Patents

Literature

477 results about "Secondary Packaging" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The process of placing a finished product within an additional container or closure system.

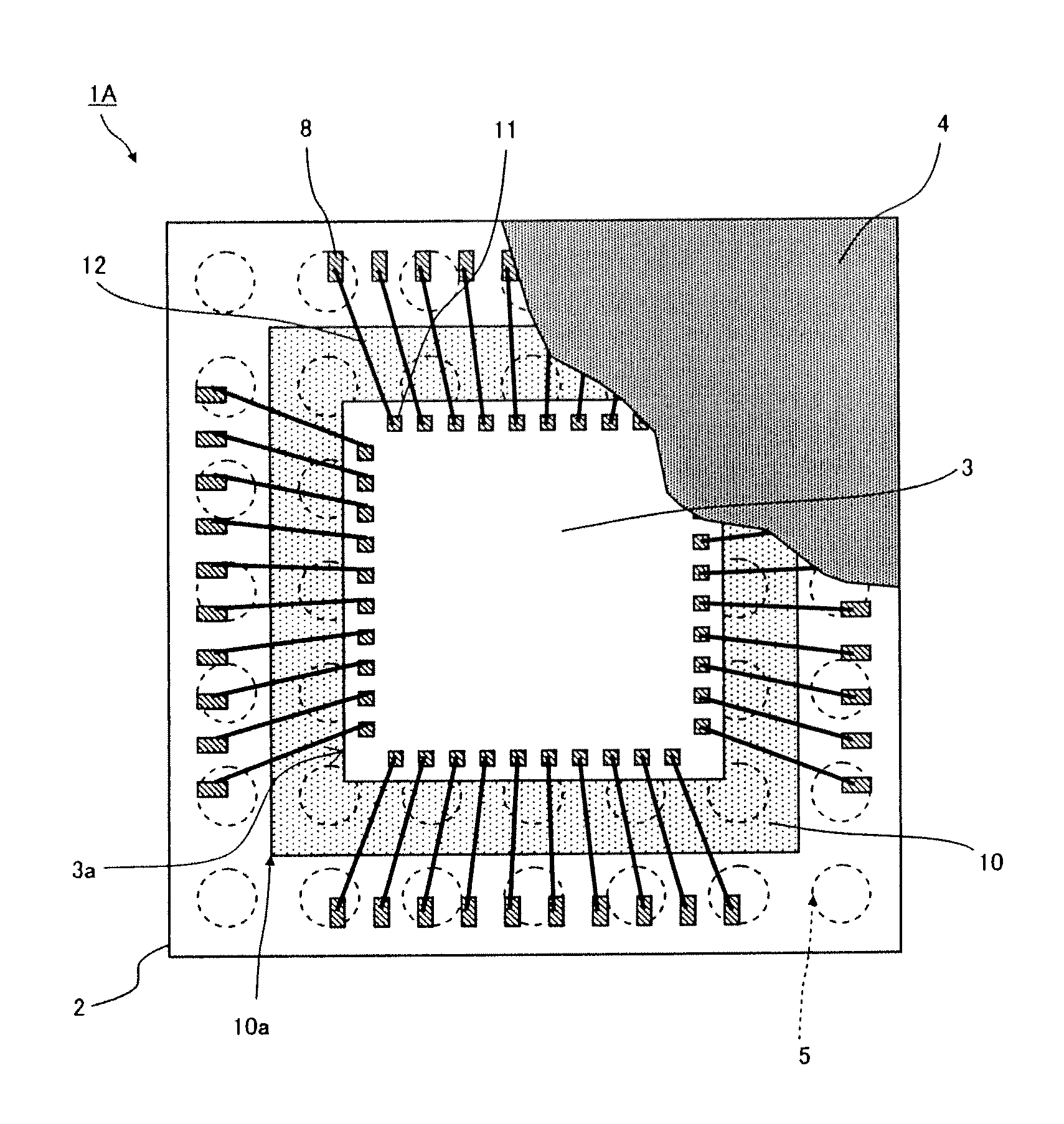

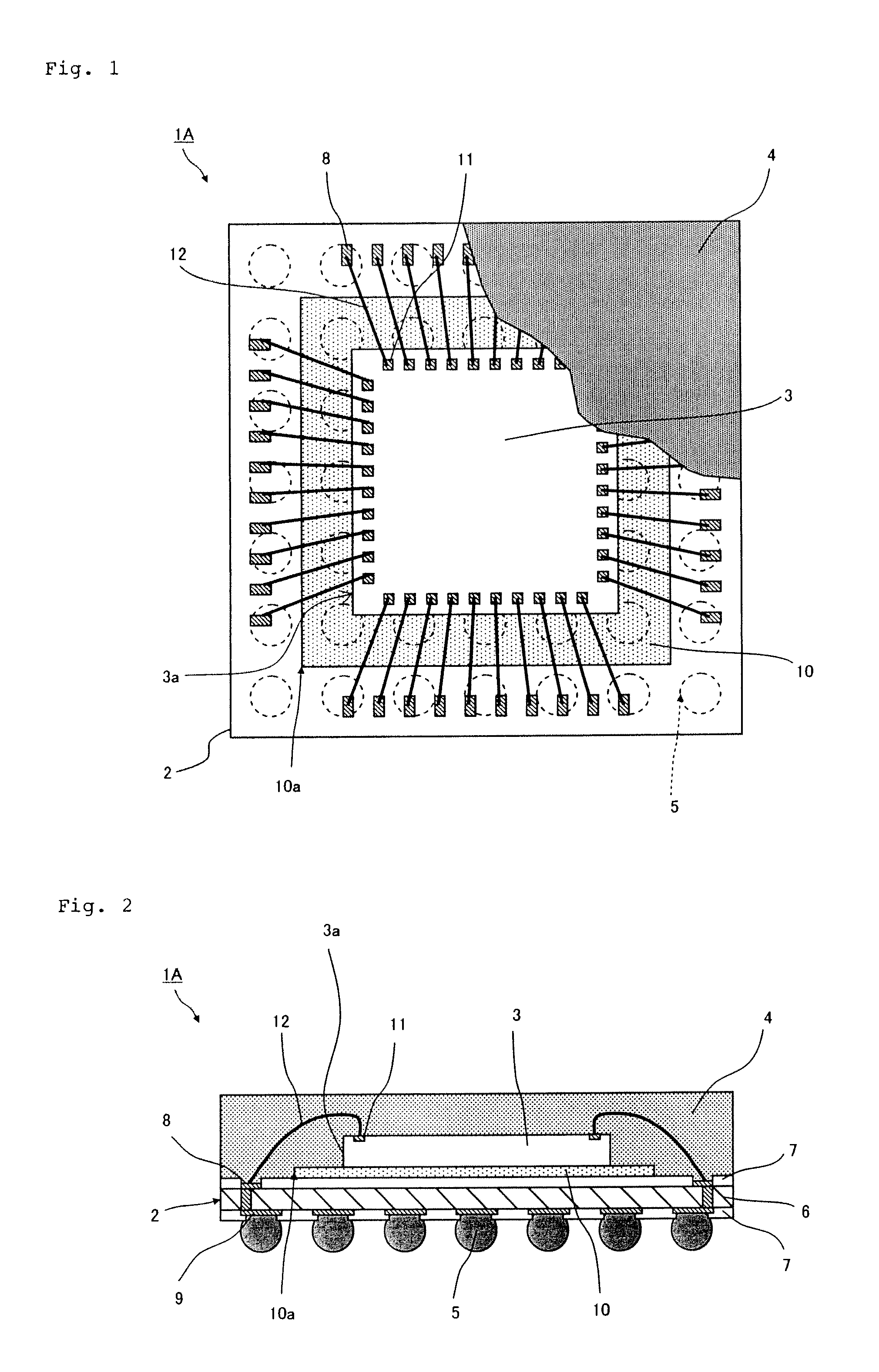

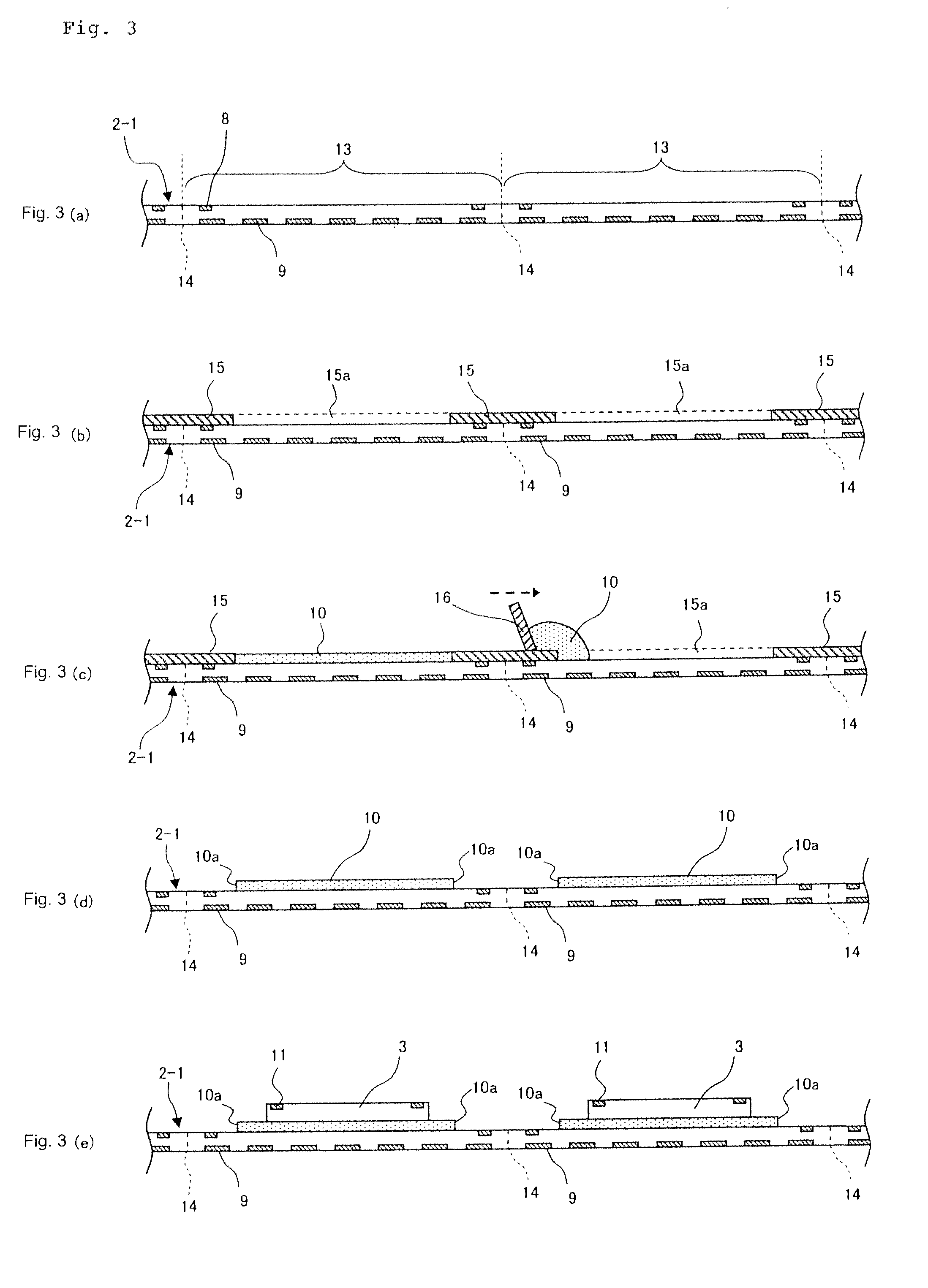

Semiconductor device

InactiveUS20120086111A1Reduce generationImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipEngineering

The present invention reduces the occurrence of fracture in external terminal connecting sections and improves the reliability of secondary packaging of a semiconductor device. Specifically, the present invention provides a semiconductor device including a wiring board, a semiconductor chip mounted on one surface of the wiring board via a bonding member, and external electrodes formed on the other surface of the wiring board and electrically connected to the semiconductor chip. In the semiconductor device, a peripheral end of the bonding member is arranged in a position where the peripheral end does not overlap the external electrodes.

Owner:PS4 LUXCO SARL

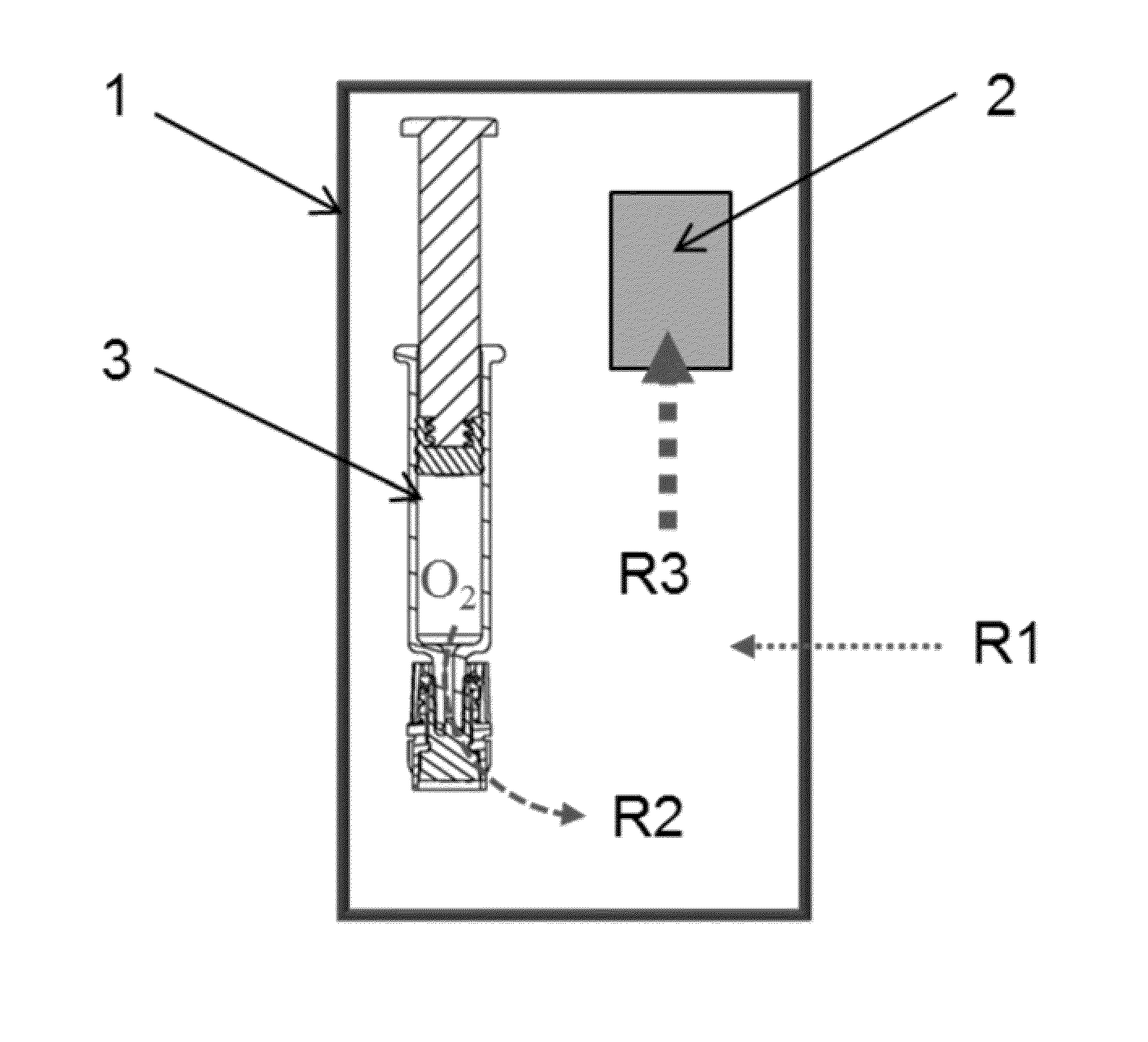

Packaging system for oxygen-sensitive drugs

ActiveUS20140262883A1Lower Level RequirementsOrganic active ingredientsFlexible coversOxygenPharmaceutical packaging

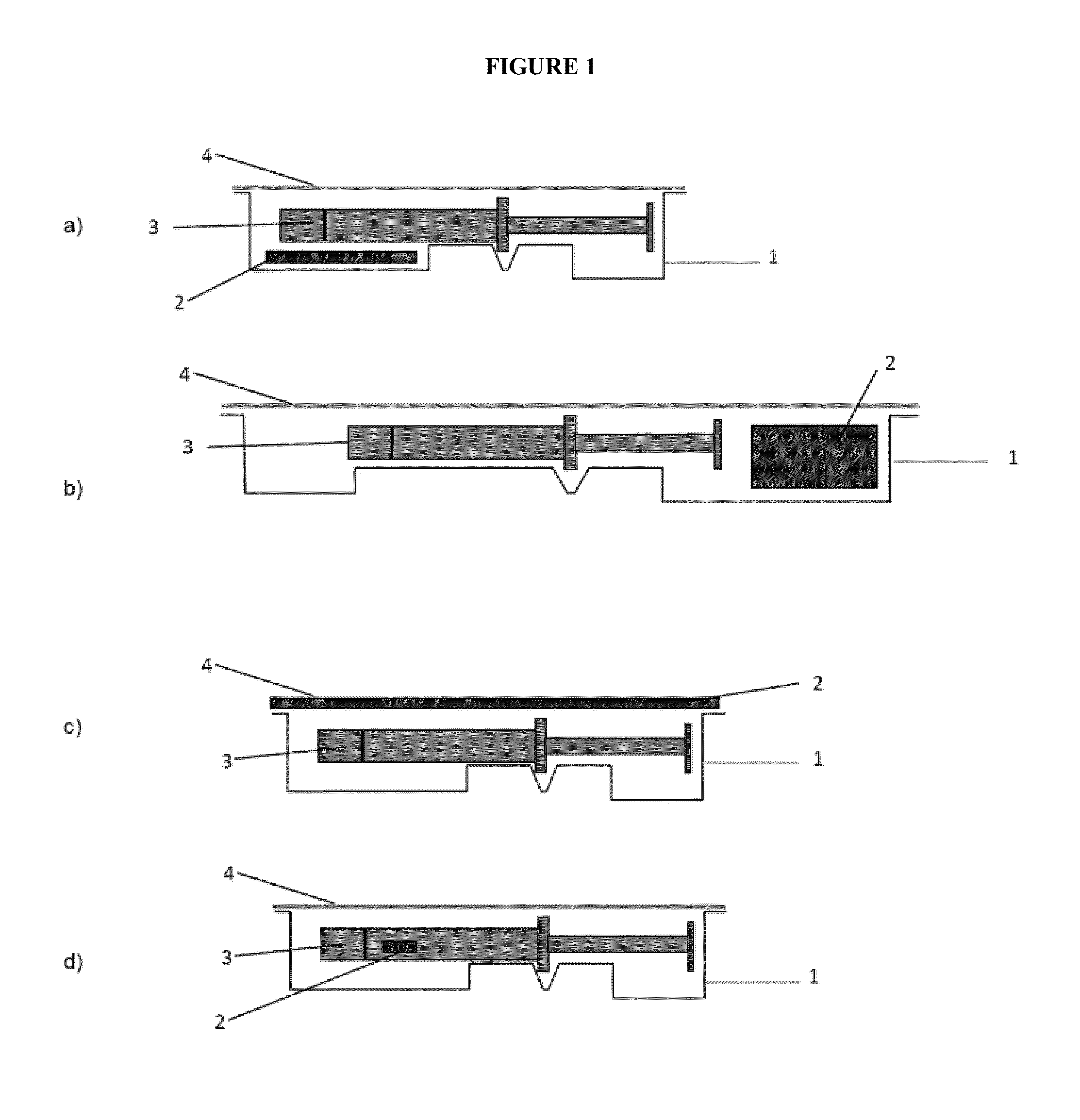

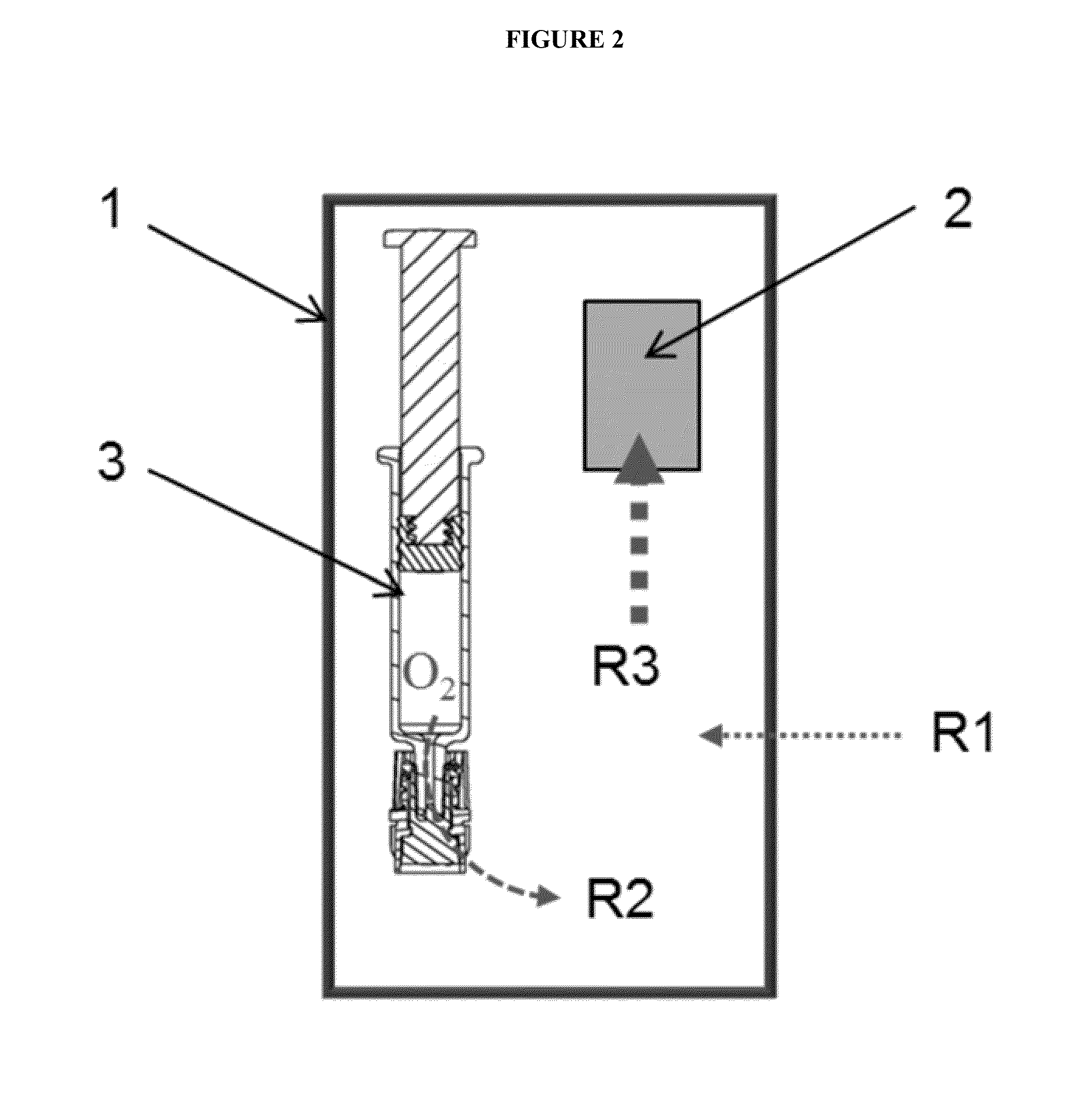

Described herein are pharmaceutical packaging systems which prevent oxidative degradation of oxygen-sensitive drugs, such systems including a primary packaging container with an oxygen permeable component, a secondary packaging with very low permeability to oxygen and an oxygen absorber.

Owner:FRESENIUS KABI DEUT GMBH

Flexible packaging composites

ActiveUS20090047525A1Increased durabilityImprove biodegradabilityWrappersDomestic containersFiberDyne

The flexible packaging composites include one or more mineral-containing layers with a bonding agent. The composite structure is used as a primary or secondary packaging container or insulating material. In addition to the mineral-containing layer, the composite can contain one or more non-mineral containing layers, including various combinations of extruded resins, cast or blown films, and fibers. The mineral-containing layer is substantially and continuously bonded to the other layers. The present invention is an unexpectedly unique and environmentally friendly composite structure containing mineral layers with bonding agents as a key component. The material is designed to form flexible and semi-rigid storage articles at equal or lower costs to prior art solutions while providing a mineral containing layer that is a very smooth, has comparatively high plasticity, and having a high quality printing surface not requiring Corona Treatment. The composite structure is used as a primary or secondary packaging container or insulating material. In addition to the mineral containing layer, the composite could contain various combinations of extruded resins, cast or blown films, and fibers. The mineral containing layer is substantially and continuously bonded to the other layers. The polymer, fiber, and mineral containing layers can be shaped, sized and manufactured such that the composite structure formed is subsequently machined to form a storage article. The composite structure has advantages including a high degree of pliability and flexibility, a minimum 37 dyne level on the surface of the mineral containing layer; a mineral containing layer that is highly 86 opaque, and has a bright, white printing surface that readily accepts coating and inks, therefore, rendering it highly attractive to consumers. Further, the composite structure has tensile strength, dead-fold, stiffness, and other characteristics that allow it to be readily machined into desired storage article forms and storage article closures, therefore, the material can be used for as a variety of food, consumer, industrial, anti-static, and commercial uses. Other mineral containing layer advantages include environmentally attractive features such photo-degradability, recyclability, compost-ability, and bio-degradability.

Owner:SMART PLANET TECH

Auxiliary material and method for preparing sliced dried beef by aid of auxiliary material

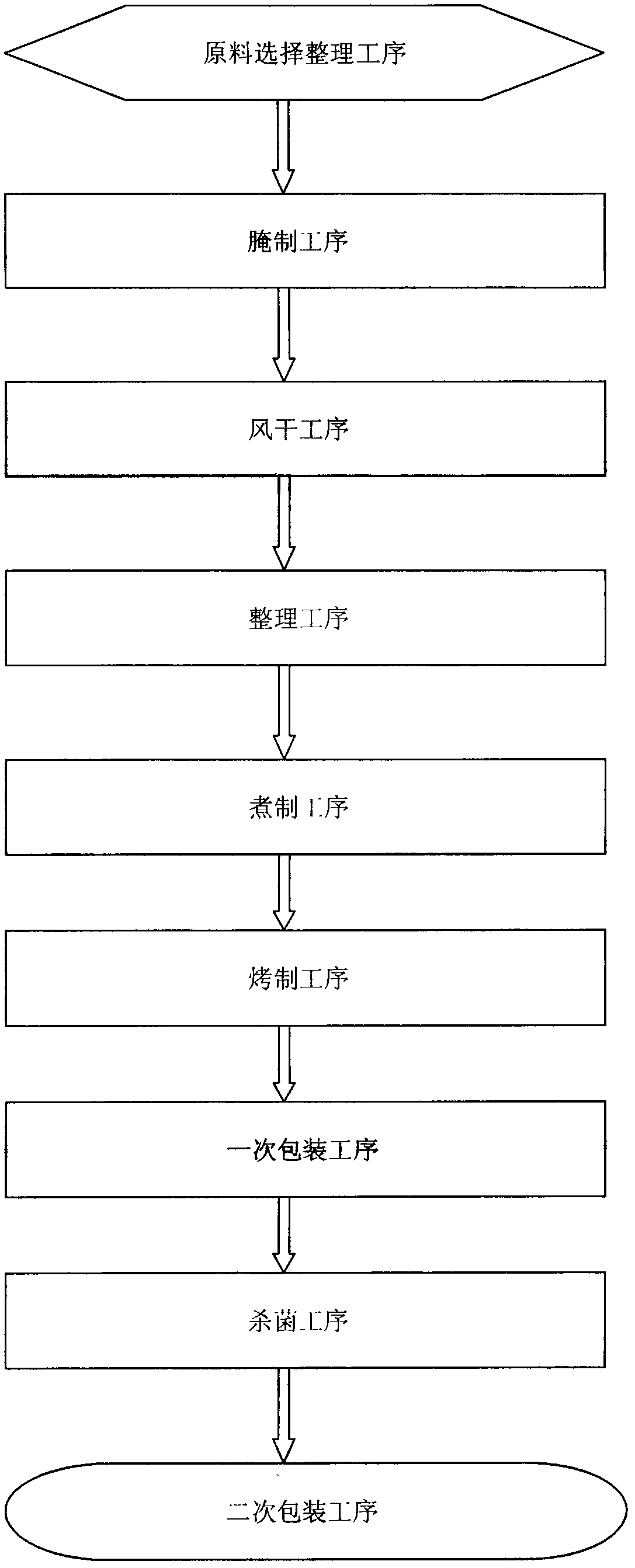

An auxiliary material and a method for preparing sliced dried beef by the aid of the auxiliary material relate to the technical field of meat processing. The auxiliary material comprises galangal, myrcia, anise, black pepper, wild pepper, spicy pepper, cinnamon, fennel, glycyrrhiza, myristica fragrans, amomum tsao-ko, lemongrass and chilli. The method for preparing sliced dried beef by the aid of the auxiliary material includes raw material selecting and neatening; a curing procedure; an air drying procedure; a neatening procedure; a cooking procedure; a baking procedure; a primary packaging procedure; a sterilizing procedure; and a secondary packaging procedure. A traditional production process including salting and natural air drying is combined with an industrial production process including microwave drying and sterilizing and high-temperature and high-pressure sterilization in the method for preparing the sliced dried beef, advantages of the traditional production process and the industrial production process are complemented, so that moistures of different layers of the sliced dried beef are distributed uniformly, production energy consumption is reduced effectively, color, fragrance, taste and nutritional substances of the sliced dried beef are kept well, a sterilizing effect is realized, storage and quality guarantee of the sliced dried beef are facilitated, a non-fried baking process is adopted, the original nutritional substances of beef are kept effectively, protein loss is reduced, coking is stopped, carbohydrate is avoided, and needs of different people groups are met to the greatest extent.

