Patents

Literature

158results about How to "Accurate packaging" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Automatic sorting system and method

ActiveCN104108491AEasy to traceAvoid the pitfalls of manual sorting and packagingPackaging automatic controlComputer terminalComputer science

The invention discloses an automatic sorting system and method. The system comprises a sorting management system, storage stations and a boxing station. The method comprises the following steps that in the sorting management system, a boxing scheme is generated according to an order of a user, a boxing scheme ID is given to the boxing scheme, and the corresponding storage station is allocated to each specification; a boxing worker inputs the boxing scheme ID through an operation terminal of the boxing station, the operation terminal sends the received boxing scheme ID to the sorting management system, the corresponding storage station conveys a corresponding number of clothes in the corresponding specification out under the control of the sorting management system, and the clothes enter the boxing station. According to the automatic sorting system and method, accurate and efficient sorting and boxing of the finished clothes are achieved.

Owner:江苏云道信息技术有限公司 +1

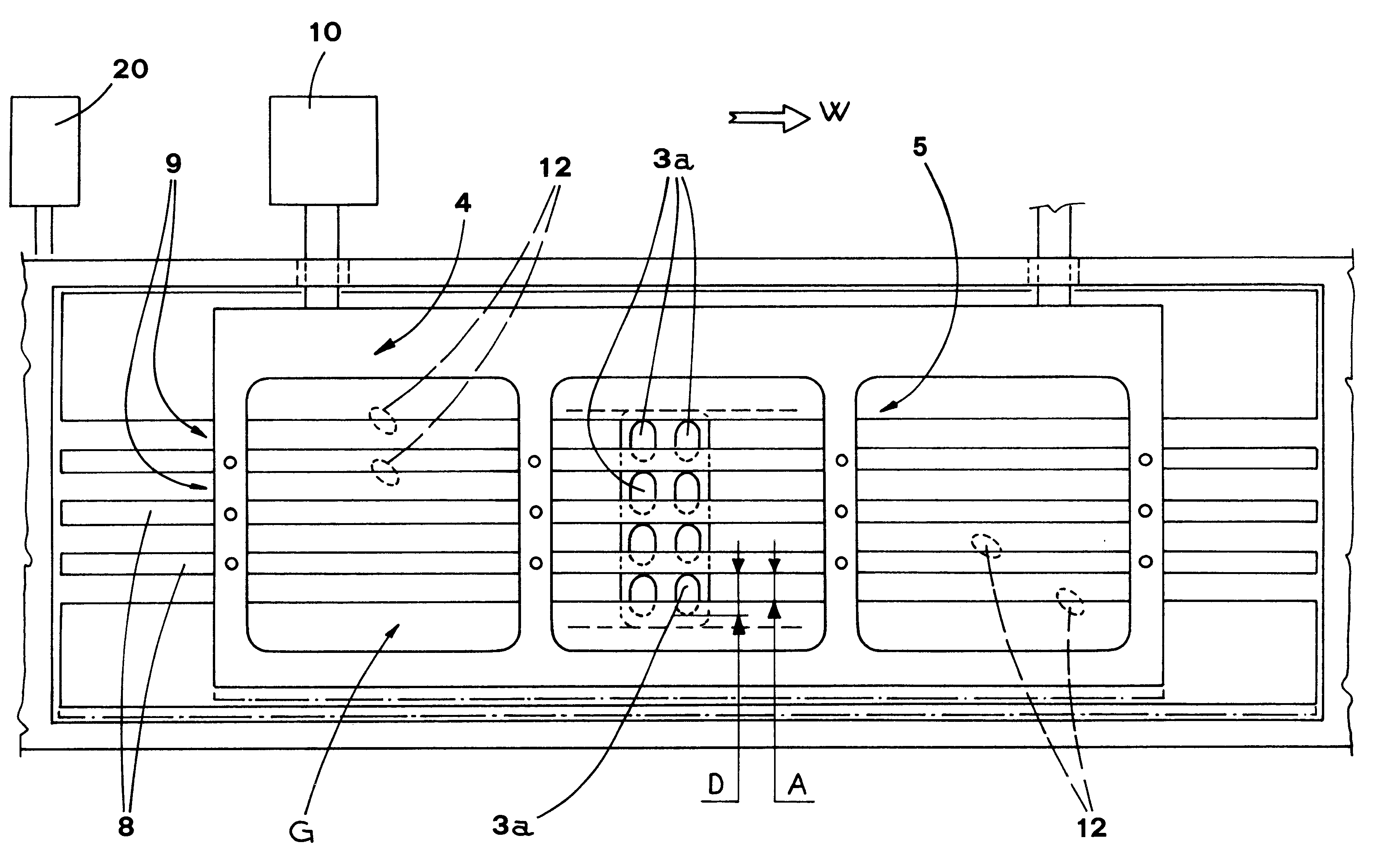

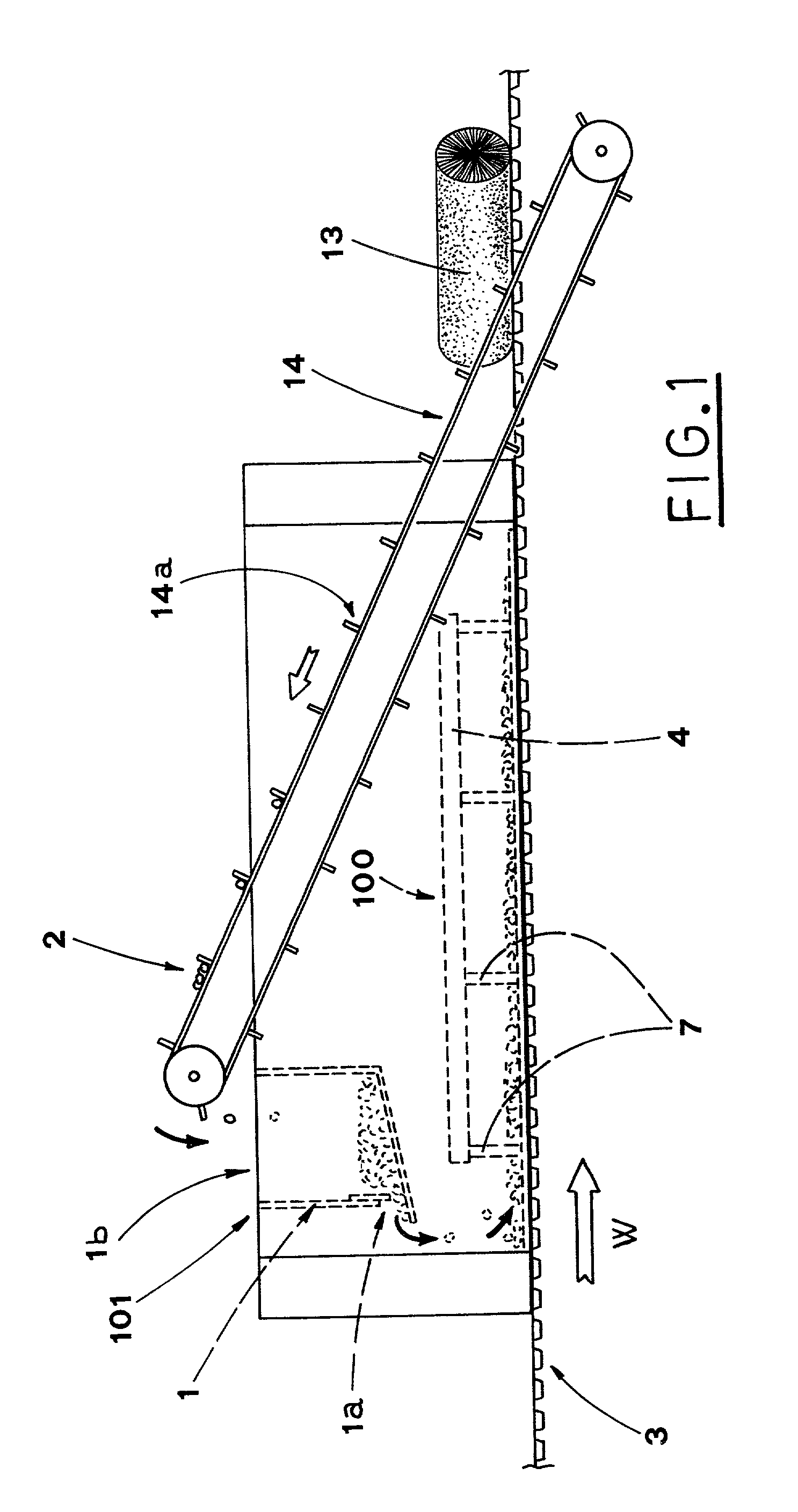

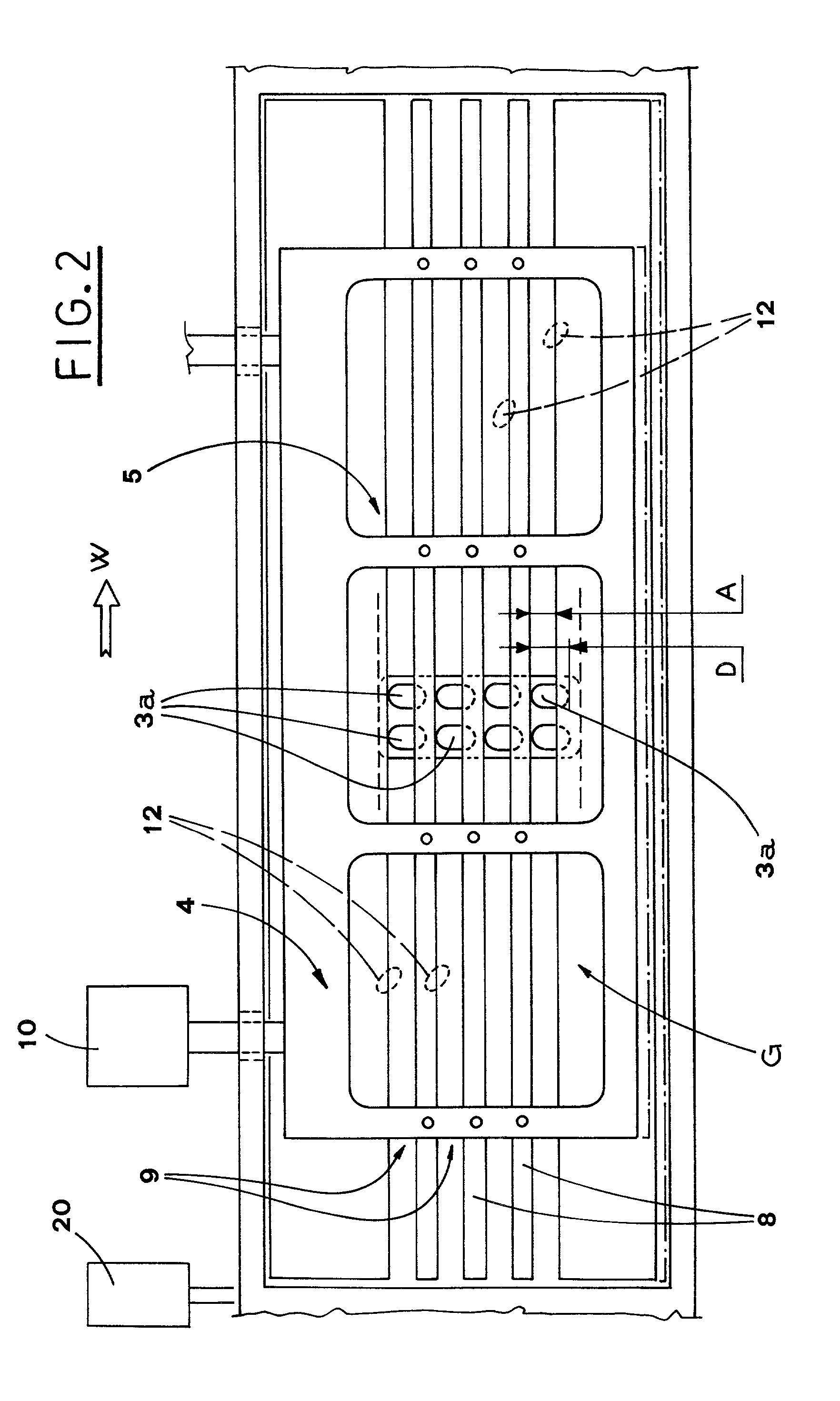

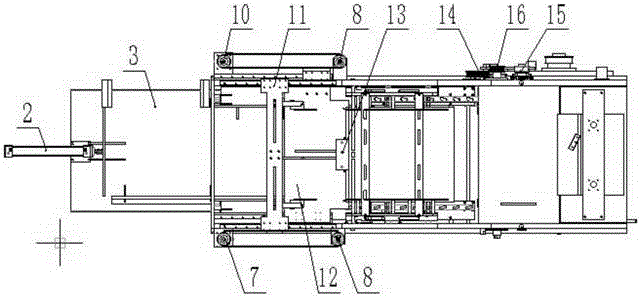

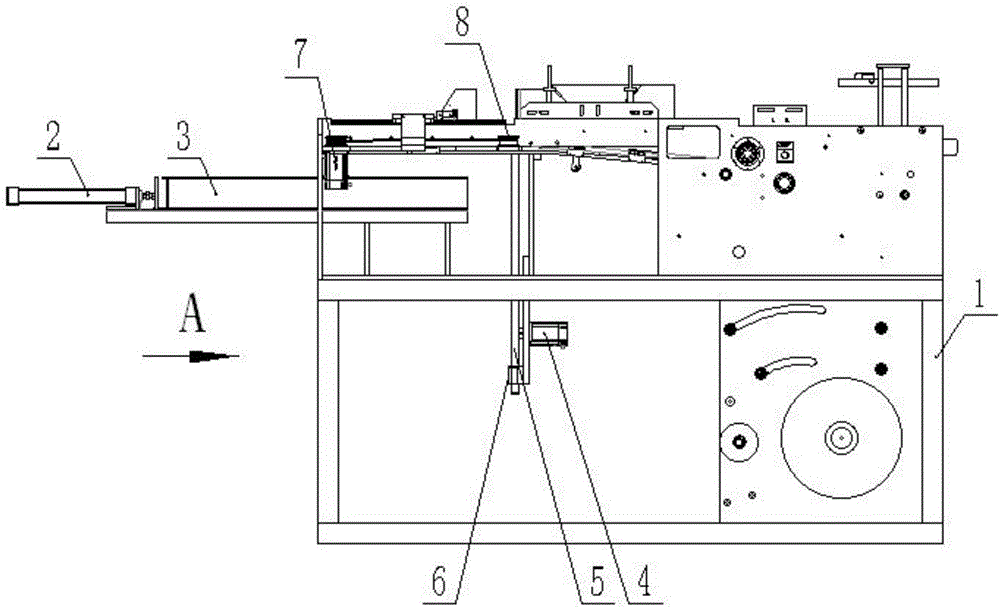

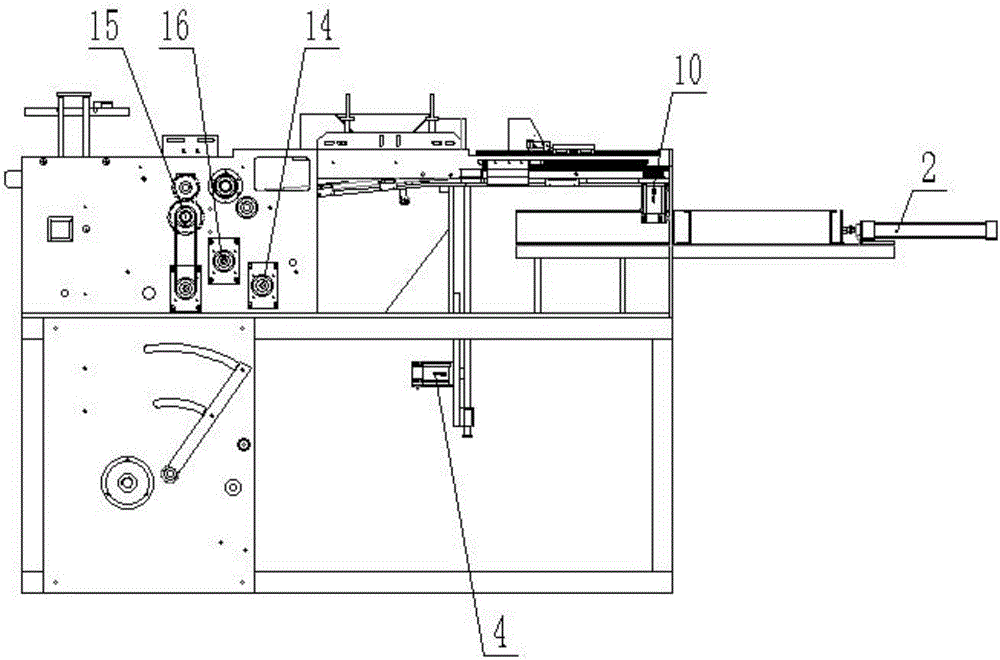

Device for feeding article to a blister band

InactiveUS6648575B2Avoid timeEasy to fillArticle unpackingSolid materialEngineeringMechanical engineering

A device (100) for feeding articles (2) to a blister band (3) moving below and having at least one row of blisters (3a) made therein for receiving corresponding articles (2). The row of blisters is parallel to the blister band forward direction (W). The device (100) has a grid (G) situated over the blister band (3), with at least one longitudinal channel (9), facing the longitudinal row of blisters (3a). A station (101) is provided for feeding the articles (2) to the grid (G), while oscillating means (10,20) generate a relative oscillating motion between the grid (G) and the corresponding blister band (3), to facilitate stabile introduction of the articles (2) into the corresponding blisters (3a) present along said longitudinal channel (9).

Owner:IMA IND MASCH AUTOMATICHE SPA

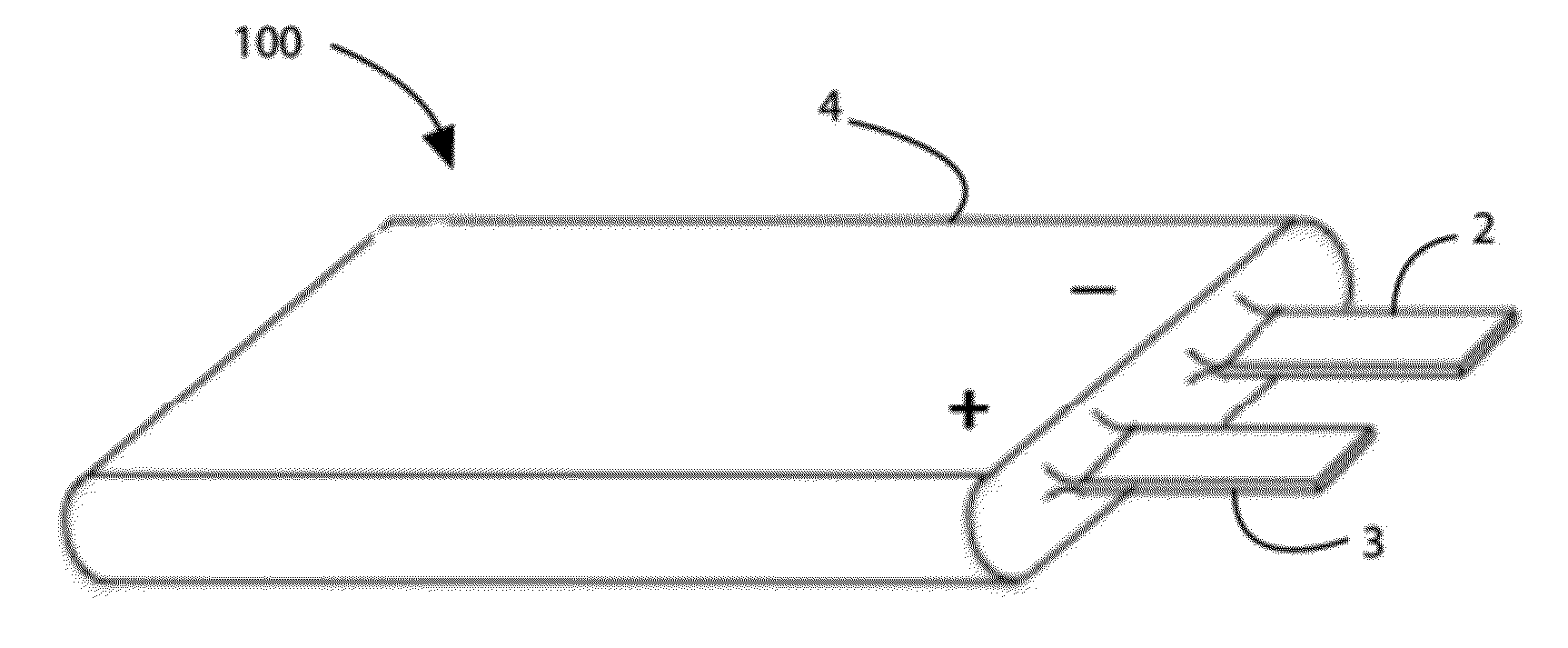

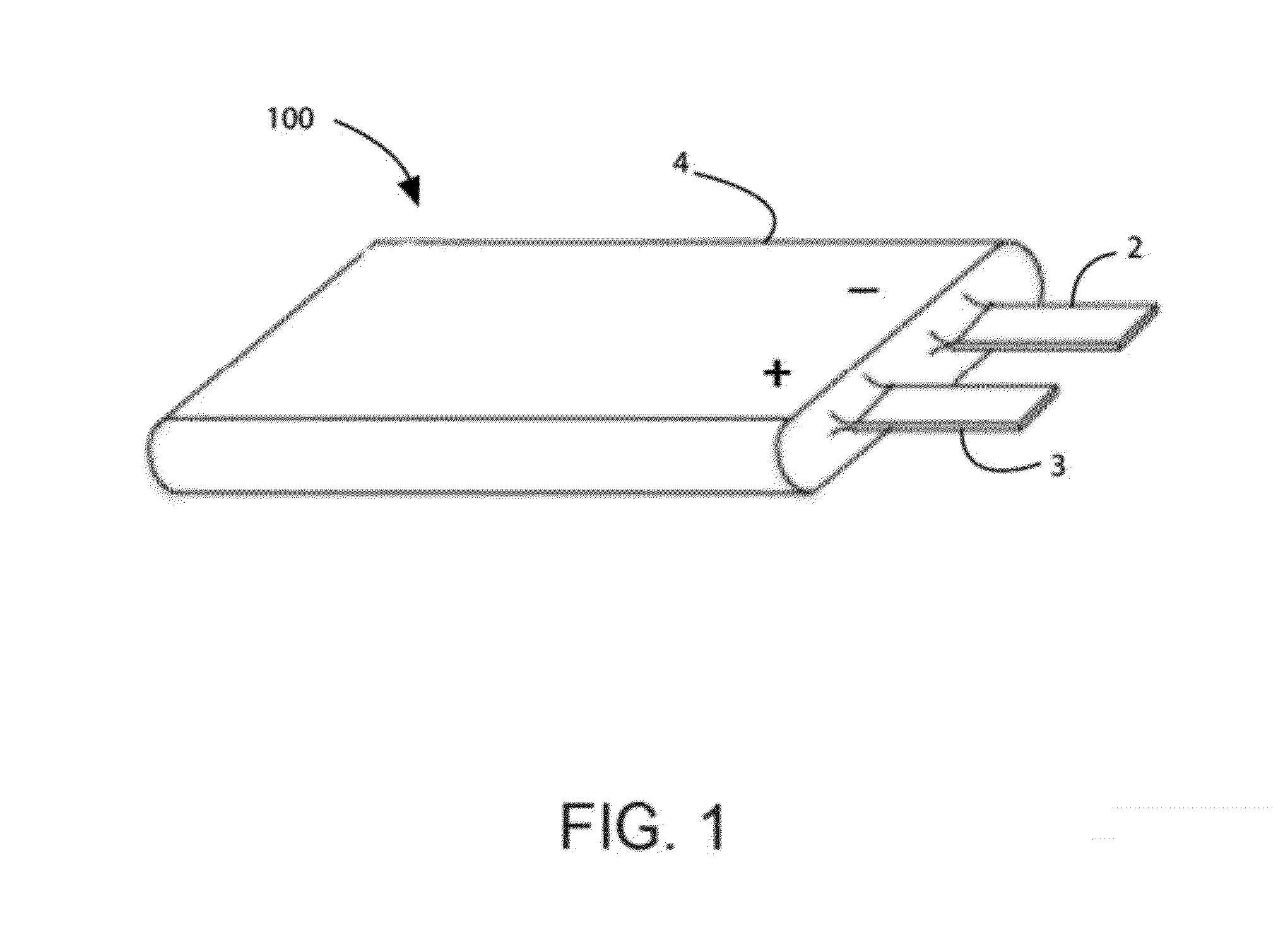

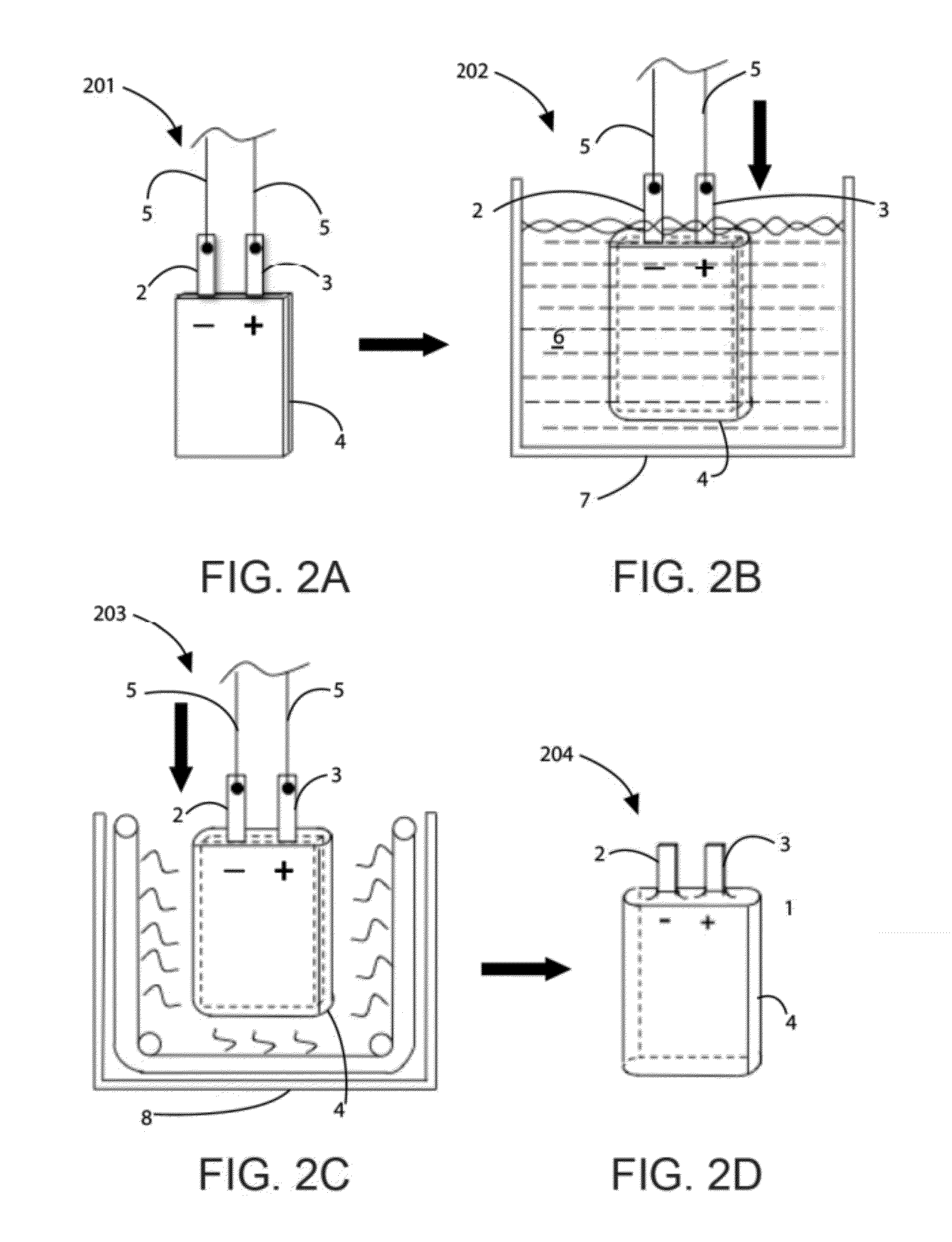

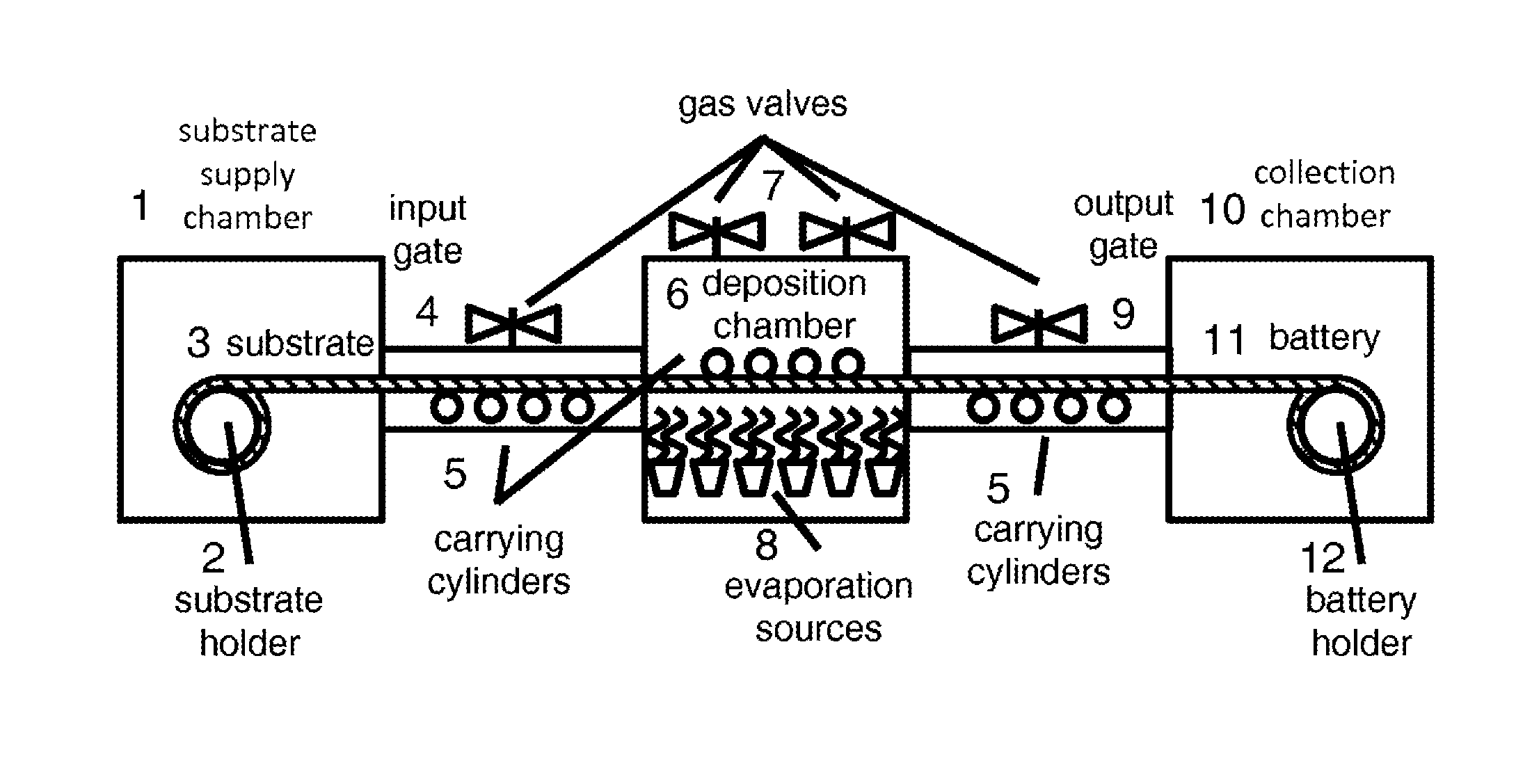

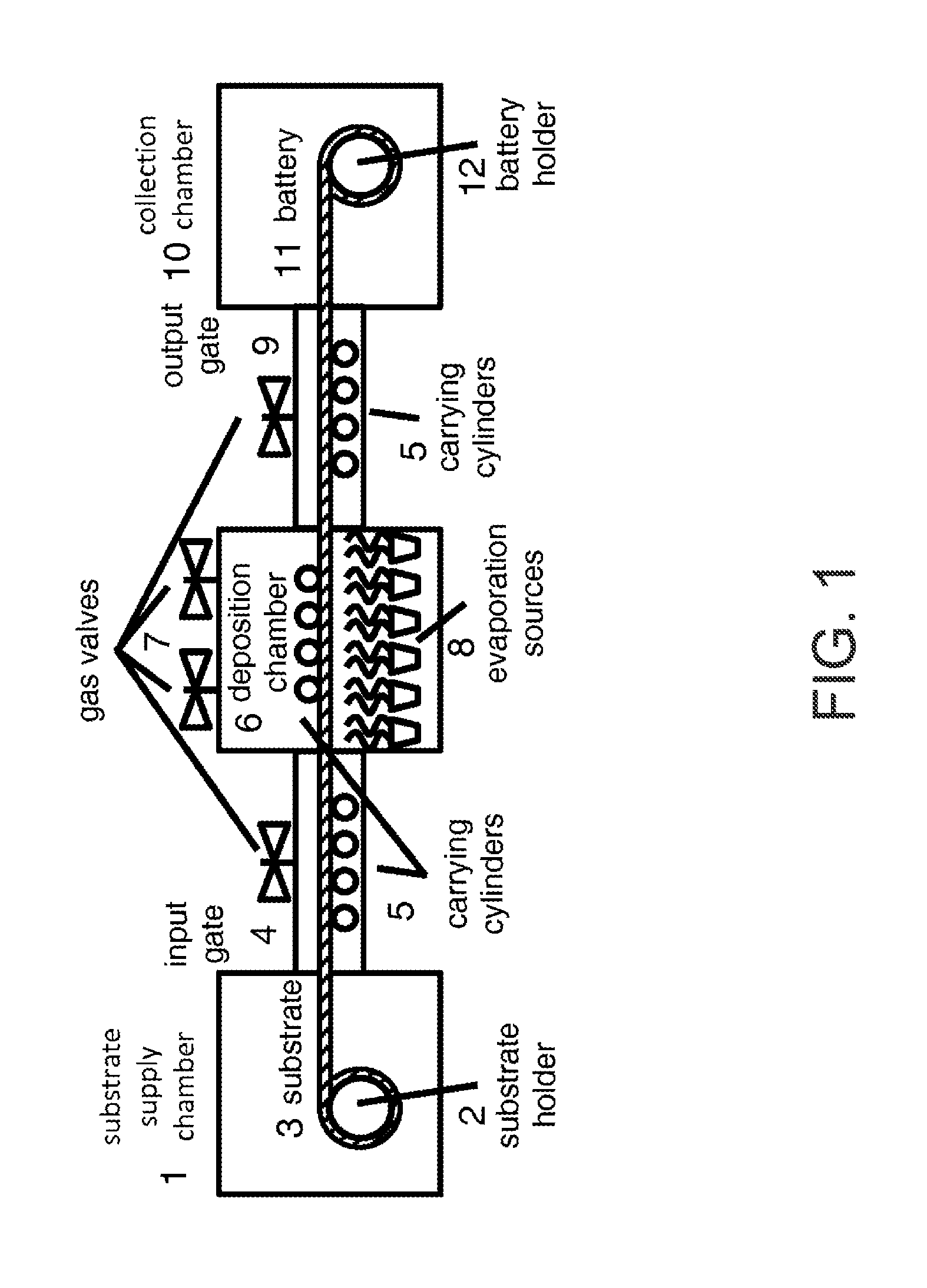

Conformal solid state package method and device for a battery device

InactiveUS20120135292A1Minimizes parasitic massMinimizes volumeMolten spray coatingElectric discharge heatingHermetic sealElectrochemical cell

A monolithically integrated thin-film solid-state lithium battery device to supply energy to a mobile communication device. The device includes a plurality of layers ranging from greater than 100 layers to less than 20,000 layers of lithium electrochemical cells, which may be connected in parallel or in series to conform to a spatial volume. The device also includes a polymer based coating characterized by a thickness to house the plurality of layers and configured as an exterior region for the battery device, the polymer based coating having a resistivity of 1012 Ω.cm and higher. The device further includes a hermetic seal provided by the polymer-based coating to enclose and house the plurality of layers.

