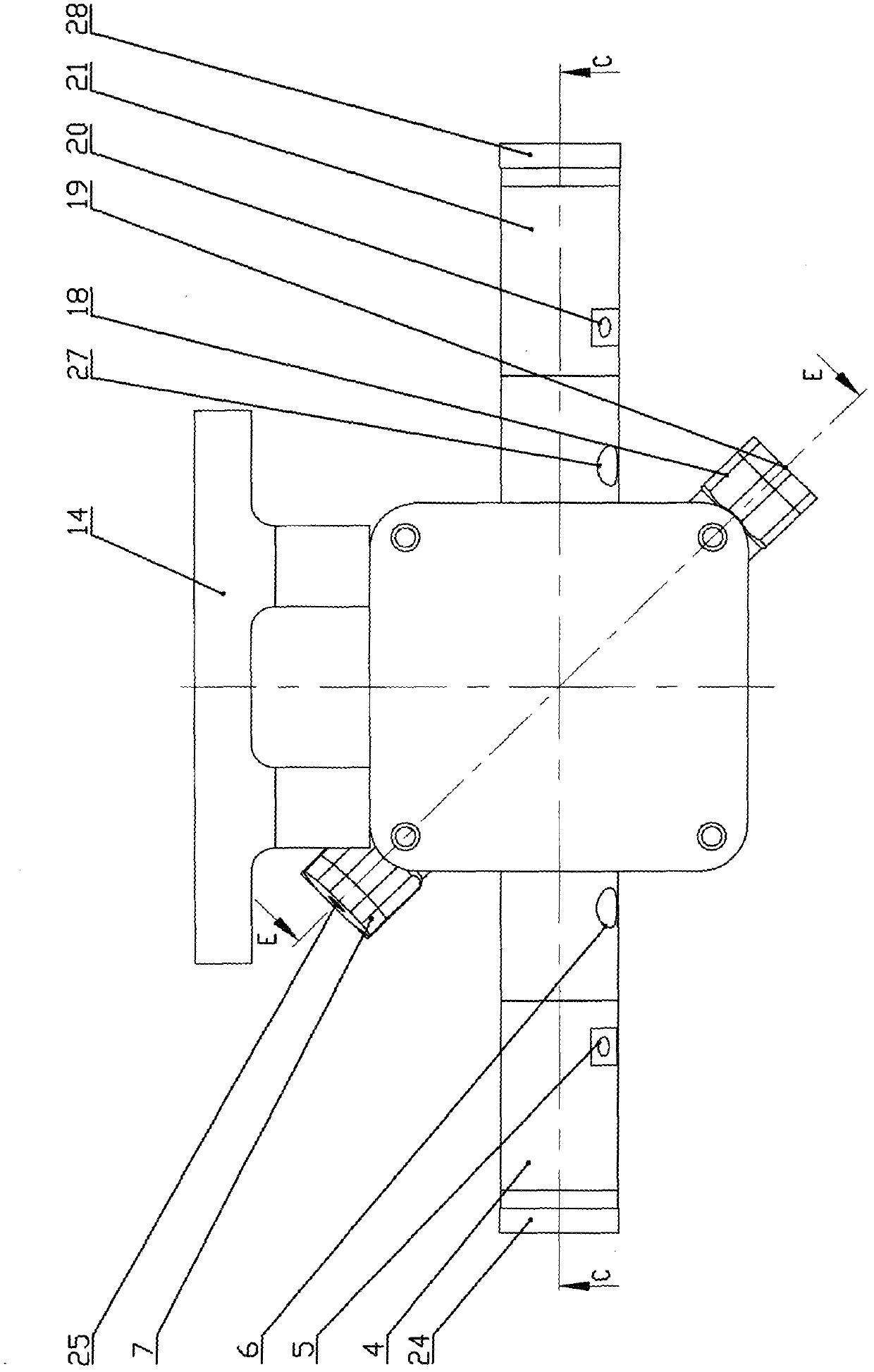

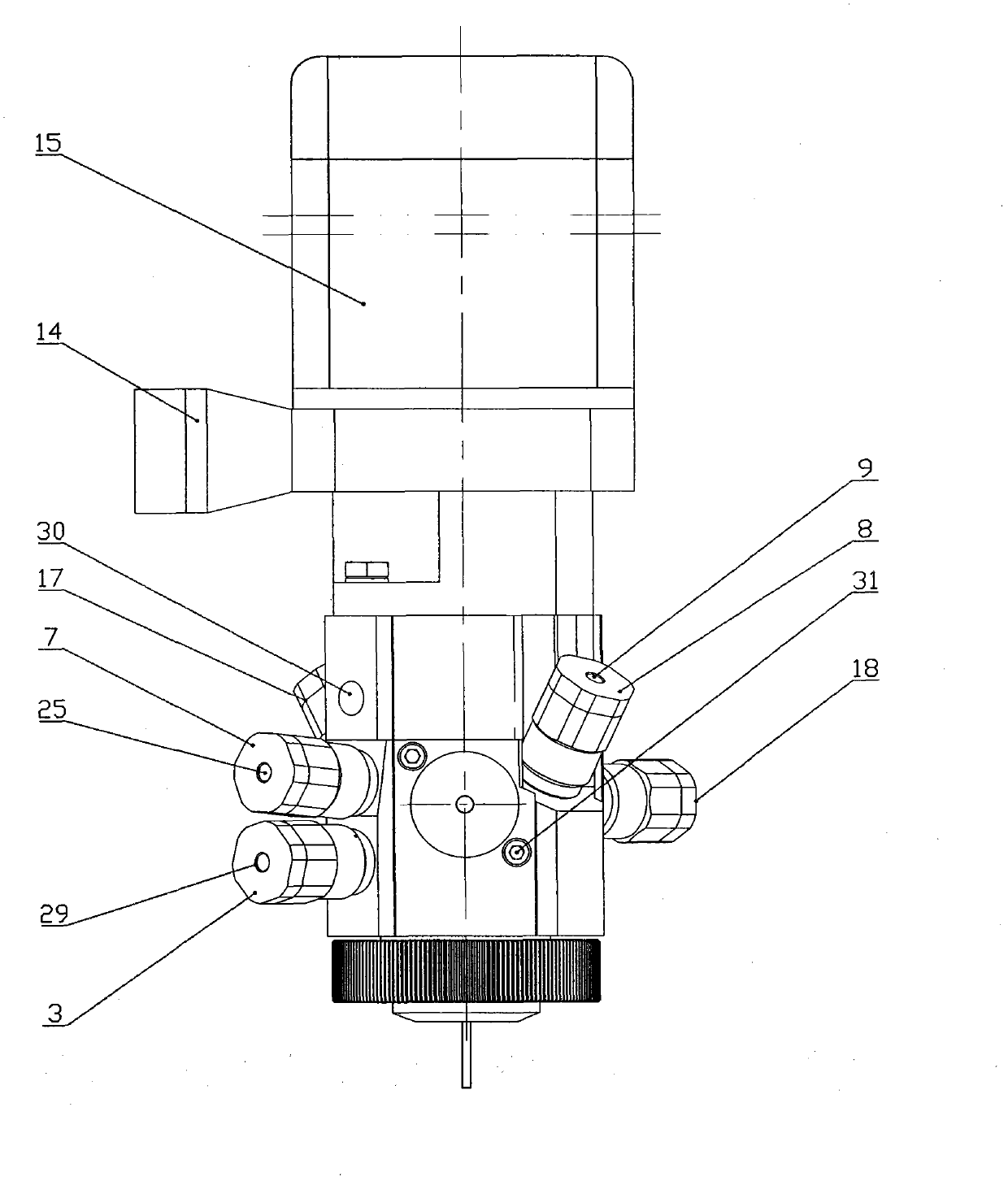

Water-cleaning gluing head for multi-component polyurethane needle valve

ActiveCN102601018ARemove threatEliminate pollutionLiquid surface applicatorsHollow article cleaningPhysical well beingEngineering

The invention relates to a water-cleaning gluing head for a multi-component polyurethane needle valve, in order to solve the problem that the traditional double-component polyurethane gluing head must be cleaned with a solvent and cannot be cleaned with water. The multi-component polyurethane water-cleaning gluing head comprises a motor, a transmission shaft, a stirring blade, a cup moving part, a valve base, a middle valve body, an upper valve body, a valve fixing plate, an component needle valve A, a component needle valve B, a water valve A, a water valve B, a water valve C, a water valve D and an air valve, wherein a cup base is connected with the valve base; a sealing ring A, a sealing ring B and a sealing ring C are mounted on an outer ring of a moving cup body; a check ring, a sealing circle and a sealing ring are mounted on an inner ring of the moving cup body; and a fixing sleeve is mounted between an ending opening on the cup base and the valve base. The manner of cleaning with water and then cleaning with compressed air is realized; the cleaning time is shortened; the threat to the health of operators and the environmental pollution caused by the solvent are eliminated; the structure is simple and compact; the mounting is convenient; the repairing is quick; and the stability is increased.

Owner:DALIAN HUAGONG INNOVATION TECH

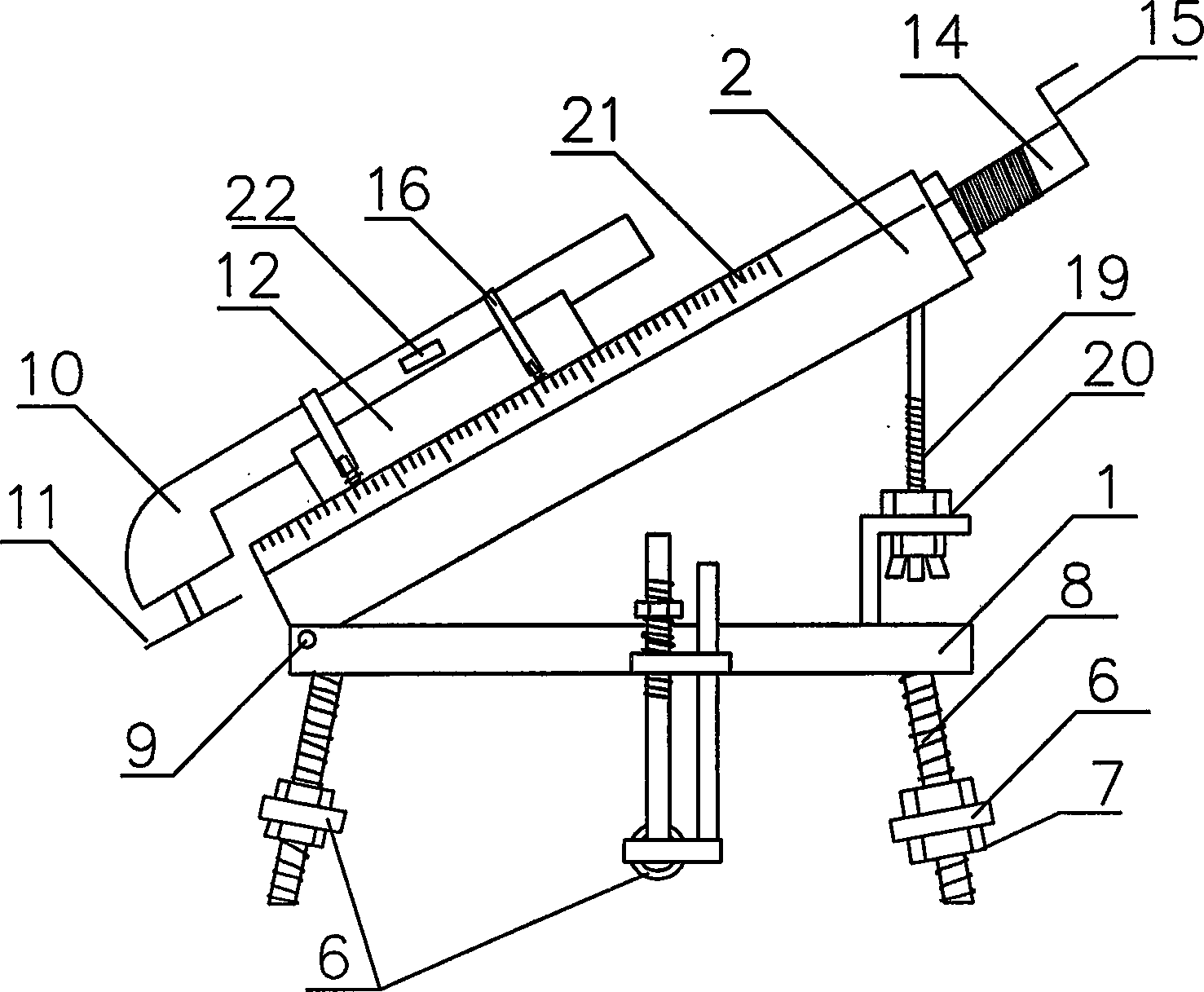

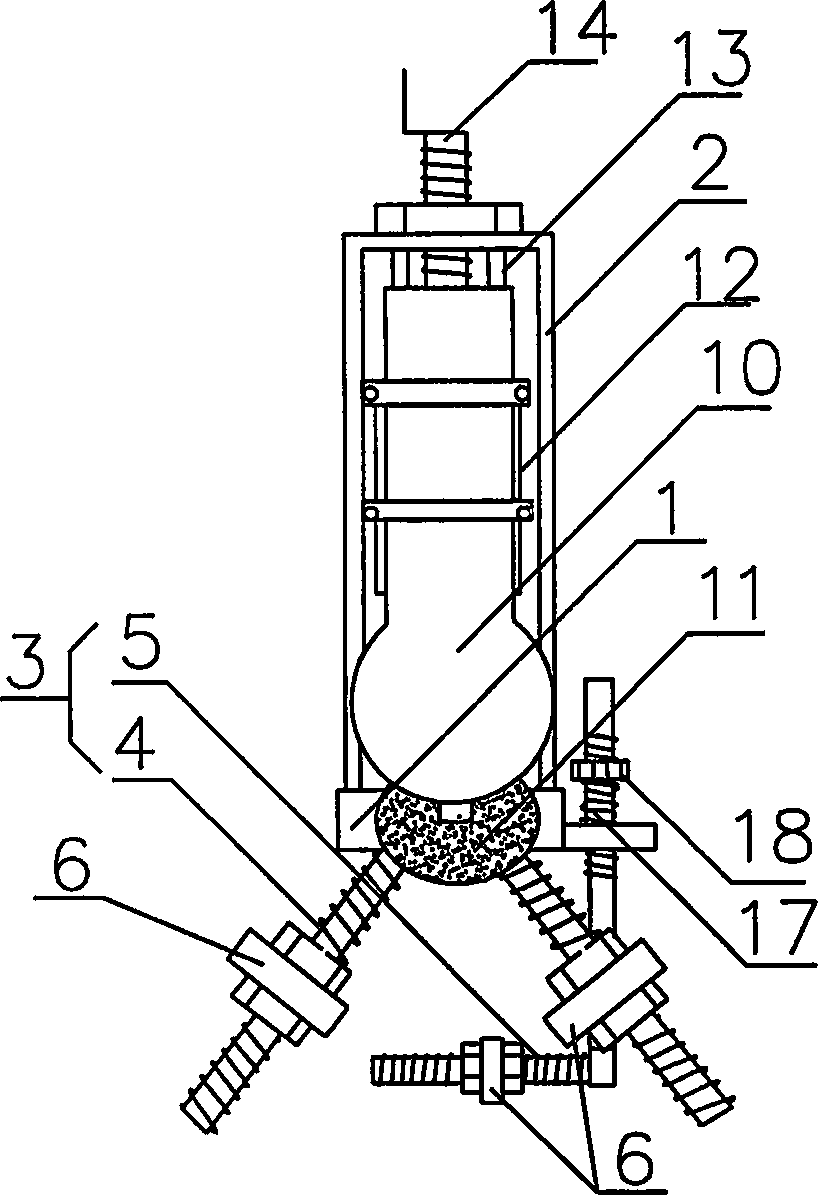

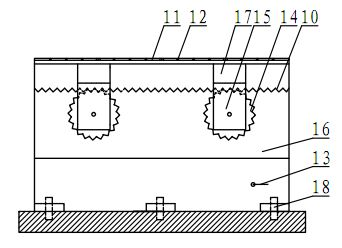

Technique for repairing surface damage on piston rod of hydraulic ram, and dedicated repairing tools

InactiveCN1872488AQuick fixQuick repairSpherical surface grinding machinesArc welding apparatusHydraulic cylinderHydraulic ram

A technology for repairing the surface damage of piston rod for hydraulic cylinder includes such steps as treating the surface at damaged position, build-up welding for filling the damaged recess, grinding and polishing. Its repair tool is composed of the hinged slide frame and grinding frame, an electric grinder with grinding wheel and fixed to the said grinding frame and a clamping arm with roller and arranged on said slide frame.

Owner:崔学斌

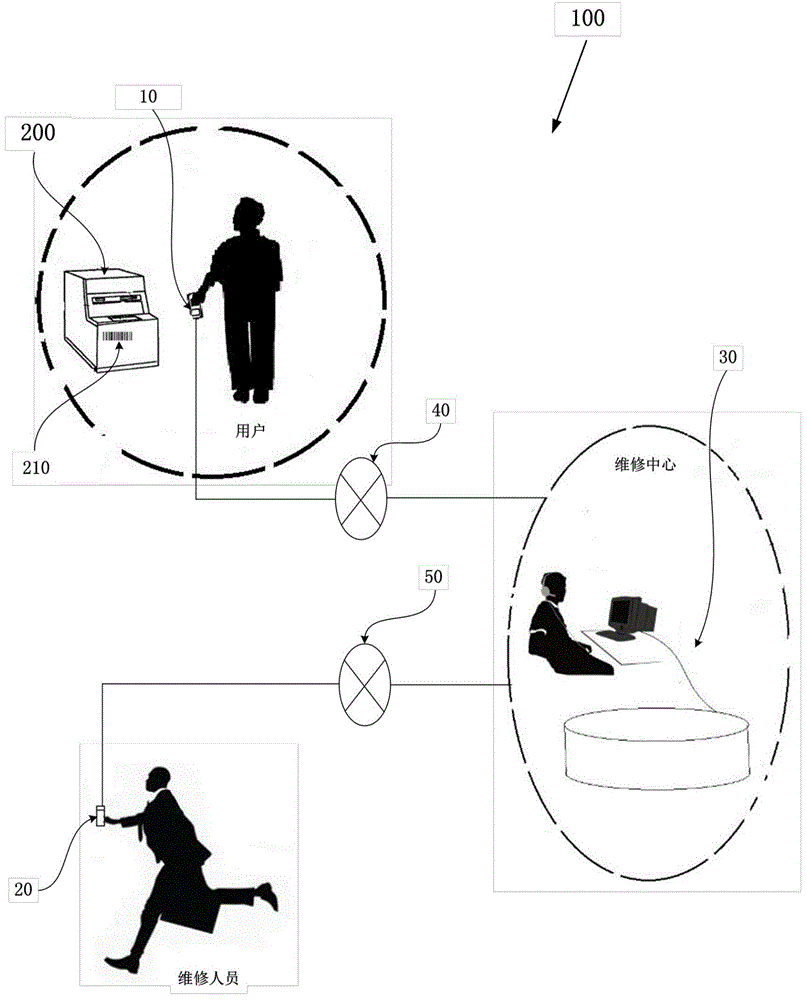

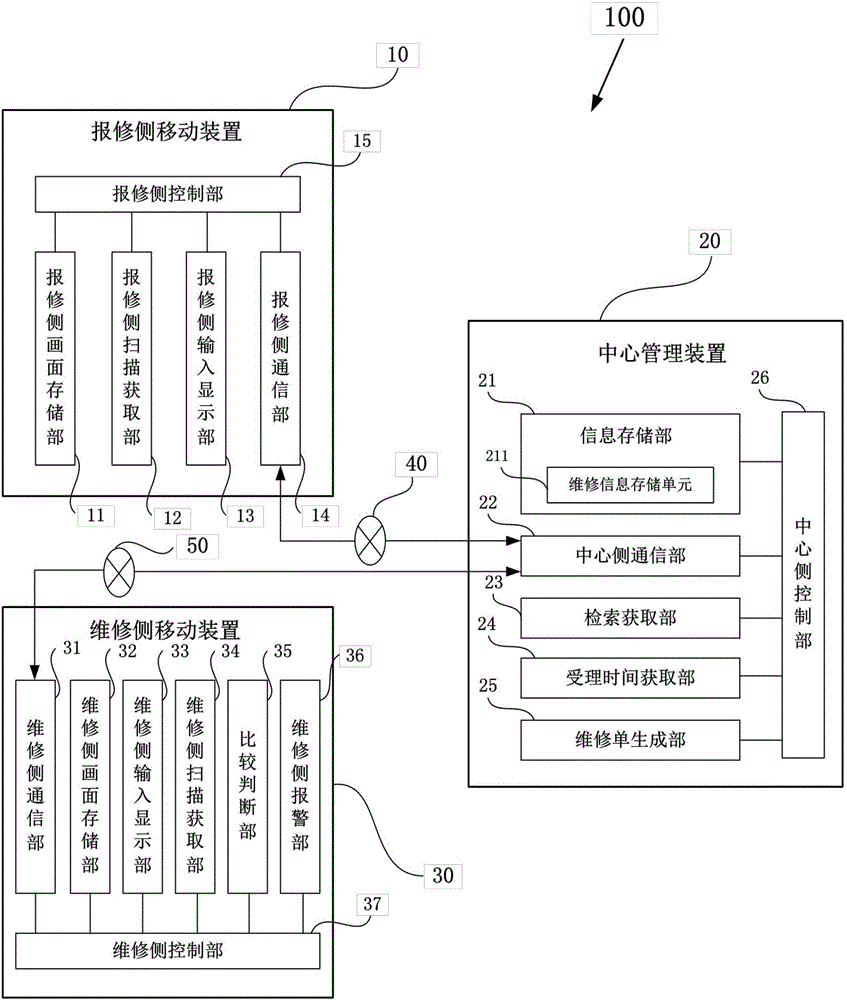

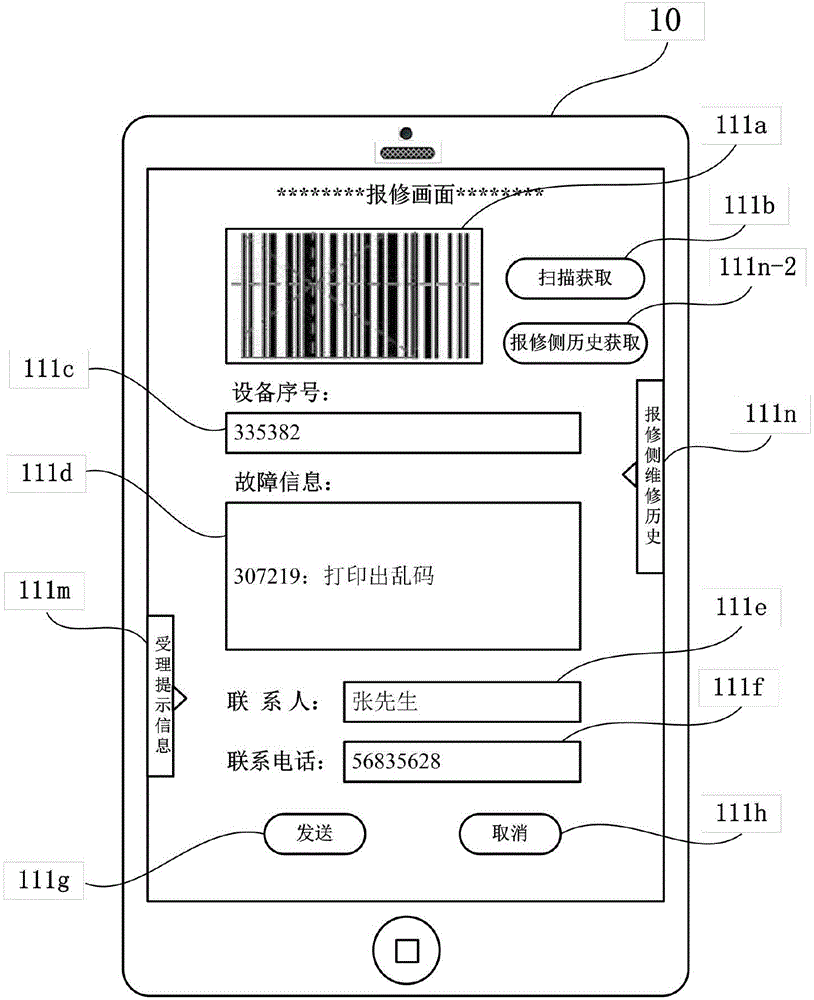

Maintenance service system

InactiveCN104091245AAccurate repairRealize the whole process of electronicResourcesService systemService provider

The invention provides a maintenance service system. A user requests maintenance according to identification codes arranged on user equipment by a maintenance service provider, and maintenance personnel of the maintenance service provider maintain and manage the equipment through the identification codes. The maintenance service system is characterized by comprising a maintenance requesting side moving device, a center management device and a maintenance side moving device, wherein the maintenance requesting side moving device is held by the user and used for requesting maintenance for the equipment, the center management device is in communication connection with the maintenance requesting side moving device and arranged on a maintenance center of the maintenance server provider, and the maintenance side moving device is in communication connection with the center management device, held by the maintenance personnel, and used for maintaining and managing the equipment to be maintained. According to the maintenance service system, the user can request maintenance rapidly and accurately, and the whole maintenance service process achieves electronization.