Owner:燕凤兰

Device and method for packaging product

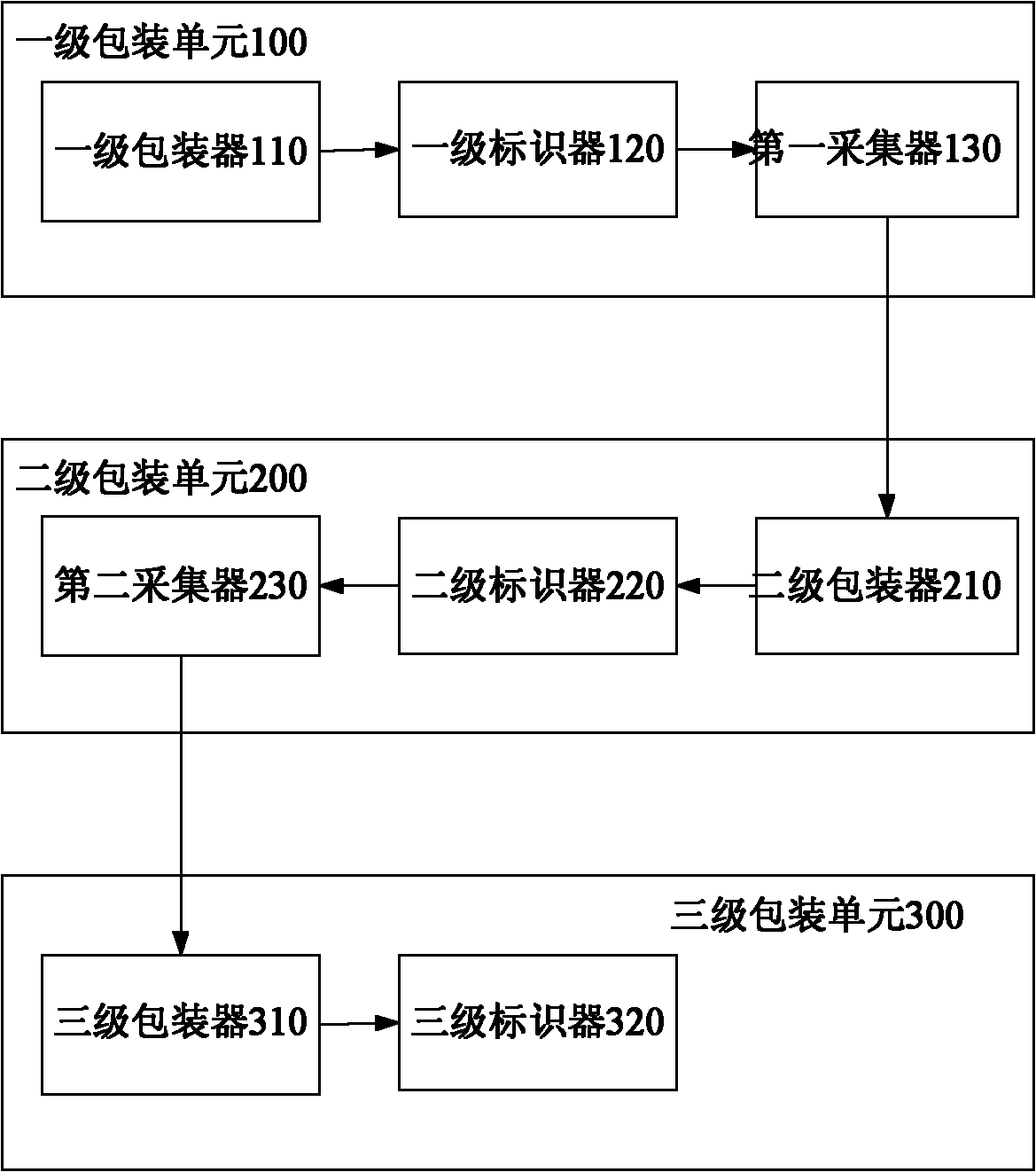

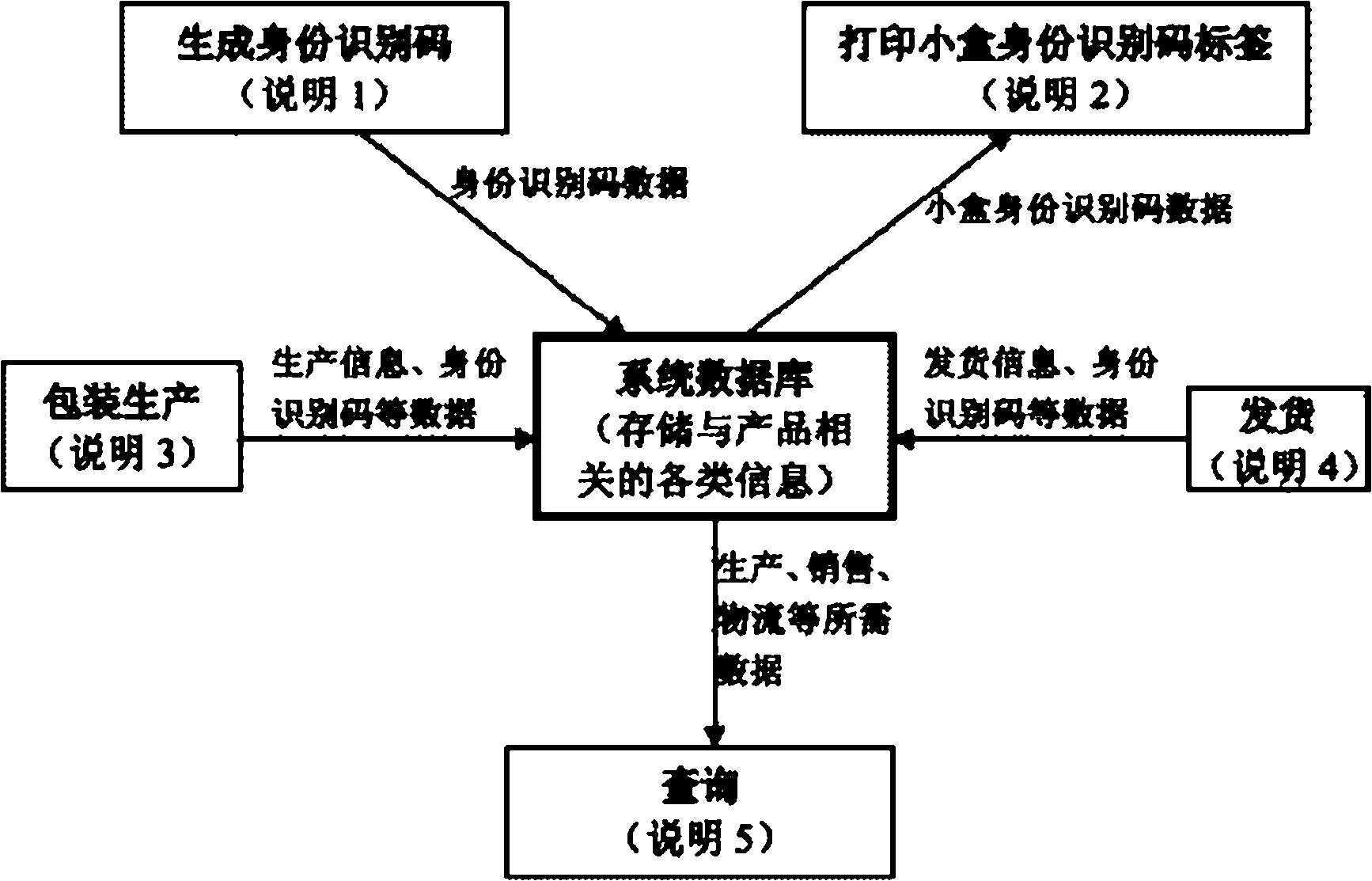

InactiveCN102730250AConvenient queryPackagingRecord carriers used with machinesWork flowComputer science

The invention discloses a device and a method for packaging a product. The device comprises a primary packaging unit and a secondary packaging unit, wherein the primary packaging unit comprises a primary packager, a primary marker, and a first collector; the primary packager is used for producing a primary package; the primary marker is used for attaching a primary mark on each primary package; the primary mark stores the information of the product attached with the primary package; the first collector is used for recording the quantity of generated primary marks; the first collector stores a preset numerical value, and generates an overflow signal when the quantity of the recorded primary marks achieves the preset numerical value; the secondary packaging unit comprises a secondary packager for receiving the overflow signal and generating a product with a secondary package according to each received overflow signal, and a secondary marker for attaching a secondary mark on each product with the secondary package, and the secondary mark comprises information of the product with the primary package in the product attached with the secondary package. According to the invention, material flow of the sold product can be tracked, and a work flow of the product can be reversely reviewed.

Owner:BEIJING HANMI PHARMA CO LTD

Preparation method of porous matrix composite phase change materials for recycling wide-temperature range afterheat

The invention belongs to the technical field of preparation of composite phase change materials, and particularly relates to a preparation method of porous matrix composite phase change materials for recycling wide-temperature range afterheat. The preparation method comprises the following steps: selecting porous materials (gamma-Al2O3, kaolin, laminated hydrotalcite, montmorillonoid and the like), which are good in heat stability, large in specific surface area, and easy to organically modify as matrix materials; and selecting different types of inorganic salts and multiple organic phase change materials as phase change core materials, and preparing a series of novel porous matrix composite phase change materials through a dispersion dipping method. The method has the advantages that 1) a simple and convenient method is developed to obtain a series of porous matrix composite phase change materials of which the phase change temperature changes in an echelon manner; 2) the prepared porous matrix composite phase change materials are capable of effectively immobilizing a phase change core material, the problems of leakage, corrosion and the like can be prevented, and the cost for secondary packaging is reduced; and 3) the method provided by the invention is simple in process, mild in reaction condition and suitable for large-scale industrial production.

Owner:UNIV OF SCI & TECH BEIJING

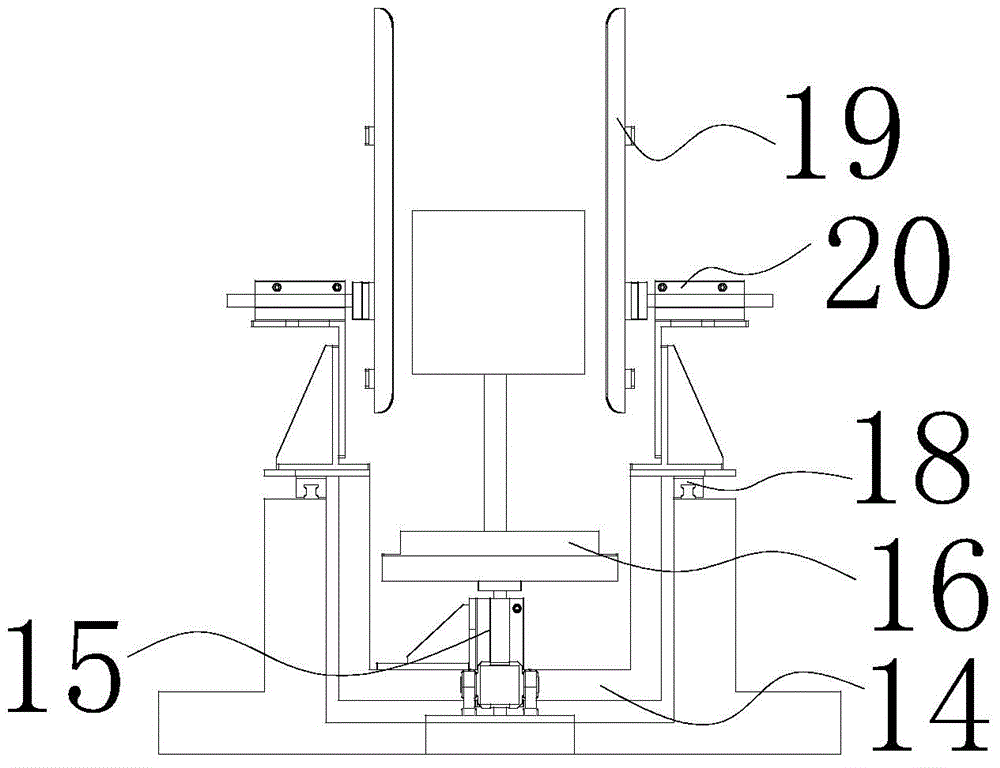

Secondary packing machine of woven bags

The invention relates to a packing machine of woven bags, in particular to a secondary packing machine of woven bags. The secondary packing machine of woven bags comprises a bag sewing conveying route, a bag preparing mechanism, a bag conveying mechanism, a bag clamping mechanism, a bag opening mechanism, a reversed M-side mechanism and a bag holding mechanism. The secondary packing mechanism of woven bags is fast in action, accurate in bag conveying position and bag clamping action and capable of greatly improving the discharging stability. The bag holding mechanism has the advantages of being compact in structure, fact and accurate in action, high in stability and the like and improves the working efficiency and the safety performance of the secondary packing machine. Meanwhile, the secondary packing machine is controlled by a closed-loop system, so that the working stability is greatly improved, consumed time on a bag opening and discharging station is shortened, and the packing efficiency of the packing machine of the woven bags is greatly improved.

Owner:ANHUI YUANHONG MACHINERY AUTOMATION

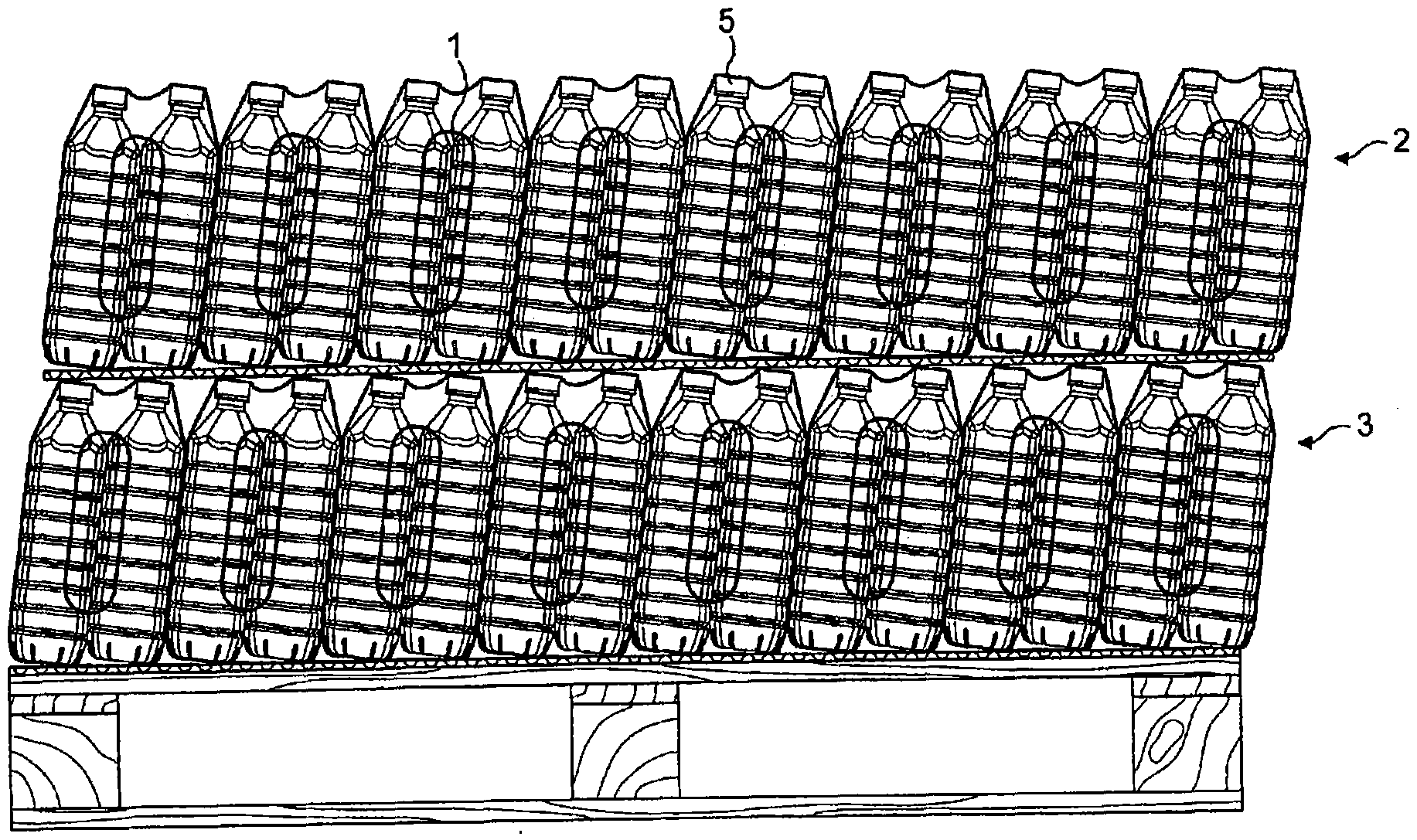

Device for overpacking at least one object into a batch

InactiveUS20100199599A1Reduce in sizeSmall sizePackaging bottlesIndividual articlesCartonEngineering

The invention relates to a device for overpacking a least one object using at least one blank of an appropriate material such as carton in order to form a batch. The device of the invention includes at least one carousel including at least one receptacle, and at least three work stations distributed about said carousel, said three stations including a work station with distribution means for distributing at least one blank of material to the at least one receptacle, a work station with loading means for loading said at least one object into said receptacle, and a work station with unloading means for unloading at least one assembled batch, wherein means for folding and / or closing the blank in order to form the overpacking are also provided.

Owner:MEADWESTVACO PACKAGING SYST LLC

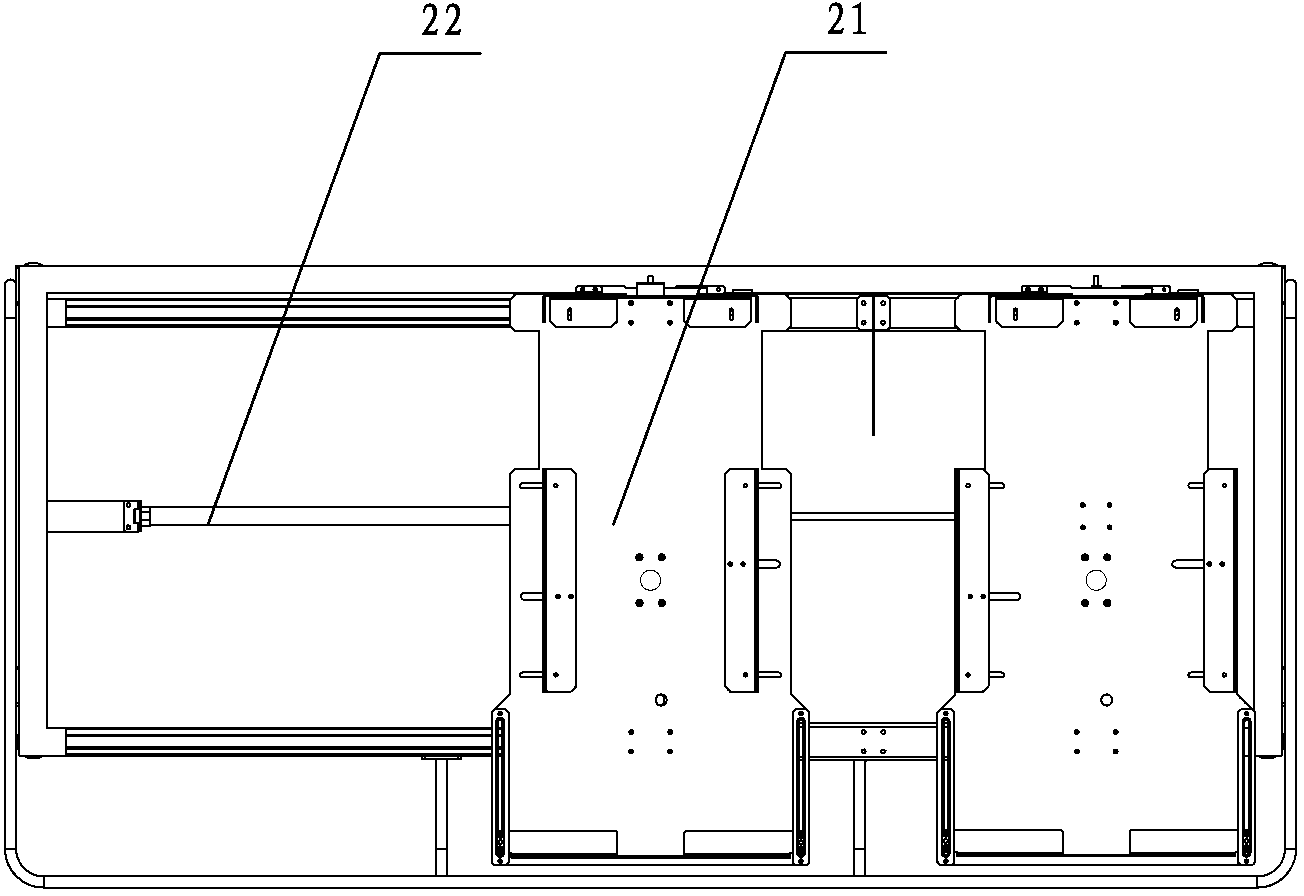

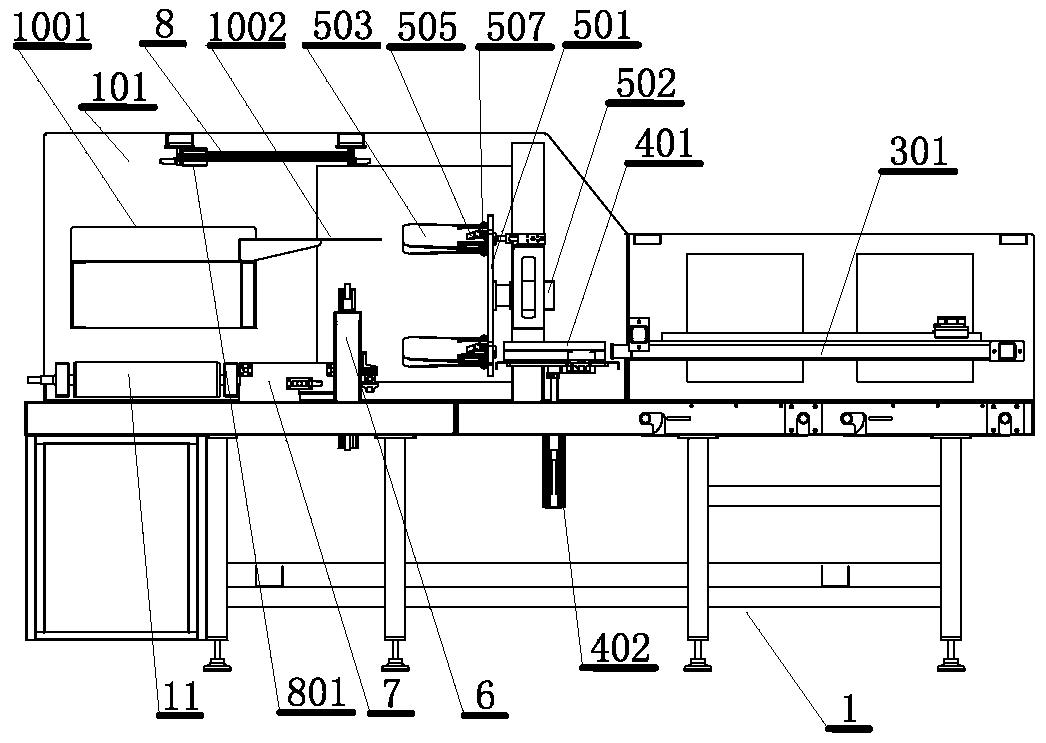

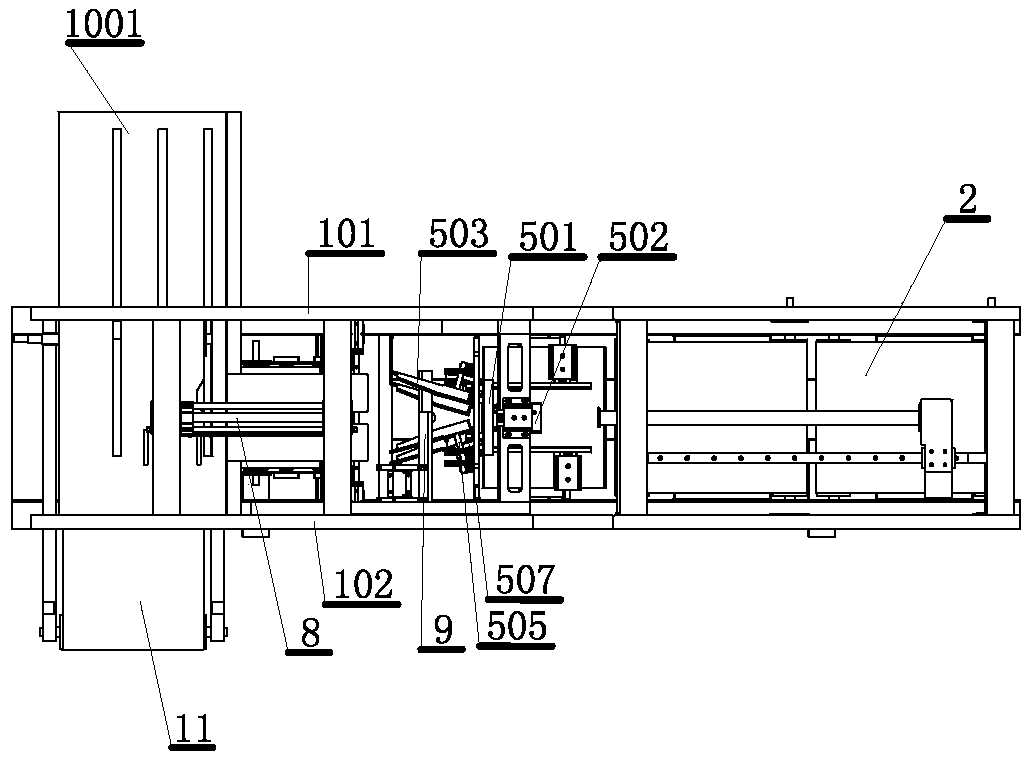

Lithium battery packaging, testing, sorting and edge-folding full automatic production line

ActiveCN105958104AHigh degree of automationIncrease productivityAssembling battery machinesFinal product manufactureProduction lineEngineering

The invention discloses a lithium battery packaging, testing, sorting and edge-folding full automatic production line. The full automatic production line comprises a secondary packaging part, a complementary packaging testing part and a cutting-folding-ironing part, wherein the secondary packaging part, the complementary packaging testing part and the cutting-folding-ironing part are arranged in sequence from one side to the other side; a discharging stay wire is arranged in front of the complementary packaging testing part and the cutting-folding-ironing part; the secondary packaging part comprises a loading station, an electric core positioning mechanism, a lead screw conveying mechanism, a packaging mechanism, an electrolyte recovering mechanism, a pre-trimming mechanism and a first manipulator reclaiming mechanism; the complementary packaging testing part comprises a secondary positioning mechanism, a complementary packaging mechanism and a testing mechanism; a second manipulator reclaiming mechanism is arranged behind the complementary packaging mechanism; and the cutting-folding-ironing part comprises a feeding positioning mechanism, a trimming mechanism, an edge-folding mechanism, an edge ironing mechanism and a third manipulator reclaiming mechanism. Through adoption of the full automatic production line, vacuum air exhausting, puncturing, electrolyte sucking, sealing, pre-trimming, edge voltage testing, fine trimming, double edge folding and edge-ironing reshaping are integrated.

