Patents

Literature

45results about How to "Quantitative uniform" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

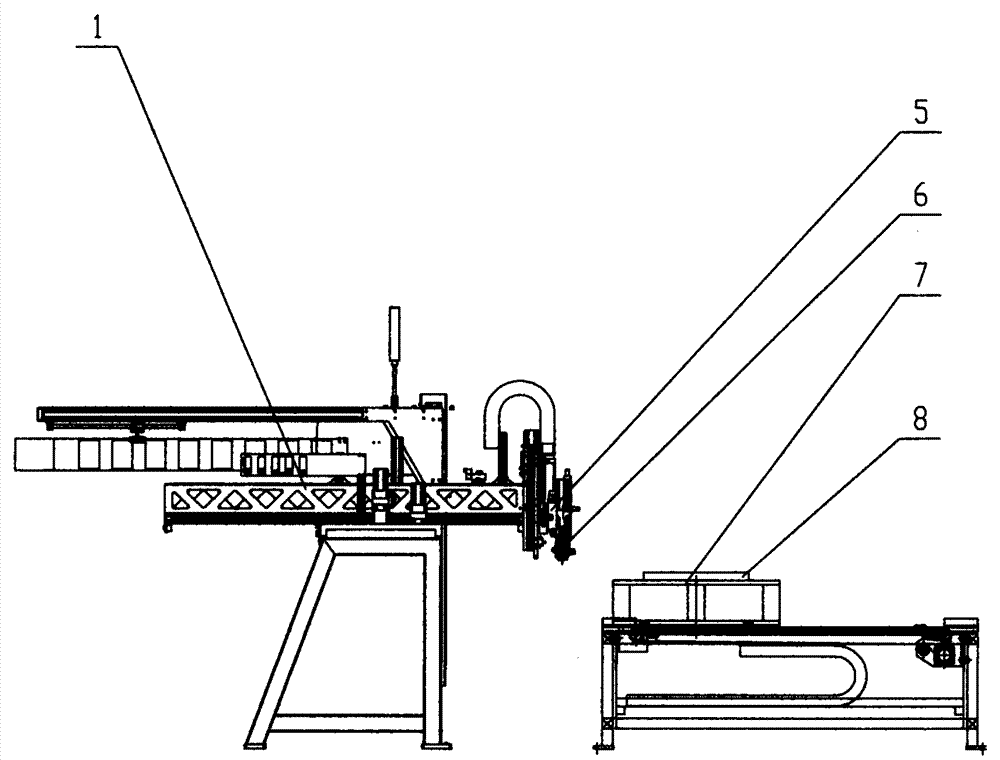

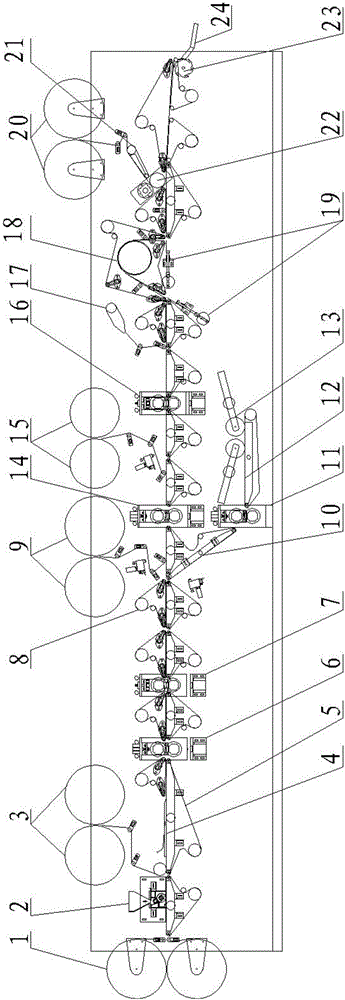

Full-automatic robot gluing equipment and process technology

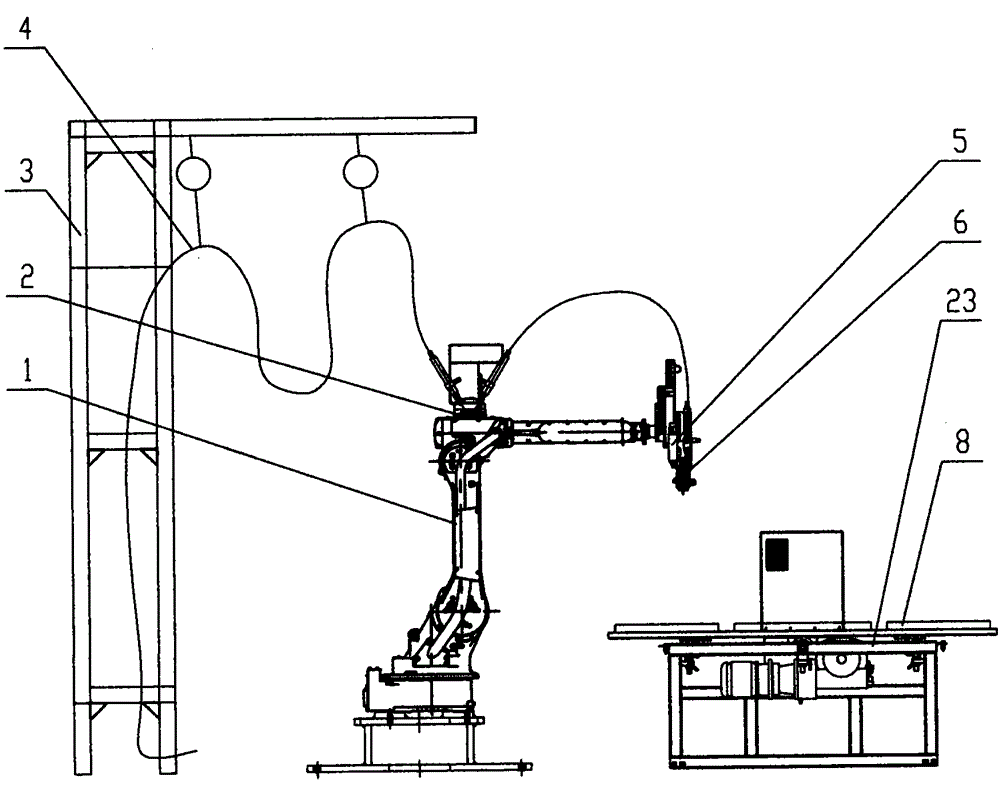

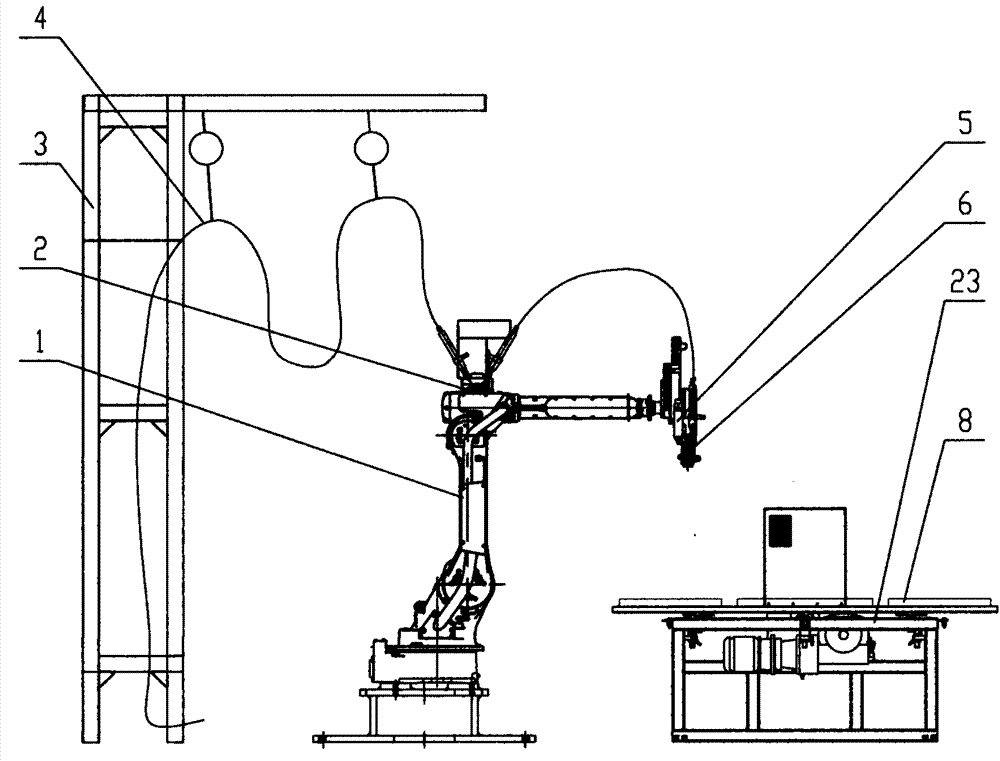

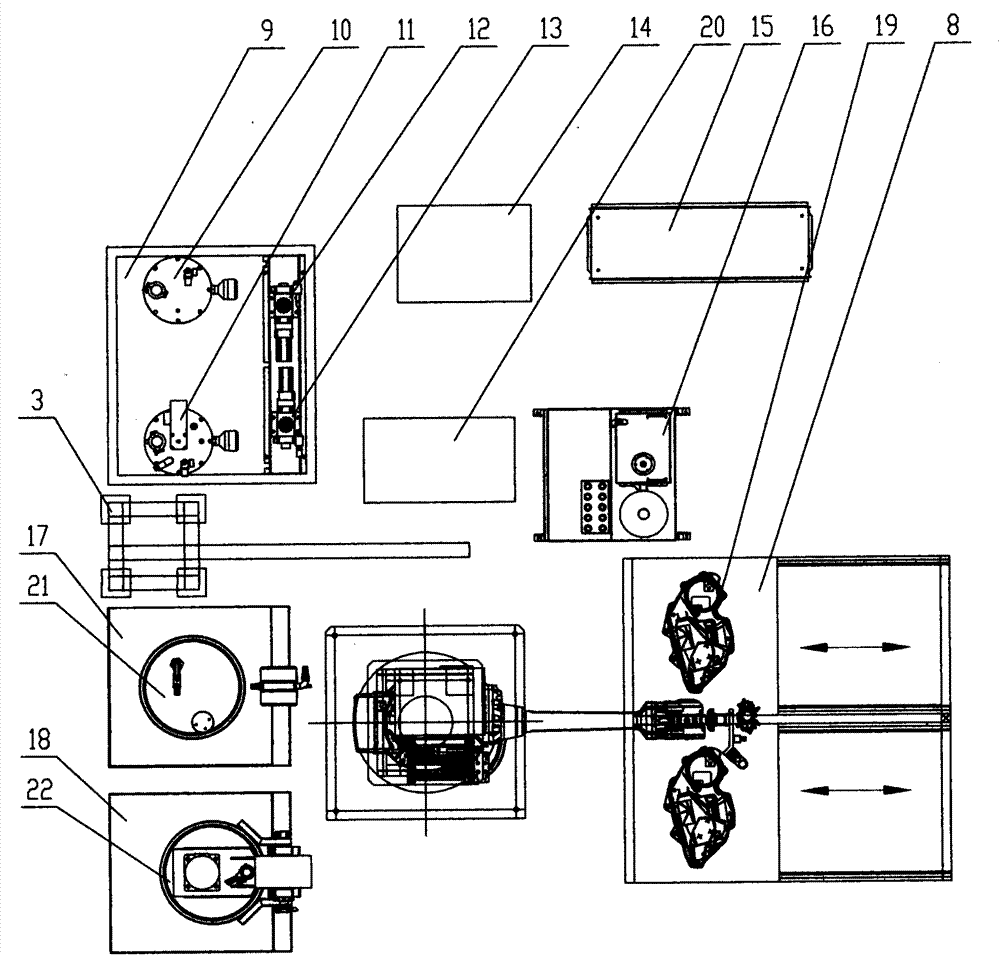

The invention relates to the technical field of gluing, in particular to full-automatic robot gluing equipment and a process technology which are used for two-component polyurethane gluing. The full-automatic robot gluing equipment is characterized in that the equipment comprises a three-axis robot or a four-axis robot or a five-axis robot or a six-axis robot, a glue supply device, a two-component gluing head, a two-station automatic gluing workbench or a multi-station automatic rotary gluing workbench, plasma treatment equipment, a waste cleaning solution recovery device and an intelligent control system. The three-axis robot or the four-axis robot is of a gantry type or cantilever type structure. The two-component gluing head and a plasma treatment head are fixed to the three-axis robot or the four-axis robot and can be linked in the X axis, the Y axis and the Z axis. The five-axis robot or the six-axis robot is an articulated robot, and five-axis linkage or six-axis linkage of the two-component gluing head and the plasma treatment head can be achieved. According to the novel polyurethane gluing equipment and the process technology, the proportion is precise, glue tape performance is stable, and the sealing effect is good.

Owner:DALIAN HUAGONG INNOVATION TECH

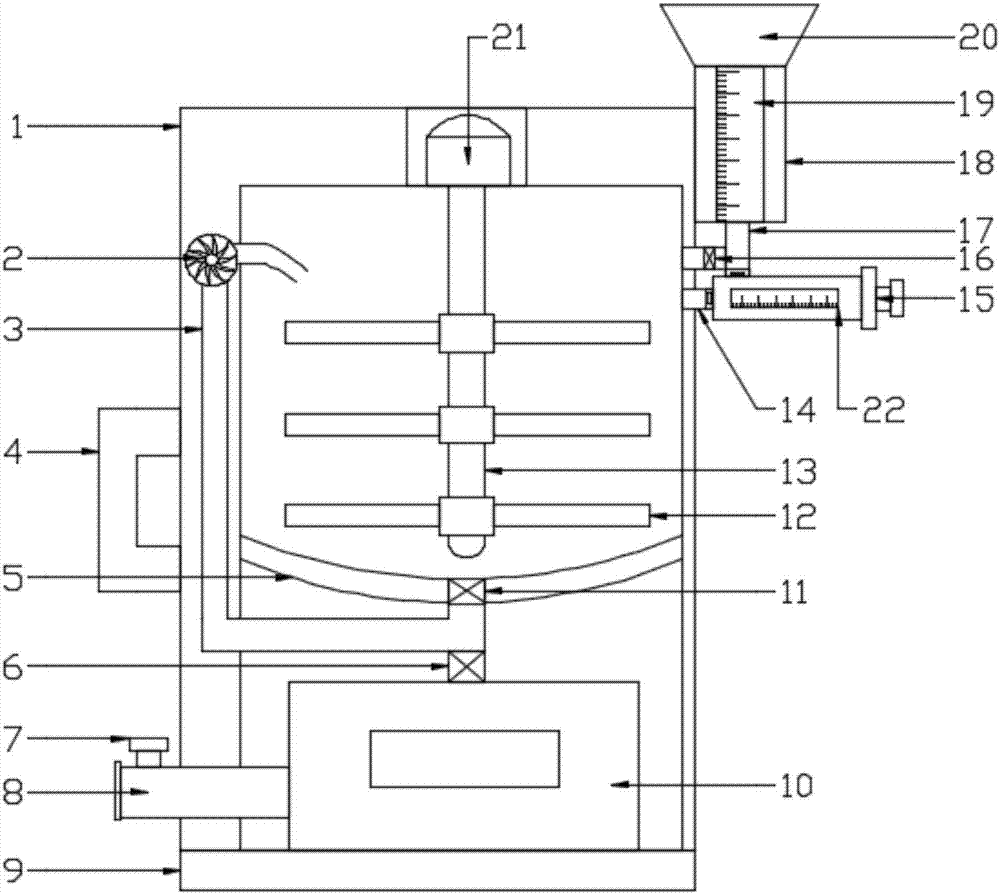

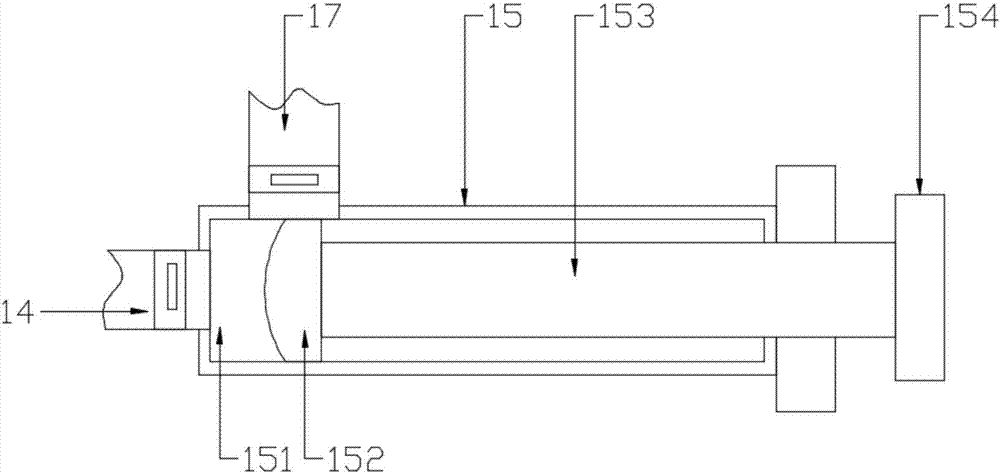

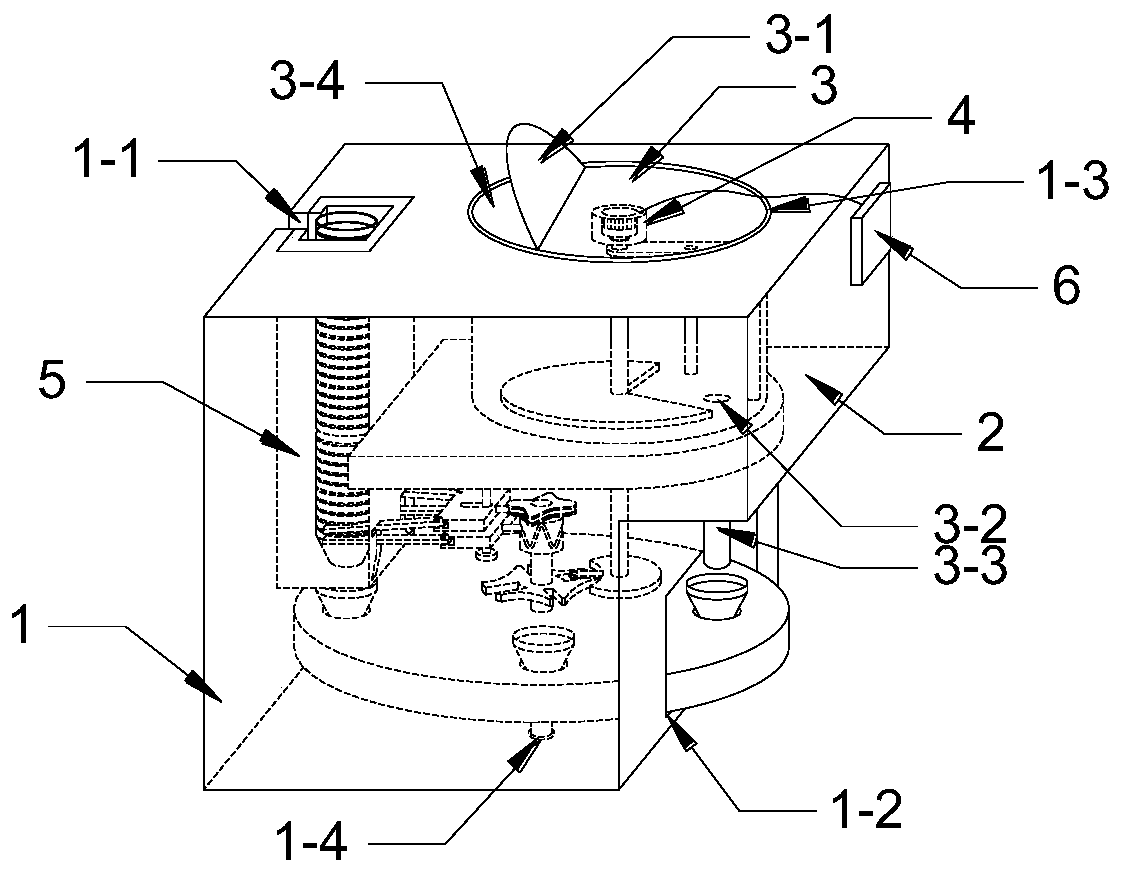

Quantitative mixing equipment for medical liquid medicament

InactiveCN107537363AImprove mixing efficiencyImprove user comfortRotary stirring mixersMixer accessoriesPistonThermal insulation

The invention discloses a quantitative mixing equipment for medical liquid medicament. The quantitative mixing equipment comprises an equipment shell, a thermal insulation heating box, a quantitativesyringe and a liquid measurement pipe, wherein the upper end of the equipment shell is provided with a motor; the lower end of the motor is rotatably connected with a spindle; the spindle is providedwith stirring paddles in array distribution; the lower end of the spindle is provided with a clapboard; the lower end of the clapboard is connected with a circulation pipe; shunting pipes in array distribution are arranged in the thermal insulation heating box; a heating plate is arranged between adjacent shunting pipes; an inner cavity is arranged in the quantitative syringe; a piston head is arranged in the inner cavity; the right side of the piston head is fixedly provided with a push rod; the right side of the push rod is provided with a pushing plate; the lower end of the liquid measurement pipe is provided with a second connecting pipe; the left side of the second connecting pipe is communicated with the equipment shell through a fifth connecting pipe. According to the quantitative mixing equipment for the medical liquid medicament, quantitative even mixing is realized, medicine flowing is realized so as to bring convenience for mixing different liquid medicaments, medicament mixing efficiency is improved, thermal insulation medicament liquid is heated, and the use comfort level of a patient is improved.