Owner:上海佳图软件有限公司

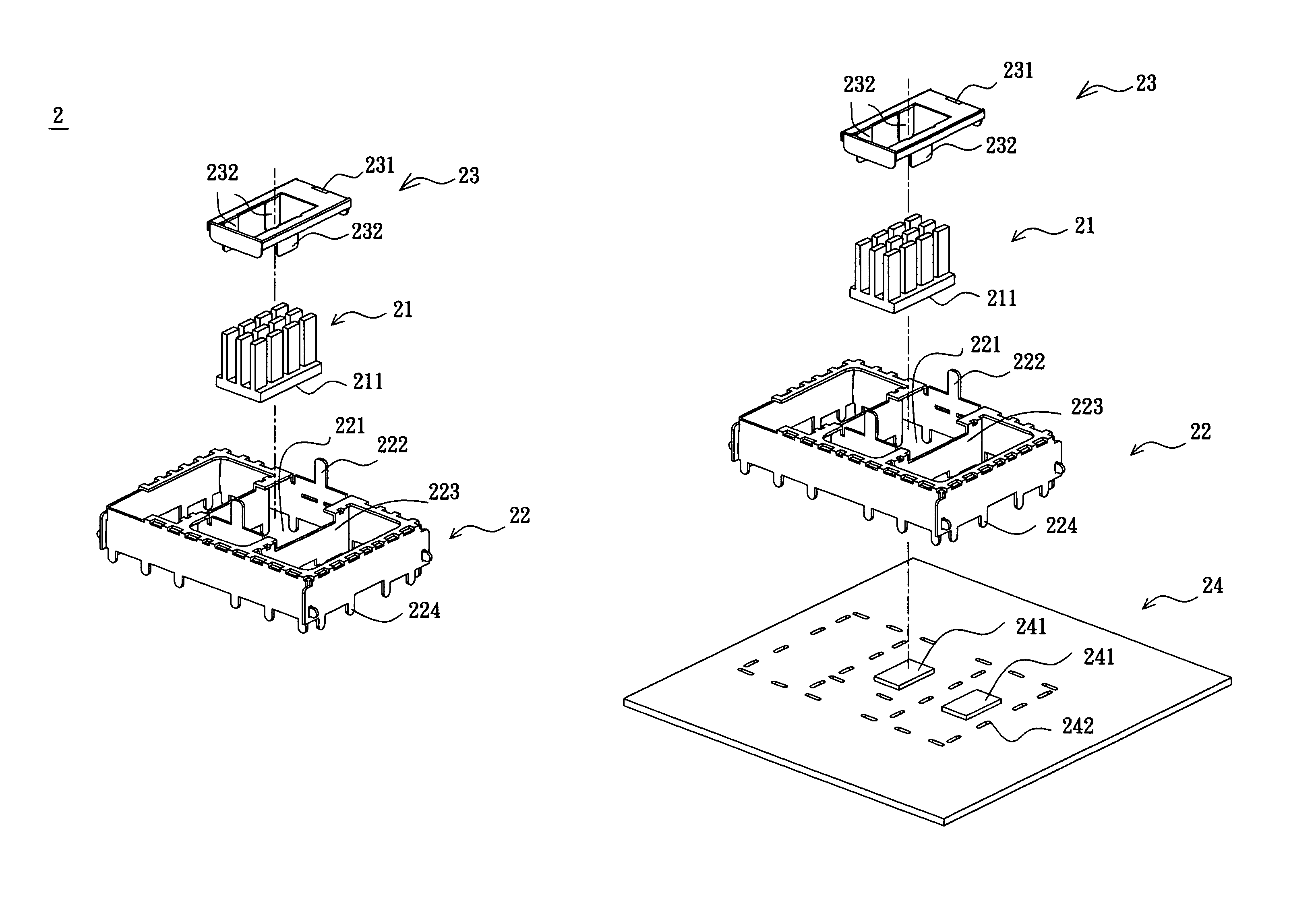

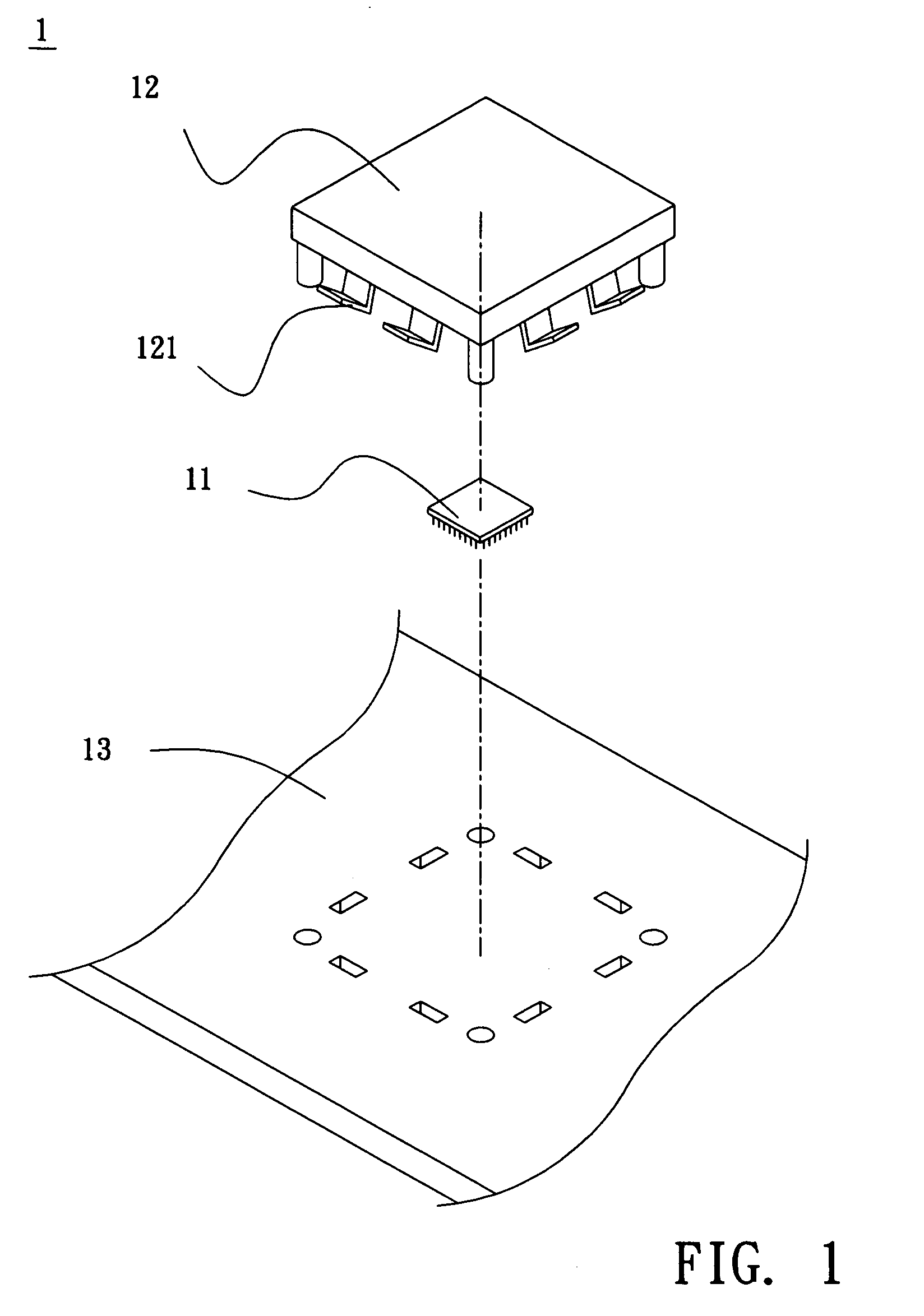

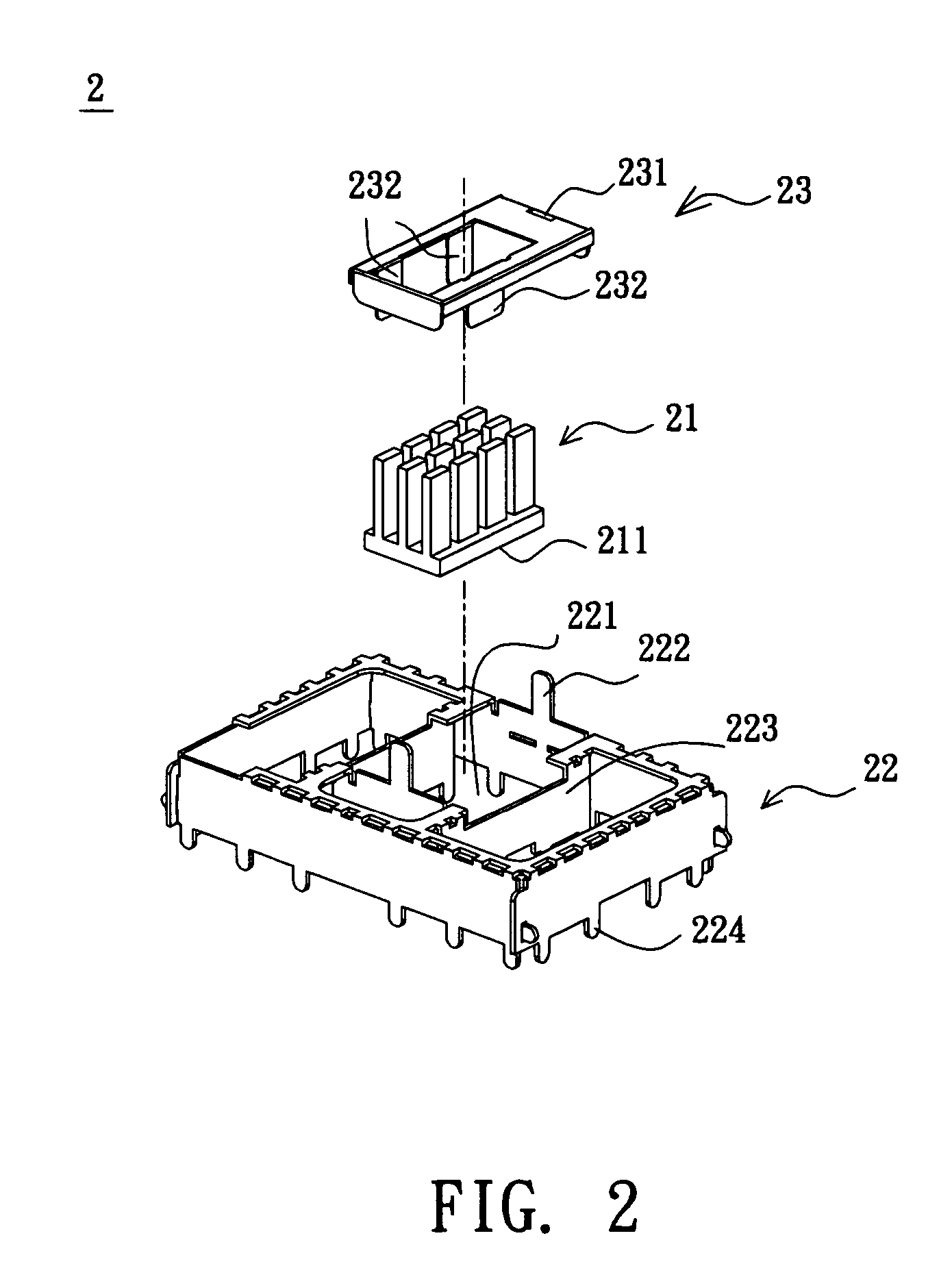

Electronic apparatus and shielding module thereof

ActiveUS7061773B2Easy to assemblePromote repairMagnetic/electric field screeningRack/frame constructionElectrical devicesElectronic equipment

Owner:ASUSTEK COMPUTER INC

Turn-indicator light module for a vehicle mirror assembly and vehicle mirror assembly comprising a turn-indicator light module

ActiveUS20110157907A1Shorten the timeSave moneyLighting support devicesVehicle interior lightingLight reflectionRear-view mirror

A turn-indicator light module for an external rear view mirror assembly has at least one or more light emitting sources mounted on one or more printed circuit boards (PCBs). A reflector and a front housing unit create a lens. At least a major portion of the light module follows a portion of said outer contour of the mirror assembly in the driving direction. The PCB is arranged with respect to the reflector to emit light indirectly by light reflection by the reflector along the major portion of the lens portion of the front housing unit.