Owner:SAKTI3

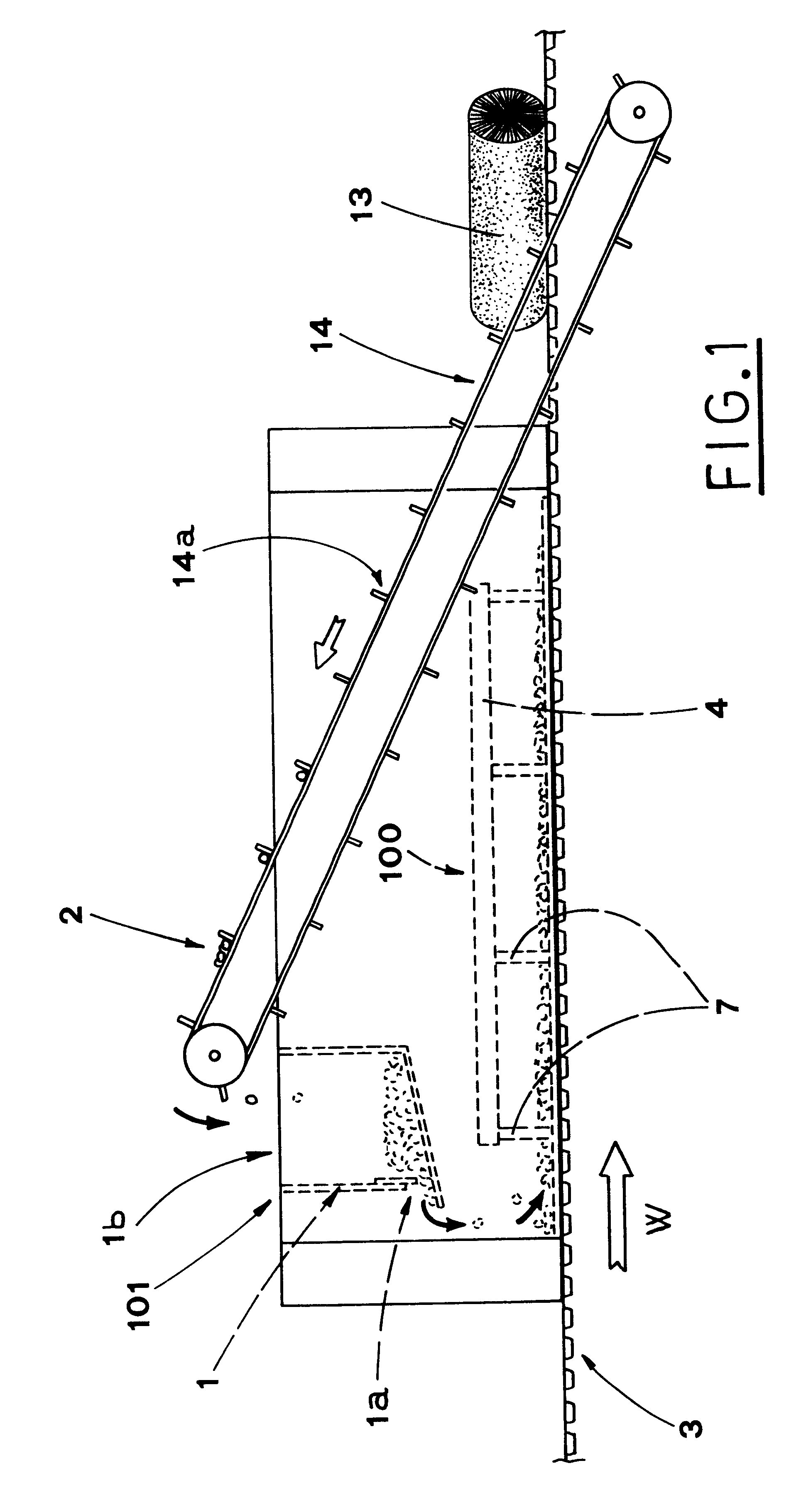

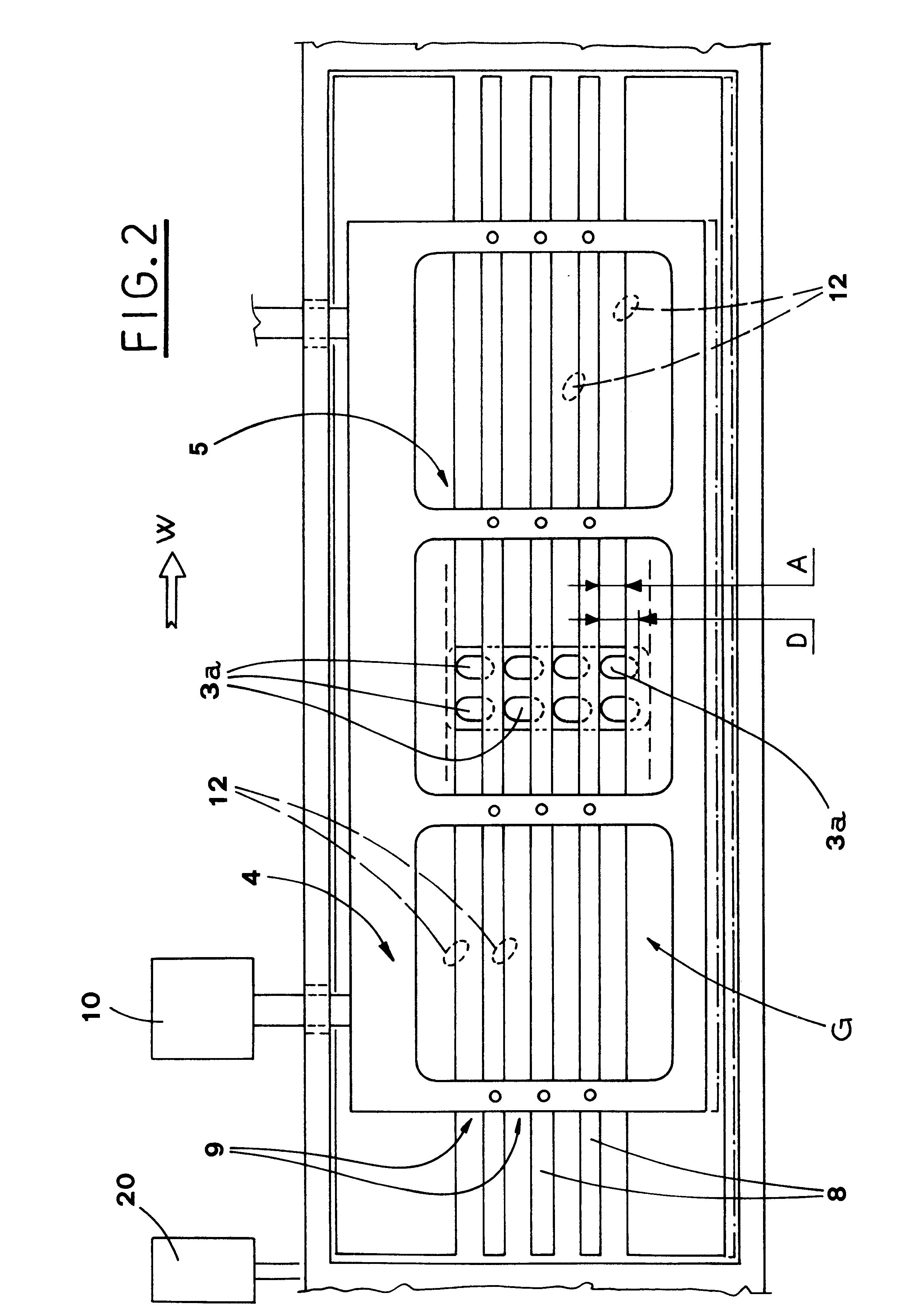

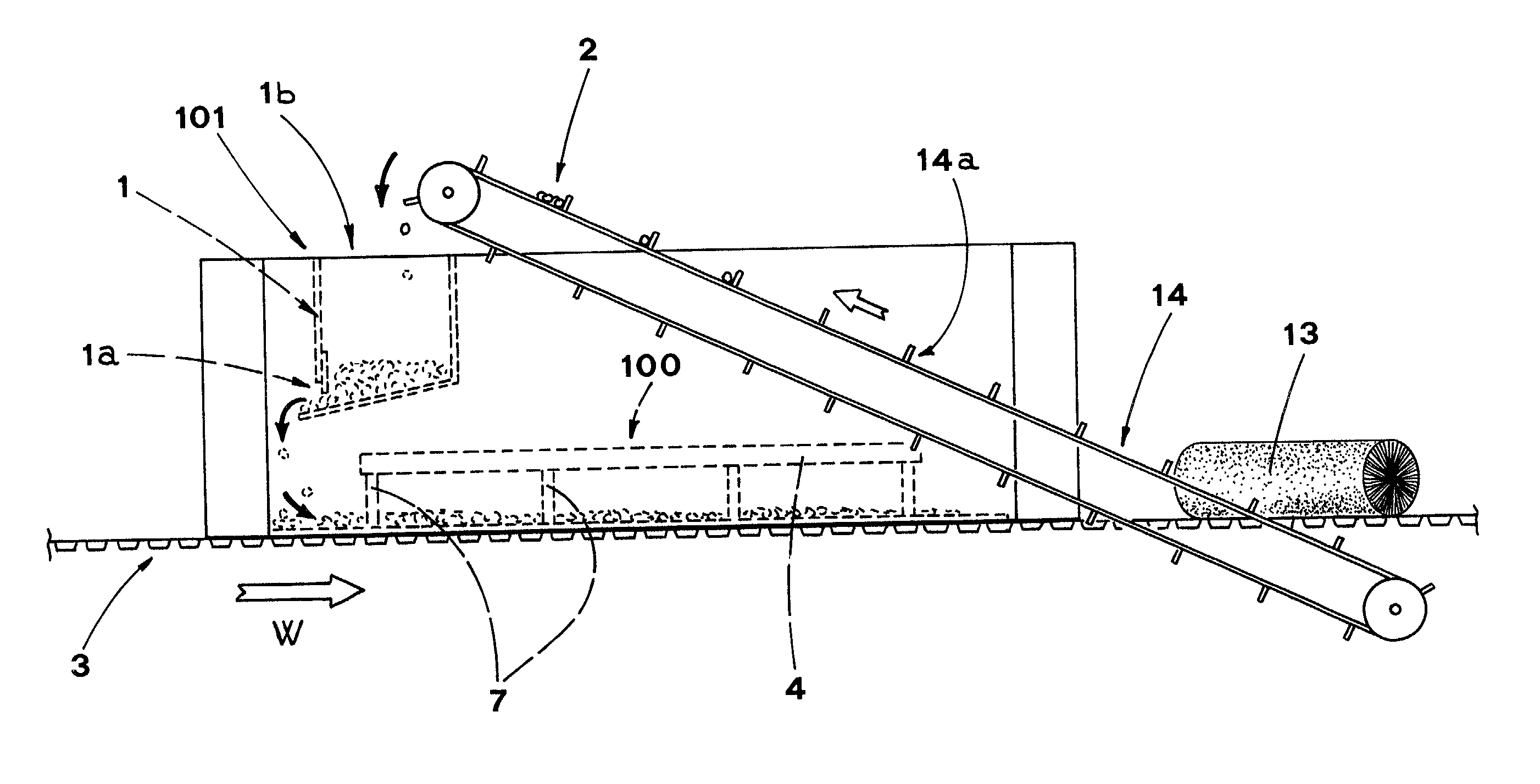

Device for feeding article to a blister band

InactiveUS20020136619A1Improve reliabilityIncrease productivityArticle unpackingSolid materialEngineeringMechanical engineering

A device (100) for feeding articles (2) to a blister band (3) moving below and having at least one row of blisters (3a) made therein for receiving corresponding articles (2). The row of blisters is parallel to the blister band forward direction (W). The device (100) has a grid (G) situated over the blister band (3), with at least one longitudinal channel (9), facing the longitudinal row of blisters (3a). A station (101) is provided for feeding the articles (2) to the grid (G), while oscillating means (10,20) generate a relative oscillating motion between the grid (G) and the corresponding blister band (3), to facilitate stabile introduction of the articles (2) into the corresponding blisters (3a) present along said longitudinal channel (9).

Owner:IMA IND MASCH AUTOMATICHE SPA

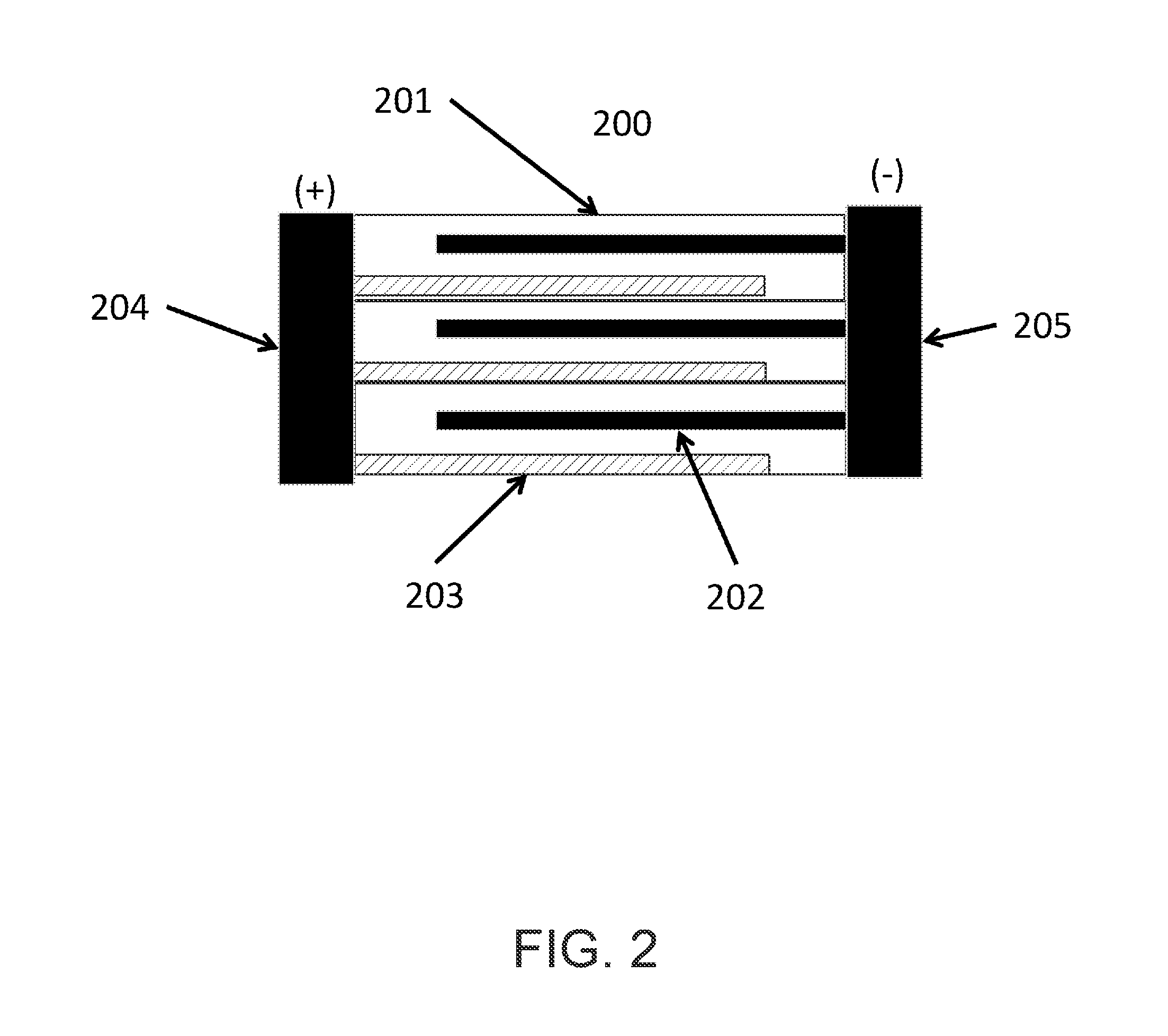

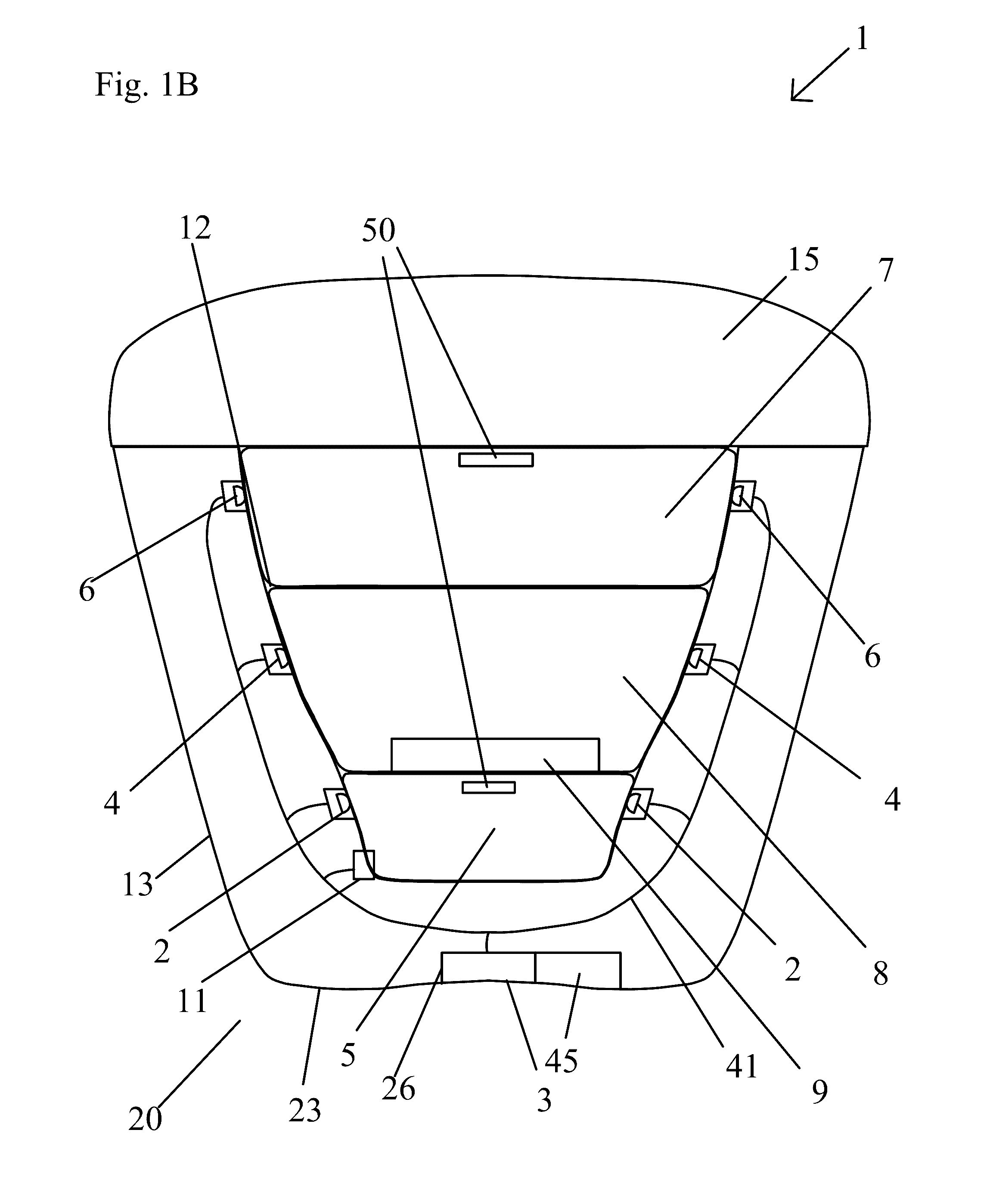

Packaging and termination structure for a solid state battery

ActiveUS20160293907A1Accurate packagingMinimized massLiquid surface applicatorsFinal product manufactureElectrical batteryCell region

A method for fabricating a solid state battery device. The device can include electrochemically active layers and an overlaying barrier material, with an inter-digitated layer structure configured with a post terminated lead structure. The method can include forming a plurality of battery device cell regions (1−N) formed in a multi-stacked configuration, wherein each of the battery device cell regions comprises a first current collector and a second current collector. The method can also include forming a thickness of a first and second lead material to cause formation of a first and second lead structure to interconnect each of the first and second current collectors associated with each of the plurality of battery device cell regions and to isolate each of the second current collectors extending spatially outside of the battery device cell region within a first and second isolated region, respectively.

Owner:SAKTI3

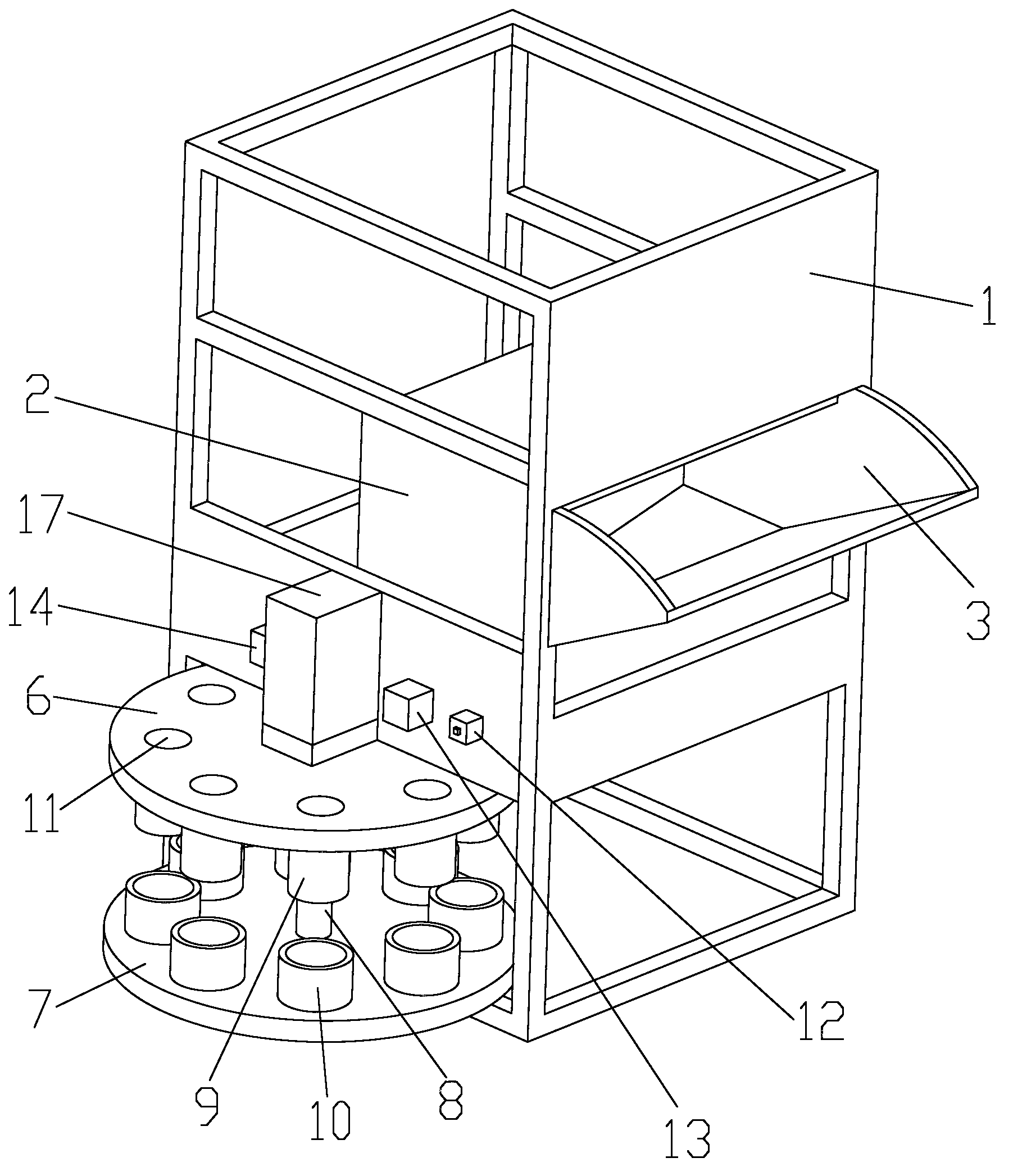

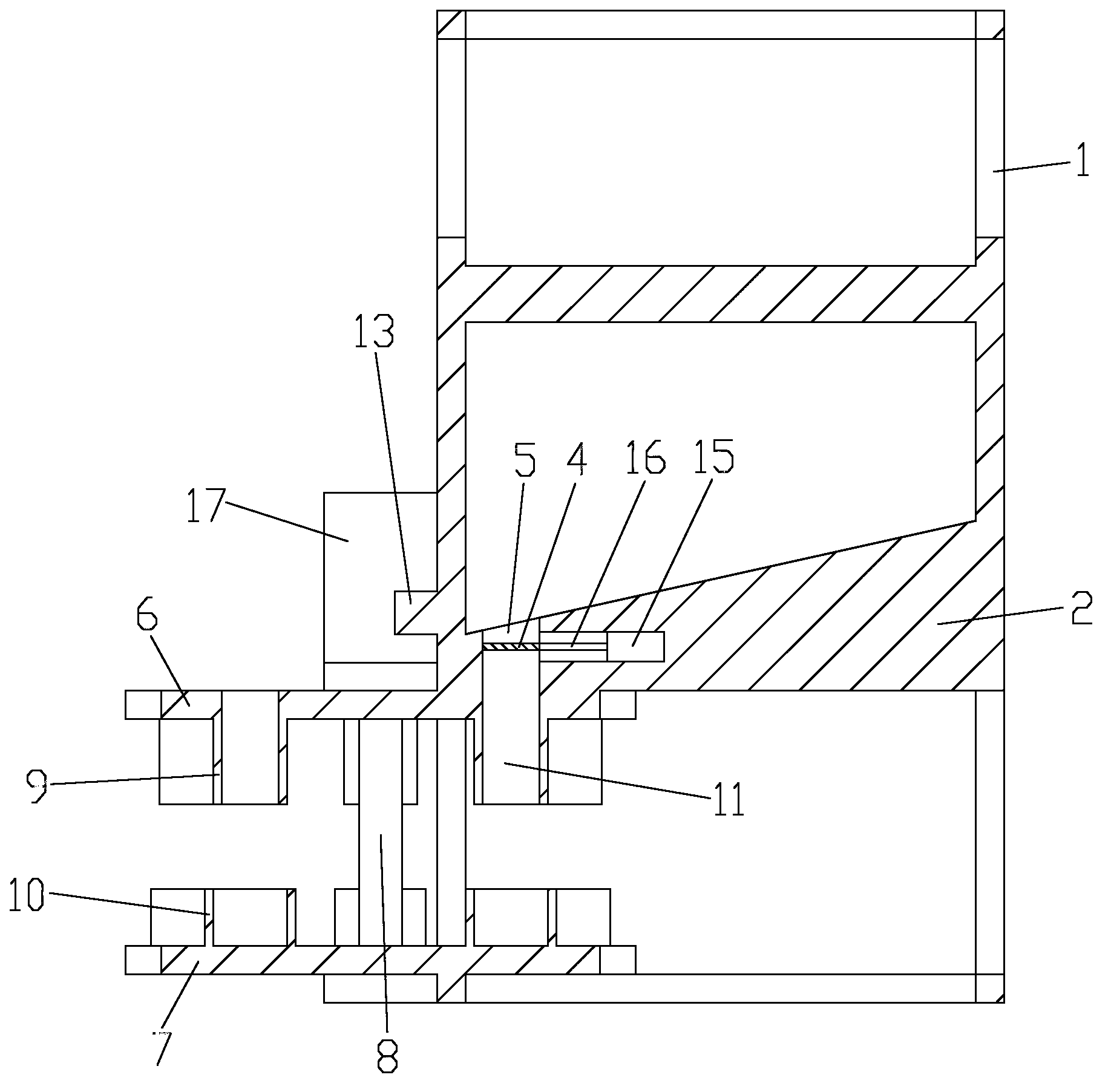

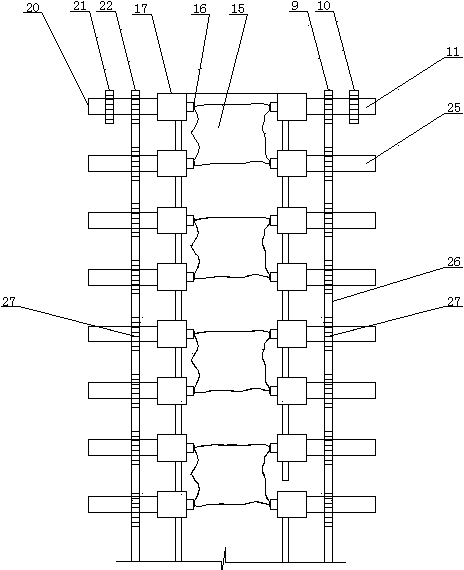

Steel ball racking machine

ActiveCN102910301ARealize automatic packagingReduce labor intensitySolid materialControl systemSteel ball

The invention discloses a steel ball racking machine comprising a rack, a funnel arranged on the rack, an upper valve sealing mechanism, a lower valve sealing mechanism, a racking cylinder, an upper chute, a discharge cylinder, a lower chute, a discharge pipe and a control system, wherein the upper valve sealing mechanism comprises a first supporting plate arranged on the rack, a first driving mechanism is arranged on the first supporting plate, a first transmission mechanism is connected to the first driving mechanism, a first propelling mechanism is connected to the first transmission mechanism, and an upper valve is connected to the first propelling mechanism; the discharge cylinder is arranged on the bottom surface of a second supporting plate, a discharge hole is arranged in the discharge cylinder, a material storage cavity is communicated with the discharge hole, and a lower valve can simultaneously seal the outlet of the material storage cavity and the inlet of the discharge hole; the lower chute is arranged on the discharge cylinder, the lower valve is located in the lower chute, and the inlet of the discharge hole is located in the bottom surface of the lower chute; the discharge pipe is connected with the discharge cylinder; and the control system is electrically connected with the first driving mechanism and a second driving mechanism.

