Patch equipment of joint motion sensor

A joint motion and sensor technology, applied in the field of sensors, can solve the problems of poor flipping form of double-sided patch equipment, and achieve the effect of fast efficiency and good coherence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

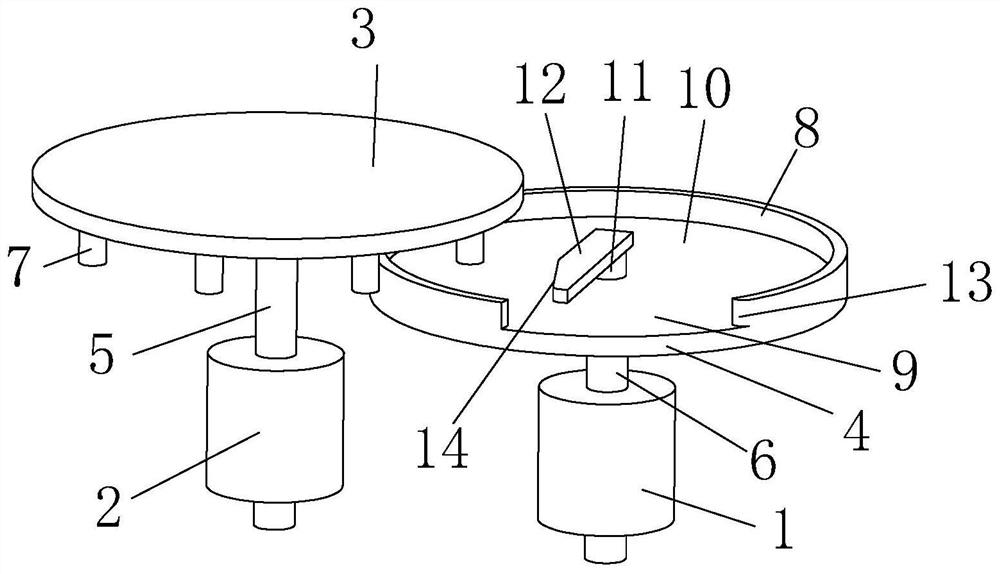

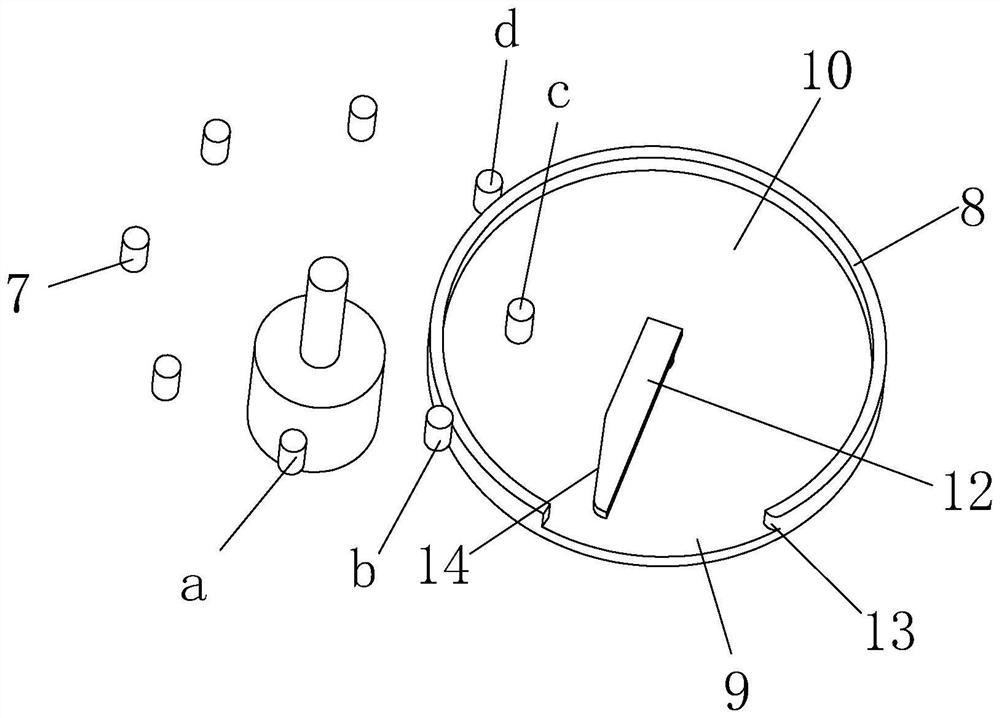

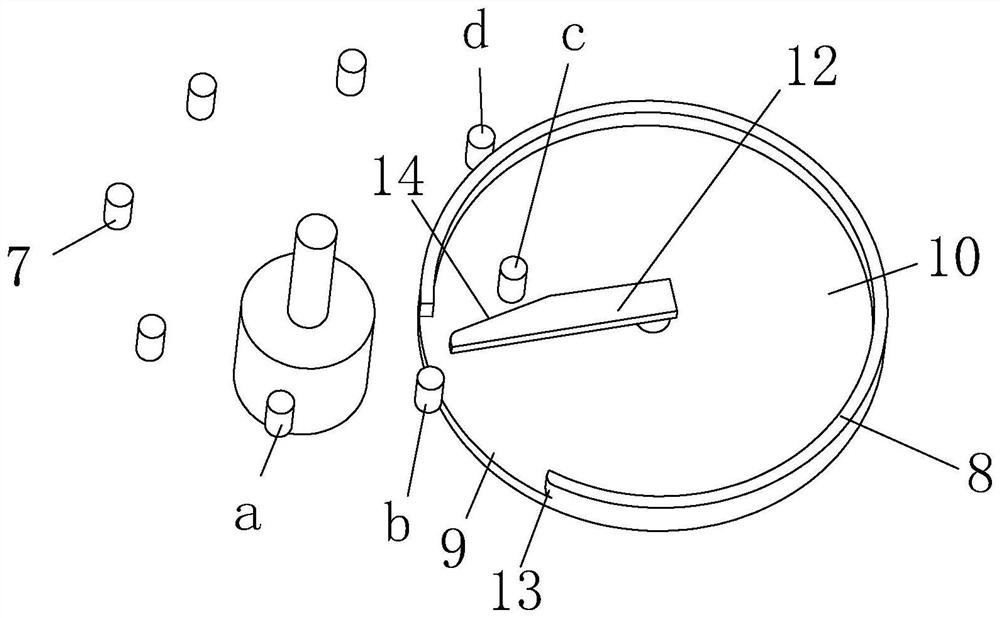

[0026] Such as Figure 8 As shown, the placement equipment of the joint motion sensor includes a station switching part for clamping the workpiece and intermittently transporting the workpiece in a circle, and a number of processing parts 17 for performing various processing operations on the workpiece (referring to the sensor). The processing parts 17 are evenly arranged around the circumference of the station switching part. The station switching part includes a switching bracket body 15 and a switching turntable 16 which is rotatably arranged on the switching bracket body 15. A plurality of clamps 18 are evenly arranged on the circumference of the switching turntable 16. The switching turntable 16 and the A periodic swi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com