Owner:SMR PATENTS S A R L

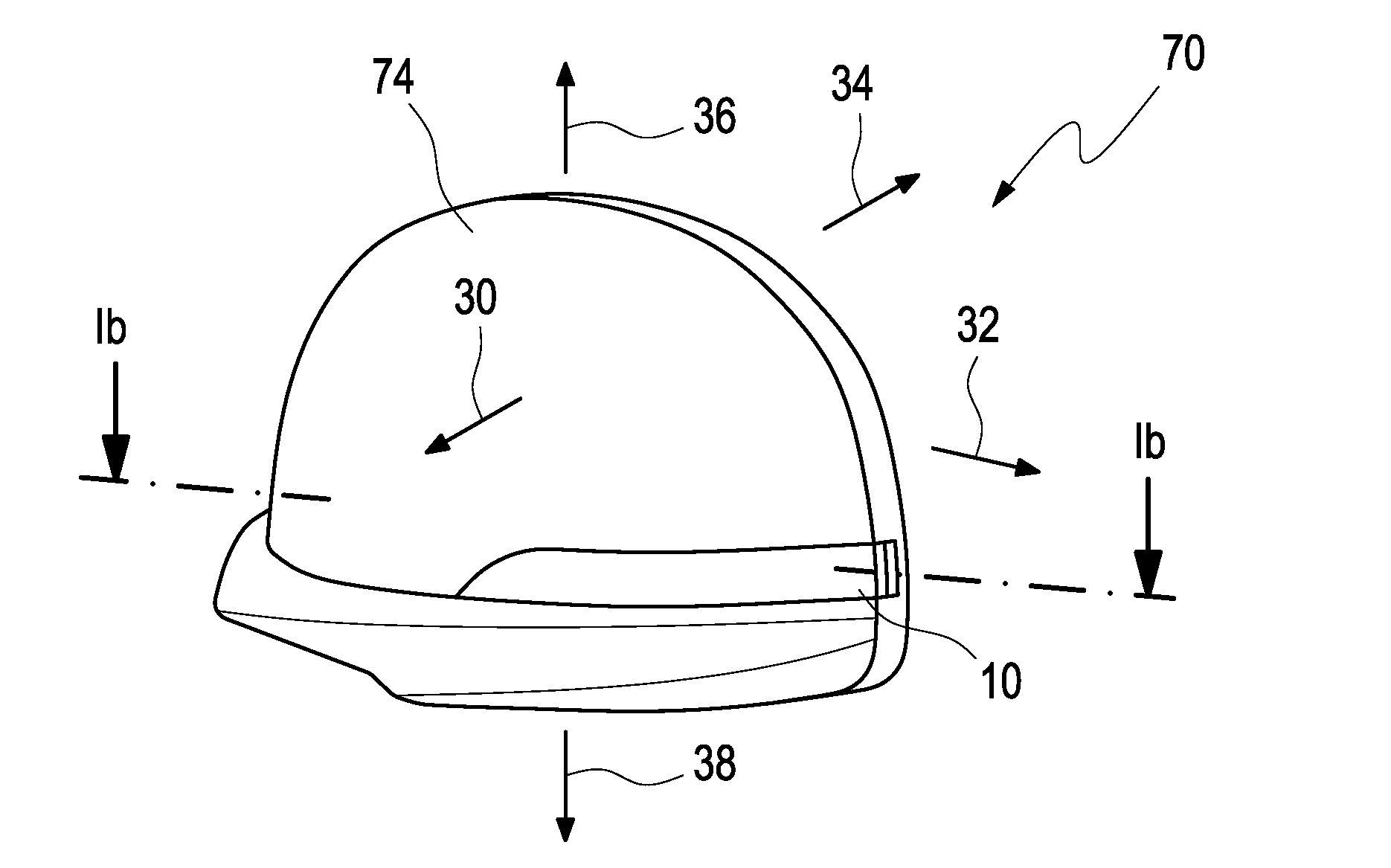

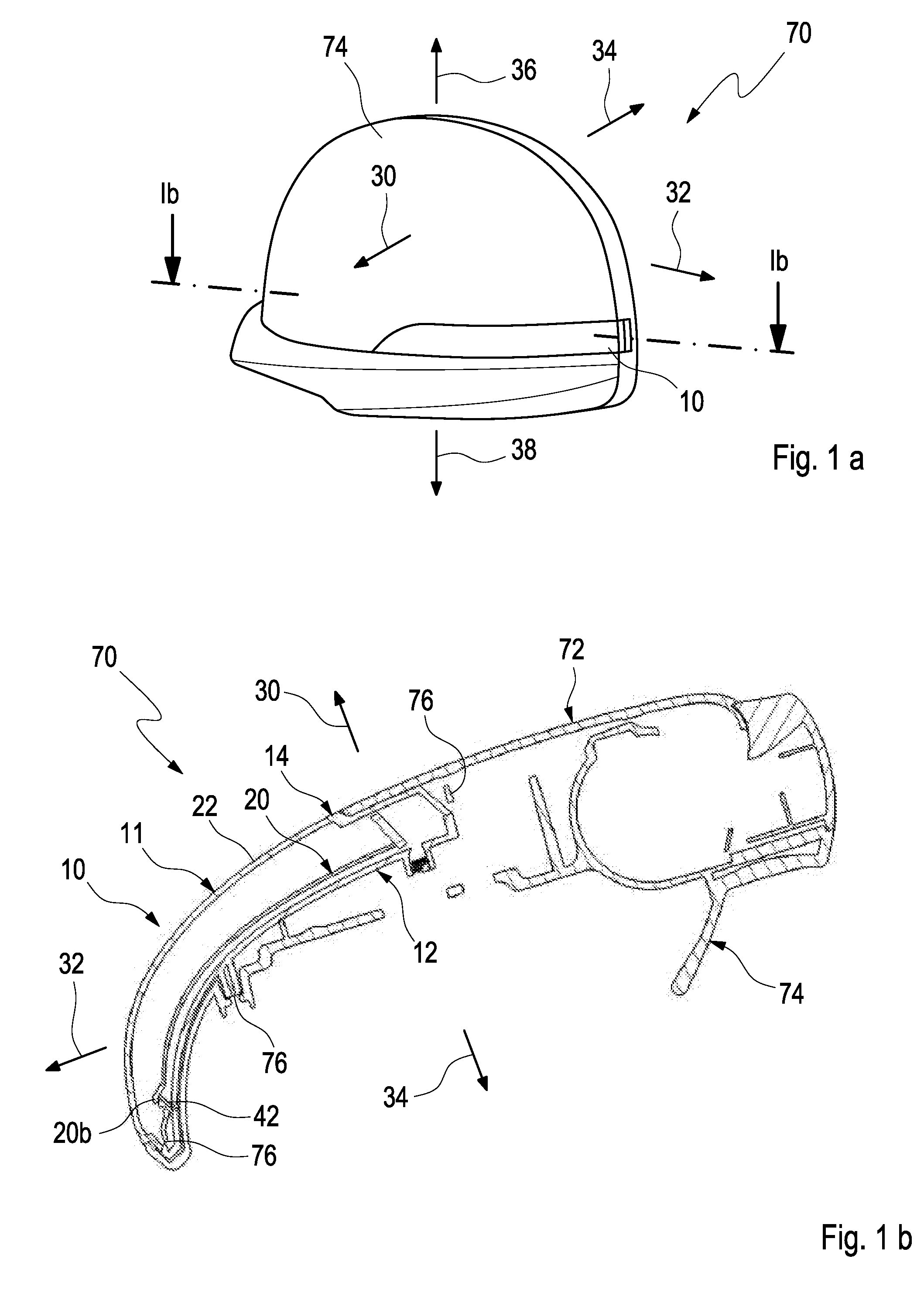

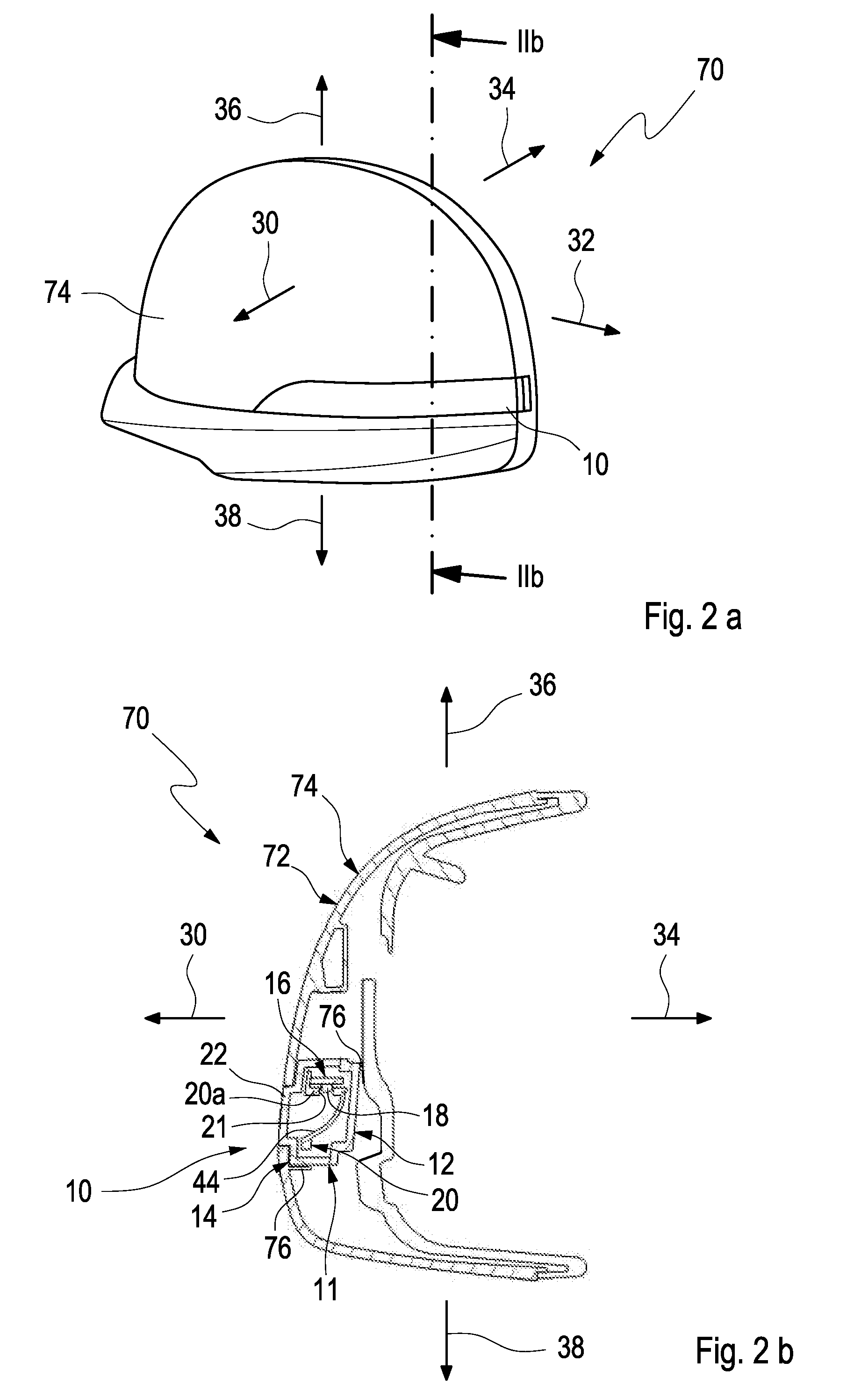

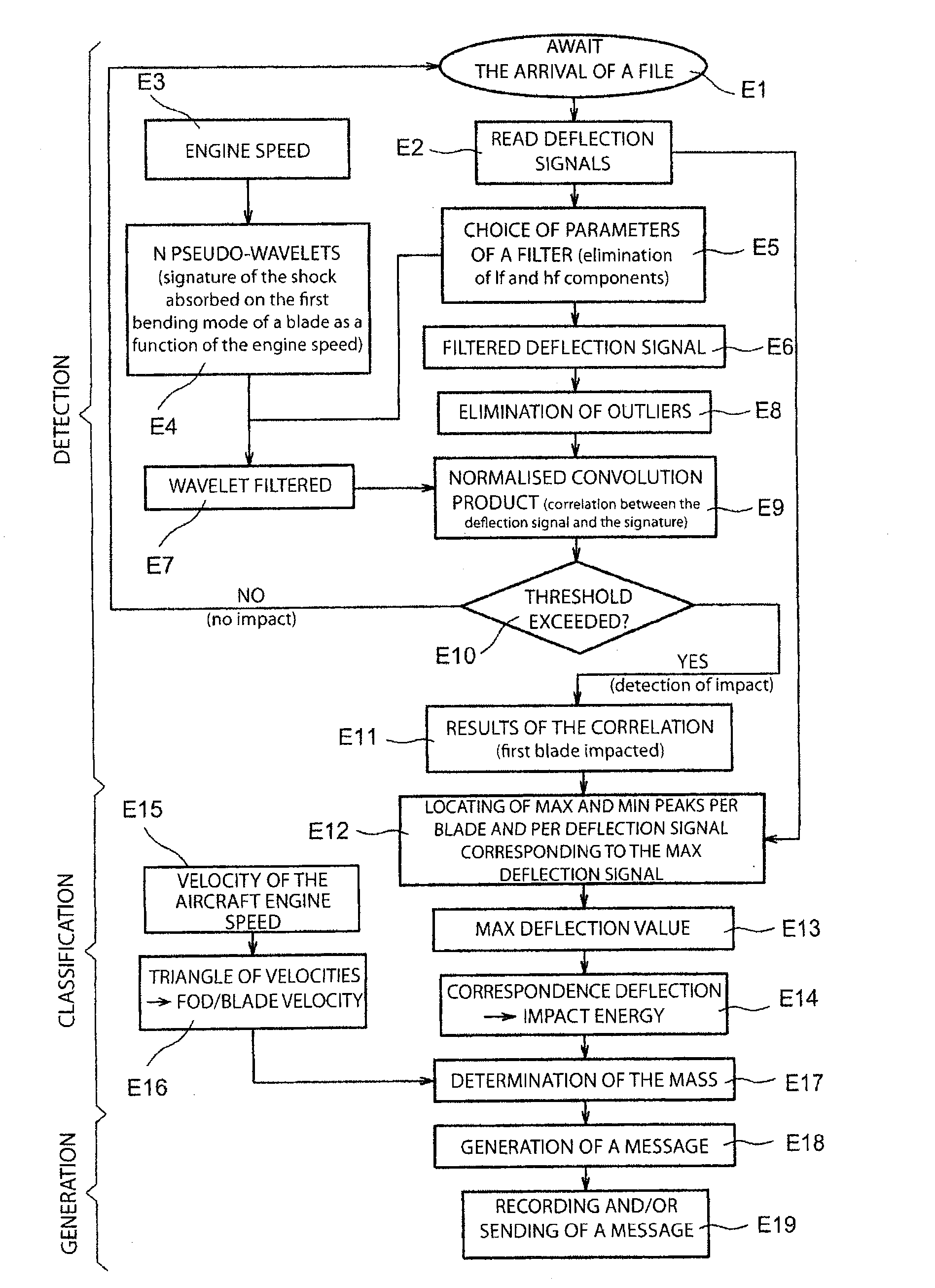

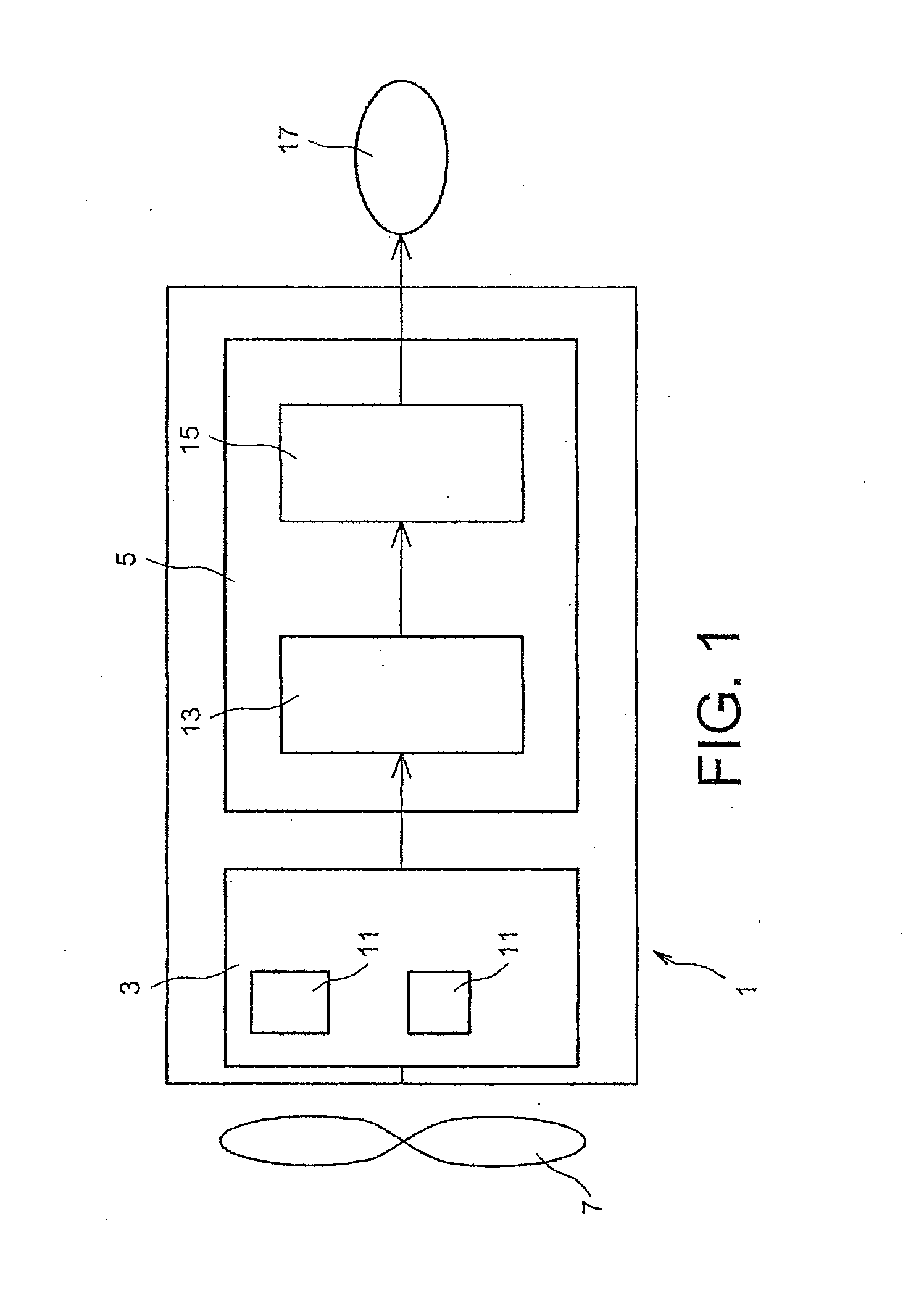

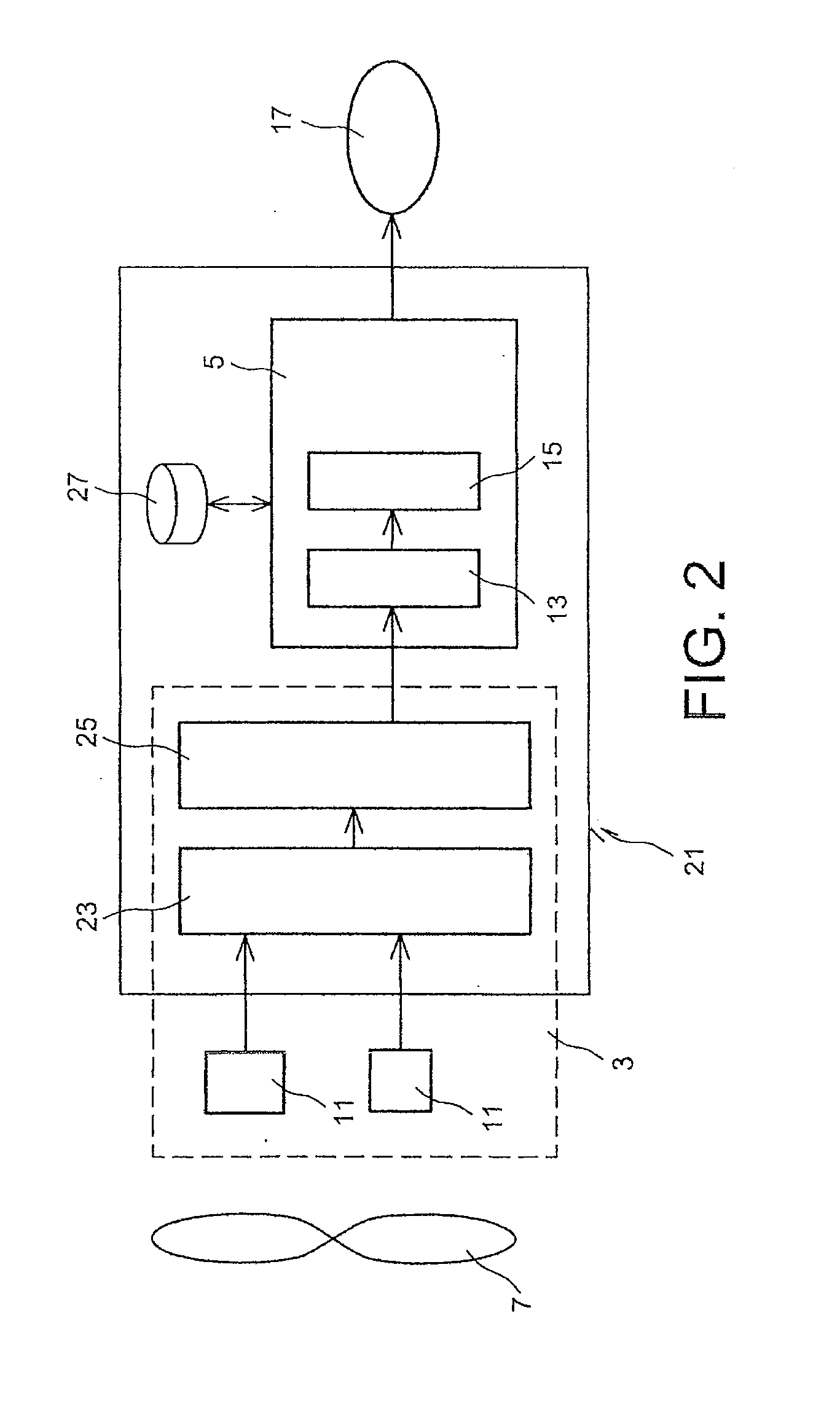

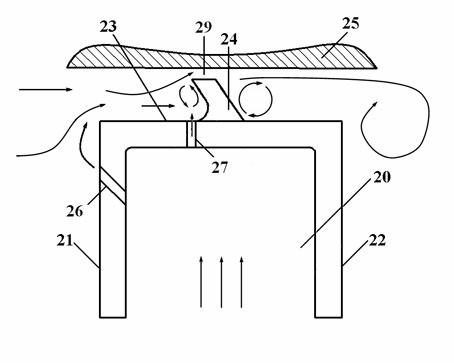

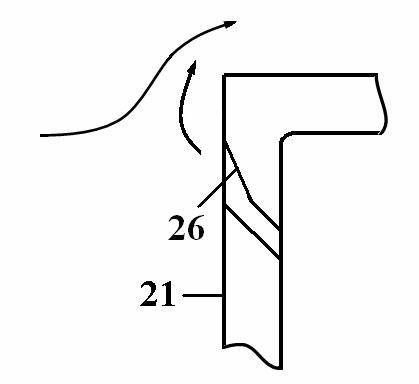

System for detecting an impact on an aircraft engine impeller wheel

ActiveUS20130197747A1Minimal calculation timeAccurate representationVibration measurement in solidsVehicle testingImpellerEngineering

The invention relates to a method and a system for detecting an impact on an impeller wheel (7) of an aircraft engine, characterised in that it comprises:acquisition means (13) for acquiring a revolutions per minute of said engine and a series of deflection signals representative of the deflections on the blades of said impeller wheel at said revolutions per minute, andcorrelation means (15) for constructing signals for detecting impact on said impeller wheel by correlating each of the deflection signals with a predetermined signature of a shock on a blade at said revolutions per minute.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

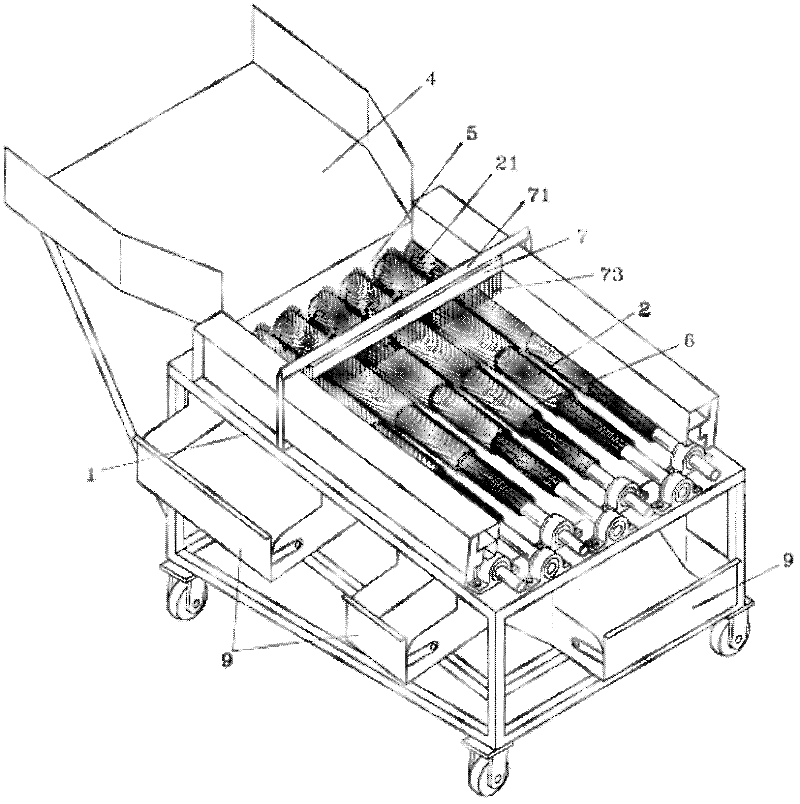

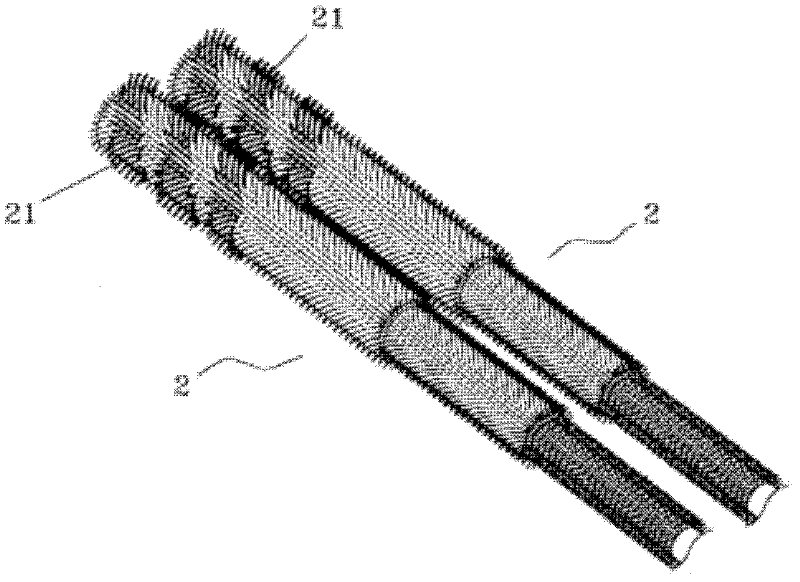

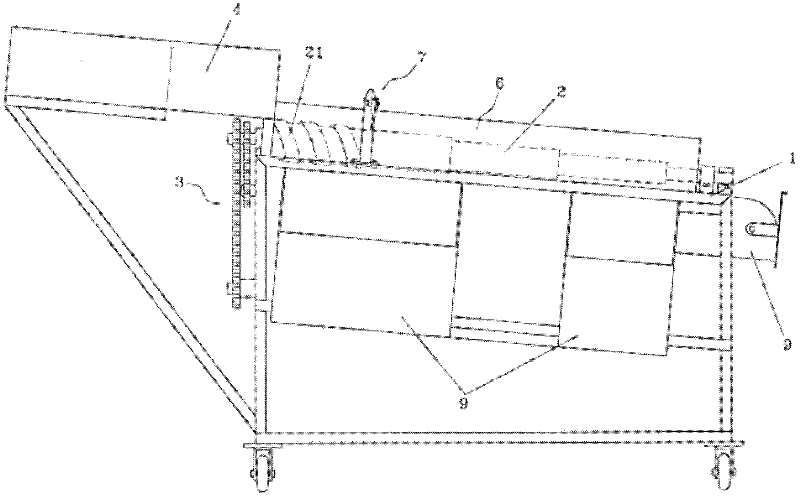

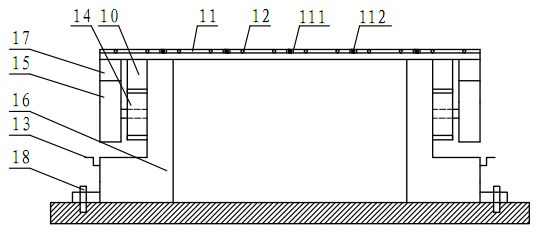

Grading vibration screening machine

InactiveCN102416376ASimple structureEasy to manufactureSievingScreeningMechanical engineeringEngineering

The invention discloses a grading vibration screening machine. The screening machine comprises a body (1), a plurality of screen rollers (2), a feeding table (4), a buffering plate (7) and collecting boxes (9); the bottom of the body (1) is provided with a plurality of movable wheels facilitating the quick movement of the body (1); the upper part of the body (1) is provided with a frame body; the feeding table (4) is connected to one side of the frame body; the feeding table (4) is flat, side plates are vertically arranged on two sides of the feeding table (4), the openings of the two sides of the feeding table (4) are different in size, the opening of the big side of the feeding table (4) is outward, and the opening of the small side of the feeding table (4) is positioned at a position connected with the body (1); and the plurality of screen rollers (2) are arranged in parallel in the frame body, the buffering plate (7) is arranged above the middle part of the frame body, and a plurality of collecting boxes (9) are arranged below the frame body. The screening machine is simple in structure and convenient to operate, maintain and replace, and saves the cost and the manpower.