Owner:李欢欢

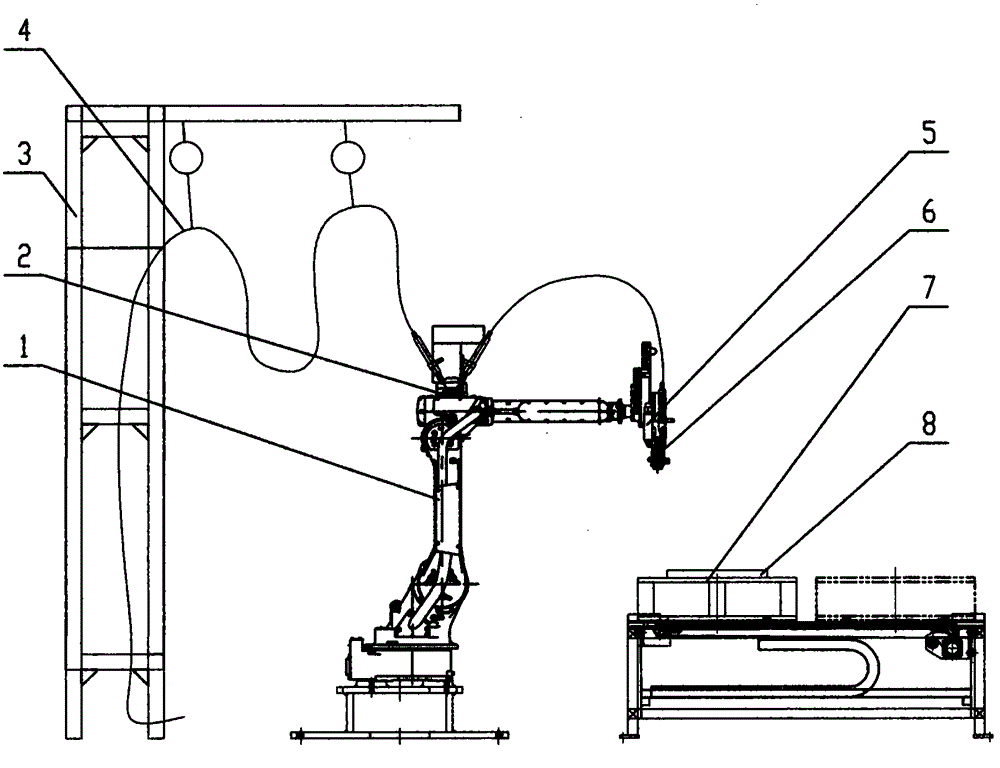

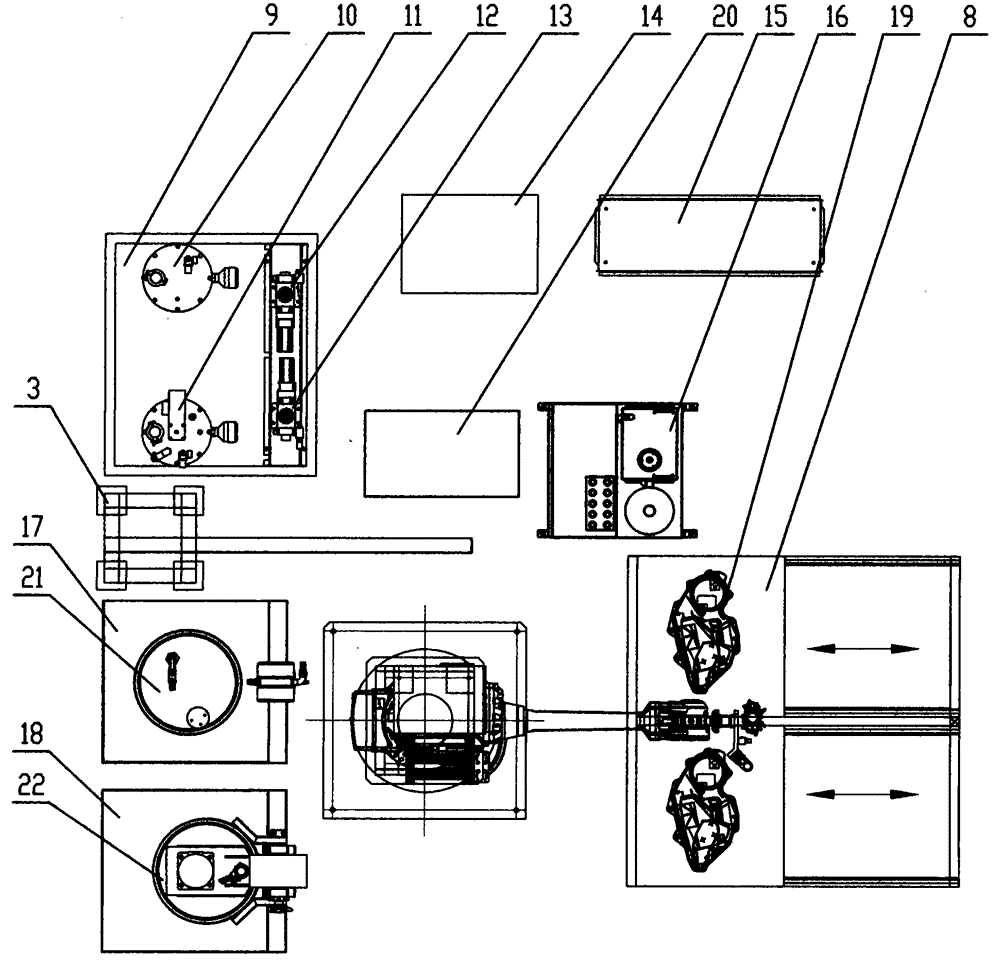

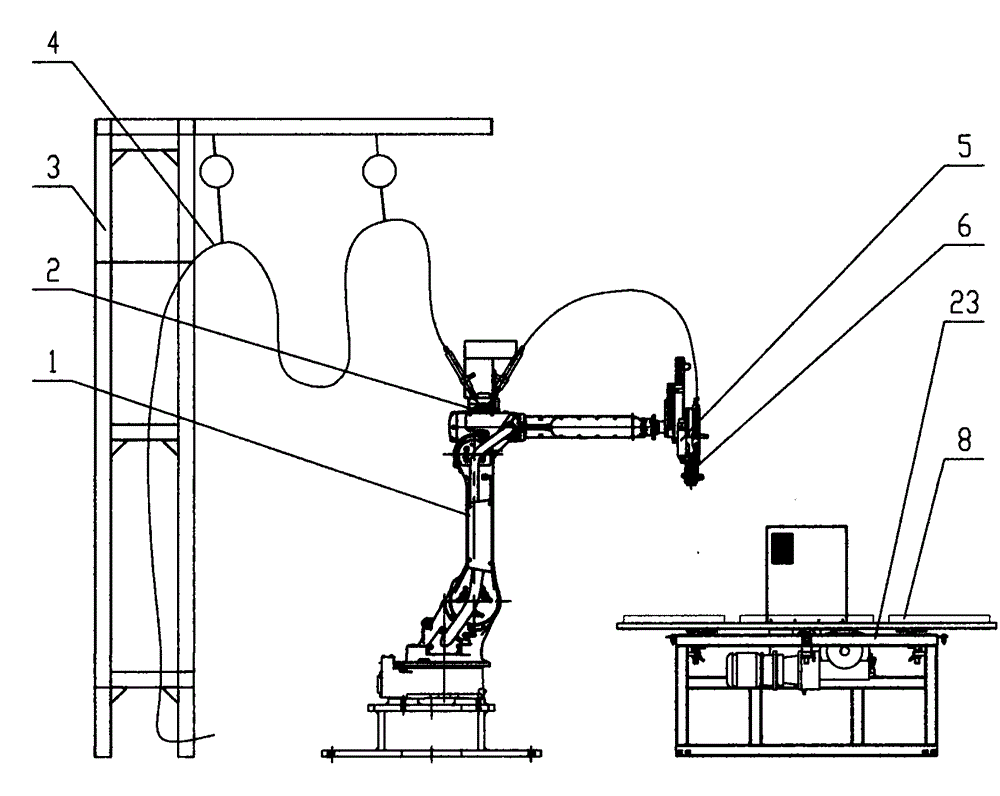

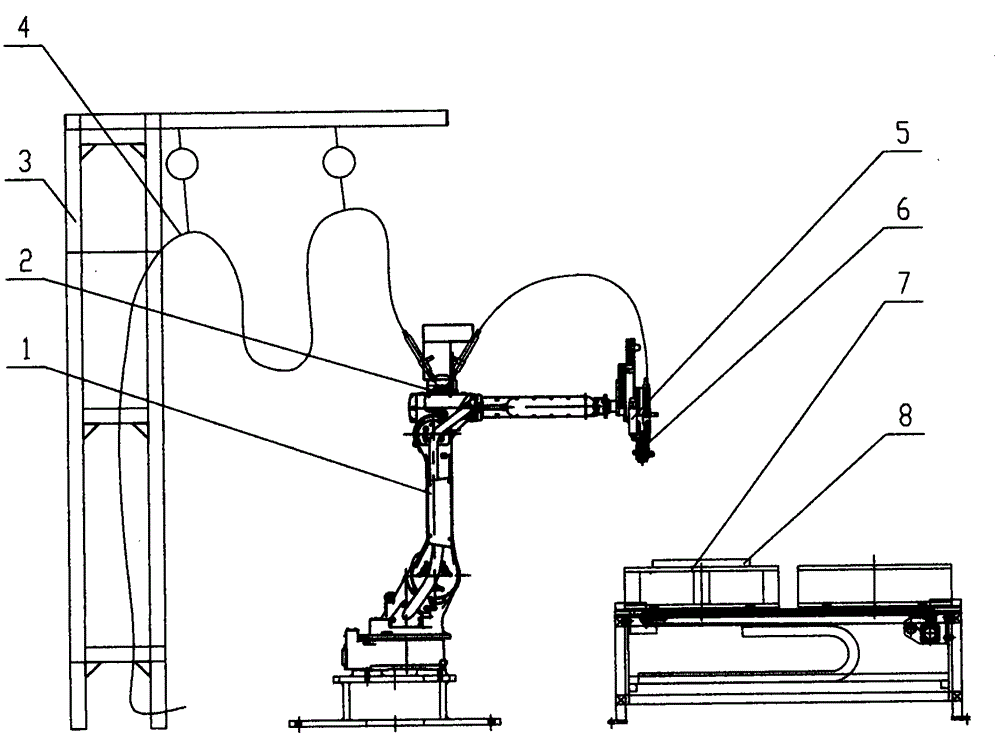

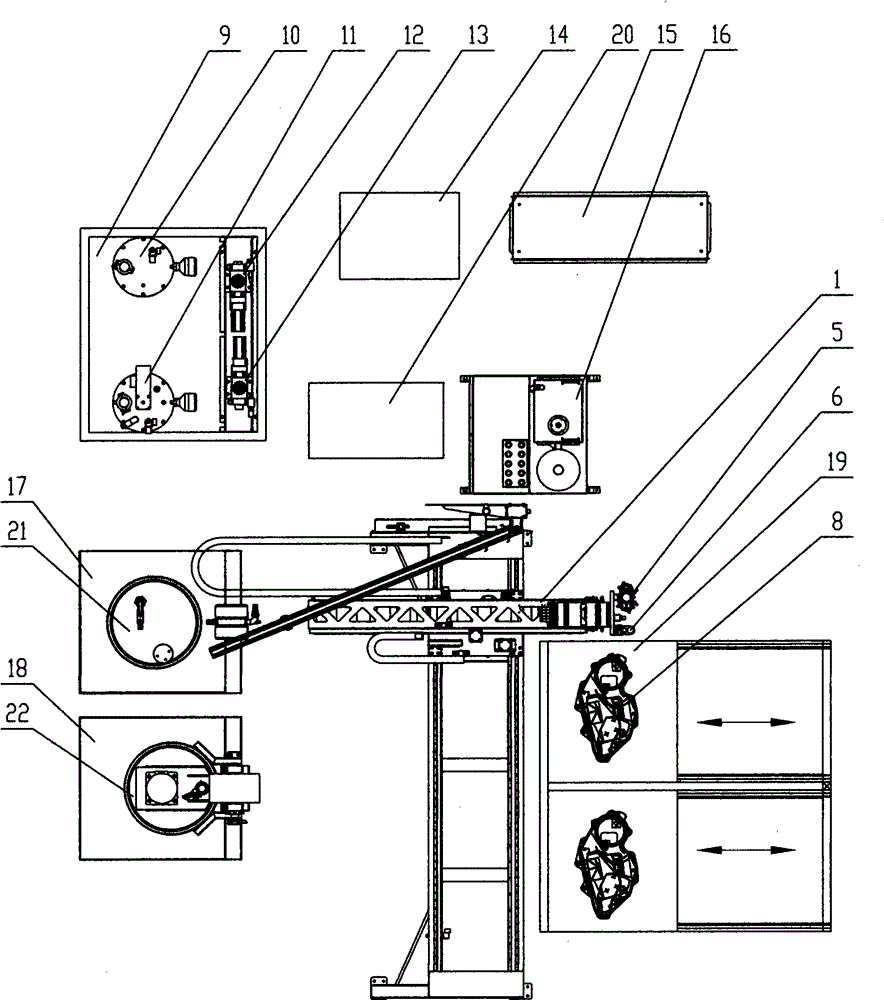

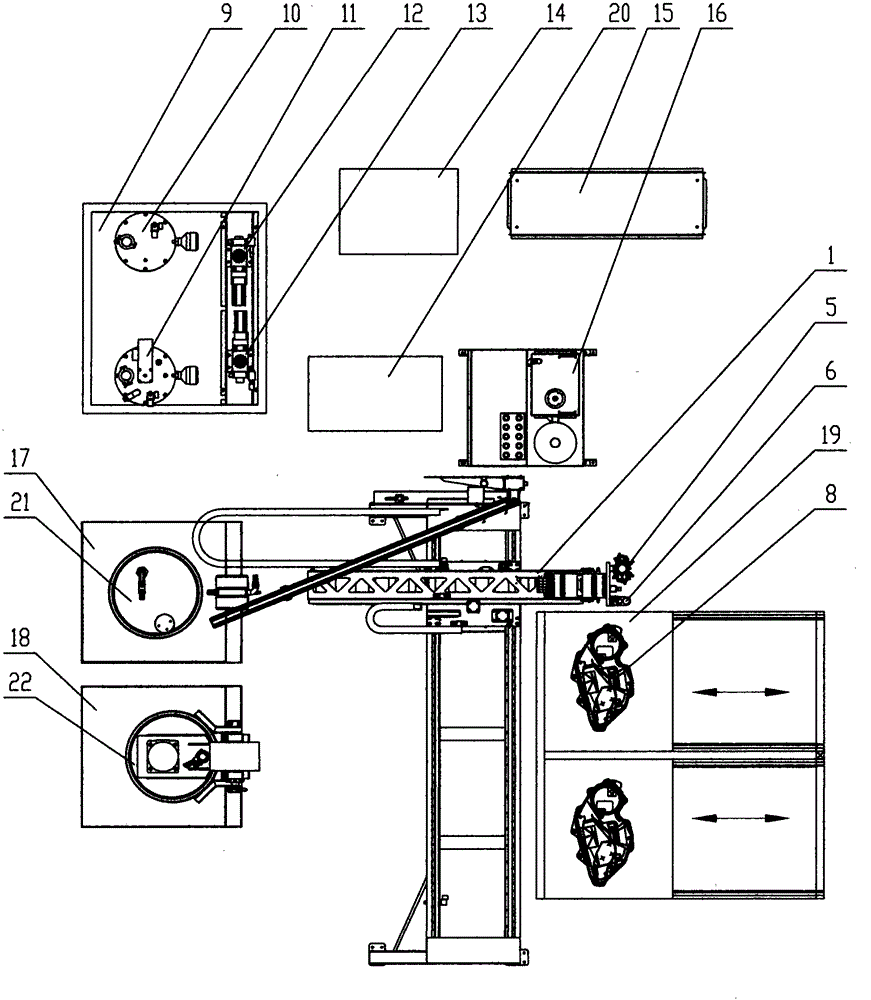

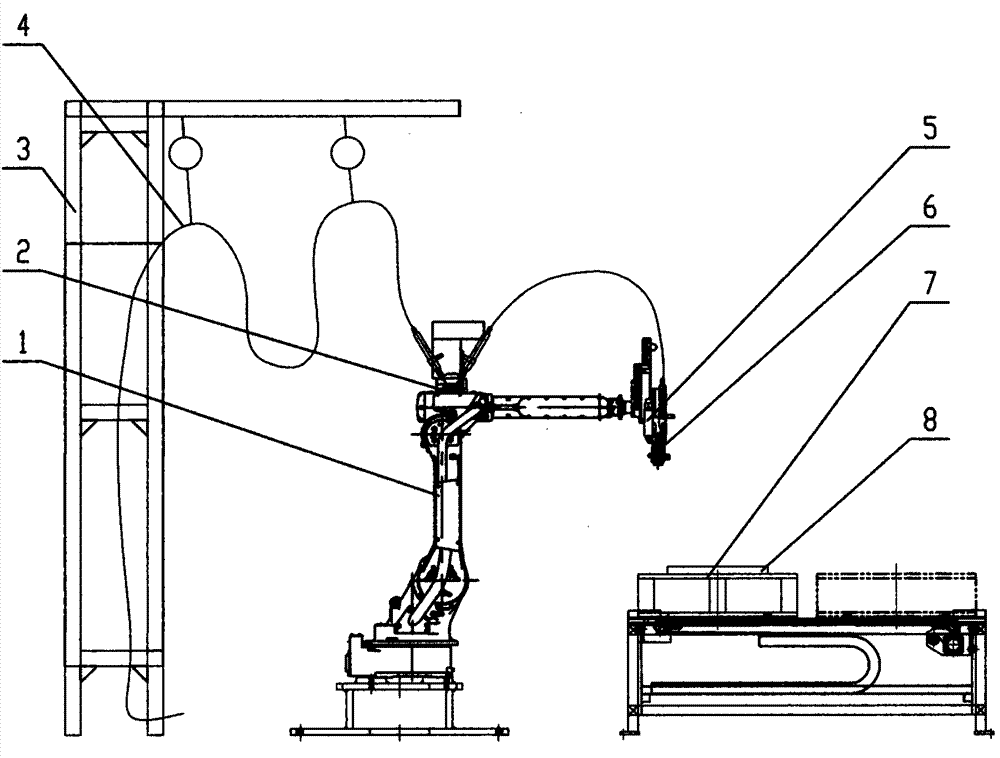

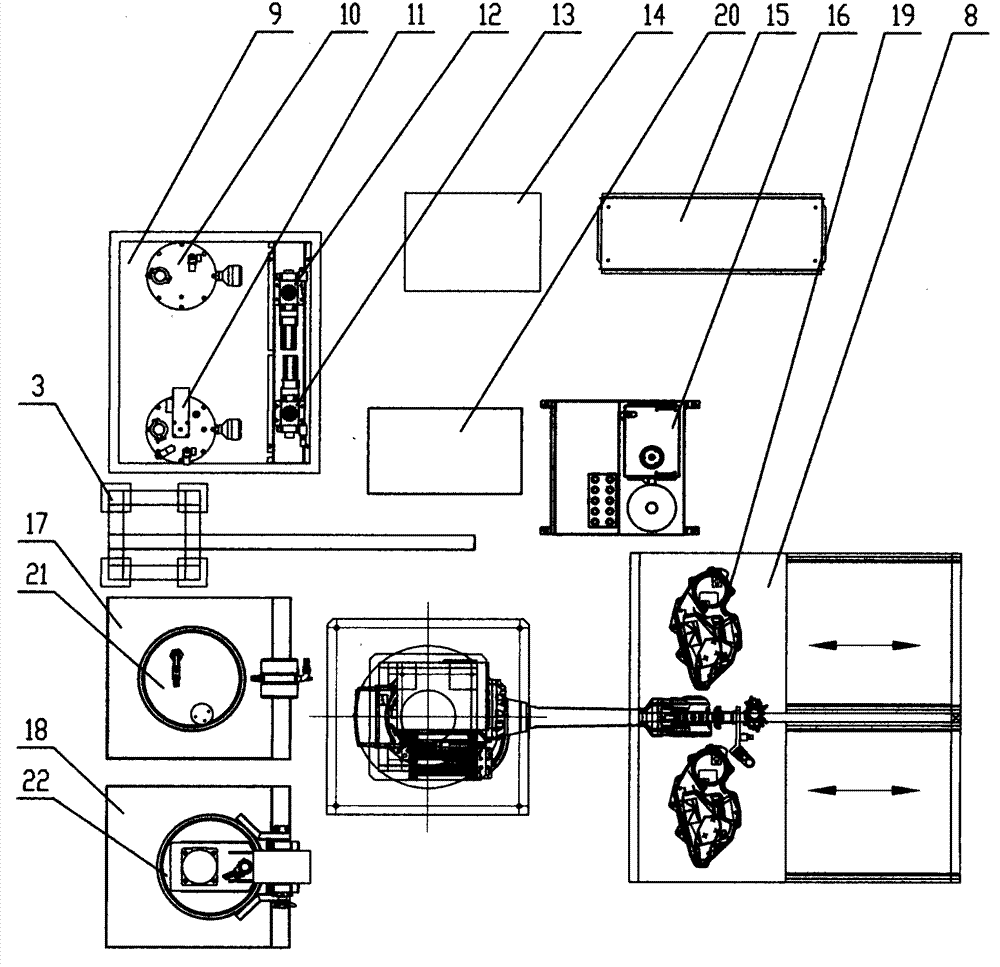

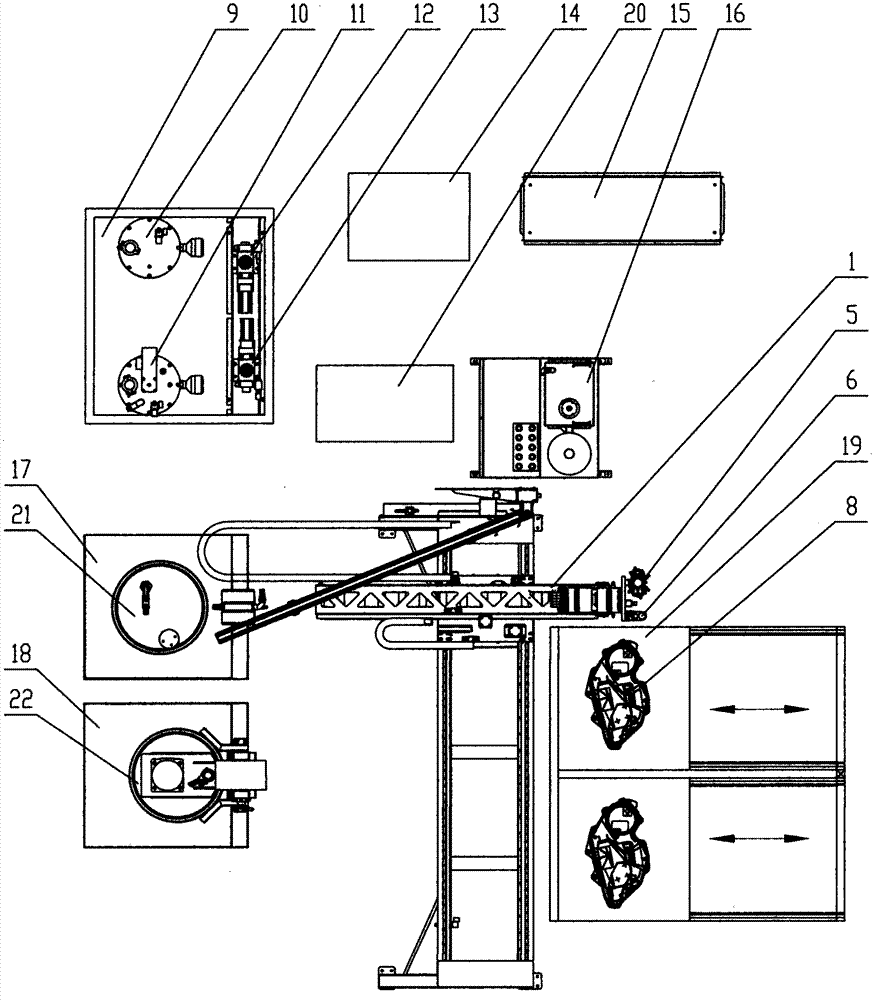

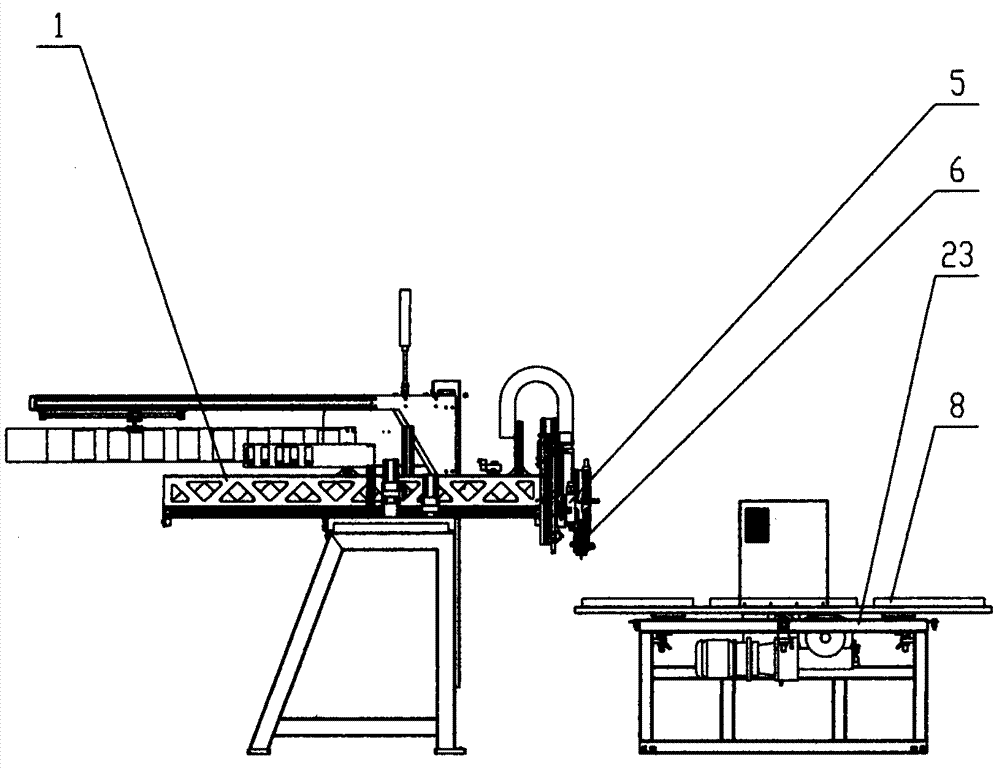

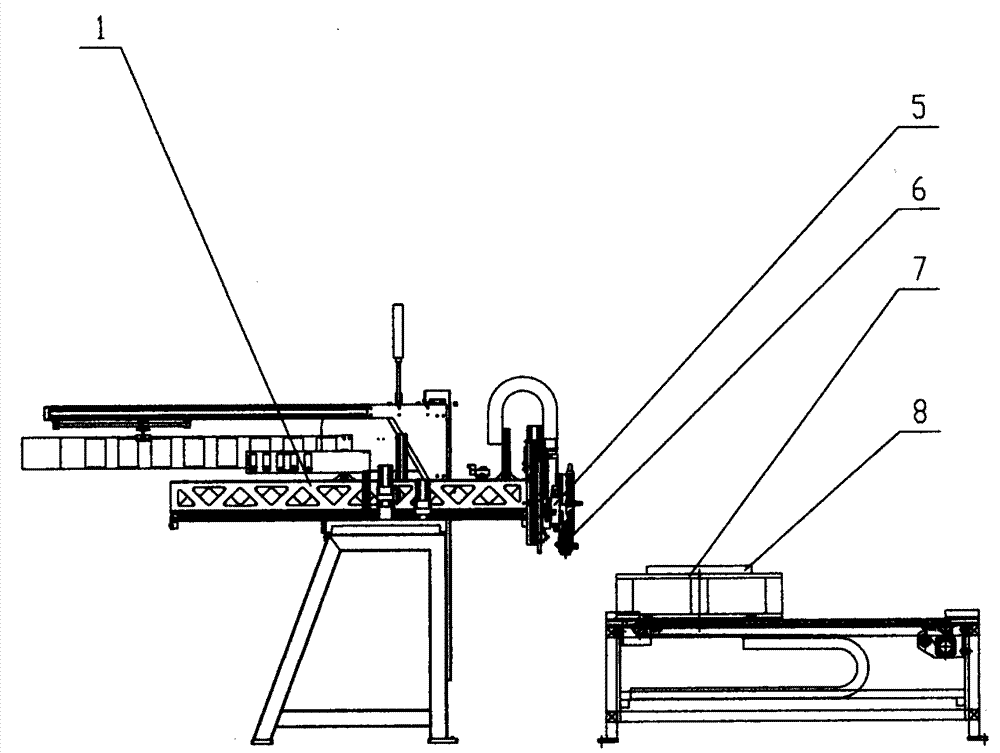

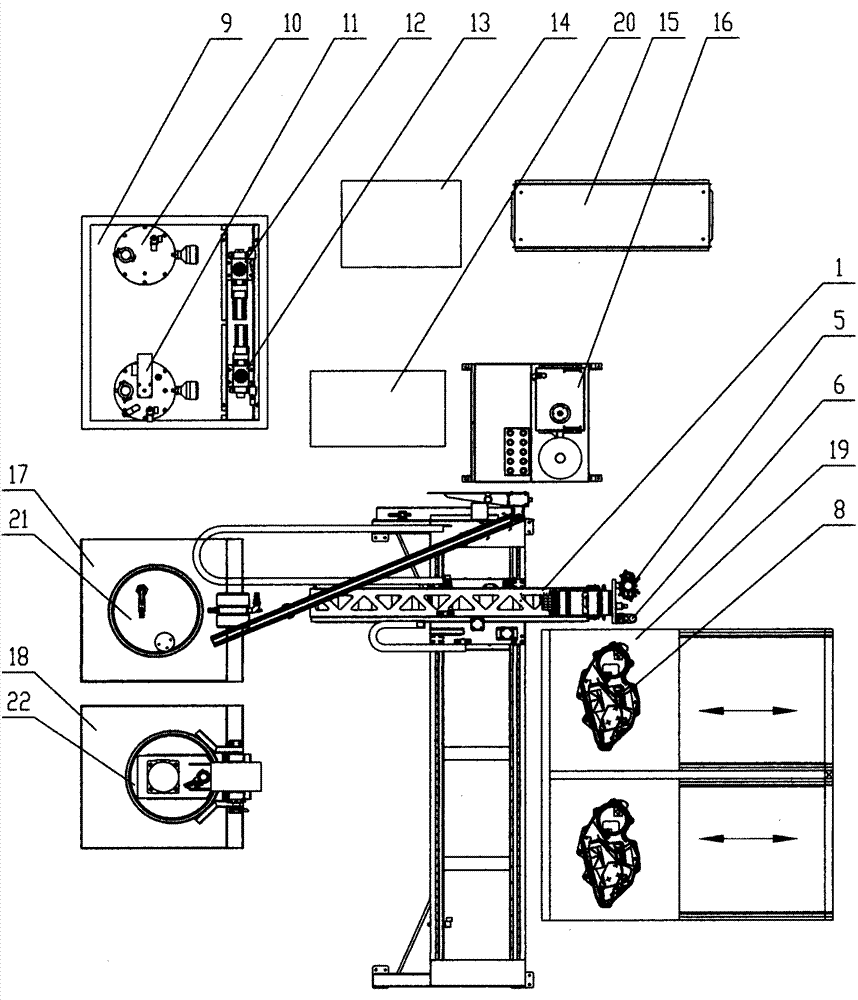

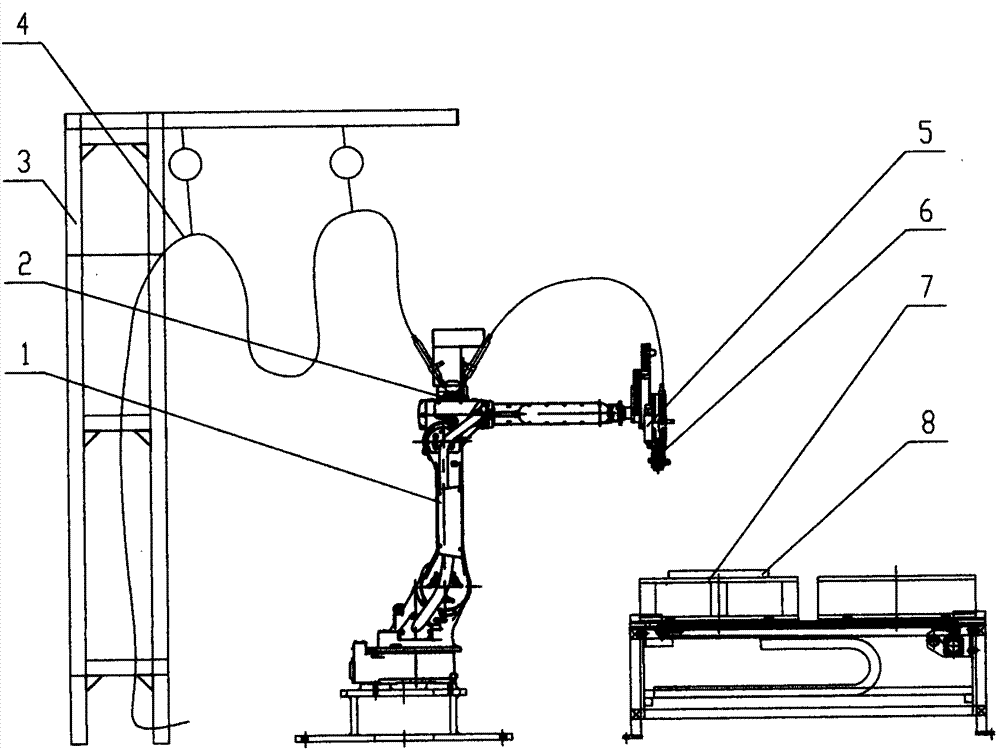

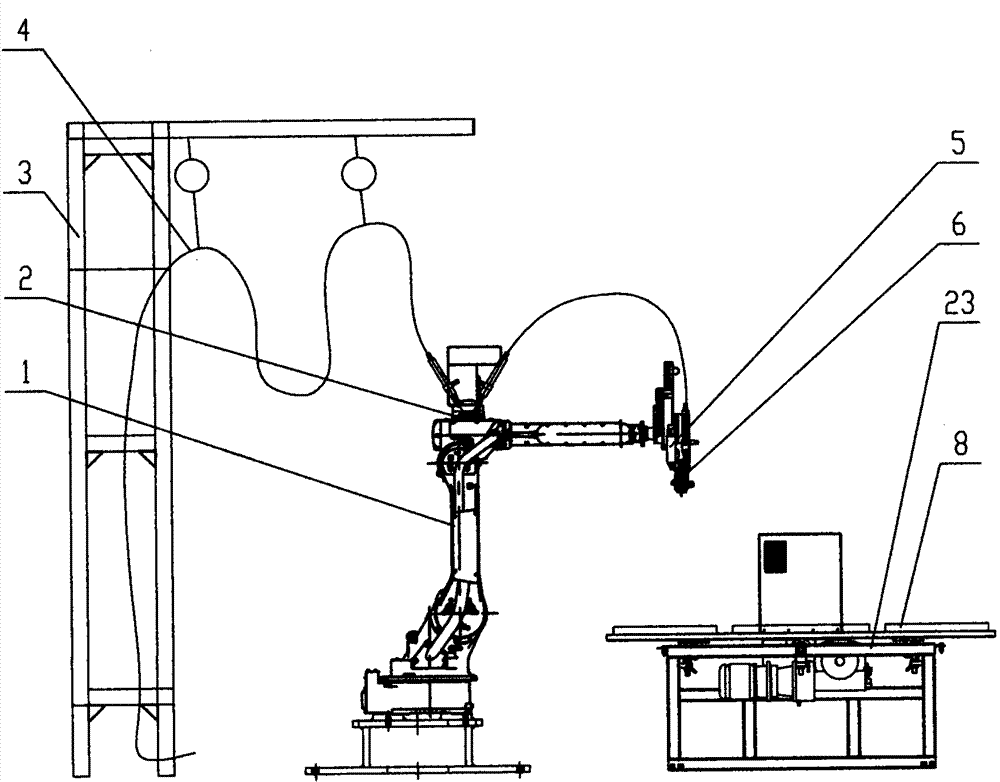

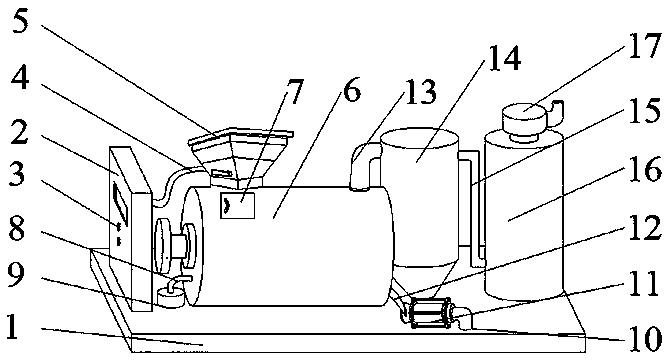

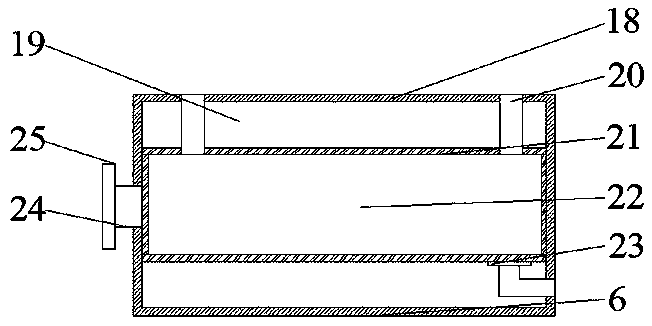

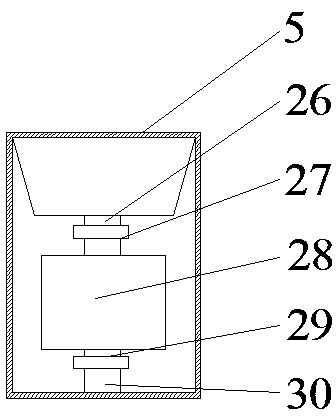

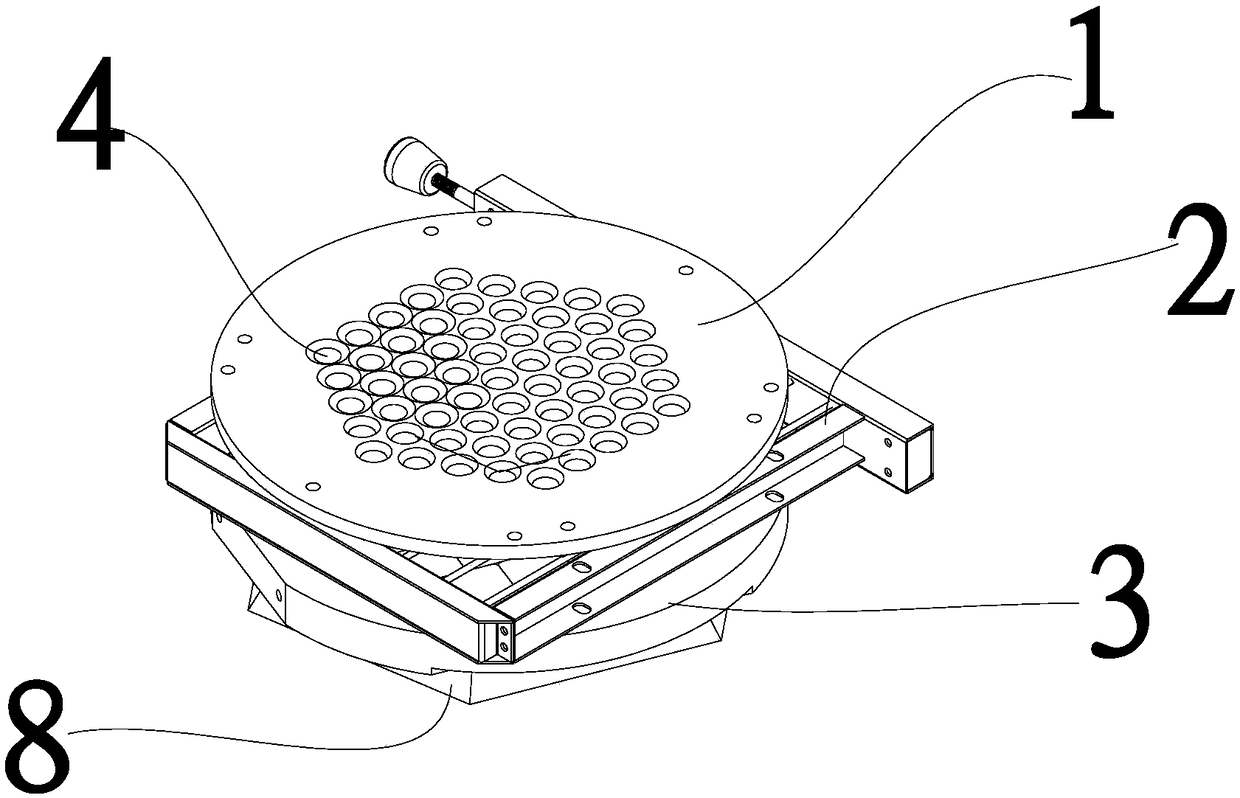

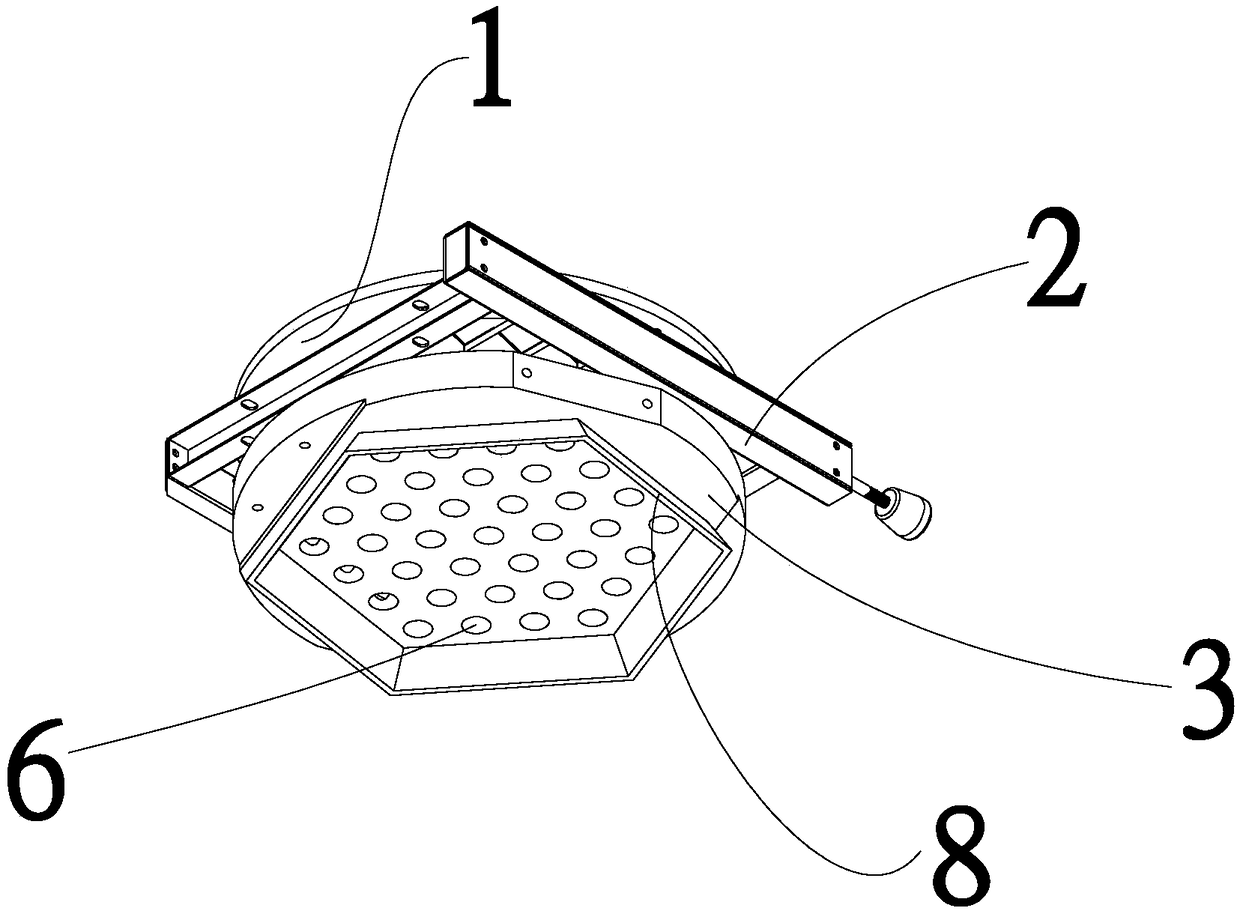

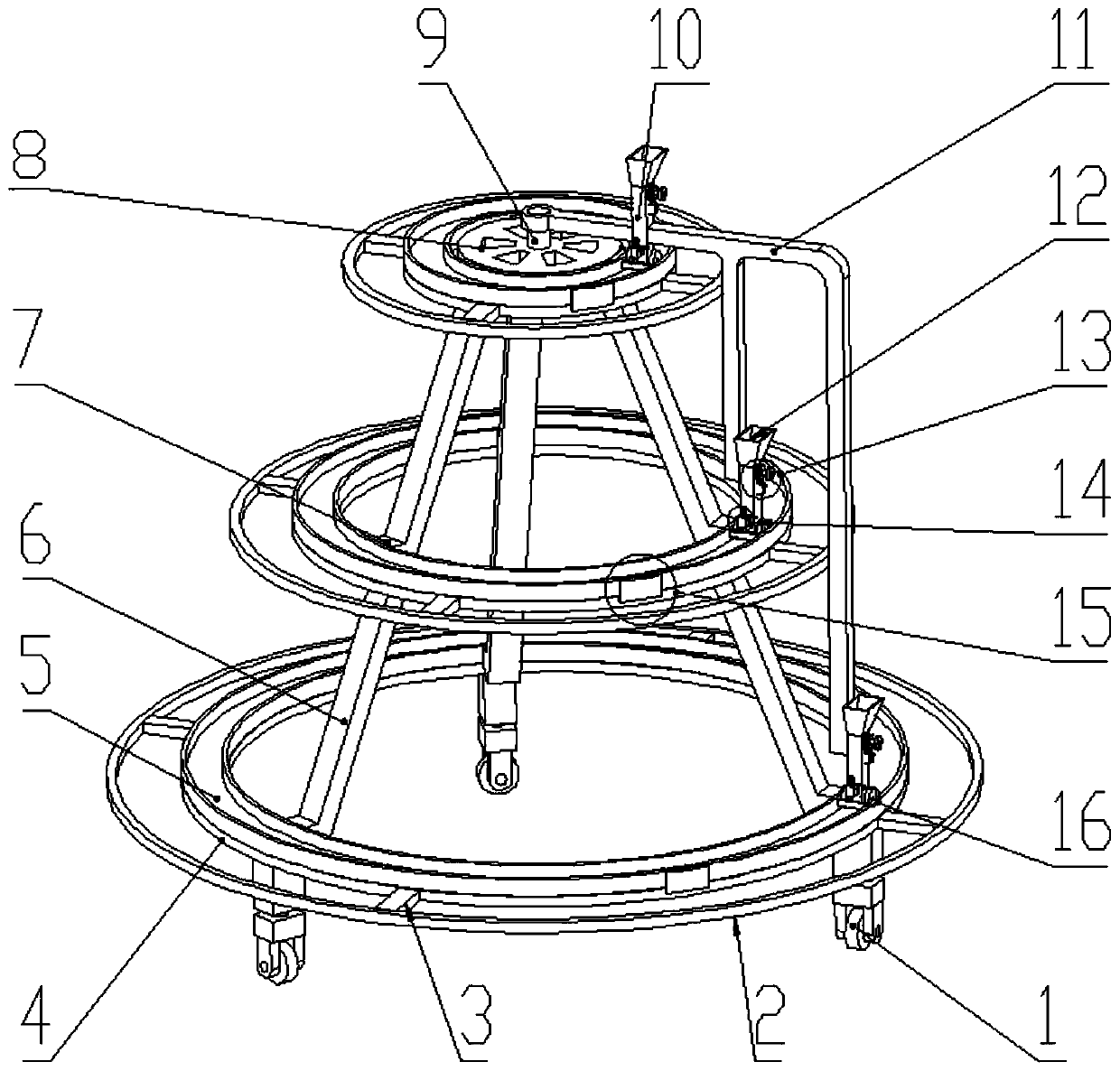

Five-axis robot gumming equipment and technology

ActiveCN104971862ASimple processFast processingProgramme-controlled manipulatorSpraying apparatusMetering pumpArthrobotrys

The invention relates to the technical field of gumming, in particular to five-axis robot gumming equipment and a technology which are used for two-component polyurethane gumming. The five-axis robot gumming equipment is characterized by comprising a five-axis robot, a gum supply device, a two-component gumming head, a double-station automatic gumming workbench or multi-station automatic and rotary gumming workbench, plasma processing equipment, a waste washing liquid recycling device and an intelligent control system. The five-axis robot is a five-joint robot. A workpiece is put on the double-station automatic gumming workbench or multi-station automatic and rotary gumming workbench. The workpiece is fixed or can rotate or swing or move along one axis. The two-component gumming head and aplasma processing head can achieve five-axis linkage. The gum supply device comprises a gum A barrel, a gum B barrel, a gum A metering pump, a gum B metering pump, a gum pipe, a gum supply pipeline, a pipeline support, a gum A material barrel and a gum B material barrel. The polyurethane gumming equipment and the technology are novel, accurate in matching ratio, stable in adhesive tape performance and good in sealing effect.

