Dropping device for rotor craft

A technology for a rotorcraft and a delivery device, which is applied to launch devices, aircraft parts, transportation and packaging, etc., can solve the problems of incapable of time-sharing, small loading, and low precision, and achieve good safety, improve efficiency, and reduce costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

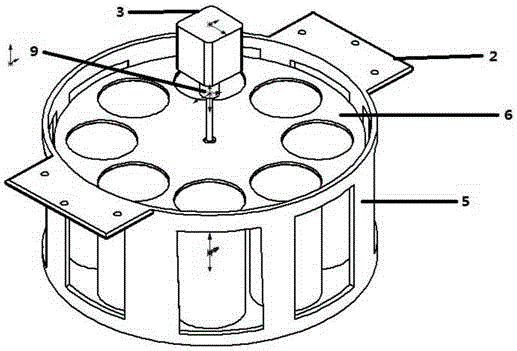

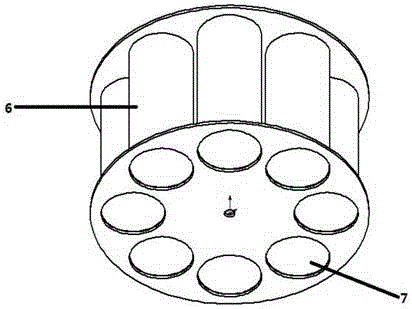

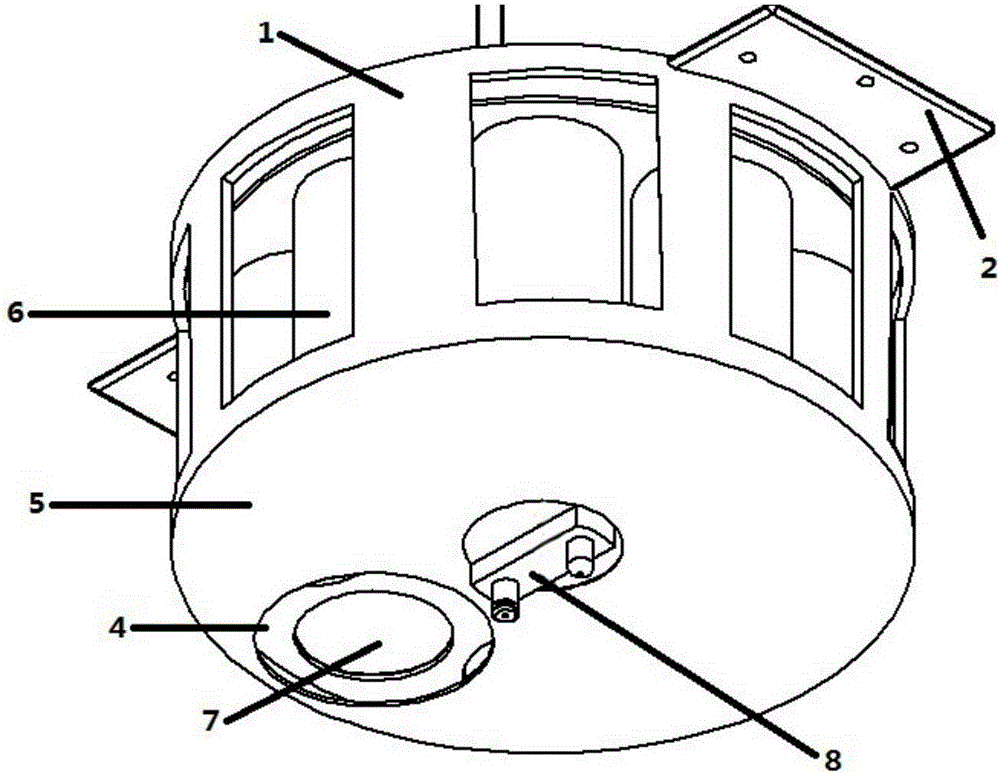

[0019] See attached Figure 1-5 , a delivery device for rotorcraft, including a delivery bin body 1, a fixed bracket 2, a motor 3, and an object delivery hole 4, the delivery bin body 1 includes a casing 5 and an inner turntable 6, the inner turntable includes a loading hole 7, and on the casing 5 A sight 8 is installed, and the sight 8 is made of a camera and a laser generator. The shell 5 is cylindrical as a whole, and the fixing bracket 2 stretches out from both sides of the shell and punches holes. The fixing bracket is installed on the aircraft chassis by screws. Keep relatively still during work, the outer shell 5 and the inner turntable 6 are connected by a rotating shaft and a bearing, so that the outer shell 5 and the inner turntable 6 are kept concentric, and a throwing hole 4 is distributed on the lower part of the shell 5, and the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com