Owner:成都鑫三洋科技发展有限公司

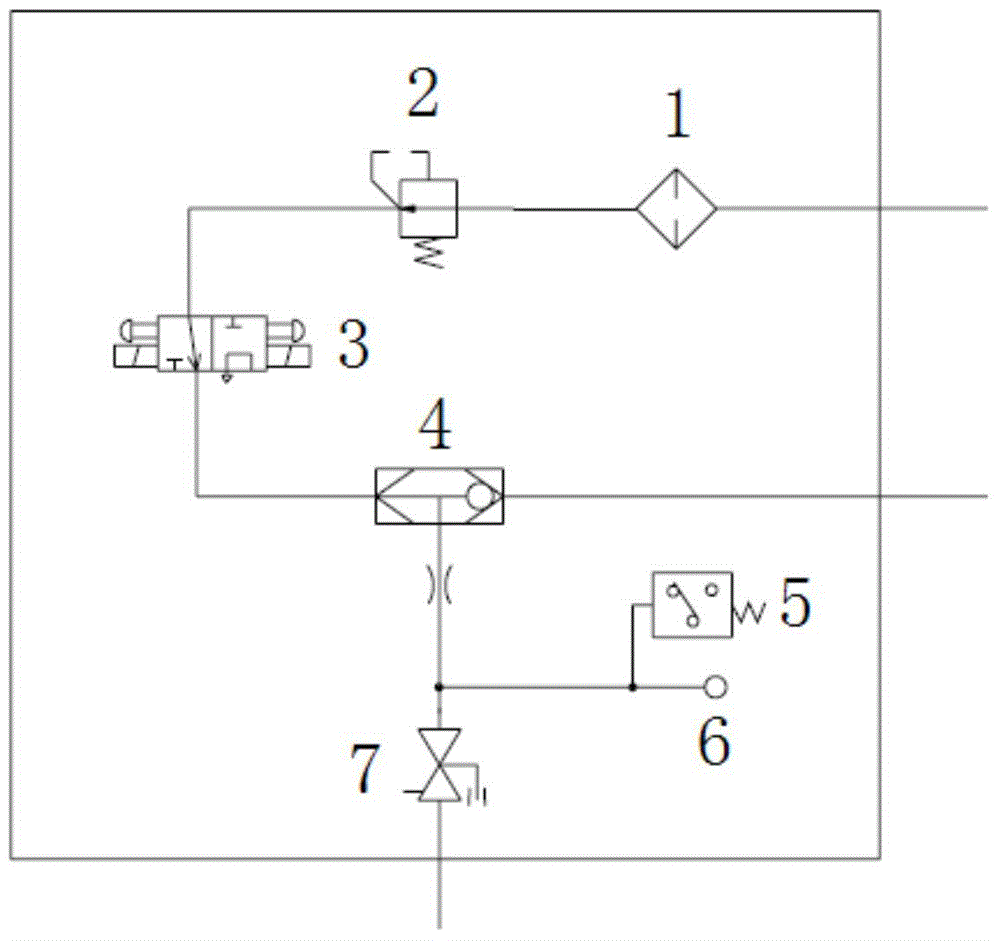

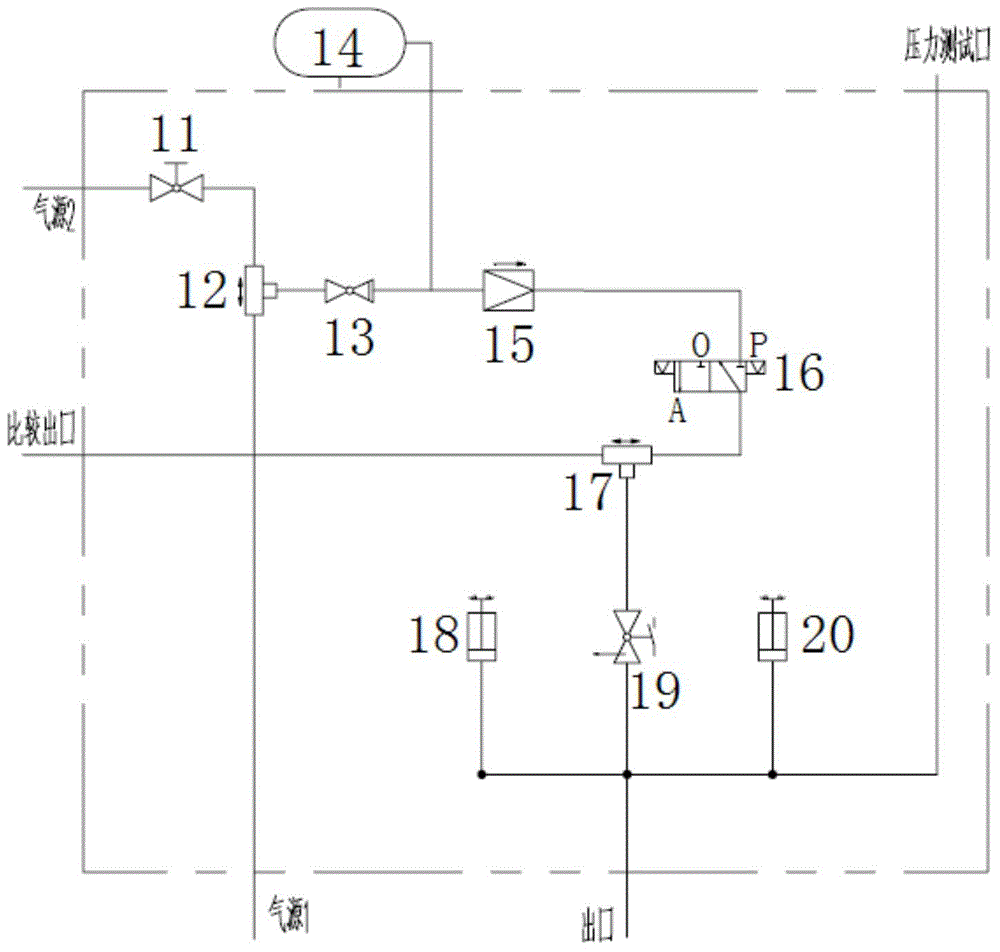

Integrated multifunctional parking braking system and control method thereof

InactiveCN104442900AAutomate implementationReduce volumeRailway hydrostatic brakesRailway hydrodynamic brakesFiltrationEngineering

The invention discloses an integrated multifunctional parking braking system and a control method thereof. A first bi-directional valve, a dust filtration check valve, a pressure reducing valve, a parking braking electromagnetic valve, a second bi-directional valve, an electric interlocking cock and an outlet in the system are connected in sequence. The first bi-directional valve is connected with a first air source and a second air source. A parking braking air cylinder is arranged between the dust filtration check valve and the pressure reducing valve. The second bi-directional valve is connected with a comparison outlet. A first pressure switch and a second pressure switch are arranged between the electric interlocking cock and the outlet. The integrated multifunctional parking braking system and the control method thereof have the advantages that the original parking braking function is reserved, meanwhile, the function of the double air sources from a total air pipe and a train pipe (or other external air sources) is achieved, and it can be guaranteed that parking braking can be automatically implemented when total air does not exist; meanwhile, the functions of parking braking status display, mechanical display or digital display, manual release and the like can be achieved; an air board integration mode is adopted, the size is small, the integration degree is high, and rapid installation or maintenance is facilitated.

Owner:CRRC ZIYANG CO LTD

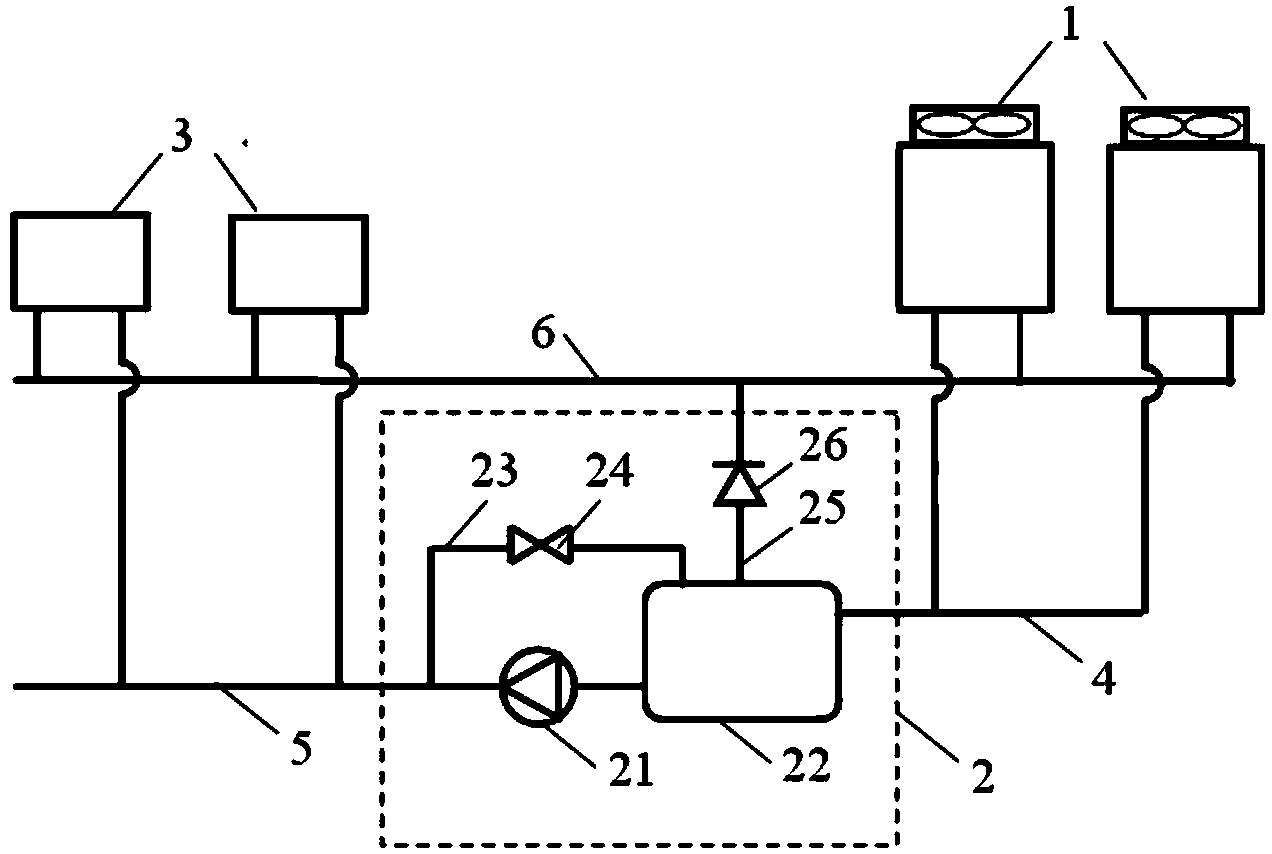

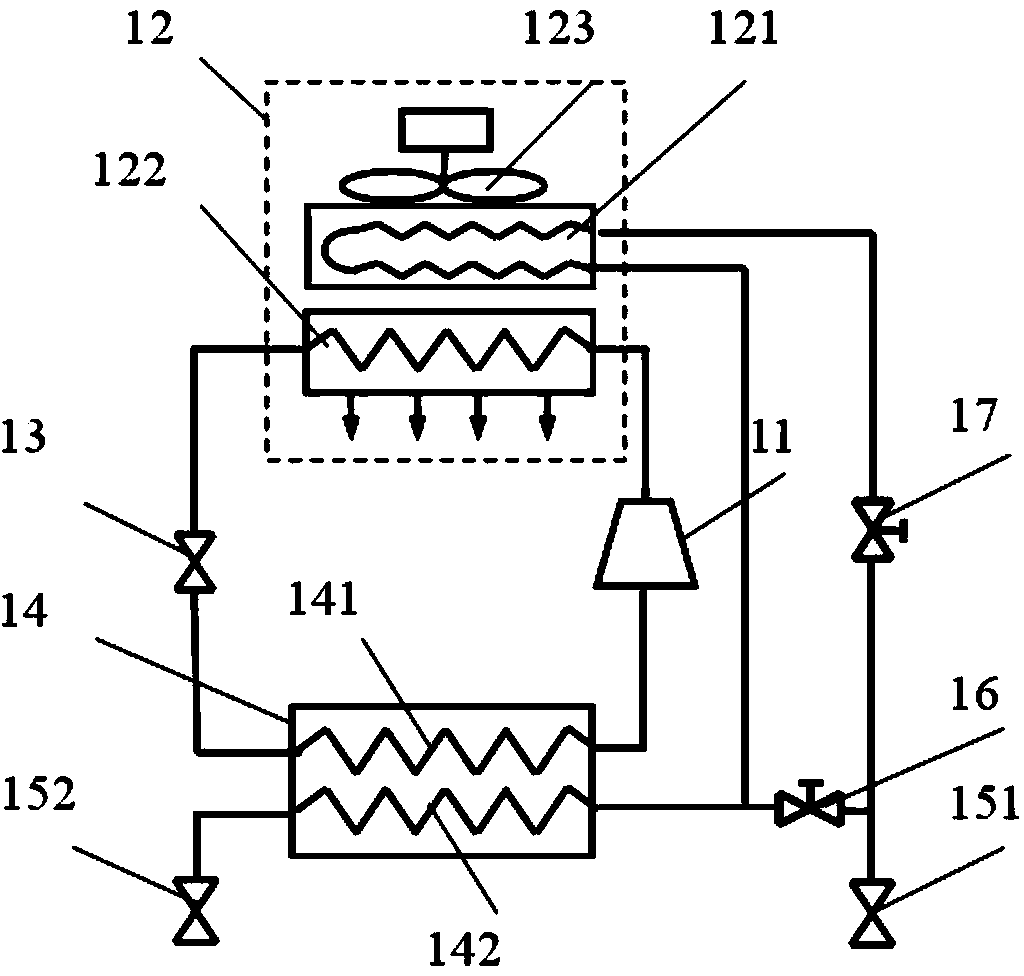

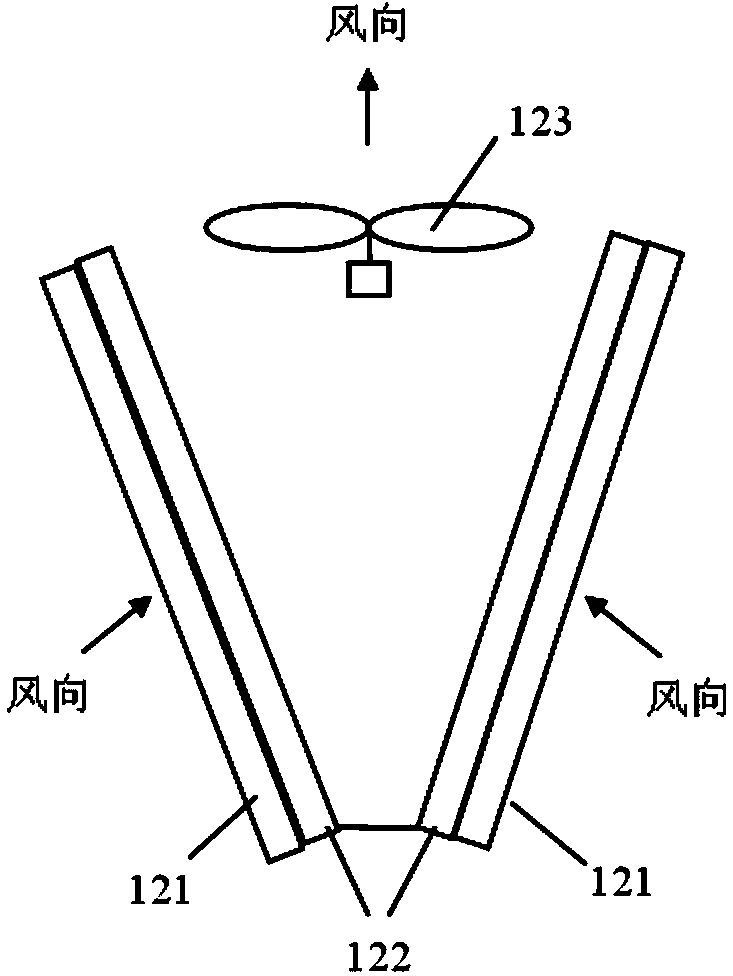

Control method for combined refrigerating multi-split air conditioner system

InactiveCN104266314ALarge working temperature zoneEasy to increase capacityMechanical apparatusSpace heating and ventilation safety systemsIndoor airTransition season

The invention discloses a control method for a combined refrigerating multi-split air conditioner system. The multi-split air conditioner system is characterized in that two or more outdoor combined refrigerating modules are arranged the outdoor side to form a cold source system of the multi-split air conditioner system, each outdoor combined refrigerating module is composed of a first refrigerant vapor compression and refrigeration circulating loop and a second refrigerant circulating loop, one or more direct evaporation type indoor air cooler modules are arranged at the indoor side, and a refrigerant storing and conveying unit is connected with the part between each outdoor combined refrigerating module and the corresponding indoor air cooler module to form a closed circulating system through a liquid collecting tube, a main liquid supply tube and a main air return tube. According to the control method for the combined refrigerating multi-split air conditioner system, the number of the indoor and outdoor modules is decided according to the designed thermal load of an air conditioner, and the control method precisely regulates the refrigerating capacity to meet the heat control needs of round-the-clock running data machine rooms and electronic equipment; the control method for the combined refrigerating multi-split air conditioner system is capable of making the maximum use of the natural cold source of the day and night, transition season and winter so as to realize the great energy conservation and emission reduction of the air conditioner system.

Owner:CHINA YANGZI GRP CHUZHOU YANGZI AIR CONDITIONERCO

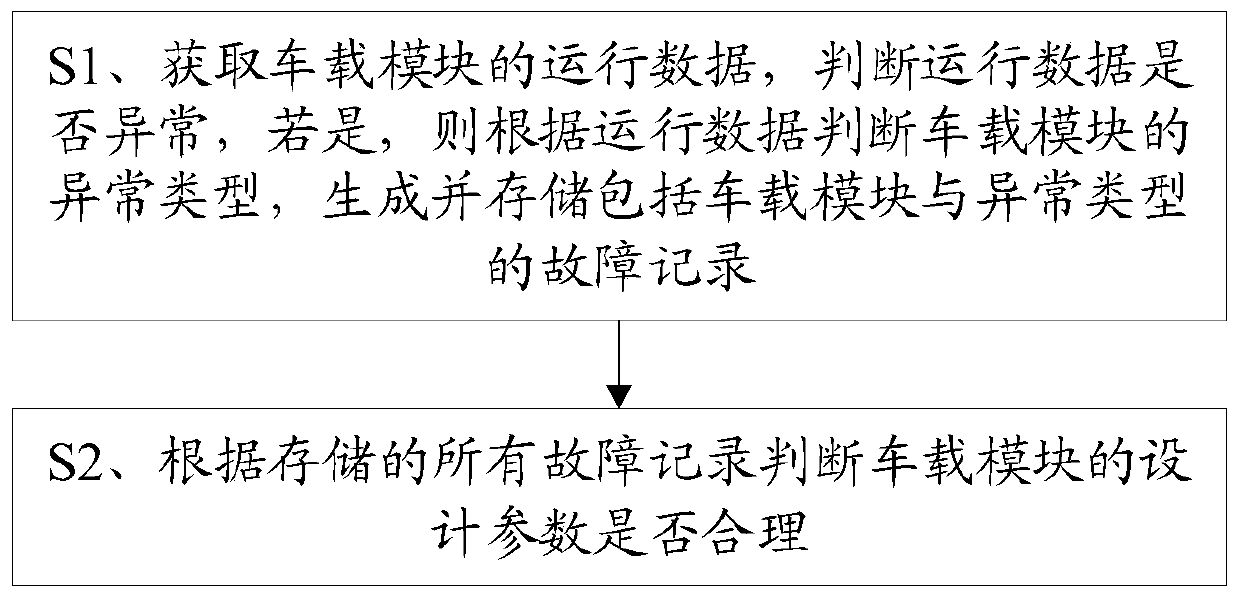

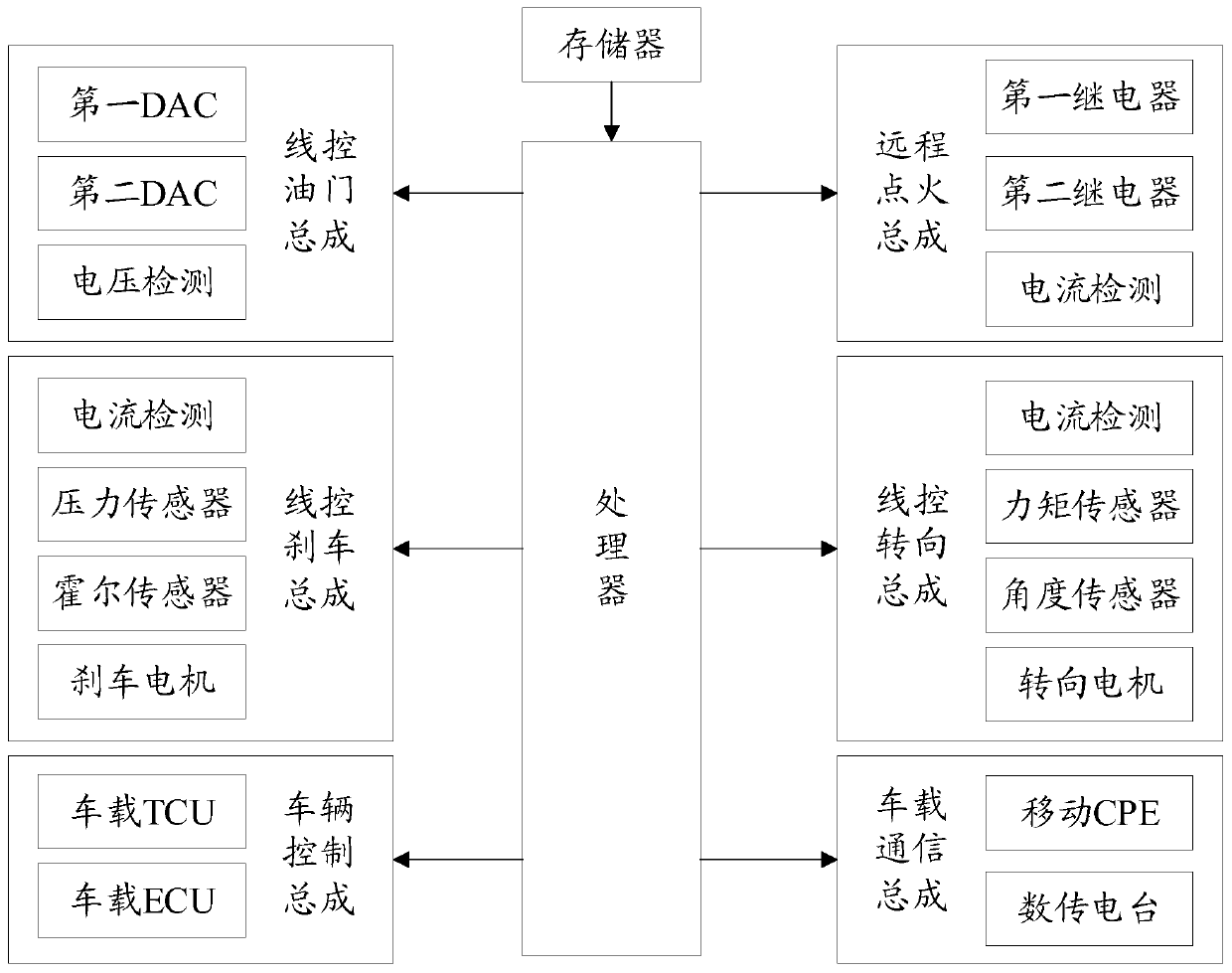

Rapid diagnosis method and terminal for unmanned vehicle

ActiveCN110174885AQuick functionQuick diagnosis functionProgramme controlElectric testing/monitoringEmbedded systemDiagnosis methods

