Rotary type container loader

A cartoner, rotary technology, applied in packaging, bottle packaging, packaging protection, etc., can solve problems such as rigid impact, and achieve the effect of reducing extrusion, good continuity and high production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The rotary box packing machine of the present invention will be further described below in conjunction with the accompanying drawings:

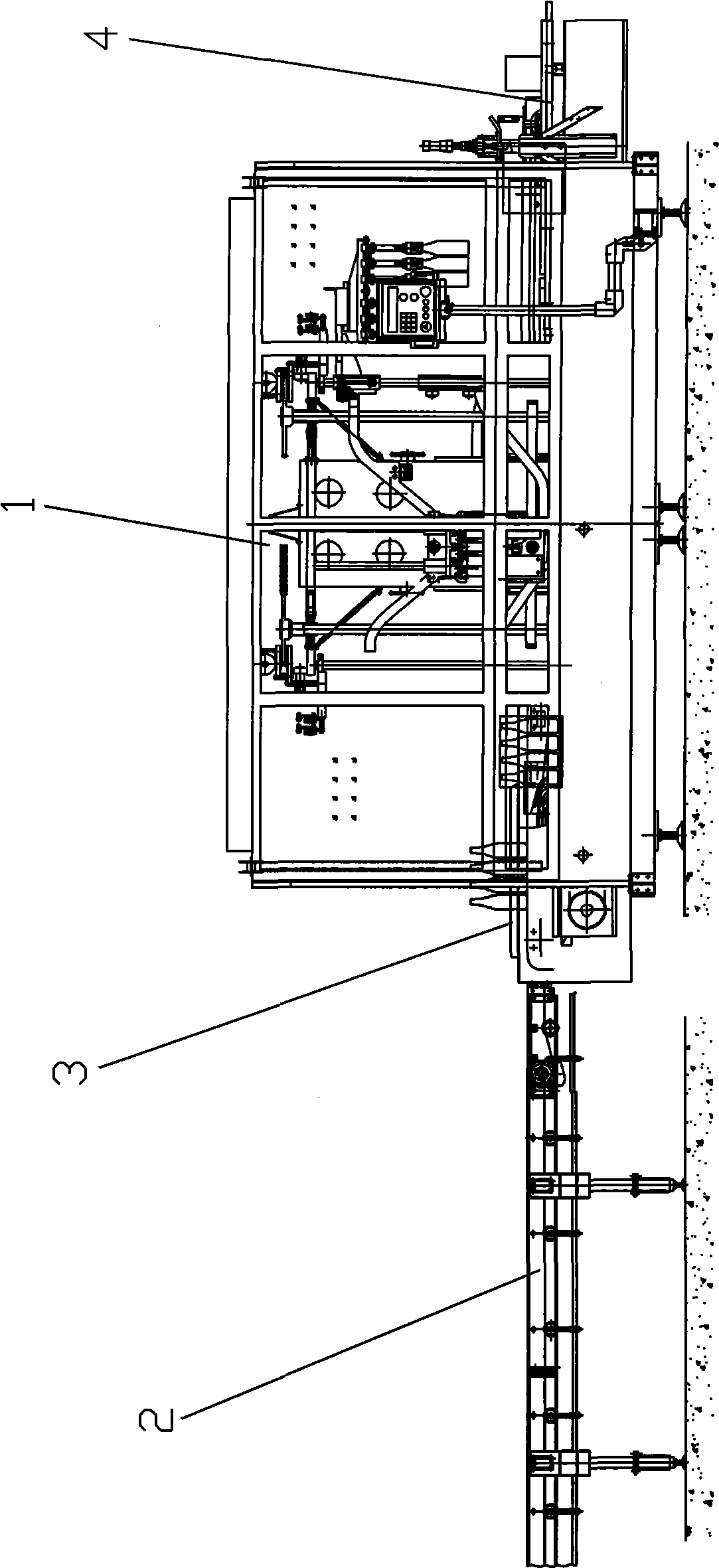