Owner:东营慧达科技创业服务有限公司

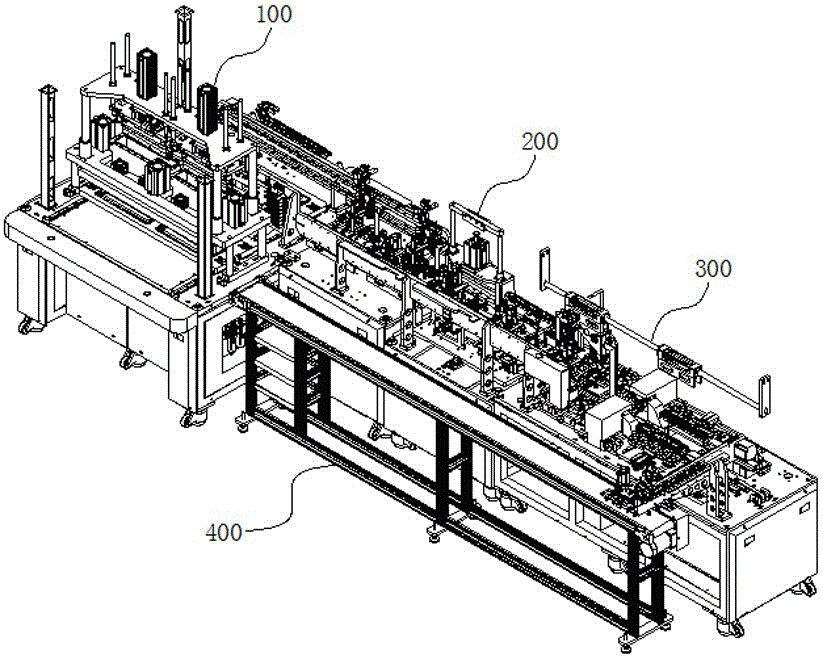

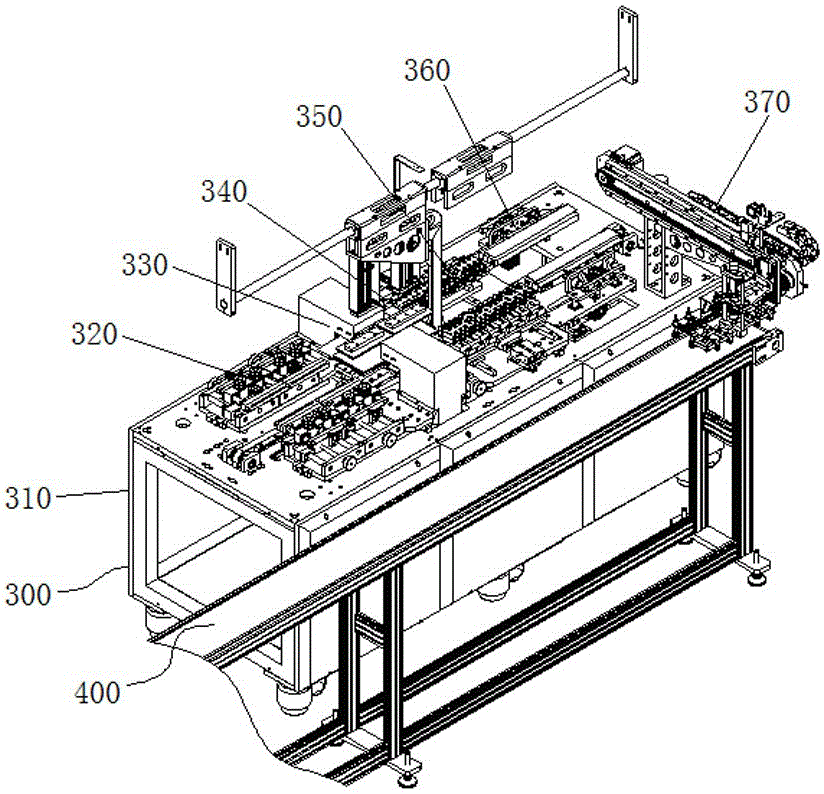

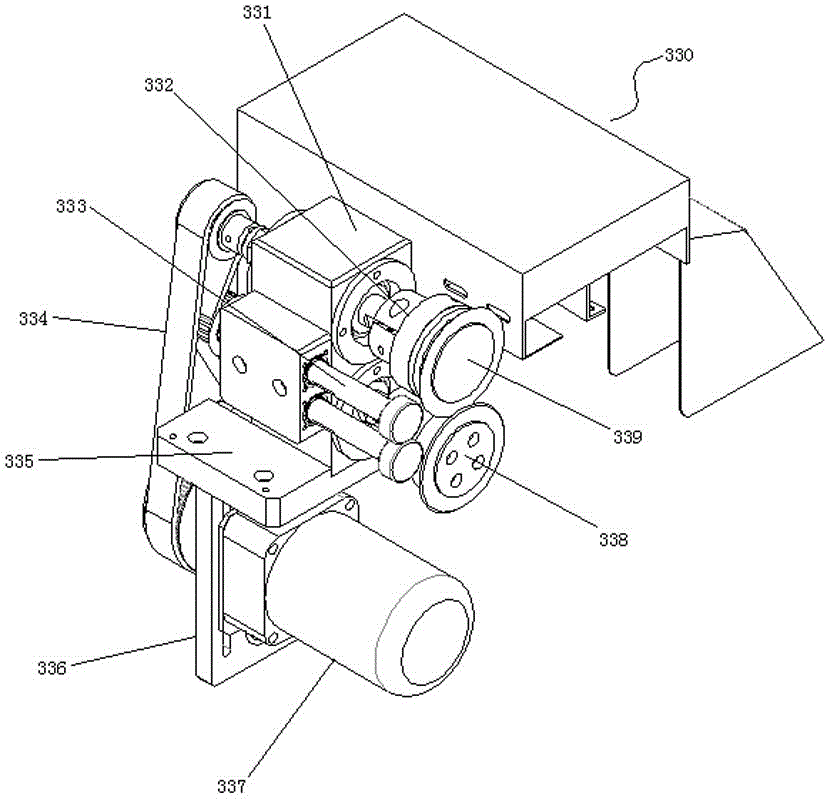

Package bag secondary automatic packaging system

ActiveCN103979144AImprove stabilityReduce labor intensityWrapper twisting/gatheringSecondary PackagingPackaging machine

The invention discloses a package bag secondary automatic packaging system, which comprises a secondary packaging automatic bag arranging mechanism, a secondary packing machine bag collecting cabin, a secondary packaging machine bag taking and bag opening mechanism, a secondary packaging machine bag storing mechanism, a secondary packaging machine bag supporting mechanism, a secondary packaging machine bag opening shaping and hot sealing mechanism and a secondary packaging machine bag dragging and bag holding mechanism. The package bag secondary automatic packaging system has the advantages that the automatic bag arranging, bag taking and bag conveying positions are accurate, the packaging stability is greatly improved, and the whole packaging system adopts a plurality of sensors, so the work efficiency is greatly improved, the work intensity of workers is reduced, and in addition, the installation performance is greatly enhanced.

Owner:HEFEI SANGUAN PACKING SCI & TECH

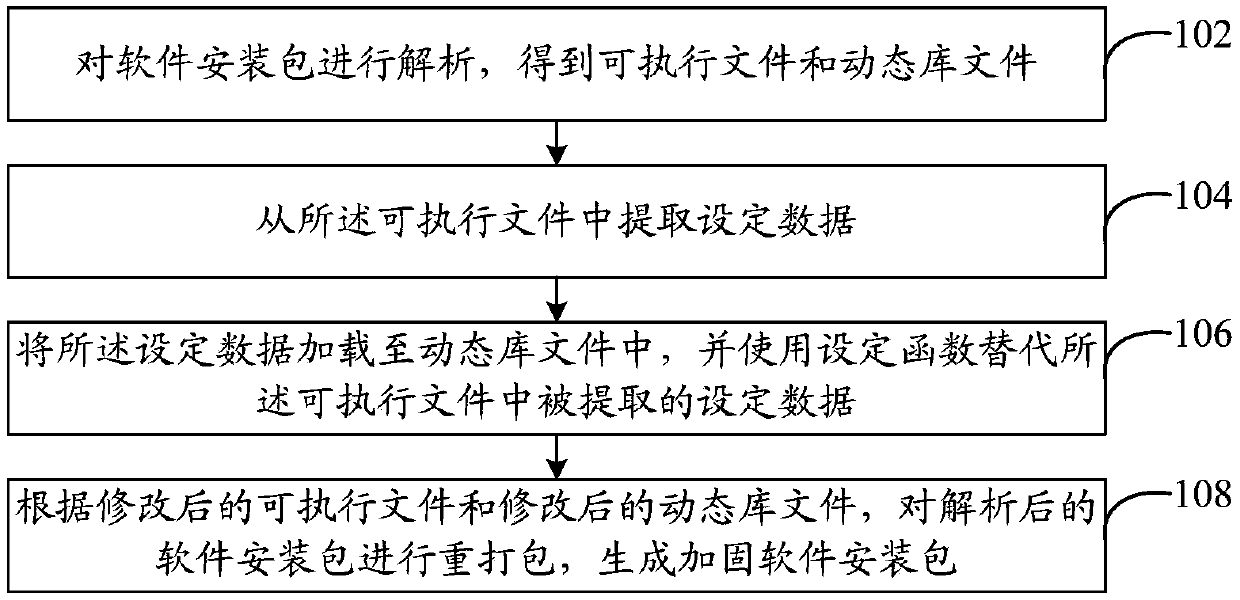

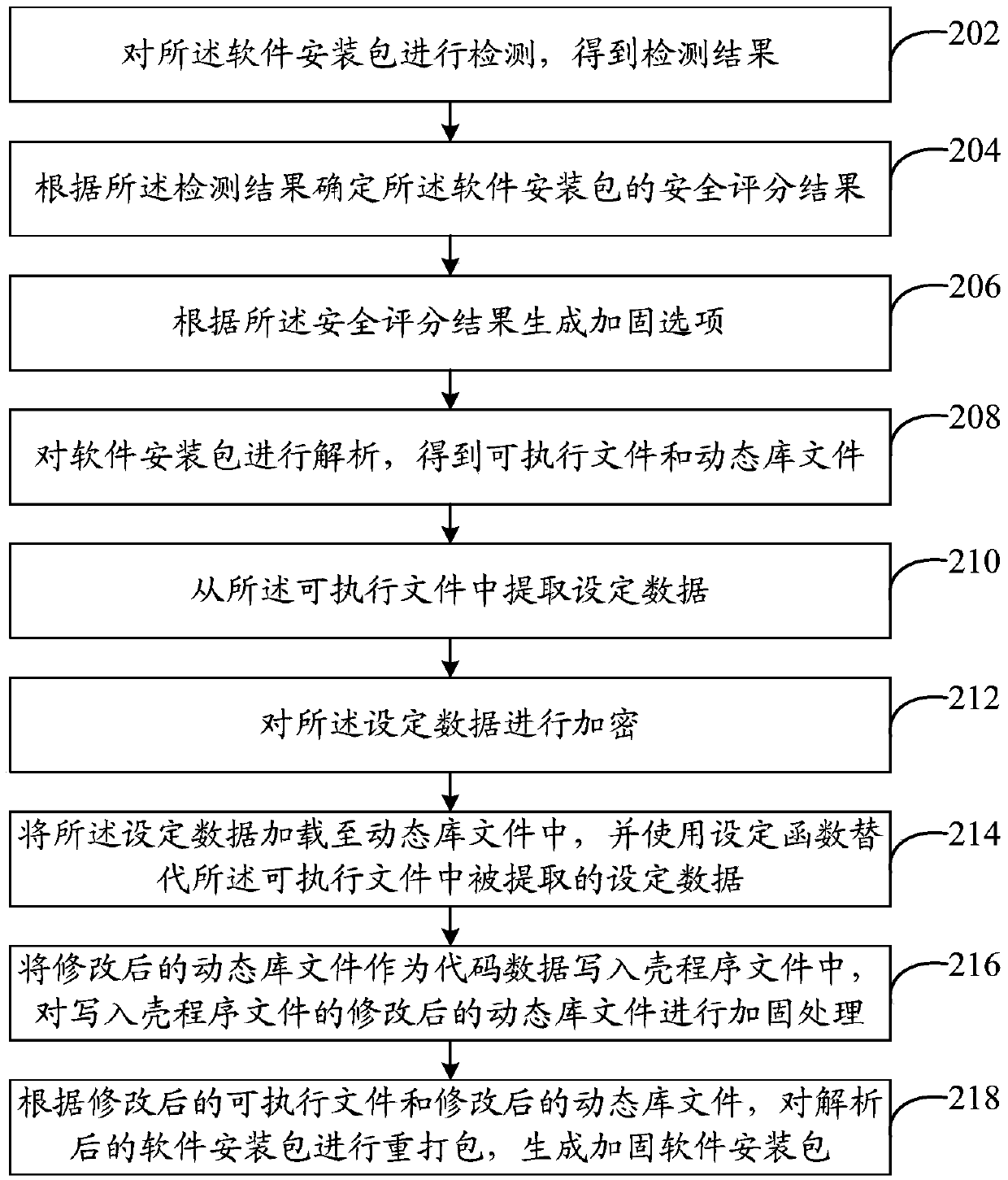

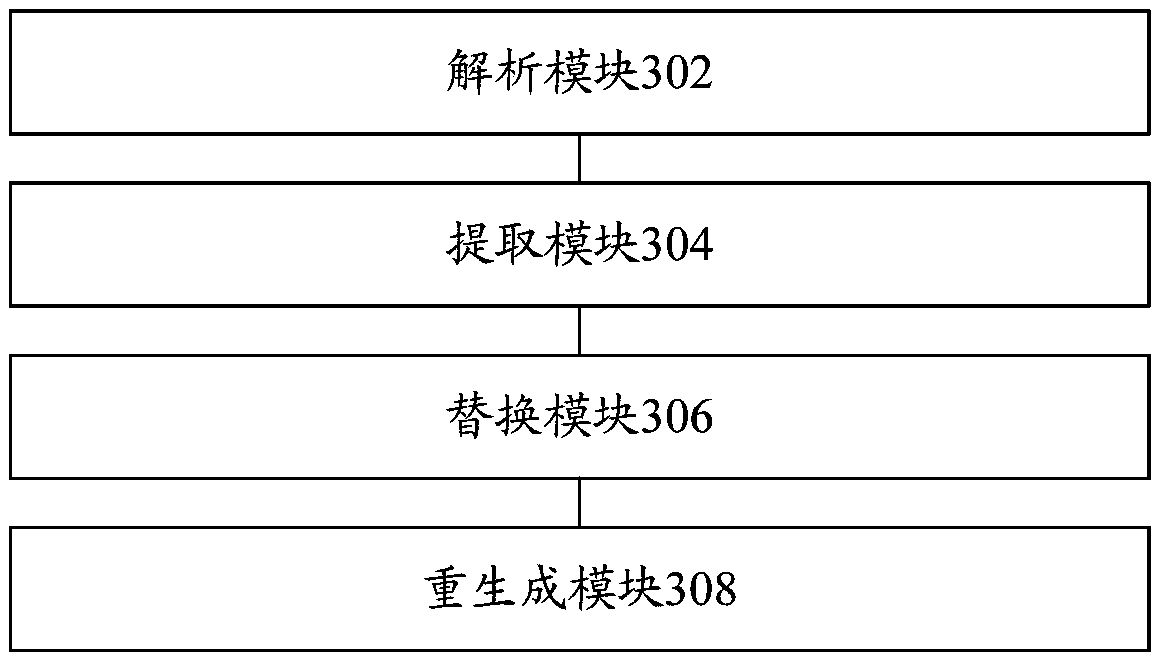

Reinforcement and protection method and system for software installation package

InactiveCN105512521AEnsure safetyImprove security levelProgram/content distribution protectionSoftware engineeringReverse engineering

The invention discloses a reinforcement and protection method and system for a software installation package. The method comprises the steps that the software installation package is analyzed to obtain an executable file and a dynamic library file; setting data is extracted from the executable file; the setting data is loaded into the dynamic library file, a setting function is used for replacing the setting data extracted from the executable file, wherein the setting function is used for indicating the loading position of the setting data in the dynamic library file; according to the modified executable file and the modified dynamic library file, the analyzed software installation package is packaged again, and the reinforced software installation package is generated. According to the reinforcement and protection method and system for the software installation package, the safety of the software installation package is improved, and the difficulty of reverse engineering, decompilation, debugging, cracking and / or secondary packaging of the software installation package is increased.

Owner:BEIJING QIHOO TECH CO LTD +1

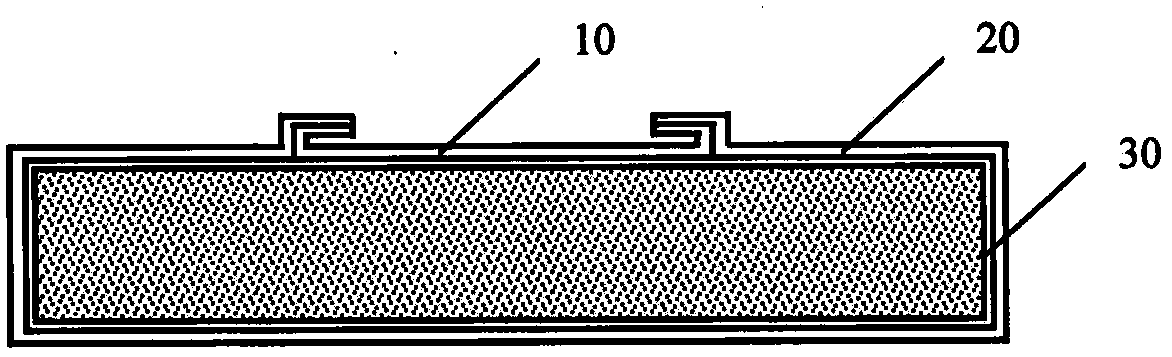

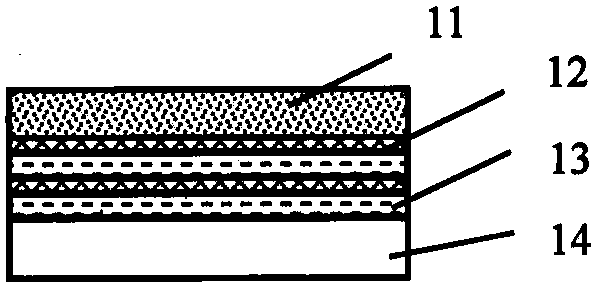

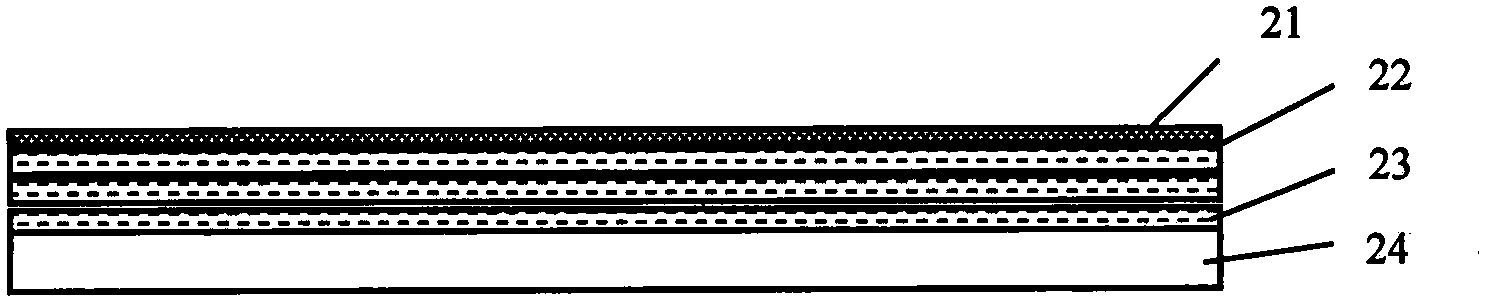

Low-thermal-bridge vacuum insulated panel

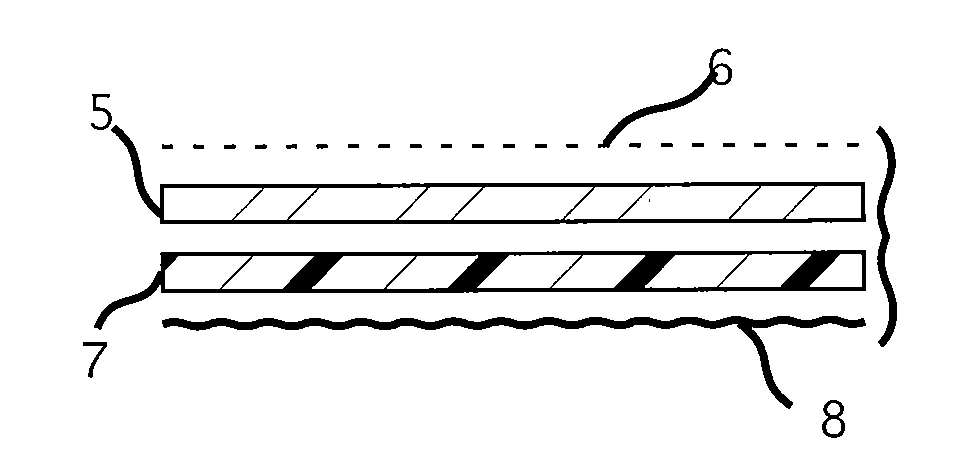

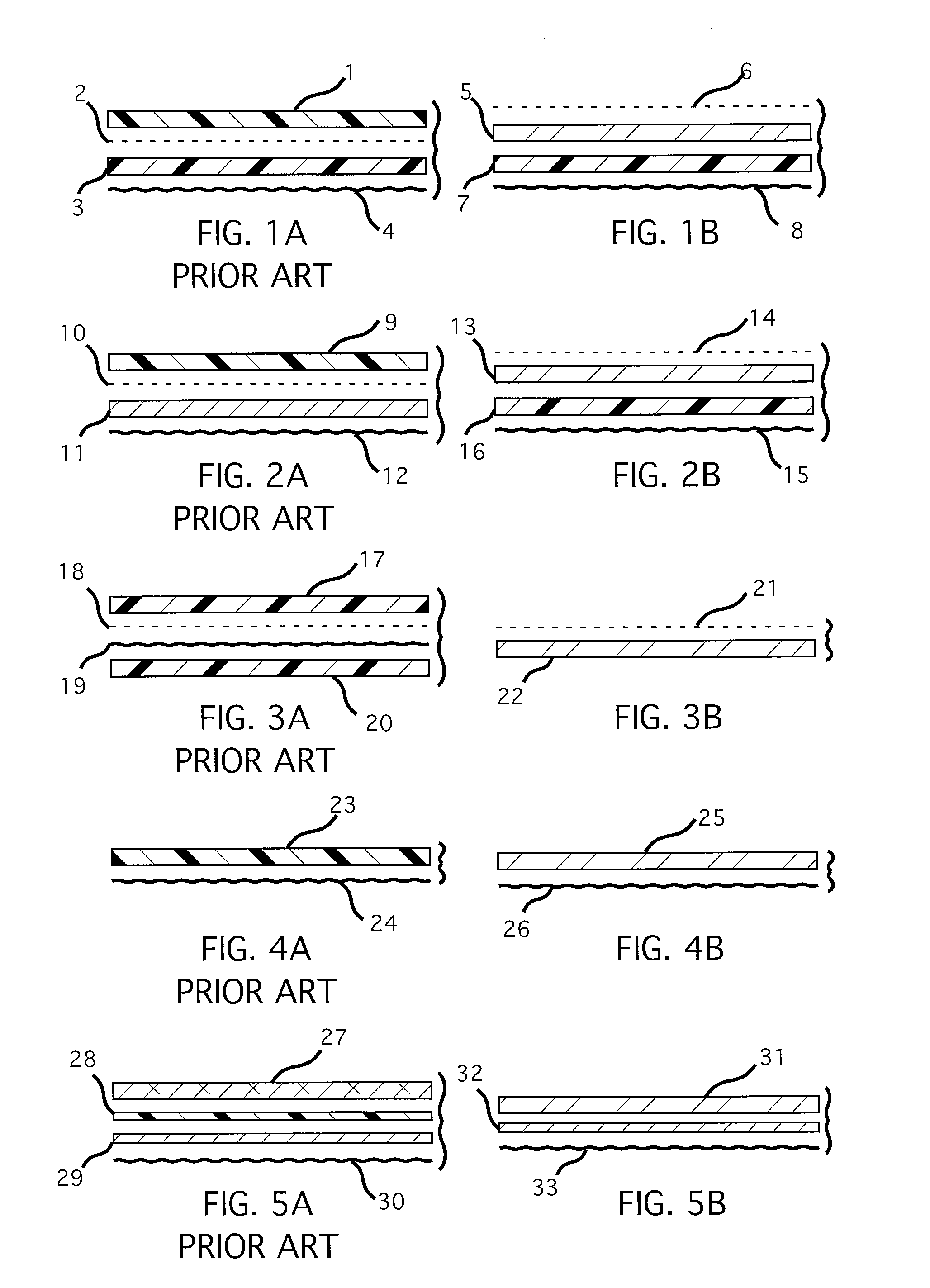

ActiveCN104295861AReduce surface thermal bridgingReduce weightThermal insulationSynthetic resin layered productsPolyesterFiber

Disclosed is a low-thermal-bridge vacuum insulated panel. The vacuum insulated panel comprises an upper edge sealing structure and a lower edge sealing structure and are formed by packaging of two high-resistance membranes. The membrane with the large area, namely a main packaging membrane, wraps the periphery of a core. The membrane with the small area, namely a secondary packaging membrane, locally covers the upper or the lower packaging surface of the vacuum insulated panel. The main packaging membrane comprises a plurality of aluminum membrane layers. The thickness of a single aluminum membrane layer is 20-100 nanometers, the outermost layer is of amorphous-state polyamide (PA) or carbon-fiber gridding cloth of 10-15 micrometers, the innermost layer is of a polyethylene (PE) membrane of 50 micrometers, and two to four layers of polyethylene terephthalate (PET) and aluminum membranes are contained in the middle. The thickness of a single polyethylene terephthalate (PET) layer is 15-20 micrometers. The outermost layer of the secondary packaging membrane is of a nanometer PET membrane, inflame-retardant nanometer particles in a nanometer size are evenly distributed in a PET base body, and the layer thickness is 30-50 micrometers; the innermost layer is of a polyethylene (PE) membrane of 50 micrometers, one to three layers of polypropylene (PP) and polyethylene terephthalate (PET) are contained in the middle, and the thickness of the single layer is 12-24 micrometers. The vacuum insulated panel has low surface thermal-bridge effect and good heat insulation effect.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