Owner:福建盛海智能科技有限公司

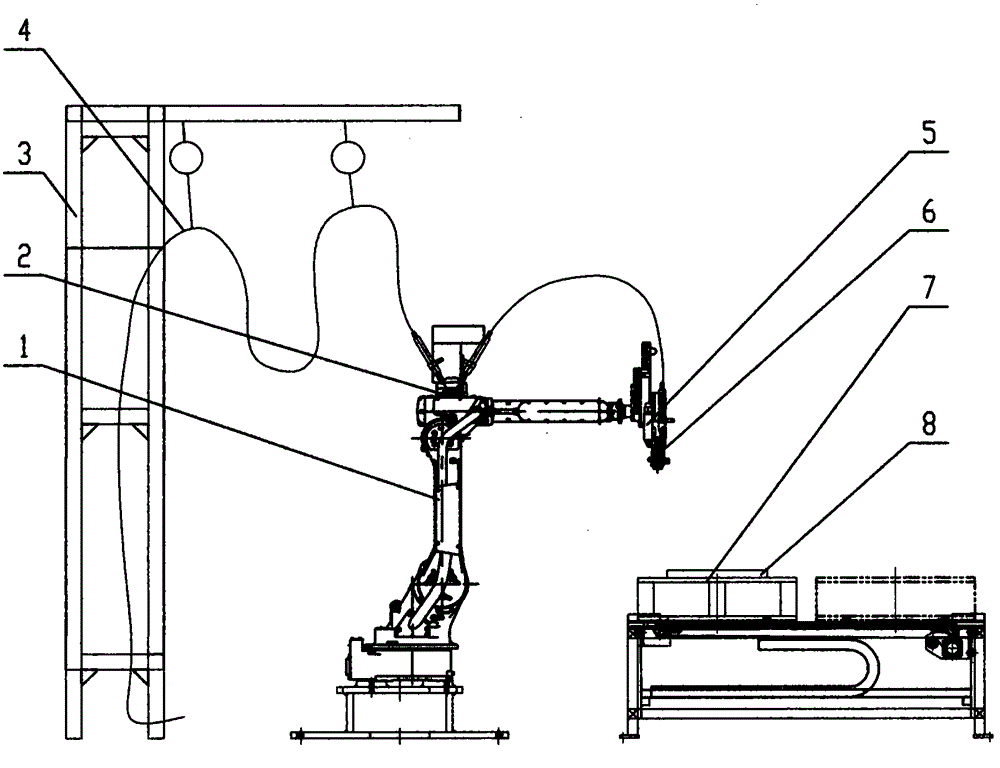

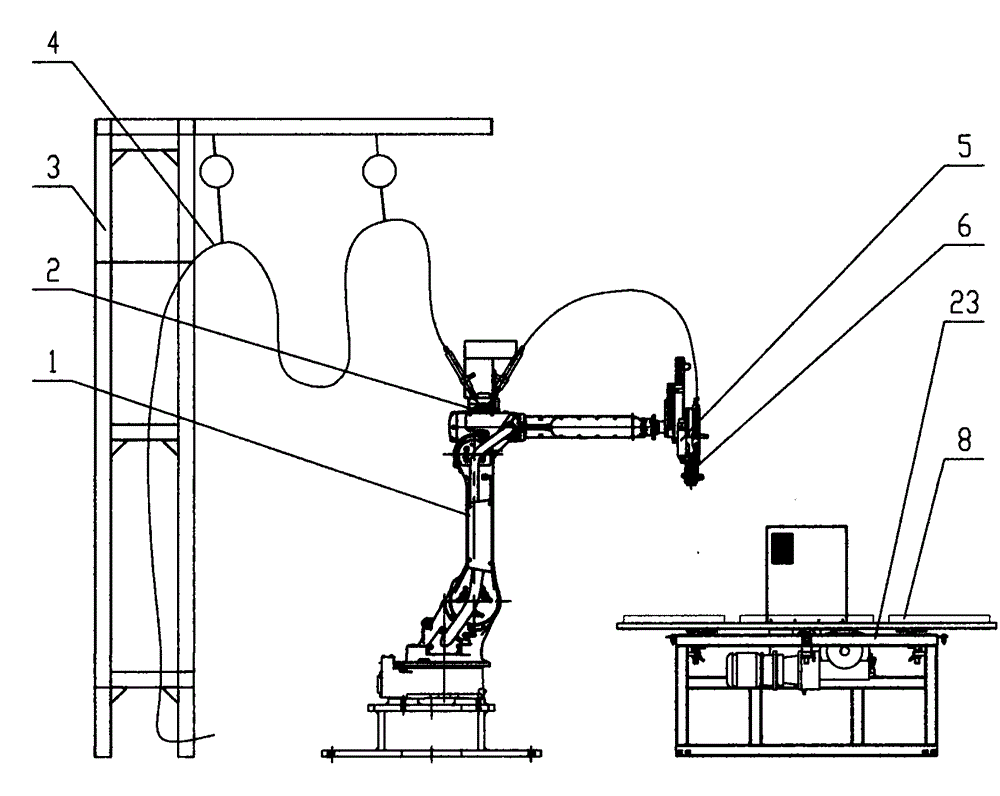

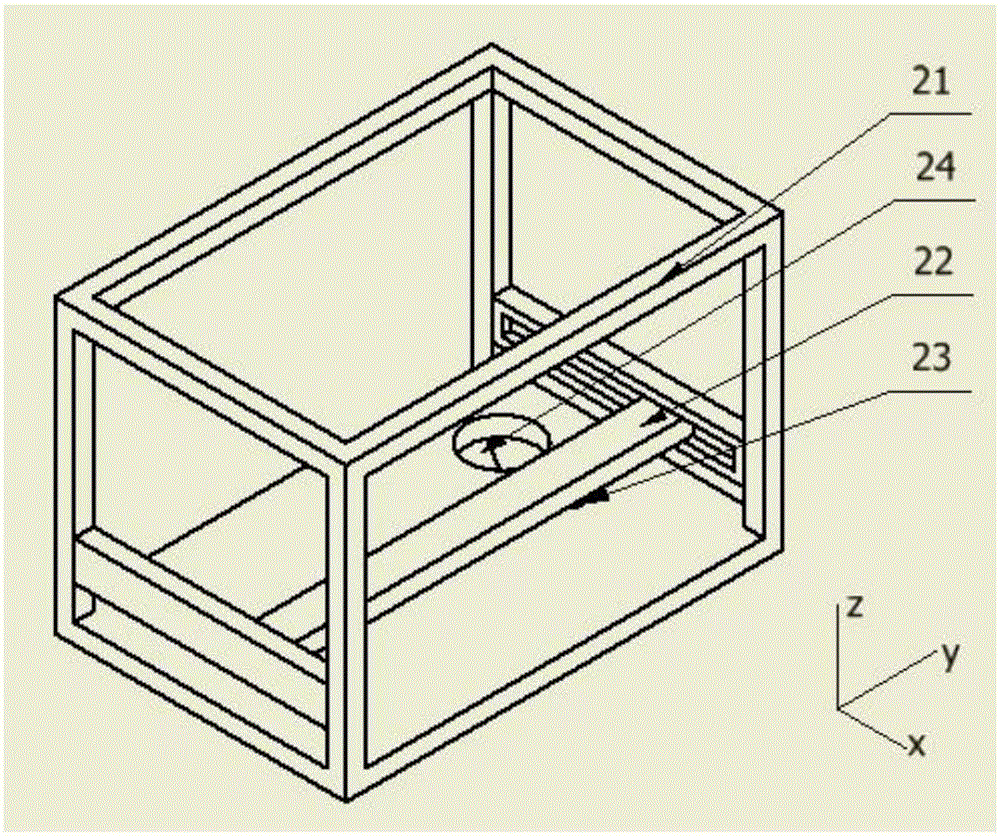

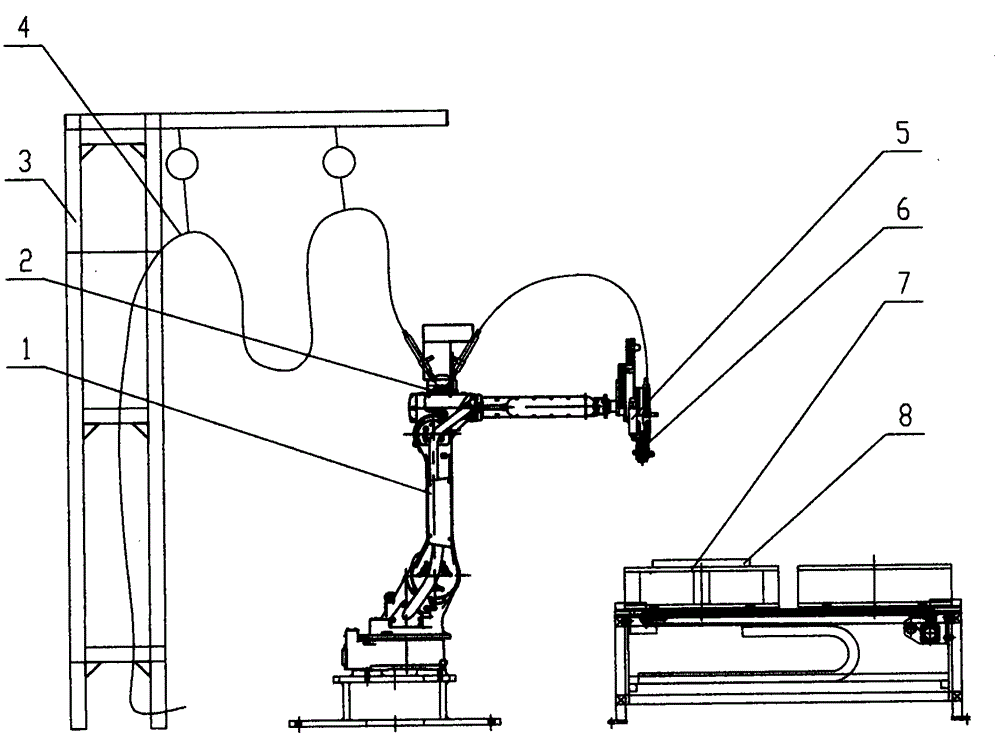

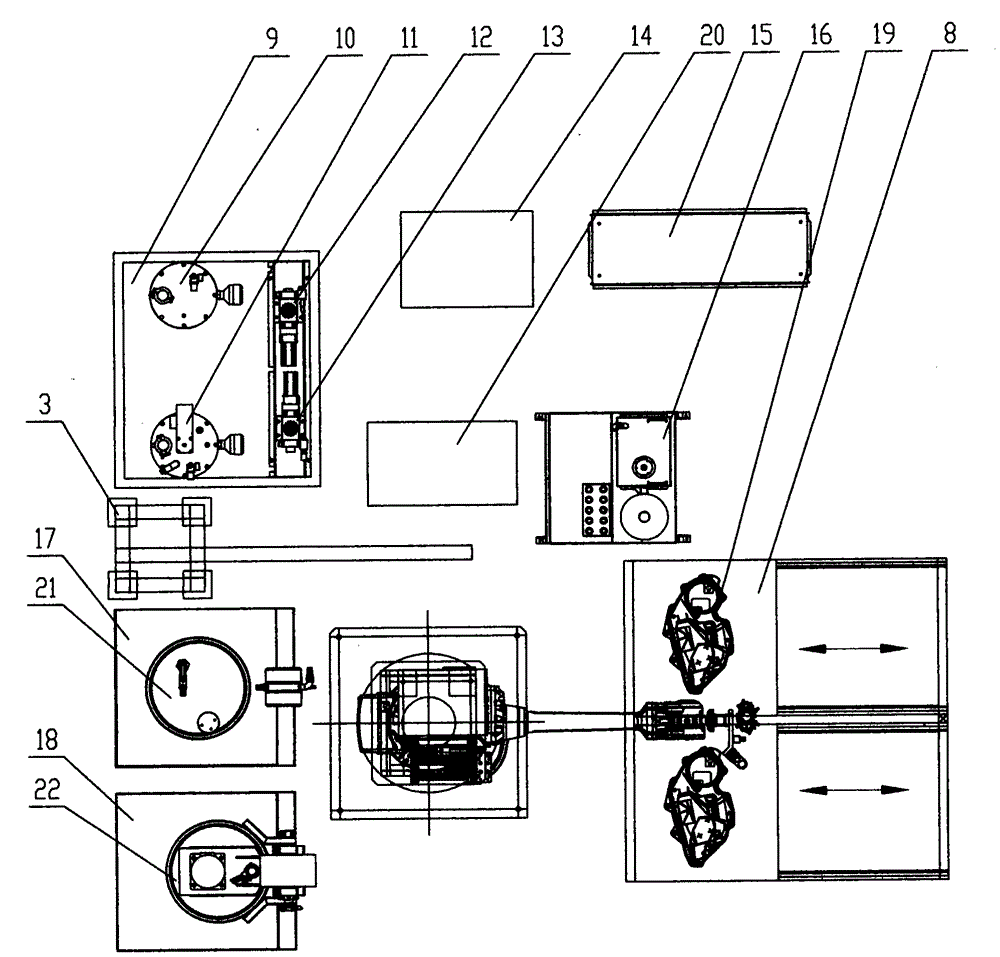

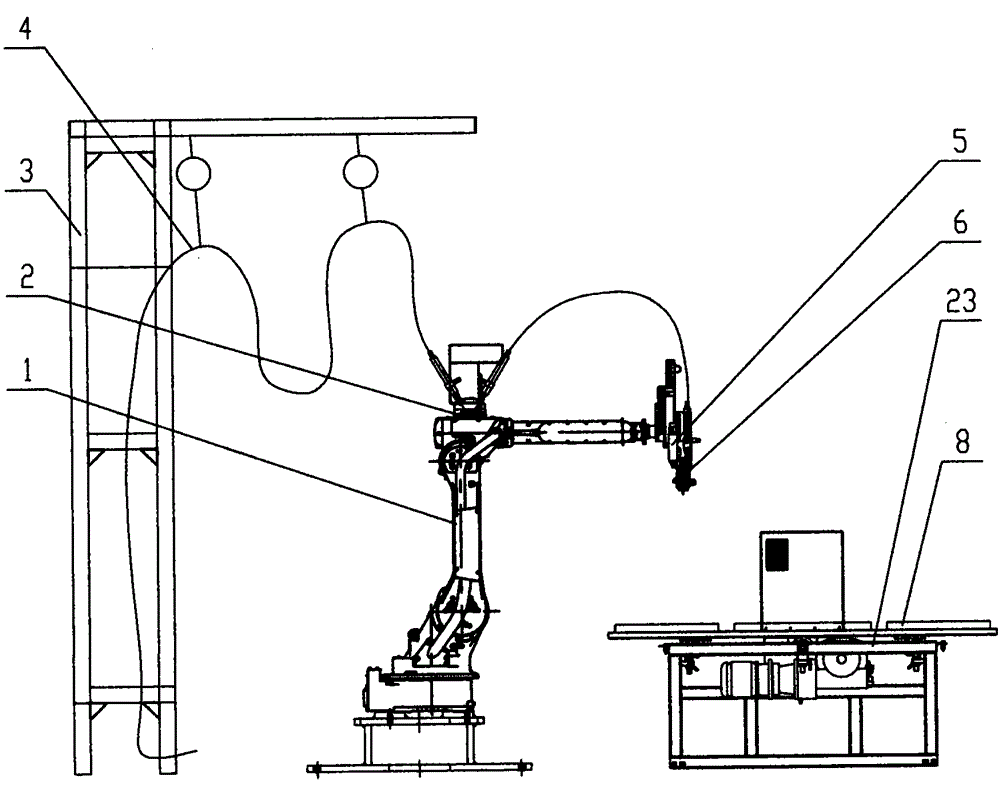

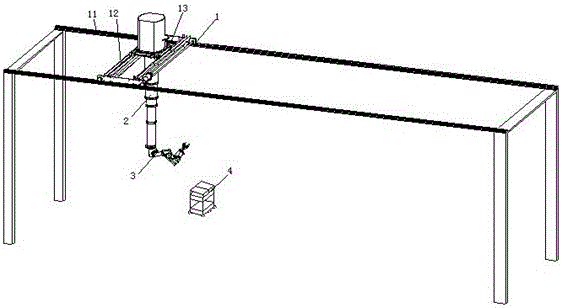

Full-automatic robot gluing equipment and process technology

The invention relates to the technical field of gluing, in particular to full-automatic robot gluing equipment and a process technology which are used for two-component polyurethane gluing. The full-automatic robot gluing equipment is characterized in that the equipment comprises a three-axis robot or a four-axis robot or a five-axis robot or a six-axis robot, a glue supply device, a two-component gluing head, a two-station automatic gluing workbench or a multi-station automatic rotary gluing workbench, plasma treatment equipment, a waste cleaning solution recovery device and an intelligent control system. The three-axis robot or the four-axis robot is of a gantry type or cantilever type structure. The two-component gluing head and a plasma treatment head are fixed to the three-axis robot or the four-axis robot and can be linked in the X axis, the Y axis and the Z axis. The five-axis robot or the six-axis robot is an articulated robot, and five-axis linkage or six-axis linkage of the two-component gluing head and the plasma treatment head can be achieved. According to the novel polyurethane gluing equipment and the process technology, the proportion is precise, glue tape performance is stable, and the sealing effect is good.

Owner:DALIAN HUAGONG INNOVATION TECH

Optimization method of embodiment for overhauling power distribution network

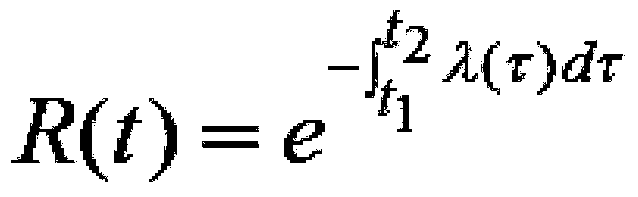

ActiveCN103400209APrecise maintenanceQuick repairForecastingInformation technology support systemFailure rateProgram planning

The invention discloses an optimization method of an embodiment for overhauling a power distribution network. The method comprises the following steps: collecting information of the power distribution network and power distribution equipment; calculating the failure rate of the power distribution equipment; evaluating operational risks of the power distribution network and the overhauling yield of the overhauling scheme; and optimizing the overhauling scheme by using a particle swarm optimization algorithm, wherein the particle fitness value is the overhauling yield of the overhauling scheme. Compared with the existing optimization method of the overhauling schedule of the power distribution network, the method disclosed by the invention has the beneficial effects that the optimization method is more complete and accurate in evaluating the risks of the power distribution network, and interaction of various factors is comprehensively considered, so that the overhauling scheme obtained by optimization is more scientific and reasonable, and is beneficial for effectively conducting the overhauling work and lowering the cost.

Owner:STATE GRID CORP OF CHINA +3

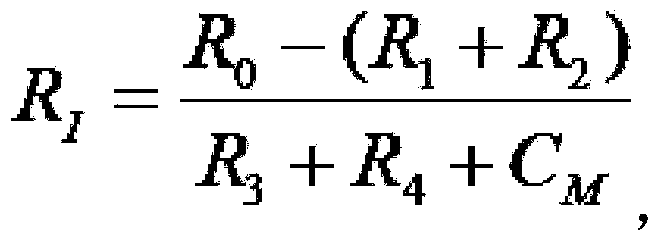

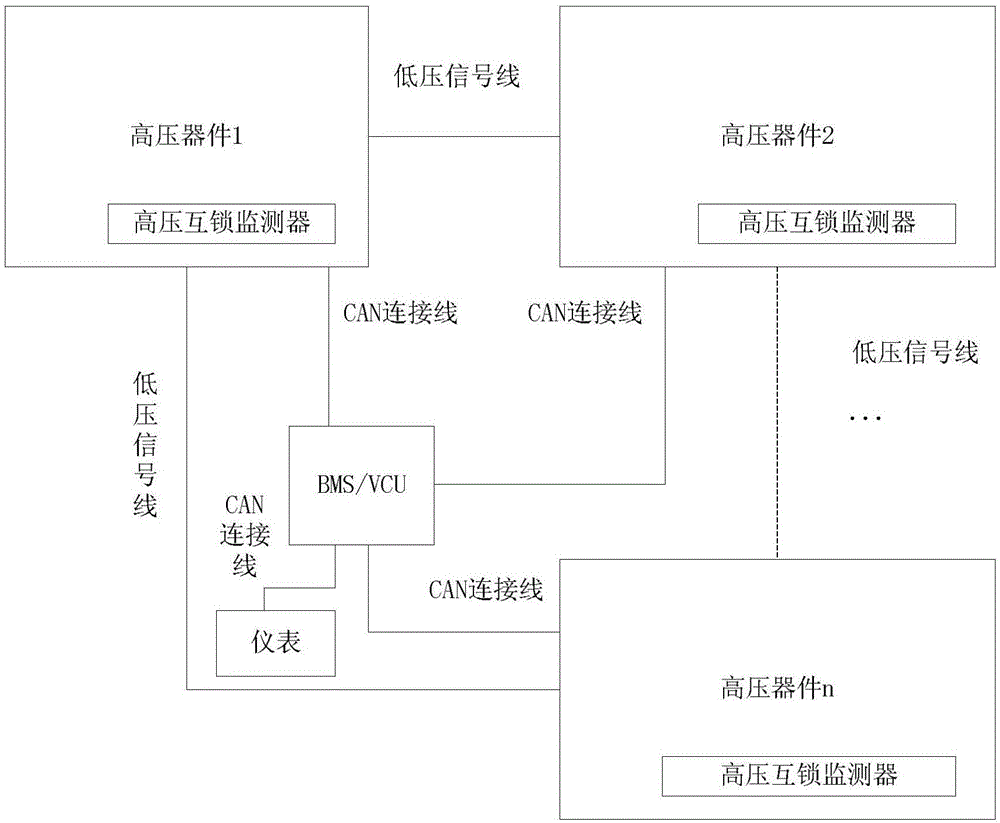

Electromobile and high-voltage device fault detection system and method for same

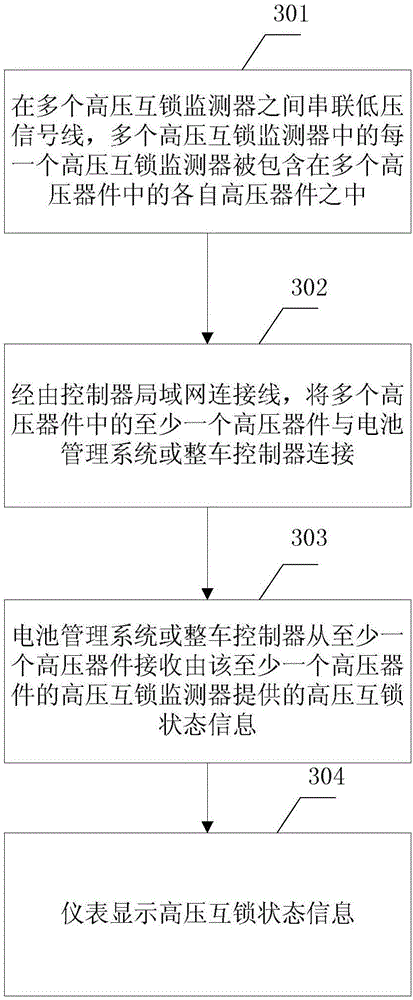

The invention provides an electromobile and a high-voltage device fault detection system and method for the same. The high-voltage device fault detection system comprises multiple high-voltage devices respectively comprising respective high-voltage interlocking monitors, a low-voltage signal line, a battery management system or a vehicle control unit and an instrument, the low-voltage signal line is serially connected among the high-voltage interlocking monitors of the high-voltage devices, the battery management system or the vehicle control unit is connected with at least one of the high-voltage devices through a controller area network connecting line and used for receiving high-voltage interlocking state information provided by the high-voltage interlocking monitors of the high-voltage devices from the high-voltage devices, and the instrument is used for displaying the high-voltage interlocking state information. After high-voltage danger appears, when a user expects to detect and find out a position with high-voltage interlocking fault, the position with the fault can be quickly located through display of the instrument without checking high-voltage wiring harnesses and the high-voltage devices one by one, so that convenience is brought to quick maintenance.

Owner:CH AUTO TECH CORP CO LTD

Laser anti-corrosion and wear-resistant process for trunnion of movable guide vanes of turbines

InactiveCN101629289ASolve technical bottlenecksLow dilution rateMetallic material coating processesNumerical controlWear resistant

The invention relates to a laser anti-corrosion and wear-resistant process for the trunnion of movable guide vanes of turbines. The process comprises the following steps: useing liquid penetrant test detection to detect the whole guide vane trunnion so as to determine cracks, air cavities and slag in the erosive wear area; and making balancing weights according to the shape and poise error of the guide vanes; removing the fatigue layer of the erosive wear area of the guide vanes; and carrying out cleaning technology treatment after clearing. A special powder feeding device is used to carry out laser cladding for special alloy materials which have good fusion property, high bonding strength and good anti-corrosion and wear-resistant properties. The specific parameters of the cladding process are as follows: the laser power is 3,200W, the spot diameter is 3.2 mm, the latus spots are used, the scanning speed of numerical control programming is 700 mm / min, the lapping rate is 25%, argon protection is used, and the alloy materials are delivered into the melting bath of laser cladding in an angle of 15 DEG by a special laser powder feeding device in a synchronous powder feeding way. All movable guide vanes to be repaired in the invention do not need sending to the manufacturer for treating, huge transport expenditure is not needed, and the whole repair period can be greatly shortened.