Owner:DALIAN HUAGONG INNOVATION TECH

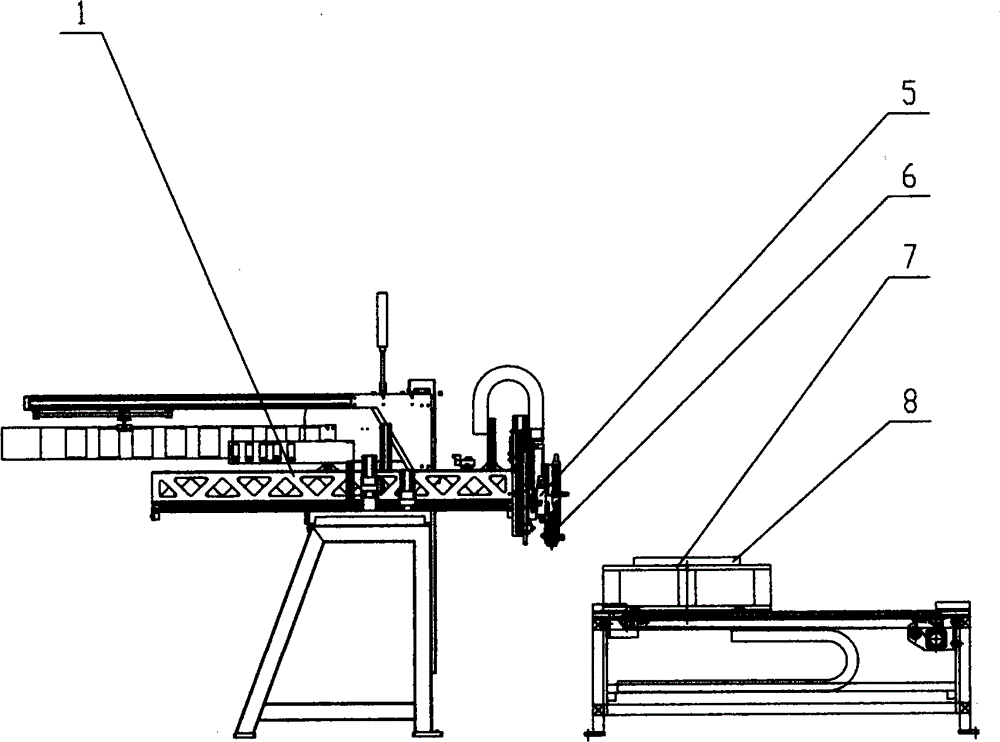

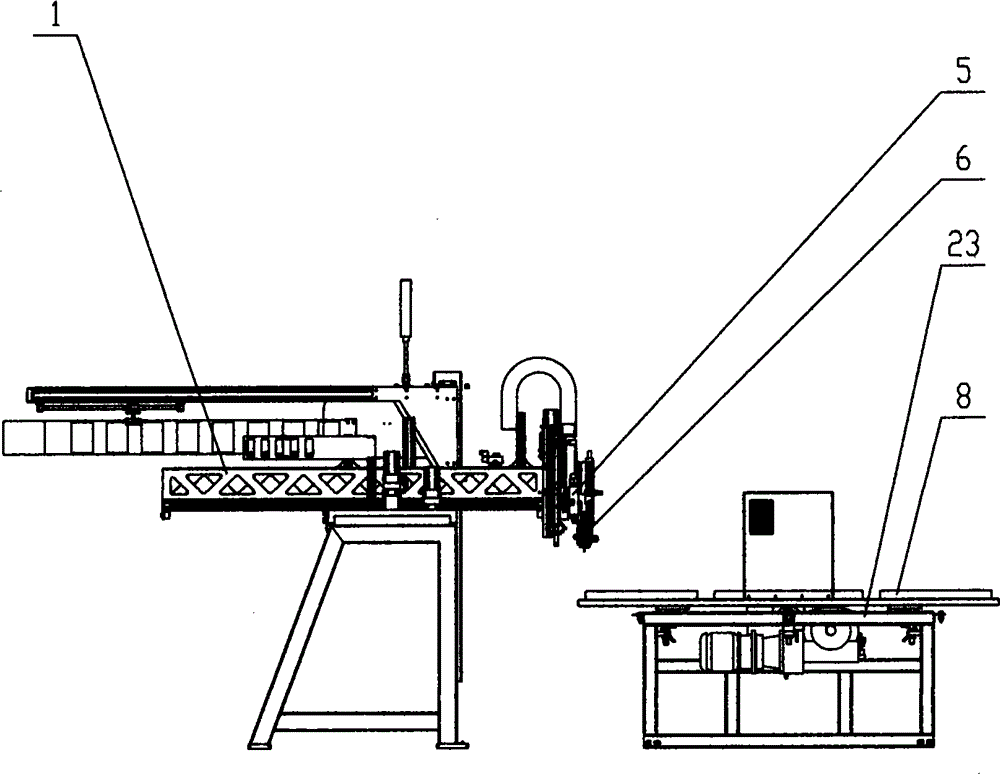

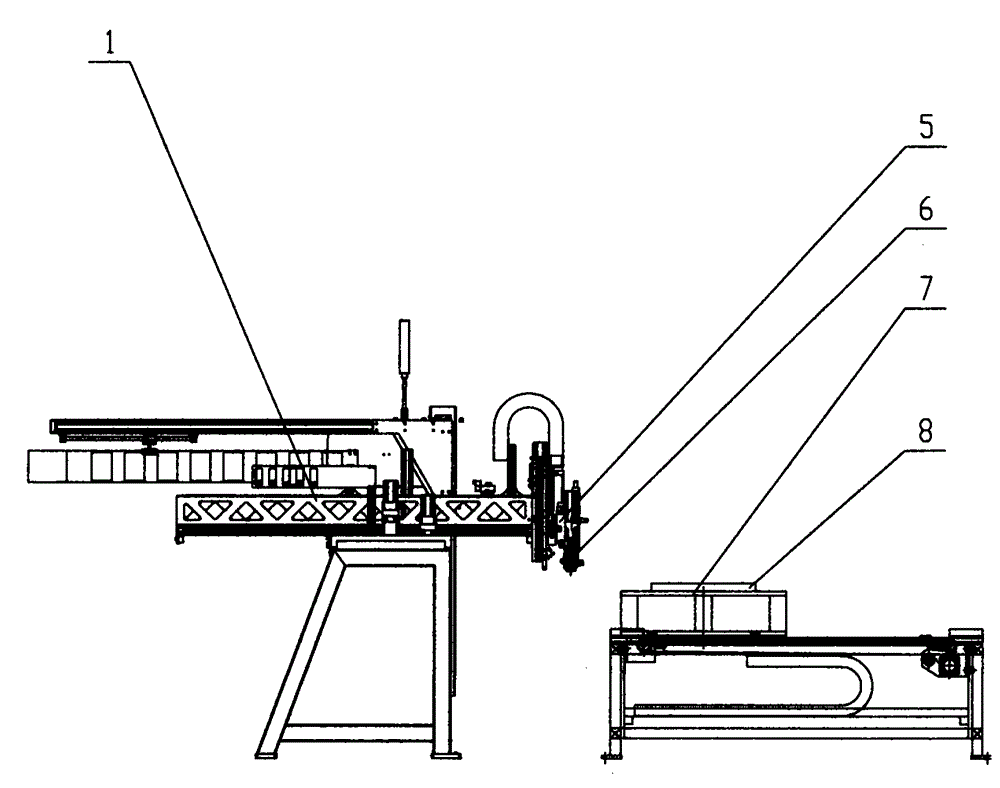

Four-axis robot gumming equipment and technology

ActiveCN104971863ASimple processFast processingProgramme-controlled manipulatorSpraying apparatusEngineeringCantilever

The invention relates to the technical field of gumming, in particular to four-axis robot gumming equipment and a technology which are used for two-component polyurethane gumming. The four-axis robot gumming equipment is characterized by comprising a four-axis robot, a gum supply device, a two-component gumming head, a double-station automatic gumming workbench or multi-station automatic and rotary gumming workbench, plasma processing equipment, a waste washing liquid recycling device and an intelligent control system. The four-axis robot is of a gantry type or cantilever type structure. The two-component gumming head and aplasma processing head are fixed on the four-axis robot and can achieve X-axis, Y-axis and Z-axis linkage. A workpiece is put on the double-station automatic gumming workbench or multi-station automatic and rotary gumming workbench and is fixed. The two-component gumming head and the plasma processing head are linked along the X-axis, Y-axis and Z-axis to achieve gumming. The polyurethane gumming equipment and the technology are novel, accurate in matching ratio, stable in adhesive tape performance and good in sealing effect.

Owner:DALIAN HUAGONG INNOVATION TECH

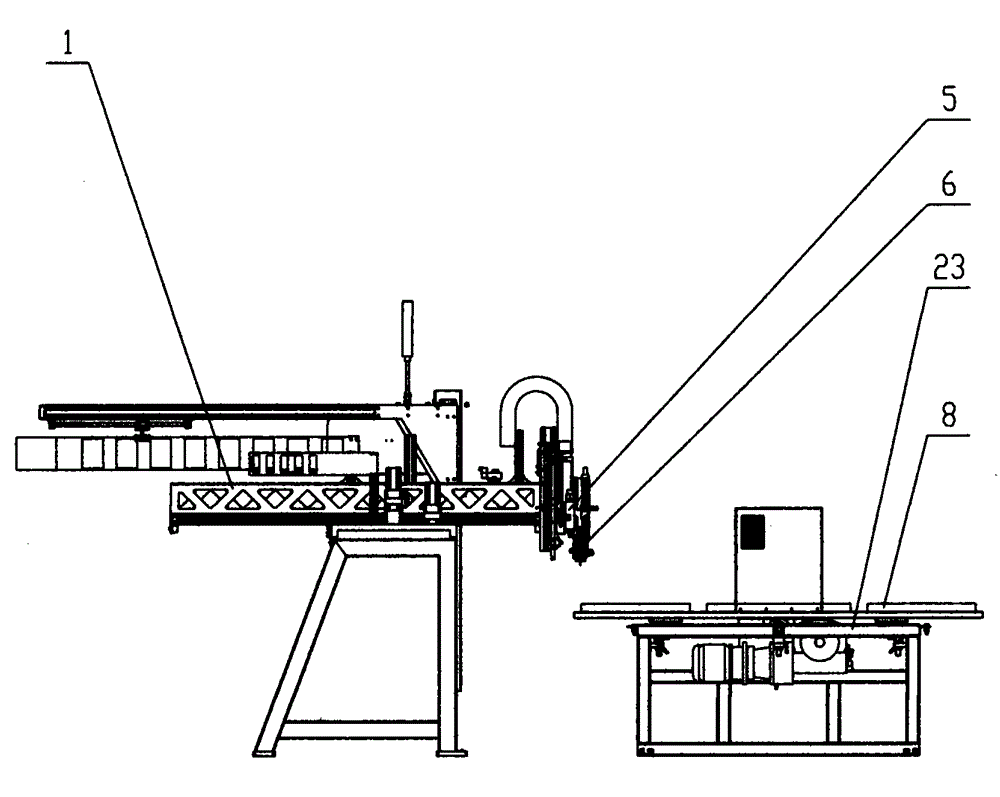

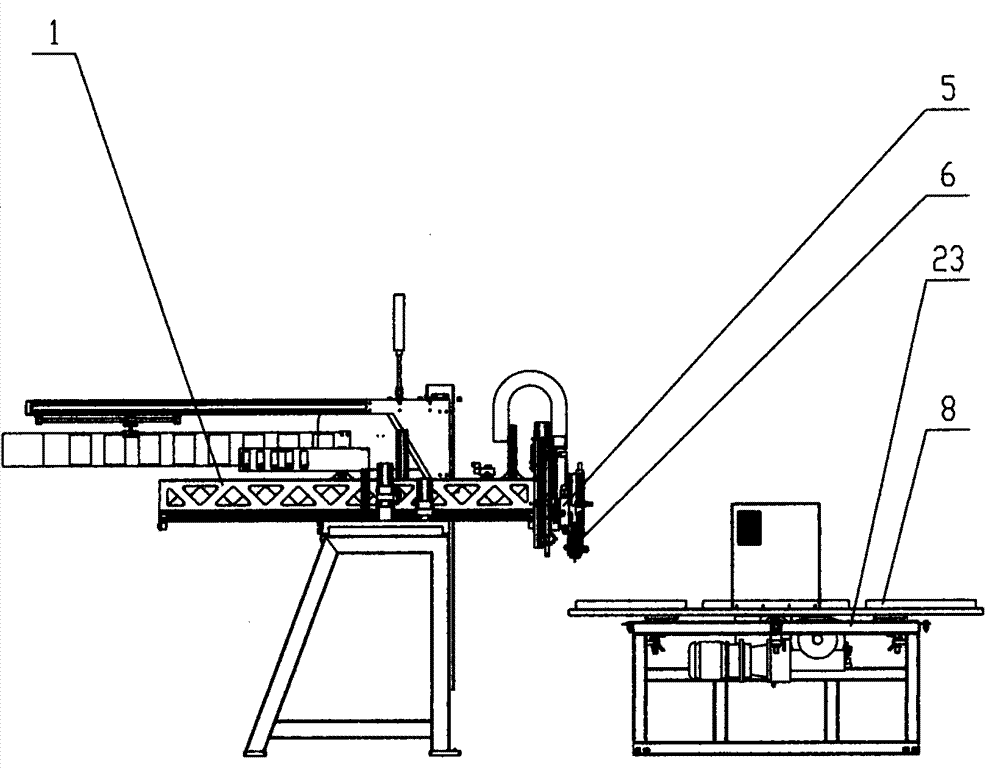

Three-axis robot gluing equipment and process technology

The invention relates to the technical field of gluing, in particular to three-axis robot gluing equipment and a process technology which are used for two-component polyurethane gluing. The three-axis robot gluing equipment is characterized in that the equipment comprises a three-axis robot, a glue supply device, a two-component gluing head, a two-station automatic gluing workbench or a multi-station automatic rotary gluing workbench, plasma treatment equipment, a waste cleaning solution recovery device and an intelligent control system. The three-axis robot is of a gantry type or cantilever type structure. The two-component gluing head and a plasma treatment head are fixed to the three-axis robot and can be linked in the X axis, the Y axis and the Z axis. Workpieces are fixedly placed on the two-station automatic gluing workbench or the multi-station automatic rotary gluing workbench, and therefore gluing is achieved. The glue supply device comprises a glue A barrel, a glue B barrel, a glue A metering pump, a glue B metering pump, glue pipes, glue supply pipelines, a glue A bucket and a glue B bucket. According to the novel polyurethane gluing equipment and the process technology, the proportion is precise, glue tape performance is stable, and the sealing effect is good.

Owner:DALIAN HUAGONG INNOVATION TECH

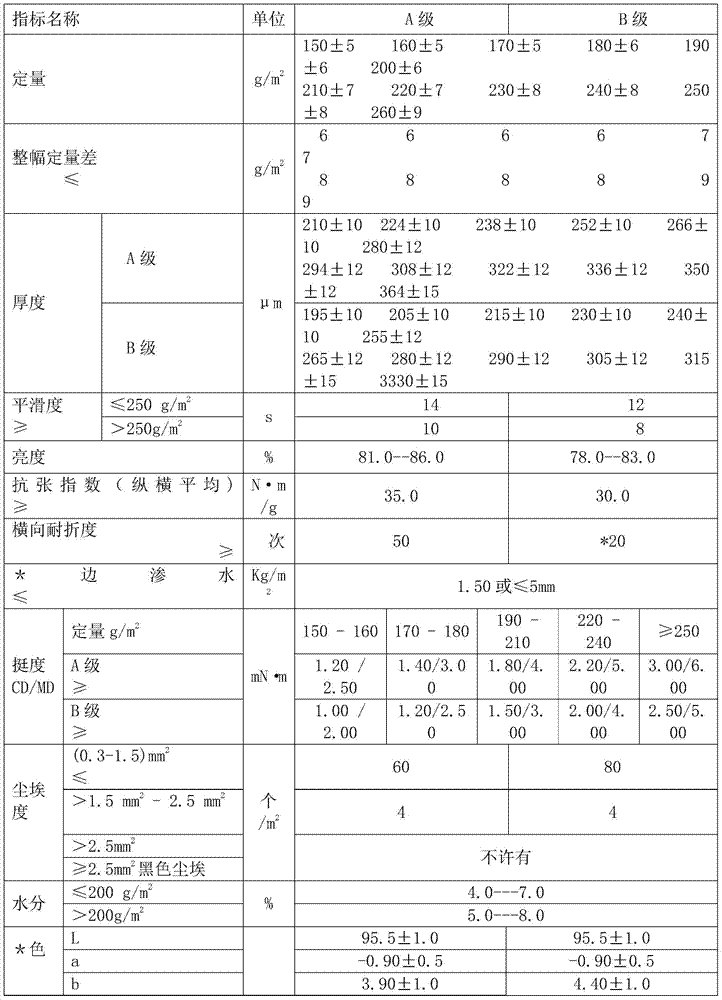

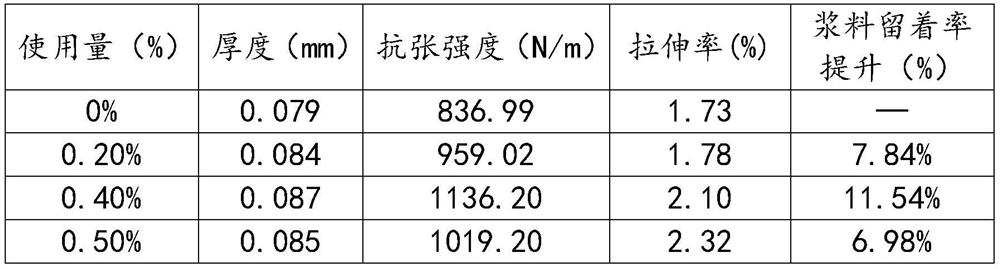

Low quantitative coating type food package raw paper, and preparation method thereof

The invention discloses a low quantitative coating type food package raw paper, and a preparation method thereof. The preparation method comprises following steps: firstly, cationic starch is added into a PCC suspension solution, uniform mixing is carried out, then gelatinization is carried out so as to form a partically-crosslinked gel substance, and normal temperature cooling and dispersion treatment are carried out so as to obtain a starch coated PCC filling material; bleached sulfate softwood pulp, and bleached sulfate hardwood pulp are subjected to mixing pulping, the starch coated PCC filling material, a wet strength agent, a sizing agent, and a retention agent are added, and concentration adjusting, slag removing, and sieving are carried out so as to obtain a slurry for wet loadingpaper making; the slurry is subjected to fourdrinier dehydration moulding and squeezing, and pre-drying; and at last, paper surface glue applying, soft calendaring, and rolling are carried out to obtain a finished product. According to the preparation method, no expensive titanium dioxide is adopted as a filling material, production cost is low, the retention rate of the filling material and finefiber is high, environment pollution caused by white water discharge is reduced, the obtained paper is uniform, full width tightness is constant, paper surfaces are flat and fine, surface strength andwet tensile strength are high, and water based coating quality requirements are satisfied.