Owner:中山市乾润精密钢球制造有限公司

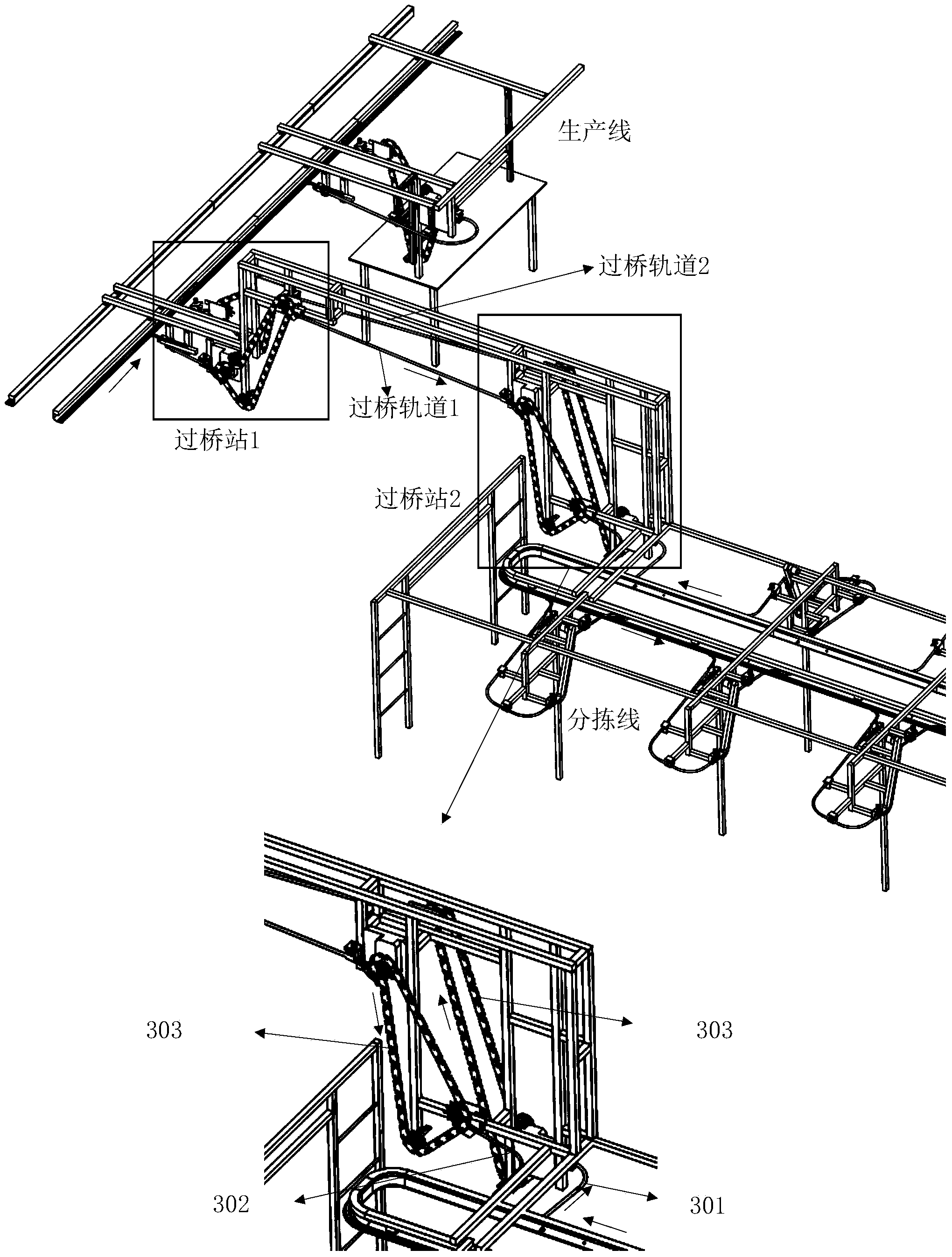

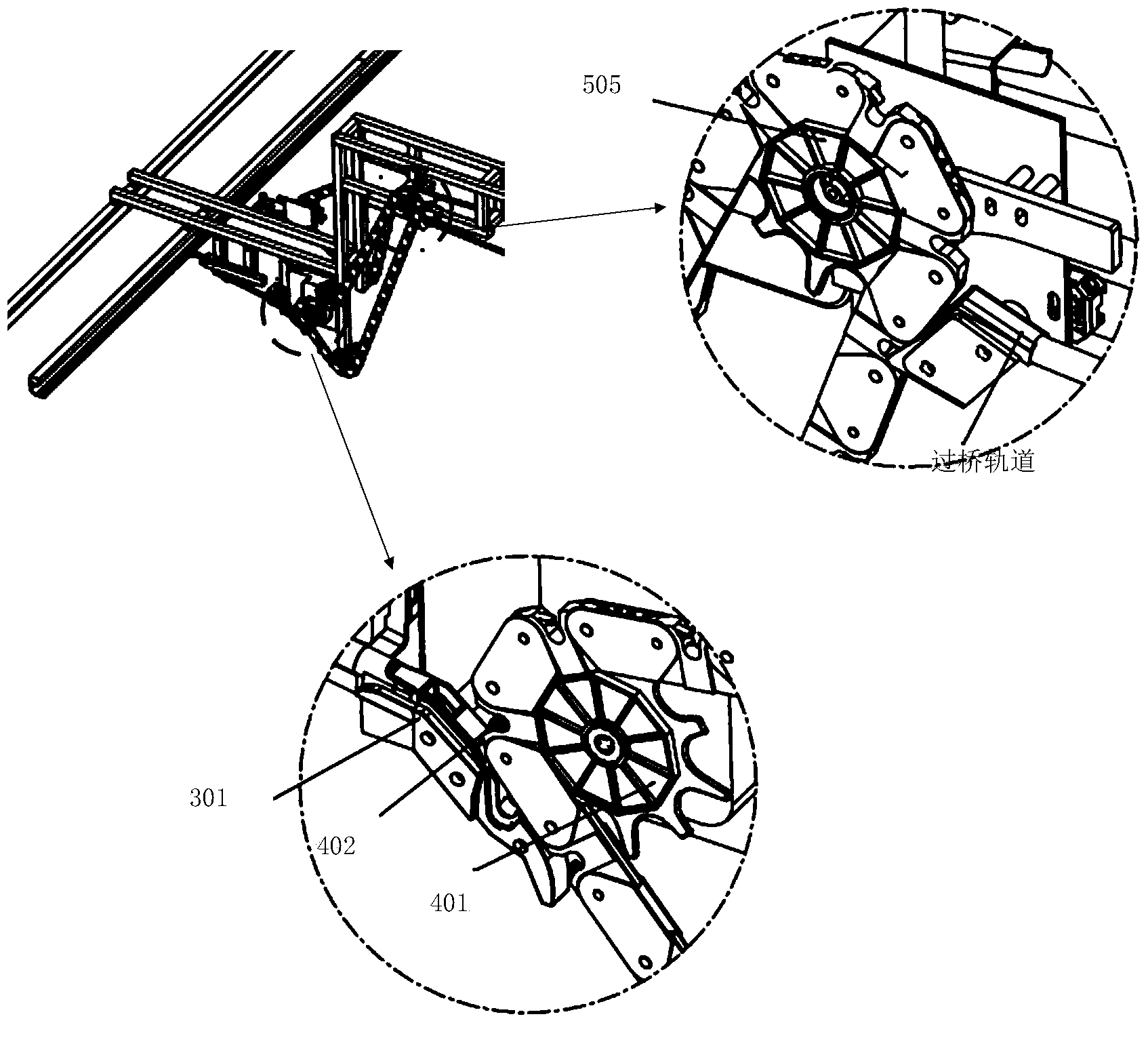

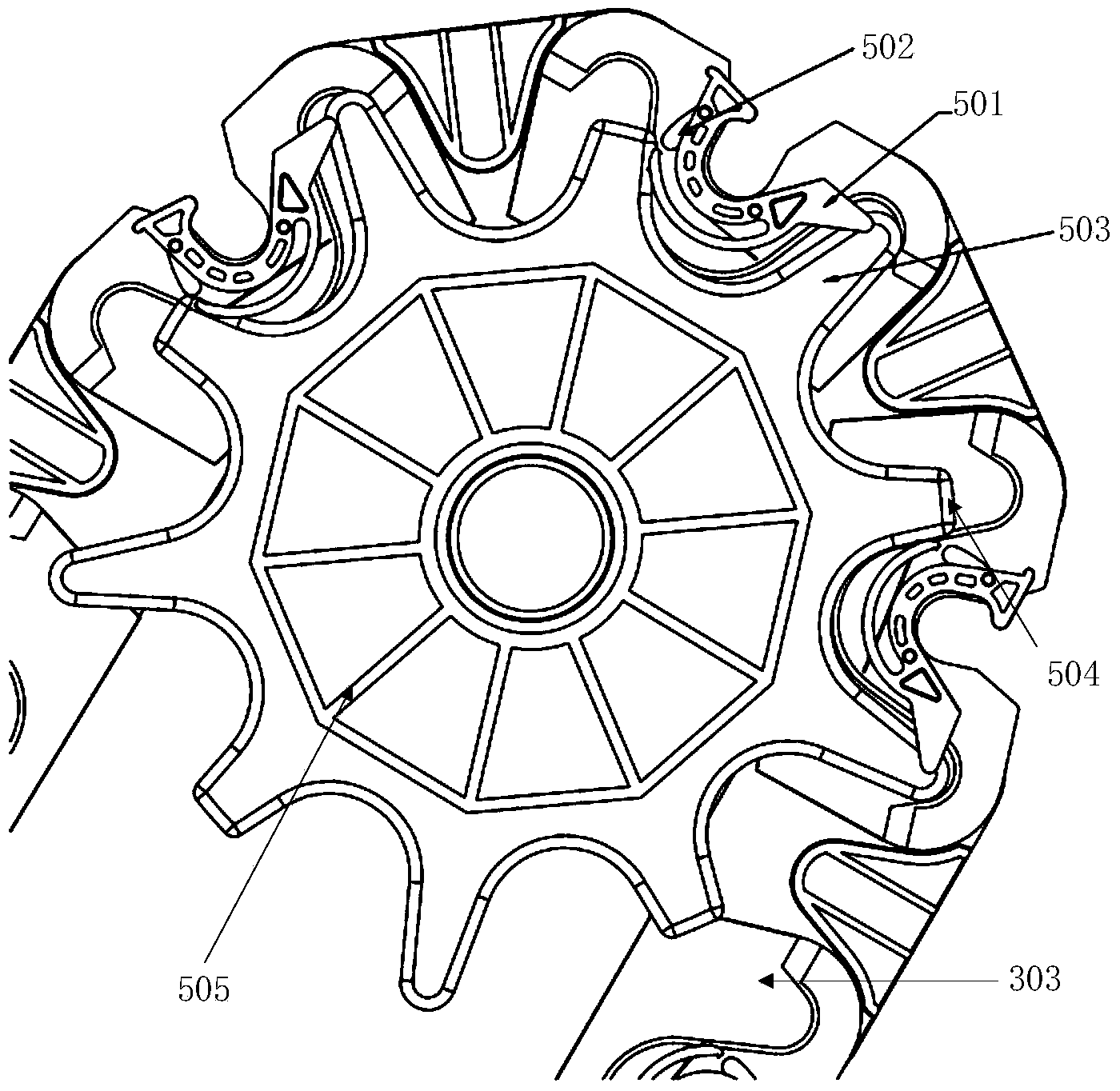

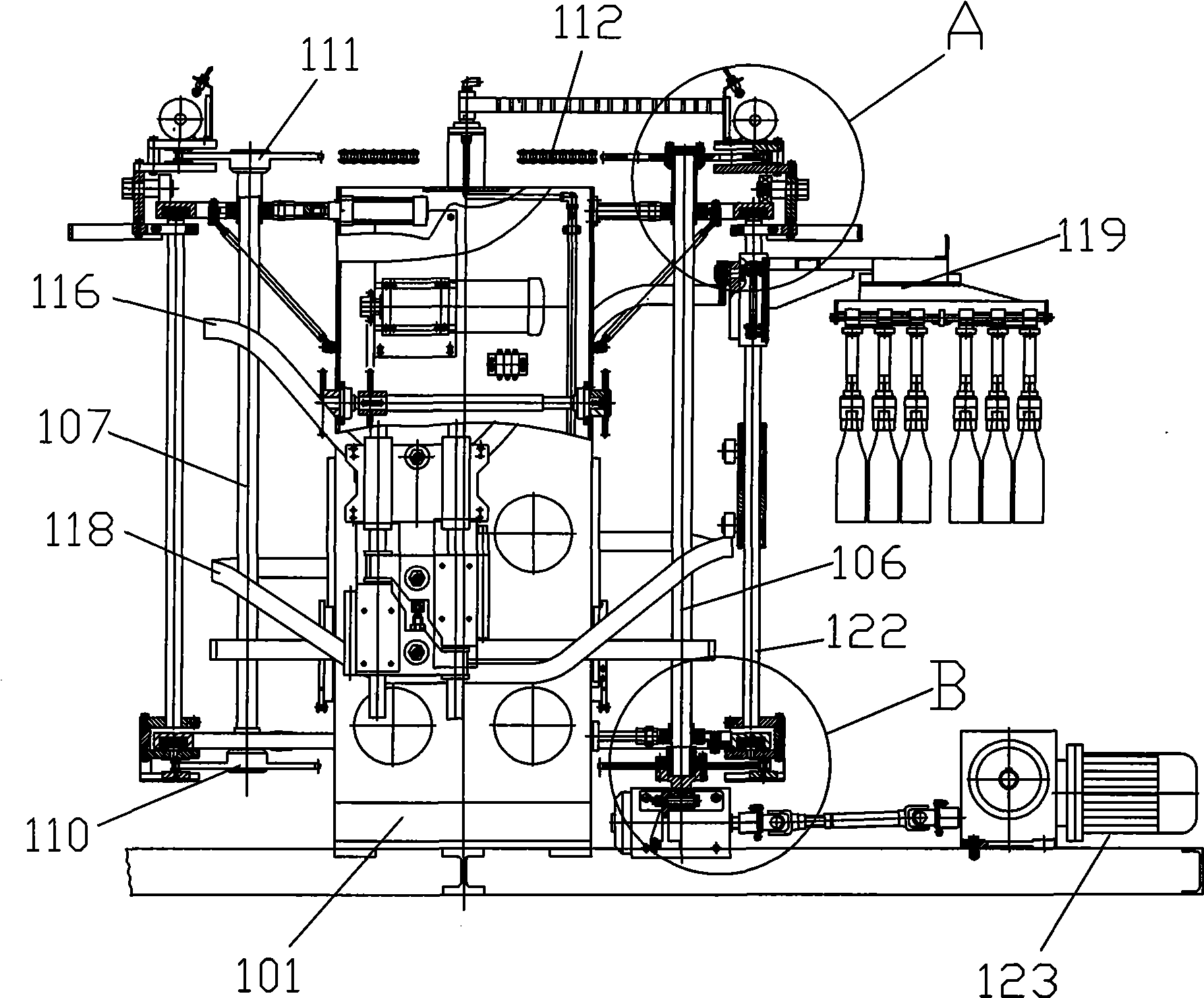

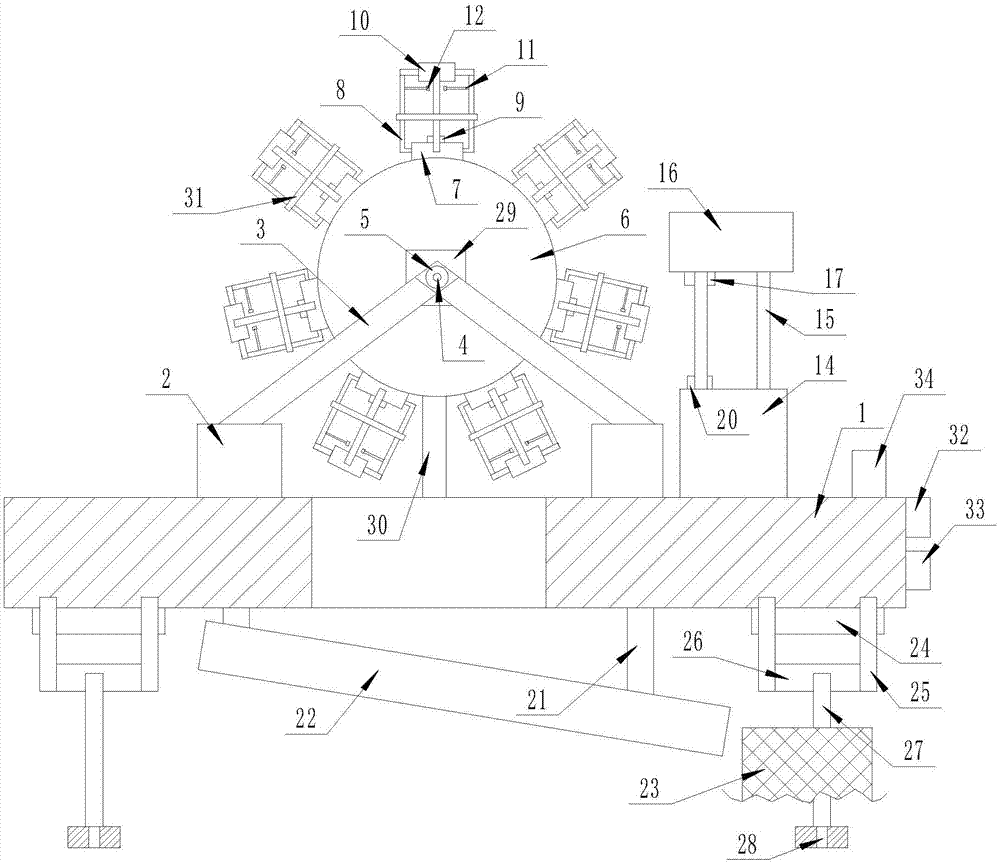

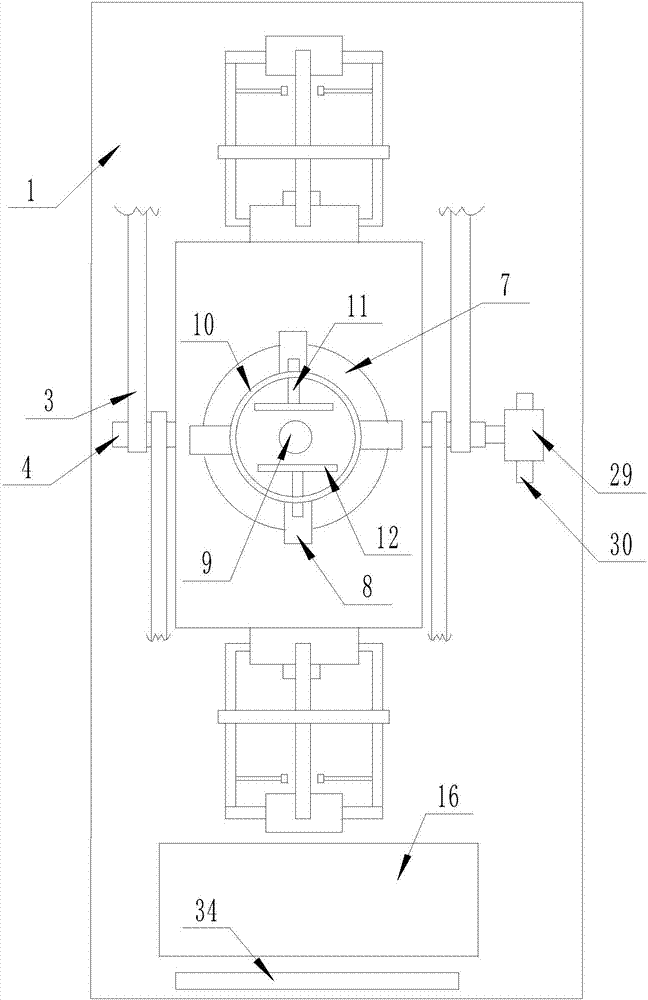

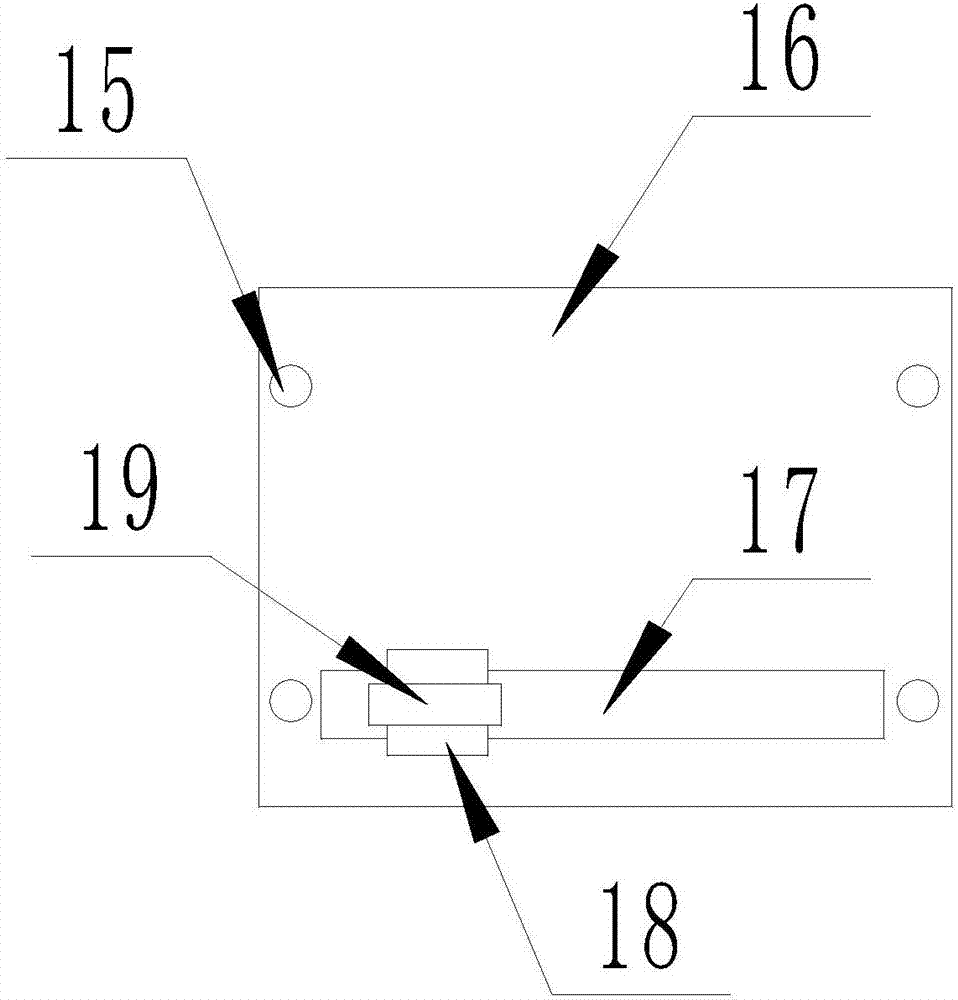

Rotary type container loader

InactiveCN101508350AAccurate bottle grasping and packingGood coherencePackaging automatic controlPackaging bottlesSprocketMotor drive

The invention discloses a rotary type box filler in the field of secondary packing machinery, which comprises a box filling device, conveying systems, a corresponding programmed control system and a servo motor driving system, wherein the box filling device comprises a bottle-grabbing device, a bottle-blocking device and a box-fixing device. The rotary type box filler is characterized in that the box filling device also comprises a turning central system which comprises a central tower frame, annular rails, a guiding supporting rod, a bottle-grabbing guide rail, a bottle-blocking guide rail and a guide box guide rail, two ends of the guiding supporting rod are arranged between the annular rails through a sliding device which is driven by a chain wheel device, and the bottle-grabbing device, the bottle-blocking device and the box-fixing device are arranged on the guiding supporting rod. The turning type box filler finishes the bottom grabbing and the box filling processes in motion without rigid impact, the bottle grabbing and the box filling are particularly accurate, the consistency of the box filling is good, the productivity is high, a reflux type bottle conveying device is adopted to reduce the extrusion between bottles, and a module structure is adopted to provide high degree of flexibility.

Owner:广州市万世德智能装备科技有限公司

Full-automatic polypeptide extraction time-of-flight mass spectrum detector

ActiveCN109142501AAccurate extractionReduce infectionWithdrawing sample devicesPreparing sample for investigationPhysical chemistryMass analyzer