Owner:岳阳大陆激光技术有限公司

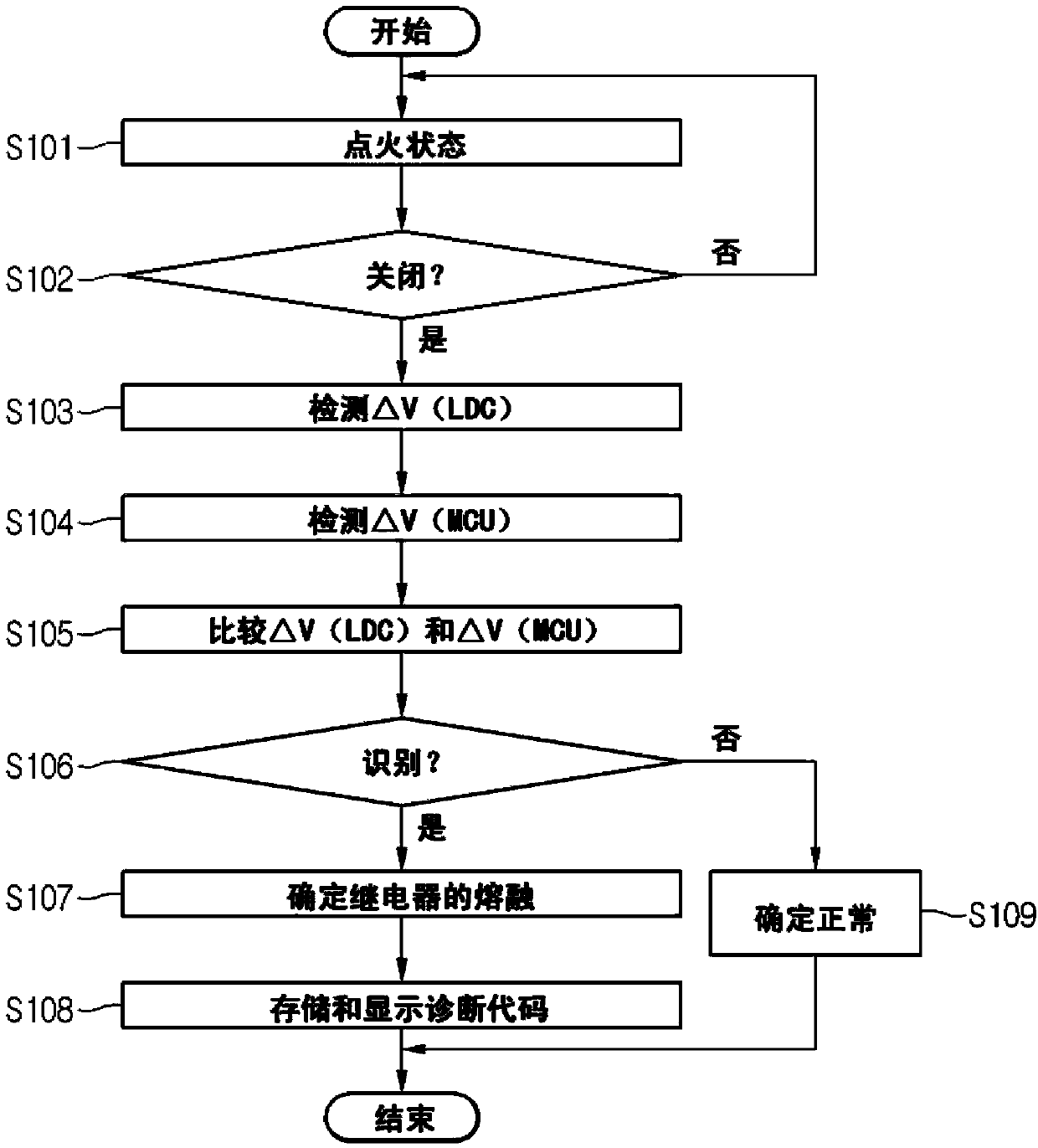

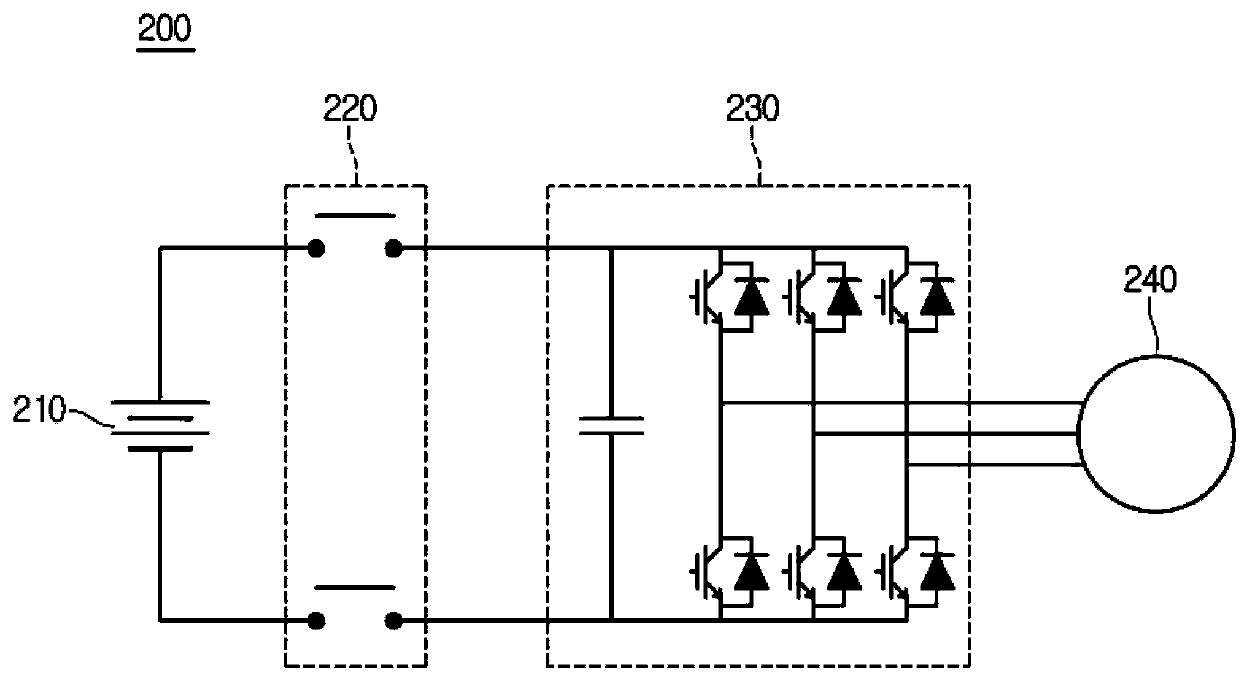

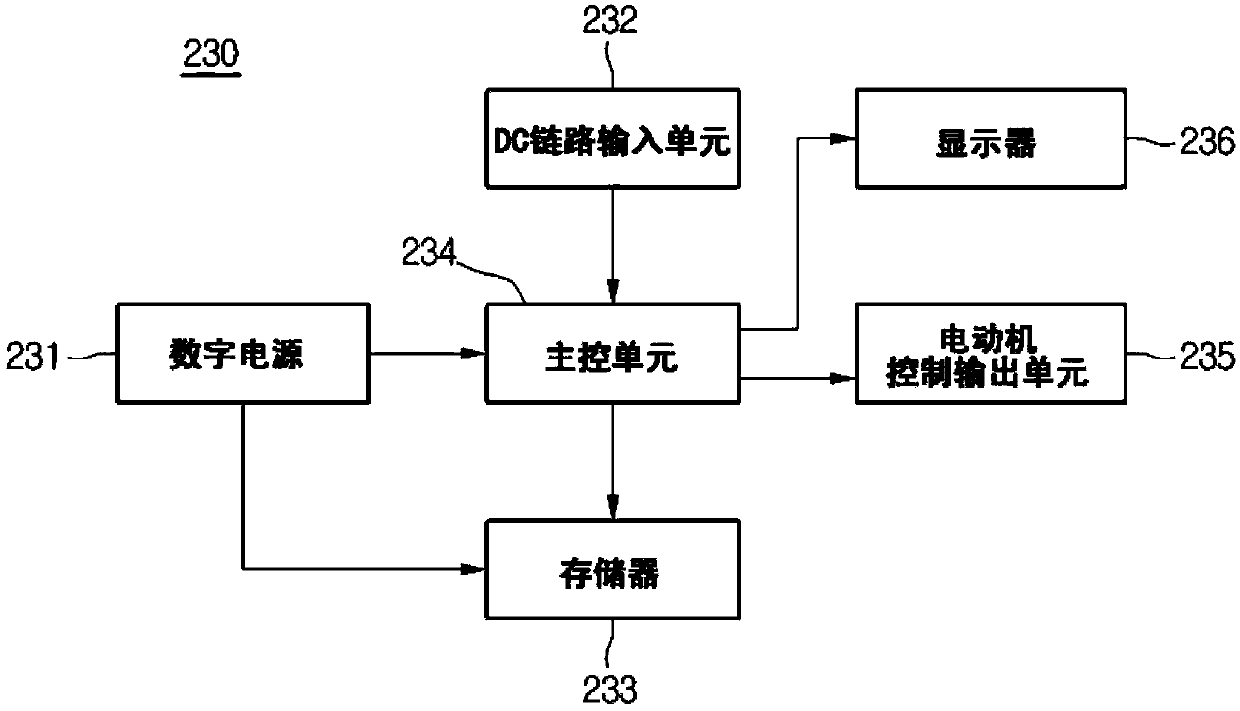

Apparatus for diagnosing relay contact of electric vehicle and method thereof

InactiveCN103424690AQuick repairQuick changeTesting electric installations on transportPropulsion by batteries/cellsPower inverterHigh voltage battery

Disclosed are an apparatus for diagnosing a relay contact of an electric vehicle and a method thereof. The method includes measuring a first voltage input from a high-voltage battery to an inverter; comparing the first voltage with a second voltage output through the high-voltage battery; identifying a detection time point of the first voltage when the first voltage is greater than the second voltage; and determining whether a high-voltage relay, which intermits an output voltage of the high-voltage battery, is malfunctioned based on the identified detection time point.

Owner:LSIS CO LTD

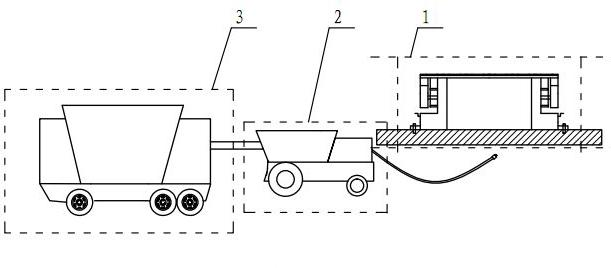

Concrete pouring fast construction method

ActiveCN102359276ASimple structureEasy to useIn situ pavingsClimate change adaptationContinuous/uninterruptedBridge deck

The invention discloses a concrete pouring fast construction system which comprises a moving formwork device, a concrete wet spraying and pouring device and a concrete moving blending device, wherein the concrete moving blending device is connected with the concrete wet spraying and pouring device through a pipeline, the moving formwork device comprises formworks, each formwork is of a thin plate-like unit body, the unit bodies of the formworks are spliced into a whole plate through bolts, and the whole plate is supported by formwork slideways positioned at the two ends of the whole plate. The concrete pouring fast construction system has the advantages of realizing continuous and uninterrupted concrete fast pouring and realizing fast, continuous and emergency repair construction of bridge deck paving, as well as fast construction and emergency repair fast construction of airfield runways and military emergency works. The concrete pouring fast construction system is simple in structure and simple and convenient to operate, and can be used for not only improving the construction efficiency of large-range wide-amplitude thin plate concrete in a slope or a plane, but also greatly shortening the opening time of a concrete repair region and meeting harsh requirements on the construction speed during the large-range application of fast hardening concrete.

Owner:SHIJIAZHUANG TIEDAO UNIV

Turbine cooling blade with blade tip leakage prevention structure

InactiveCN102678189ASimple structureLight in massBlade accessoriesMachines/enginesLeading edgeTurbine blade

The invention relates to a turbine cooling blade with a blade tip leakage prevention structure. A blade body is internally provided with a cooling channel; a blade tip partition rib extending from the front edge of the blade body to the tail edge of the blade body is arranged on the outer surface of a blade tip plate of the blade body; and more than one jet hole communicated with the cooling channel is distributed on the blade tip plate from the front edge to the tail edge of the blade body and is positioned at one side or two sides of the blade tip partition rib along the extending direction of the blade tip partition rib. According to the turbine cooling blade with the blade tip leakage prevention structure, the blade tip partition rib is arranged on the outer surface of the blade tip plate from the front edge to the tail edge of the blade body; when in use, the blade tip partition rib is positioned in a gap between the turbine blade and the sealing structure so as to replace the existing blade tip girdle structure, so that gas loss in the blade tip gap can be reduced, and no blade tip girdle structure is needed; and at the same time, the structure of the blade tip partition rib is simple, so that the blade tip partition rib can be rapidly maintained when being abraded or damaged after long time work of the turbine blade; and therefore, the turbine blade has high maintainability.

Owner:HENAN UNIV OF SCI & TECH

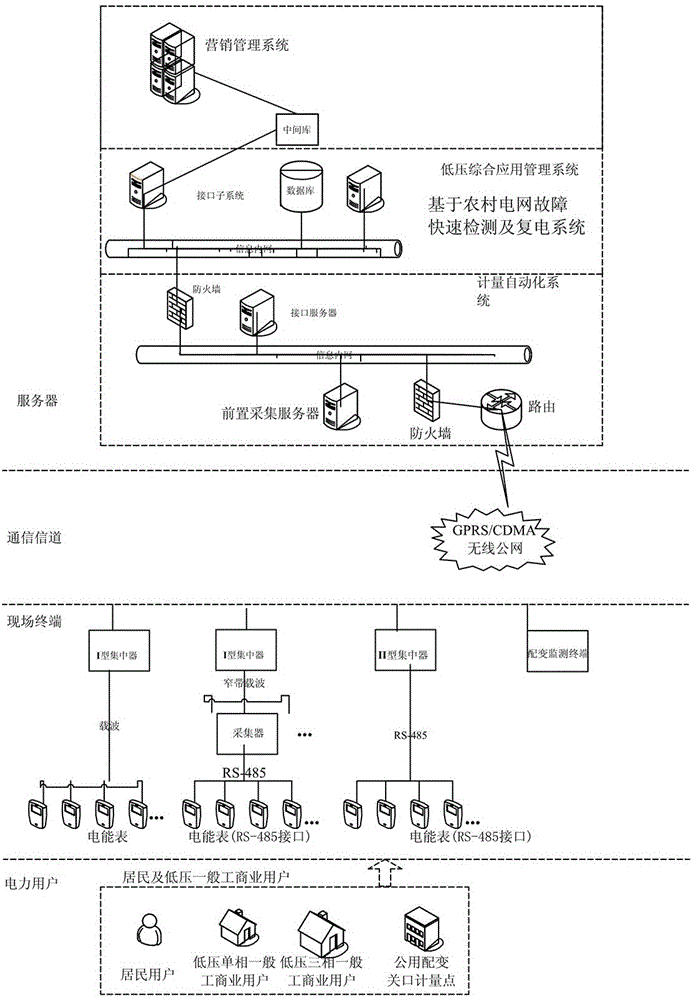

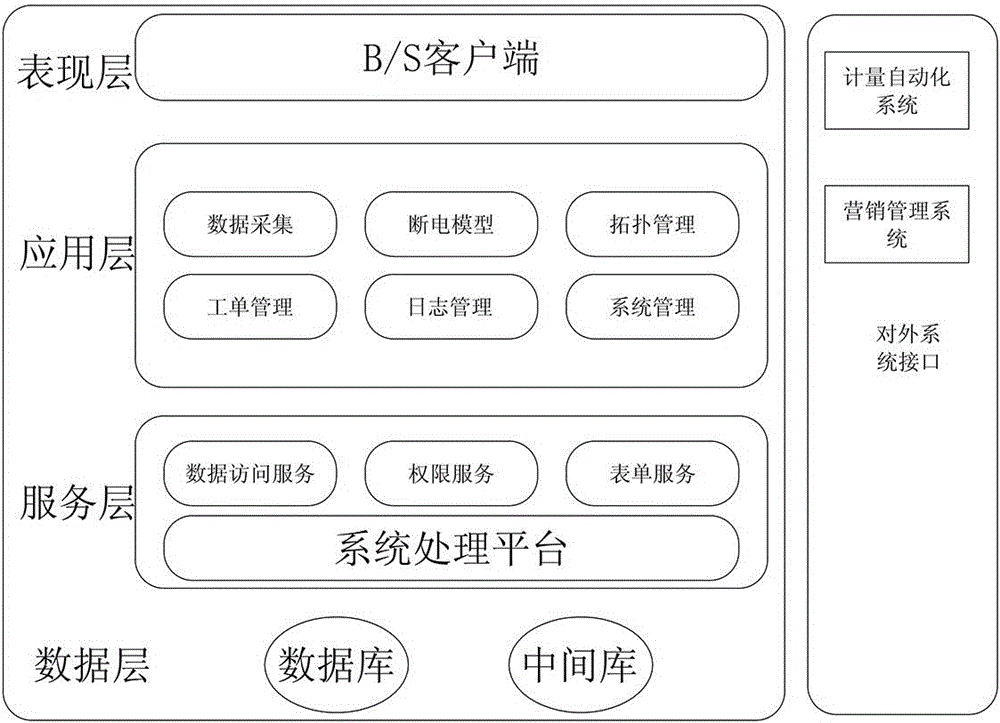

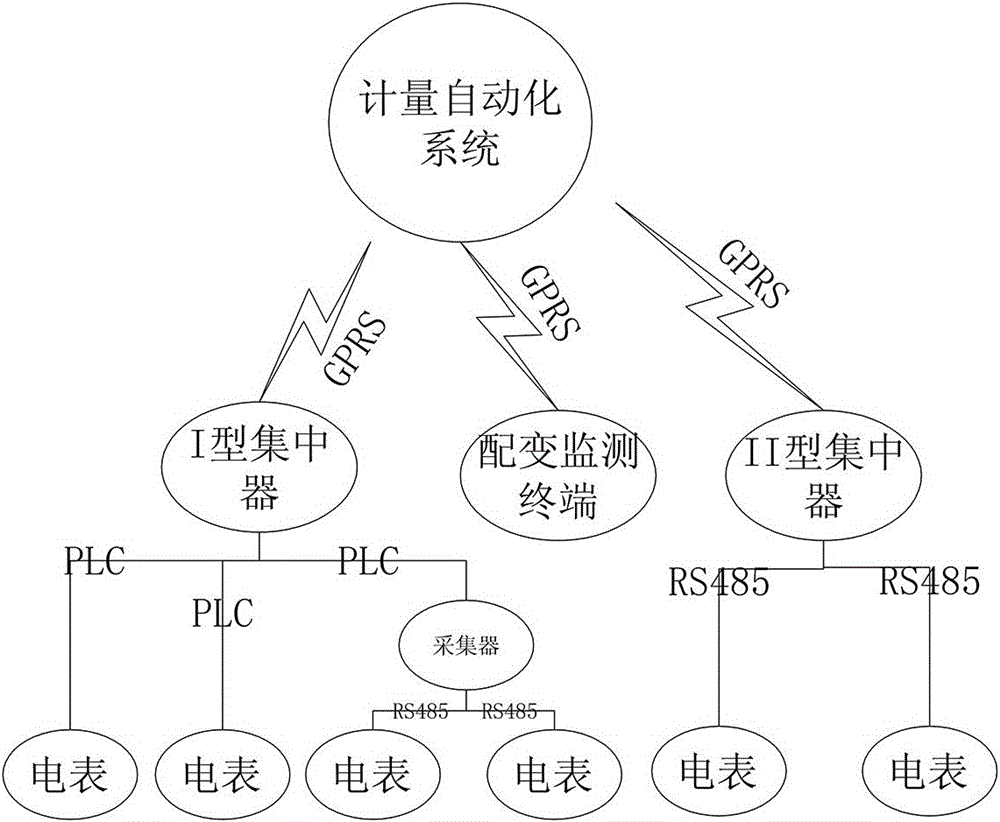

Rapid fault detection and power recovery system based on rural power network, and concentrator detection method thereof

ActiveCN105915398AOptimize network structureReduce in quantityElectric signal transmission systemsPower distribution line transmissionLow voltageEngineering

The invention relates to a rapid fault detection and power recovery system based on a rural power network, and a concentrator detection method thereof. The rapid fault detection and power recovery system comprises an automatic metering system, a communication interface and a terminal and further comprises an alarm module; processed data comes from the automatic metering system and a marketing management system; the processed data is fed back to a low-voltage comprehensive application management system; the terminal comprises a distribution transform monitoring terminal, a concentrator and a metering unit group; the minimum detection voltage of a voltage detection module of the concentrator is 10V; both the distribution transform monitoring terminal and the concentrator are each provided with a wireless communication module communicated with the automatic metering system, and periodically perform data communication with the automatic metering system; the heartbeat cycle of the distribution transform monitoring terminal is 15 m; and the heartbeat cycle of the concentrator is 5 m. According to the rapid fault detection and power recovery system based on the rural power network, and the concentrator detection method thereof disclosed by the invention, the alarm precision is finely divided into four kinds by upgrading software in the existing concentrator, completing the interface of the automatic metering system and shortening the data interaction cycle of the concentrator and an ammeter; different maintainers can be dispatched easily; and thus, active and rapid first-aid repair is realized.