Owner:ZHEJIANG HENGDA NEW MATERIAL CO LTD

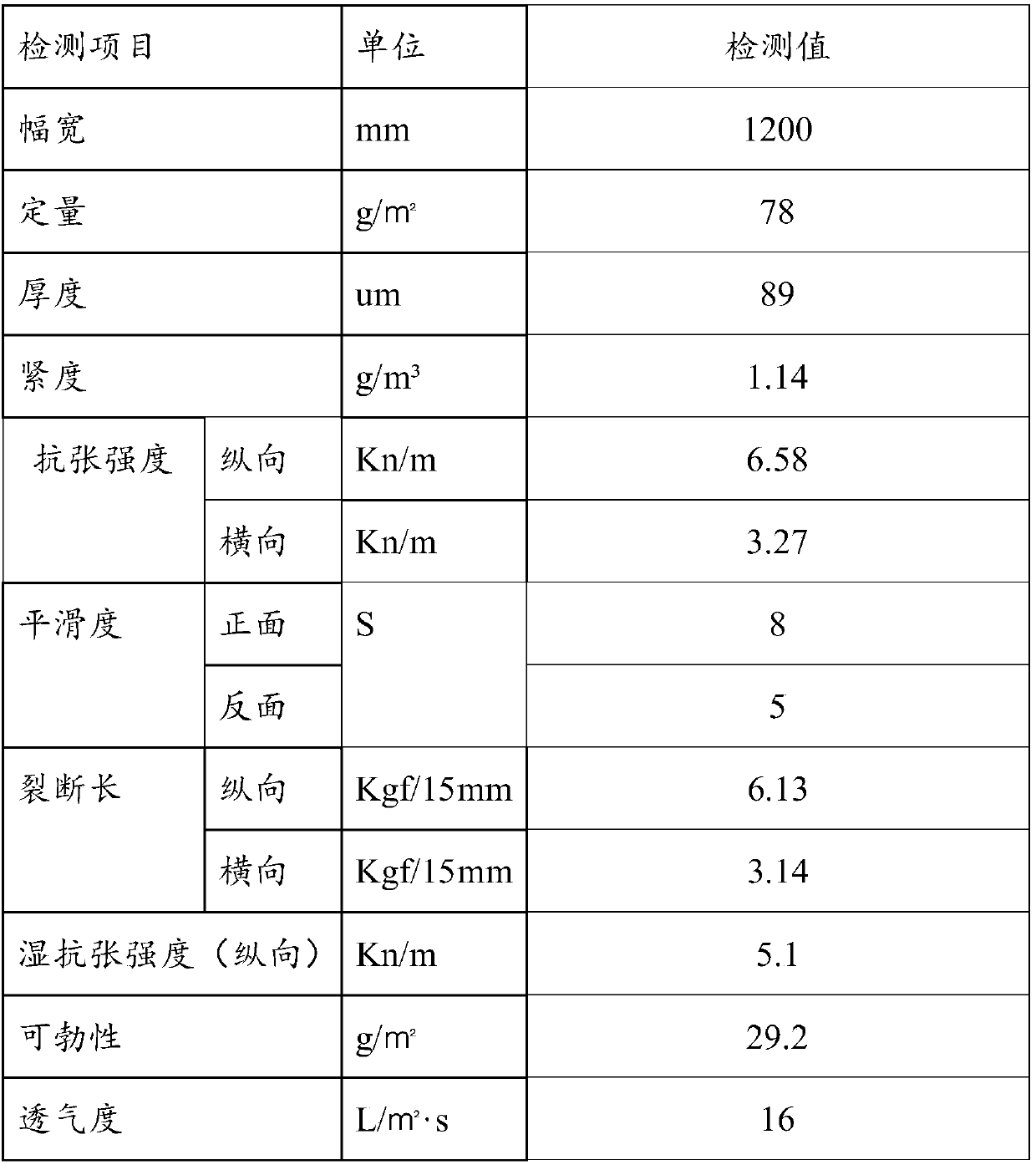

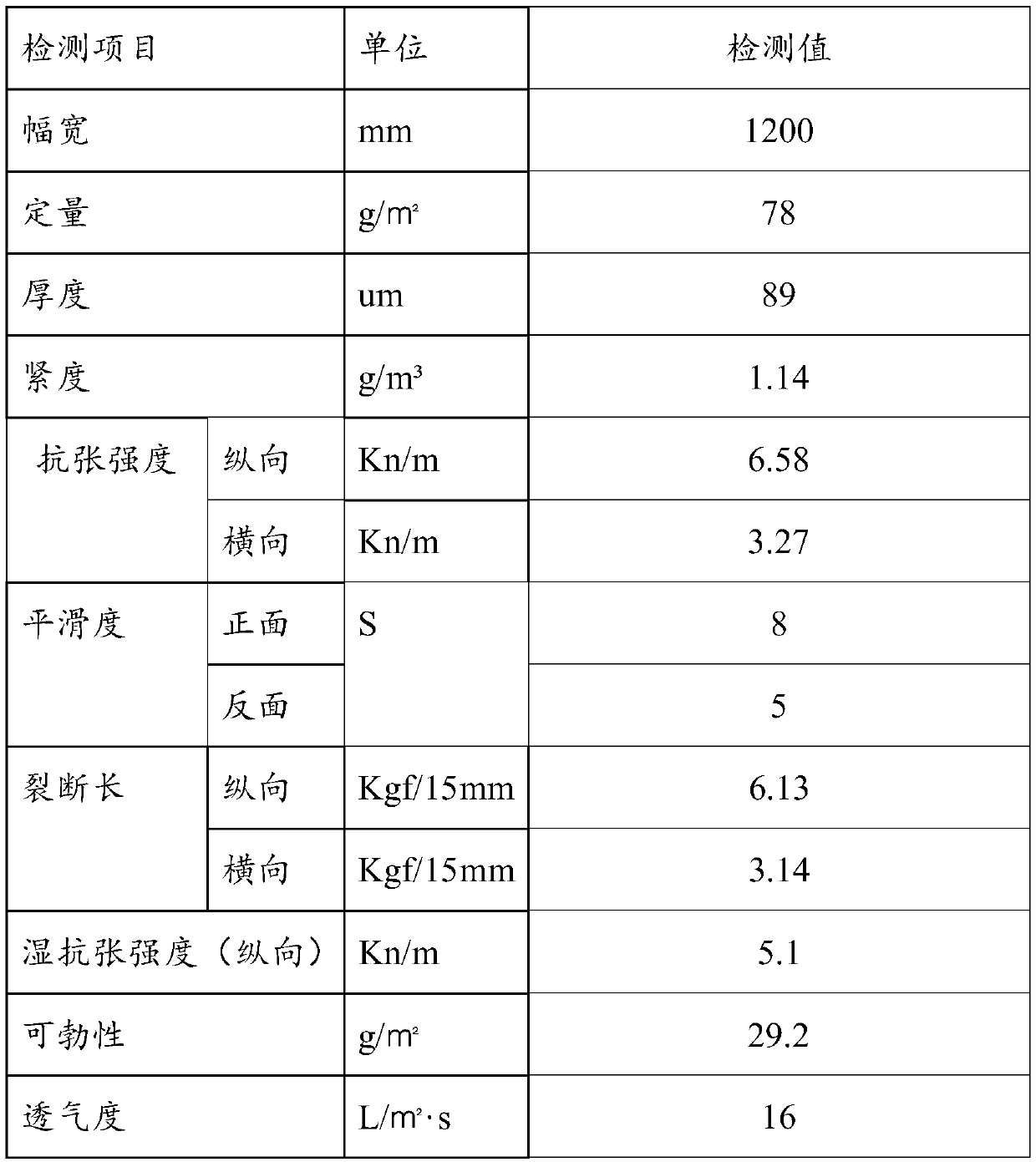

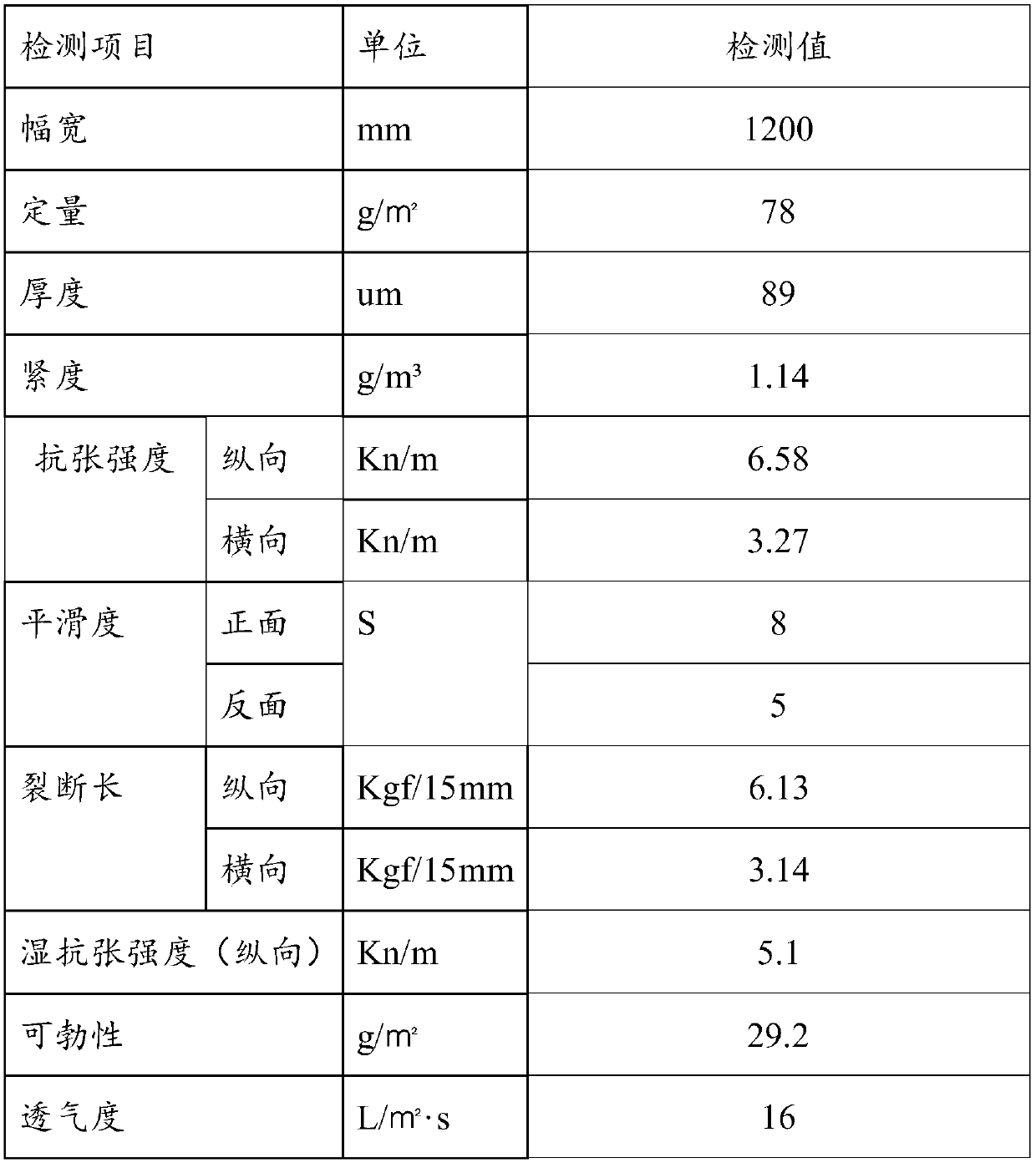

Production method for lining paper for cigarette

ActiveCN102899957AGood paper evennessUniform moistureWater-repelling agents additionPaper/cardboardPaper sheetHardwood

The invention discloses a production method for a lining paper for a cigarette. The production method comprises the following steps: A) preparing grinding pulp, and then allocating the pulp which contains 15-30 wt.% of bleached needle bush pulp, 55-75 wt.% of bleached hardwood pulp and 10-15 wt.% of straw pulp, separately pulping, and then mixing the grinding pulp, and controlling pulp intensity at 30-40 OSR and wet weight being 2.5-5.5g; B) adding padding and a degassing agent before primarily slushing the pulp, and then entering into multi-stage deslagging; C) adding pulp glue and starting the secondary slushing; D) after ending the secondary slushing, adding a sizing agent, placing into a pressure screen for treating, and adding a retention agent at an outlet of the pressure screen; E) pouring the pulp into a pulp flowing box, loading a net and preparing paper with the pulp; F) extracting and dewatering; G) drying; H) performing soft calendaring dual-pressing treatment; and I) coiling, rewinding and cutting, packaging and putting into a storage. The lining paper for the cigarette produced according to the production method has the beneficial effects: the paper sheet uniformity is excellent; the horizontal width rated difference is small; the tensile force is high; the lining paper is easy to cut; the front surface of the paper sheet has higher smoothness; and the back surface of the paper sheet has certain smoothness.

Owner:XIANHE CO LTD

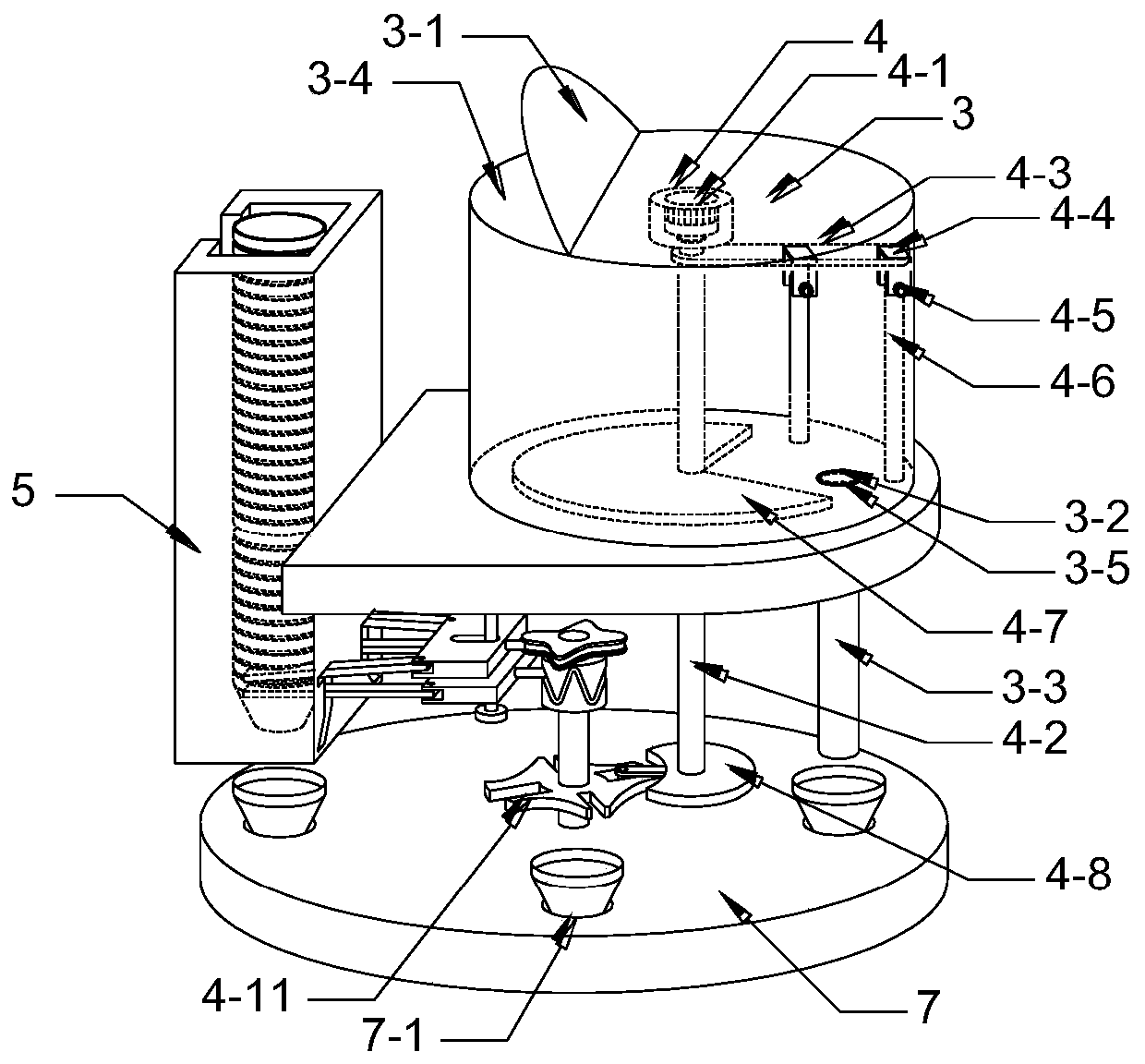

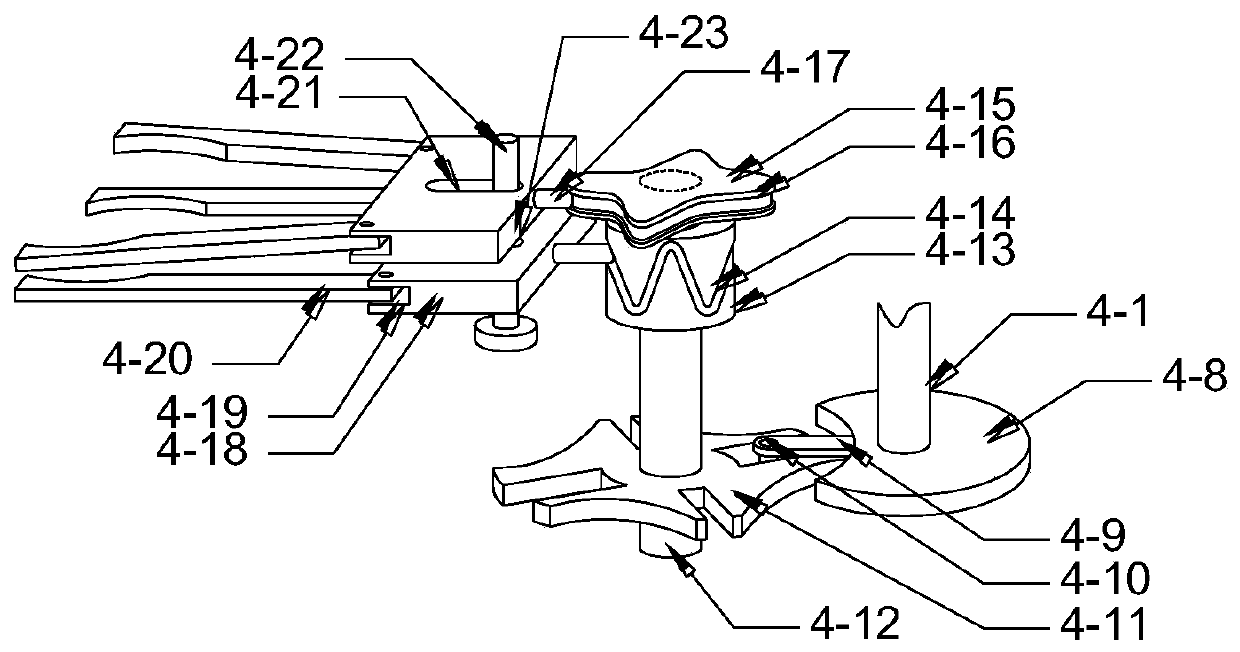

Quantitative explosive feeding device

The invention discloses a quantitative explosive feeding device which comprises a constant volume tube (2), an upper gate disc (7), a lower grate disc (9) and a uniform explosive distribution tube (1), wherein the upper gate disc (7) which is used for opening or closing the upper end of the constant volume tube is arranged between the upper end of the constant volume tube (2) and a hopper (5), the lower gate disc (9) which is used for closing or opening the lower end of the constant volume tube is arranged at the lower end of the constant volume tube, the uniform explosive distribution tube (1) is arranged below the lower gate disc, an orifice at the upper end of the uniform explosive distribution tube corresponds to an orifice at the lower end of the constant volume tube, and an orifice at the lower end of the uniform explosive distribution tube corresponds to a paper tube. The quantitative explosive feeding device has the beneficial effects of uniform explosive distribution, accurate quantification, quick blanking and directional feeding, also has capabilities of avoiding explosive scattering, causing small explosive waste, improving explosive feeding efficiency and lowering production cost of firecrackers and fireworks, and is beneficial to environmental protection. The quantitative explosive feeding device has the advantages of compact structure and convenience for production and maintenance, and is applicable to massive explosive feeding of various types of firecracker and firework paper tubes with different sizes; and in addition, since the explosive feeding operation is carried out in a closed environment, the production is safe and has high reliability.

Owner:JIANGXI JIALIAN TECH

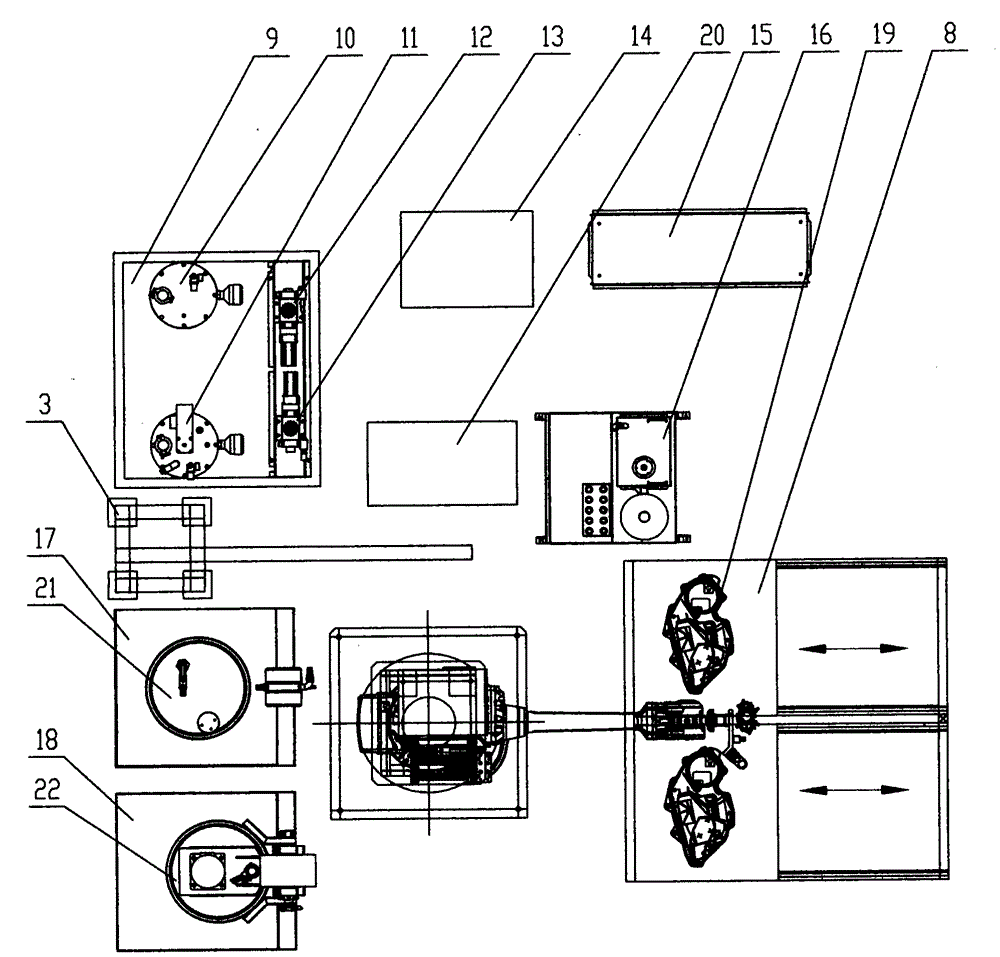

Fully automatic robot gluing equipment and technology

The invention relates to the technical field of gluing, which is used for two-component polyurethane gluing, and in particular to a fully automatic robot gluing equipment and process technology, which is characterized in that it includes a three-axis robot or a four-axis robot or a five-axis robot or a six-axis robot Robot, gluing device, two-component gluing head, double-station automatic gluing workbench or multi-station automatic rotating gluing workbench, plasma treatment equipment, cleaning waste liquid recovery device, intelligent control system; the three-axis The structure of the robot and the four-axis robot is gantry type or cantilever type. The two-component gluing head and the plasma treatment head are fixed on the three-axis robot and the four-axis robot and can realize the three-axis linkage of X, Y, and Z. The five The two-axis robot and the six-axis robot are joint robots, and the two-component gluing head and the plasma processing head can realize five-axis linkage or six-axis linkage; Polyurethane gluing equipment and process technology.