Owner:BIOYONG TECH

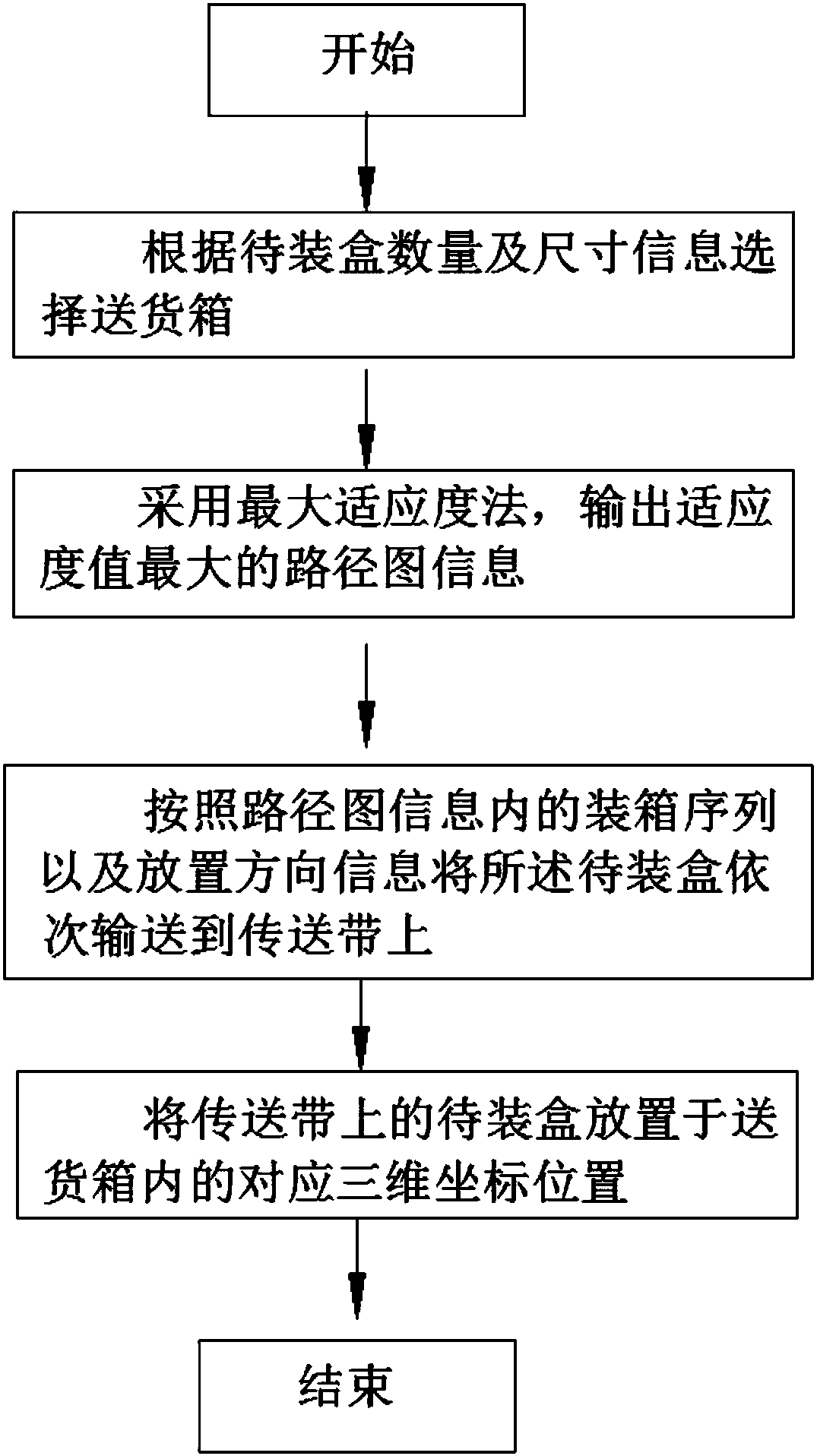

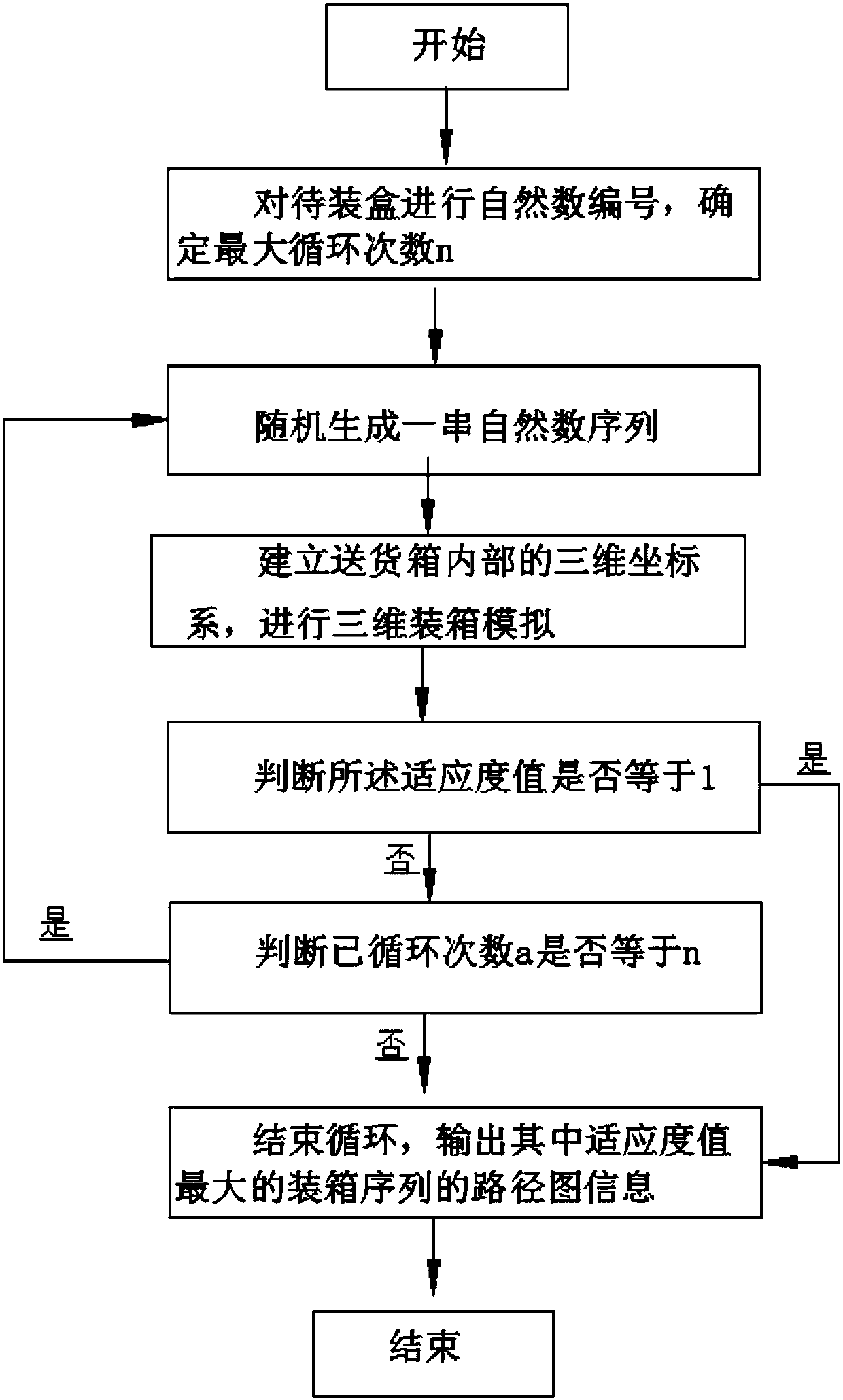

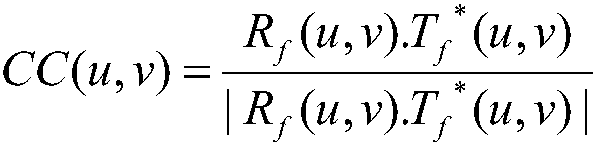

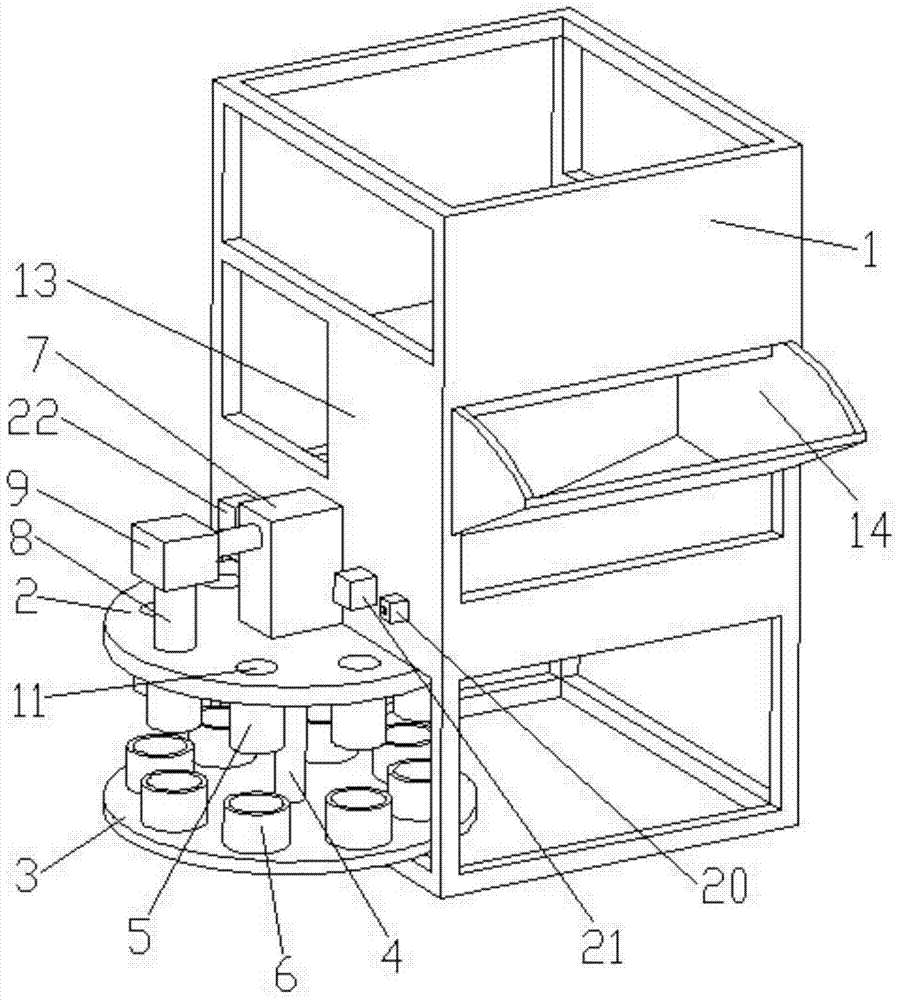

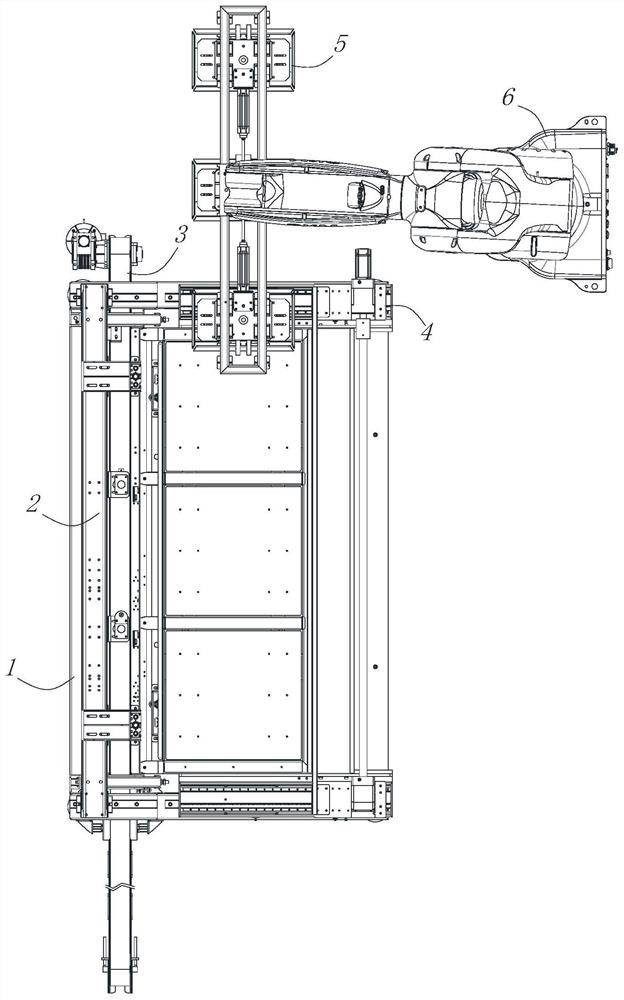

Robot boxing method based on three-dimensional boxing positioning

ActiveCN107839947AIncrease productivityReduce labor costsPackaging automatic controlThree Dimensional SizePath diagram

The invention discloses a robot boxing method based on three-dimensional boxing positioning. The robot boxing method comprises the following steps that S1, order information is obtained, wherein the order information comprises to-be-boxed box number information and three-dimensional size information, the to-be-boxed box total volume is calculated according to the to-be-boxed box number informationand the three-dimensional size information, and a cargo delivering box with the volume larger than the total volume is selected; S2, according to the order information and the selected cargo delivering box, a maximum fitness method is adopted for conducting three-dimensional boxing simulation, and path diagram information with the maximum fitness value is output; S3, according to the boxing sequence and containing direction information, to-be-boxed boxes are sequentially conveyed to a conveying belt; and S4, according to three-dimensional coordinate information of all to-be-boxed boxes in thecargo delivering box, and the to-be-boxed boxes on the conveying belt are placed at the corresponding positions of the cargo delivering box. According to the robot boxing method, automatic boxing isachieved, the production efficiency is improved, manual cost is reduced, and accurate boxing of the to-be-boxed boxes is achieved.

Owner:XIAMEN UNIV OF TECH

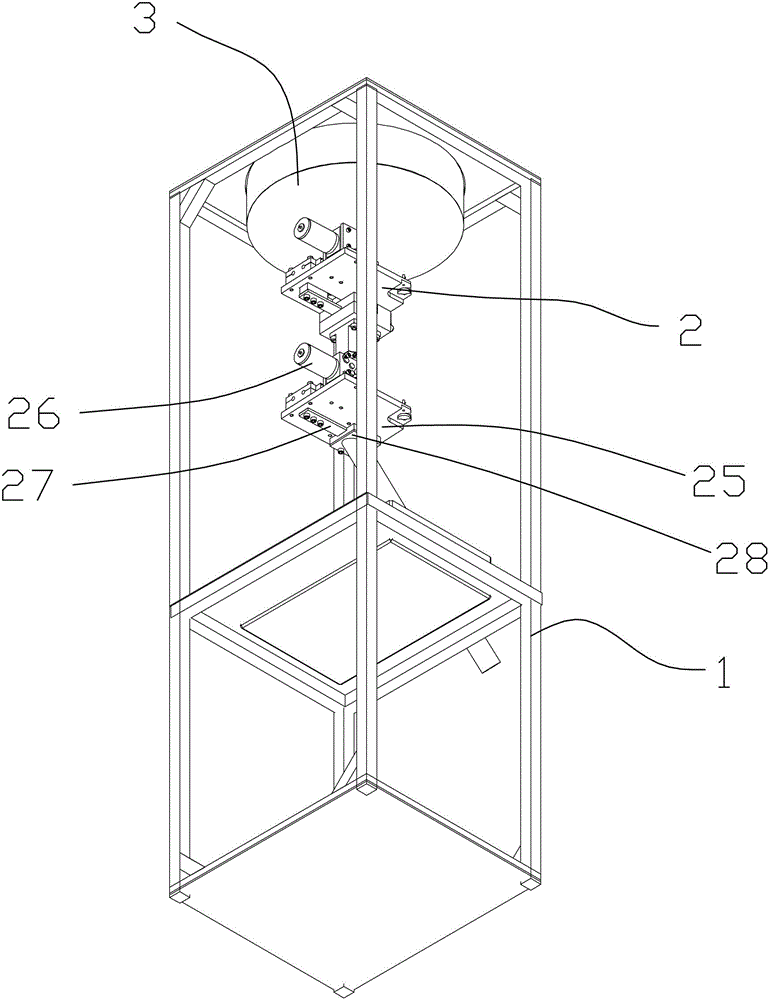

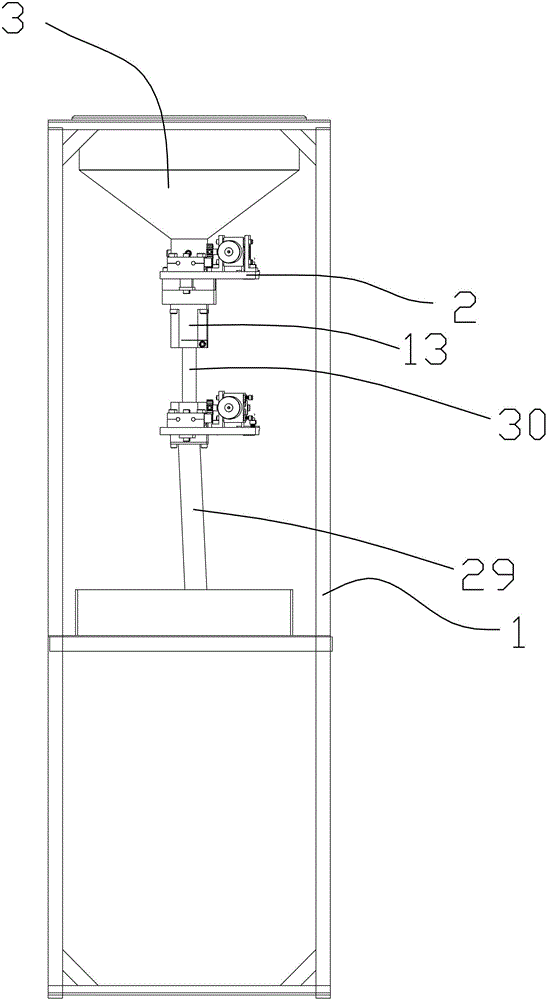

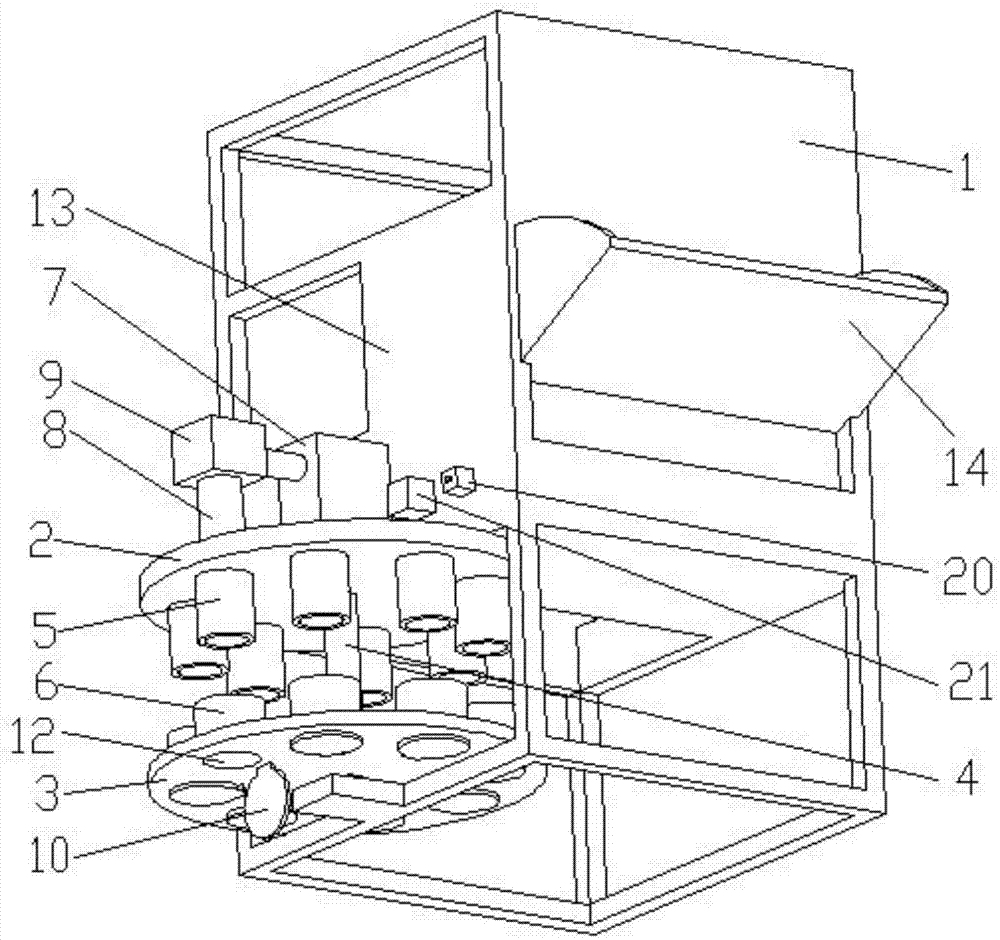

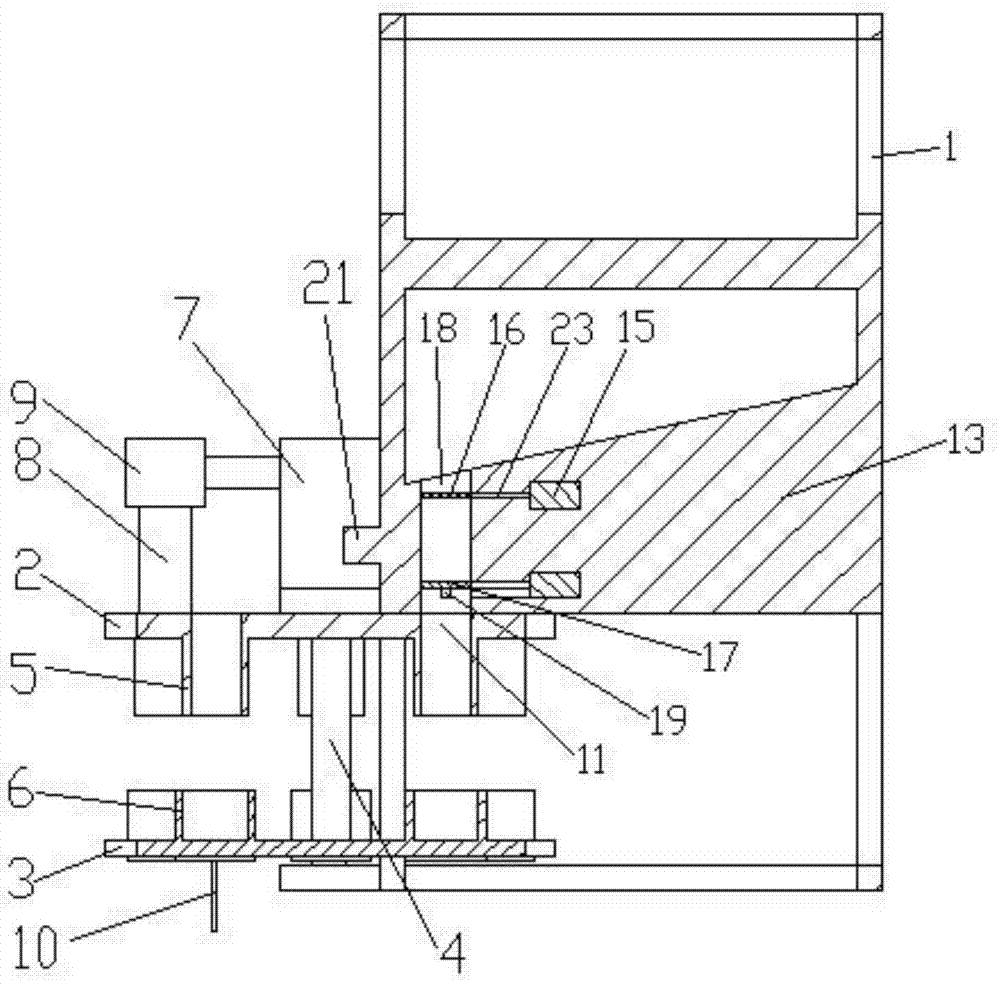

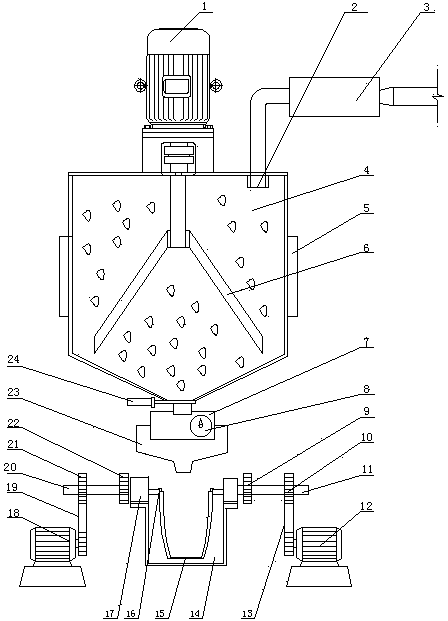

Culture medium packer

InactiveCN104494863AReasonable tightnessQuality improvementSolid materialCultivating equipmentsEngineeringCulture mediums

The invention discloses a culture medium packer comprising a frame, a feeder, a packing device and a first control device. The feeder, the packing device and the first control device are disposed on the frame. The feeder is connected with the packing device. The first control device controls material in the feeder to enter the packing device for packing; a rotating lower disc of the packing device is provided with discharge holes; an openable discharge hole cover is connected below each discharge hole; packed bags are quickly dropped. The culture medium packer employs mechanical packing instead of original manual packing, manpower is saved, packing efficiency is greatly improved, packing is precise, and quality of cultivated edible fungi is improved.

Owner:SUZHOU JINGWEI AGRI PROD

Menantine hydrochloride soft capsule and preparing method

InactiveCN1742712AMask bad smellDisintegrates quicklyNervous disorderCapsule deliveryDiseaseMemantine Hydrochloride

The present invention relates to a memantine hydrochloride soft capsule for curing senile dementia and its preparation method. It is made up by using memantine hydrochloride as raw material and adding a certain auxiliary material according to conventional process.

Owner:FUKANGREN BIO PHARMA

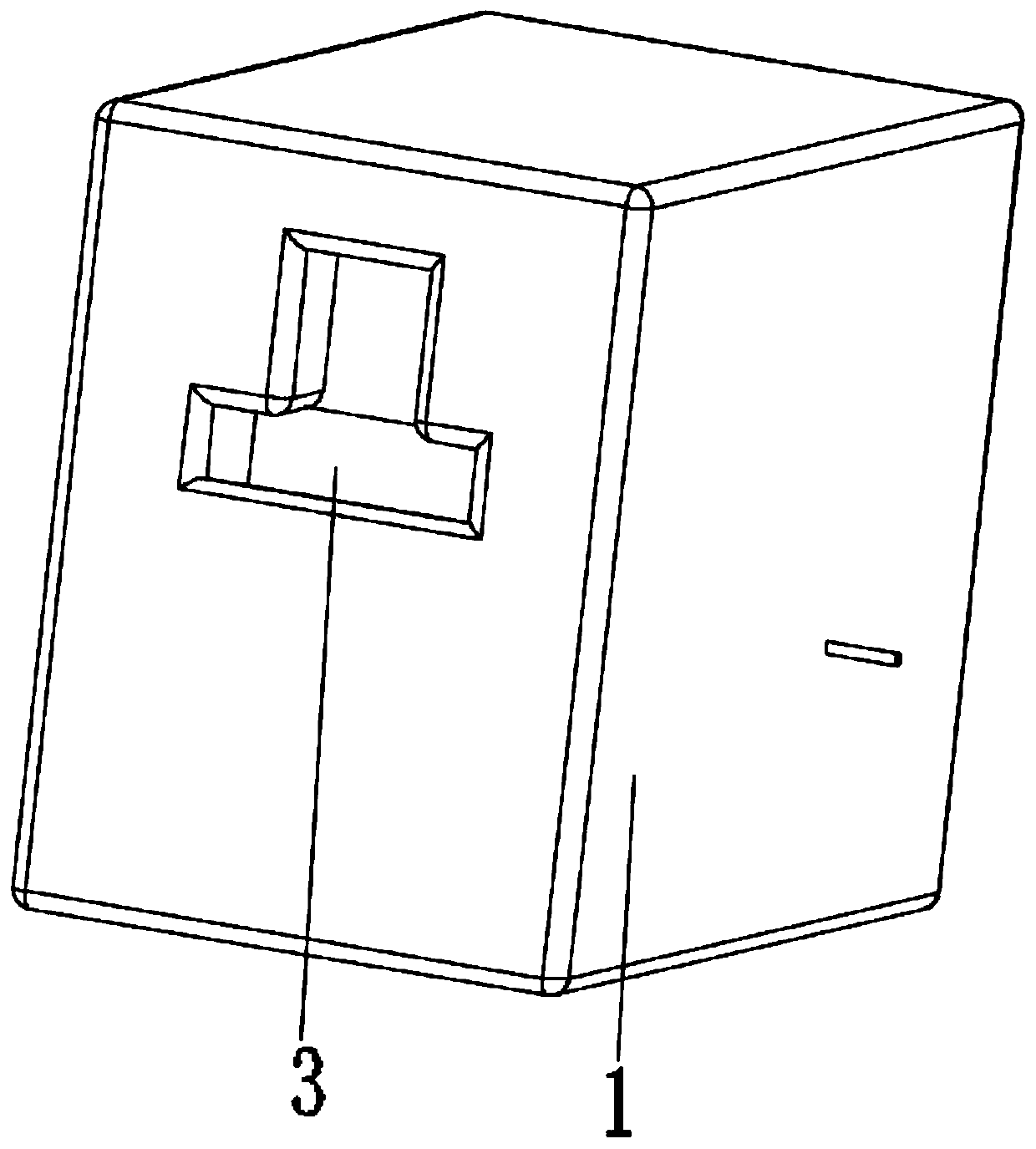

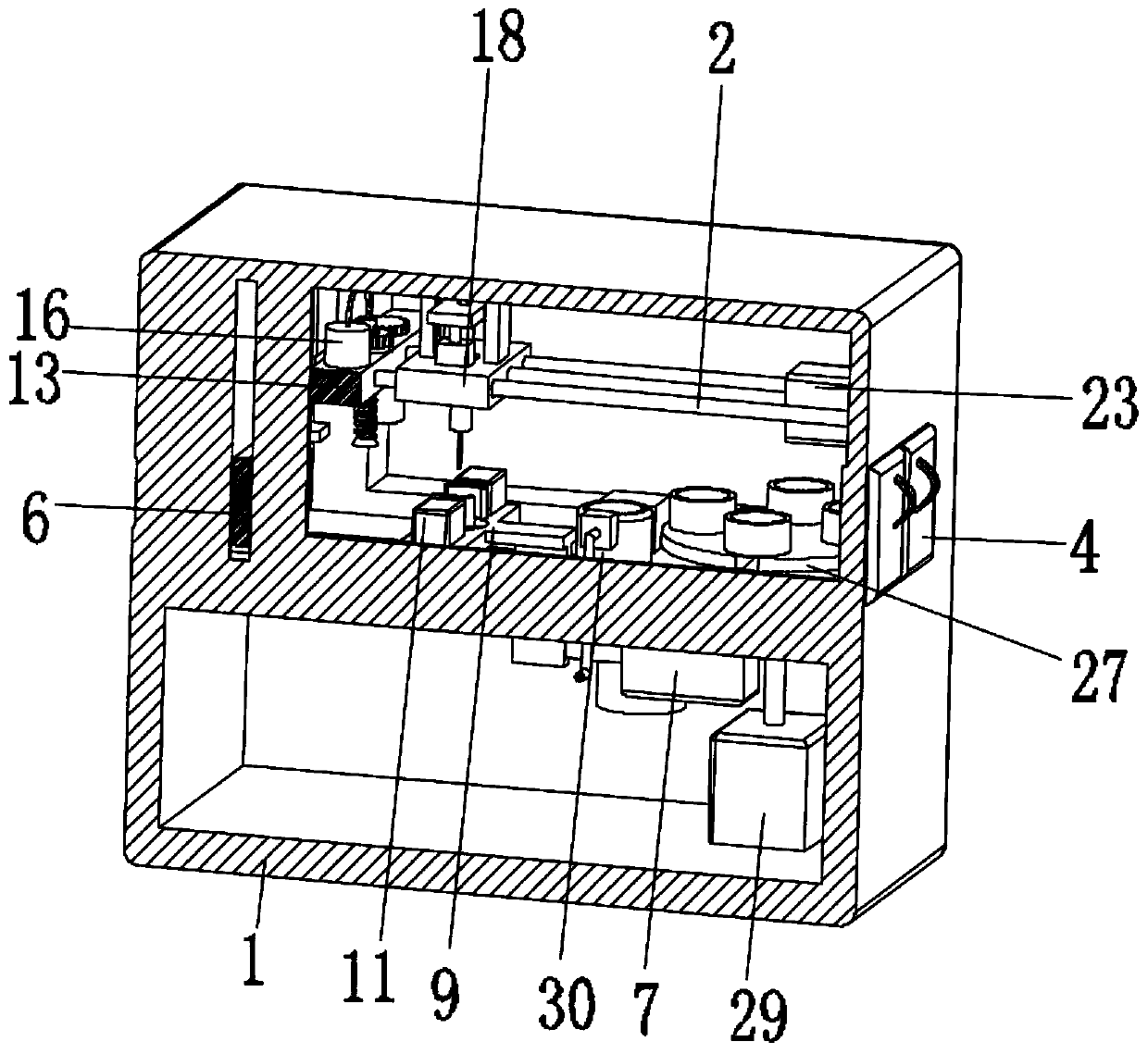

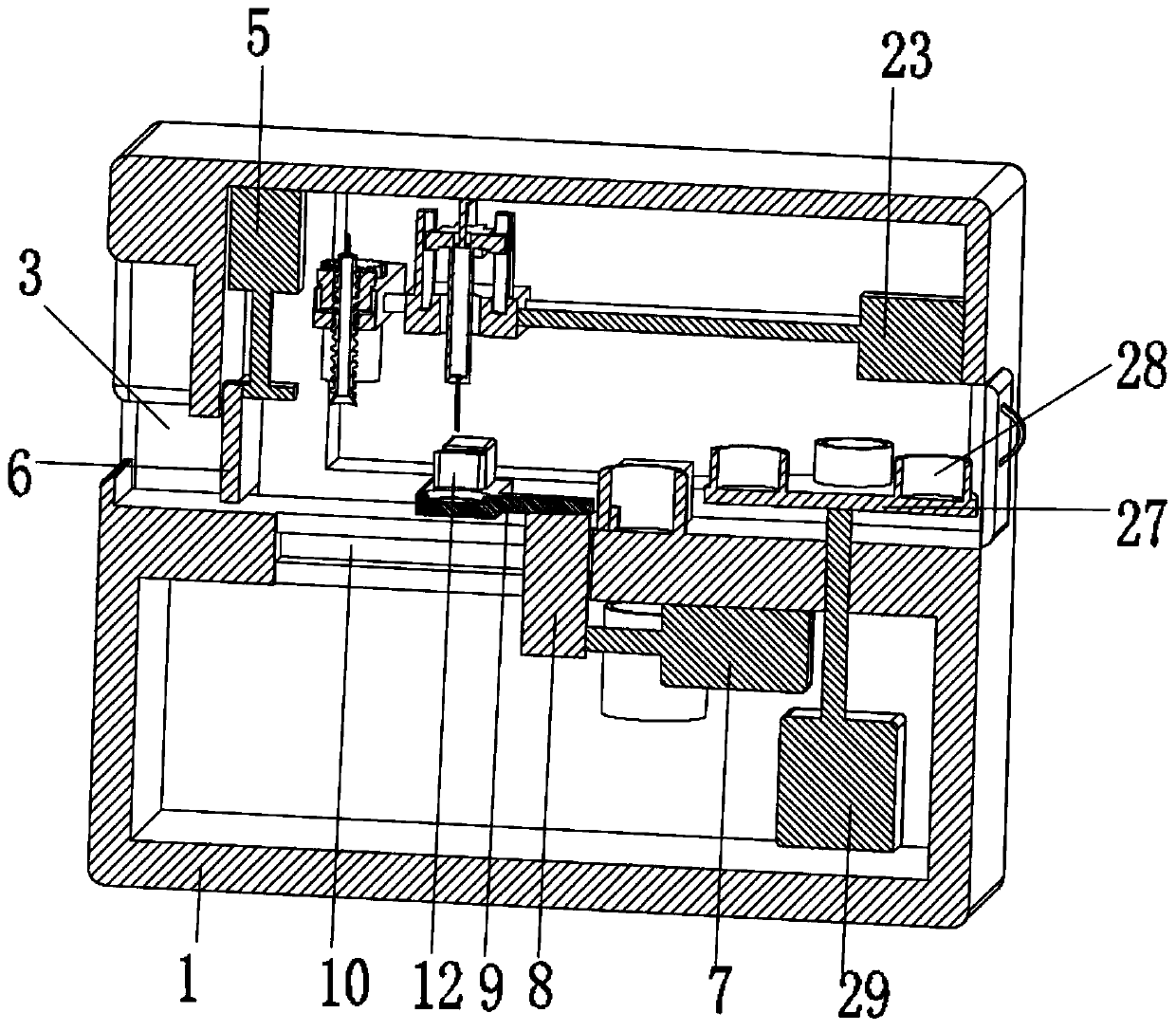

Radioactive drug micro-radiation sub-packaging device

InactiveCN109896054ARealize mixing and dispensingAvoid wearingSolid materialPackaging machinesWorking pressureMedicine

The invention relates to the technical field of radioactive drug sub-packaging, in particular to a radioactive drug micro-radiation sub-packaging device. The radioactive drug micro-radiation sub-packaging device comprises a shell body, wherein the shell body is provided with an upper cavity body and a lower cavity body through a partition plate, an opening and closing door mechanism, a sliding mechanism, a clamping mechanism, a cover taking mechanism, a medicine taking mechanism, a medicine tray mechanism and a cleaning mechanism are arranged in the shell body according to the sub-packaging steps. According to the radioactive drug micro-radiation sub-packaging device, different mechanism are mutually matched in the closed shell, so that the automatic sub-packaging of radioactive drugs andthe mixed separation of the different radioactive drugs are realized, the method is efficient and simple, medical workers can be prevented from wearing protective clothing, the manual sub-packaging tedious steps can be reduced, the sub-packaging efficiency can be improved, the mechanical electrification control can be realized, the distribution of the accurate radioactive drugs is realized, and the working pressure of the medical workers is reduced; and meanwhile, bottle caps are installed, fixed and taken out from the device, the whole process almost has the effect of reducing external bacterial infection and sub-packaging drugs in a closed environment.