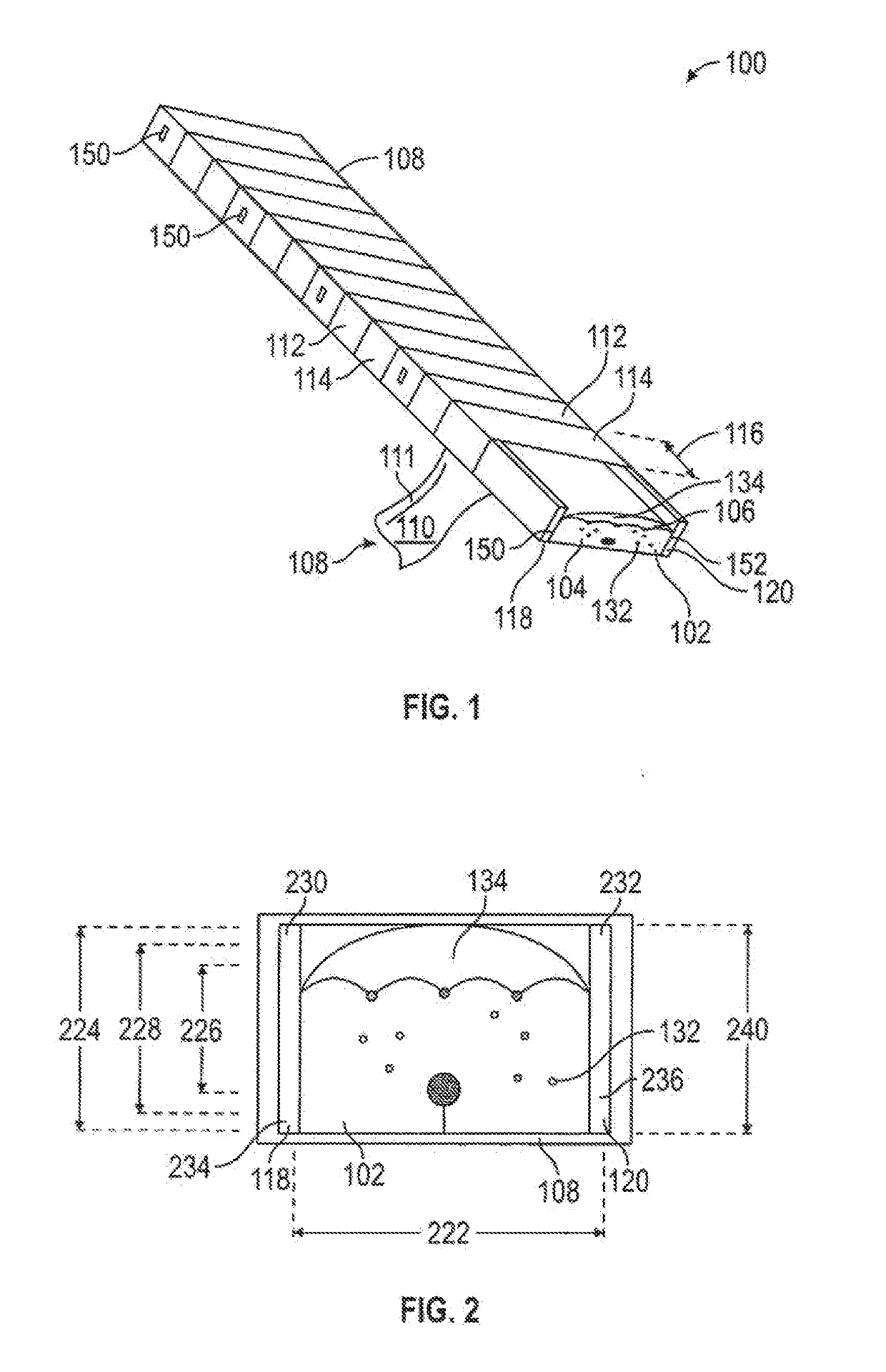

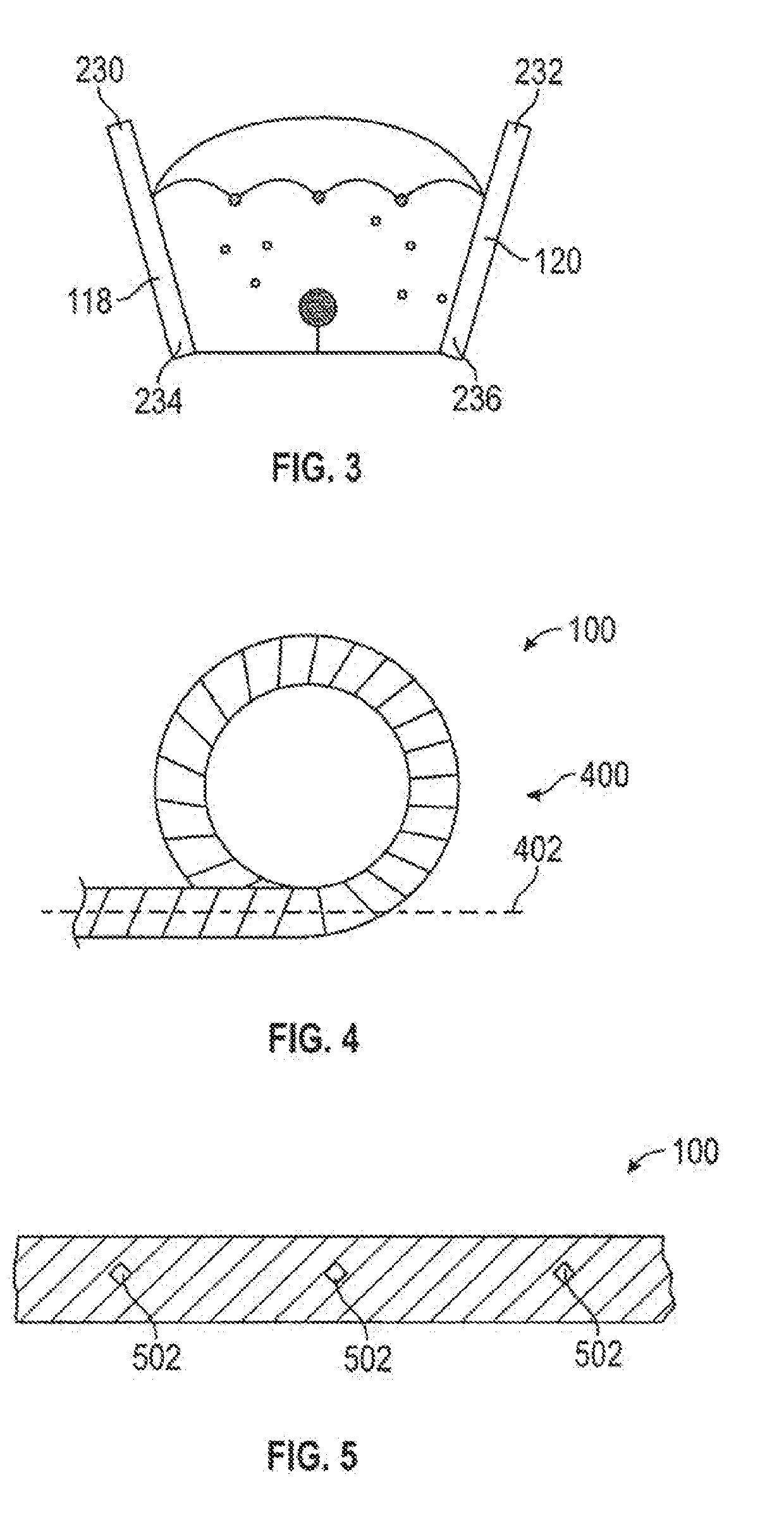

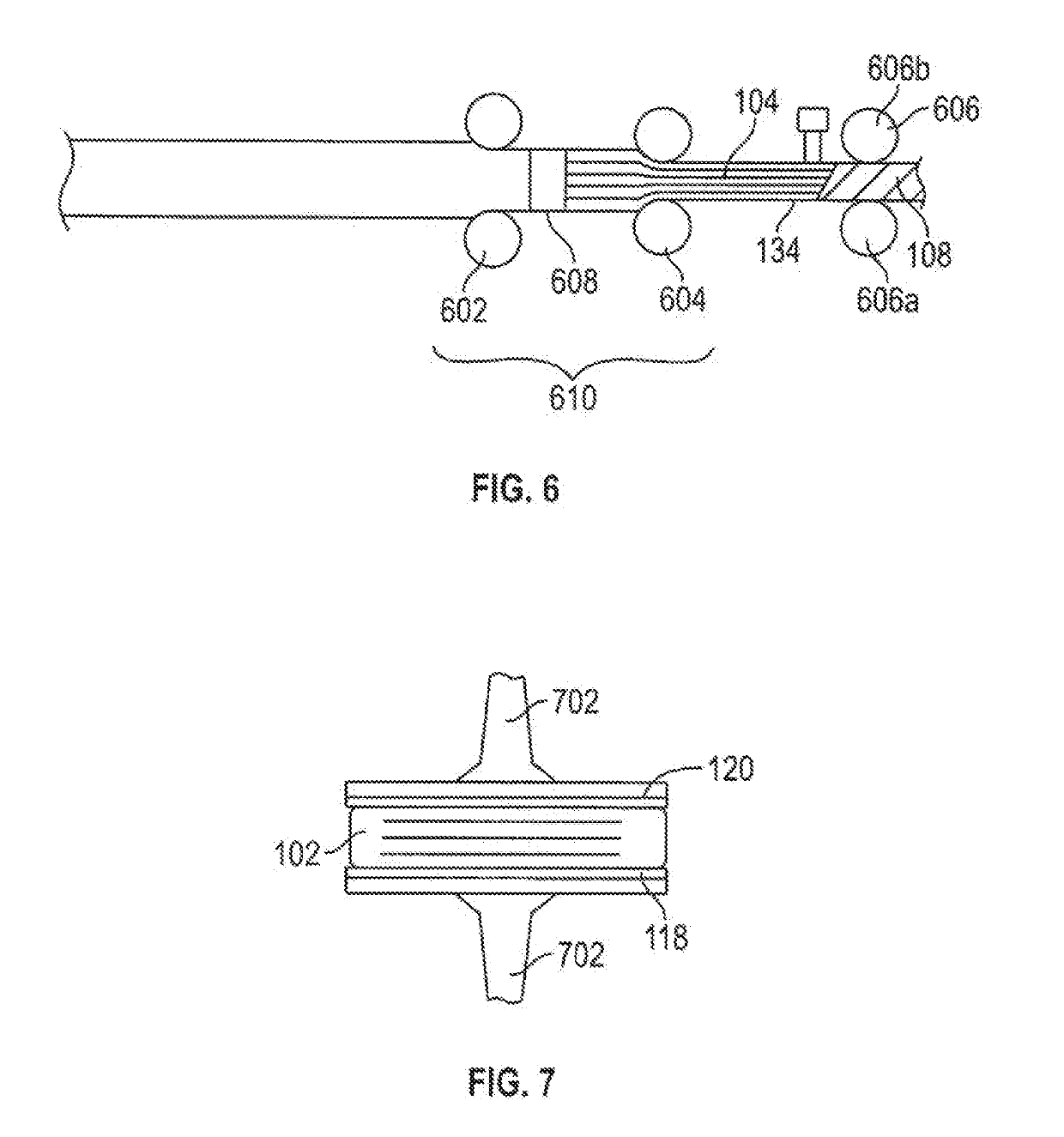

Helically-packaged expansion joint seal system with coiling, tear strips or secondary packaging

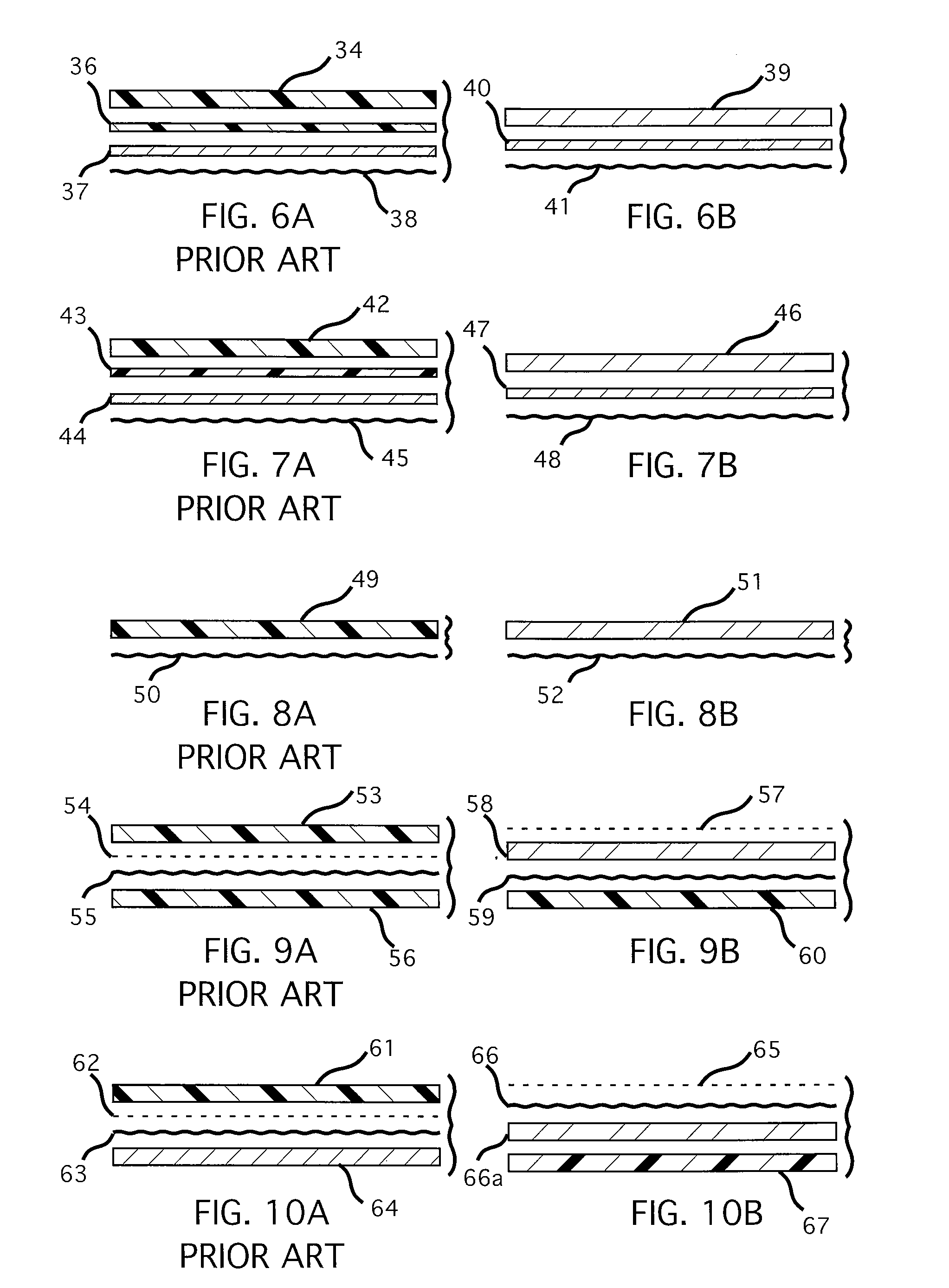

InactiveUS20190194880A1Facilitates constant and equal compressionAvoid lostFlexible coversWrappersEngineeringExpansion joint

A foam-based expansion joint seal system packaging which facilitates transport and reduces the need for internal splices.

Owner:SCHUL INT COMPANY

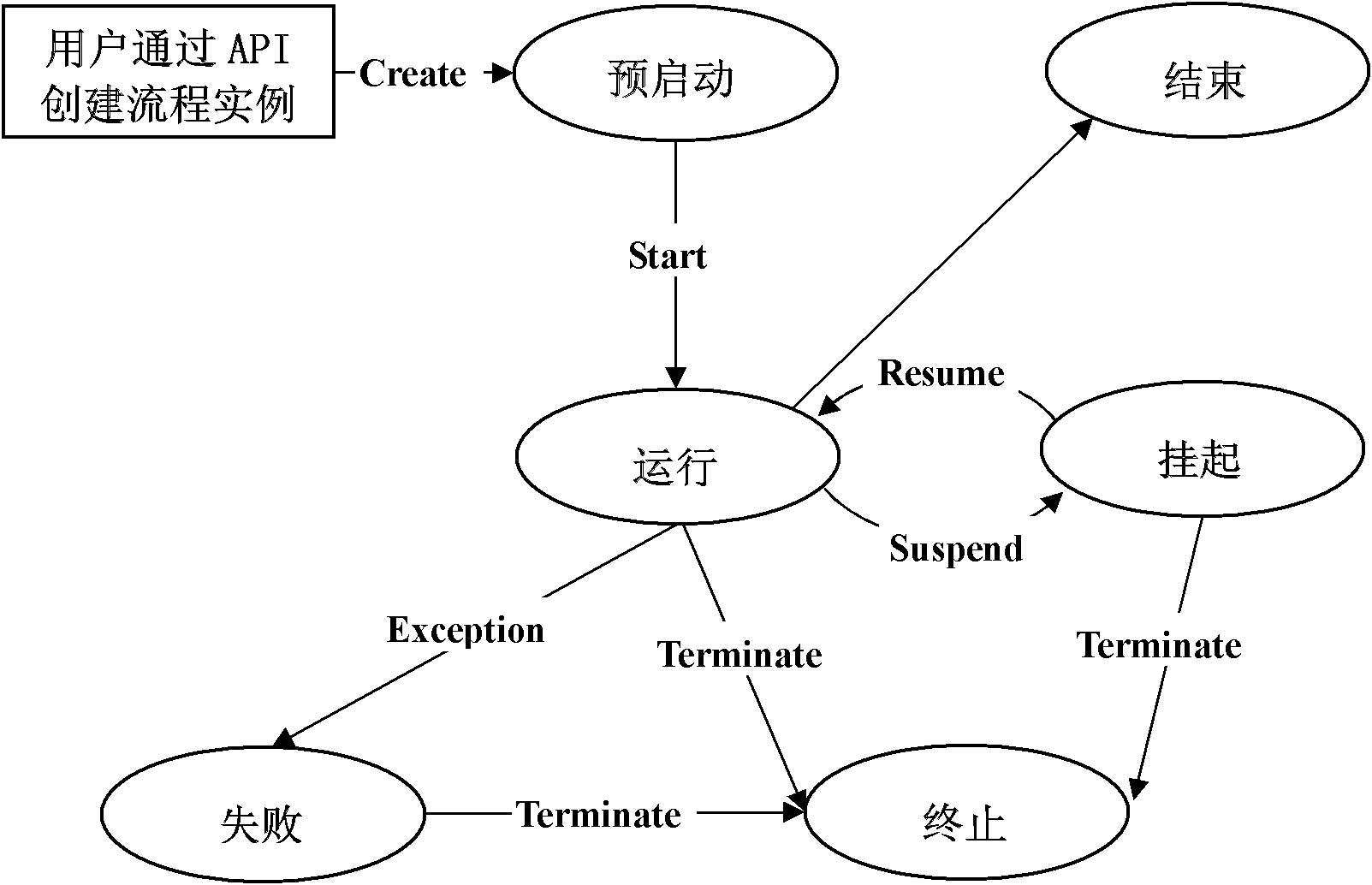

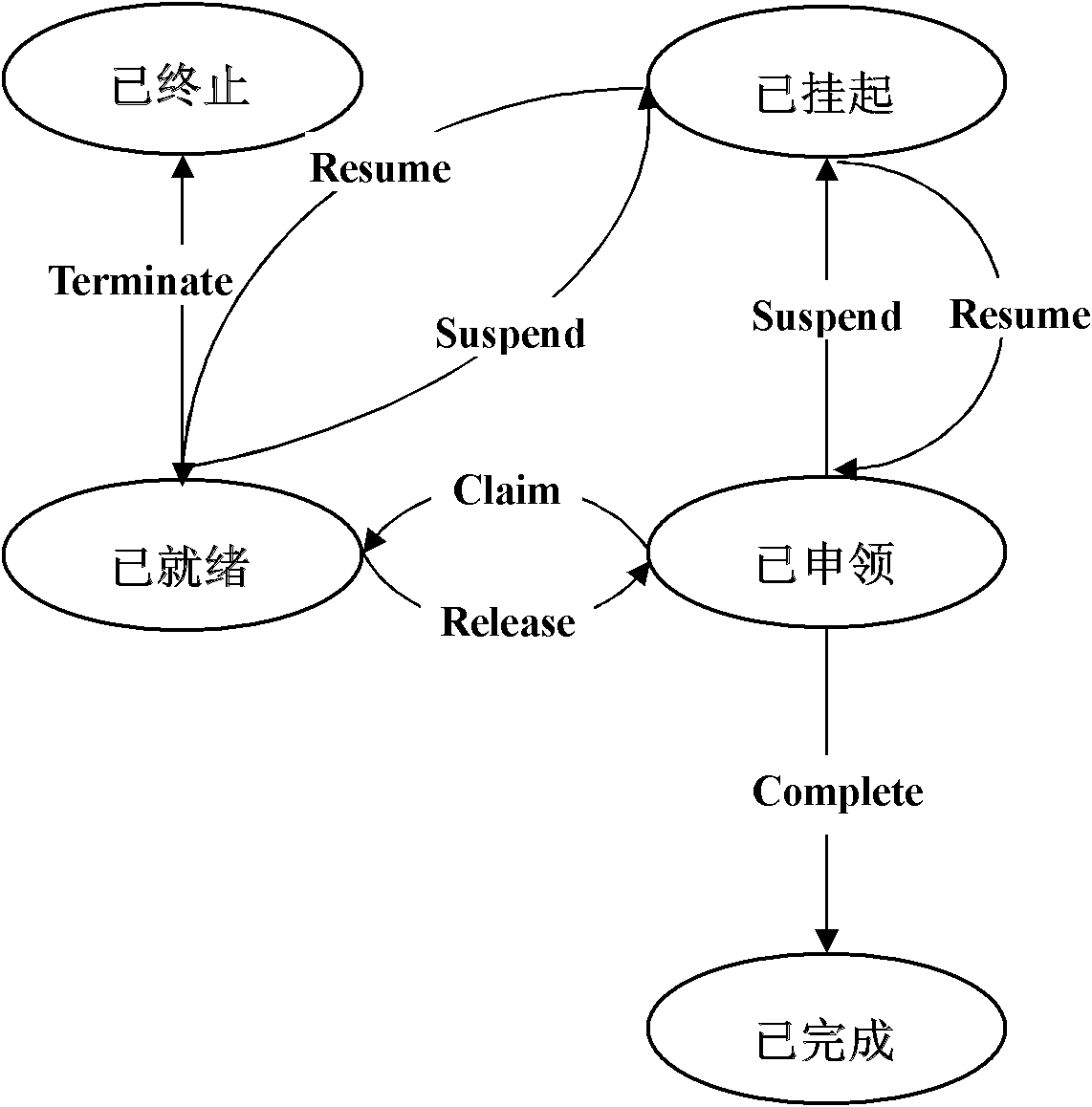

Implementation method and system for universal business process management interfaces

InactiveCN102156642AShort implementation periodQuick implementationSpecific program execution arrangementsIntegratorSoftware engineering

The invention provides an implementation method and system for universal business process management interfaces, which are beneficial to promoting the software productization concerned by software integrators, and are also beneficial to meeting the switching requirements on users for process management products. The implementation method is characterized by comprising the following steps of: working out a business model of a business process, extracting a universal API (application program interface) for the business process management according to a business model, and enabling the universal API to receive the invocation of a business system; and performing secondary packaging on a special API of a selected process management product, and enabling the bottom layer of the special API to shield the business system to ensure that the business system cannot directly invoke the special API, but invokes the universal API so as to realize decoupling between the business system and the process management product.

Owner:BEIJING NANTIAN SOFTWARE

Cup milky tea containing fruit and vegetable juice bag

InactiveCN103960367AFull of nutritionGreat market potentialMilk preparationPre-extraction tea treatmentFood additiveAdditive ingredient

The invention discloses cup milky tea containing a fruit and vegetable juice bag. The cup milky tea is characterized by containing a milky tea powder bag and the fruit and vegetable juice bag. The invention relates to the field of production of food beverages and particularly relates to the cup milky tea containing the fruit and vegetable juice bag. The milky tea powder bag contains one or more than one milk powder or a milk product, non-dairy creamer or acid-resisting non-dairy creamer. Ingredients, a condiment, a food additive and the like are added in a step of preparing materials; the milky tea powder bag is prepared by the procedures of blending, mixing, filling, sterilizing and the like; when a product is packaged, the fruit and vegetable juice bags with different flavors are selected and added according to requirements of the product and secondary packaging is carried out so that the disadvantages that the milky tea has no nutrition and the taste is single are overcome and multiple types of cup milky tea with different flavors can be formed.

Owner:宋信宇

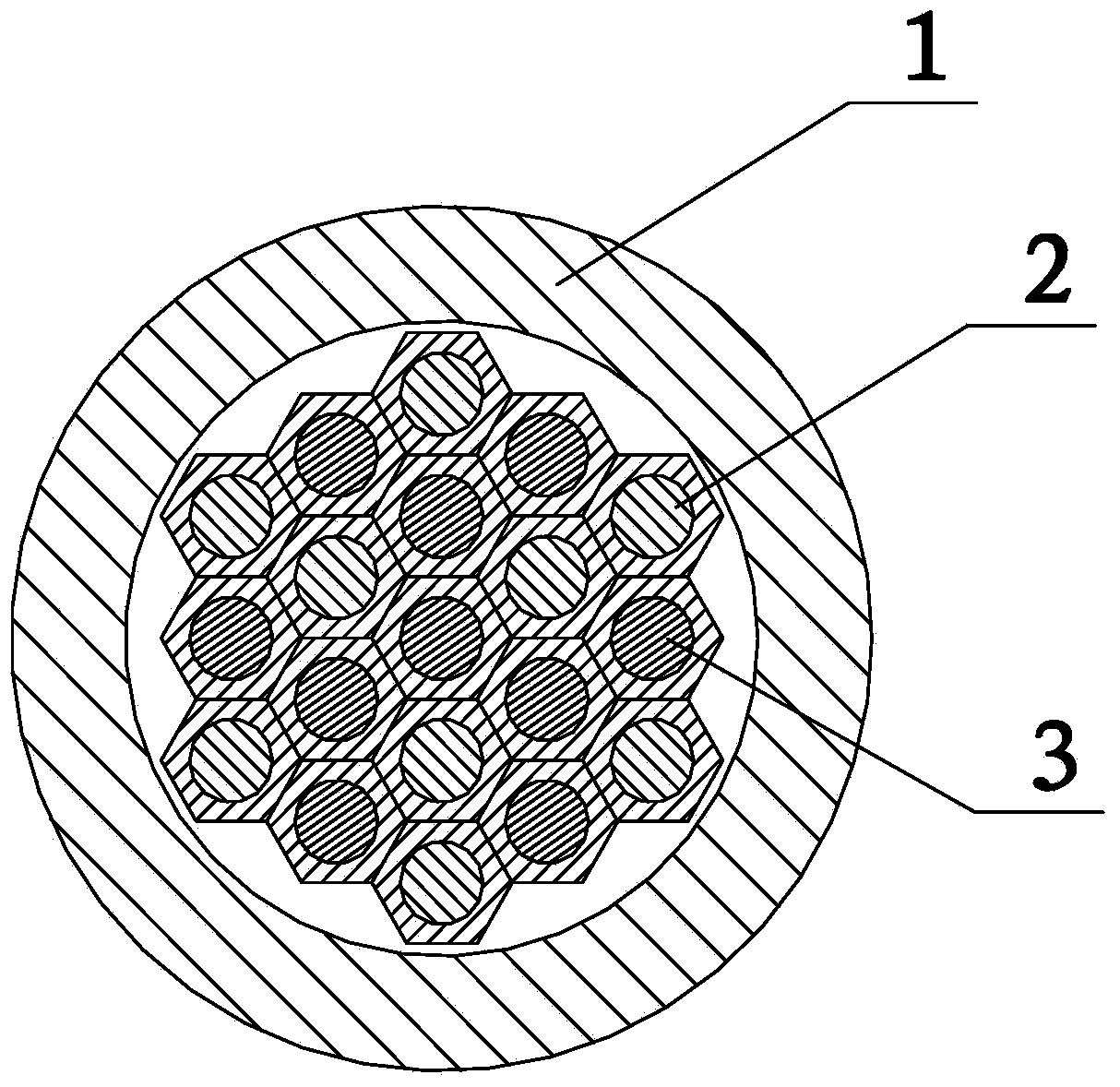

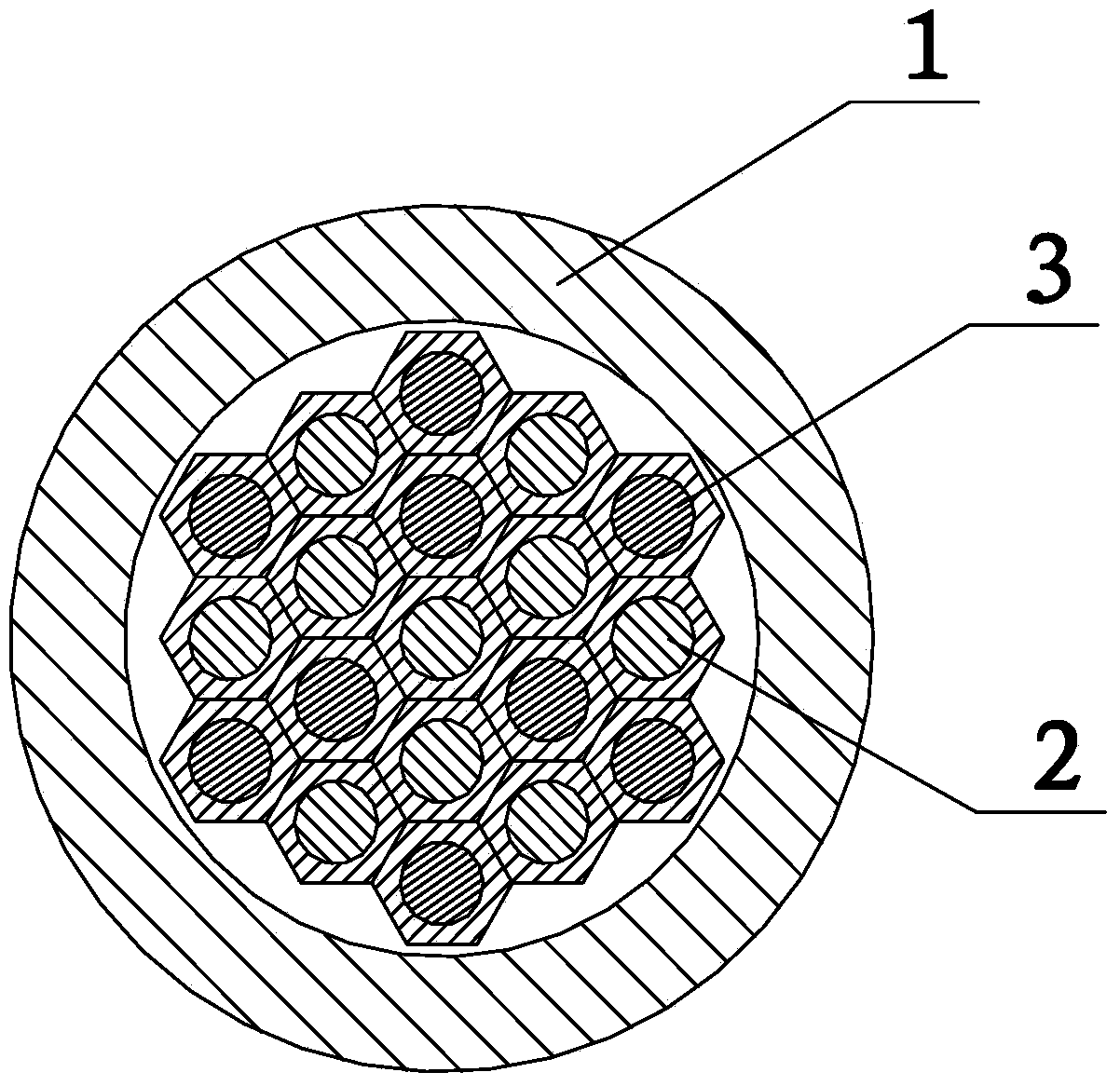

Preparation method of rectangular multicore composite superconductive strip

ActiveCN103440931AEvenly distributedNo reunionSuperconductors/hyperconductorsSuperconductor devicesAlloySlurry

The invention discloses a preparation method of a rectangular multicore composite superconductive strip. The preparation method comprises the following steps of step one. preparing mixed slurry by using amorphous boron powder, magnesium powder and a malic acid ethanol solution; step two. preparing tubing precursor powder; step three. tubing, carrying out rotary swaging, and drawing, thus obtaining a Cu-Nb-MgB2 single-core rod; step four. placing the Cu-Nb-MgB2 single-core rod and a Cu-NbTi single-core rod in a Cu-Ni alloy tube for secondary packaging, thus obtaining a secondary complex; five. processing the secondary complex into a wire rod, then carrying out rotary swaging and drawing so as to obtain a rectangular multicore composite strip; step six. winding a high-silica glass fiber to form a disk, and clamping the two ends of the disk to be flat; and step seven. carrying out thermal treatment so as to obtain the rectangular multicore composite superconductive strip. Compared with a single MgB2 and NbTi superconducting material, the composite superconductive strip prepared by the method is relatively wide in temperature using range and has relatively high using magnetic field.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH +1

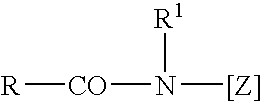

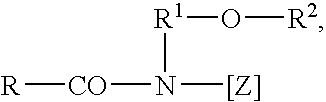

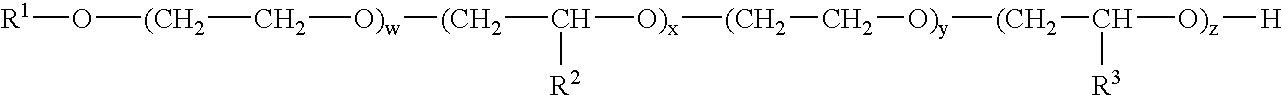

Packaging system for detergents or cleansers

InactiveUS20080261851A1Good storage stabilityMaintain stabilityDetergent materialsPackagingCleansers skinWater insoluble

Packaging systems for detergent or cleanser dosing units comprising: a) a primary packaging system in the form of a number (n)>2 of water-insoluble bags, each of these bags containing a number (x)>2 of detergent or cleanser dosing units, and; b) a secondary packaging system in the form of a water-insoluble bag that contains the (n) water-insoluble bags of the first packaging system. The inventive packaging systems are suited for increasing the stability of the detergent or cleanser dosing units contained therein.