Owner:DALIAN HUAGONG INNOVATION TECH

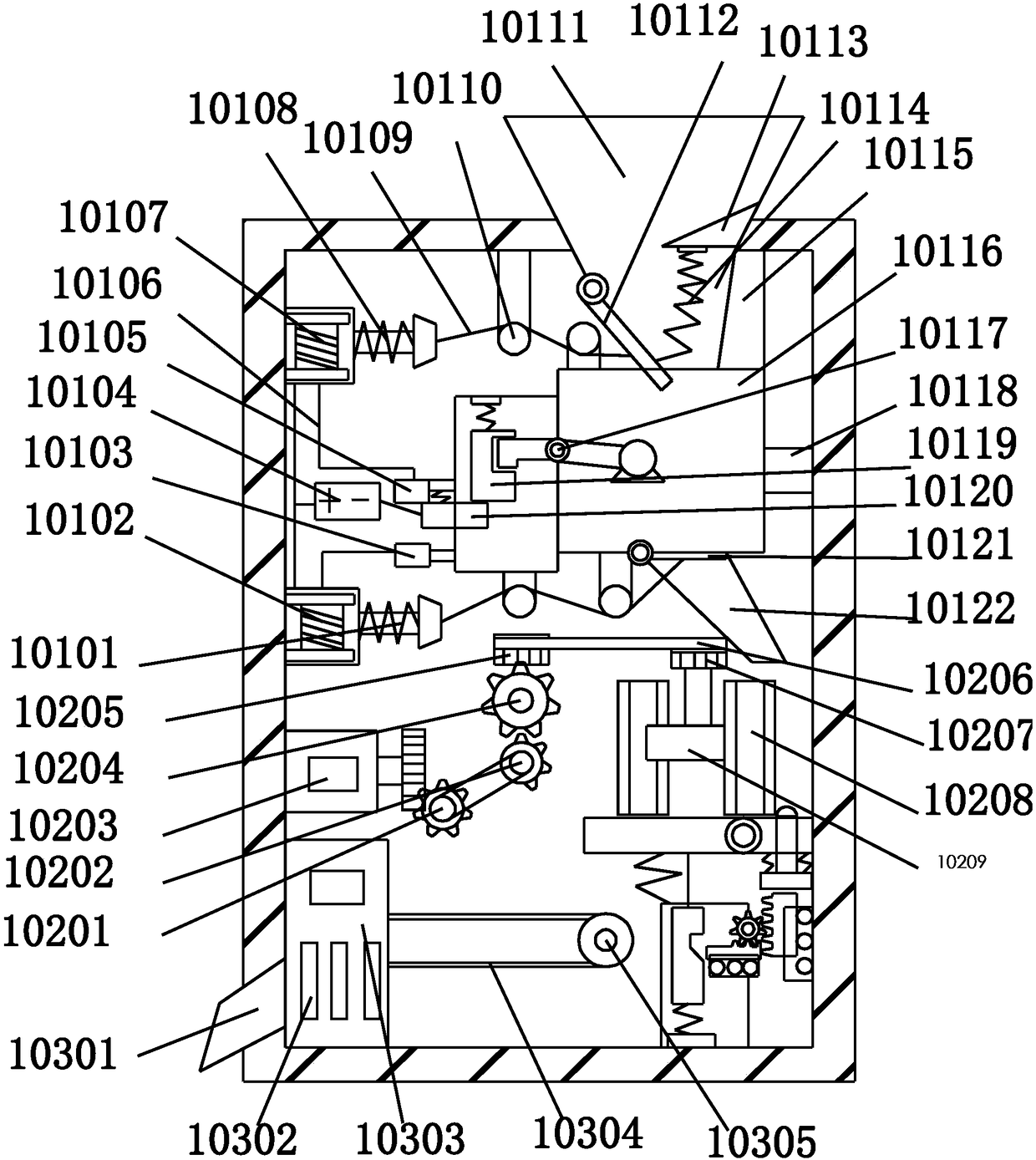

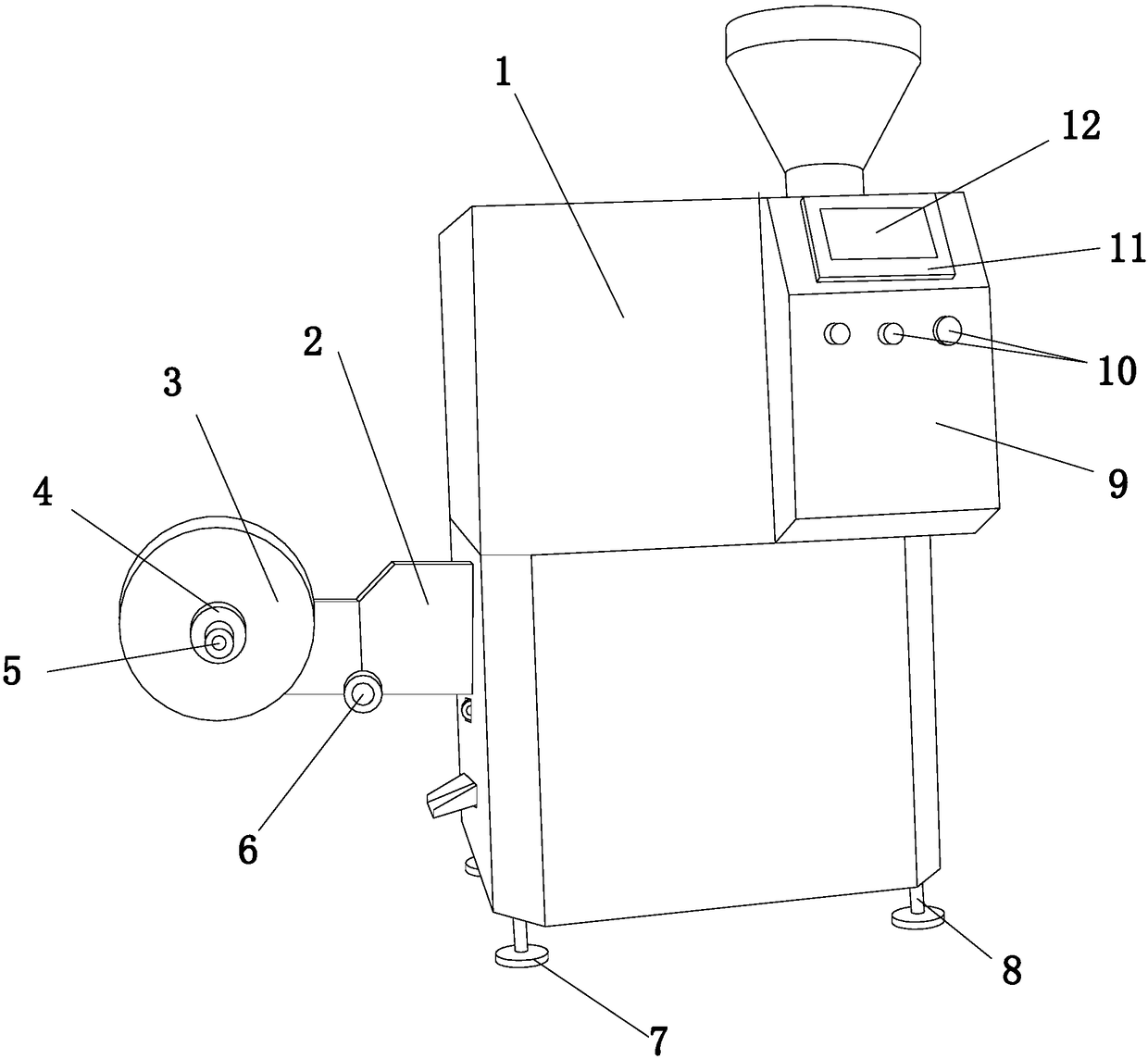

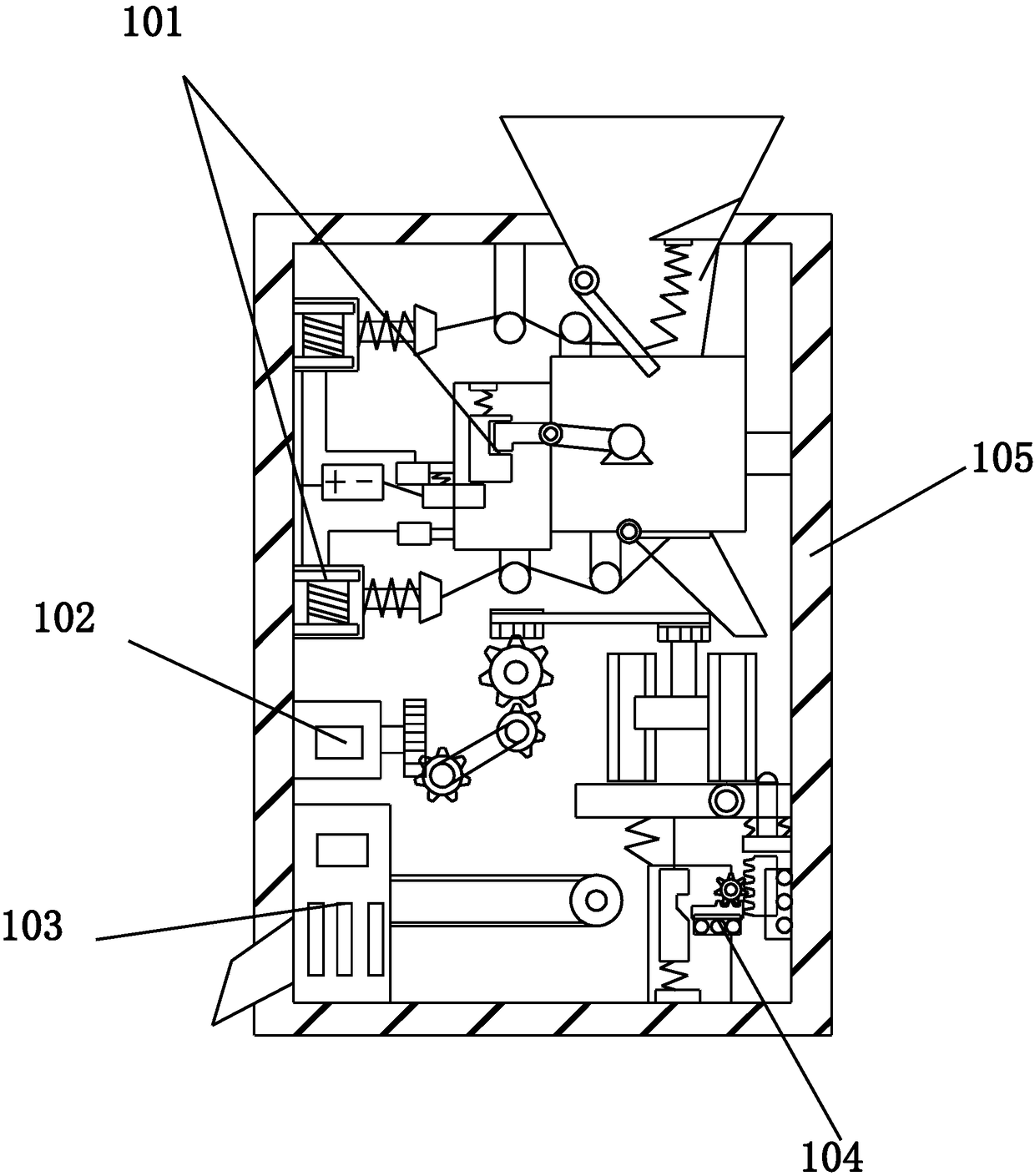

Automatic tea packaging machine

The invention discloses an automatic tea packaging machine which structurally comprises a packaging machine structure, a rotary table support plate, a packaging bag rotary table, a chuck plate, a rotary rod, a packaging bag pulley, non-slip mats, load-bearing foot stands, an operation panel, operation buttons, a screen fixing frame and a display screen. The right end of the rotary table support plate is welded with the left end of the packaging machine; the left end of the rotary table support plate is connected with the rear end of the packaging bag rotary table through the rotary rod; the rear end of the rotary rod communicates with the front end of the packaging bag rotary table; and the rear end of the chuck plate fits the front end of the packaging bag rotary table, and is parallel tothe front end of the packaging bag rotary table. According to the automatic tea packaging machine provided by the invention, a packaging machine structure is arranged structurally, and the device automatically feeds intermittently, so that an internal environment keeps clear, the occurrence of the phenomenon that the operation is blocked by excessive tea leaves is avoided, and the service life isprolonged; and with quantitative packaging and cyclic feeding, each tea package tends to be uniformly quantitated, and the number of tea packages required to be reworked caused by nonuniform distribution in tea packaging is reduced, so that the working efficiency is improved.

Owner:万欣宇

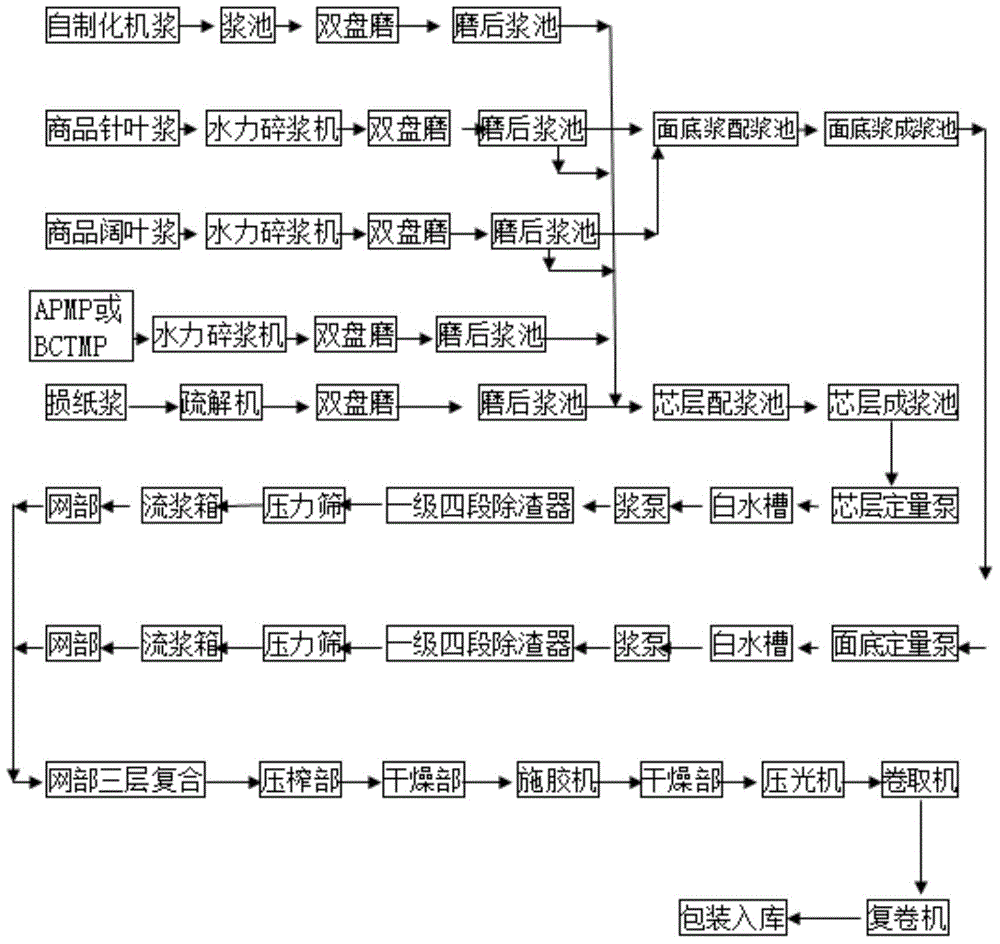

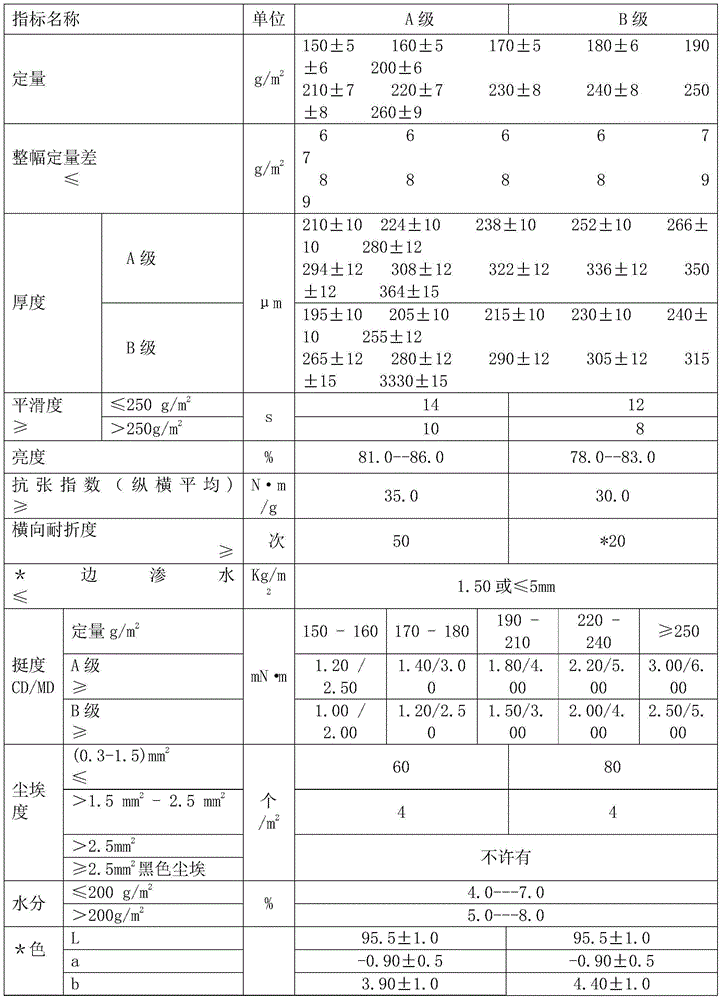

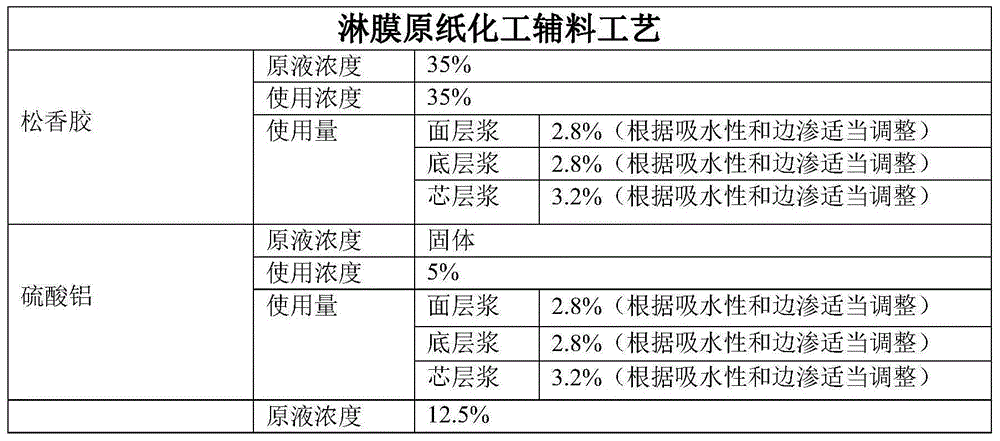

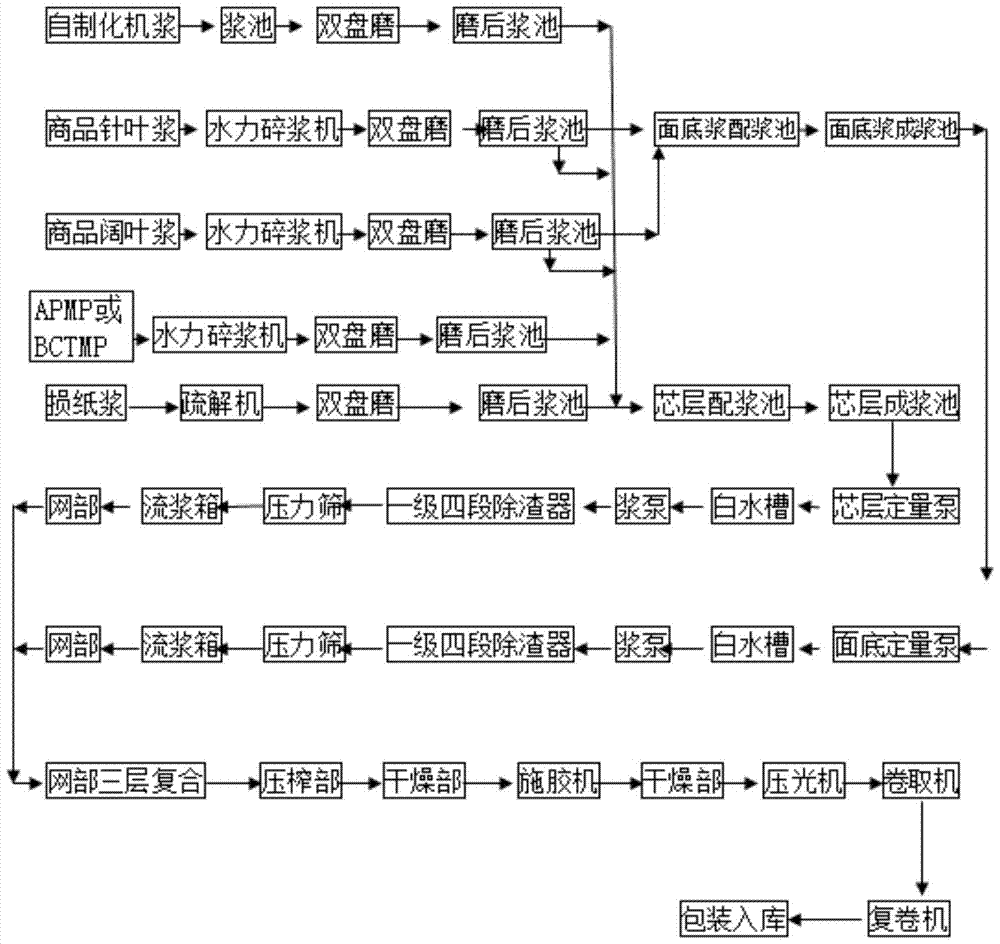

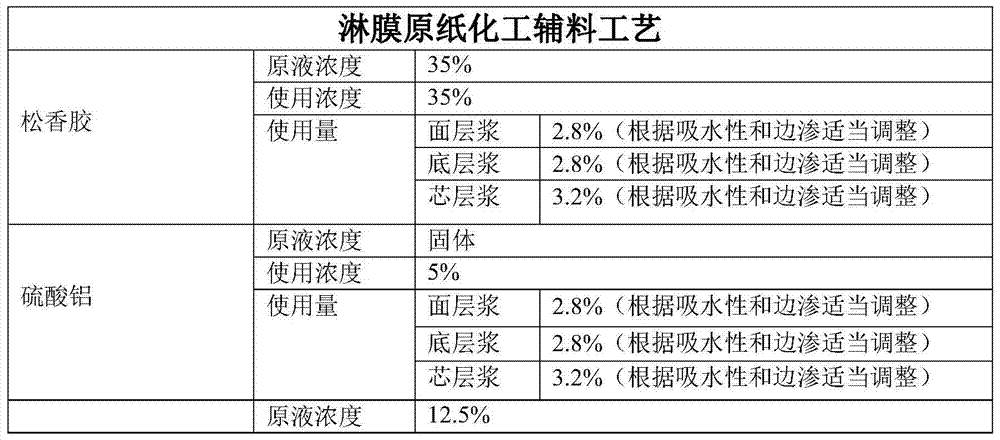

Film-coated base paper and production process thereof

ActiveCN105040507AReduce dosageQuantitative uniformReinforcing agents additionRosin additionSurface layerPulp and paper industry

The invention discloses film-coated base paper and a production process thereof. The process comprises the steps: mixing chemi-mechanical pulp, needle leave pulp, broad leave pulp and waste stuff to obtain film-coated base paper core layer pulp; mixing the needle leave pulp and broad leave pulp to obtain a surface layer pulp; mixing the needle leave pulp and the broad leave pulp to obtain surface layer pulp bottom layer pulp; facilitating the three parts of pulp to enter a pulp flow box by virtue of a quantization pump and then enter a net part to be composited, and then sequentially squeezing, drying, gluing, drying, press polishing to obtain a finished product. On the premise of guaranteeing the product quality, by improving the pulp proportion and the process, the waste stuff is added into the traditional process formula, so that the use amount of the chemi-mechanical pulp can be increased, the use amount of the broad leave pulp and the needle leave pulp can be reduced, and particularly the use amount of imported pulp can be reduced.

