Full-automatic robot gluing equipment and process technology

A robotic and fully automatic technology, applied in the direction of coating, liquid coating device on the surface, surface pretreatment, etc., to achieve the effect of easy gluing, simplified process and improved processing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

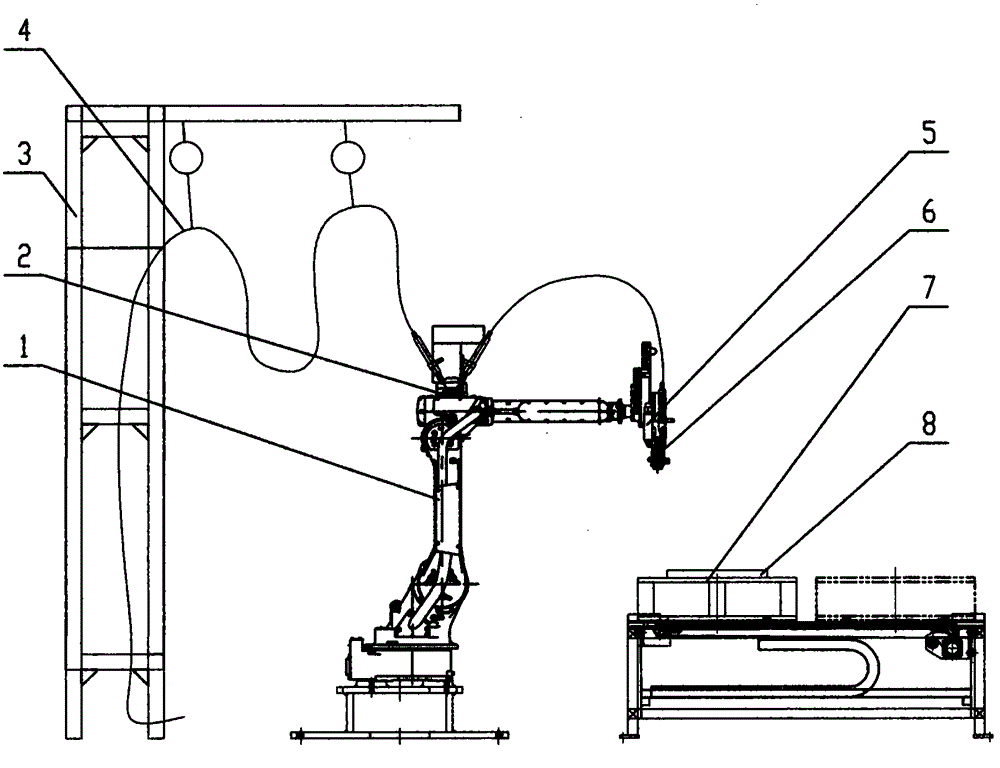

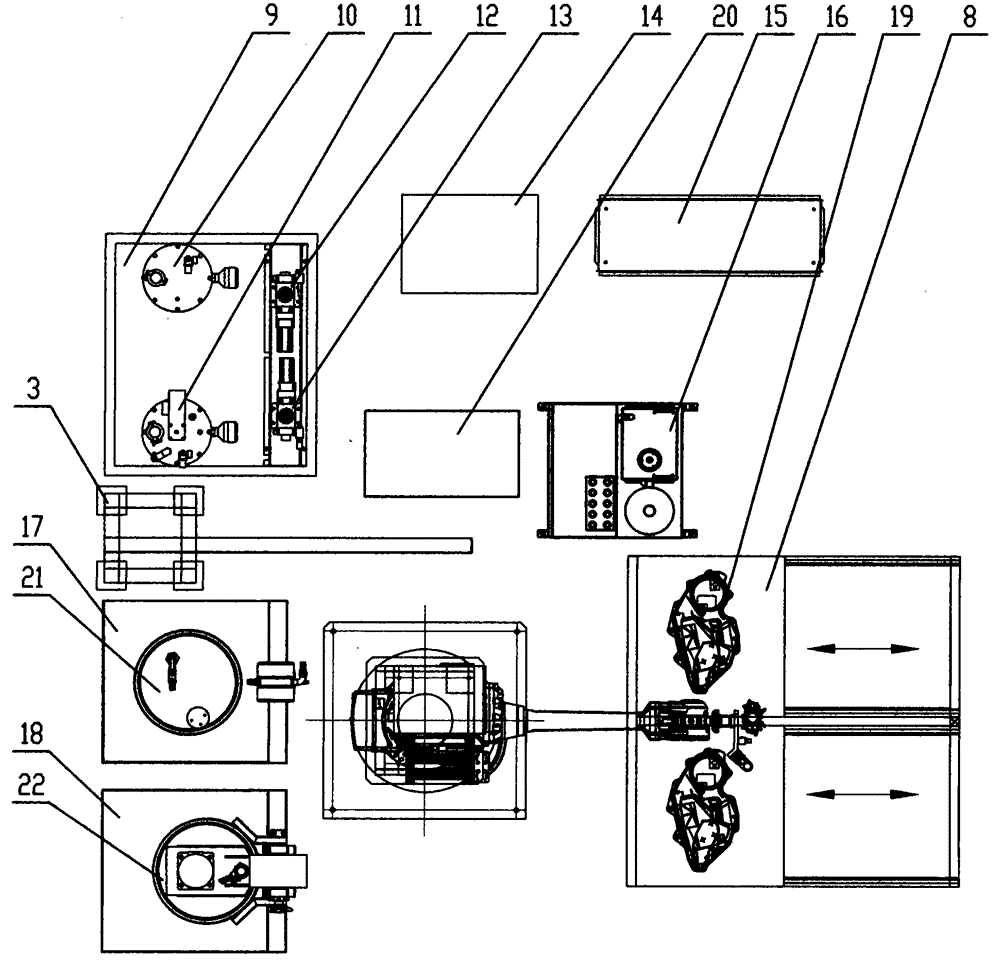

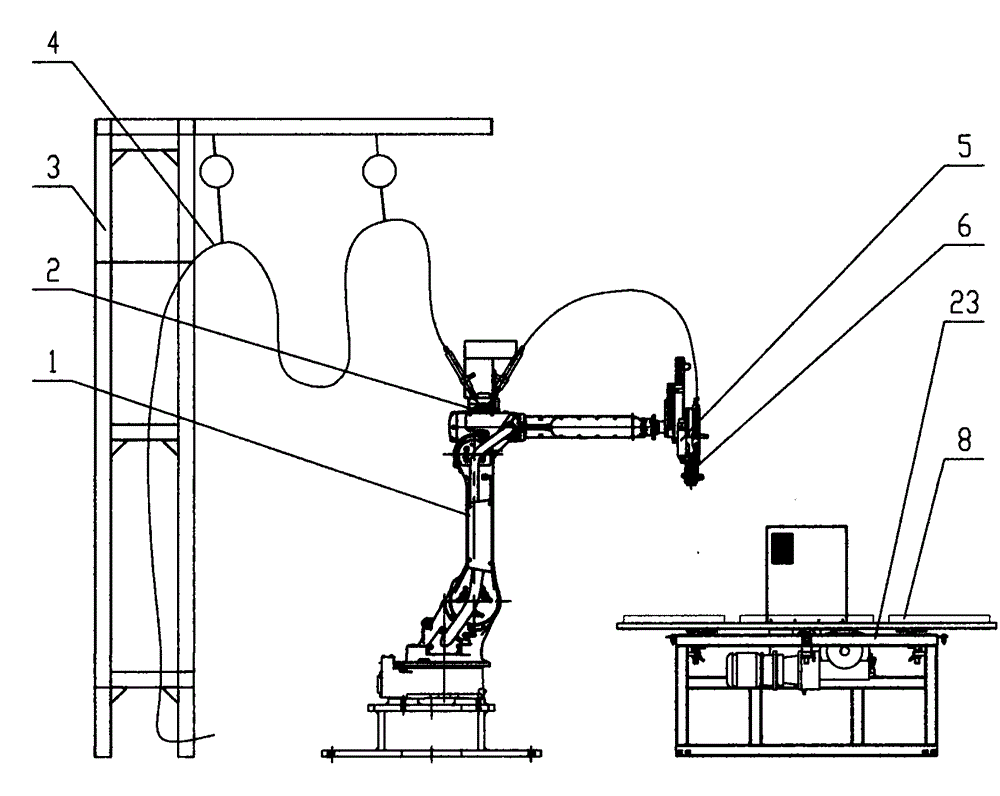

[0031] Specific implementation mode one: as Figure 1-8 As shown, a fully automatic robot gluing equipment and process technology is characterized in that it includes a three-axis robot or a four-axis robot or a five-axis robot or a six-axis robot 1, a glue supply device 9, a two-component gluing head 6, Double-station automatic gluing workbench 8 or multi-station automatic rotating gluing workbench 23, plasma treatment equipment 20, cleaning waste liquid recovery device 16, intelligent control system;

[0032] The structural forms of the three-axis robot and the four-axis robot are gantry-type or cantilever-type linear robots, and the two-component gluing head 6 and the plasma processing head 5 are fixed on the three-axis robot or the four-axis robot and can realize X, Y , Z three-axis linkage, the main motion transmission parts adopt linear guide rails, linear bearings, ball screws, rack and pinion or gears, toothed belts, servo motors or stepping motors; the three-axis robo...

specific Embodiment approach 2

[0041] Specific implementation mode two: as Figure 1-8 As shown, the fully automatic robot gluing equipment and process technology are characterized in that: it includes a three-axis robot or a four-axis robot or a five-axis robot or a six-axis robot 1, a glue supply device 9, and a two-component gluing head 6 , Double-station automatic gluing workbench 8 or multi-station automatic rotating gluing workbench 23, cleaning waste liquid recovery device 16, intelligent control system; only realize automatic gluing work on workpiece 19, without surface plasma treatment. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0042] Specific implementation mode three: as Figure 1-8 As shown, the fully automatic robot gluing equipment and process technology are characterized in that: the intelligent control system includes a robot control cabinet 14, an electric control cabinet 15, an industrial computer, a touch screen and control software, and the control system adopts an intelligent design , automatic control of three-axis robot or four-axis robot or five-axis robot or six-axis robot 1, plasma processing equipment 20, double-station automatic gluing workbench 8 or multi-station automatic rotating gluing workbench 23, glue supply device 9 , Two-component gluing head 6. Other compositions and connections are the same as those in Embodiments 1 and 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com