Owner:HENKEL KGAA

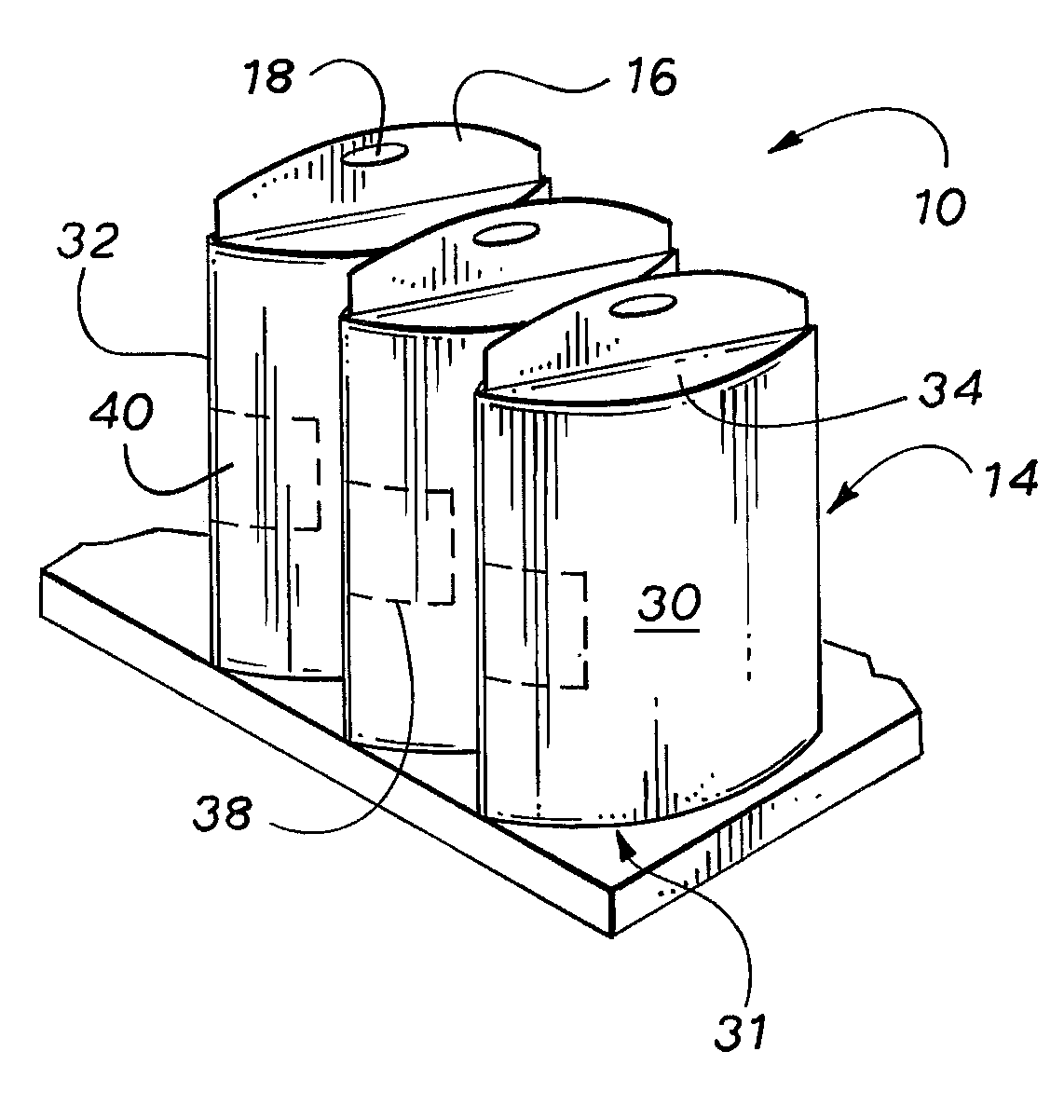

Reinforced packaging assembly

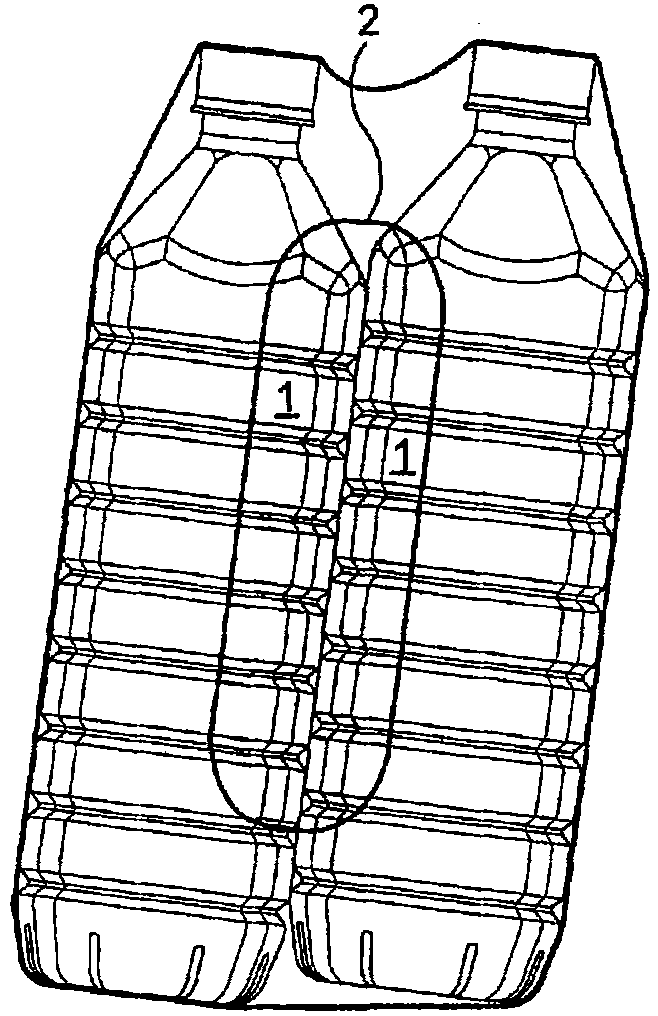

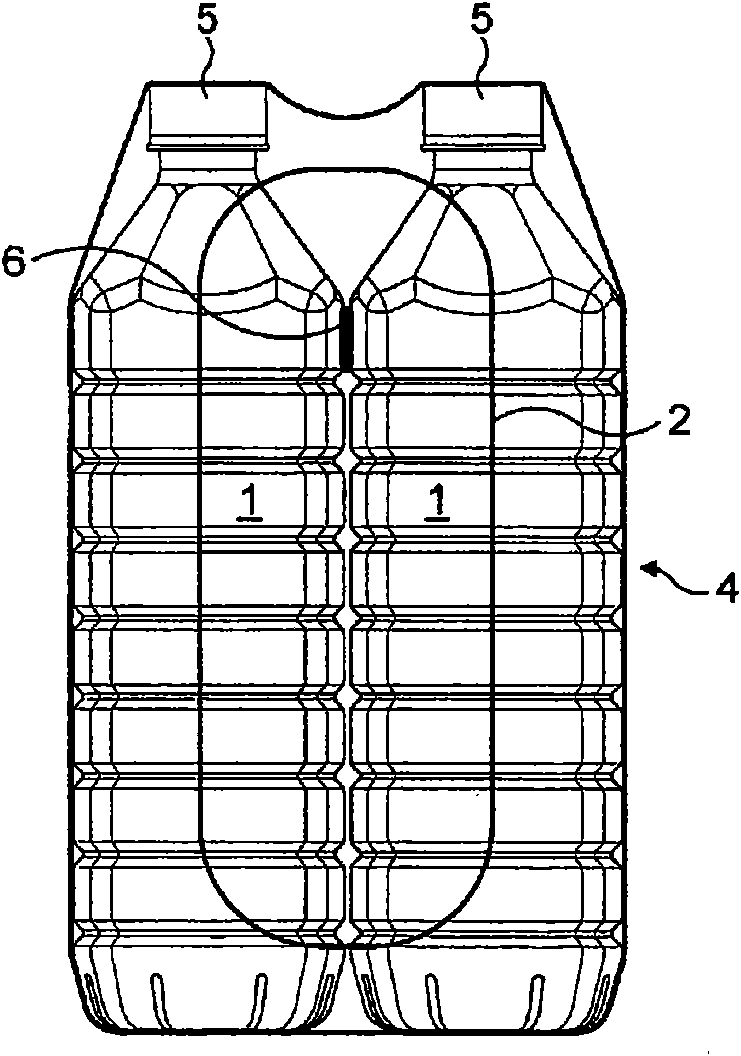

InactiveCN101959763APrevent movementRigid containersContainers with multiple articlesEngineeringSecondary Packaging

The present invention is directed to a secondary packaging (4) comprising a plurality of individual primary packages (1) and at least one envelope (2) that gathers and holds the said primary packages together, characterized in that at least two adjacent individual primary packages within the envelope (2) comprise attaching means (6) so as to prevent any movement of one primary package relative to the other.

Owner:NESTEC SA

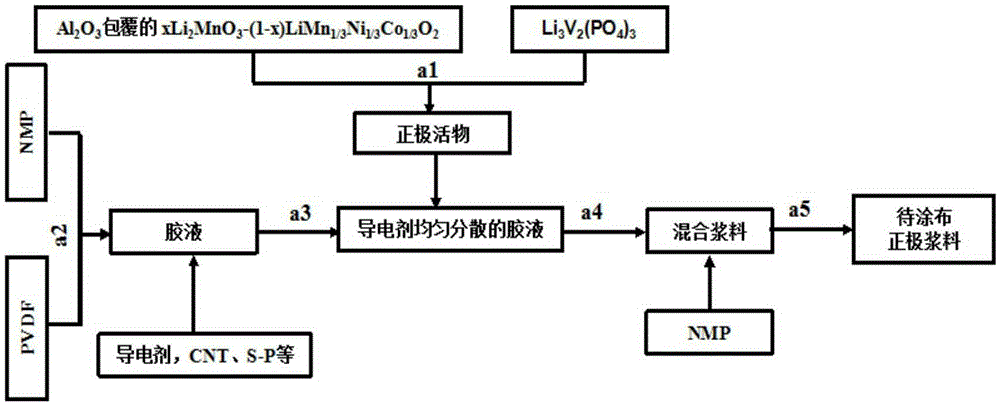

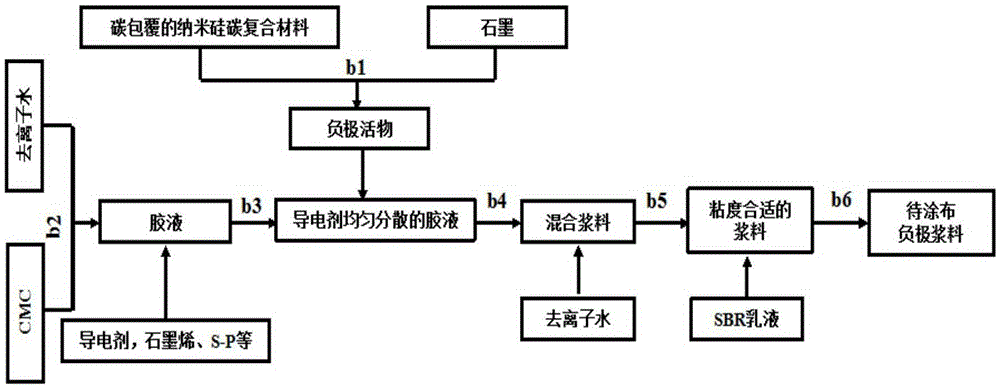

Lithium-rich manganese-based high-energy-density lithium-ion battery and preparation method thereof

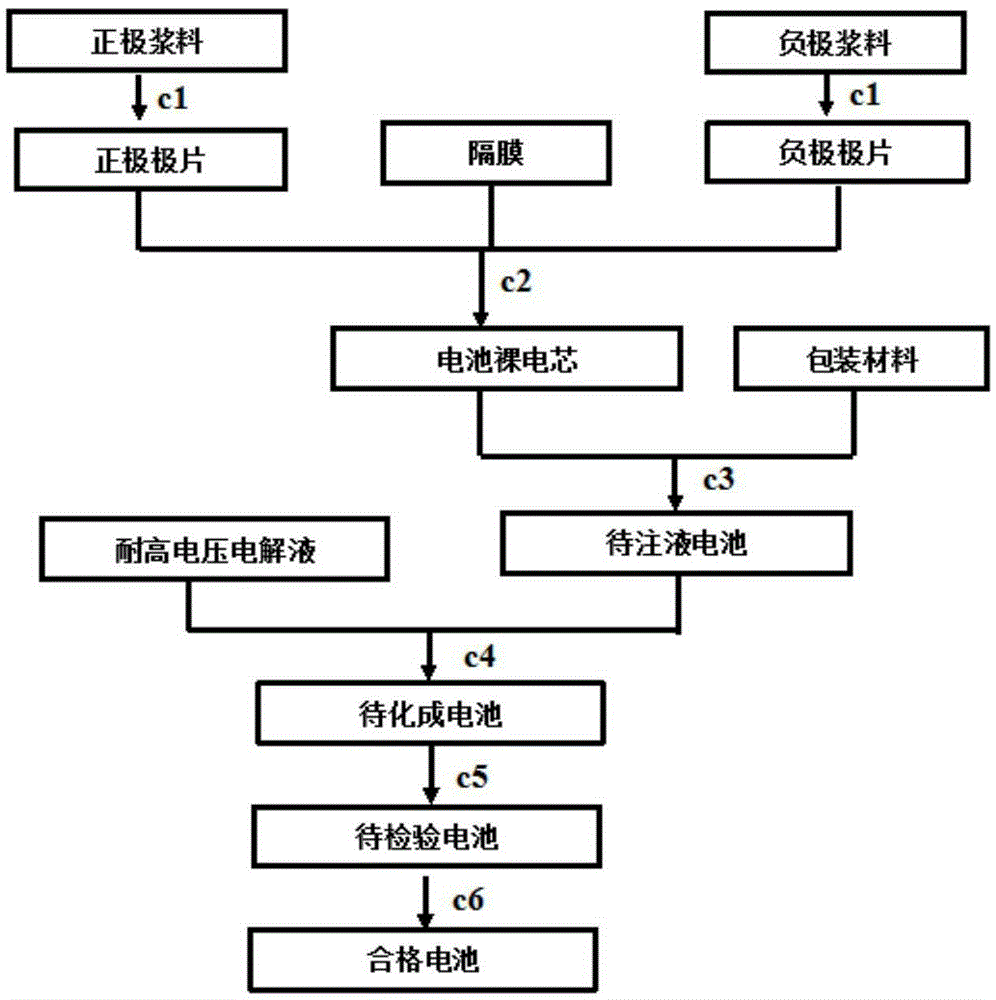

InactiveCN105355819AIncrease energy densityImprove cycle performanceFinal product manufactureCell electrodesElectrolytic agentCyclic process

The invention discloses a lithium-rich manganese-based high-energy-density lithium-ion battery and a preparation method thereof. According to the battery, with a lithium-rich manganese-based material doped with lithium vanadium phosphate as a positive electrode and a mixed material of a nano silicon-carbon material and graphite as a negative electrode, through optimal configuration of a conductive agent, a diaphragm, an electrolyte and the like, the influences to the battery performance due to the structure change of the lithium-rich manganese-based material and silicon volume expansion in a cyclic process are effectively reduced. The preparation process of the battery comprises the following steps: active material premixing, pulping, film production, winding / laminating, packaging, liquid injection, secondary packaging, formation, inspection and the like. The battery has the advantages of high energy density, high safety coefficient, relatively long cycle lifetime and the like and can be used as a dynamical chemical power source.