Owner:CHANGZHOU NO 2 PEOPLES HOSPITAL

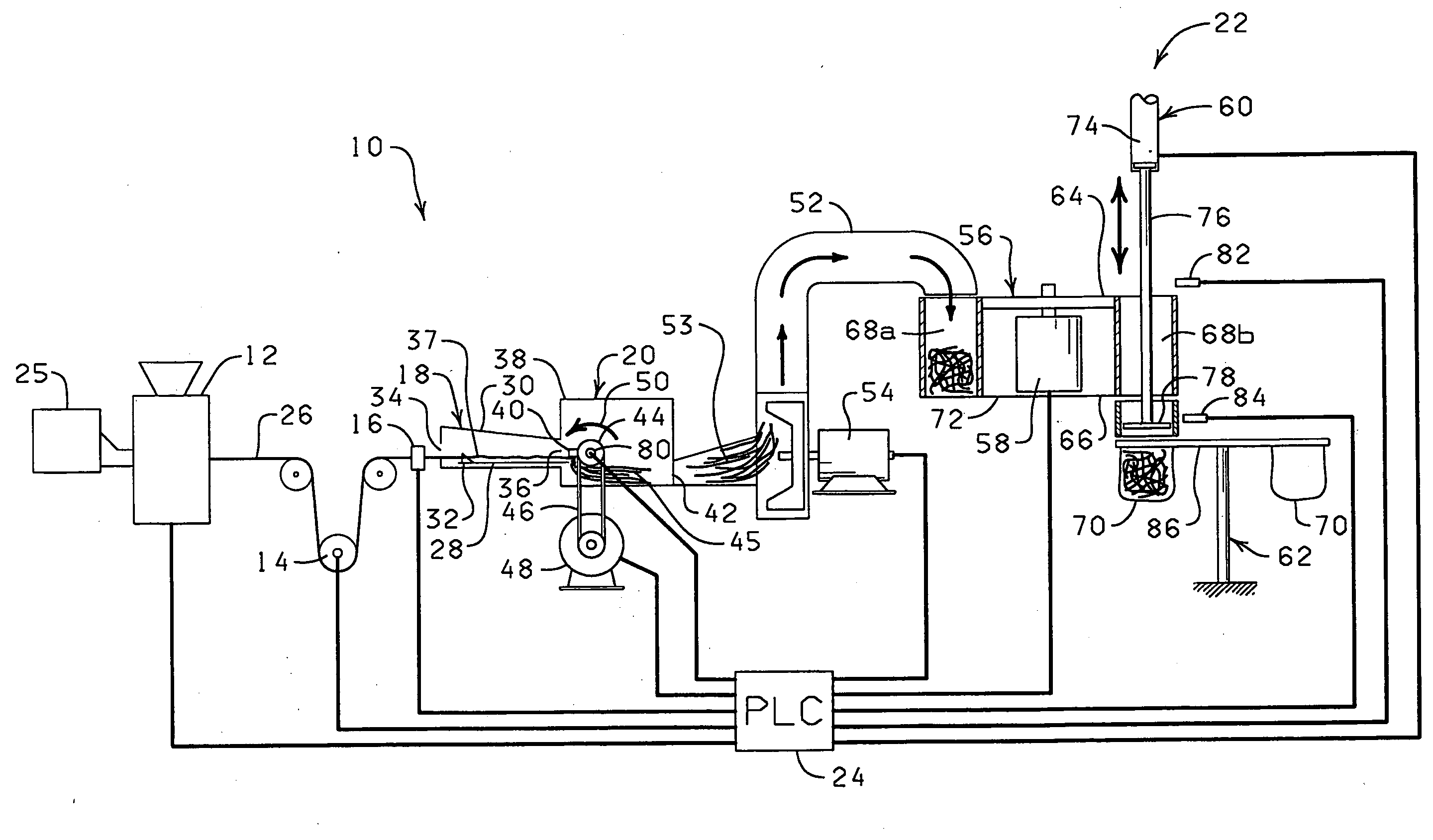

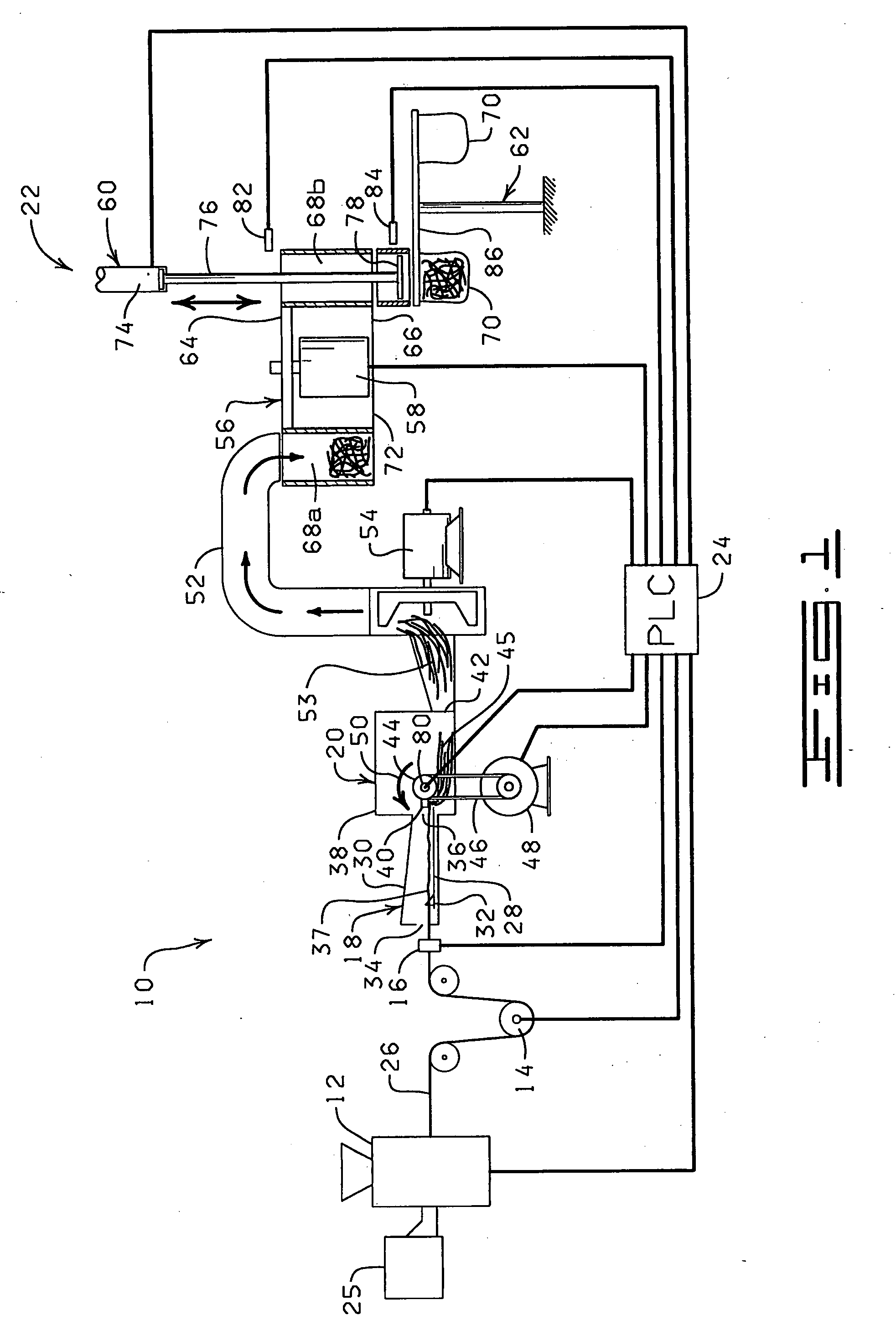

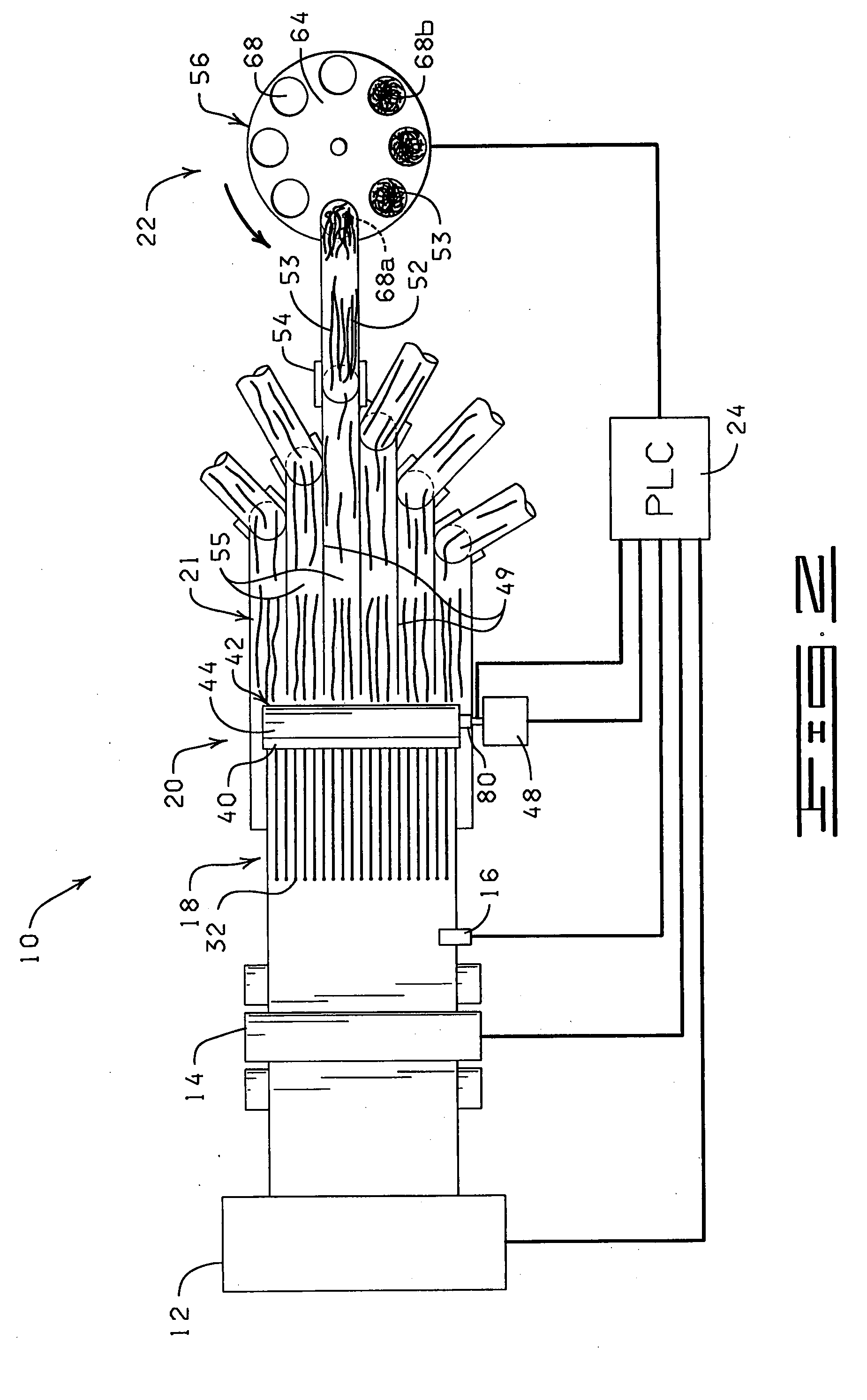

Apparatus and method for making and bagging decorative grass

InactiveUS20070130887A1Increase widthConvenient and accurateSolid materialBaked article cutting/slicingProgrammable logic controllerEngineering

Owner:WEDER DONALD E

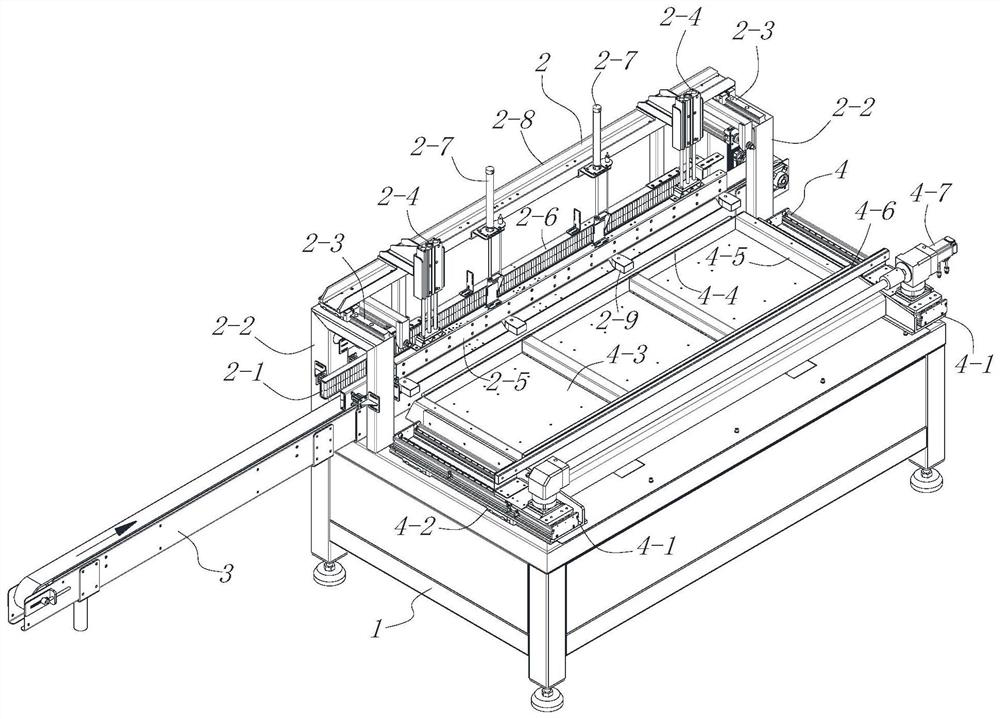

Packing machine

The invention discloses a packing machine. The packing machine comprises a frame, a feeding device, a packing device and a first control device. The feeding device, the packing device and the first control device are arranged on the frame; the feeding device is connected with the packing device; the first control device controls and enables materials inside the feeding device to enter the packing device for packing. The packing machine replaces an original manual packing mode with a mechanical packing mode, thereby reducing manual work, greatly improving the packing efficiency, achieving accurate packing and improving the quality of cultivated edible fungus.

Owner:SUZHOU JINGWEI AGRI PROD

Biologic Stability, Delivery Logistics and Administration of Time and/or Temperature Sensitive Biologic Based Materials

ActiveUS20160341711A1Accurate packagingContainer decorationsLevel indicationsCountdown timerRadiation sensor

In some embodiments, alerts are sent to appropriate parties if an insulated container is not properly packed out to insure the approximate safe temperature of the materials. In other embodiments, a countdown timer is used to keep track of the time that the biologic has been in transit, and ensure that the amount of time does not exceed the known shelf life of the biologic. In still other embodiments, the payload container is equipped with its own sensors, such as temperature sensors, and communications devices, such as a close range communication device, capable of transmitting information regarding a range of parameters, including, but not limited to, temperature, humidity, location and time, from the payload container to an end user. In other embodiments, shielding and / or radiation sensors are included in insulated shipping or storage containers, or payload containers, to shield and monitor the radiation exposure of the payload.

Owner:SAVSU TECH INC

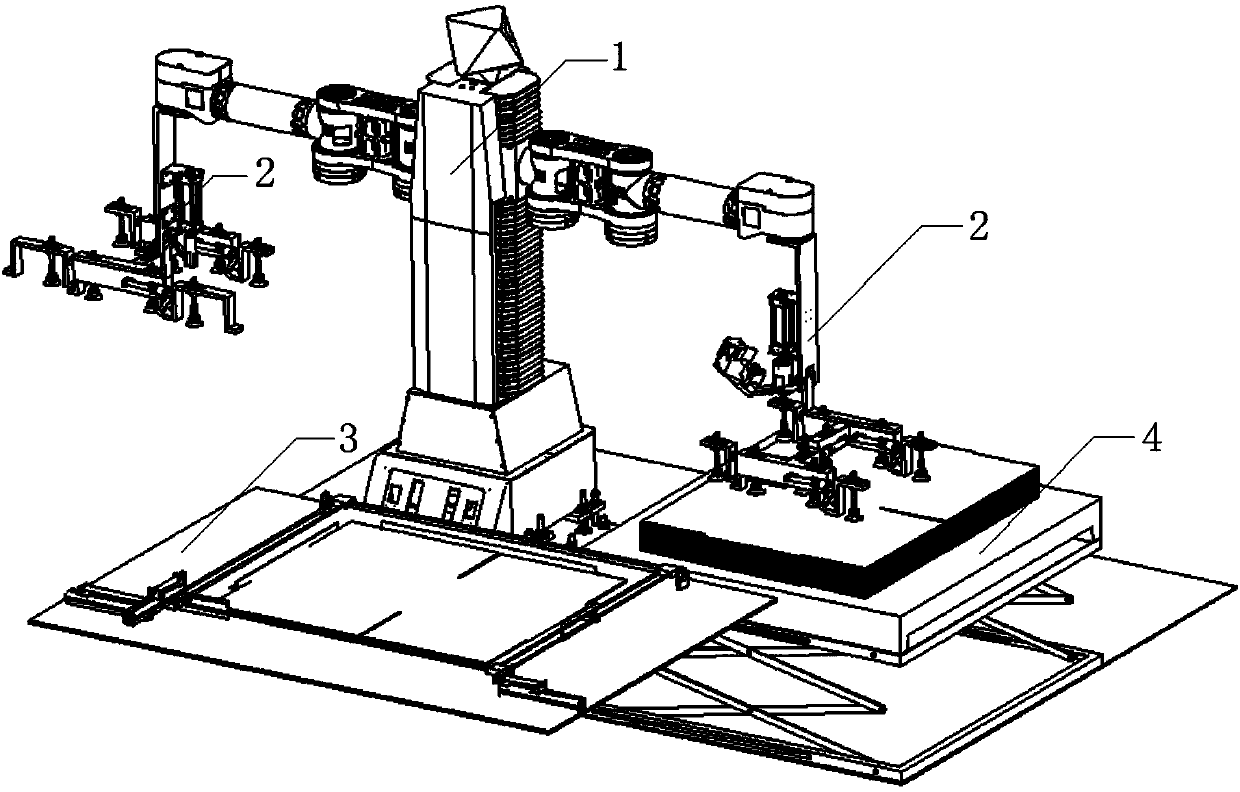

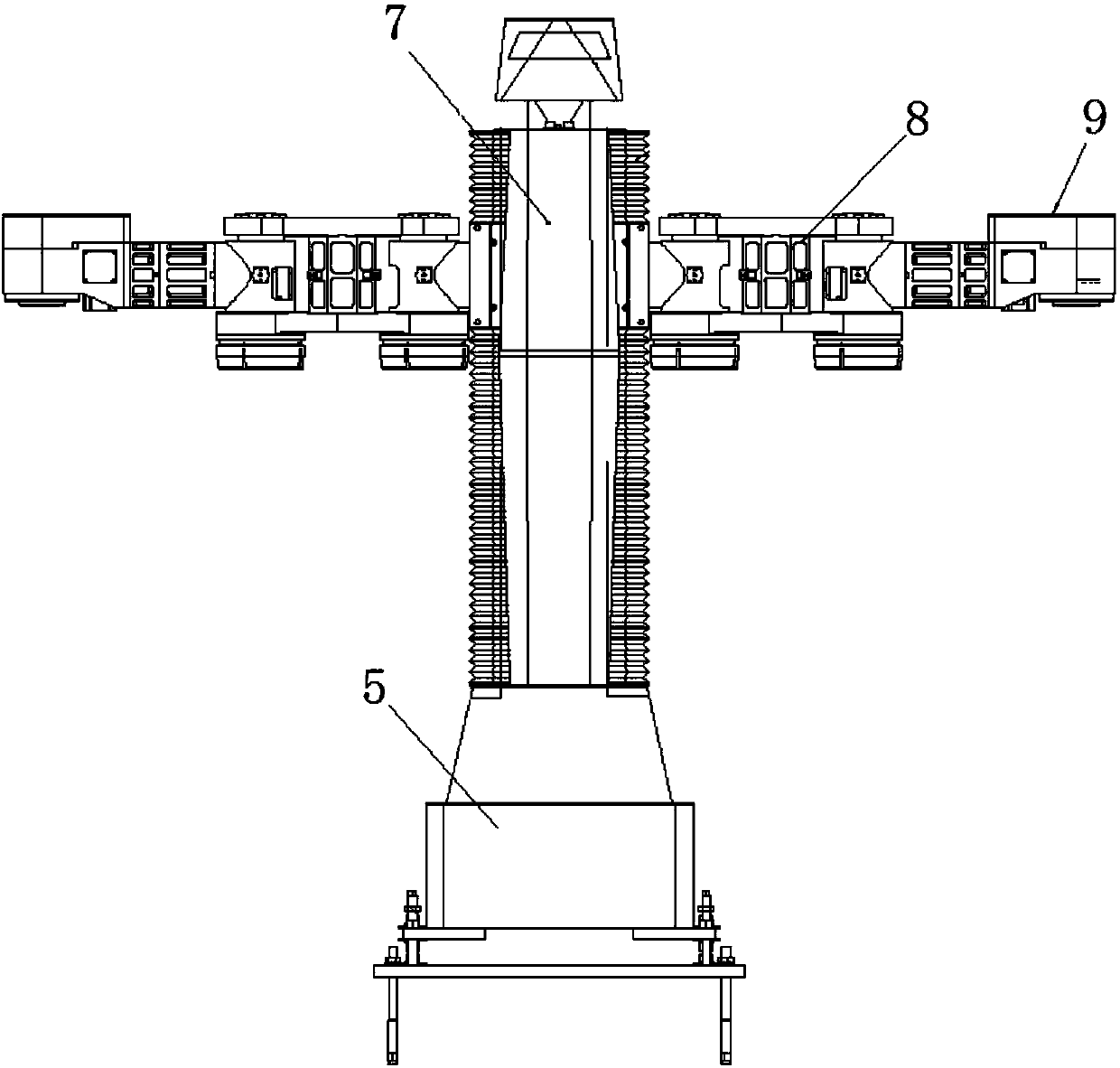

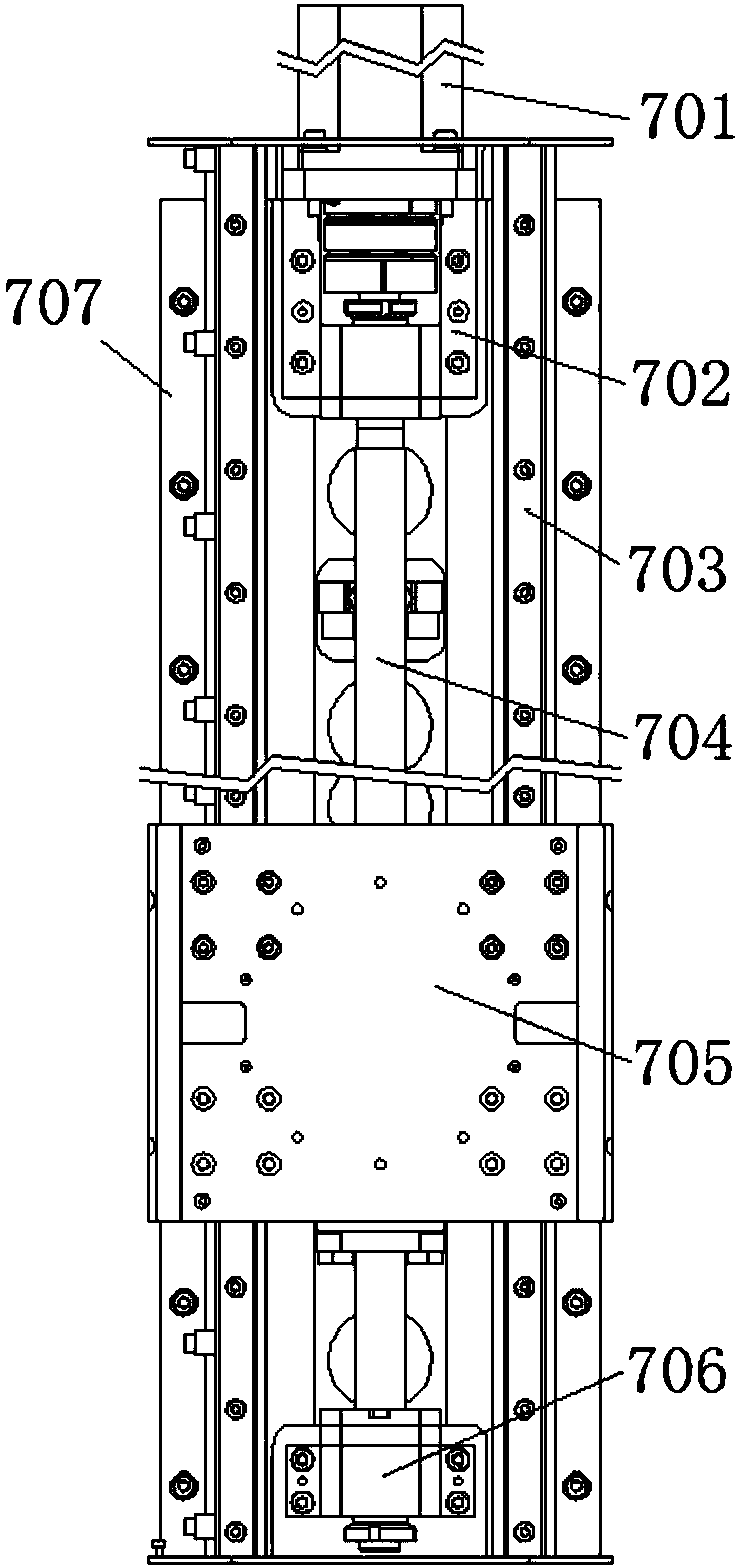

Packaging system based on double-arm robot

InactiveCN109866216AAccurate packagingIncrease productivityProgramme-controlled manipulatorWrapper twisting/gatheringAgricultural engineeringSmall footprint

The invention relates to the field of packaging equipment, in particular to a packaging system based on a double-arm robot. The packaging system comprises the double-arm robot, folding finger mechanisms and a positioning mechanism, wherein the free ends of mechanical arms on both sides of the double-arm robot are each provided with one folding finger mechanism, and the positioning mechanism is arranged on the packaging station. Each folding finger mechanism comprises a connecting plate, a main palm seat, a main palm seat turnover mechanism, an auxiliary palm seat and an auxiliary palm seat turnover mechanism, wherein the upper end of the connecting plate is connected with the free end of the corresponding mechanical arm of the double-arm robot; the lower end of the connecting plate is hinged to the main palm seat; the main palm seat turnover mechanism for driving the main palm seat to overturn is arranged on the connecting plate; the auxiliary palm seat is hinged to the main palm seat;the main palm seat is provided with the auxiliary palm seat turnover mechanism for driving the auxiliary palm seat to overturn; and the two sides of the main palm seat and the auxiliary palm seat areeach provided with a finger driving mechanism and a finger sucker assembly which is driven to overturn through the finger driving mechanism. The production efficiency is greatly improved, the occupied area is small, and the flexibility degree is high.

Owner:沈阳自动化研究所(昆山)智能装备研究院 +1

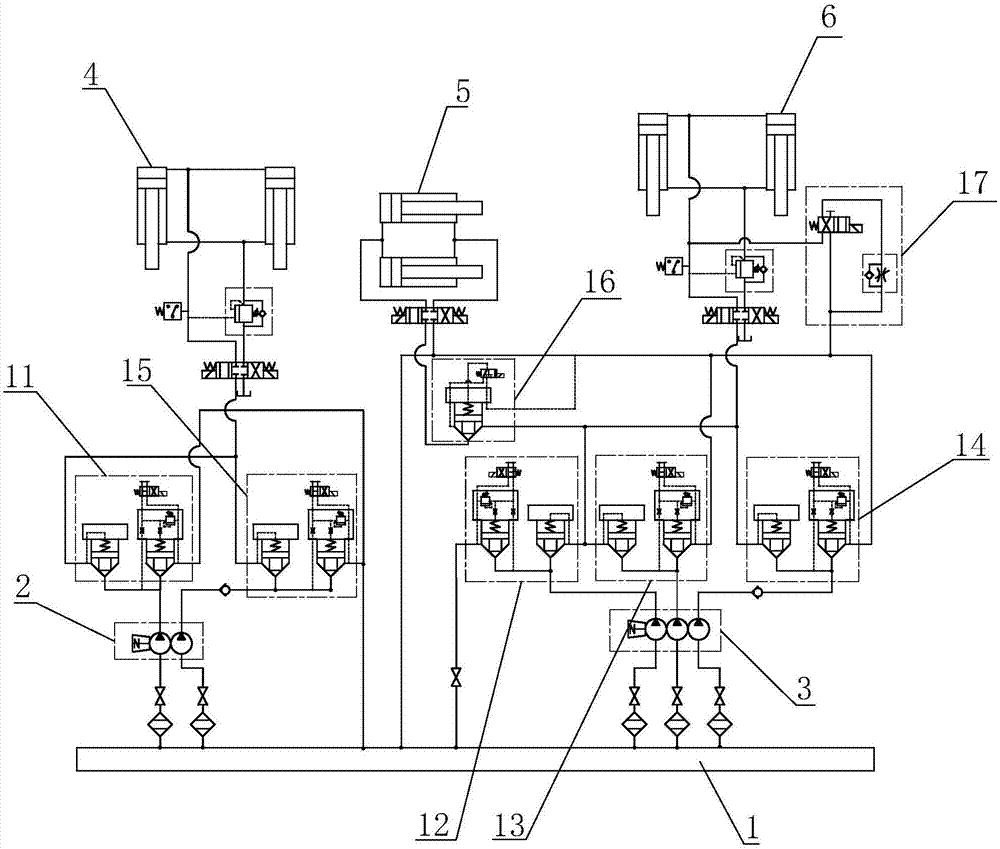

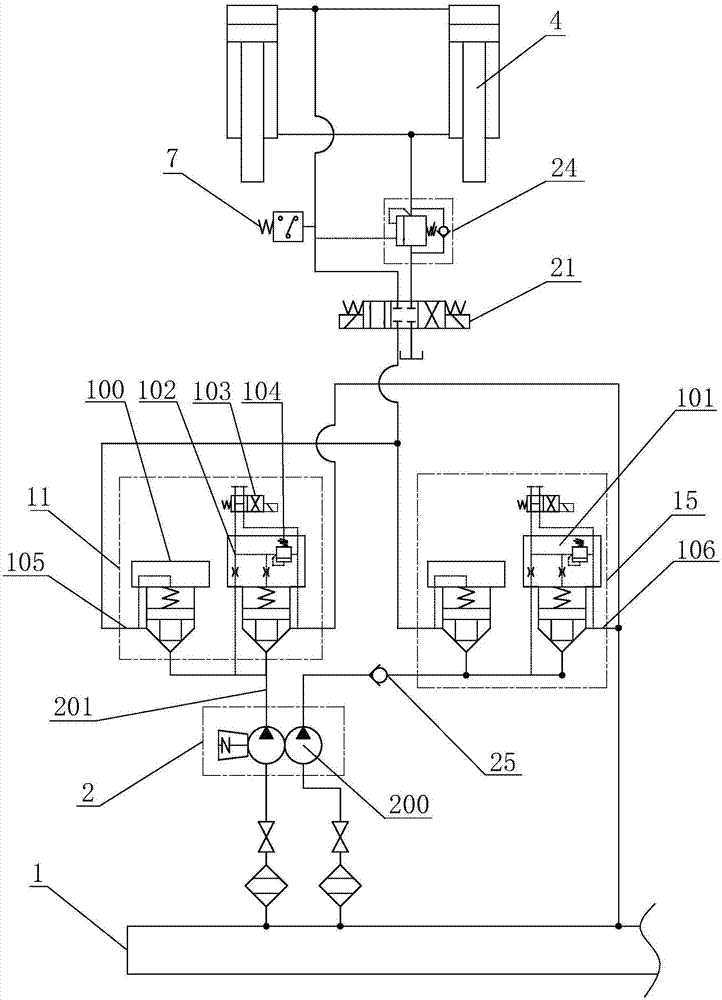

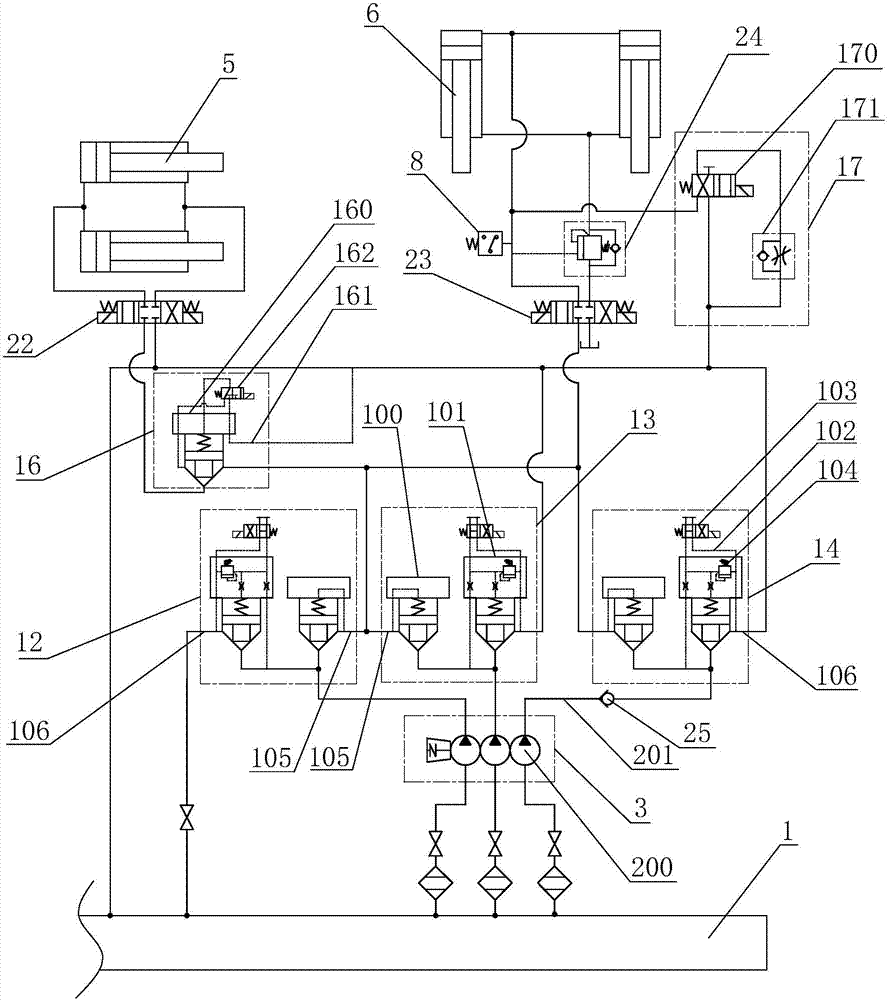

Hydraulic system for packaging machine and working method thereof

ActiveCN107420363AUnobstructed protectionNormal on and offServomotor componentsServomotorsFour-way valveEngineering

The invention discloses a hydraulic system for a packaging machine. The hydraulic system for the packaging machine comprises a hydraulic source; the hydraulic source is connected with a first oil pump and a second oil pump; the first oil pump is connected with a first cartridge valve bank; the first cartridge valve bank communicates with a first three-position four-way valve; the first three-position four-way valve is connected with a pre-loading cylinder; the second oil pump is connected with a second cartridge valve bank, a third cartridge valve bank and a fourth cartridge valve bank simultaneously; the cartridge valve banks are connected with a second three-position four-way valve and a third three-position four-way valve; the second three-position four-way valve is connected with a box body cylinder; and the third three-position four-way valve is connected with a main pressure cylinder. According to the hydraulic system for the packaging machine, the cartridge valve banks cooperate with the three-position four-way valves to achieve the effects of protecting and controlling an oil way; the pre-loading cylinder moves independently and can be selectively controlled; the box body cylinder and the main pressure cylinder mainly achieve an effect of assisting packaging; power resources are saved; power usage efficiency is improved; the oil way is controlled through a plurality of control ends; normal connecting and disconnecting of the oil way in a working process of the packaging machine are ensured; the packaging machine is safer; meanwhile, a plurality of moving stations of the packaging machine are controlled through three cylinder blocks; and the operation is more convenient.