Owner:GUANGXI POWER GRID CO LTD NANNING POWER SUPPLY BUREAU

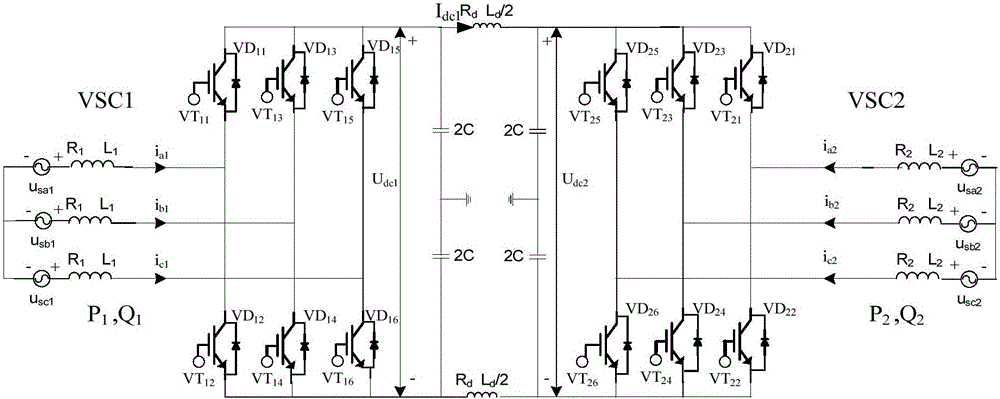

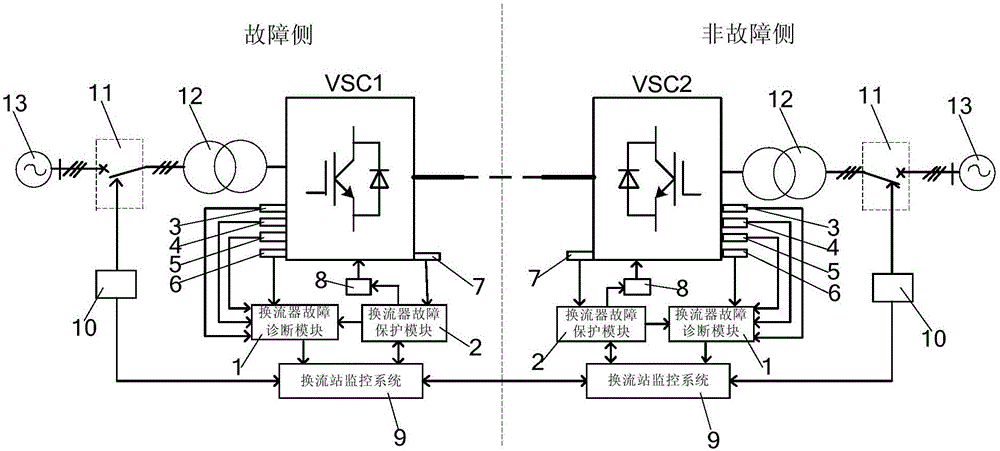

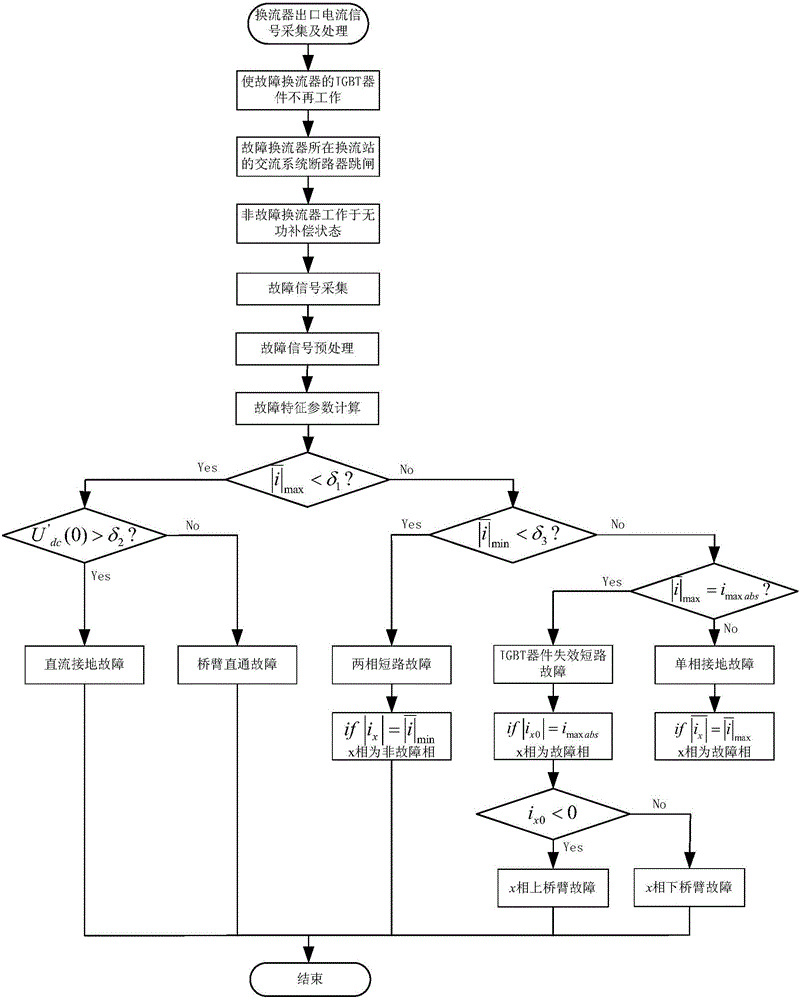

Two-level flexible direct current power transmission converter fault protection and fault diagnosis method

InactiveCN105896476AThe method steps are simpleEasy to implementEmergency protective circuit arrangementsPower supply testingDiagnosis methodsComputer module

The invention discloses a two-level flexible direct current power transmission converter fault protection and fault diagnosis method. The method provided by the invention is characterized in that a step 1 converter fault protection comprises: a step 101, converter outlet current signal acquisition and processing, a step 102, interruption of working of IGBT devices of a faulted converter, a step 103, the tripping-out of the alternating current system circuit breaker of the convertor station of the faulted converter, a step 104, working of normally functioning converters in a passive compensation state; a step 2 converter fault diagnosis comprises: a step 201, fault signal acquisition, a step 202, preprocessing of fault signals, a step 203, fault characteristic parameter calculation, a step 204, converter fault diagnosis of a converter fault diagnosis module by adopting a layering method. The two-level flexible direct current power transmission converter fault protection and fault diagnosis method is advantageous in that the steps are simple, the realization is convenient, the cost is low, the fault diagnosis identification rate is high, the practicability is strong, the use effect is good, and the popularization and the application are facilitated.

Owner:XIAN UNIV OF SCI & TECH

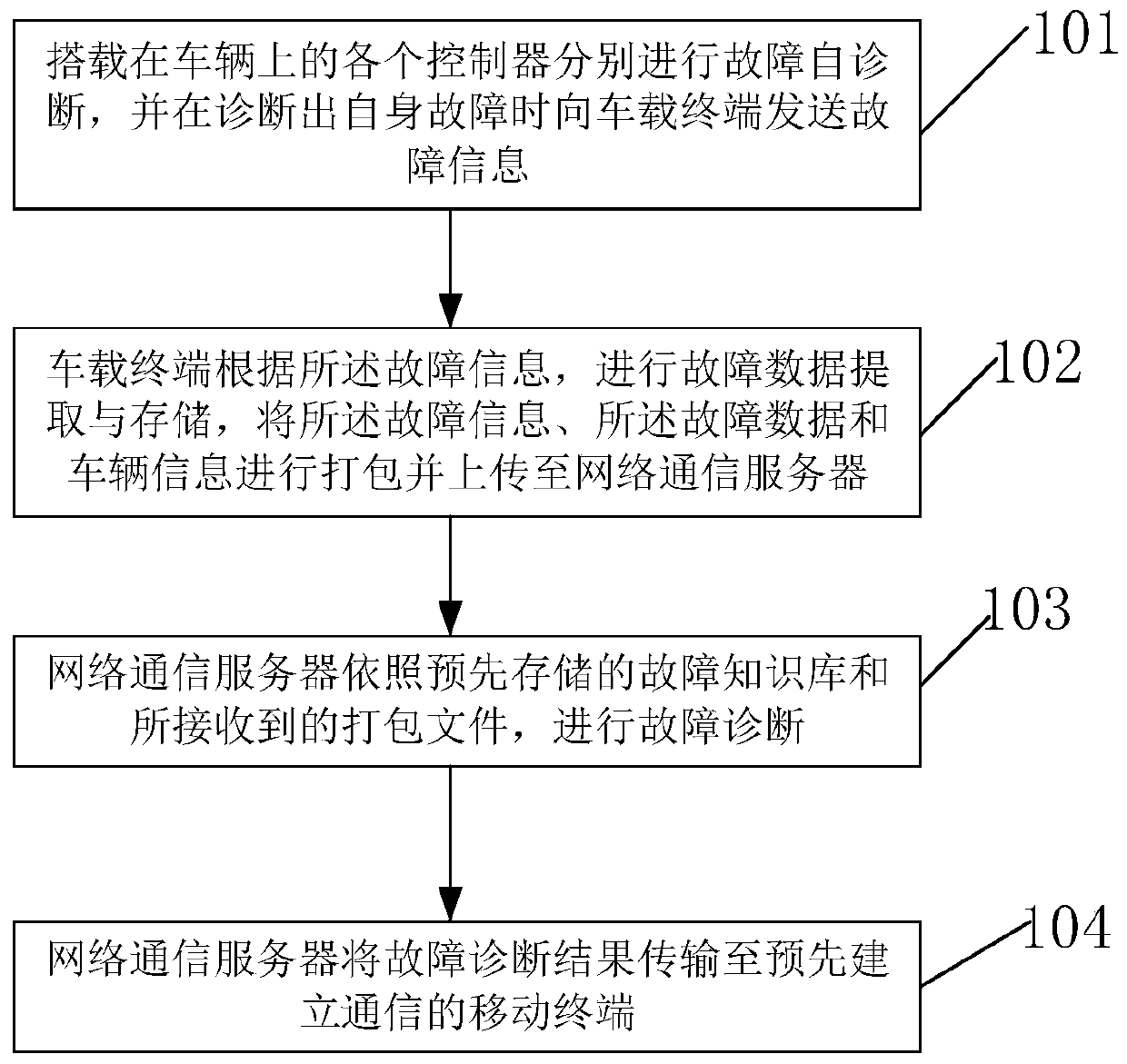

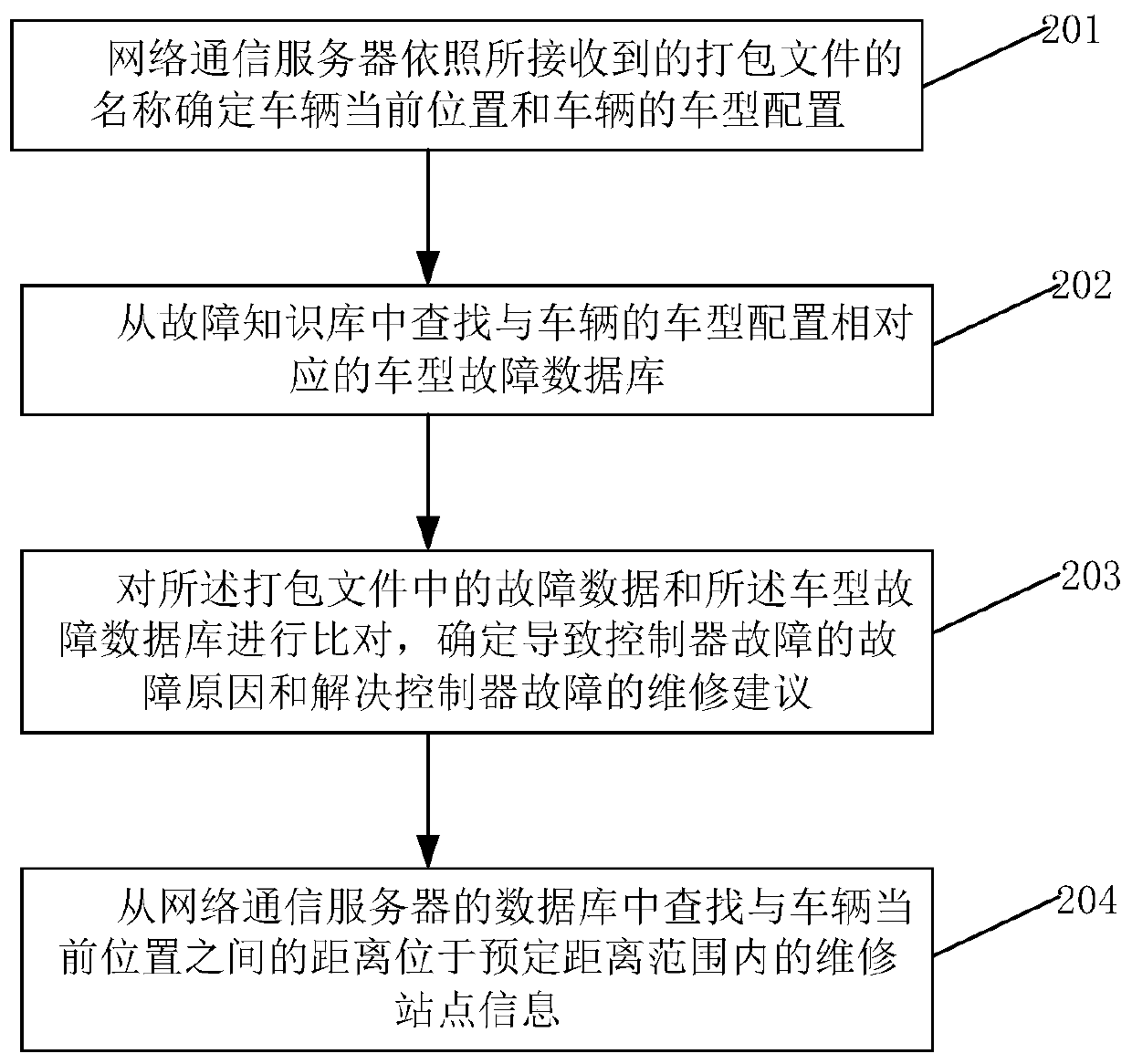

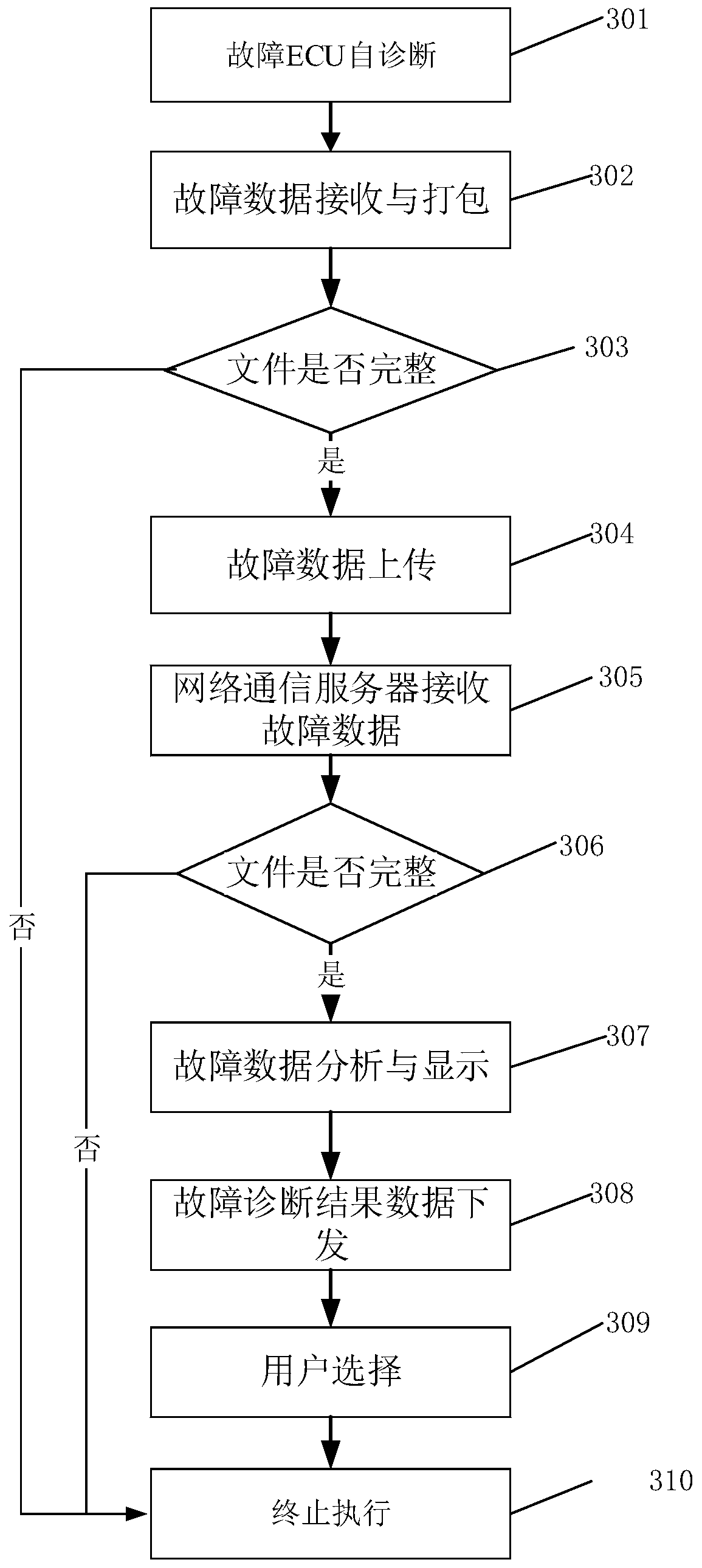

Remote fault diagnosis method and system for new energy vehicle

InactiveCN110109447AQuick repairReduce cost pressureProgramme controlElectric testing/monitoringNew energyDiagnosis methods

The invention relates to a remote fault diagnosis method and system for a new energy vehicle. Specific data at the fault occurring moment are collected, packed, uploaded and analyzed so as to solve the problems of unclear fault positioning and low positioning efficiency in the prior art; and by pushing fault suggestions and maintenance sites, the problem that the new energy vehicle cannot feed vehicle faults and a maintenance scheme back to a user in time is solved. The remote fault diagnosis method for the new energy vehicle comprises the steps that all controllers carried on the vehicle conduct fault self-diagnosis and send fault information to a vehicle-mounted terminal when the faults of the vehicle are diagnosed; the vehicle-mounted terminal extracts and stores fault data according tothe fault information, and the fault information, the fault data and vehicle information are packed and uploaded to a network communication server; and the network communication server conducts faultdiagnosis according to a pre-stored fault knowledge base and a received package file; and the network communication server transmits a fault diagnosis result to a mobile terminal pre-establishing communication with the network communication server.

Owner:深蓝汽车科技有限公司

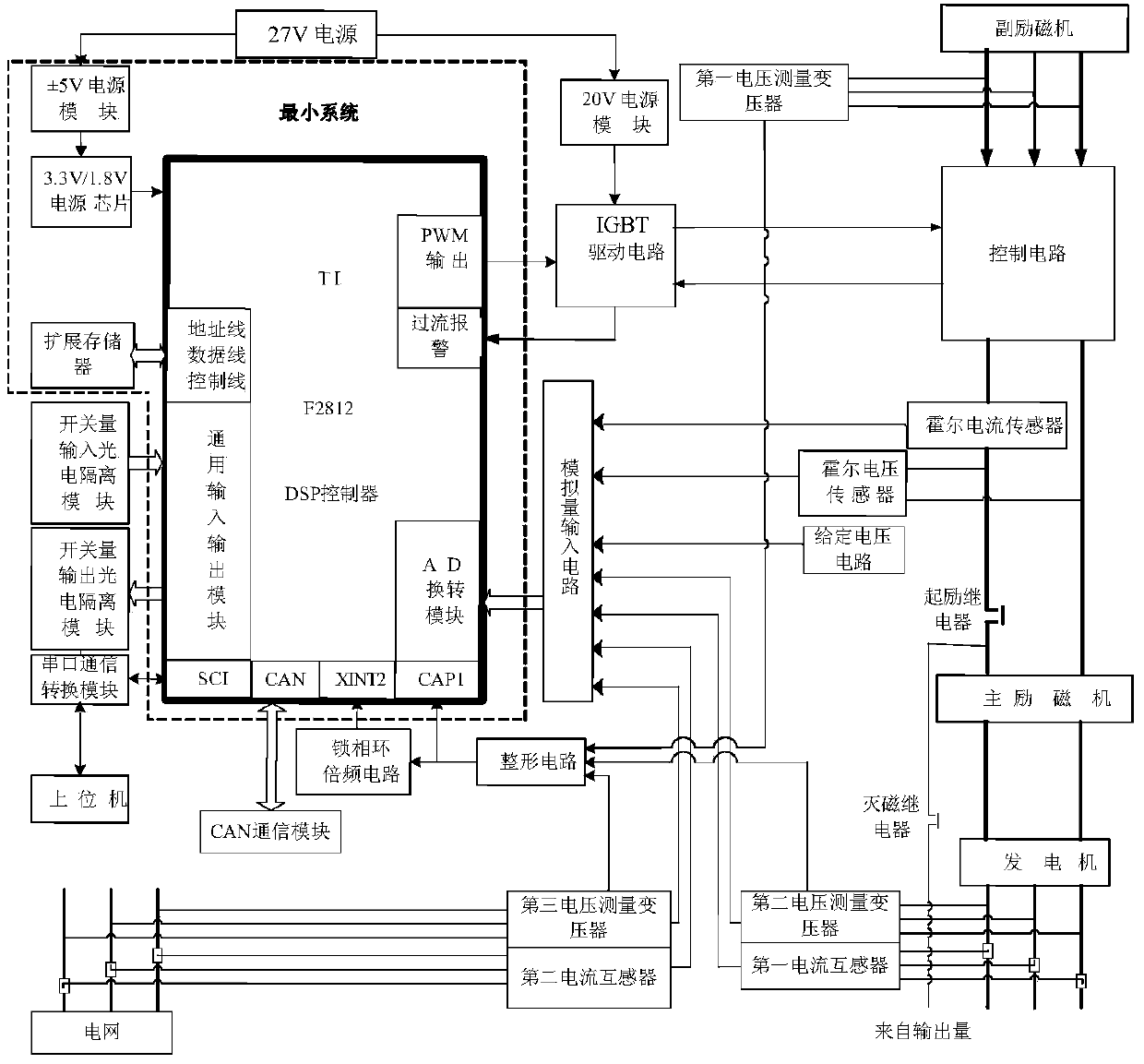

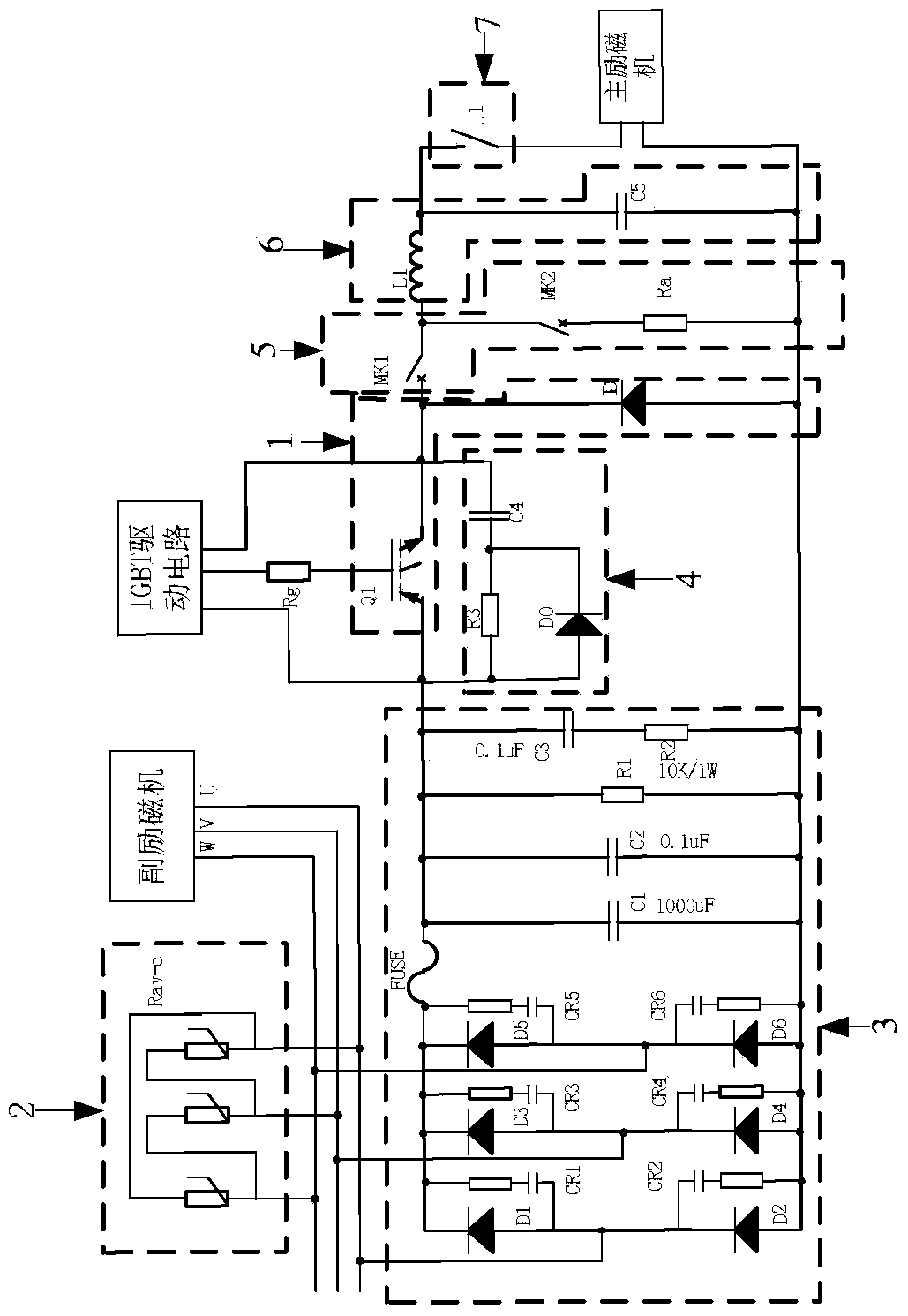

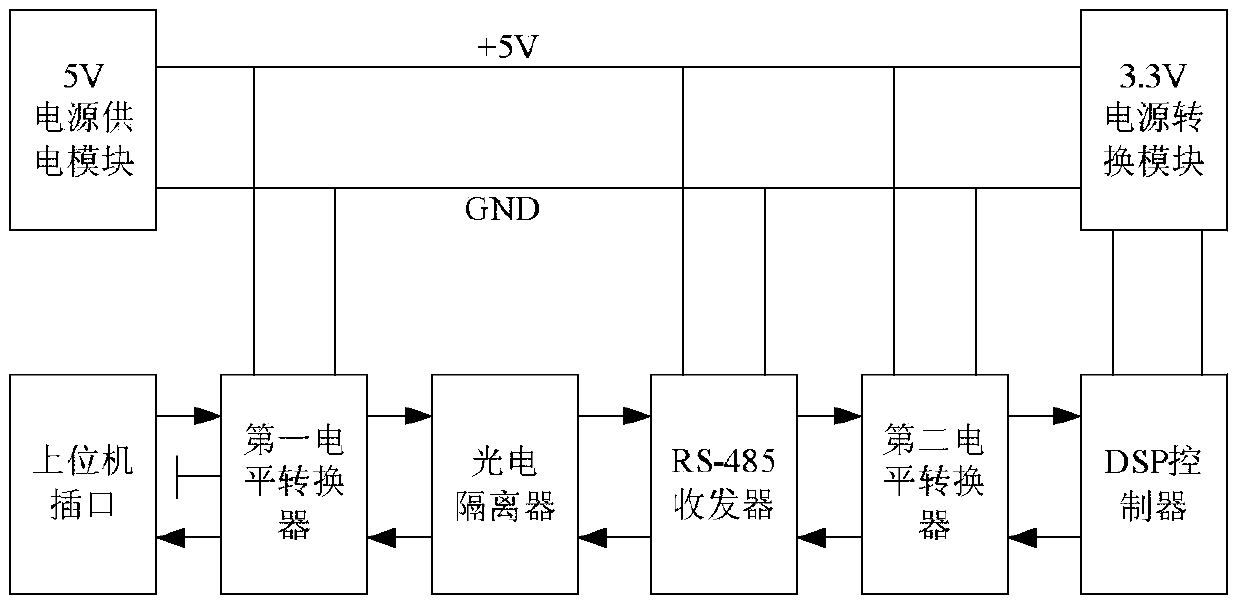

Single-tube IGBT (Insulated Gate Bipolar Translator)-based three-stage brushless generator power control device and power control method