Owner:SHENZHEN HONGTAI BATTERY TECH

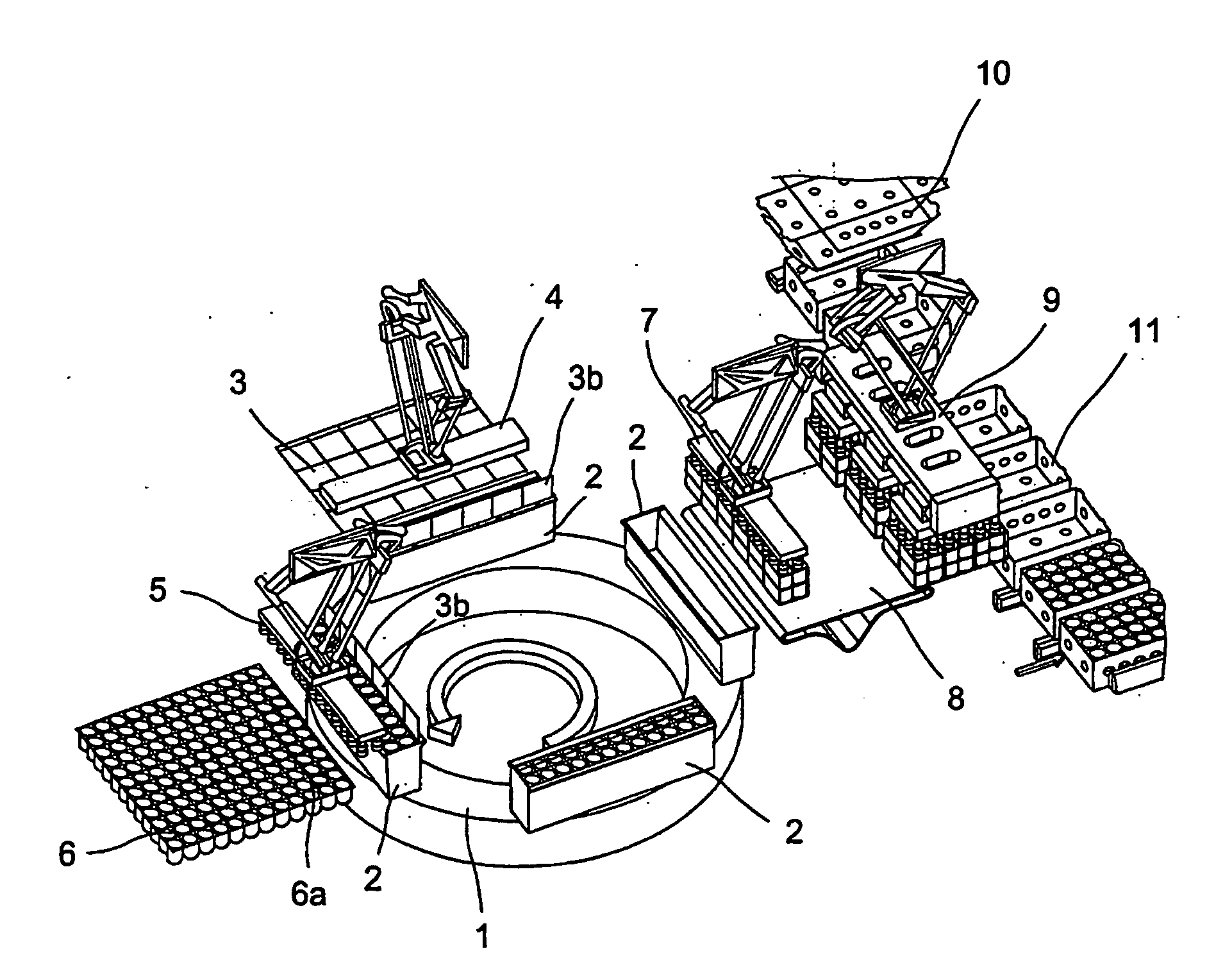

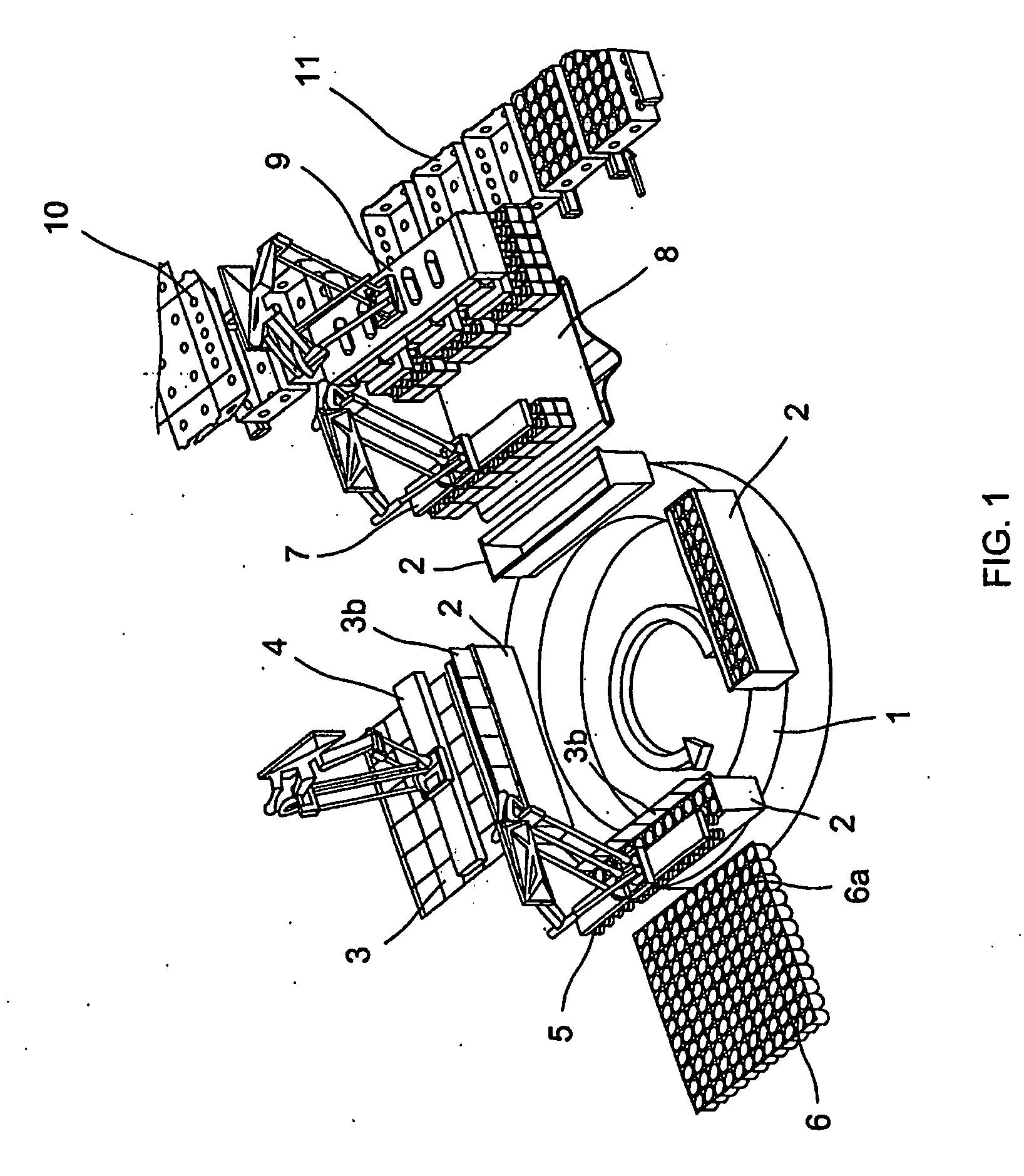

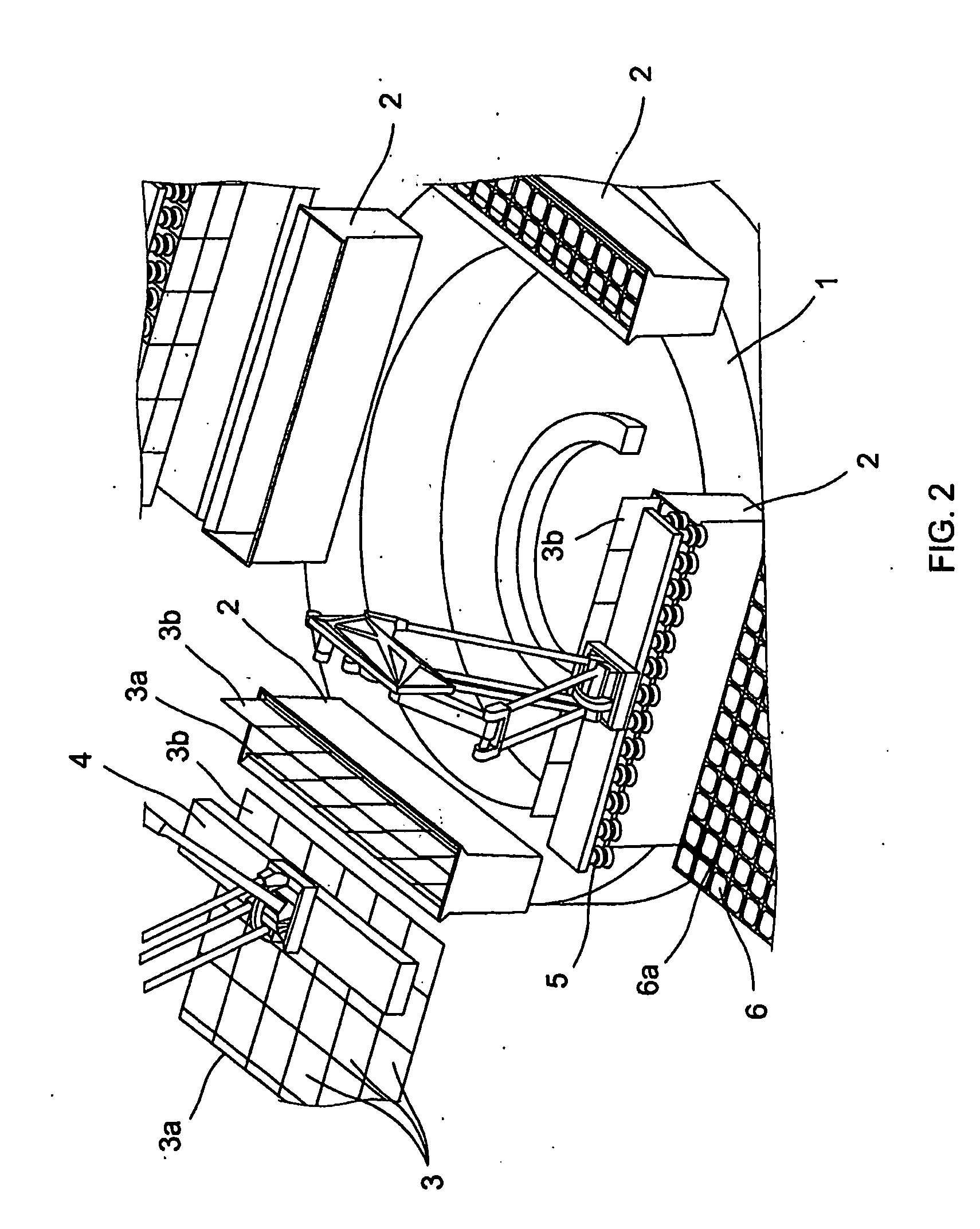

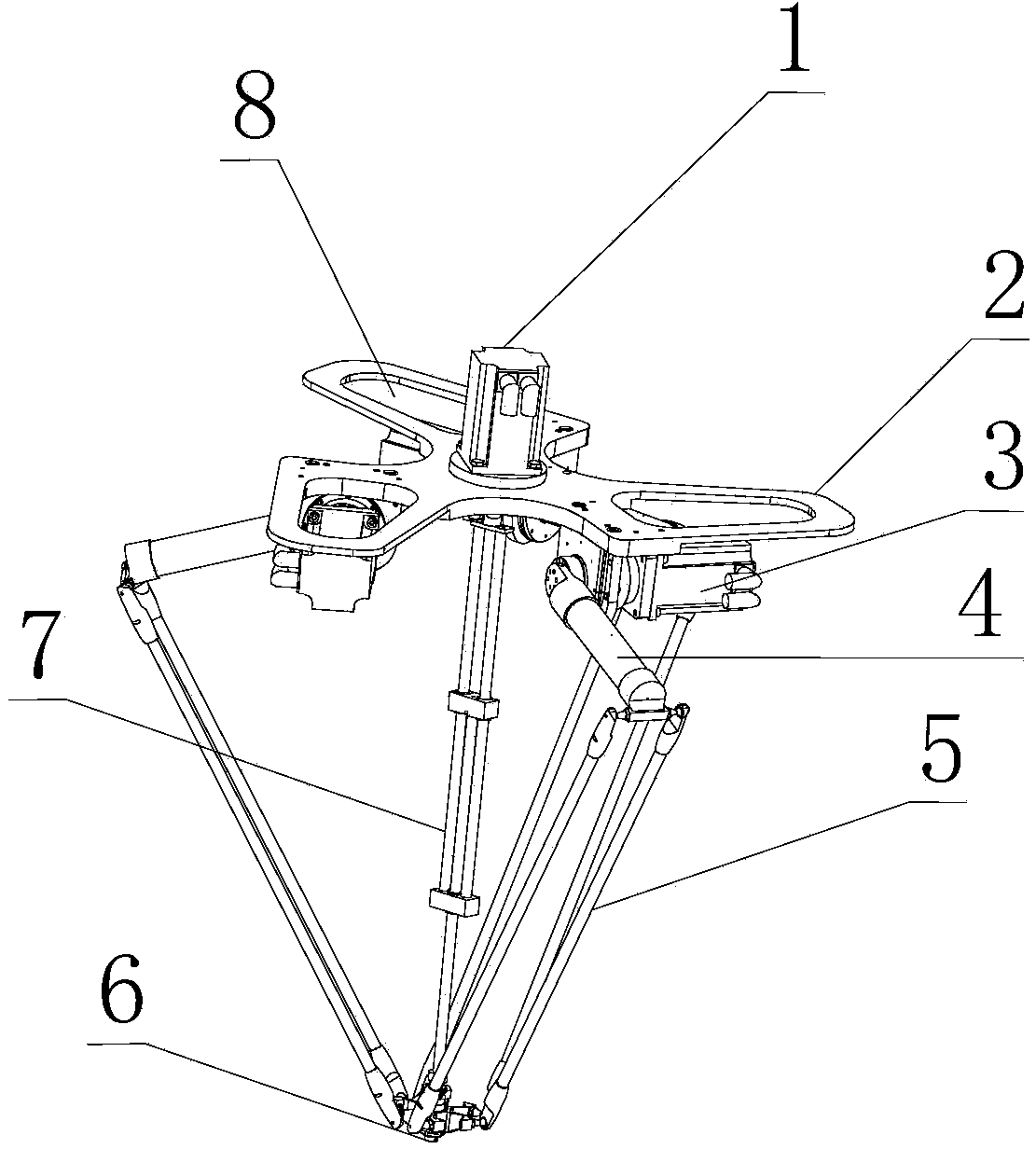

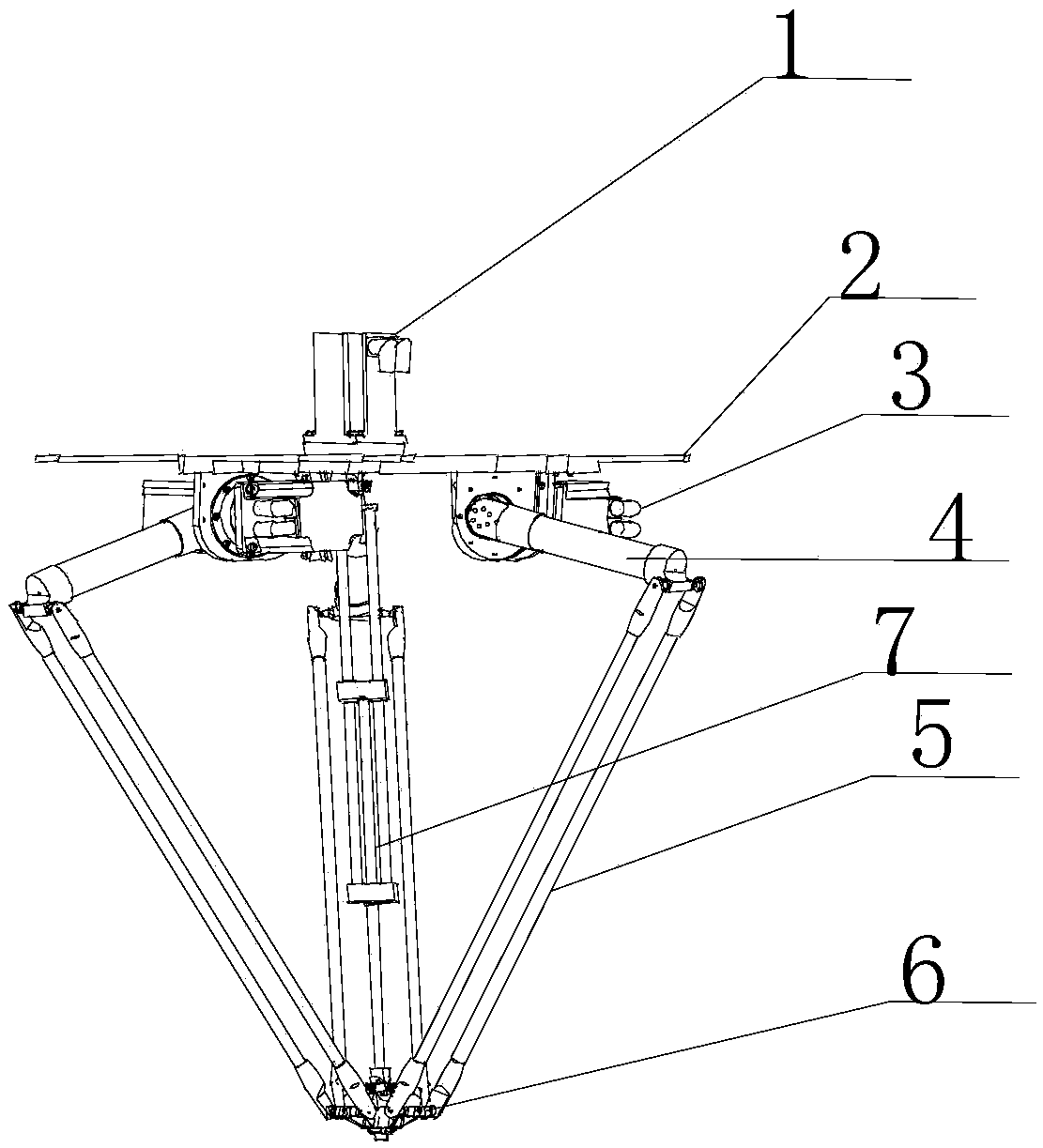

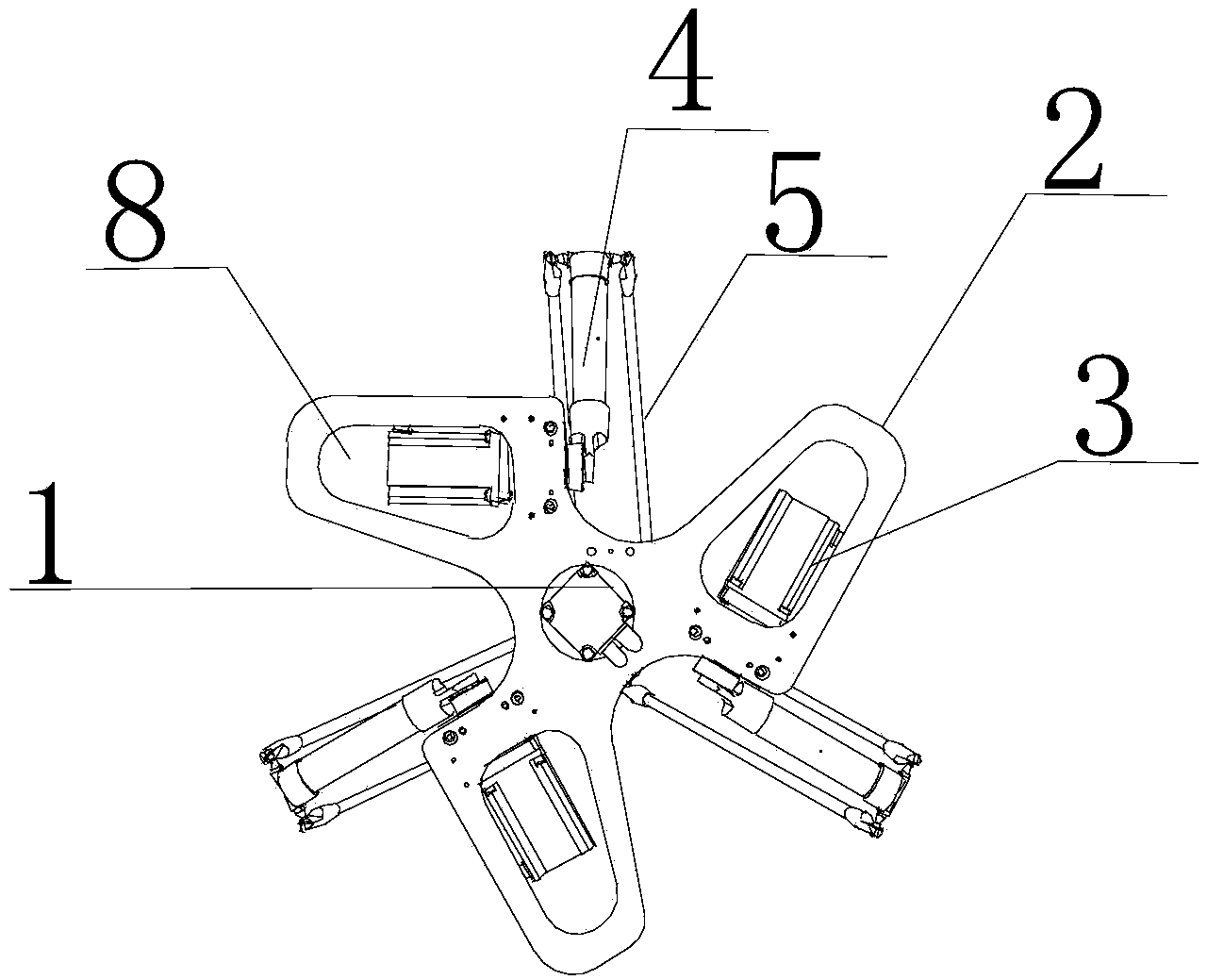

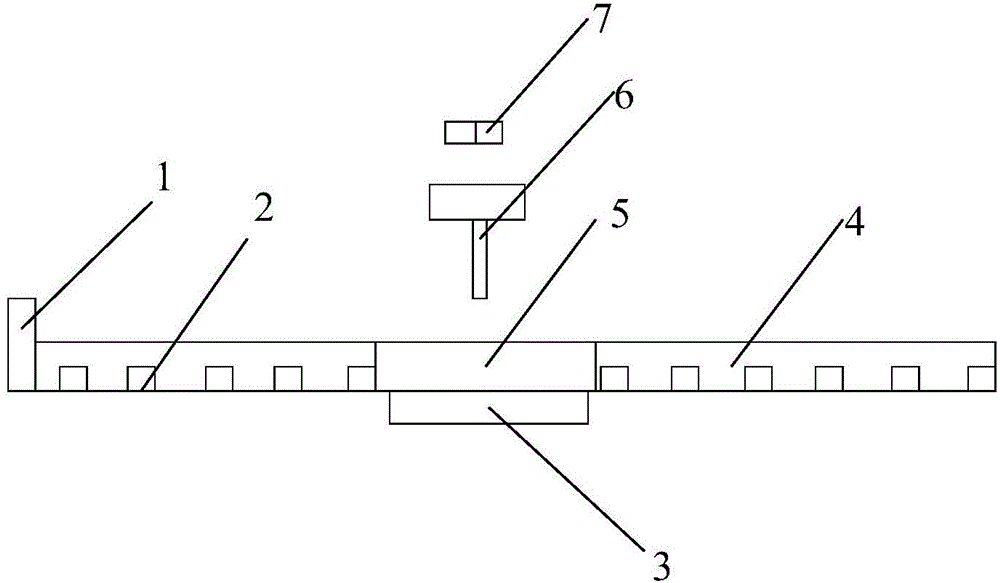

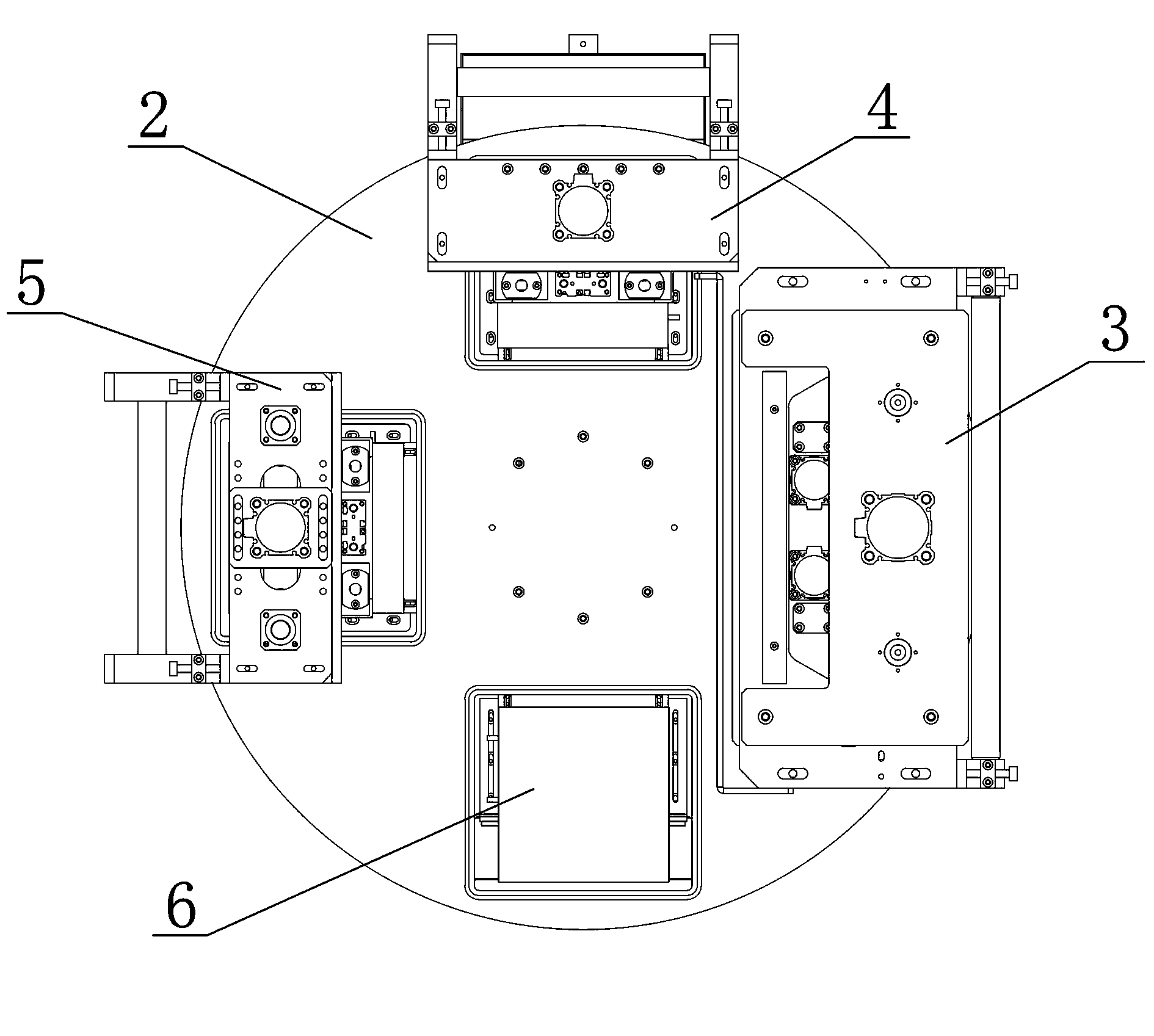

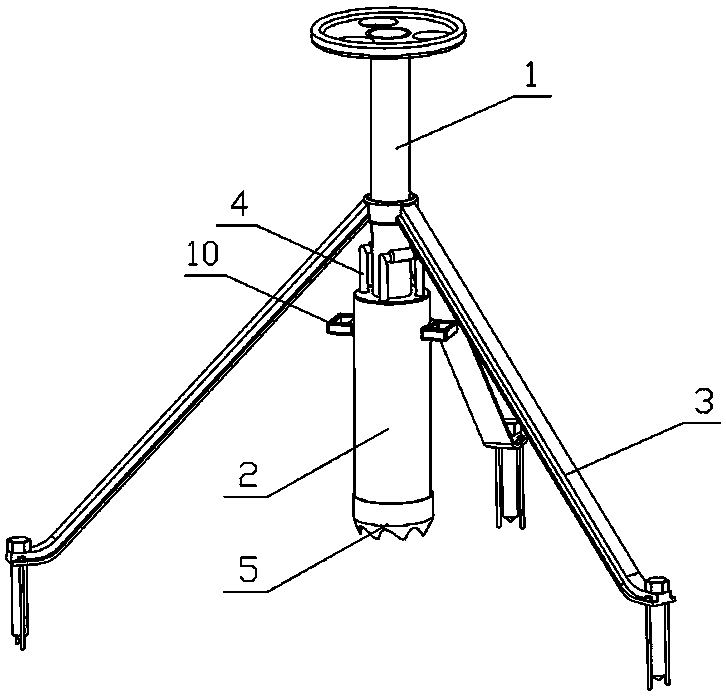

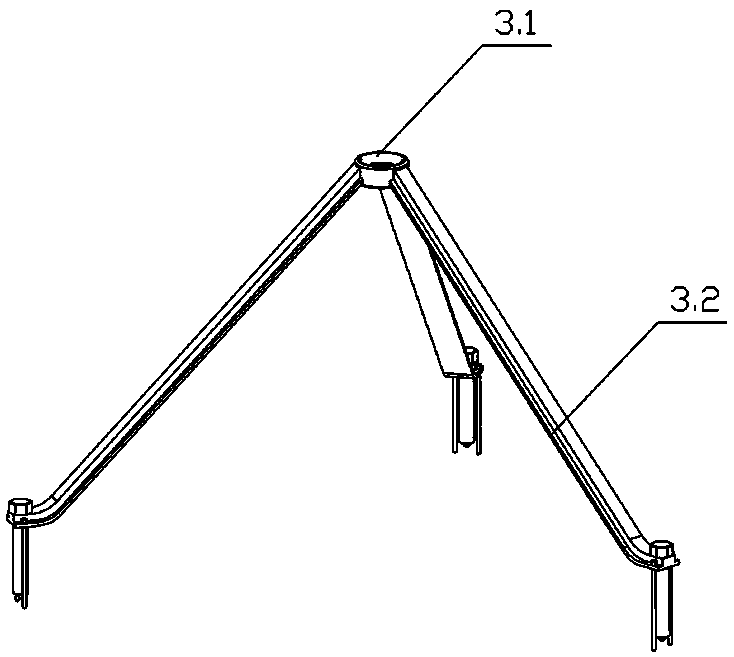

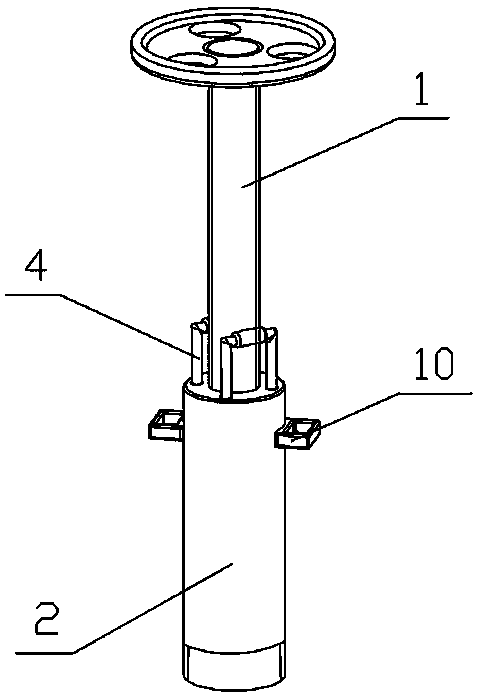

Parallel robot

InactiveCN103802094AEasy to installReasonable structure layoutProgramme-controlled manipulatorArmsRolling resistanceEngineering

The invention discloses a parallel robot which comprises a center motor (1), a robot bottom plate (2), motor reducer assemblies (3), an upper arm (4), a lower arm (5), a lower chassis (6) and a center telescopic rod (7). The parallel robot is characterized in that the motor reducer assemblies (3) are installed below the robot bottom plate (2) and distributed in the angle of 120 degrees at the center of the robot bottom plate (2). The upper arm (4) and the lower arm (5) are connected through a ball-shaped joint head to form an arm. The motor reducer assemblies (3) and the lower chassis (6) are connected through the three arms. The center telescopic rod (7) is connected with the center motor (1) and a center rotation shaft of the lower chassis (6). The parallel robot is reasonable in structural layout, light in weight, large in telescopic extent of the center telescopic rod (7) and little in rolling friction resistance and is applied to secondary packaging and material sorting in industrial production. The lengths of the arms can be adjusted according to different products.

Owner:QINGDAO PHAESTUS IS ENG CO LTD

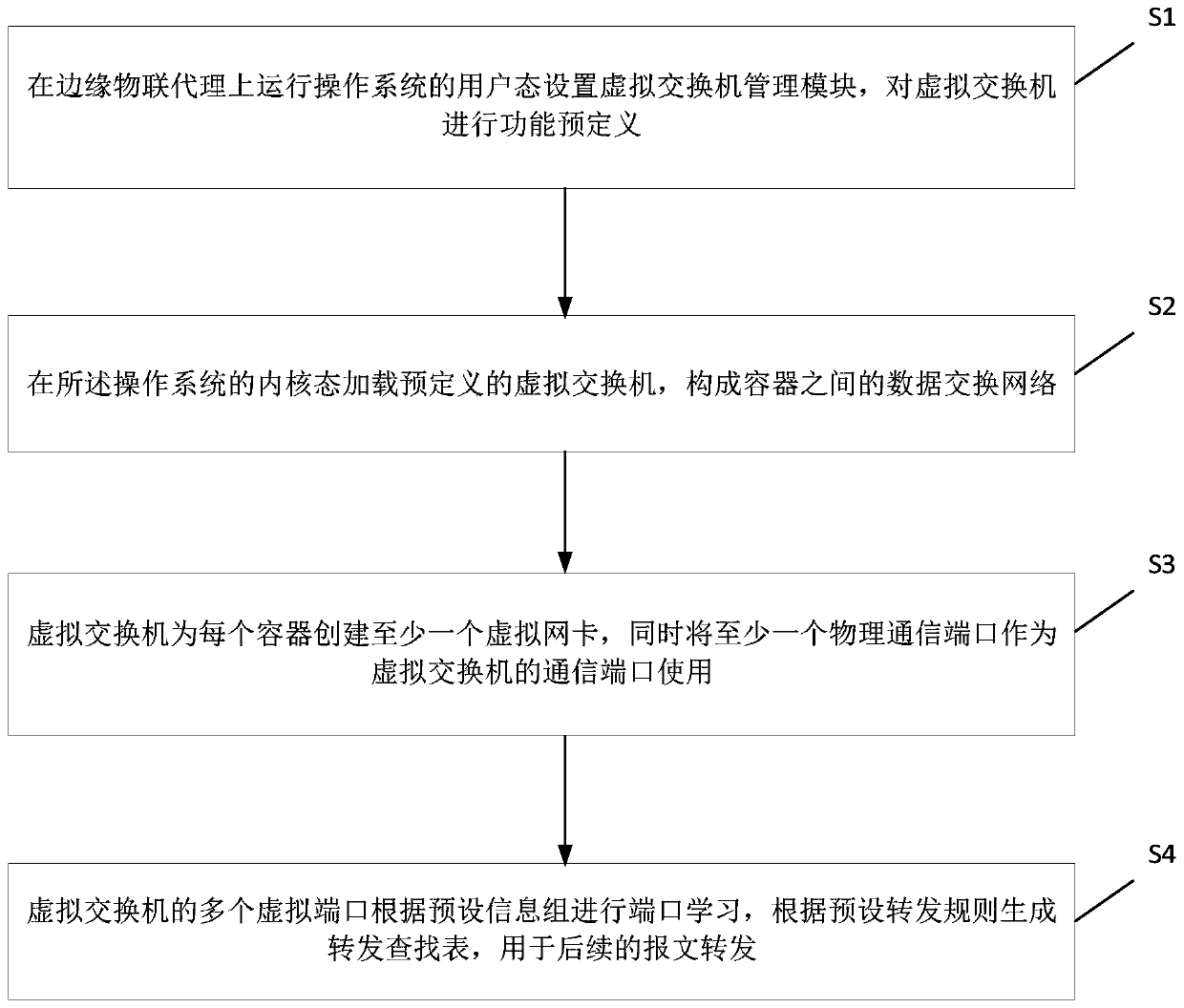

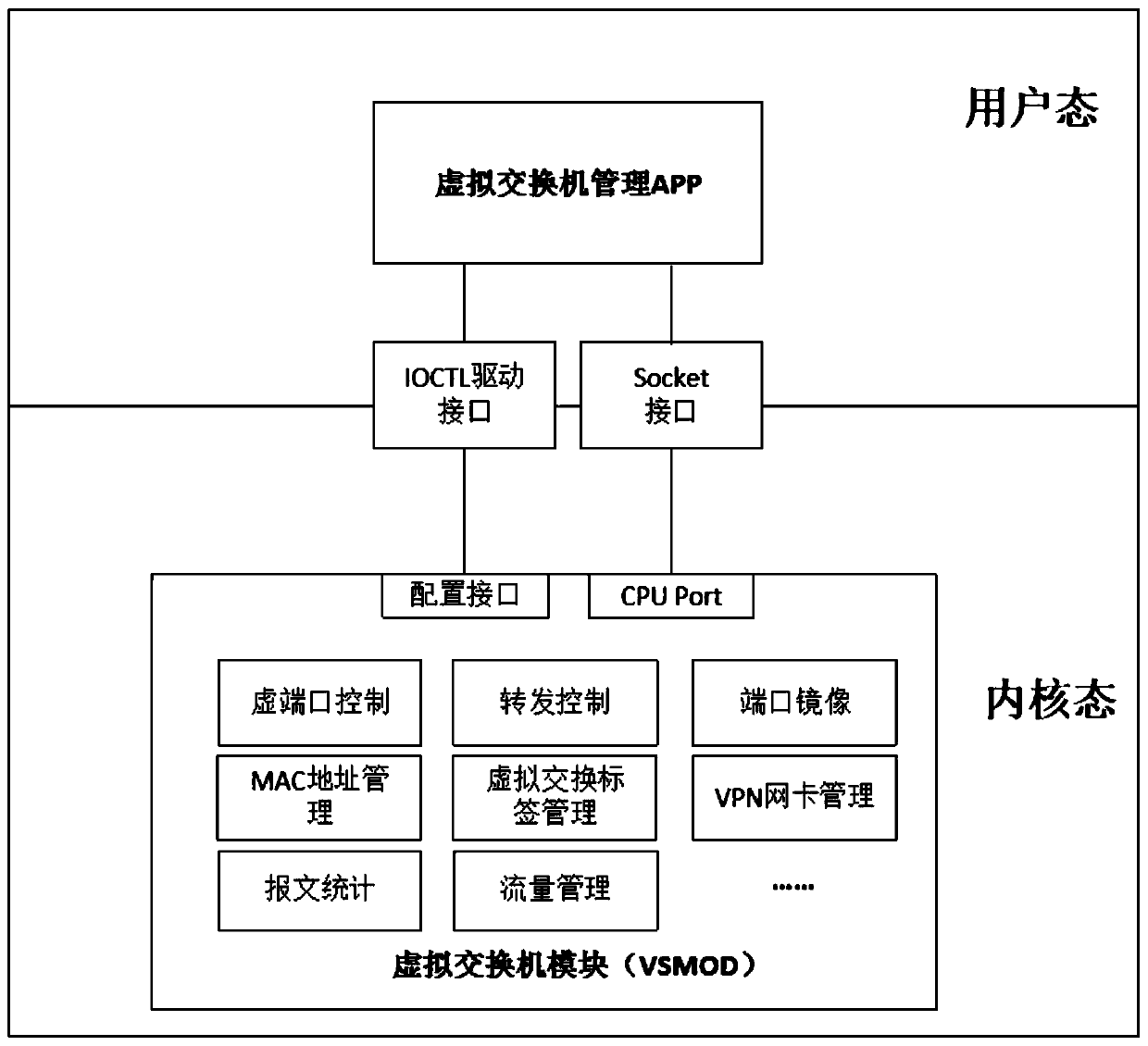

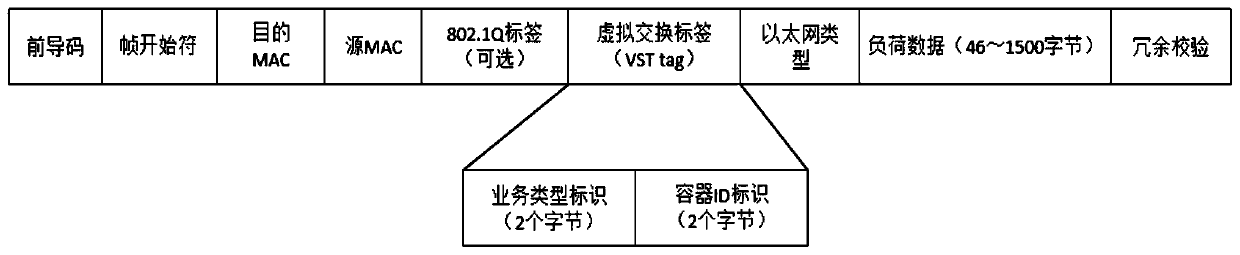

Data interaction method between internal containers of electric power edge Internet-of-things agent

ActiveCN111556136AThe recognition effect is accuratePrecise managementData switching networksSoftware simulation/interpretation/emulationData packOperational system

The invention discloses a data interaction method between internal containers of an electric power edge Internet-of-things agent, comprising the following steps of: running a user mode of an operatingsystem on the edge Internet-of-things agent to set a virtual switch management module, and performing function pre-definition on a virtual switch; loading a predefined virtual switch in a kernel modeof the operating system to form a data exchange network between the containers; creating at least one virtual network card for each container by the virtual switch, and using at least one physical communication port as a communication port of the virtual switch; performing port learning according to a preset information group by the plurality of virtual ports; generating a forwarding lookup tablefor subsequent message forwarding according to a preset forwarding rule, according to the method, the network data packet can be accurately identified and managed, and secondary packaging is carriedout by adopting a self-defined security protocol, so that the security of network interaction data is enhanced, the isolation strength between containers is improved, an original APP can directly runwithout modifying a TCP / IP protocol communication code, and the compatibility of the APP is ensured.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +5

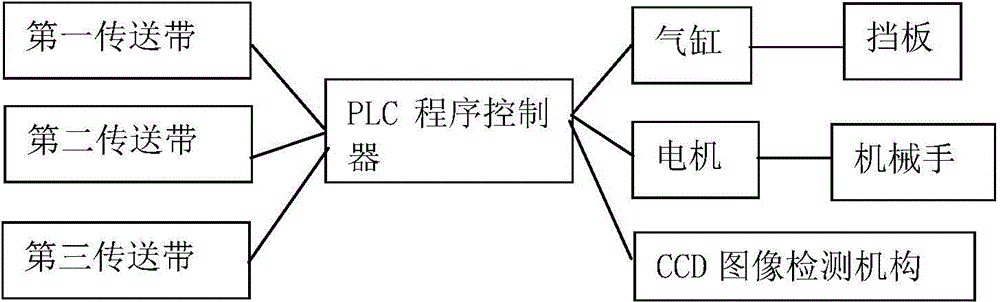

Automatic rejecting device of filling and packaging machine

InactiveCN104085565AUniform weightReasonable designPackaging automatic controlImage detectionManipulator

The invention provides an automatic rejecting device of a filling and packaging machine. The automatic rejecting device comprises a first conveyor belt, a second conveyor belt, a third conveyor belt, a baffle, a feeding bottom plate, a mechanical hand, a CCD image detection mechanism, a rejecting platform and a PLC. The mechanical hand is arranged above the rejecting mechanism, the first conveyor belt and the second conveyor belt are arranged on the two corresponding sides of the rejecting platform, the feeding bottom plate is arranged at one end of the first conveyor belt, the baffle is arranged on the third conveyor belt used for conveying unqualified package bags and connected with the PLC through an air cylinder, the CCD image detection mechanism is arranged above the rejecting platform, and a weight sensor is arranged below the rejecting platform. The automatic rejecting device is reasonable in design, simple in structure, high in practicability and worthy of application and popularization, fully relieves labor intensity while improving the automation degree, ensures uniformity and standards of weight of materials packaged secondarily, improves working efficiency and guarantees product quality.