Owner:上海意称液压系统有限公司

Grain packaging machine

ActiveCN103612779ASolve the problems of slow manual packaging and low production efficiencyAccurate packagingSolid materialDrive shaftSprocket

The invention discloses a grain packaging machine comprising a stirring motor (1), a grain entry (2), a feed pipe (3), a material box (4), a box support (5), a stirring rod (6), a first motor (12) and a second motor (18). The grain packaging machine is characterized in that an electric switch (24) is disposed below the material box (4), a metering box (7) is disposed below the electric switch (24) in a communicated manner, and a driven sprocket (27) is disposed on a driven shaft (25). Compared to the prior art, the grain packaging machine has the advantages of high production efficiency, accuracy of metering, high packaging speed and the like, and has promising market prospect.

Owner:山东方宇商标事务所有限公司

Processing method for drug protective pad

PendingCN105816275AIntermittent precisionAccurate packagingLaminationLamination apparatusMedicineDrug powder

The invention relates to a production method for disposable sanitary products, in particular to a processing method for a drug protective pad. The method comprises the steps of transferring a drug to a drug package material and conveying the drug package material into a coating device for coating; conveying the coated drug package material into a drug package hot-press bonding device for hot-press bonding; putting the cut drug package on a base membrane material; conveying an undershirt cloth material by utilizing an adsorptive conveying belt, performing embossing through an embossing device, performing hot-press bonding through a finished product hot-press bonding device, and performing cutting forming through a finished product cutting device; recovering wastes through a finished product waste recovery device; performing tri-folding on a product by a tri-folding device; pasting a quick and easy sticker to finish a product production process; and arranging and outputting the finished product. The drug prepared with the method is accurate to cut and package, uniform to quantify and small in drug powder amount error; due to the consideration of the particularity and easy rolling property of the undershirt cloth material, an adsorptive conveying mode is adopted; and the product in the production process is small in shape and size error and flat and attractive in appearance.

Owner:JIANGSU JWC MACHINERY

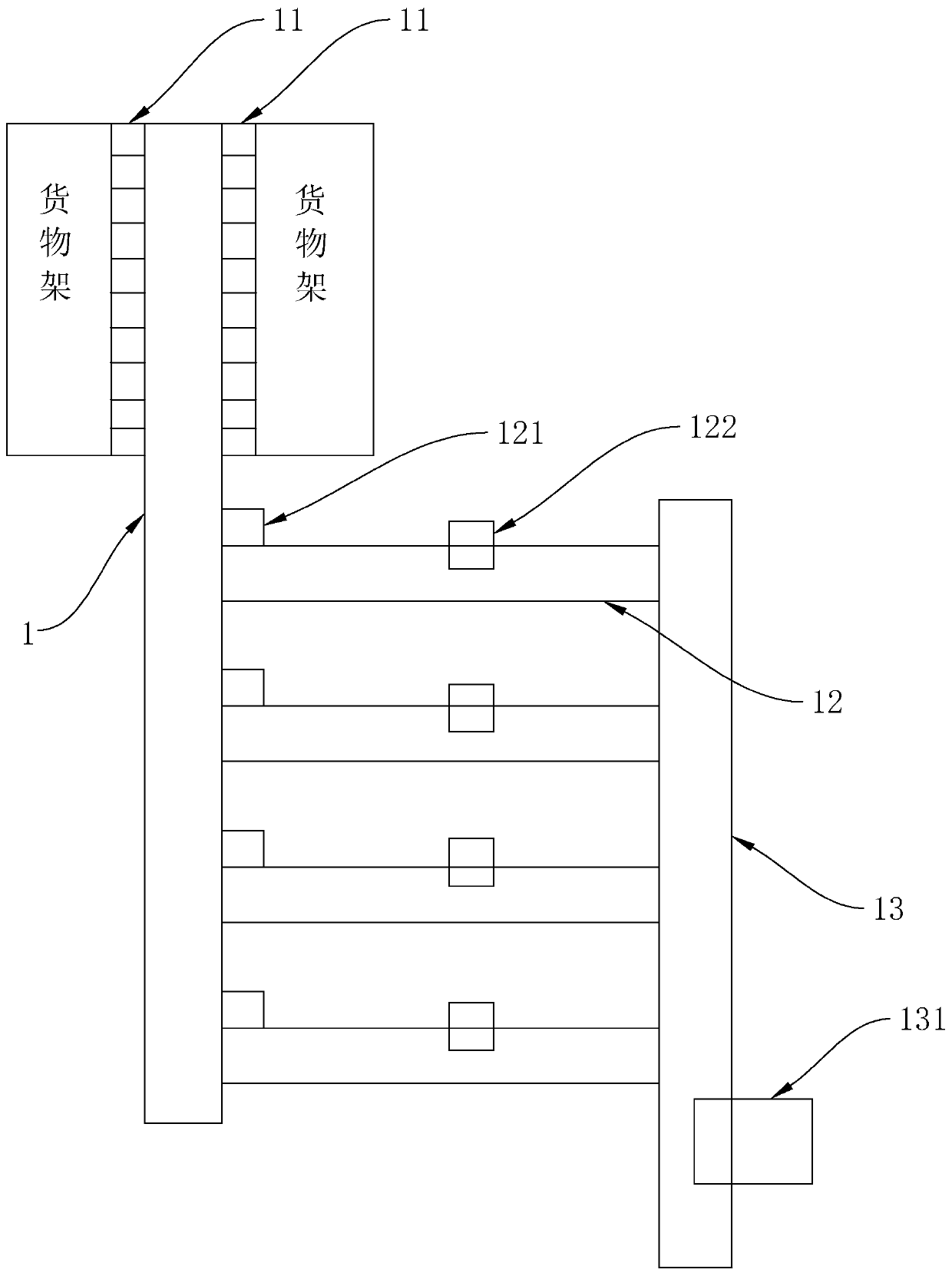

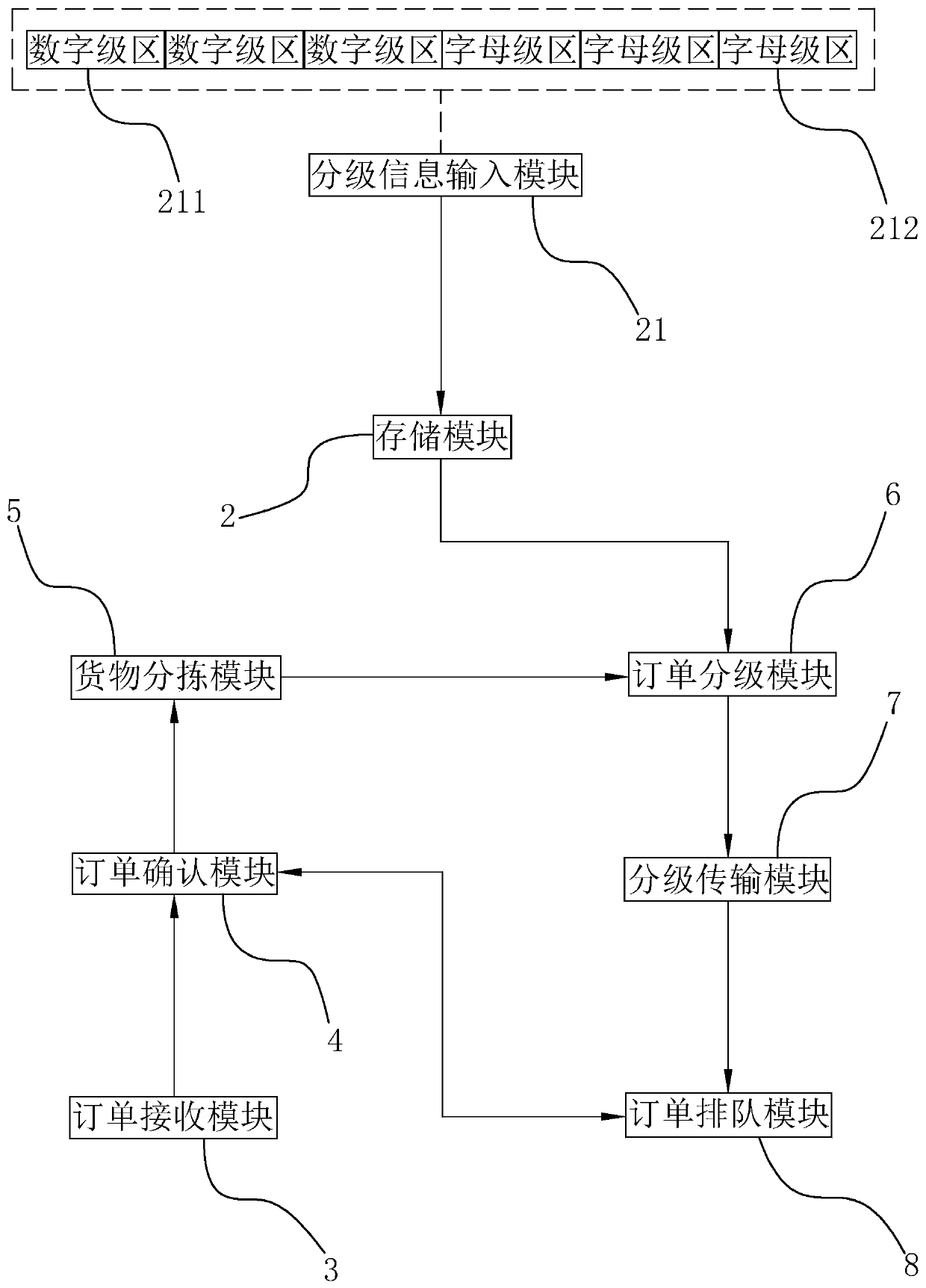

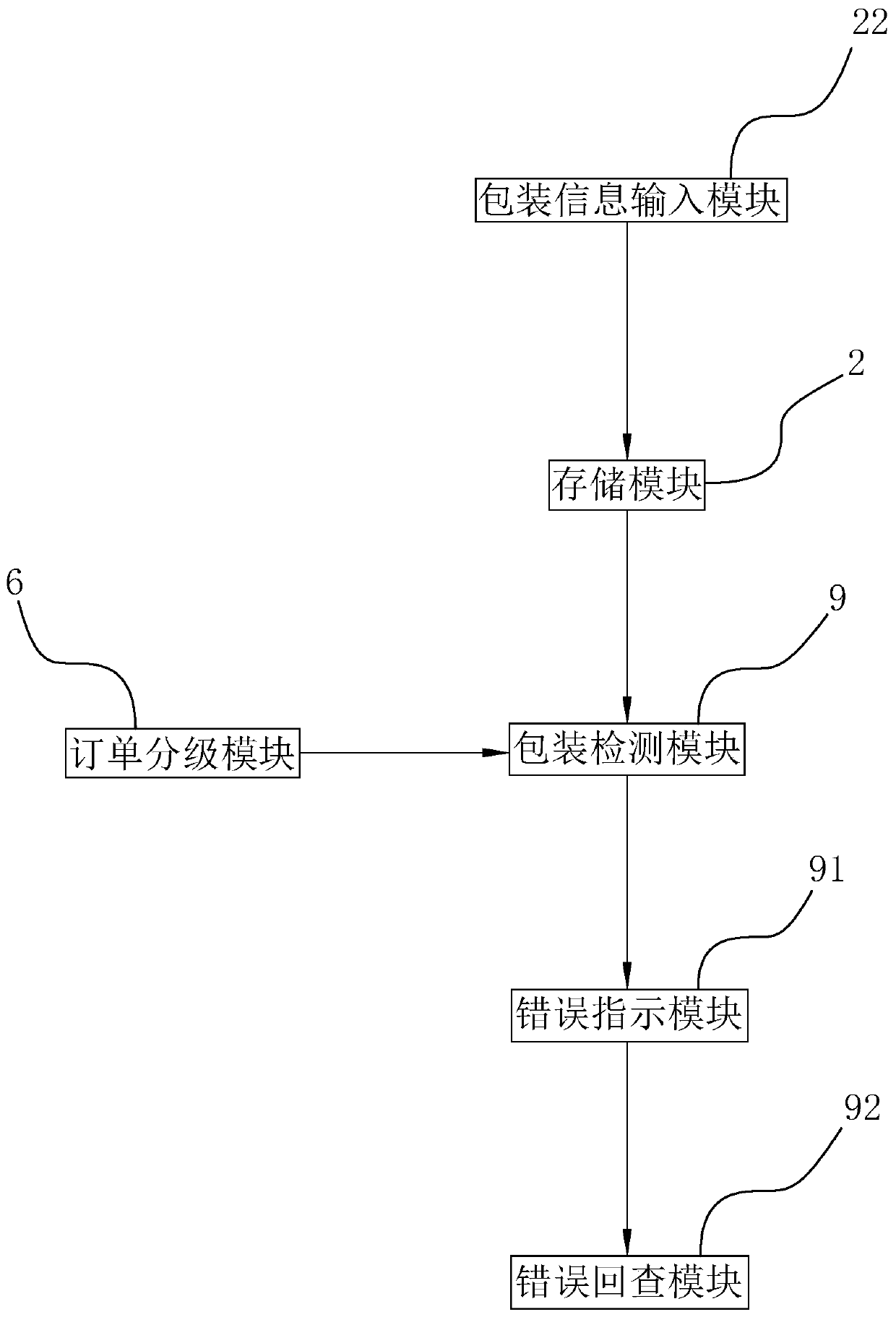

Fully-automatic cargo sorting and packaging system for logistics distribution, and method thereof

InactiveCN109848069AAvoid confusionGuaranteed packaging qualitySortingLogistics managementEngineering

The invention discloses a fully-automatic cargo sorting and packaging system for logistics distribution, and a method thereof, and belongs to the field of logistics distribution systems. The fully-automatic cargo sorting and packaging system for logistics distribution comprises a sorting conveying belt, a cargo taking manipulator arranged aside a cargo shelf, a plurality of packaging conveying belts connected with the sorting conveying belt, a grading manipulator arranged at a position close to the sorting conveying belt, of each packaging conveying belt, and an automatic packaging machine arranged on each packaging conveying belt, wherein the packaging conveying belts are sequenced according to grades in the length direction of the sorting conveying belt; a control terminal receives orderinformation and then grades the order information, conveys cargoes onto the corresponding packaging conveying belts according to order grades, and packages; and the control terminal cannot accept thenext order before the packaging of one order is not completed. The fully-automatic cargo sorting and packaging system for logistics distribution has the effect of automatically sorting and packagingthe cargos, so that good packaging quality for the cargos in different orders is ensured.

Owner:深圳市宏大供应链服务有限公司

Full-servo three-dimensional wrapping machine

The invention relates to a full-servo three-dimensional wrapping machine which comprises a frame, and a to-be-packaged product conveying mechanism, a lifting mechanism, a propelling mechanism, a packaging paper transfer mechanism, a film conveying mechanism, a film cutting mechanism and a PLC programmable controller which are mounted on the frame, wherein the PLC programmable controller is in circuit connection to the to-be-packaged product conveying mechanism, the lifting mechanism, the propelling mechanism, the packaging paper transfer mechanism, the film conveying mechanism and the film cutting mechanism separately. Compared with the prior art, the equipment vibrates, the operating noise is greatly reduced, and the difficulty of mounting and debugging and producing operation is greatly reduced, and accurate packaging can be realized by simply inputting dimension by a worker; and due to the characteristic of motor drive, compared with the previous cam drive mode, the expected service life and the maintenance period of the equipment are greatly prolonged.

Owner:王柏挺

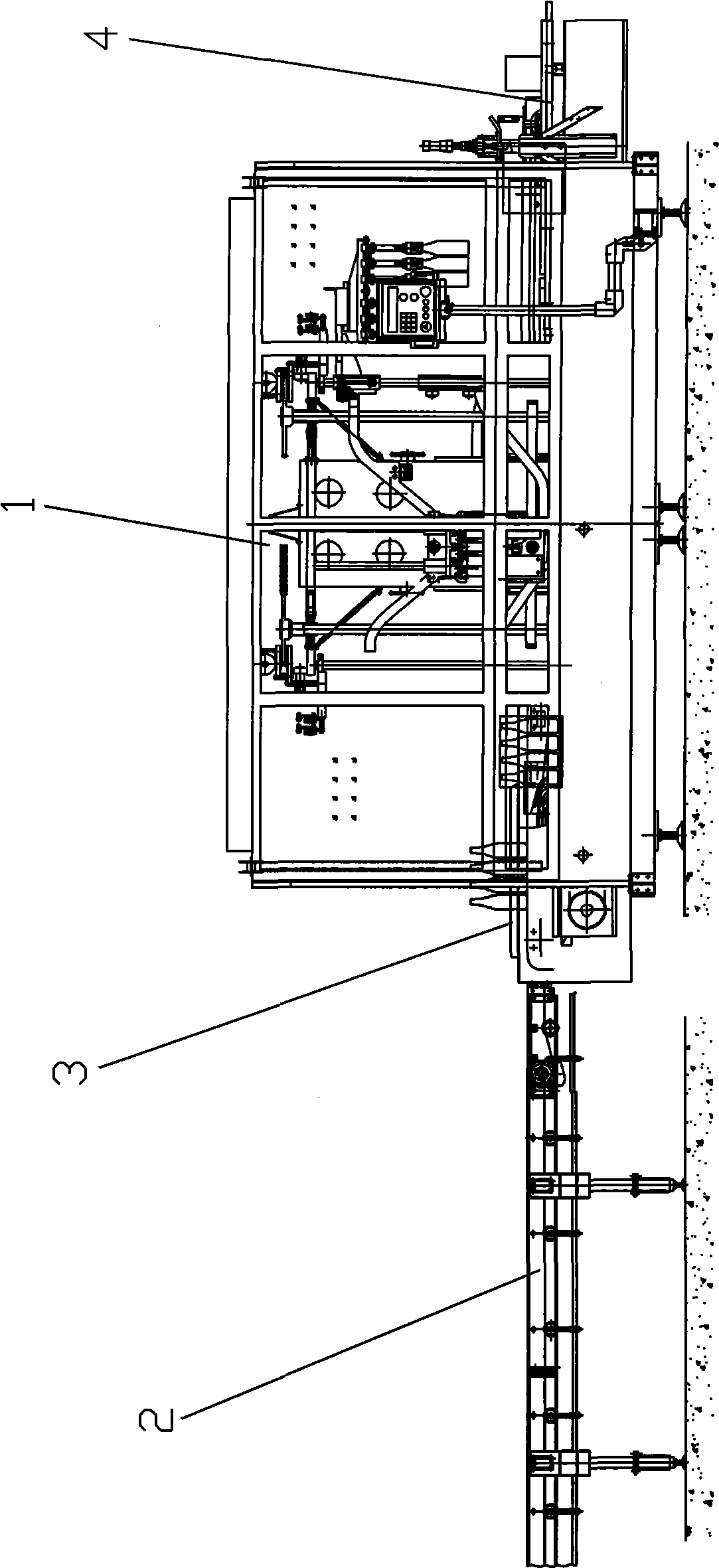

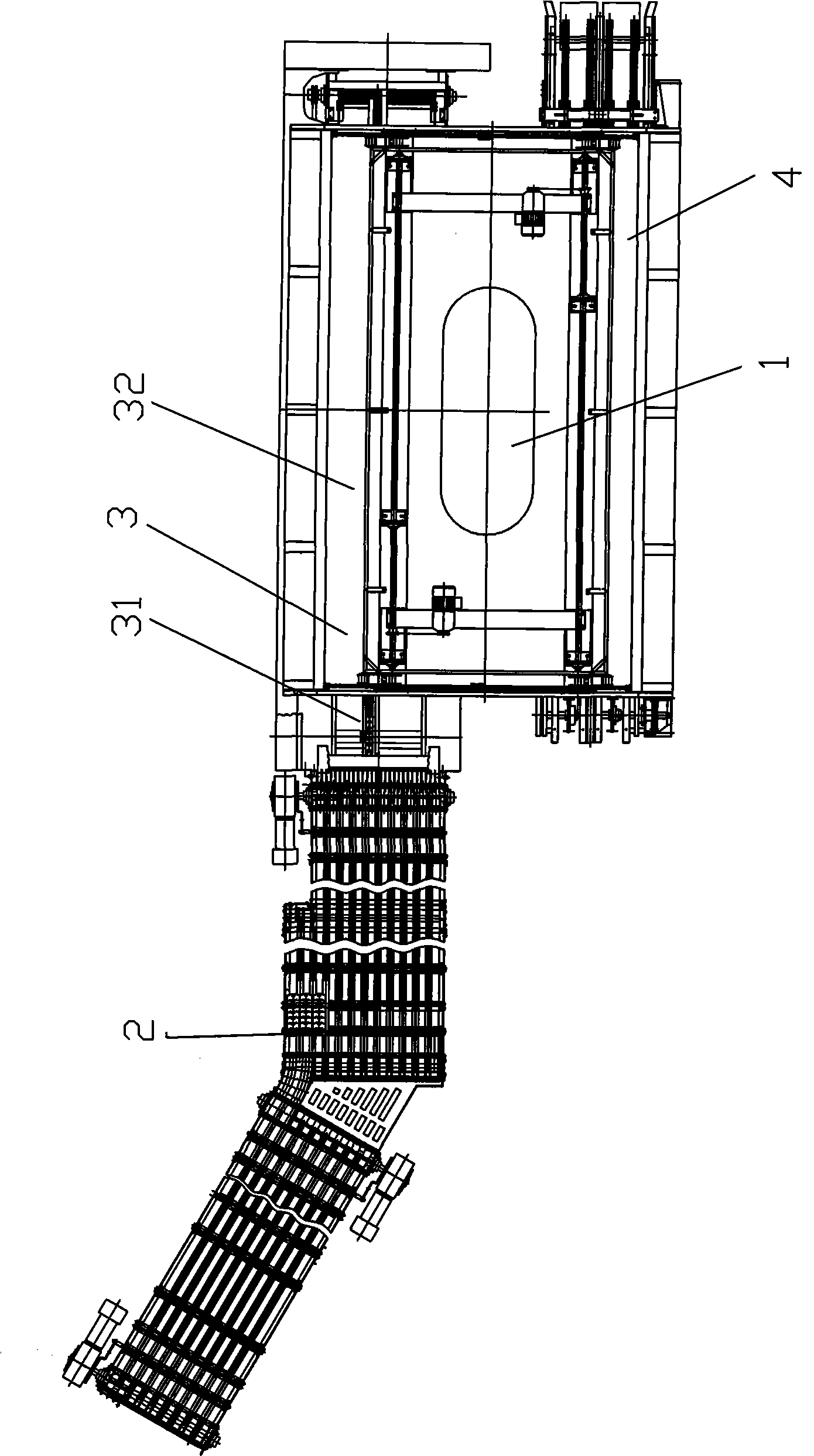

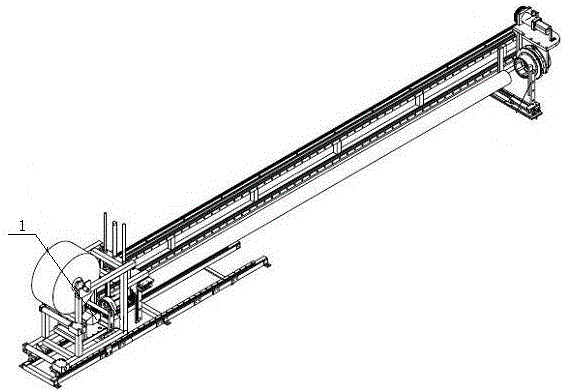

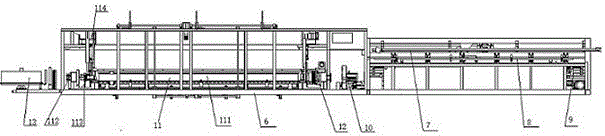

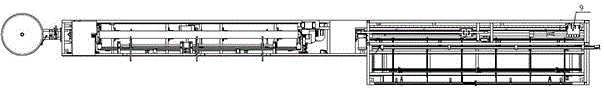

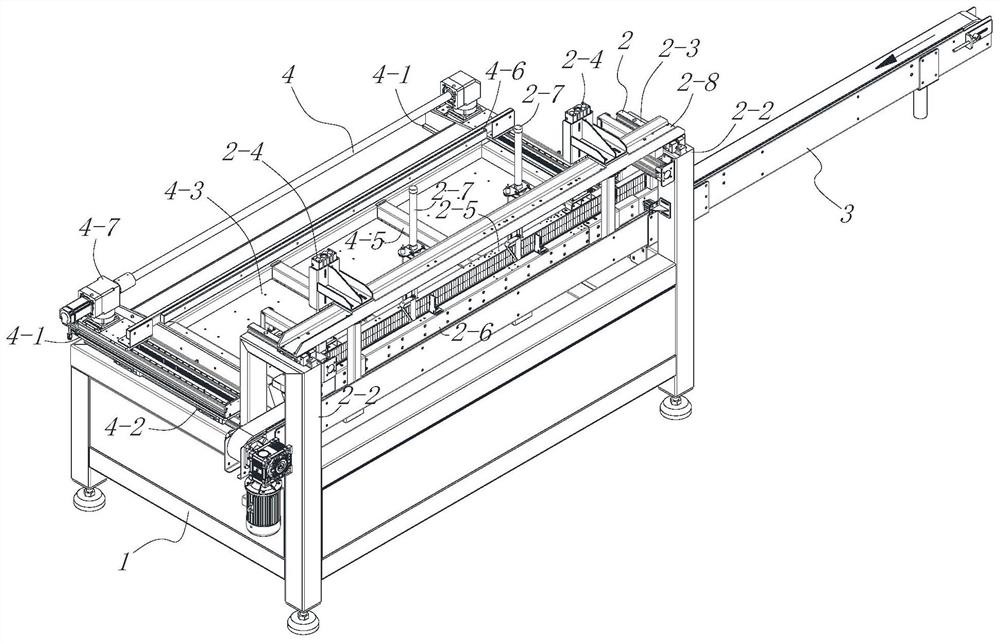

Automatic bundling, woven bag filling, labeling, sewing and packaging machine for plastic pipes

ActiveCN106115023ARealize automatic strappingAccurate packagingWrapper twisting/gatheringPackaging machinesHorizontal axisTurning frames

The invention discloses an automatic bundling, woven bag filling, labeling, sewing and packaging machine for plastic pipes. The automatic bundling, woven bag filling, labeling, sewing and packaging machine comprises a rack. A material turning frame and a material supporting and pressing mechanism are arranged on the rack. A material push mechanism, a bundling mechanism and a bagging mechanism which are located in the same horizontal axis are sequentially arranged behind the material supporting and pressing mechanism from right to left. The bagging mechanism comprises a bagging region capable of containing the pipes. A bag expansion device is arranged at one end of the bagging region and used in cooperation with a bag clamping device arranged on the bagging region. A label conveying device is arranged on one side of the bagging region. A sewing device is arranged above the bagging region. The bag expansion device is used for expanding woven bags to contain the pipes. The label conveying device is used for labeling the positions, close to bag openings, of the woven bags after the pipes are put into the woven bags. The sewing device is used for sewing and packaging the bag openings of the woven bags. By the adoption of the automatic bundling, woven bag filling, labeling, sewing and packaging machine, a serious of working procedures of automatic bundling, woven bag filling, labeling, sewing and the like of the pipes are achieved.

Owner:GUANGDONG LIANSU MACHINERY MFG

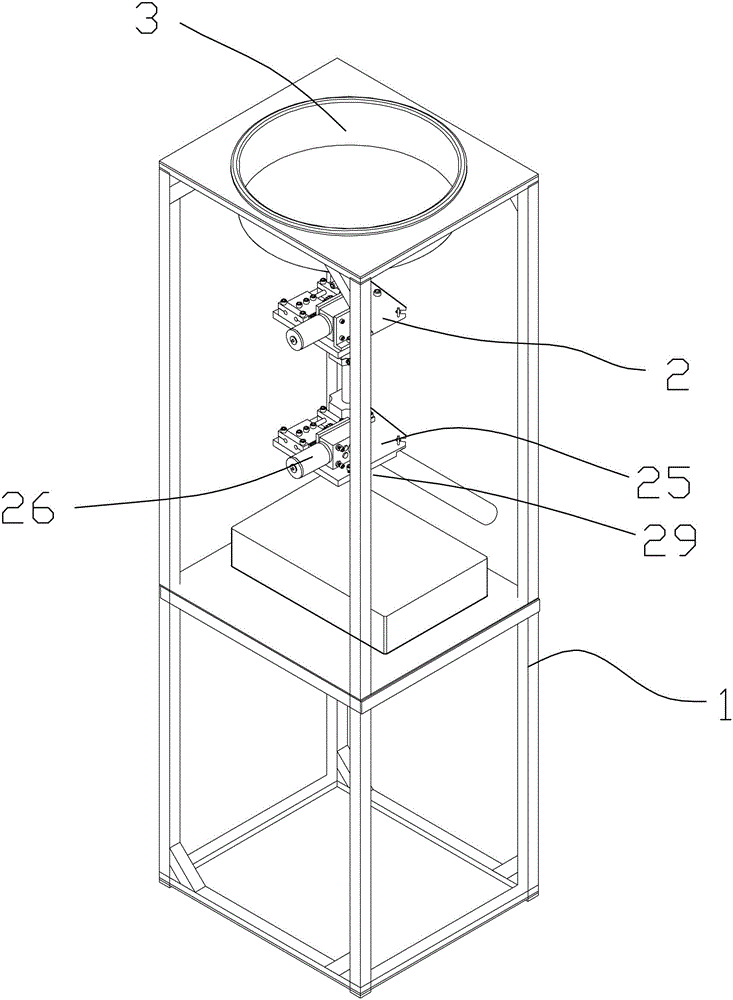

Full-automatic polypeptide extraction time-of-flight mass spectrometry detector

ActiveCN104977349AAccurate extractionReduce infectionPreparing sample for investigationMaterial analysis by electric/magnetic meansTime-of-flight mass spectrometryMass analyzer

The present invention provides a full-automatic polypeptide extraction time-of-flight mass spectrometry detector capable of concurrently extracting bulk samples. The full-automatic polypeptide extraction time-of-flight mass spectrometry detector comprises a polypeptide extraction and purification device, a pipetting distributing device, an automatic sample adding device and a mass spectrometer. According to the present invention, the electromagnetic rod and magnet rod sleeve mode is used so as to completely separate the sample; the polypeptide chip is prepared through the automatic sample adding device; the polypeptide mass spectrum map is obtained through the laser sampling of the mass spectrometer; and the full-automatic polypeptide extraction time-of-flight mass spectrometry detector has characteristics of less time consumption, high efficiency, good uniformity and sample cross-contamination avoiding, and can achieve the same technical effect as the manual operation effect of the existing mass spectrometer.

