Turbine cooling blade with blade tip leakage prevention structure

A turbine cooling and anti-leakage technology, applied in the direction of blade support components, engine components, machines/engines, etc., can solve the problems of inconvenient maintenance, long maintenance cycle, complex structure, etc., to achieve easy processing and molding, long maintenance cycle, and reduce overall quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

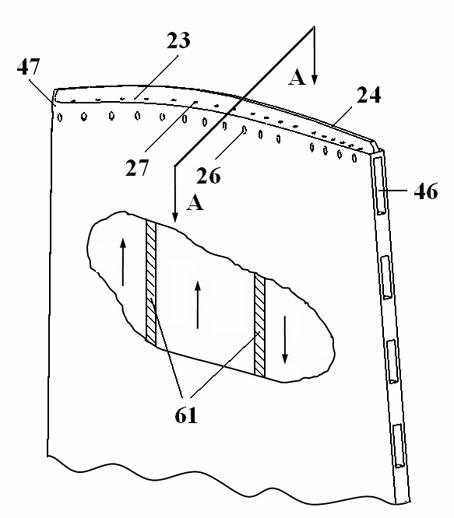

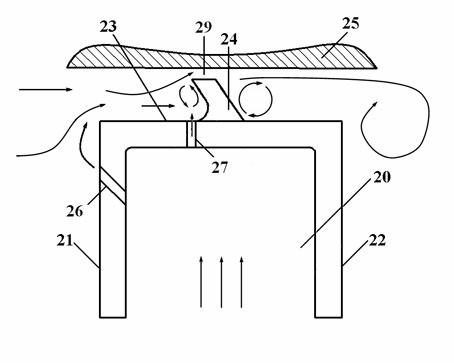

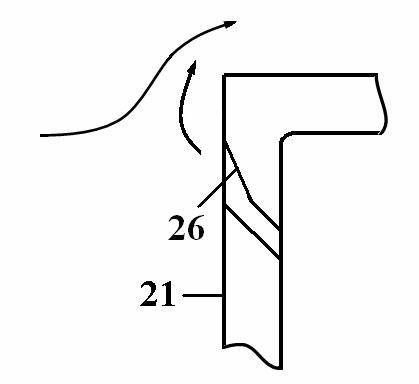

[0022] Embodiment 1 of a turbine cooling blade with a blade top leakage prevention structure, in Figure 1~3 , including the blade body, the blade body has a cooling channel 20, the cooling channel 20 is composed of the pressure surface 21 and the suction surface 22 of the blade body, and the leading edge 47 and the trailing edge connecting the two ends of the pressure surface 21 and the suction surface 22 together built around. The top of the blade body has a blade top top plate that seals the cooling channel 20. The blade top rib 24 is integrally formed on the outer surface of the blade top top plate. The blade top rib 24 extends from the leading edge 47 of the blade body to the trailing edge. The blade tip partition rib 24 extends along the central arc of the blade tip top plate at the center arc of the blade tip top plate. The blade tip ribs 24 are obliquely arranged on the blade tip top plate, and the blade tip ribs 24 obliquely face the pressure surface 21 . There is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com