Owner:天津尚永科技有限公司

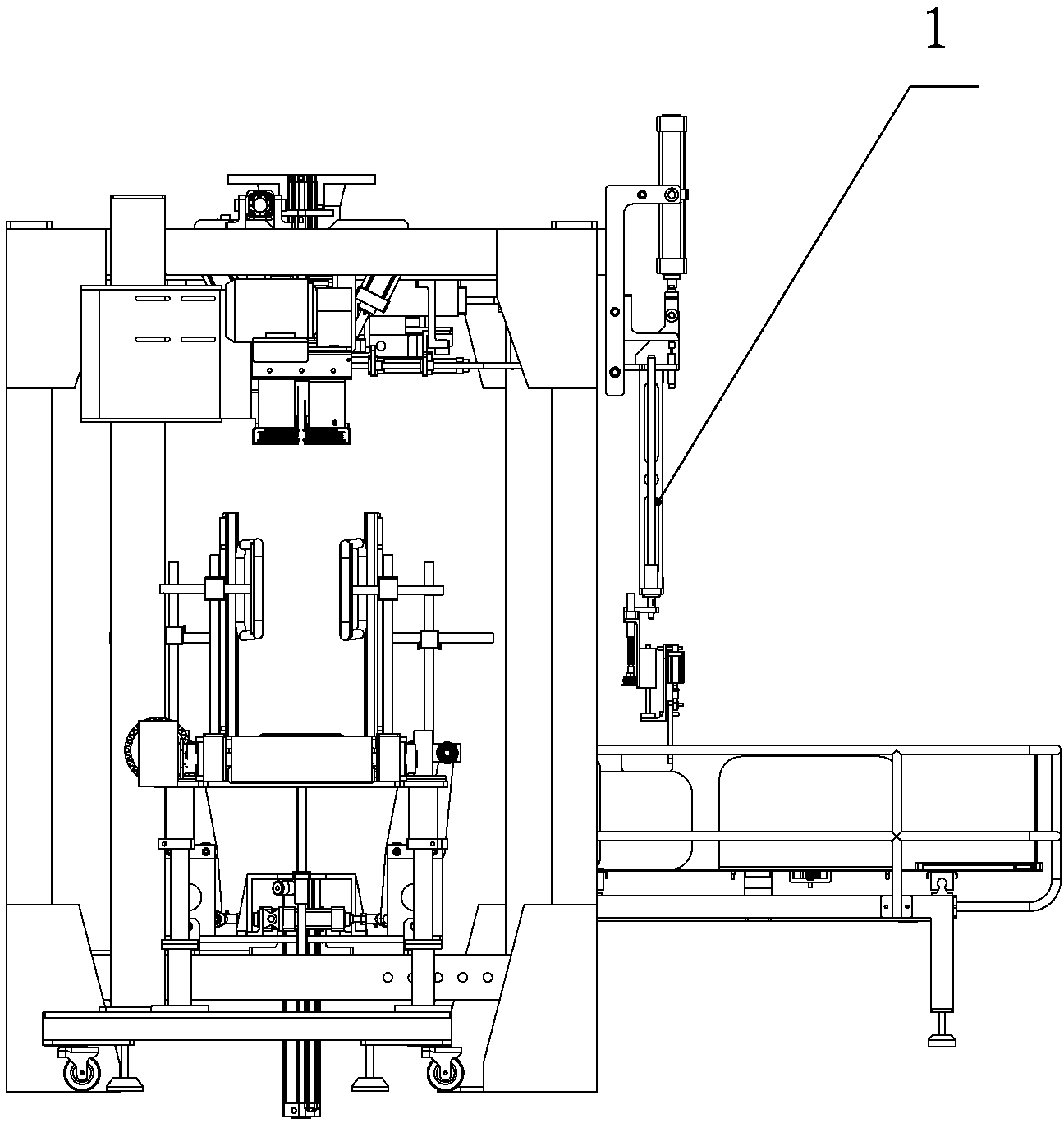

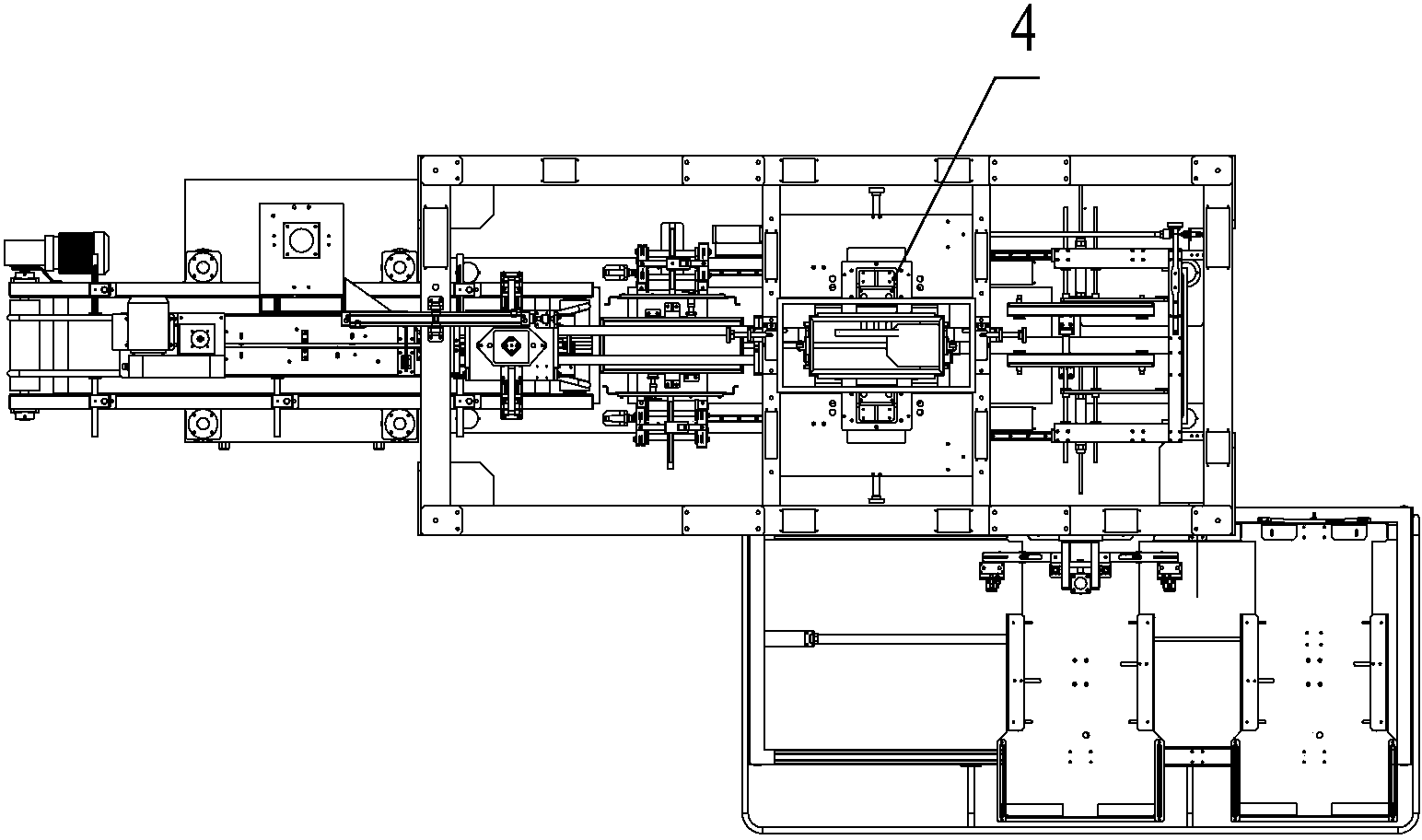

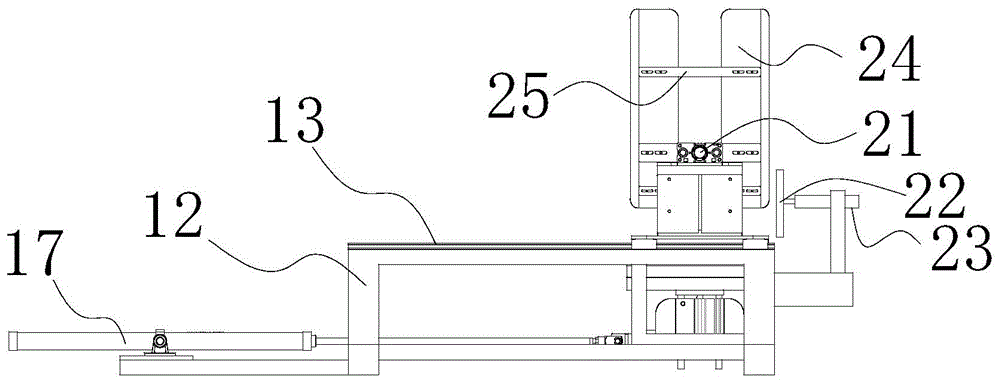

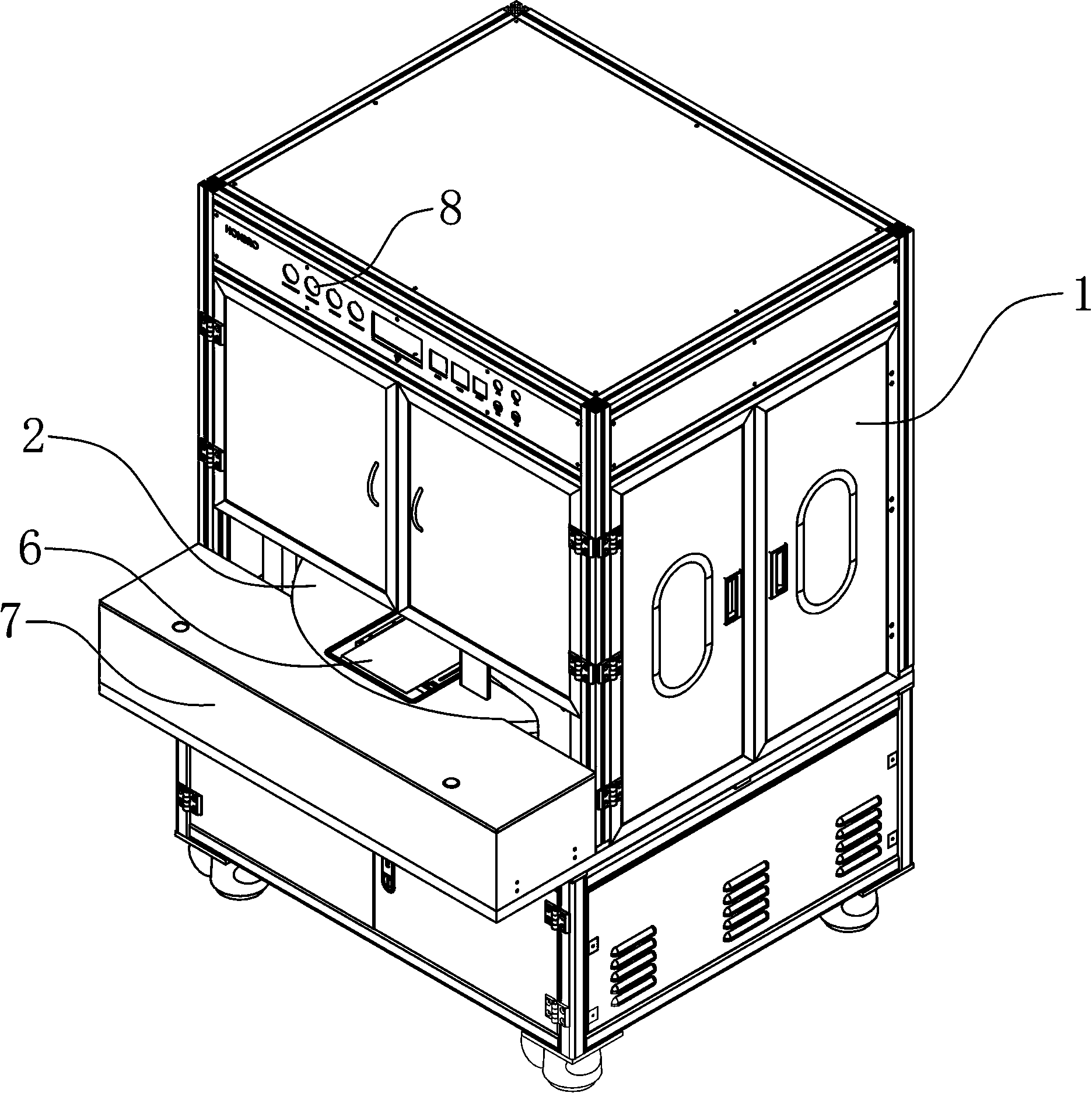

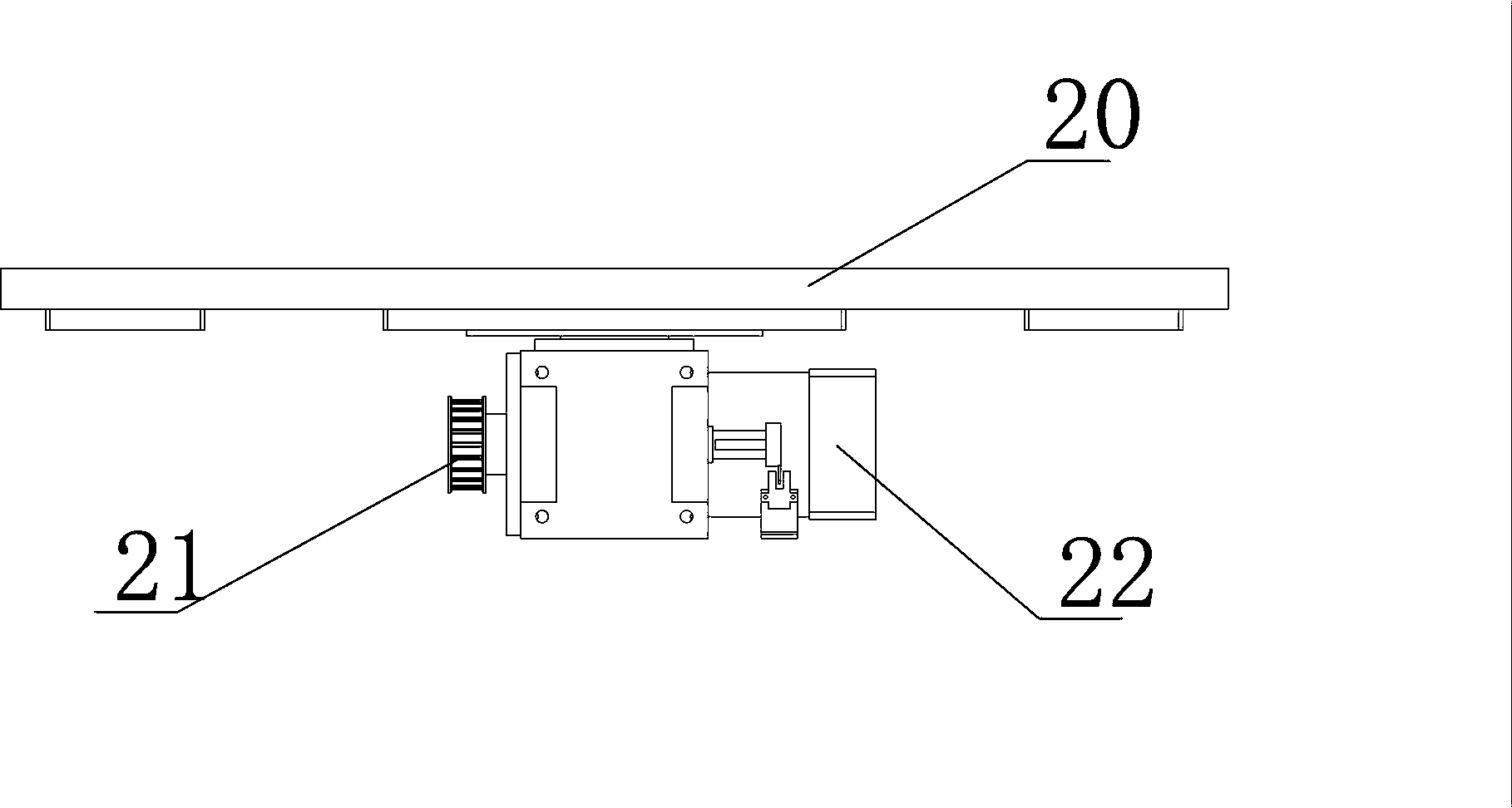

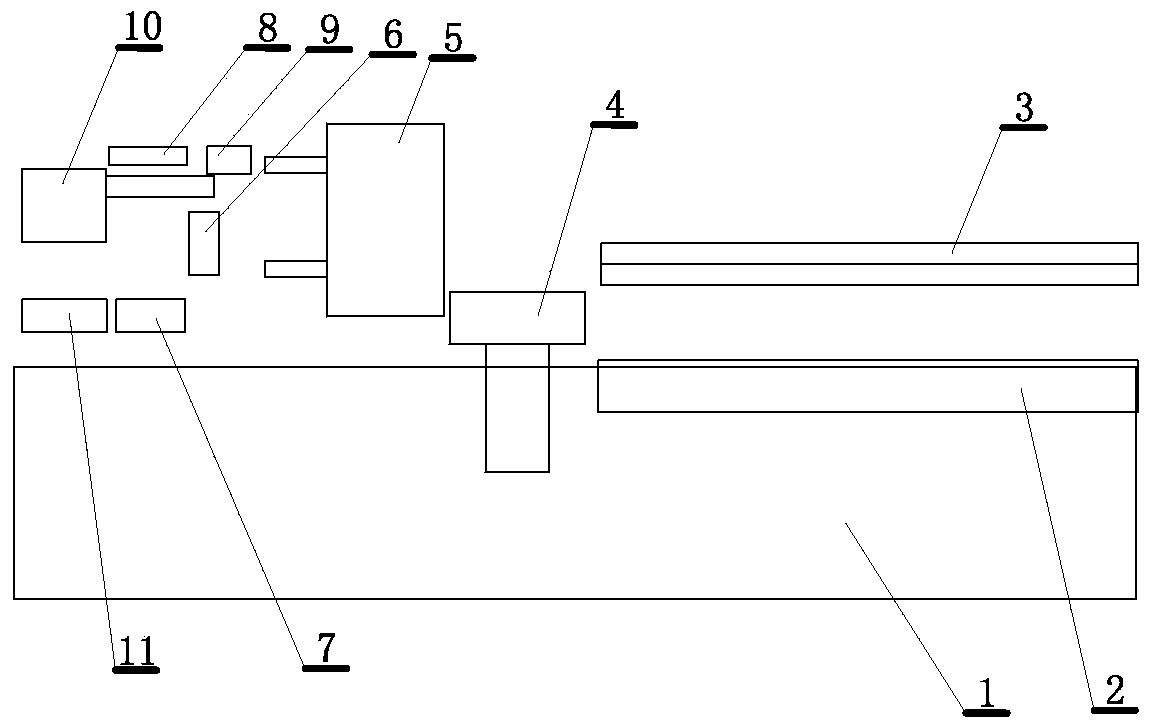

Vacuum packaging, edge cutting and secondary packaging machine

ActiveCN103490097AImprove production efficiencyCompact structureAssembling battery machinesFinal product manufactureMachine buildingEngineering

The invention discloses a vacuum packaging, edge cutting and secondary packaging machine which is characterized by comprising a machine case, a rotary disc mechanism, a vacuum packaging mechanism, an edge cutting mechanism (4) and a secondary packaging mechanism. The rotary disc mechanism is arranged inside the machine case, and the vacuum packaging mechanism, the edge cutting mechanism (4) and the secondary packaging mechanism are respectively arranged in the quartering directions of the circumference of the rotary disc mechanism. The rotary disc mechanism comprises a circular rotary disc, a cutting device and a motor, a feeding station and at least two machining stations are evenly arranged on the rotary disc at intervals in the circumferential direction, and a piece to be machined is placed on the feeding station. The vacuum packaging, edge cutting and secondary packaging machine is compact in structure, saves space and enables the structure to be optimized, the production efficiency is improved through reasonable combinations, the production cost is saved, the productivity achieves 4-6PPM, the packaging thickness and non-packaging areas are accurately and stably controlled, the edge cutting accuracy achieves + / -0.2MM, the product pass percent of the whole machine is higher than 99.9%, and the interactive rate is higher than 97%. According to the vacuum packaging, edge cutting and secondary packaging machine, unified standardization is carried out on parts of various structures or with similar functions in a traditional vacuum packaging, edge cutting and secondary packaging machine, the manufacturing efficiency of the machine is greatly improved, and equipment maintenance difficulty is simplified.

Owner:DONGGUAN HONBRO LI BATTERY EQUIP TECH

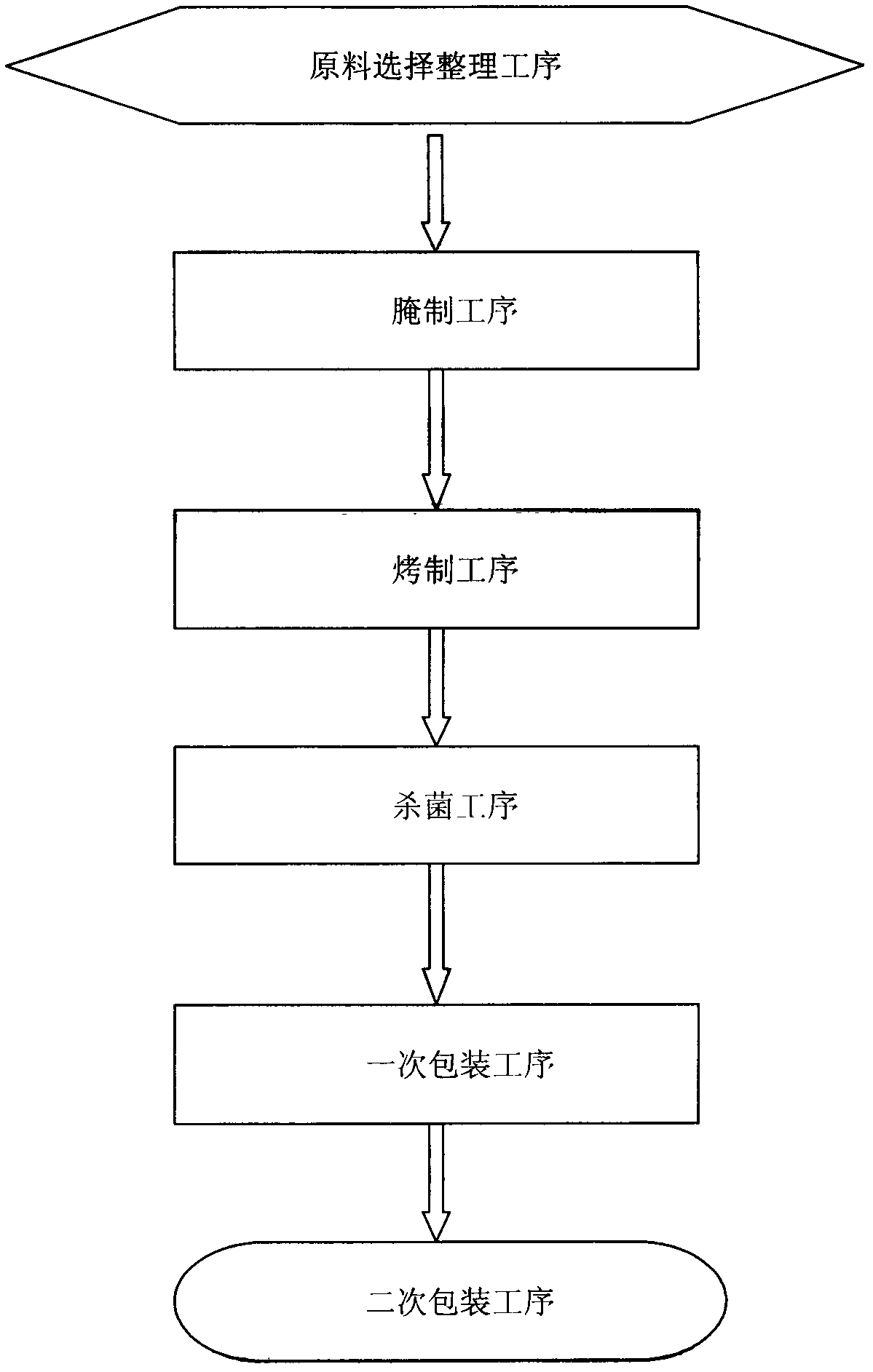

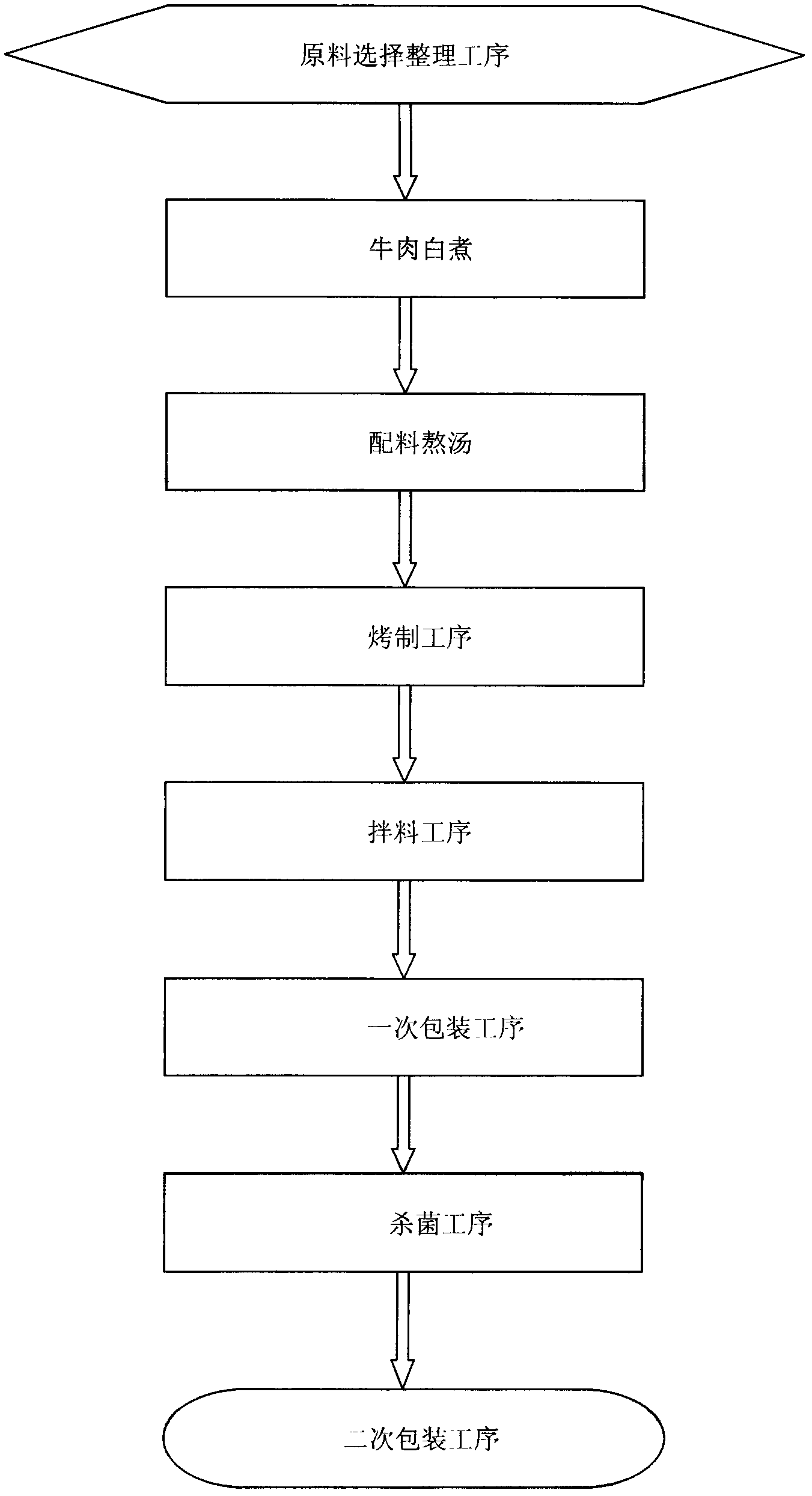

Accessories and method for making marinated products using accessories

Accessories and a method for making marinated products using the accessories relate to the technical field of meat processing. The accessories include galangal, dried bay leaves, star anise, pepper, Chinese red pepper, Sichuan pepper, cassia bark, fennel seeds, licorice root, nutmeg, amomum fruits, lemongrass and chili pepper. The method for making marinated products using the accessories mainly includes the steps of raw material selection and sorting, pre-boiling, stewing the accessories, re-boiling to season the raw material, primary packaging, sterilization and secondary packaging. The method combining traditional production process and industrial production process has complementary advantages of the traditional production process and the industrial production process, marinated products made by the method well retain color, fragrance, flavor and nutrients of sliced dried beef, the storage and quality guarantee of the products are facilitated , high chewiness of the products is maintained, and the products have the characteristics of uniform color, high yield and the like. The products produced by the method can meet needs of different people to the maximum extent.