Owner:BIOYONG TECH

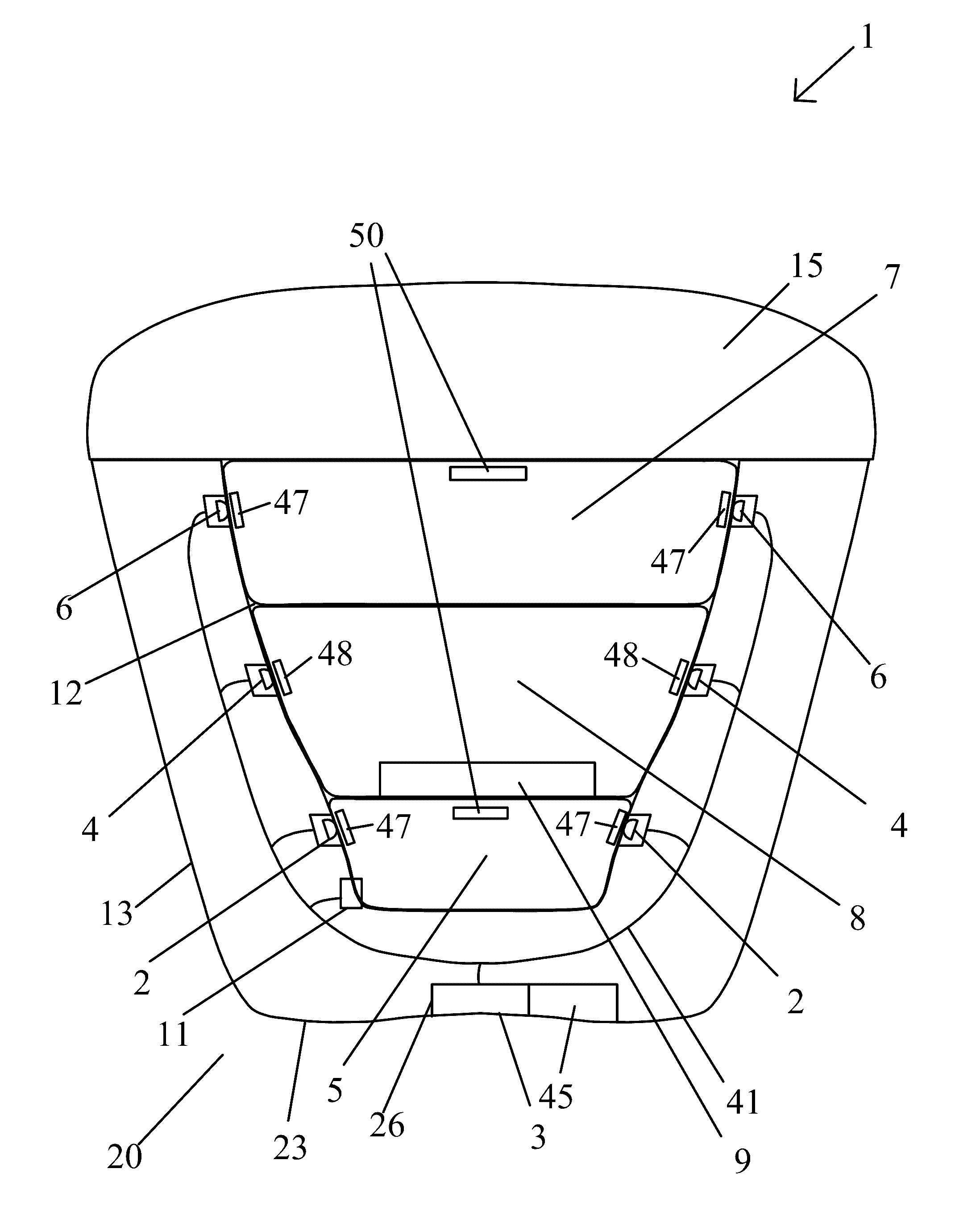

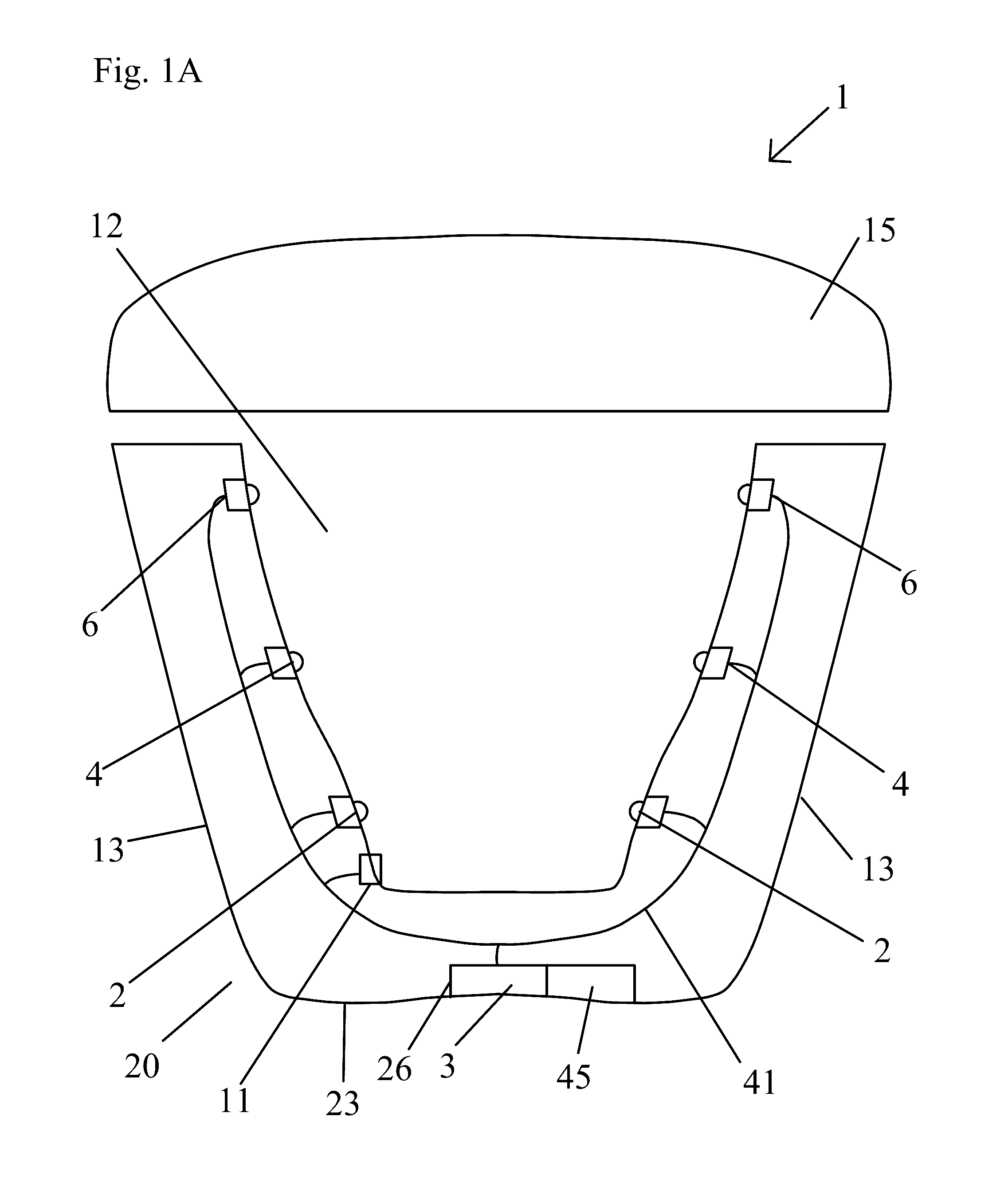

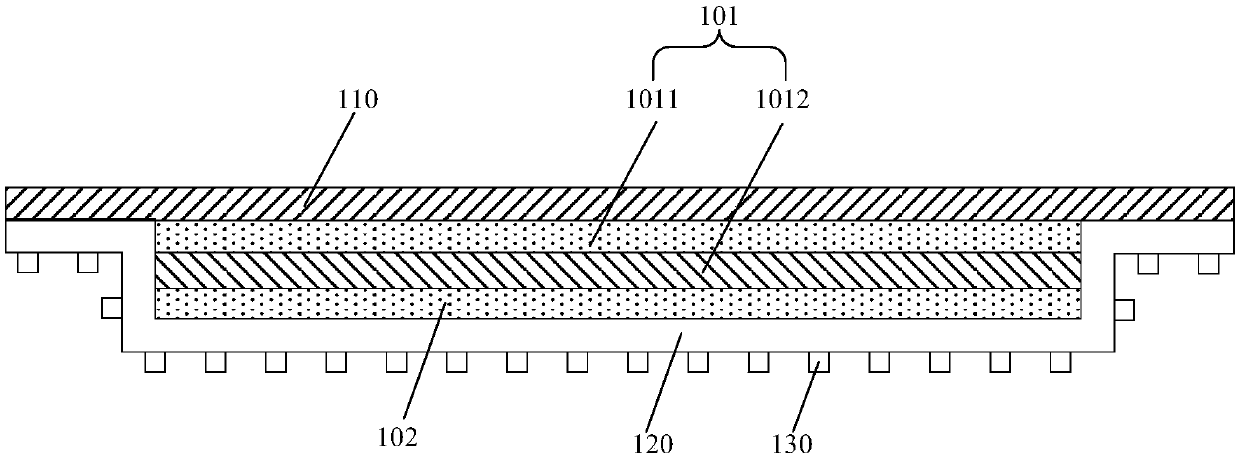

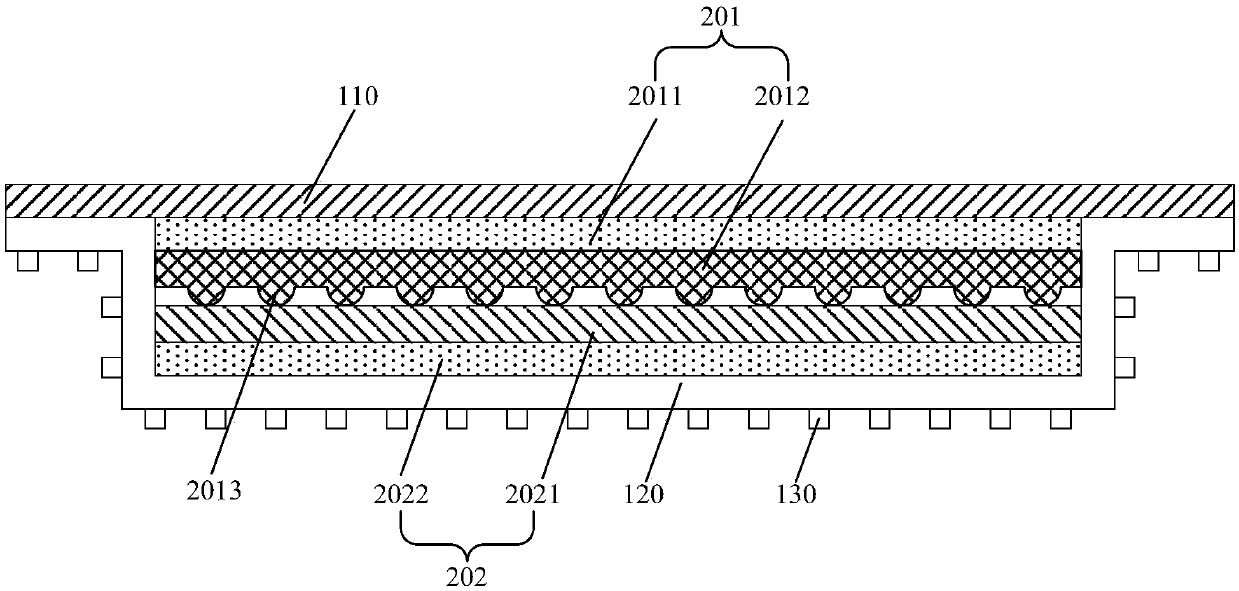

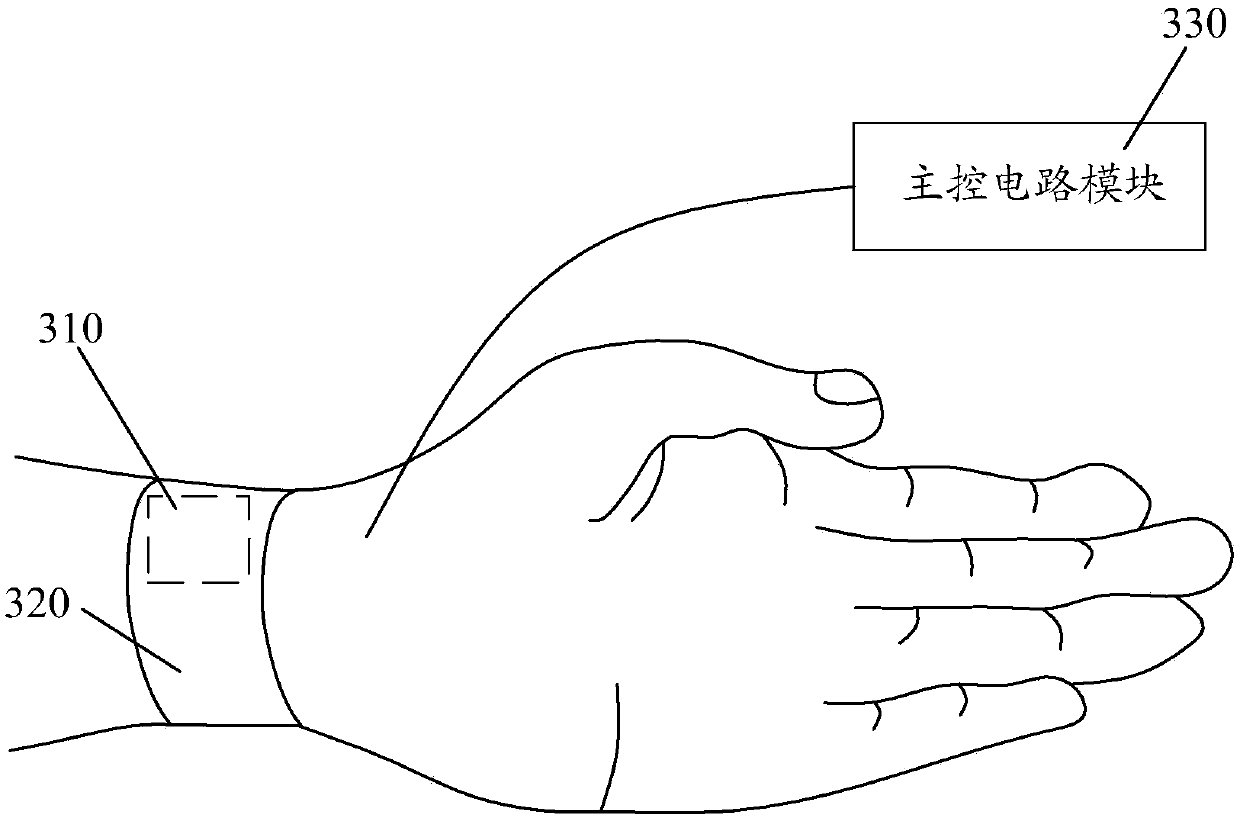

Pulse monitoring sensor, preparation method and pulse monitoring device and system

PendingCN109662698AHigh sensitivityEfficient packagingCatheterDiagnostic recording/measuringManufacturing technologyBiochemical engineering

The invention discloses a pulse monitoring sensor, a preparation method and a pulse monitoring device and system. The pulse monitoring sensor comprises a friction electricity generation part, a firstencapsulation layer and a second encapsulation layer, wherein the first and second encapsulation layers are used for encapsulating the friction electricity generation part. The friction electricity generation part comprises a first friction assembly and a second friction assembly which are stacked in sequence, the first friction assembly comprises a first electrode layer and a first high-molecularpolymer insulating layer which are stacked, and the second friction assembly comprises a second electrode layer. The first encapsulation layer is arranged on the surface of the portion, away from thefirst high-molecular polymer insulating layer, of the first electrode layer; the second encapsulation layer is arranged on the portion, away from the first friction assembly, of the second electrodelayer and the lateral surface of the friction electricity generation part; a concave-convex array structure is arranged on the surface, making contact with the skin of a user, of the second encapsulation layer. By means of the technical scheme, the sensitivity of the pulse monitoring sensor is improved, the pulse beat of the user can be accurately monitored, the structure and the manufacturing technology are simple, and the cost is low.

Owner:NAZHIYUAN TECH TANGSHAN LLC

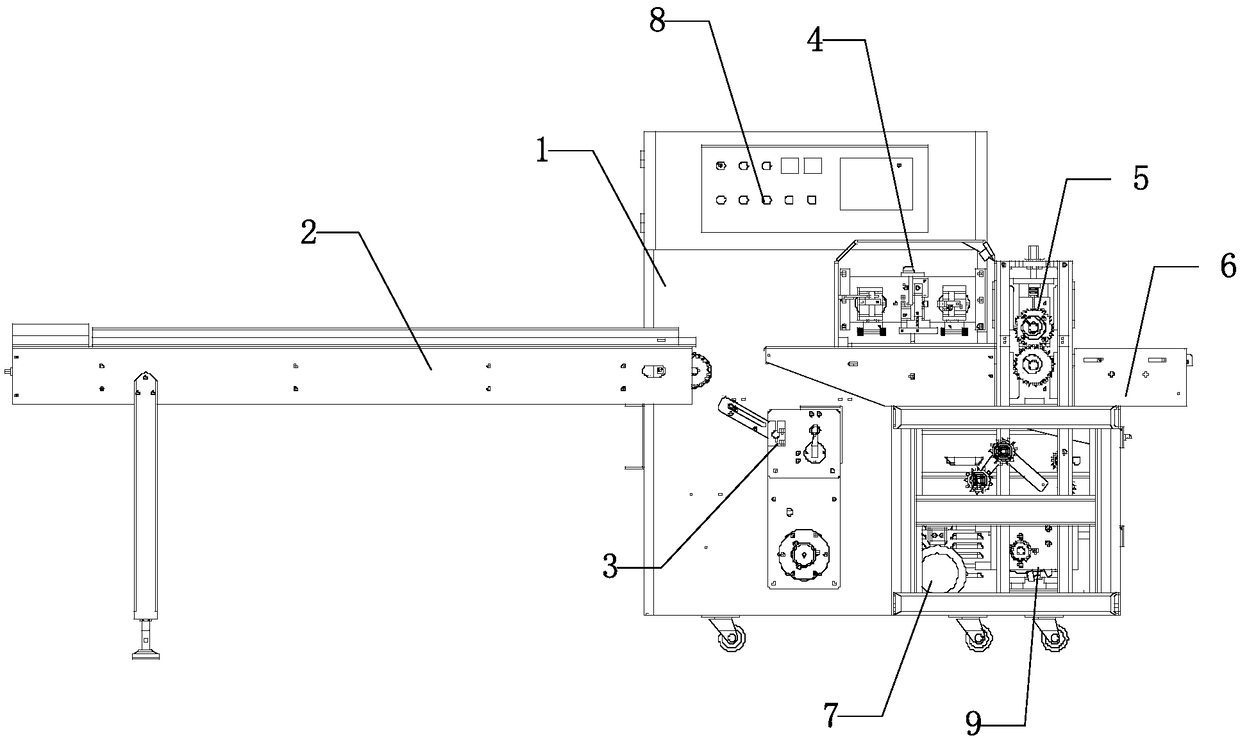

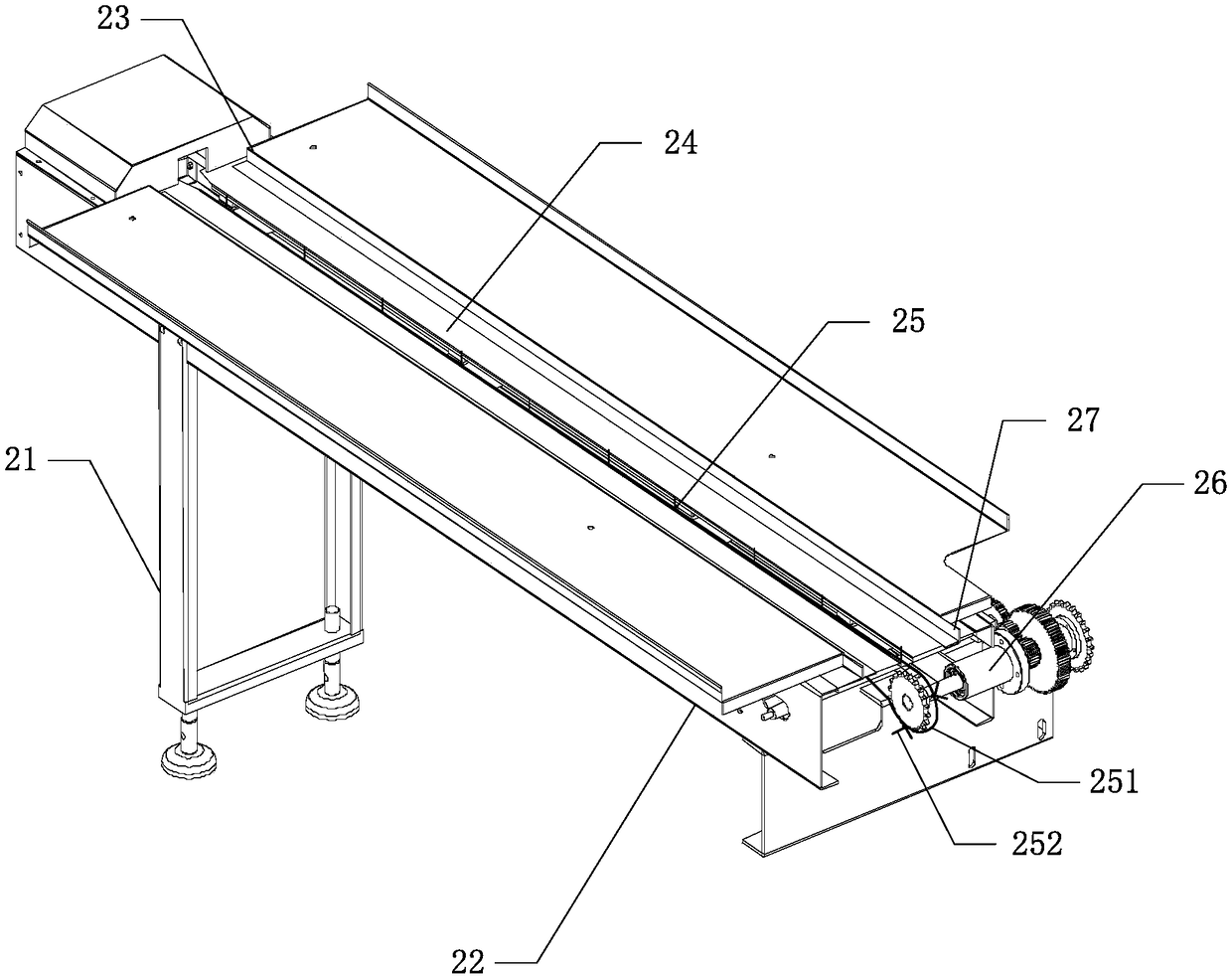

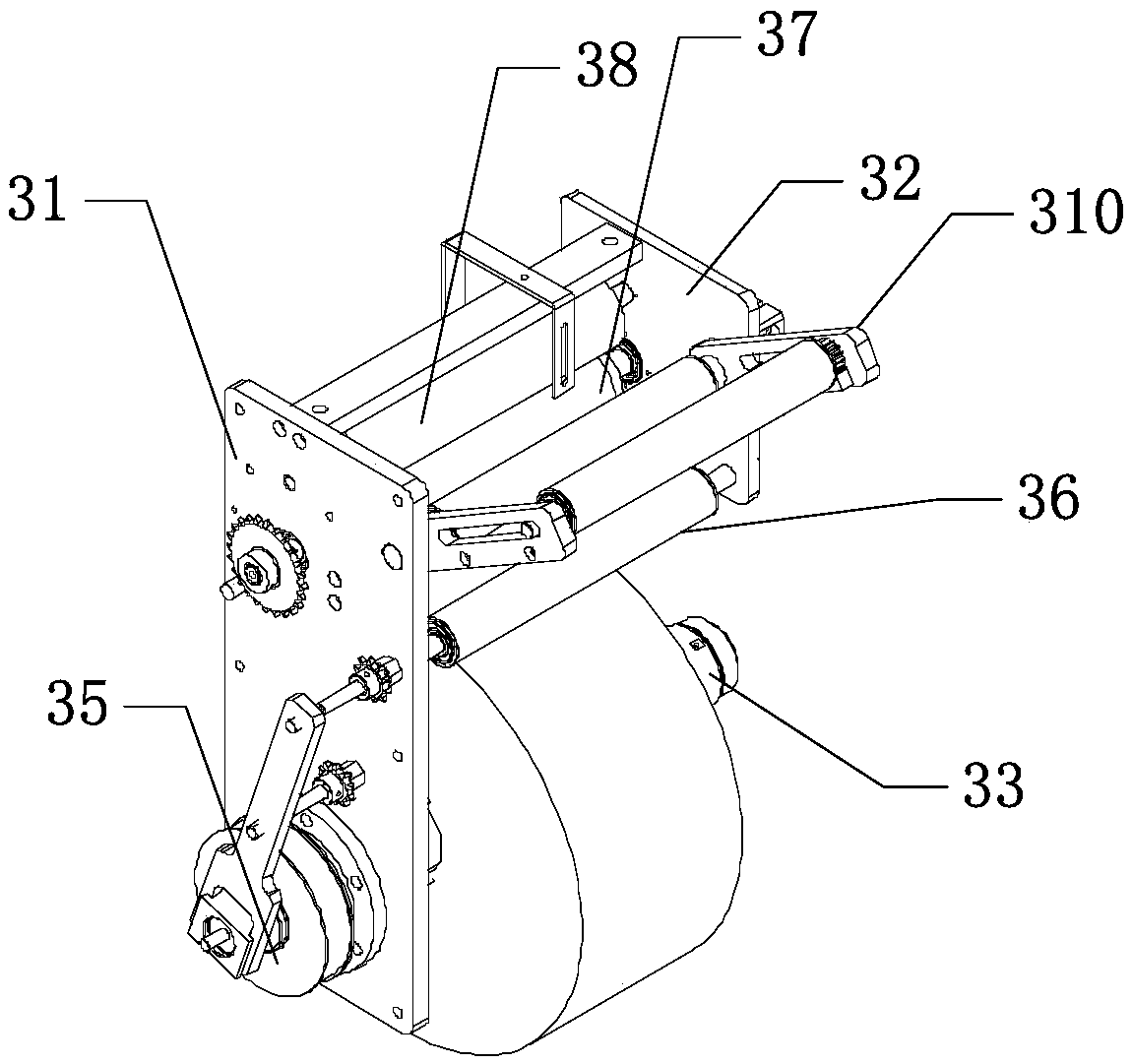

3D glasses downward paper feeding pillow type packaging machine

ActiveCN108995844ARealize automatic packaging productionImprove the packaging environmentPackage sterilisationPackaging automatic controlPulp and paper industryPaper sheet

The invention discloses a 3D glasses downward paper feeding pillow type packaging machine. The 3D glasses downward paper feeding pillow type packaging machine can realize automatic packaging production of 3D glasses by arranging a machine frame, a feeding tail frame, a paper feeding mechanism, a longitudinal sealing mechanism, an end sealing mechanism, a discharging mechanism, a motor, a control device and a transmission box, and solves the problems of pollution, low efficiency and the like caused by manual packaging. A way of downward paper feeding is adopted in the packaging machine, the paper feeding mechanism is arranged below the packaging machine, the centering adjustment of a packaging paper film is simple, the paper film is fast to install, the clamping adjustment is convenient, the overall structure is compact, the problem of large occupied area is solved, and the efficiency of integrated packaging is improved. The 3D glasses downward paper feeding pillow type packaging machine has simple structure, good packaging effect for the 3D glasses and high mechanical operation reliability.

Owner:广东太川智能设备有限公司

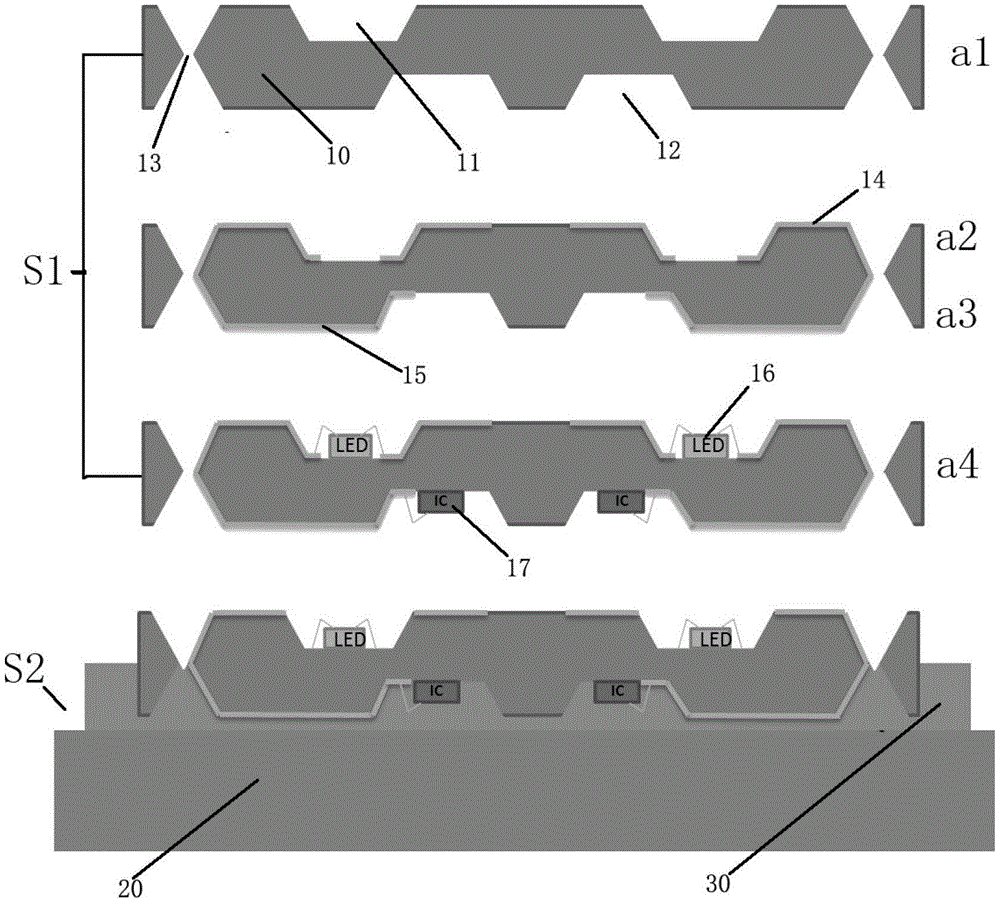

LED integration package structure based on two-sided silicon substrate and production method of structure

ActiveCN103337496AReduce connectivityShorten the lengthSolid-state devicesSemiconductor devicesElectricityHeat resistance

The invention discloses an LED (Light-emitting Diode) integration package structure based on a two-sided silicon substrate and a production method of the structure. The structure is characterized in that wires, LED chips and drive chips are integrated on the two side faces of the silicon substrate; the structure is small in size, and flexible, saves bracket cost, and does not require external drive; a lamp is simple to assemble; the wires are integrated on the silicon substrate; connections and lengths of conductors are reduced; and heat resistance of mechanical connection is reduced, so that the power loss of electric connection is lowered, and power is increased. The production method of the structure can adopt a micromachining technology; etching and wiring of a micro dimension is controlled accurately; the LED chips and the drive chips are mounted and packaged precisely; the size of the structure is decreased as far as possible; a three-dimensional package technology is adopted to integrally package elements on the two sides of the silicon substrate; the area of the substrate can be utilized sufficiently; the dimension of an LED module is decreased; an additional drive module is not required due to miniaturization of the LED module; a larger space can be made for placing other control modules due to heat sink of the lamp; and intelligent illumination is realized.

Owner:GUANGDONG UNILUMIN ENERGY SAVINGS TECH

Rotary adaptation food sealing equipment

ActiveCN106945887AEasy to operateEasy to fillWrapper twisting/gatheringEngineeringUltimate tensile strength

The invention discloses rotary adaptation food sealing equipment. The rotary adaptation food sealing equipment comprises a strip-shaped bearing base, wherein a rotary adaptation mechanism is arranged at one end of the upper surface of the strip-shaped bearing base; a sealing mechanism is arranged at the other end of the upper surface of the strip-shaped bearing base; an end product collection mechanism is arranged on the upper surface of the strip-shaped bearing base and right under the rotary adaptation mechanism; and a supporting and fixing mechanism is arranged on the lower surface of the strip-shaped bearing base. The rotary adaptation food sealing equipment has the following beneficial effects: the operation is simple, filling is convenient, package is quick and accurate, the working efficiency is improved, the quality is guaranteed, and the labor intensity is relieved.

