Apparatus and method for making and bagging decorative grass

a technology of decorative grass and filaments, which is applied in the directions of packaging, transportation and packaging, packaging, etc., can solve the problems of not providing uniform charges for decorative grass, and achieve the effect of increasing efficiency and profitability, reducing labor intensity, and increasing width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

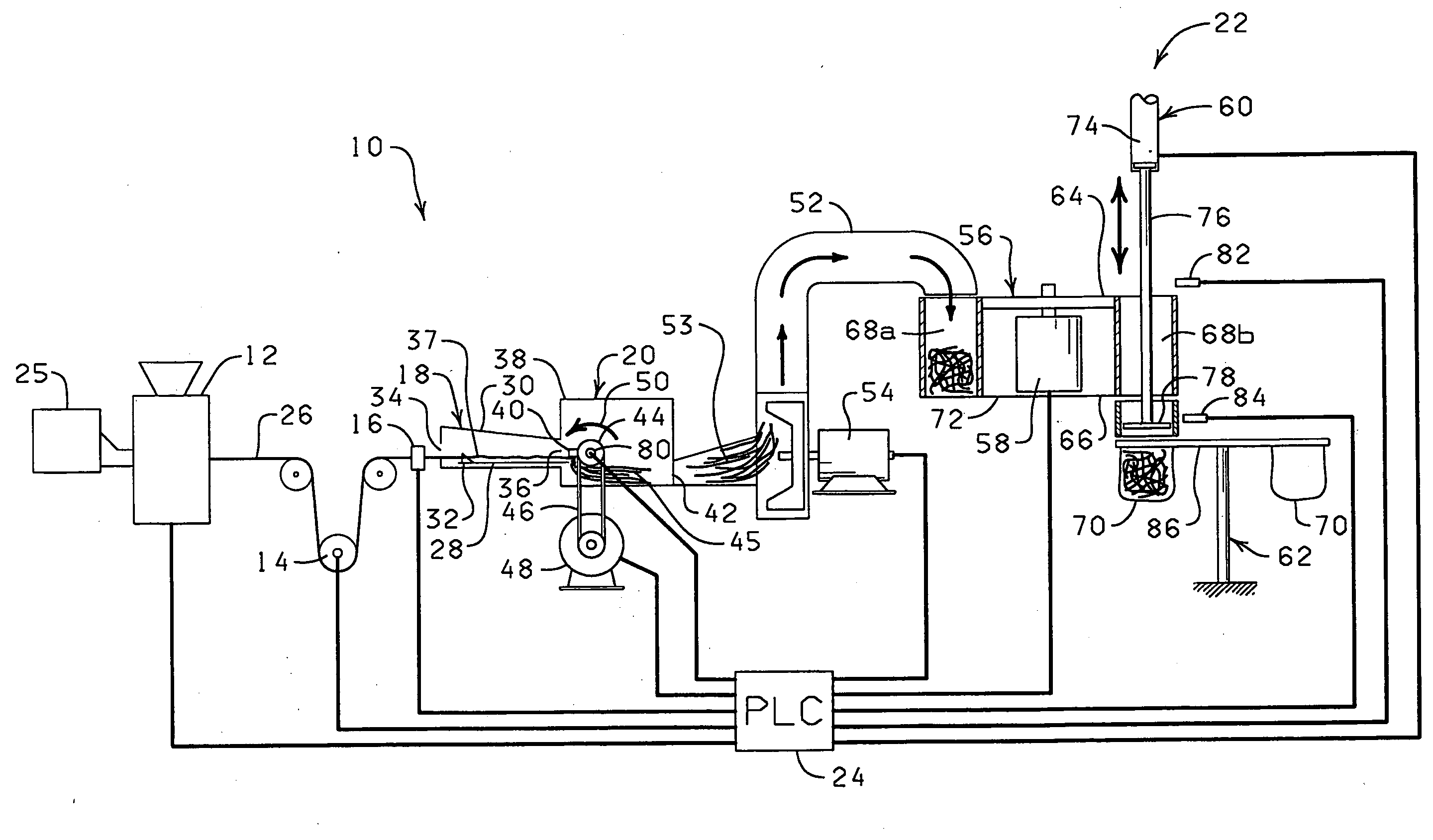

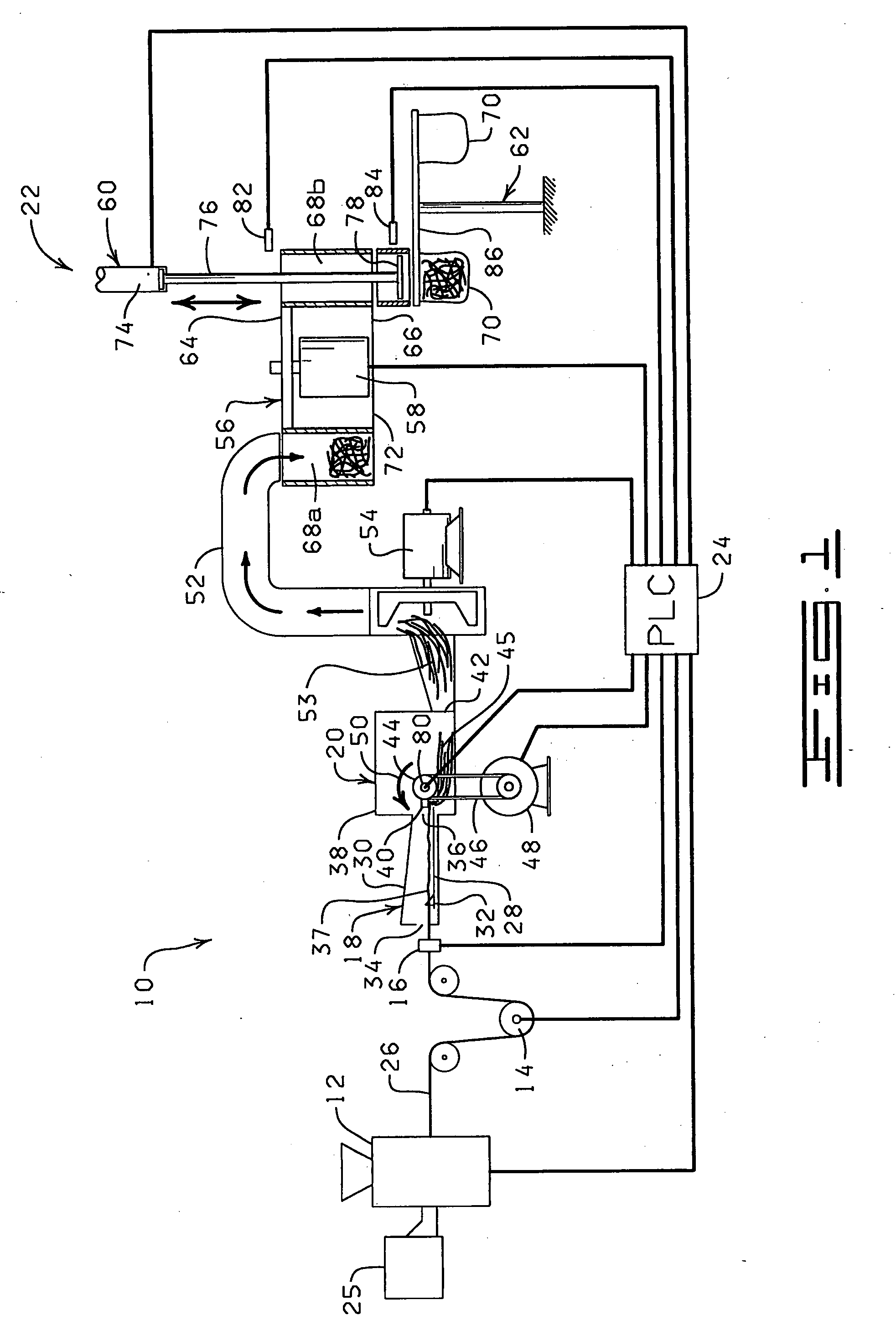

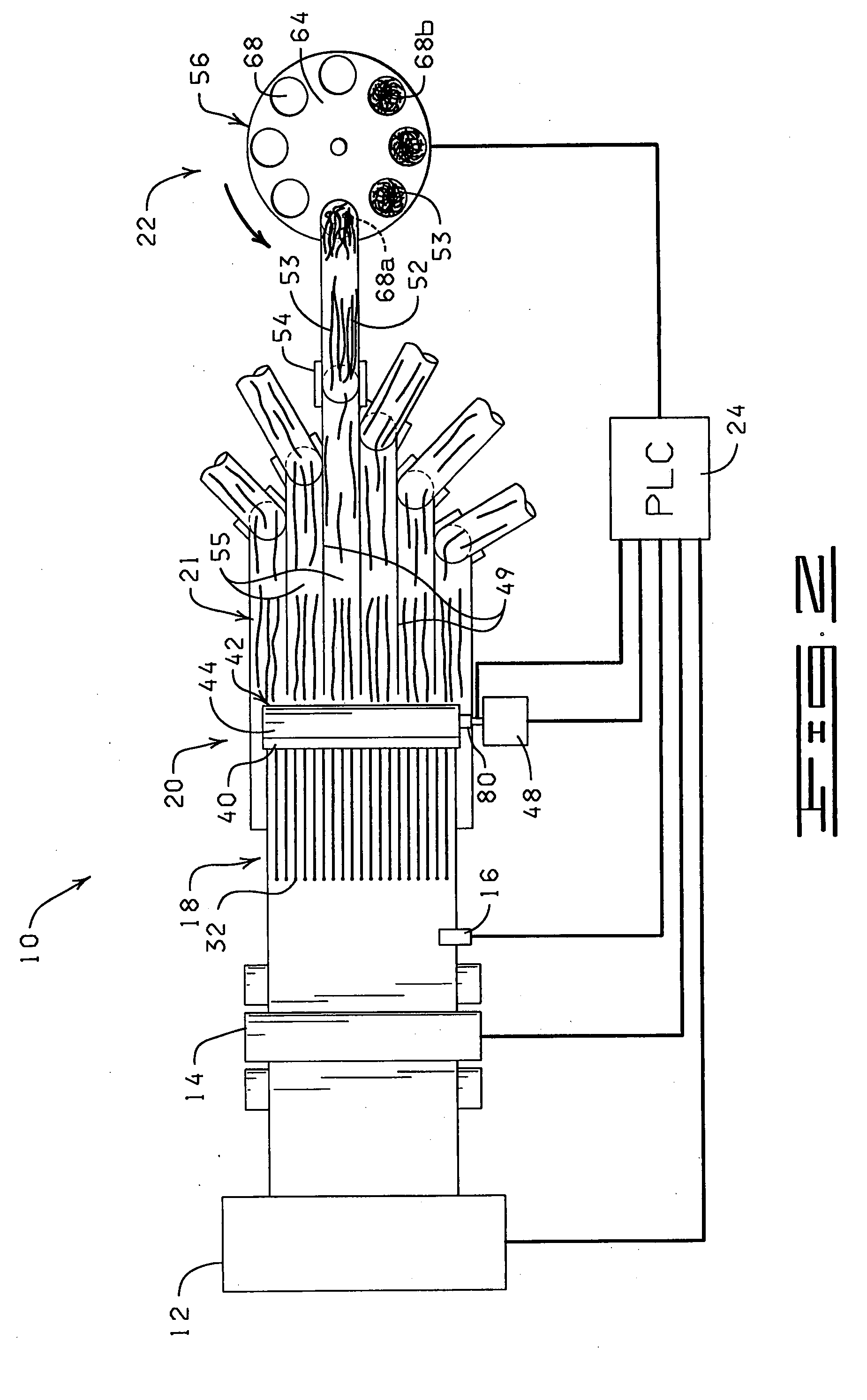

[0036] Referring to the drawings in general, and to FIG. 1 in particular, shown therein and designated by the general reference numeral 10 is an apparatus for making and bagging decorative grass, which includes an extruder 12, a godet 14, a thickness gauge 16, a slitter 18, a cutter 20, a divider 21, a plurality of bagging assemblies 22 and a programmable logic controller (PLC) 24.

[0037] The extruder 12 is any conventional machine which produces a continuous sheet of flexible material from resins, colorants, additives, anti-static agents and flame retardants. A suitable extruder is disclosed in U.S. Pat. No. 4,292,266 issued Sep. 29, 1981 to Weder et al., which is hereby incorporated by reference.

[0038] Similarly, the godet 14 may be any known device for feeding sheet material from one location to another. A typical godet includes a plurality of rollers which are rotatable to dispense a continuous web of sheet of flexible material 26. In the present invention, the godet 14 receive...

PUM

| Property | Measurement | Unit |

|---|---|---|

| cutting rate | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com