Owner:河南新亚新科技包装材料有限公司

Three-axis robot gluing equipment and technology

ActiveCN105032709BSimple processFast processingPretreated surfacesCoatingsPolyurethane adhesiveEngineering

The invention relates to the technical field of gluing, which is used for two-component polyurethane gluing, and in particular to a three-axis robot gluing equipment and technology, which is characterized in that it includes a three-axis robot, a glue supply device, a two-component gluing head, Double-station automatic gluing workbench or multi-station automatic rotating gluing workbench, plasma treatment equipment, cleaning waste liquid recovery device, intelligent control system; the structure of the three-axis robot is gantry or cantilever, double The gluing head and the plasma processing head are fixed on the three-axis robot and can realize the three-axis linkage of X, Y, and Z. The workpiece is placed on the double-station automatic gluing worktable or the multi-station automatic rotary gluing workbench. The glue supply device includes A glue barrel, B glue barrel, A glue metering pump, B glue metering pump, rubber hose, glue supply pipeline, A glue material barrel, B glue material barrel, the present invention is a A novel polyurethane gluing equipment and process technology with precise proportioning, stable strip performance and good sealing effect.

Owner:DALIAN HUAGONG INNOVATION TECH

Four-axis robot gluing equipment and technology

ActiveCN104971863BSimple processFast processingProgramme-controlled manipulatorSpraying apparatusEngineeringMechanical engineering

The invention relates to the technical field of gluing, which is used for two-component polyurethane gluing, and in particular to a four-axis robot gluing equipment and process technology, which is characterized in that it includes a four-axis robot, a glue supply device, a two-component gluing head, Double-station automatic gluing workbench or multi-station automatic rotating gluing workbench, plasma treatment equipment, cleaning waste liquid recovery device, intelligent control system; the structure of the four-axis robot is gantry or cantilever, double The gluing head and the plasma processing head are fixed on the four-axis robot and can realize the three-axis linkage of X, Y, and Z. The workpiece is placed on the double-station automatic gluing workbench or the multi-station automatic rotating gluing workbench. The invention is a novel polyurethane gluing equipment and technology with precise proportioning, stable performance of rubber strips and good sealing effect.

Owner:DALIAN HUAGONG INNOVATION TECH

Five-axis robot gluing equipment and technology

ActiveCN104971862BSimple processFast processingProgramme-controlled manipulatorSpraying apparatusEngineeringMetering pump

The invention relates to the technical field of gumming, in particular to five-axis robot gumming equipment and a technology which are used for two-component polyurethane gumming. The five-axis robot gumming equipment is characterized by comprising a five-axis robot, a gum supply device, a two-component gumming head, a double-station automatic gumming workbench or multi-station automatic and rotary gumming workbench, plasma processing equipment, a waste washing liquid recycling device and an intelligent control system. The five-axis robot is a five-joint robot. A workpiece is put on the double-station automatic gumming workbench or multi-station automatic and rotary gumming workbench. The workpiece is fixed or can rotate or swing or move along one axis. The two-component gumming head and aplasma processing head can achieve five-axis linkage. The gum supply device comprises a gum A barrel, a gum B barrel, a gum A metering pump, a gum B metering pump, a gum pipe, a gum supply pipeline, a pipeline support, a gum A material barrel and a gum B material barrel. The polyurethane gumming equipment and the technology are novel, accurate in matching ratio, stable in adhesive tape performance and good in sealing effect.

Owner:DALIAN HUAGONG INNOVATION TECH

Processing method for drug protective pad

PendingCN105816275AIntermittent precisionAccurate packagingLaminationLamination apparatusMedicineDrug powder

The invention relates to a production method for disposable sanitary products, in particular to a processing method for a drug protective pad. The method comprises the steps of transferring a drug to a drug package material and conveying the drug package material into a coating device for coating; conveying the coated drug package material into a drug package hot-press bonding device for hot-press bonding; putting the cut drug package on a base membrane material; conveying an undershirt cloth material by utilizing an adsorptive conveying belt, performing embossing through an embossing device, performing hot-press bonding through a finished product hot-press bonding device, and performing cutting forming through a finished product cutting device; recovering wastes through a finished product waste recovery device; performing tri-folding on a product by a tri-folding device; pasting a quick and easy sticker to finish a product production process; and arranging and outputting the finished product. The drug prepared with the method is accurate to cut and package, uniform to quantify and small in drug powder amount error; due to the consideration of the particularity and easy rolling property of the undershirt cloth material, an adsorptive conveying mode is adopted; and the product in the production process is small in shape and size error and flat and attractive in appearance.

Owner:JIANGSU JWC MACHINERY

Student canteen fluid food automatic distribution device

InactiveCN110053792AReasonable structural designQuantitative uniformLiquid materialElectric machineryWheel drive

The invention relates to the technical field of canteen tools, in particular to a student canteen fluid food automatic distribution device. The student canteen fluid food and food automatic distribution device comprises an L-shaped main box, a material storage barrel and an automatic porridge discharging device, wherein a supporting frame is fixedly connected to the middle of the right end of a bowl placing frame, the upper end of the supporting frame is fixedly connected to the material storage barrel, the upper end of the material storage cylinder is inserted into a first through hole in theright upper end of the L-shaped main box, and an arc-shaped through hole is formed in the left upper end of the material storage cylinder. The student canteen fluid food automatic distribution deviceis reasonable in structural design, a motor drives a driving disc on a first rotating shaft to rotate for one circle, a driven groove wheel drives a rotating drum, a cross rotating disc and a first rotating disc to rotate by 1 / 4 circle, under the common limit of a first sliding groove, a second sliding groove, a first limiting groove and a second limiting groove, so that an alternate process of an upper clamping plate is "loose-tight-loose" and a lower clamping plate is "tight downwards moving (loose) and upwards moving (tight)" is achieved, the process of automatically discharging the porridge from the bowl is realized, the opening and closing of a second through hole and the stirring of a stirring rod on the porridge are realized through a baffle plate, the uniformity and the quantification of the porridge are ensured, and the student canteen fluid food automatic distribution device has a good development prospect.

Owner:任晓坤

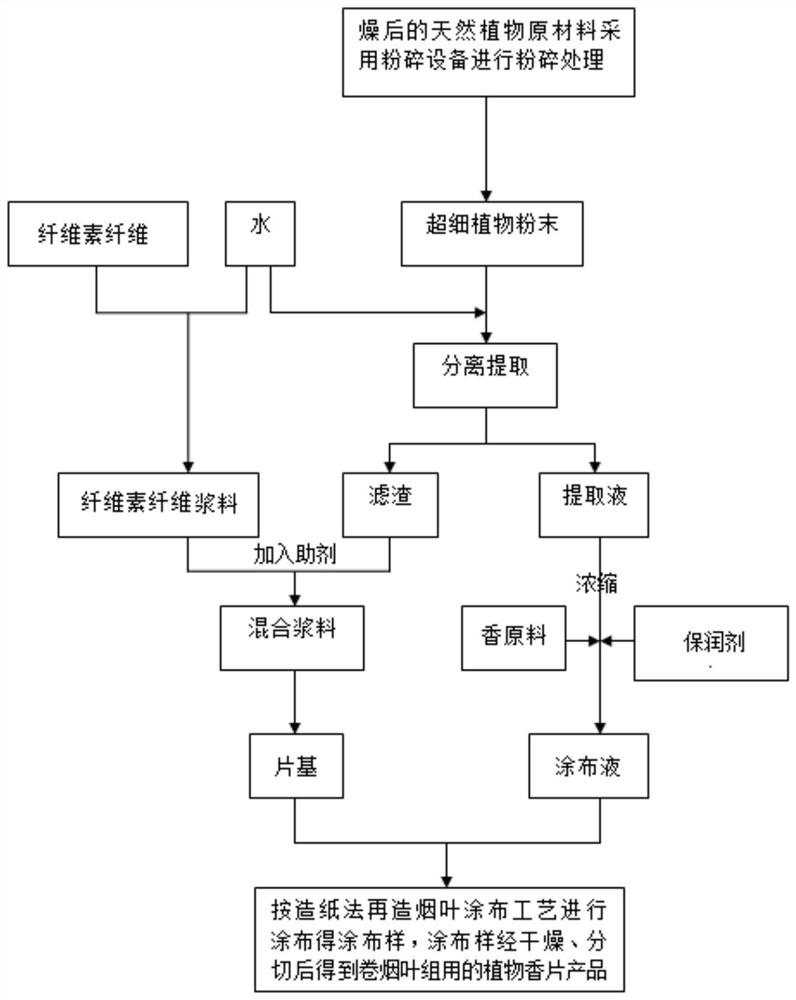

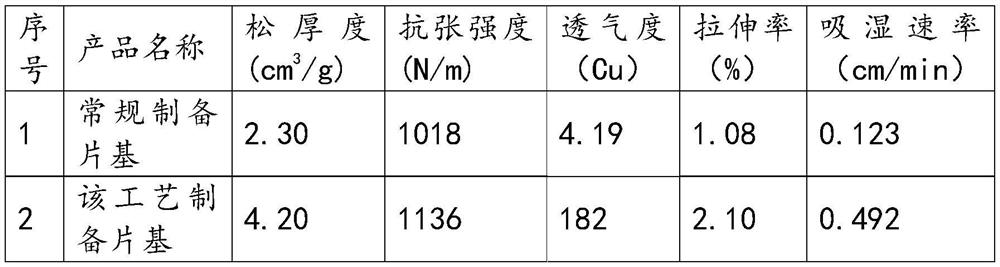

Plant scented sheet for cigarette leaf group and preparation method thereof

The invention discloses a plant scented sheet for cigarette leaf group and a preparation method thereof. The preparation method comprises the following steps: taking natural plant superfine powder with characteristic fragrance or taste as a raw material, carrying out extraction, solid-liquid separation, concentration and blending processes to obtain a coating solution; obtaining a sheet base through a papermaking forming process; coating the sheet base by a coating process to obtain a coating sample; and drying and slitting the coating sample to prepare the plant scented sheet product for thecigarette leaf group. The prepared plant scented sheet for the cigarette leaf group retains the characteristic aroma and taste of natural plant raw materials, can be used as a cigarette raw material formula, and has better functions and effects on shaping cigarette style characteristics, coordinating cigarette aroma, improving cigarette smoking quality and replacing raw materials, essence and spice.

Owner:ZHONGYAN SHIWEICE (YUNNAN) RECONSTITUTED TOBACCO CO LTD

Method for detecting sulfite in food

InactiveCN111337617AOvercoming the problem of uneven distributionAvoid defectsComponent separationSulfate radicalsDistillation

The invention relates to a method for detecting sulfite in food, and the method comprises the following steps: weighing a proper amount of sample, putting the sample into a distillation flask, addingwater, and adding a defoaming agent and hydrochloric acid; heating the distillation flask, cooling water evaporated by reflux by using a spherical condenser, and blowing nitrogen into the distillationflask near the bottom at the same time; absorbing nitrogen overflowing from the upper end of the condenser by using a proper amount of hydrogen peroxide; properly diluting the absorption liquid, anddetermining the content of sulfate radicals by using an ion chromatograph; and calculating the content of sulfite in the sample according to the measured value of sulfate radical. The method has the advantages of safety, no pollution, clean absorption liquid, no need of retreatment, simple work flow, high sensitivity, accurate quantification, overcoming of many defects of national standard methods, good applicability, simple operation, accurate detection result, no use of lead-containing reagents, and environmental protection.

Owner:安徽国泰众信检测技术有限公司

A kind of coated base paper and its production process

ActiveCN105040507BReduce dosageQuantitative uniformReinforcing agents additionRosin additionSurface layerPulp and paper industry

The invention discloses film-coated base paper and a production process thereof. The process comprises the steps: mixing chemi-mechanical pulp, needle leave pulp, broad leave pulp and waste stuff to obtain film-coated base paper core layer pulp; mixing the needle leave pulp and broad leave pulp to obtain a surface layer pulp; mixing the needle leave pulp and the broad leave pulp to obtain surface layer pulp bottom layer pulp; facilitating the three parts of pulp to enter a pulp flow box by virtue of a quantization pump and then enter a net part to be composited, and then sequentially squeezing, drying, gluing, drying, press polishing to obtain a finished product. On the premise of guaranteeing the product quality, by improving the pulp proportion and the process, the waste stuff is added into the traditional process formula, so that the use amount of the chemi-mechanical pulp can be increased, the use amount of the broad leave pulp and the needle leave pulp can be reduced, and particularly the use amount of imported pulp can be reduced.

