Grading vibration screening machine

A vibrating screening machine and screening machine technology, applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of difficult maintenance and maintenance, inconvenient maintenance and maintenance, large volume, etc., and achieve simple structure, convenient replacement and maintenance, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

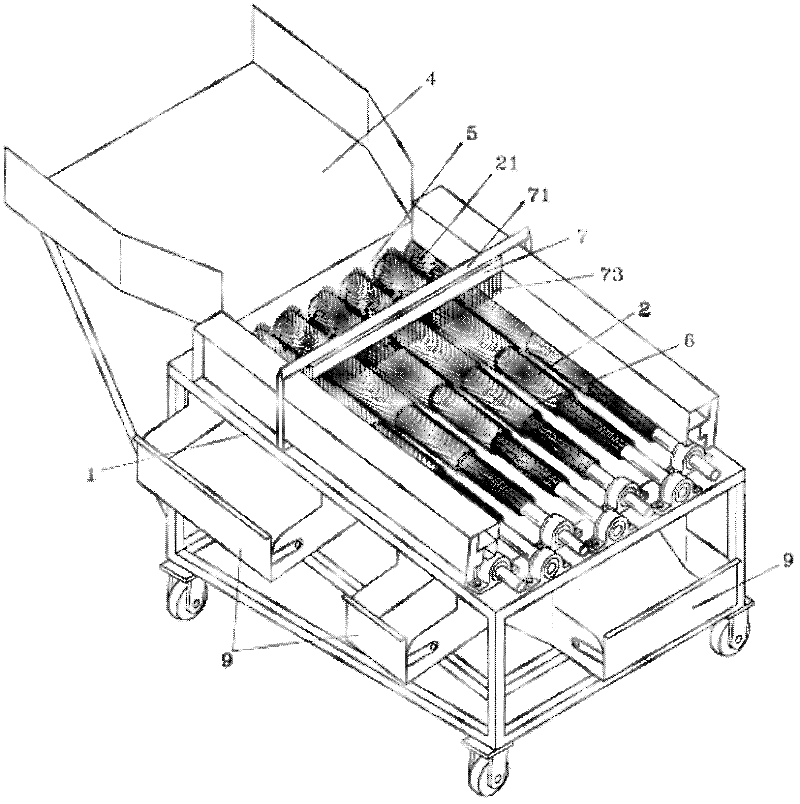

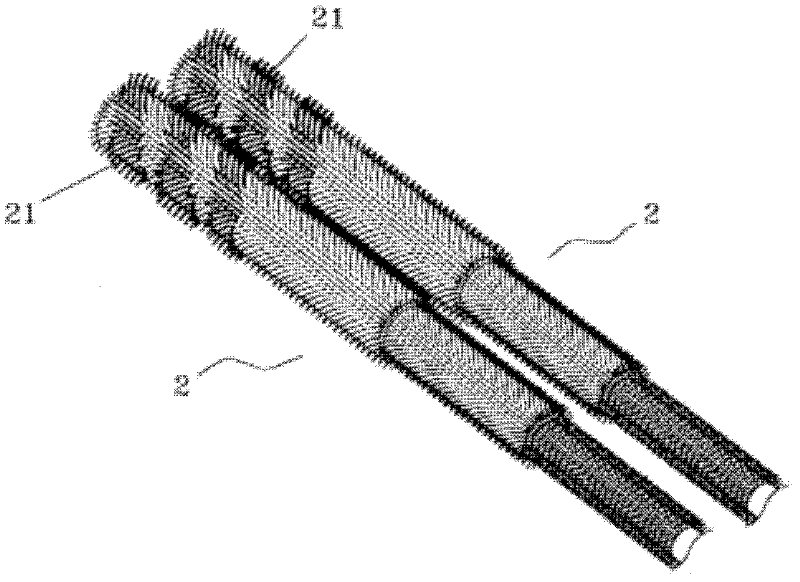

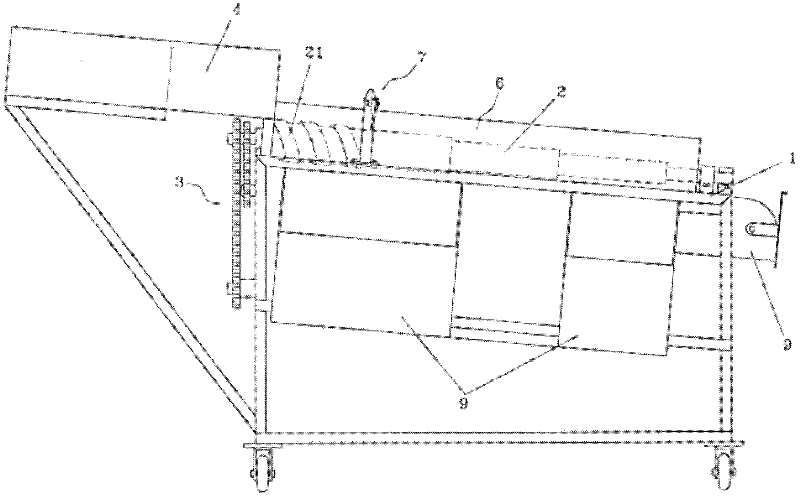

[0028] see figure 1 , shows a three-dimensional schematic view of the grading vibration screening machine of the present invention, the screening machine includes a body 1, a plurality of screen rollers 2, a feeding platform 4, a buffer plate 7 and a collection box 9, and the bottom of the body 1 is provided with a plurality of movable wheels, The plurality of movable wheels can facilitate the fast movement of the body 1. The upper part of the body 1 is a frame, and one side of the frame is connected with a feeding table 4. The feeding table 4 is flat, and both sides are vertically provided with side plates. The openings on both sides of table 4 are different in size, the larger side opening is outward, and the smaller side opening is located at the position connected with the body 1, a plurality of screen rollers 2 are arranged in parallel in the frame body, and a The buffer plate 7 is provided with a plurality of collection boxes 9 below the frame. see figure 2 , shows a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com