Hydraulic system for packaging machine and working method thereof

A hydraulic system and hydraulic source technology, applied in mechanical equipment, fluid pressure actuators, servo motors, etc., can solve problems such as low packaging efficiency and easy failures, and achieve the goals of convenient operation, safety assurance, and power resource saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

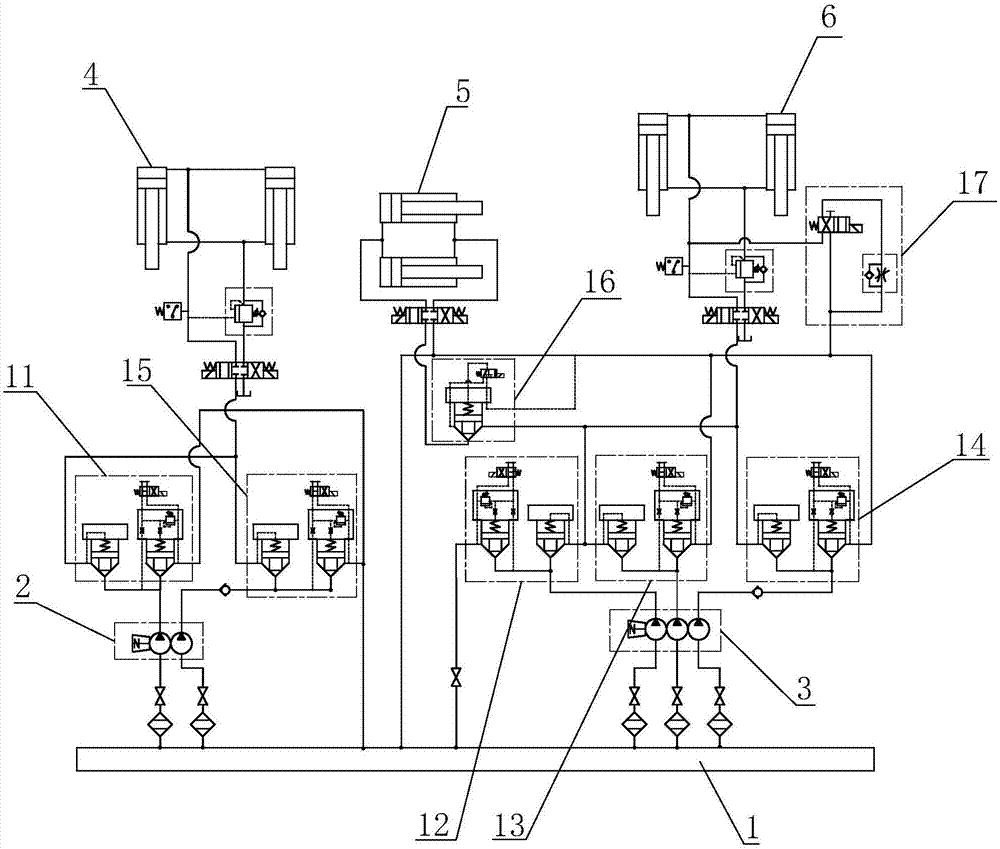

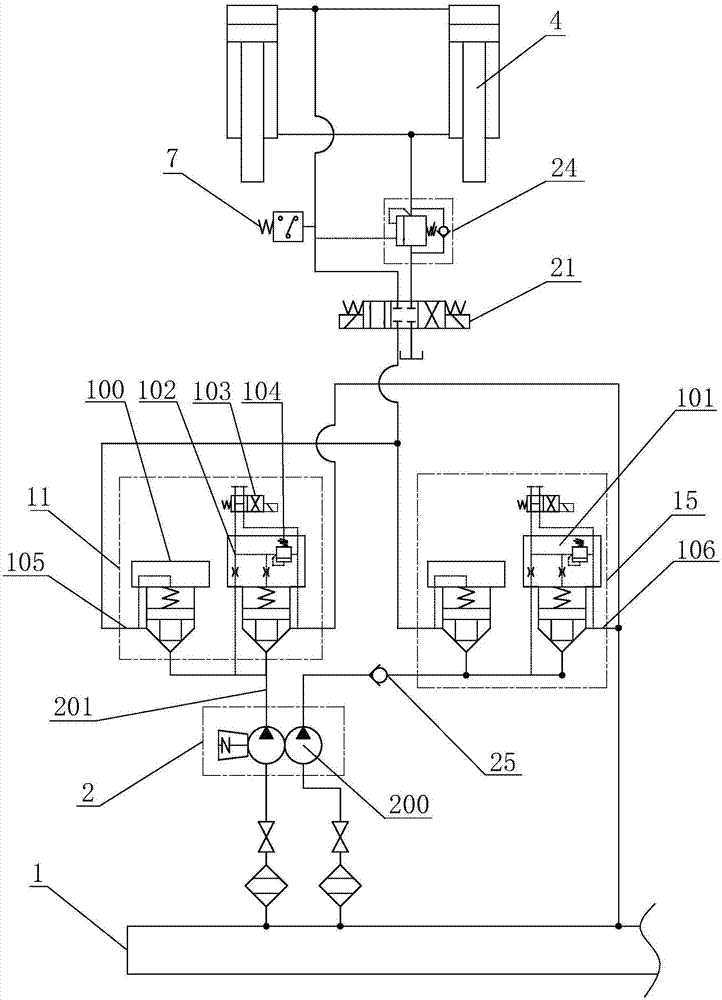

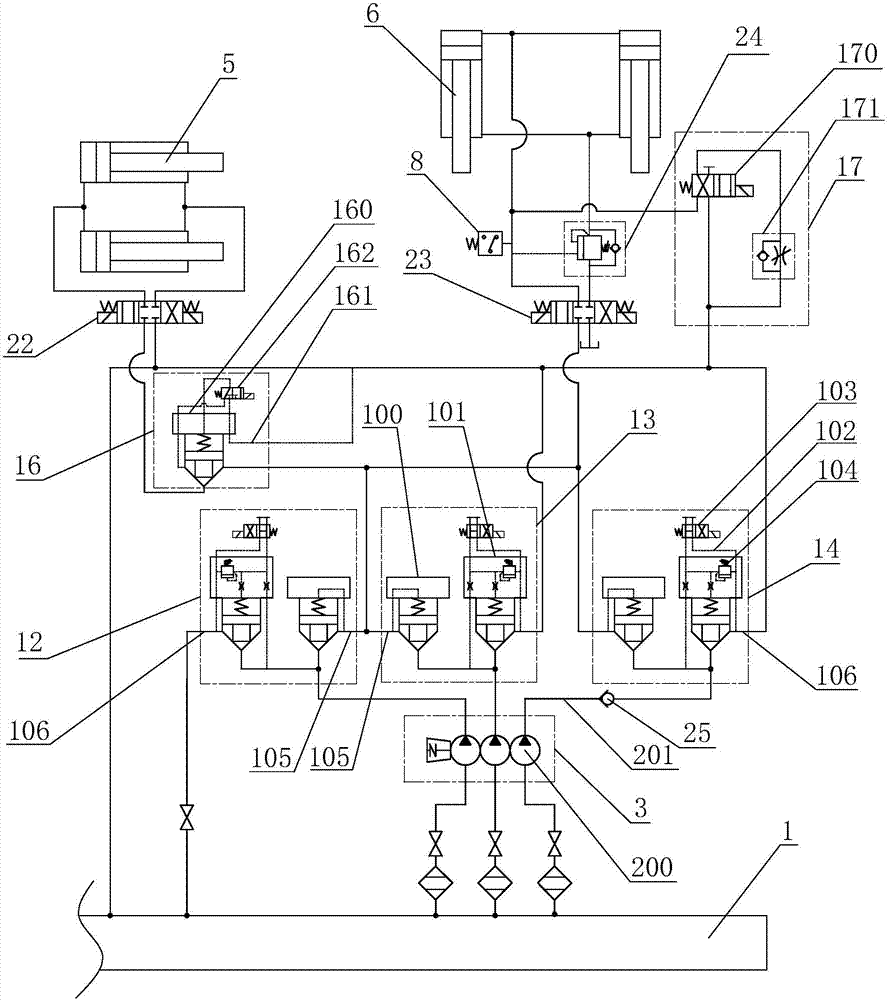

[0046]In order to make the purpose, technical solutions and beneficial effects of the present invention clearer, the present invention will be further described in detail below in conjunction with the examples and accompanying drawings, but the embodiments of the present invention are not limited thereto.

[0047] The solid line in the figure is the working pipeline, the dotted line is the control pipeline, and the dotted line is the module group.

[0048] A hydraulic system of a baler, such as figure 1 As shown, the hydraulic source 1 is included, and the hydraulic source 1 is connected with the first oil pump 2 and the second oil pump 3; the first oil pump 2 includes two hydraulic pumps 200 connected in parallel, and the oil outlet of the first oil pump 2 is connected with two oil outlet pipelines 201 and lead to the first cartridge valve group 11 and the fifth cartridge valve group 15 respectively, the second oil pump 3 includes three hydraulic pumps 200 connected in parall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com