Owner:河南新亚新科技包装材料有限公司

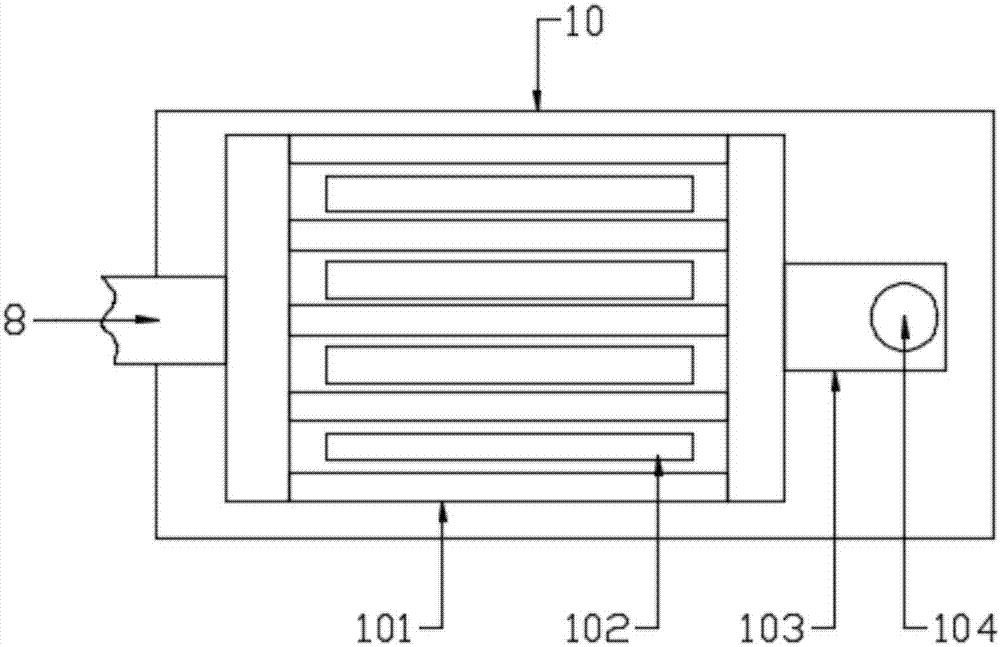

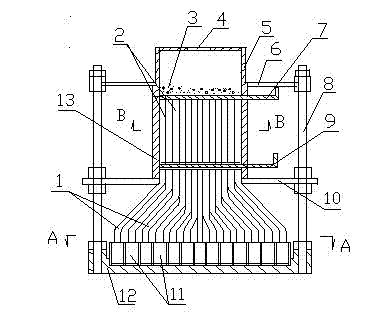

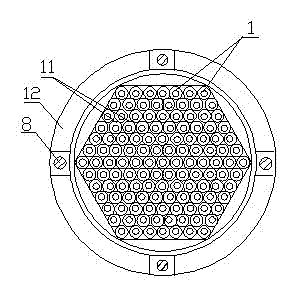

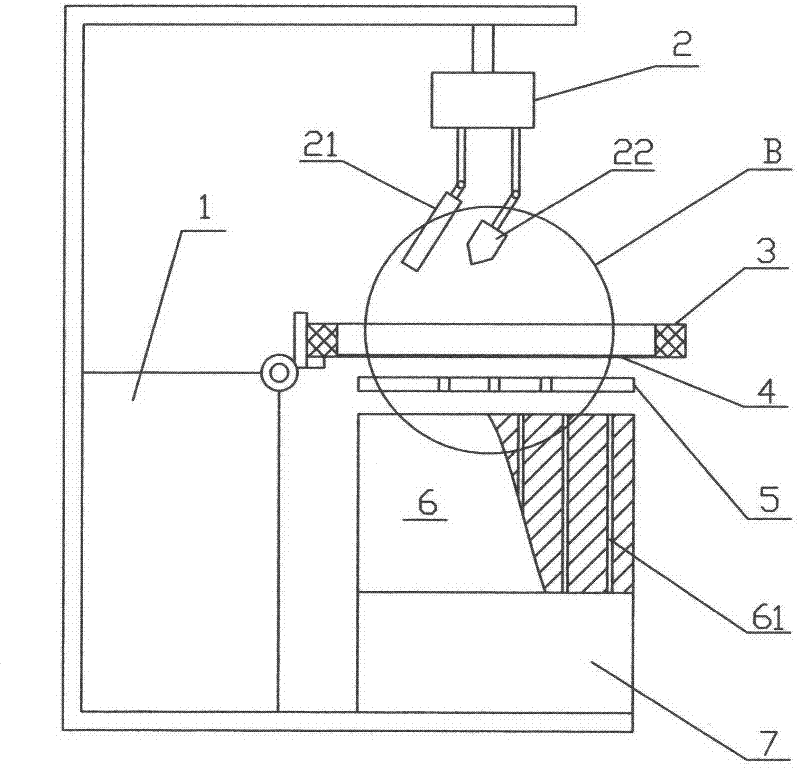

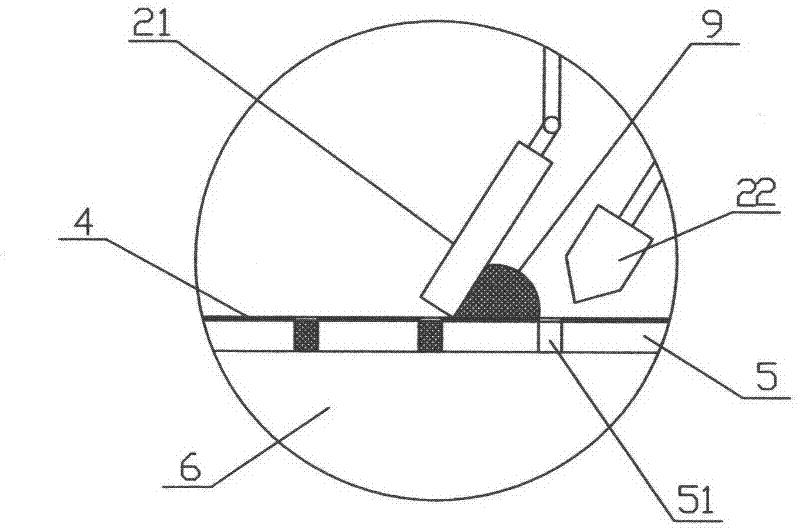

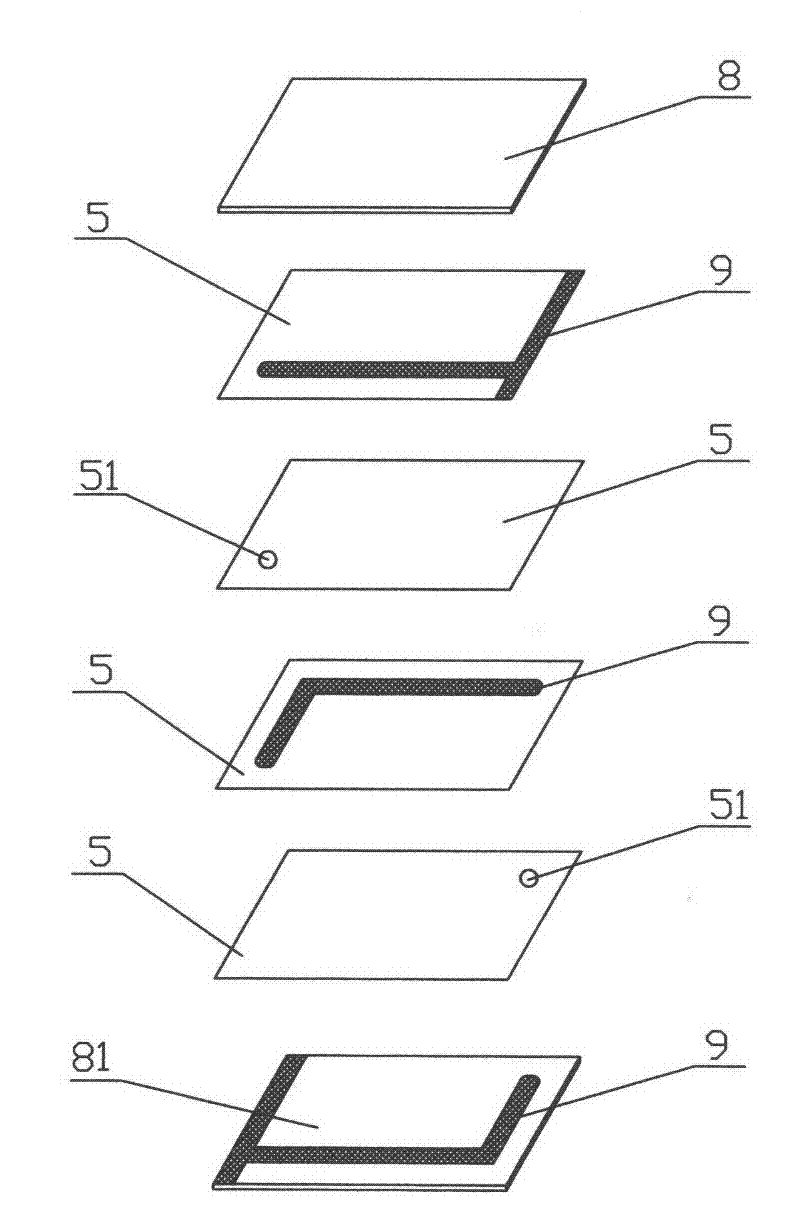

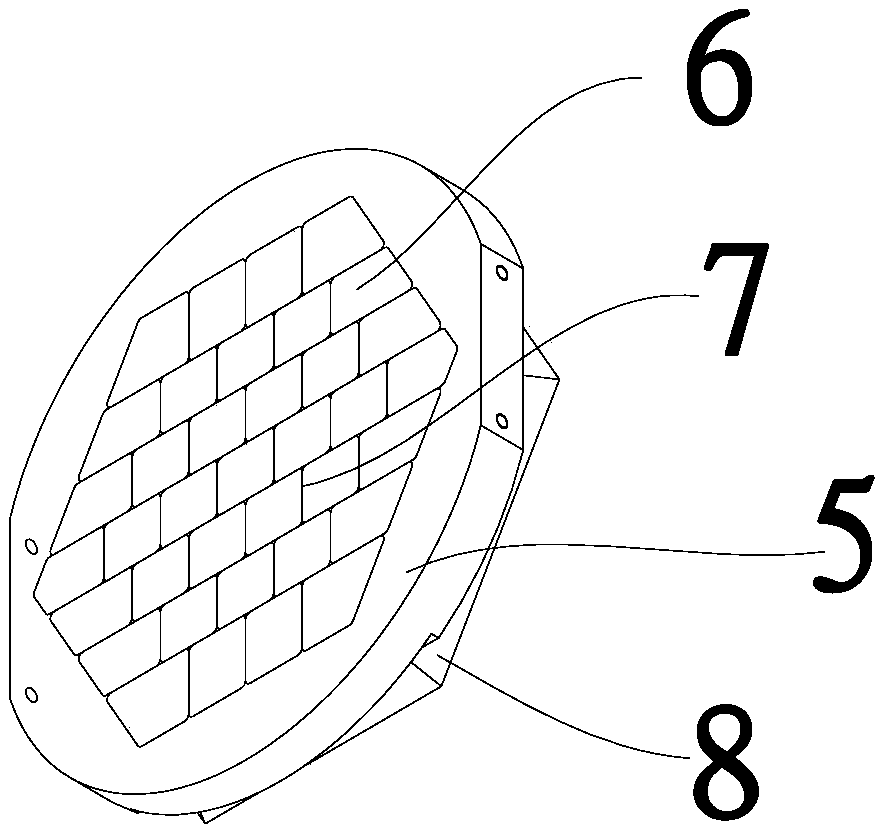

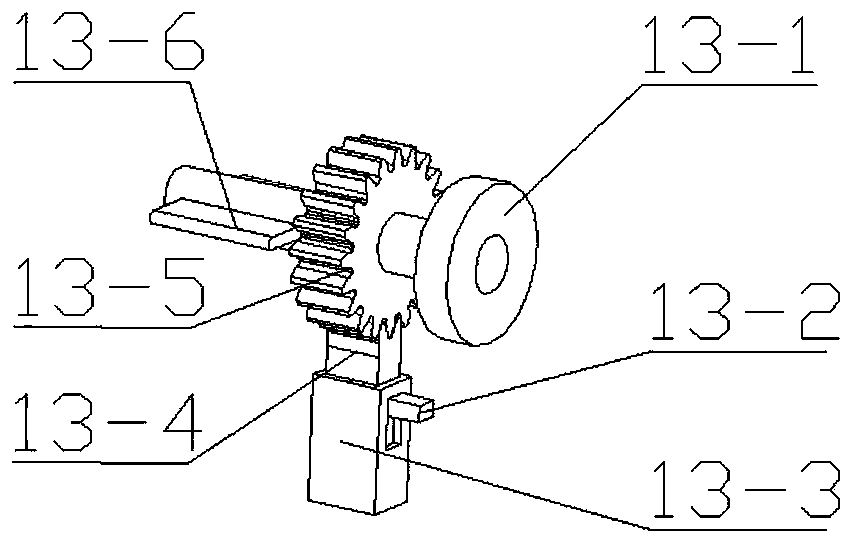

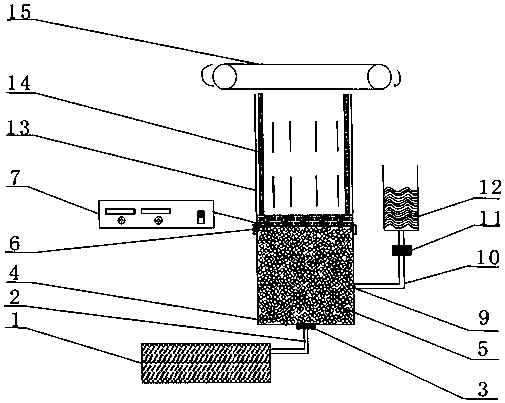

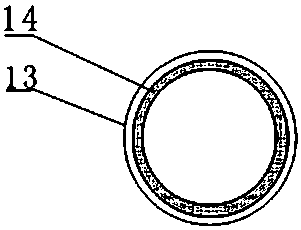

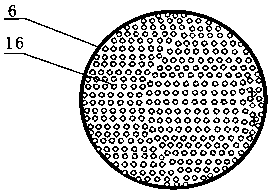

Ceramic diaphragm printing pore filling machine

InactiveCN102582222AFast printing and hole fillingQuantitative uniformScreen printersConductive pasteManufacturing technology

The invention relates to a ceramic diaphragm printing pore filling machine for producing sheet electronic products in the technical field of electronic element manufacturing, which comprises a sucker mechanism, a screen frame, a printing scraper mechanism and a frame. The sucker mechanism comprises a porous ceramic plate and a vacuum system, wherein the porous ceramic plate is communicated with the vacuum system. The screen frame consists of a framework and a screen mesh with patterns, conductive paste is distributed on the patterns of the screen mesh, and a hinge connected with the frame is arranged at the edge of the framework. A printing scraper comprises an elastic scraper board and a paste spread board, the elastic scraper board is made of rubber or silicon rubber, and the paste spread board is made of aluminum alloy materials. The printing pore filling machine is quick in printing pore filling, uniformly quantitative and high in efficiency and quality. Further, since pores of the ceramic diaphragms are filled with the conductive paste, inner electrodes between the ceramic diaphragms can be well connected, and high reliability is achieved.

Owner:肇庆市宏华电子科技有限公司

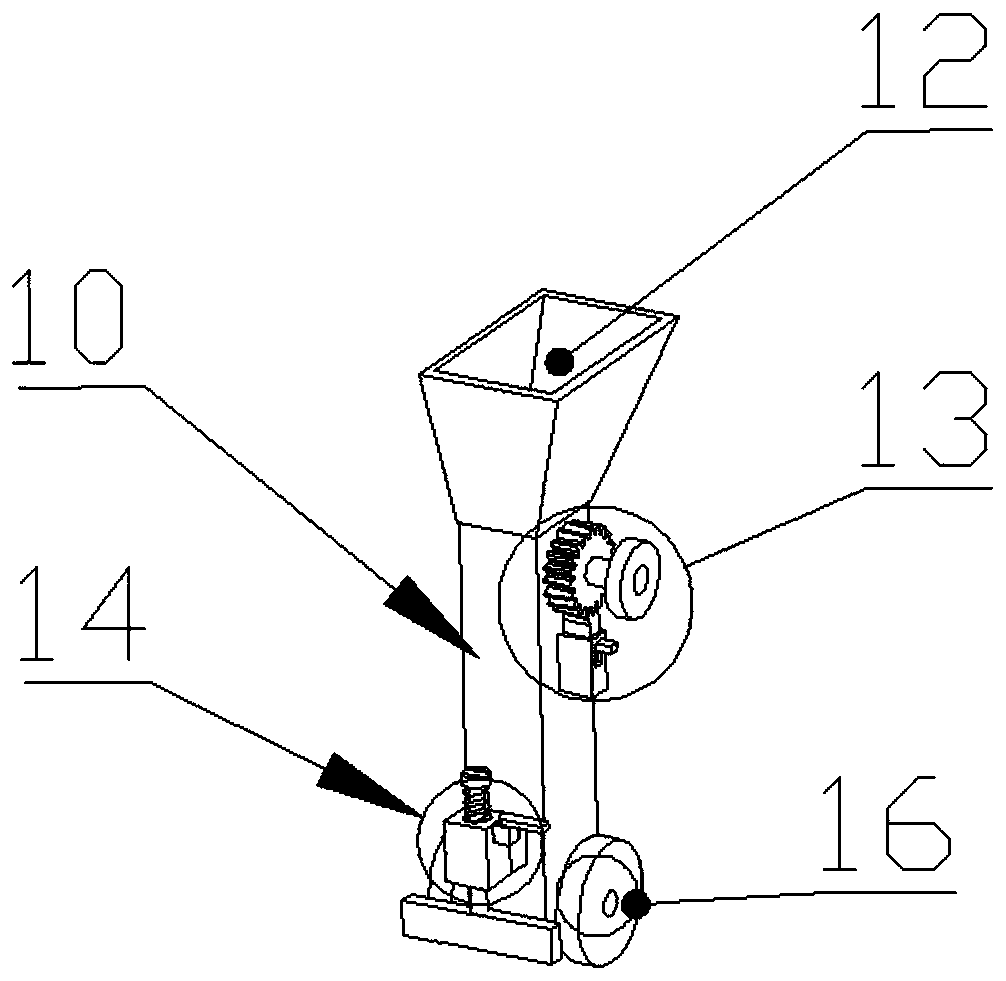

High-efficiency automatic coal-fired heating device

InactiveCN110848663AUniform feedingQuantitative uniformSolid fuel combustionChamber doorsActivated carbonCombustion chamber

The invention discloses a high-efficiency automatic coal-fired heating device. The device comprises a base, a control cabinet, a combustion main body, an overhaul door, a water pump, a high-temperature-resistant cloth bag dust remover, an activated carbon box body, an induced draft fan, a condensation pipe, a combustion chamber and a gas purification chamber; the base is located at the bottom endof the whole device; the control cabinet is arranged at the upper end of the base; the activated carbon box body is arranged on one side of the high-temperature-resistant cloth bag dust remover; and the induced draft fan is arranged at the upper end of the activated carbon box body. According to the device, system full-automatic discharging is adopted, a worker only needs to add coal materials toa feeding funnel, when the combustion chamber is short of the coal materials, the control cabinet controls a first electromagnetic valve to quantitatively discharge materials to a discharging tank andthen closes the first electromagnetic valve and opens a second electromagnetic valve to discharge materials to the combustion chamber, generated flue gas enters the high-temperature-resistant cloth bag dust remover through a smoke outlet pipe for large-particle dust removal, the condensation pipe is arranged to cool the combustion chamber, and the whole device is cleaned through the water pump, so that the service life of the device is prolonged.

Owner:河北昊天热力发展有限公司

A bud-opening drug filling device

The invention relates to a bud opening explosive filling device. By means of a barrel cake clamping device, a firework barrel cake is accurately positioned below a bud opening explosive quantification device, discharging holes of the bud opening explosive quantification device and explosive filling holes of the firework barrel cake are accurately aligned, and therefore it is guaranteed that filled bud opening explosive evenly and quantitatively flows into each explosive filling hole, even and quantitative filling in the bud opening explosive filling process of the firework barrel cake is achieved, and the product quality and yield are improved. In particular, when it is detected that some firework barrel cake is transmitted from a barrel cake conveying device, a connecting rod is driven by a driving device to stretch out and drawback, the connecting rod stretches out and draws back to drive a positioning stopping arm to rotate on a first box by a certain angle, the firework barrel cake is accurately positioned below the bud opening explosive quantification device through the positioning stopping arm, and accurate positioning of the firework barrel cake is achieved.

Owner:浏阳市荷花精工机械制造有限公司

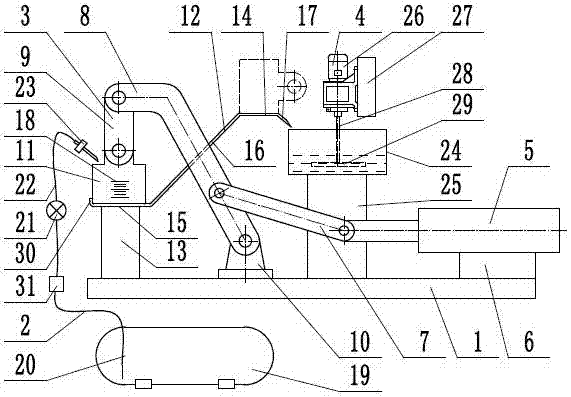

Quantitative dye delivery device

ActiveCN105174185AImplement filteringImprove filtering effectLiquid transferring devicesEngineeringPiston rod

The invention provides a quantitative dye delivery device and belongs to the technical field of textile machinery. The quantitative dye delivery device comprises an injection mechanism, a delivery mechanism and a stirring mechanism. An upper platform and a lower platform of a guiding rail of the delivery mechanism are connected through an inclined platform, the front end of a piston rod of a cylinder is hinged to one end of a first connecting rod, and the other end of the first connecting rod is hinged to a rocker. The lower end of the rocker is hinged to a rocker supporting seat, and the upper end of the rocker is hinged to the upper end of a second connecting rod. The lower end of the second connecting rod is hinged to the upper end of a dye container. One end of a pump of the injection mechanism is connected with a dye tank through a first branch pipe, and the other end of the pump is connected with an injection head through a second branch pipe. A stirring box of the stirring mechanism is mounted on a box body support, a stirring motor is located over the stirring box, a stirring bar is coaxially connected to the stirring motor, and stirring blades are arranged at the lower end of the stirring bar. By means of the quantitative dye delivery device, quantitative delivery of dye is automatically achieved, the manual labor intensity is greatly lowered, and efficiency is improved.

Owner:ZHEJIANG HUAYUE PRINTING CO LTD

Production method for lining paper for cigarette

ActiveCN102899957BImprove uniformityModerate evennessWater-repelling agents additionPaper/cardboardPulp and paper industryHardwood

The invention discloses a production method for a lining paper for a cigarette. The production method comprises the following steps: A) preparing grinding pulp, and then allocating the pulp which contains 15-30 wt.% of bleached needle bush pulp, 55-75 wt.% of bleached hardwood pulp and 10-15 wt.% of straw pulp, separately pulping, and then mixing the grinding pulp, and controlling pulp intensity at 30-40 OSR and wet weight being 2.5-5.5g; B) adding padding and a degassing agent before primarily slushing the pulp, and then entering into multi-stage deslagging; C) adding pulp glue and starting the secondary slushing; D) after ending the secondary slushing, adding a sizing agent, placing into a pressure screen for treating, and adding a retention agent at an outlet of the pressure screen; E) pouring the pulp into a pulp flowing box, loading a net and preparing paper with the pulp; F) extracting and dewatering; G) drying; H) performing soft calendaring dual-pressing treatment; and I) coiling, rewinding and cutting, packaging and putting into a storage. The lining paper for the cigarette produced according to the production method has the beneficial effects: the paper sheet uniformity is excellent; the horizontal width rated difference is small; the tensile force is high; the lining paper is easy to cut; the front surface of the paper sheet has higher smoothness; and the back surface of the paper sheet has certain smoothness.

Owner:XIANHE CO LTD

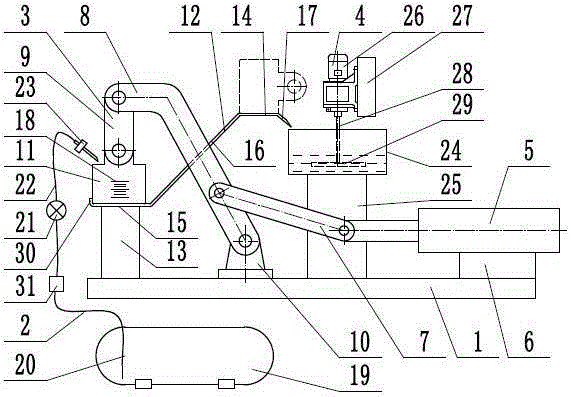

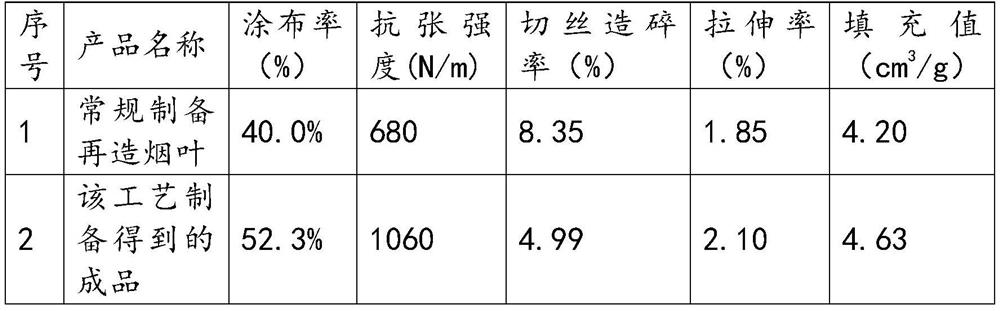

Recombinant tobacco and preparation method of recombinant tobacco

PendingCN112716026AQuantitative uniformSoft textureTobacco preparationTobacco treatmentPapermakingWater soluble

The invention discloses a recombinant tobacco and a preparation method of the recombinant tobacco, which are characterized in that a sheet base with high absorptivity and high loading capacity is obtained by a superfine tobacco powder papermaking and papermaking forming process, and the recombinant tobacco with high coating rate and high hot water soluble matter content is obtained after coating. The method solves the prominent problems of low raw material extraction yield, poor sheet base absorption performance, low reconstituted tobacco finished product coating rate, low hot water soluble matter content, product caking after coating rate improvement and the like in the traditional paper-making reconstituted tobacco production process, and the content of the prepared reconstituted tobacco hot water soluble matter is close to or reaches the level (greater than or equal to 50%) of natural tobacco raw materials. Meanwhile, the plasticity of style characteristics of the product in the preparation process is high, the inherent quality characteristics of the tobacco leaf raw materials can be highly restored, the sensory quality negative influence caused by the defects of the tobacco leaf raw materials can be improved whilethe advantages of smoke, fragrance and style characteristics of the tobacco leaf raw materials are reserved.

Owner:ZHONGYAN SHIWEICE (YUNNAN) RECONSTITUTED TOBACCO CO LTD

A dye quantitative delivery device

ActiveCN105174185BImplement filteringImprove filtering effectLiquid transferring devicesElectric machineryEngineering

The invention provides a quantitative dye delivery device and belongs to the technical field of textile machinery. The quantitative dye delivery device comprises an injection mechanism, a delivery mechanism and a stirring mechanism. An upper platform and a lower platform of a guiding rail of the delivery mechanism are connected through an inclined platform, the front end of a piston rod of a cylinder is hinged to one end of a first connecting rod, and the other end of the first connecting rod is hinged to a rocker. The lower end of the rocker is hinged to a rocker supporting seat, and the upper end of the rocker is hinged to the upper end of a second connecting rod. The lower end of the second connecting rod is hinged to the upper end of a dye container. One end of a pump of the injection mechanism is connected with a dye tank through a first branch pipe, and the other end of the pump is connected with an injection head through a second branch pipe. A stirring box of the stirring mechanism is mounted on a box body support, a stirring motor is located over the stirring box, a stirring bar is coaxially connected to the stirring motor, and stirring blades are arranged at the lower end of the stirring bar. By means of the quantitative dye delivery device, quantitative delivery of dye is automatically achieved, the manual labor intensity is greatly lowered, and efficiency is improved.

Owner:ZHEJIANG HUAYUE PRINTING CO LTD

Feed quantitative adding device for poultry feeding

Owner:SHANDONG NEW HOPE LIUHE GROUP

Method for preparing environmental-friendly cardboard paper by deinked sludge of wastepaper

ActiveCN102277764BReduce pollutionOvercome the shortcoming of difficulty in comprehensive development and utilizationWater-repelling agents additionPaper recyclingCardboardPapermaking

The invention discloses a method for preparing environmental-friendly cardboard paper by deinked sludge of wastepaper. The method provided by the invention comprises the following steps of: mixing and pulping the deinked sludge of the wastepaper, recycled pulp of the papermaking white water, recycled pulp of the papermaking wastewater, slag of chemical pulp and wastepaper pulp for future use; then molding on a net, pressing, drying, calendering, winding and manufacturing paper with pulp. The method provided by the invention has the advantages of simple production process, reduced production cost and same tightness degree of the produced environmental-friendly cardboard paper rolls; the ration and the thickness are the same; the tightness degree of the paper and the ring crush compression resistance reach the quality standards which are higher than the C grade; and the paper is applied to the paper of the industries including each type of paper tube, yarn cops, fireworks and the like.

Owner:YUEYANG ANTAI IND CO LTD

Nano-filtration membrane base material production method based on wet papermaking technology

InactiveCN109629330AImprove uniformityQuantitative uniformDefoamers additionPaper/cardboardFiberFiltration membrane

The invention relates to a nano-filtration membrane base material production method based on a wet papermaking technology. The nano-filtration membrane base material production method comprises: S1, preparing disintegrated chemical fiber, and then preparing a slurry, wherein the mass concentration of the slurry is controlled at 0.5-3%; S2, adding a dispersant and an anti-foaming agent before firstslurry rinsing, and feeding into a sand removing device, wherein the dispersant accounts for 1-3% of the mass of the slurry, the anti-foaming agent accounts for 0.01-0.03% of the mass of the slurry,and the sand removing device is divided into at least three sections; S3, feeding into second slurry rinsing; S4, after completing the second slurry rinsing, feeding into a pressure sieve, treating, and adding 0.003-0.006% by mass of a PEO retention aid at the outlet of the pressure sieve; S5, making the slurry prepared in the step S4 flow into a headbox, loading onto a net, and carrying out papermaking; S6, carrying out pressing dewatering; S7, drying; S8, treating by a calender; and S9, winding, carrying out re-winding slitting, and carrying out packaging warehouse. According to the presentinvention, the nano-filtration membrane base material produced by the method has advantages of good paper uniformity, uniform paper quantitation, uniform paper thickness, uniform paper moisture, low banner quantitative deviation and uniform banner moisture, and further has a longitudinal tensile strength of more than 11 kN / m.

Owner:衢州珮珀新材料科技有限公司

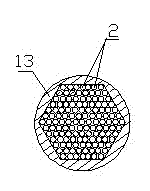

A spinning device for producing nanofibers

The invention discloses a spinning device for nanofiber production. The spinning device for nanofiber production comprises a high-pressure air pump, a spinning solution storage tank, an electrostatic generator, a metal screen and a nanofiber receiver. The electrostatic generator is connected with the metal screen, an electric field area is formed between the metal screen and the nanofiber receiver, a housing is arranged at the lower end of the metal screen and is provided with an air inlet and a liquid inlet, the air inlet is connected with the high-pressure air pump, the liquid inlet is connected with the spinning solution storage tank, spinning solution paths formed among round particles filled into the housing are formed in the housing, the liquid inlet and the air inlet are communicated with the spinning solution paths, and the metal screen is located above the spinning solution paths. Compared with existing nanofiber spinning batch-production devices, nanofiber spinning functions are diversified, and the spinning device for nanofiber production is easy to operate, convenient to use and low in power consumption.

Owner:JIAXING ZHONGXIN NANOMATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com