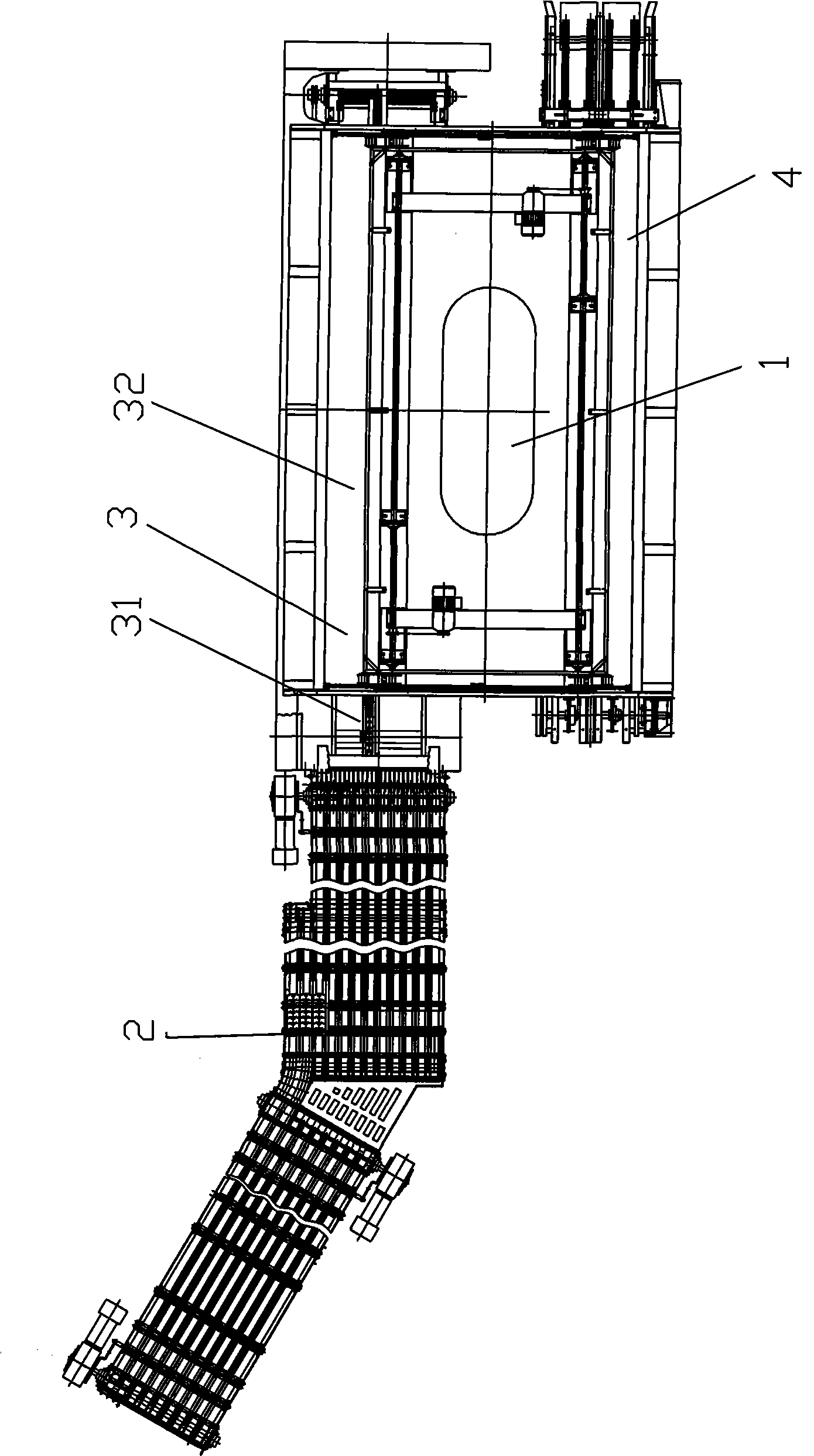

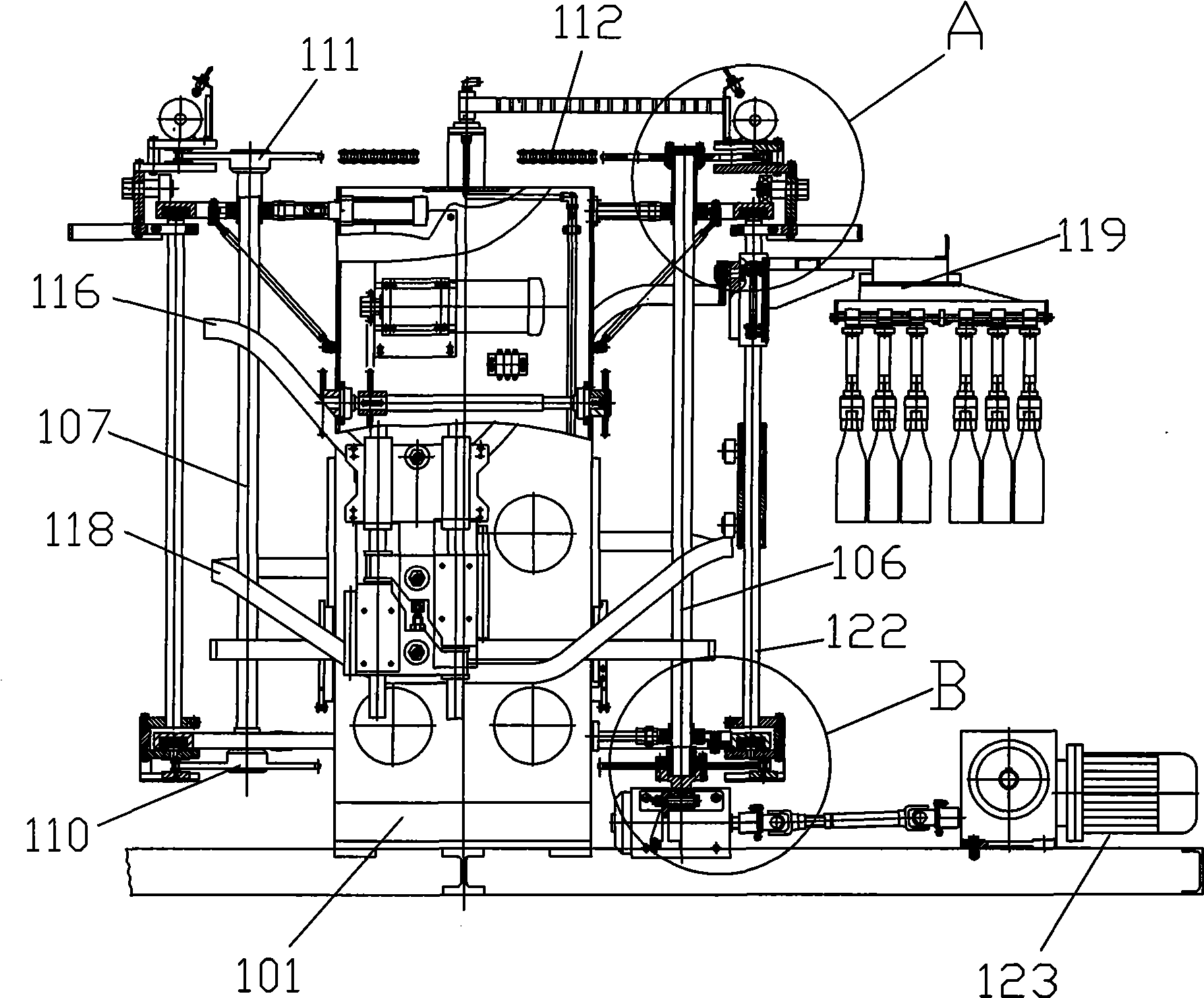

[0026] like Figure 1-6 A rotary cartoning machine shown includes a cartoning device 1, a carton conveying system 4, a bottle conveying system 2, a synchronous bottle conveying system 3 and a corresponding program control system and a servo motor drive system, and the carton conveying system 4 It is arranged on one side of the case packing device 1, and the bottle conveying system 2 and the synchronous bottle conveying system 3 are arranged on the other side of the case packing device 1. , the packing device 1 also includes a center of rotation system, and the center of rotation system includes a center tower 101, ring tracks 104, 105, guide support rods 122, bottle grabbing guide rails 116, bottle retaining guide rails 118, and box guide rails 117. The upper and lower parts of 101 are respectively provided with annular tracks 104, 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com