Owner:山东百佳调味品有限公司

Soft bottle boxing packing machine

The invention relates to a soft bottle boxing packing machine. The soft bottle boxing packing machine comprises a base, wherein a belt conveyor, a bottle clamping and conveying device and a bottle receiving device are connected to the base, and the soft bottle boxing packing machine further comprises a bottle grabbing mechanical arm used for grabbing soft bottles distributed in an array mode; thebottle clamping and conveying device comprises a bottle clamping roller structure used for clamping the soft bottles on the belt conveyor, and the bottle clamping roller structure can transversely move towards or away from the bottle receiving device; the soft bottle boxing packing machine further comprises a material distributing assembly used for grouping the plurality of groups of soft bottlesclamped by the bottle clamping roller structure; the bottle receiving device comprises a material supporting assembly used for supporting the soft bottles released by the bottle clamping and conveyingdevice and further comprises a transversely-moving bottle clamping rod capable of transversely moving towards or away from the bottle clamping and conveying device, and the transversely-moving bottleclamping rod is located above the material supporting assembly; and the soft bottle boxing packing machine further comprises lifting rod assembly arranged corresponding to the transversely-moving bottle clamping rod and used for extruding the soft bottles distributed in an array mode. The soft bottle boxing packing machine can automatically perform array arrangement, grabbing and boxing operationon the soft bottles, reduces the labor cost, improves the working efficiency, and is stable and efficient in working process.

Owner:TIANJIN HUASHUAI PHARMA MACHINERY

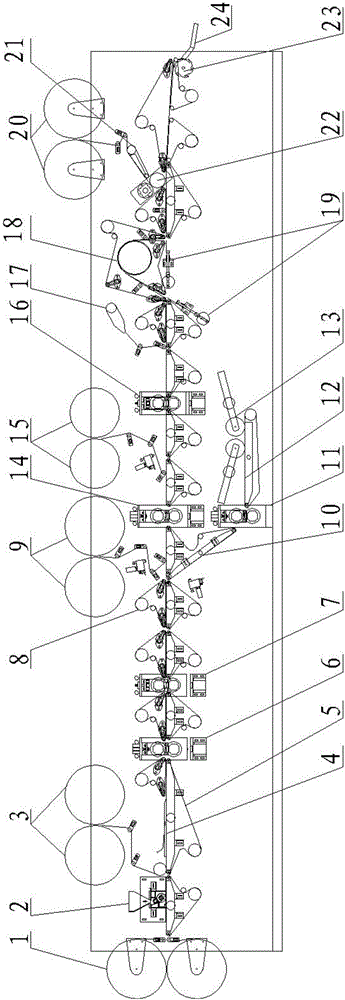

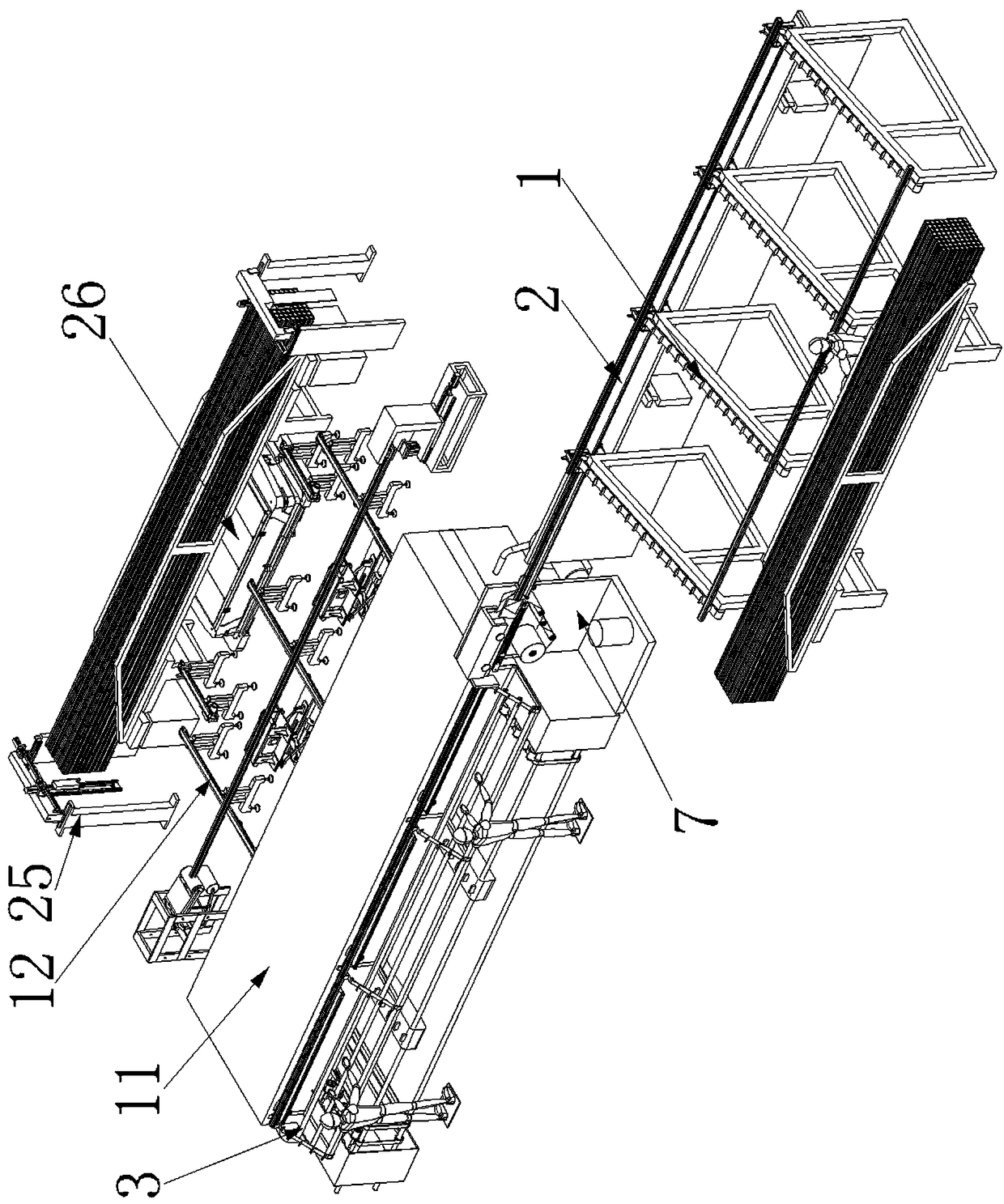

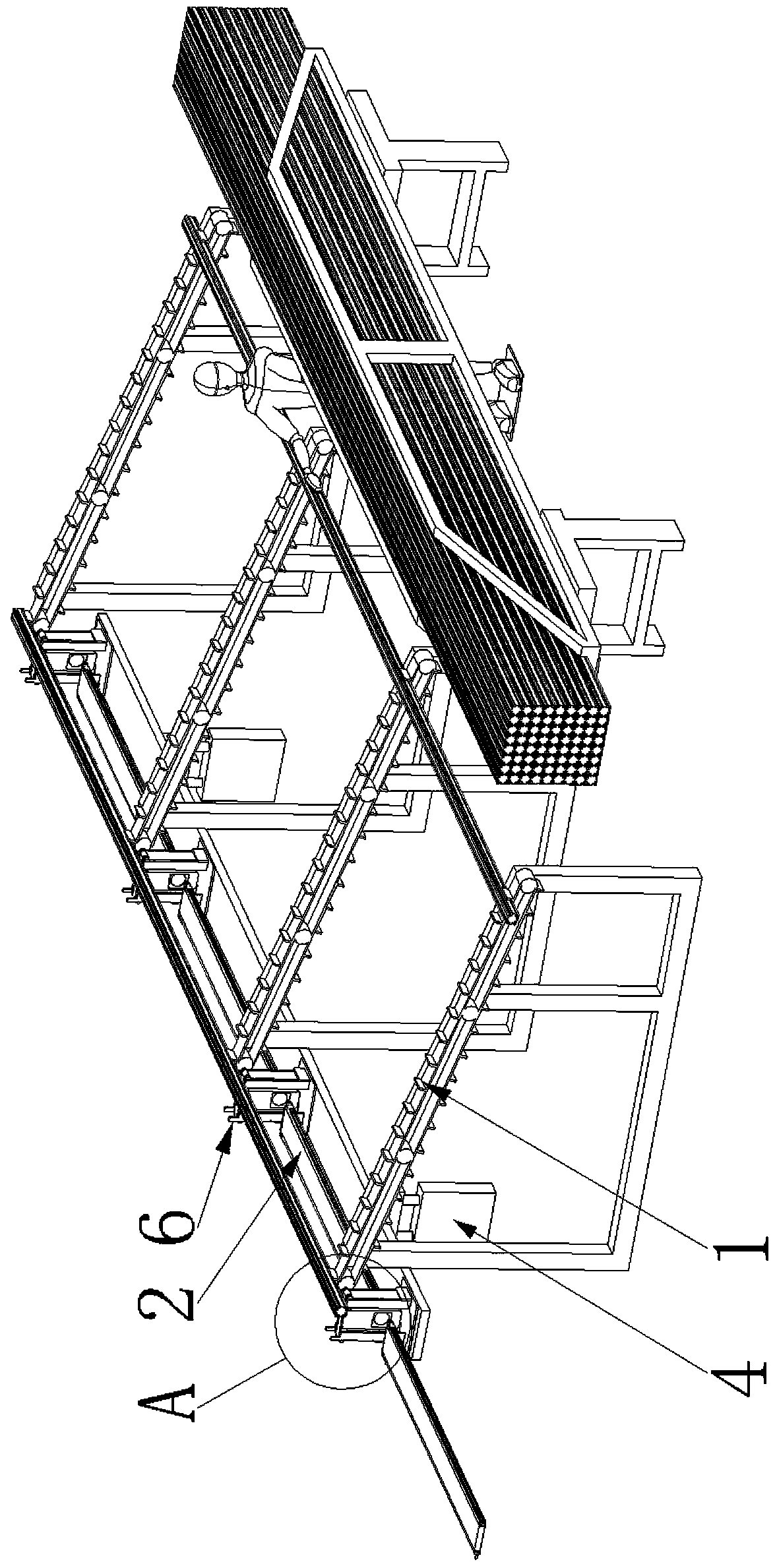

Profile efficient transfer-printing automatic production line

PendingCN108860856AAvoid disadvantagesAccurate packagingTransfer printingPackaging by pressurising/gasifyingManufacturing lineButt joint

The invention aims at providing a profile efficient transfer-printing automatic production line. The labor cost is reduced. The profile efficient transfer-printing automatic production line comprisesa feeding module, a film sleeving device, a transfer-printing module, a die stripping device and a discharging and transporting device. The feeding module comprises a material conveying mechanism, a material lifting and direction correcting mechanism and a conveying belt. The material lifting and direction correcting mechanism is arranged at the tail end of the material conveying mechanism, the conveying belt is arranged above the material lifting and direction correcting mechanism, the conveying belt is arranged in the direction vertical to the transporting direction of the material conveyingmechanism, and the conveying belt and the film sleeving device are in butt joint. The transfer-printing module comprises a feeding temporary storage device, the film sleeving device is in butt jointwith the feeding temporary storage device, the die stripping device is arranged on one side of the transfer-printing module, and the discharging and transporting device is arranged at the tail end ofthe die splitting device. The profile efficient transfer-printing automatic production line is applied to the technical field of profile transfer-printing production lines.

Owner:珠海市运泰利自动化设备有限公司

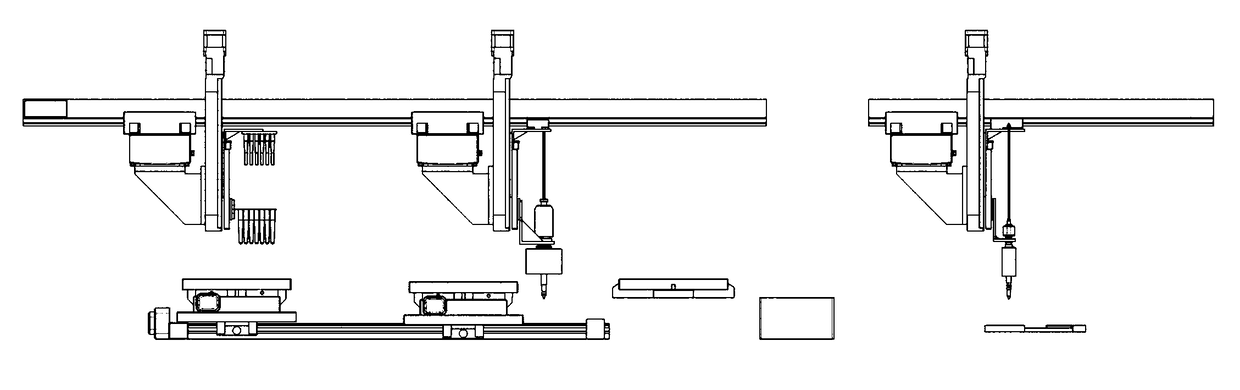

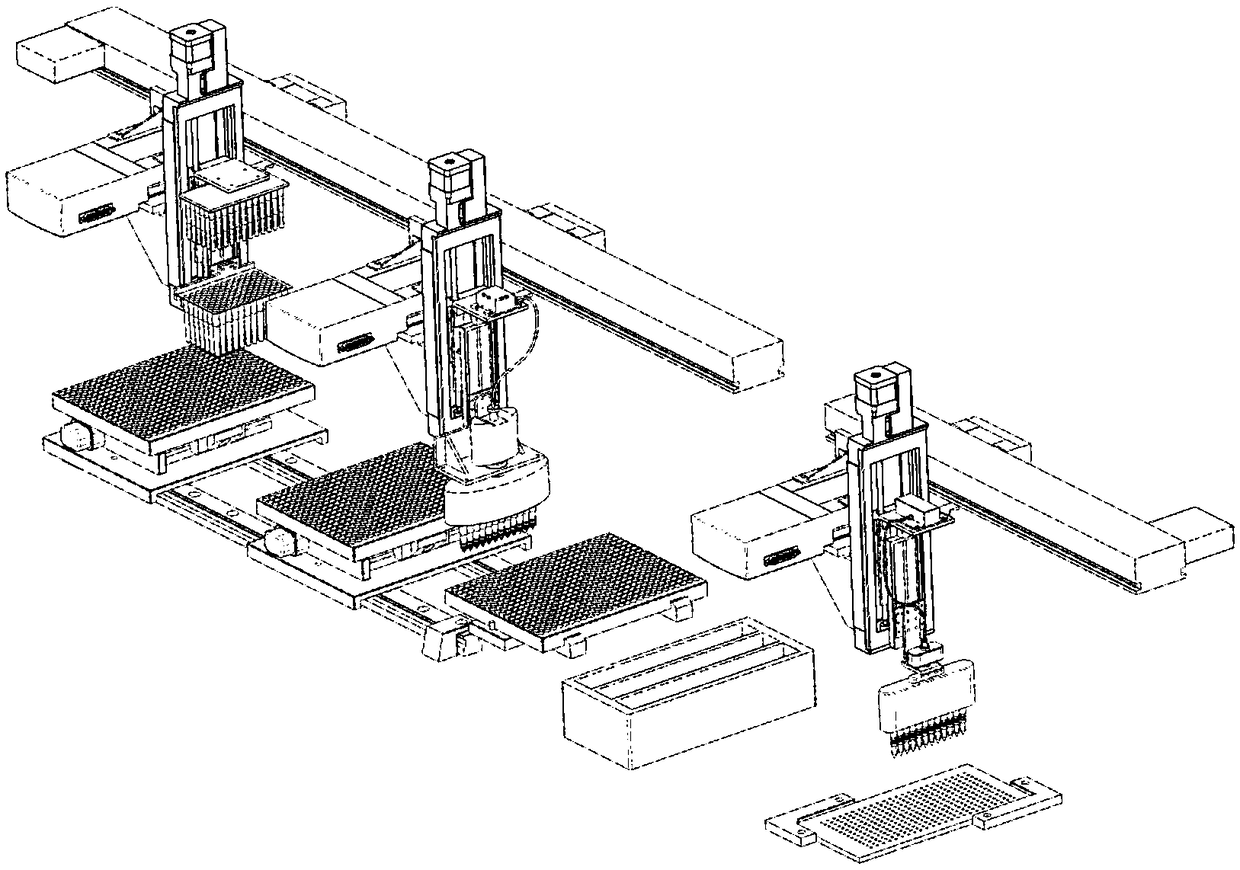

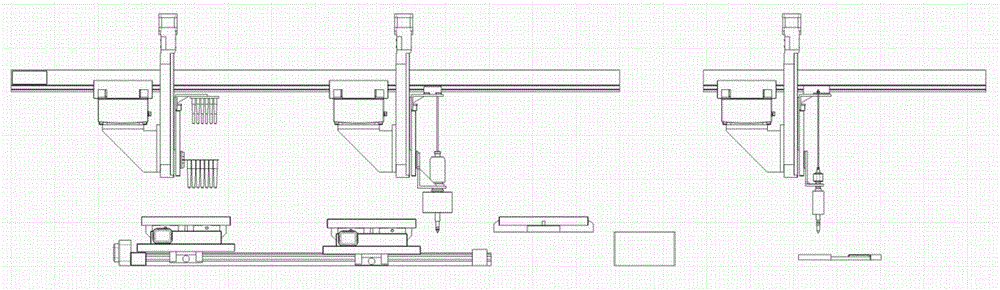

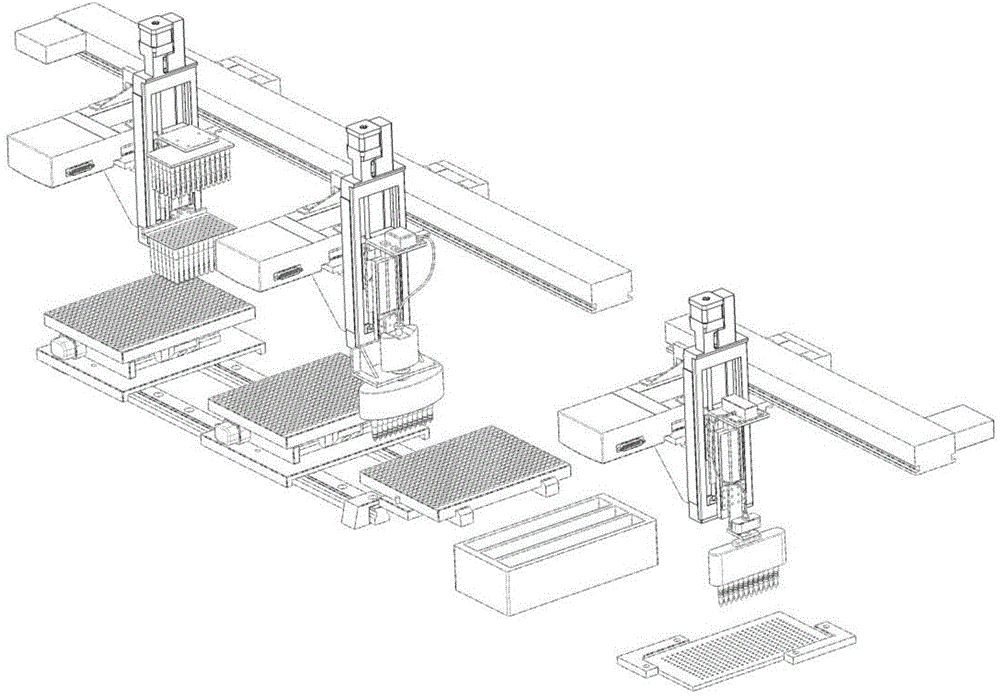

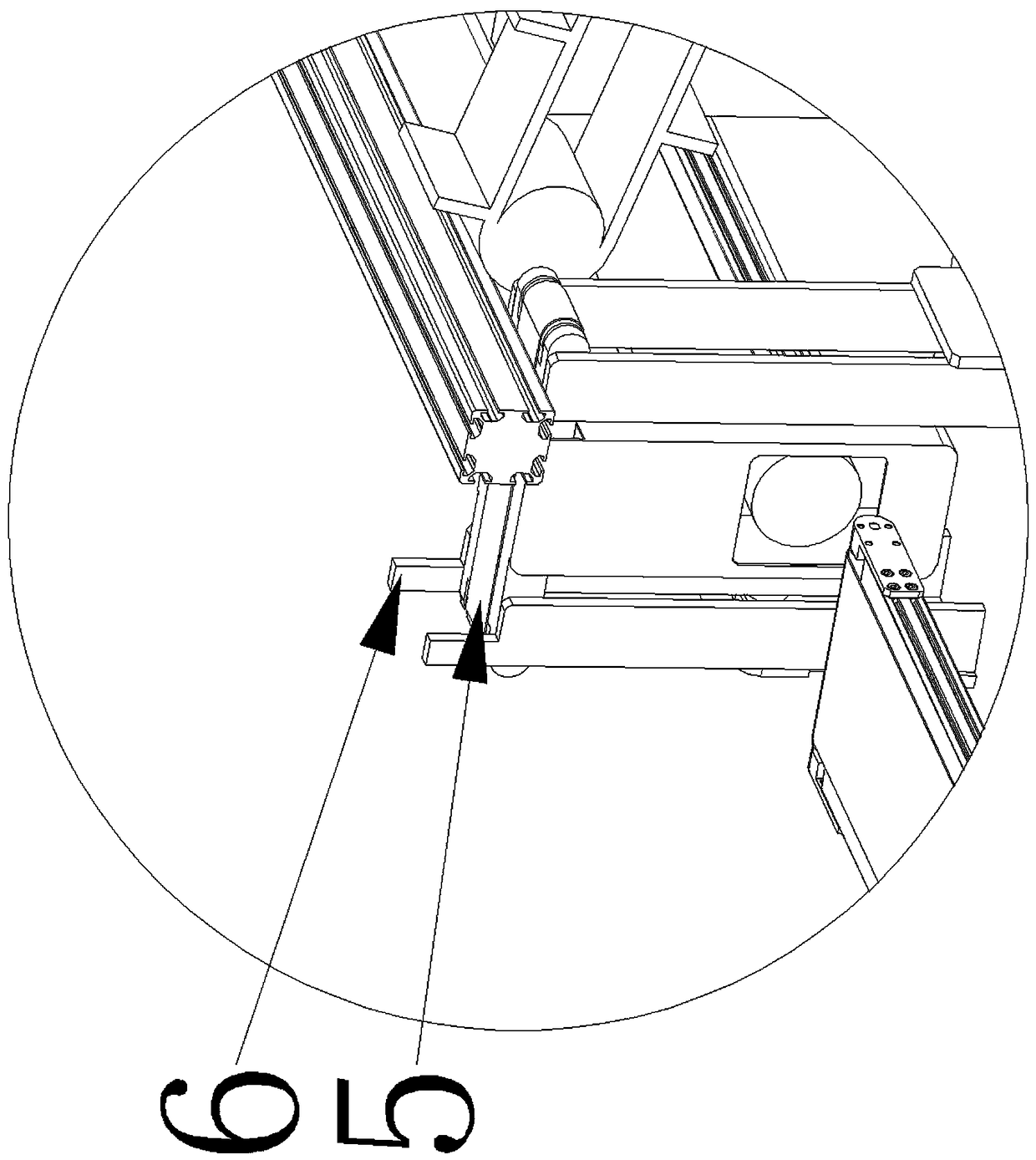

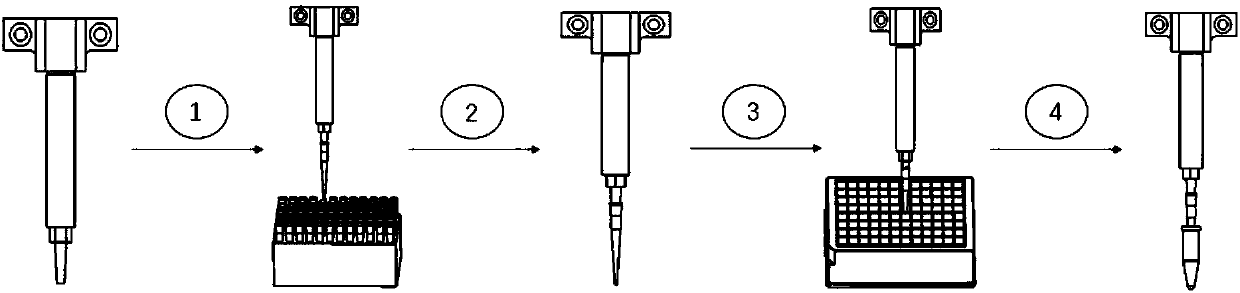

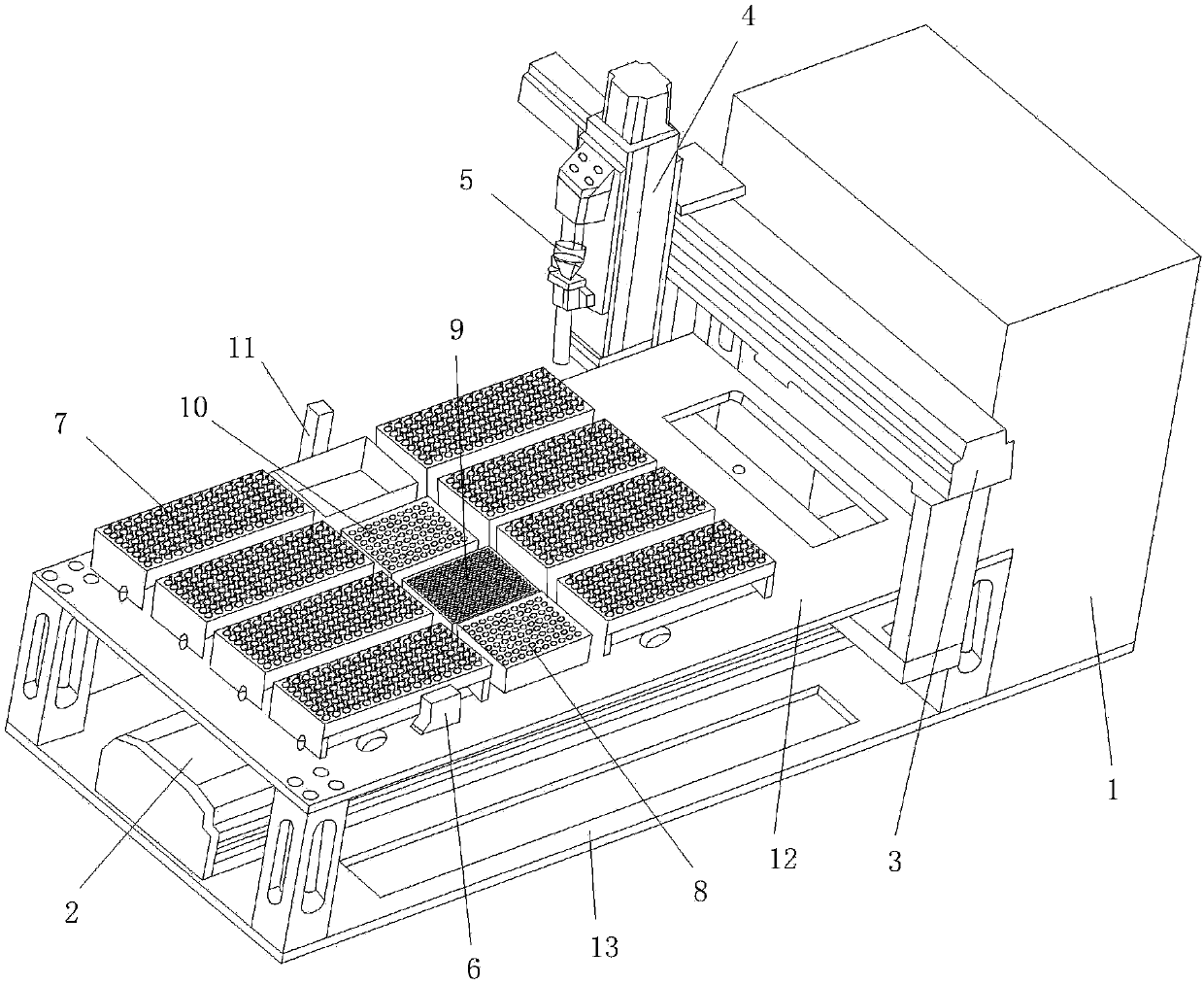

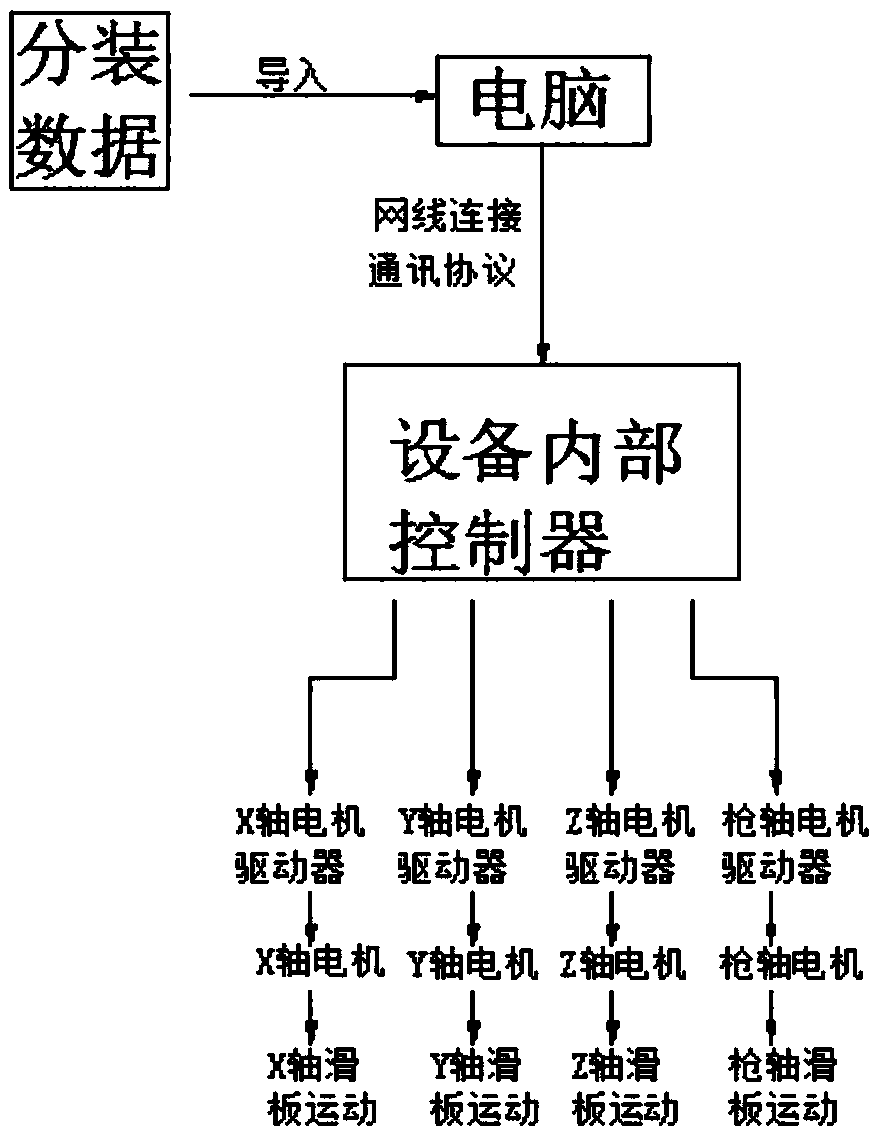

Accurate packing and mixing device for DNA primers or probes and using method of accurate packing and mixing device

PendingCN107916222ALabor savingEasy integrationBioreactor/fermenter combinationsBiological substance pretreatmentsBiomedical engineeringEngineering

The invention discloses an accurate packing and mixing device for DNA primers or probes and a using method of the accurate packing and mixing device. The accurate packing and mixing device mainly comprises a control cabinet, an executing mechanism, a working region component, a testing unit, a gun head frame, a working table board and a fixed table board; the executing mechanism consists of an X-axis sliding table, a Y-axis sliding table, a Z-axis sliding table and a gun axis sliding table; and the working region component comprises eight packing target boards, a gun head board, a stock solution board, a solution guiding target board and a gun head separator, and the working table board uses a layout form of taking the stock solution board as the center. An accurate, reliable and efficientengineering solution scheme is provided, and therefore, automatic accurate packing and mixing of the DNA primers or probes are realized. The labor can be saved, a troublesome manual solution suckingand beating process can be omitted, an operator only needs to use a mobile USB flash disk to guide required operation into software, previous preparation operation is omitted, and full-automatic operation is realized.

Owner:上海百力格生物技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com