InactiveCN103746622AReduce lossQuick responseGenerator control by field variationPower unitPhase-locked loop

The invention provides a single-tube IGBT (Insulated Gate Bipolar Translator)-based three-stage brushless generator power control device and a power control method. The single-tube IGBT-based three-stage brushless generator power control device comprises a minimum system, a control circuit, a power unit, a power module, an auxiliary exciter, a main exciter, a generator, a first voltage measurement transformer, a second voltage measurement transformer, a third voltage measurement transformer, a first current transformer, a second current transformer, a Hall voltage sensor, a Hall current sensor, a given voltage circuit, an excitation relay, a deexcitation relay, an IGBT drive circuit, an analog input circuit, a phase-locked loop frequency doubling circuit, a discrete input photoelectric isolation module and a discrete output photoelectric isolation module. Because the single-tube IGBT is adopted as a power switching device, switching loss can be effectively reduced, the response speed can be effectively increased, and the reliability is high; a controller is adopted as a main control unit to accurately control the three-stage synchronous generator; because the single-tube IGBT-based three-stage brushless generator power control device can communicates with an upper computer to monitor the system, faults can be rapidly and conveniently diagnosed and overhauled.

Owner:NORTHEASTERN UNIV +1

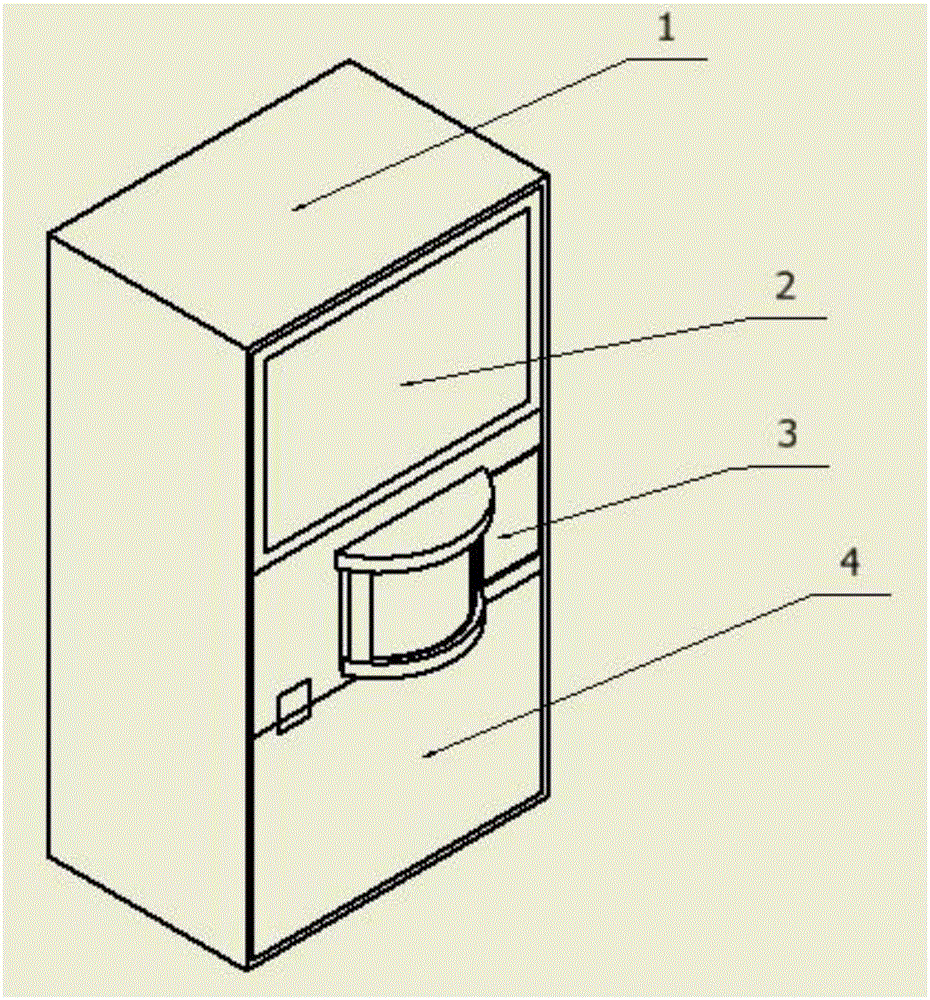

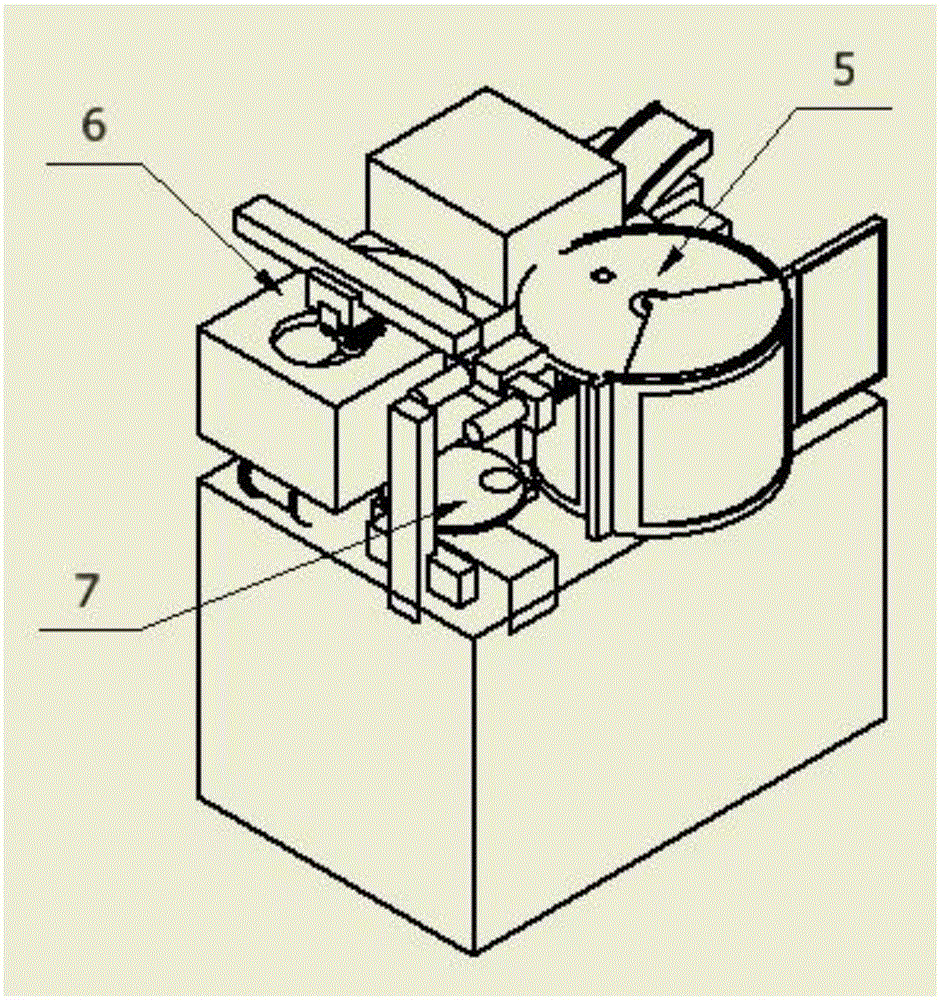

An intelligent integrated food selling terminal machine

ActiveCN106408764AGuaranteed tasteGuaranteed flavorCoin-freed apparatus detailsApparatus for dispensing discrete articlesFood safetyIntegrated operations

The invention provides an intelligent integrated food selling terminal machine which consists of a cabinet body, a base, a refrigerating module, a heating module, an output module, a packing module, a cleaning module, a man-machine interaction interface and control module and a food safety monitoring module. The refrigerating module is used for low temperature storage of food; the heating module is used for rapidly heating food; the output module outputs heated food to a meal fetching opening and processes food that is not taken away for a long time; the packing module is used for rapidly packing food; the cleaning module is used for rapid sterilization and disinfection in the machine; the man-machine interaction interface and control module is used for intelligent communication with customers and coordination control between the modules; the base bears the weight of the machine and contains functional components, such as a compressor, inside; the cabinet body consists of a plurality of panels and is used for isolating the inside of the machine from an external environment; the food safety monitoring module is used for monitoring food quality in real time. The machine can realize integrated operations of refrigeration, heating, output, packing and intelligent selling of food, has complete functions, is convenient and efficient, and can be widely applied to such places as stations for safe selling of food.

Owner:XI AN JIAOTONG UNIV

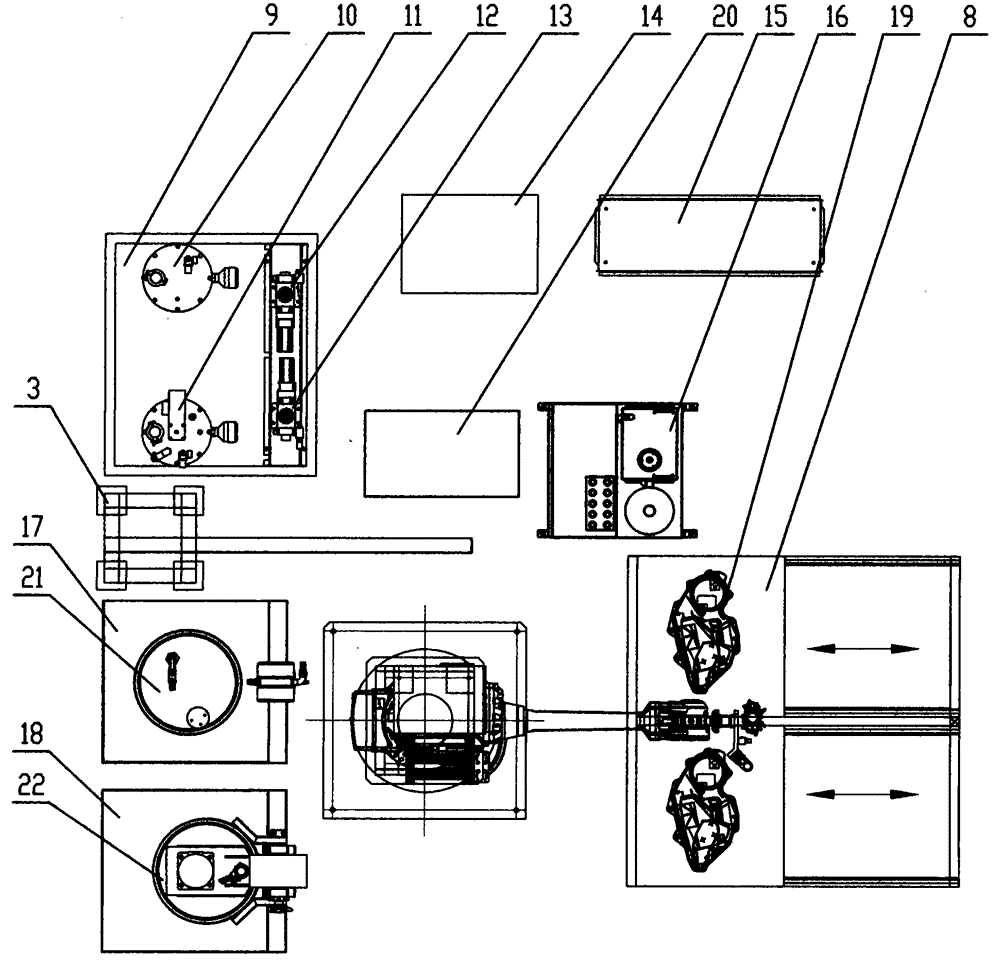

Five-axis robot gumming equipment and technology

ActiveCN104971862ASimple processFast processingProgramme-controlled manipulatorSpraying apparatusMetering pumpArthrobotrys

The invention relates to the technical field of gumming, in particular to five-axis robot gumming equipment and a technology which are used for two-component polyurethane gumming. The five-axis robot gumming equipment is characterized by comprising a five-axis robot, a gum supply device, a two-component gumming head, a double-station automatic gumming workbench or multi-station automatic and rotary gumming workbench, plasma processing equipment, a waste washing liquid recycling device and an intelligent control system. The five-axis robot is a five-joint robot. A workpiece is put on the double-station automatic gumming workbench or multi-station automatic and rotary gumming workbench. The workpiece is fixed or can rotate or swing or move along one axis. The two-component gumming head and aplasma processing head can achieve five-axis linkage. The gum supply device comprises a gum A barrel, a gum B barrel, a gum A metering pump, a gum B metering pump, a gum pipe, a gum supply pipeline, a pipeline support, a gum A material barrel and a gum B material barrel. The polyurethane gumming equipment and the technology are novel, accurate in matching ratio, stable in adhesive tape performance and good in sealing effect.

Owner:DALIAN HUAGONG INNOVATION TECH

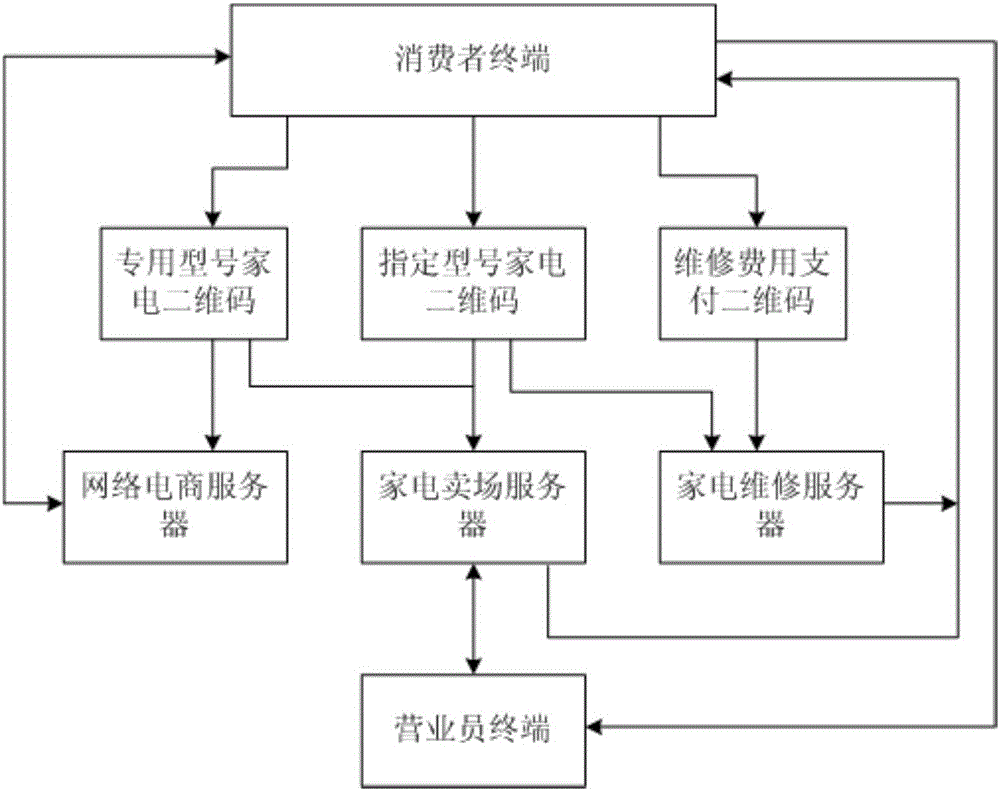

Household appliance two-dimensional code based operation platform and operation method

InactiveCN105117957AQuick repairBuying/selling/leasing transactionsMarketingRepair timeComputer terminal

The invention provides a household appliance two-dimensional based operation platform, comprising a household appliance two-dimensional code, a customer terminal, a salesperson terminal and a server. An operation method of the operation platform comprises the following steps: the customer terminal scans the household appliance two-dimensional code, uploads a household appliance purchase order, and scans the household appliance two-dimensional code to confirm a receipt when a good is received; when a household appliance goes wrong, the customer terminal scans the household appliance two-dimensional code, fills in a household appliance repair bill and uploads the household appliance repair bill to the server, and the server confirms household appliance repair time and repair cost with the customer terminal; after the household appliance is repaired, a consumer pays the repair cost; and a household appliance merchant, according to the household appliance purchase order uploaded by the consumer terminal, sends promotion information of household appliance products to the consumer terminal. The consumer, by the operation platform provided by the invention, can quickly and conveniently implement the operations of purchase, maintenance and the like on the household appliance; and by the operation platform provided by the invention, the household appliance merchant can obtain the requirement of the consumer for household appliance products from the consumer record so as to push the household appliance product information related to the requirement to the consumer.

Owner:LEADER TECH BEIJING DIGITAL TECH

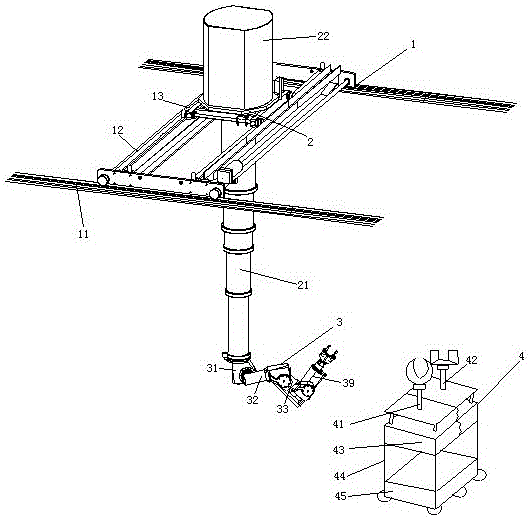

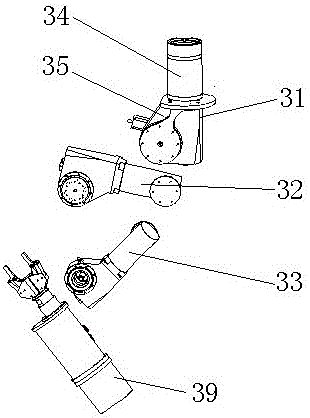

Joint type mechanical arm rapid disassembling and assembling system under nuclear radiation environment

InactiveCN105666478AEasy maintenanceEasy to replaceProgramme-controlled manipulatorMetal working apparatusNuclear radiationControl system

The invention relates to a tool device under the nuclear radiation environment, in particular to a joint type mechanical arm rapid disassembling and assembling system under the nuclear radiation environment. The joint type mechanical arm rapid disassembling and assembling system mainly comprises a mechanical arm linkage system, a mechanical arm assembling piece, an assembling and disassembling mechanism and a control system. The mechanical arm linkage system is connected with the mechanical arm assembling piece in a linked mode. The assembling and disassembling mechanism is a disassembling and assembling tool of the mechanical arm assembling piece. The mechanical arm linkage system is mainly composed of a suspended wall type linkage movement frame, a hanging type linkage telescopic cylinder and a coupler. The mechanical arm assembling piece is composed of multiple joint mechanical arms and comprises a brake part and a drive part. The brake part mainly comprises a large arm, a middle arm and a small arm which are connected with one another from top to bottom. The drive part mainly comprises a servo drive motor, a speed reducer and a worm and worm wheel transmission mechanism. The assembling and disassembling mechanism mainly comprises an upper shell body assembling and disassembling structure, a lower shell body assembling and disassembling structure, a cylinder drive lifting table, an assembling and disassembling supporting frame and a movement base. The joint type mechanical arm rapid disassembling and assembling system is used for disassembling and assembling of joints of nuclear radiation internal joint type mechanical arms, and therefore components of the mechanical arms can be conveniently maintained and replaced.

Owner:DONGGUAN UNIV OF TECH

Quick leakage-stopping agent

InactiveCN1434093AFast condensationHigh strengthOther chemical processesUltimate tensile strengthDefoaming Agents

The present invention discloses a quick leakage-stopping agent. It uses hydraulic binding cement base material, anchoring agent, hardening accelerator, solidifying agent, water-reducing agent, powdered defoaming agent and strengthening filling material as raw material, and adds these raw materials into mixing machine according to a certain order, uniformly mixes them and grinds them into 325 meshes to 400 meshes in grain size in grinding machine so as to obtain the invented product. Said product has the advantages of quick setting speed, high strength and good binding performance, so that it has good leakage-stopping and water-proofing function, and has extensive application.

Owner:刘玉军

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com