Owner:燕凤兰

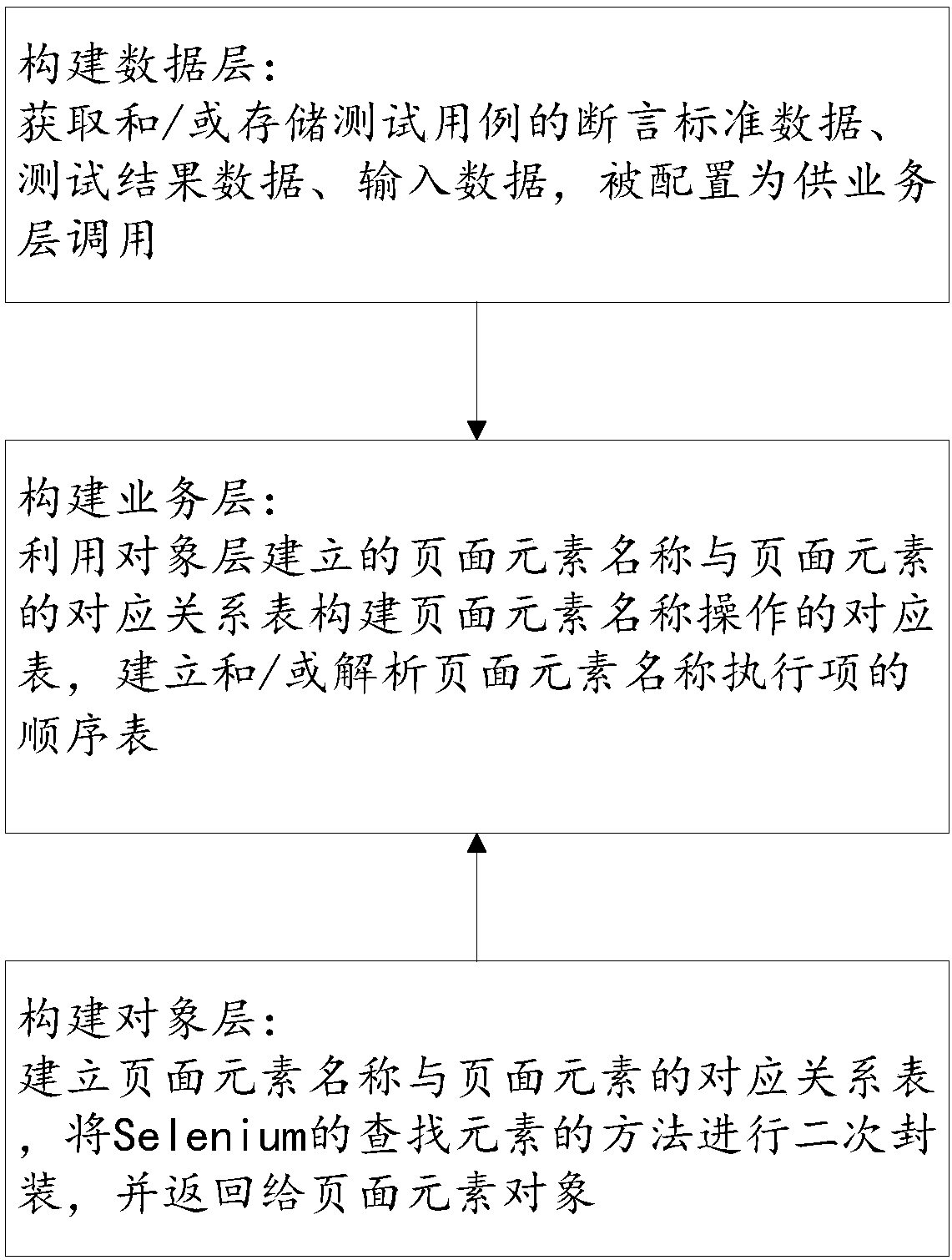

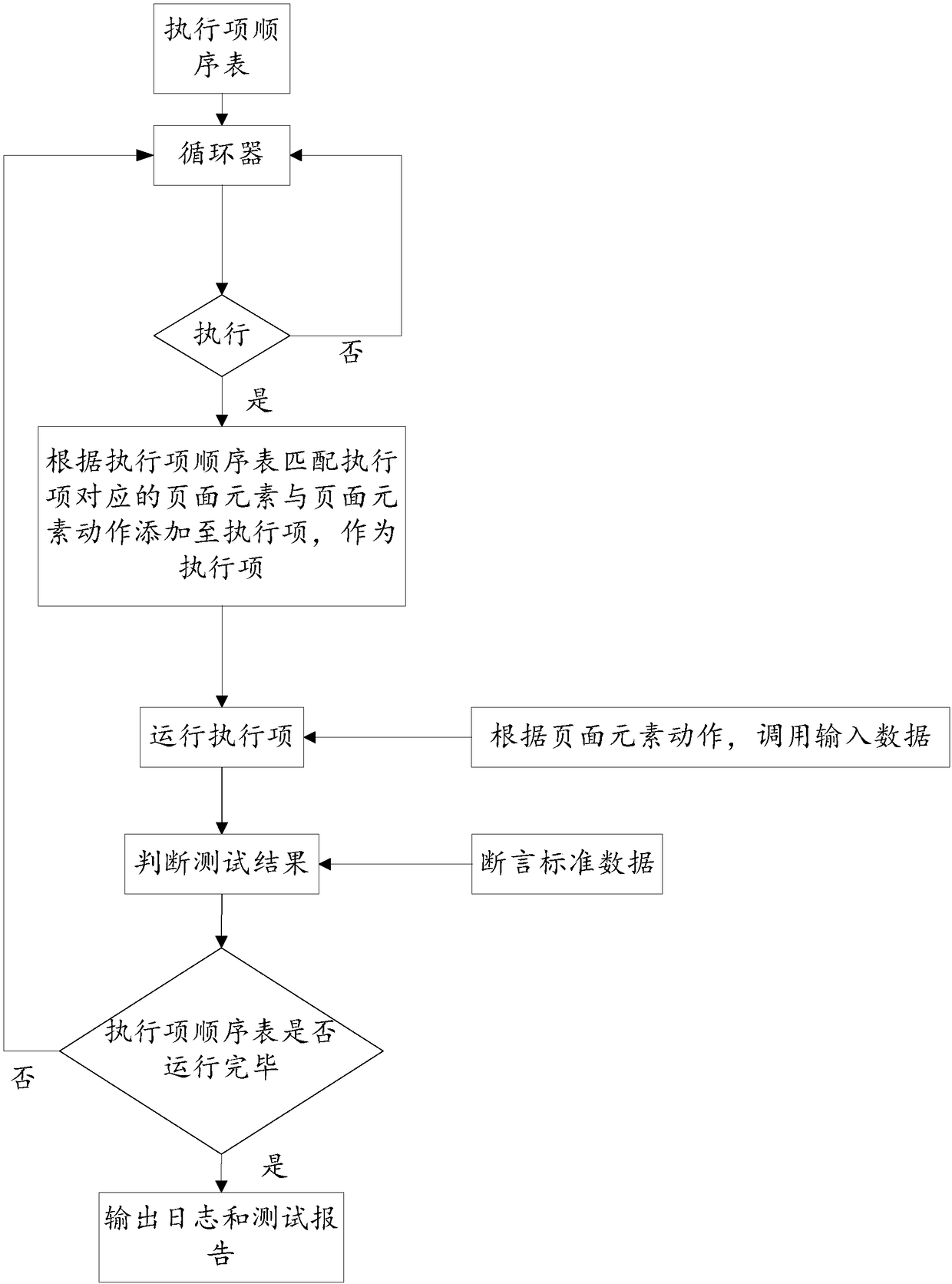

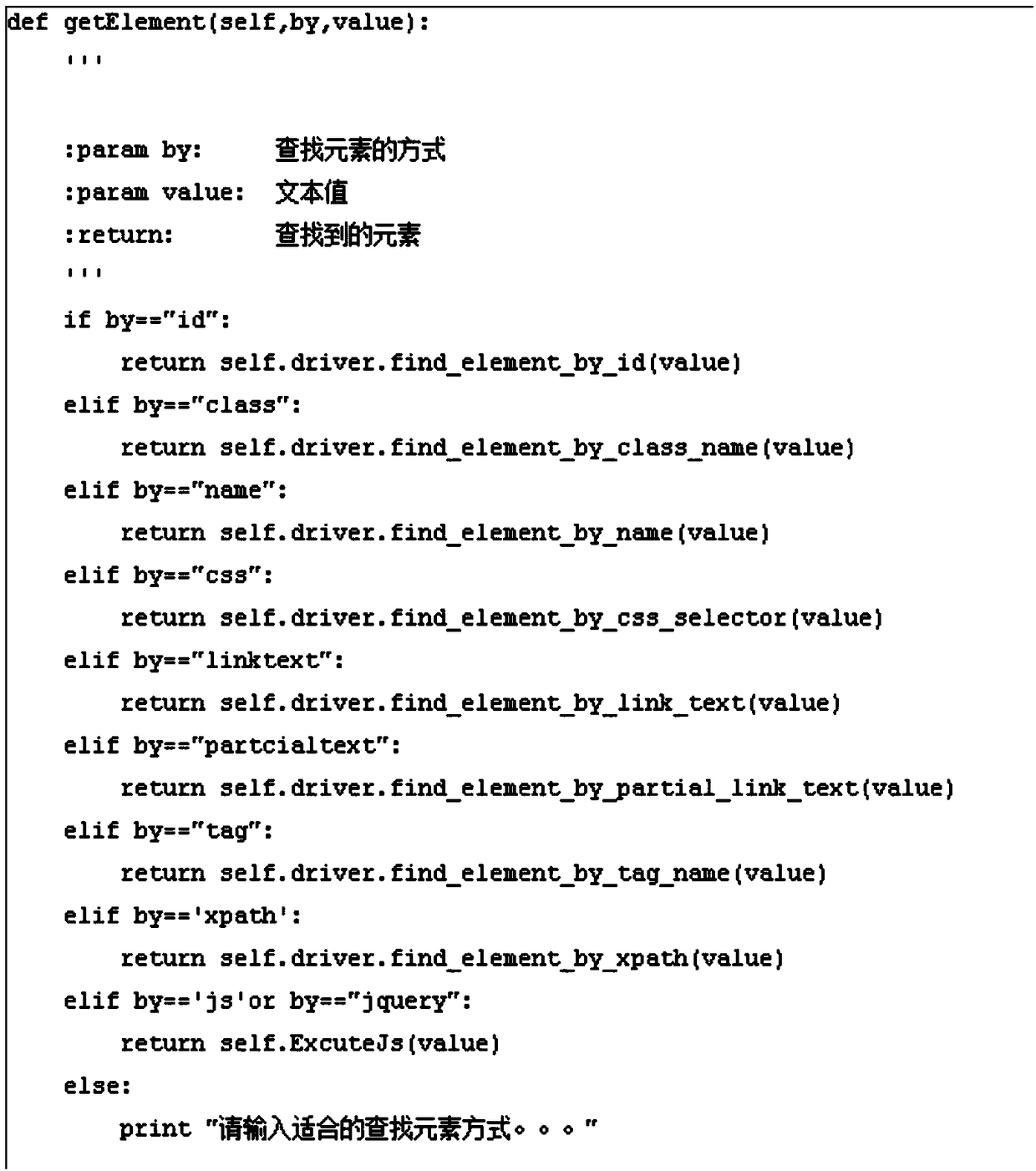

Web automation test method and method-based system

InactiveCN108491319AClear distributionEasy maintenanceSoftware testing/debuggingAutomatic testingDatabase

The invention discloses a Web automation test method and a method-based system. The Web automation test method comprises the steps of creating an automation test framework environment of Selenium; based on the environment, dividing test codes into forms of a data layer, an object layer and a business layer to perform automation testing; constructing the data layer: obtaining and / or storing assertion standard data, test result data and input data of test cases, wherein the data layer is configured to be called by the business layer; constructing an object layer: establishing a corresponding relationship table of page element names and page elements, performing secondary packaging on an element search method of the Selenium, and returning the corresponding relationship table to page elementobjects; and constructing the business layer: constructing a corresponding table of page element name operations by utilizing the corresponding relationship table of the page element names and the page elements, established by the object layer, and establishing and / or analyzing a sequence table of page element name execution items. Through hierarchical control, the data, object and business layersare mutually independent and distributed clearly, so that maintenance and modification are facilitated and flexibility is high.

Owner:GUANGZHOU LANGO ELECTRONICS TECH CO LTD

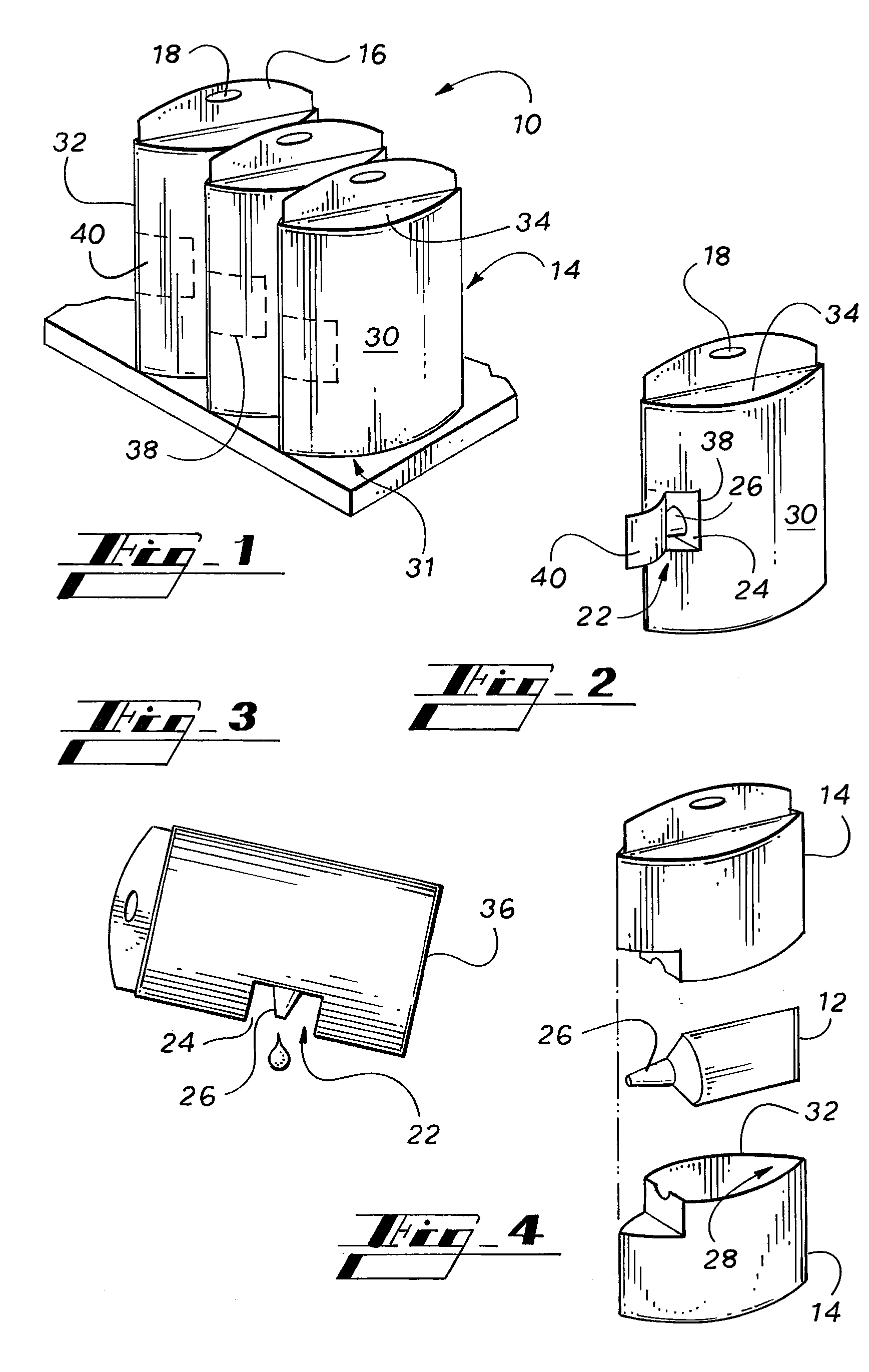

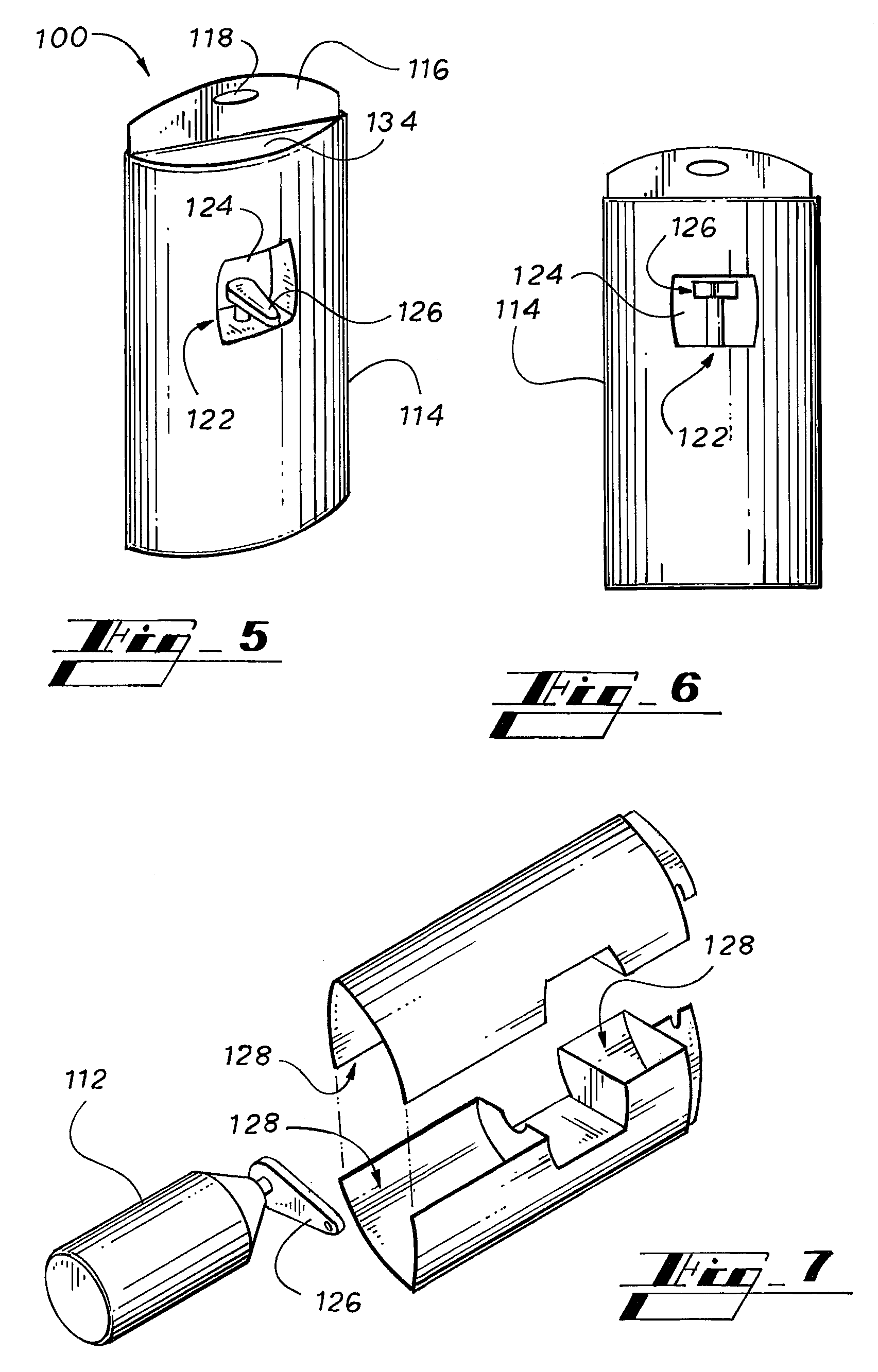

Package that provides immediate access

The present invention relates to packaging, and more specifically, to a package comprising an outer sleeve, a primary package, a severance line and means for providing access. Also disclosed is an improved secondary package comprising an outer sleeve defining a recess, at least one severance line defining a tear strip and an access aperture defined at least in part by an access window and recess. Further disclosed is a method for dispensing product from a primary container comprising acquiring a package having an outer sleeve and a primary container which includes a dispenser end, and manipulating the dispenser to allow dispensing of a limited amount of product.

Owner:MEADWESTVACO CORP

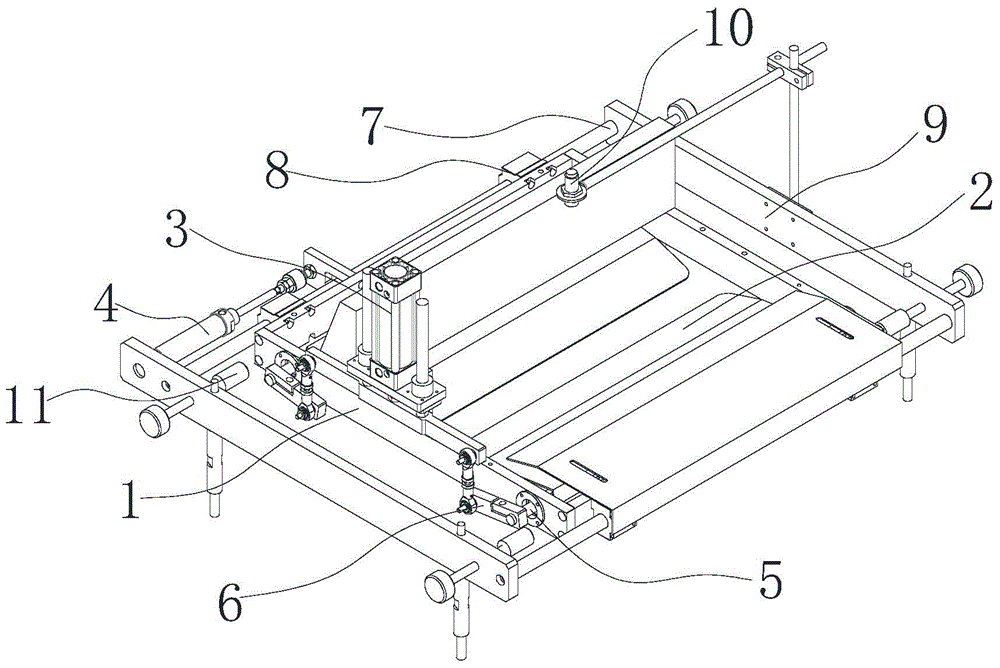

Automatic secondary bagging device and operating method thereof

PendingCN111268220AFully automatedNo waitingIndividual articlesPackaging machinesControl engineeringIndustrial engineering

The invention discloses an automatic secondary bagging device and an operating method thereof. The automatic secondary bagging device comprises a supporting rack. A feed conveying belt, a packet pushing mechanism, a packet supporting mechanism, a bag supporting mechanism, a sealing mechanism, a finished product conveying belt, a bag fetching mechanism, a bag opening mechanism, a bag supply mechanism and a warehousing conveying belt are arranged on the rack. The packet pushing mechanism is arranged above the feed conveying belt. The packet supporting mechanism is connected with the rear end ofthe feed conveying belt. The bag supporting mechanism is arranged next to the packet supporting mechanism. The sealing mechanism is arranged next to the bag supporting mechanism. The finished productconveying belt is arranged next to the sealing mechanism. The bag supply mechanism is arranged on the upper side of the warehousing conveying belt. By the adoption of the automatic secondary bagging device and the operating method thereof, full-automatic secondary packaging is realized; through the arrangement of upper and lower bag supporting arms of the bag supporting mechanism and a pushing structure, bag supporting, bagging and heat-sealing can be conducted synchronously, and complete synchronization with the packaging speed of a rice brick packaging line can be realized; and continuous feeding and bagging are realized, the labor intensity of workers is relieved, and the production efficiency is improved.

Owner:ANHUI YONGCHENG ELECTRONICS & MECHANICAL TECH

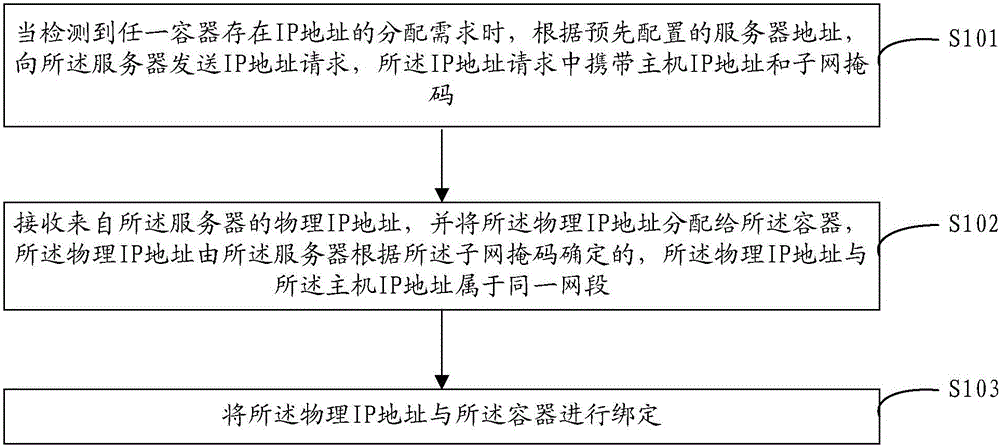

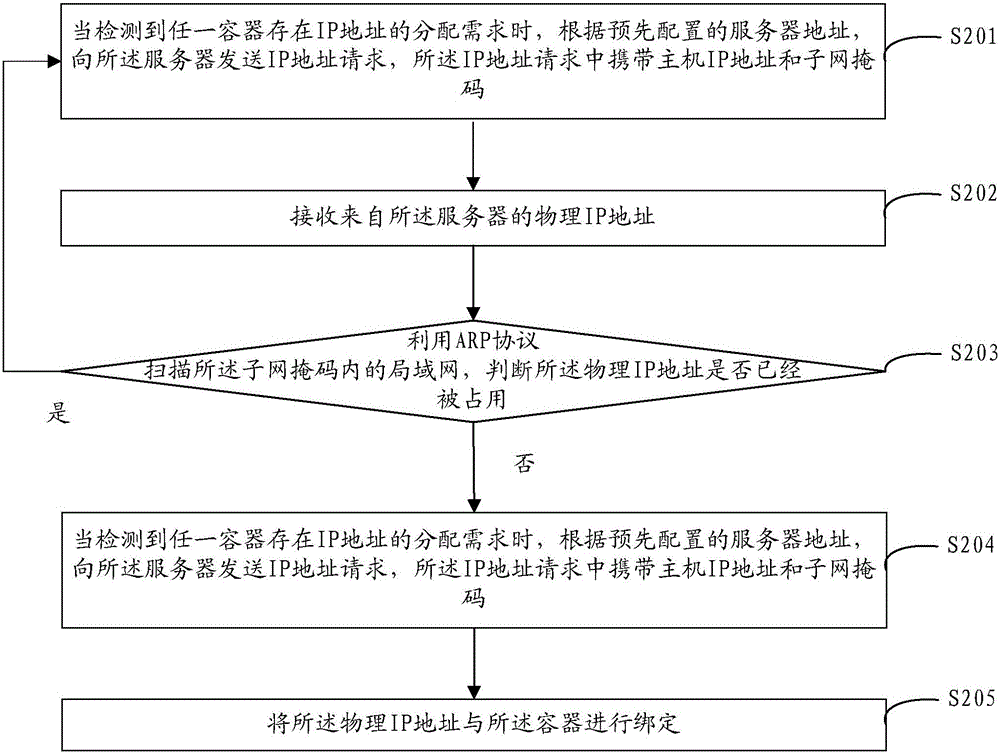

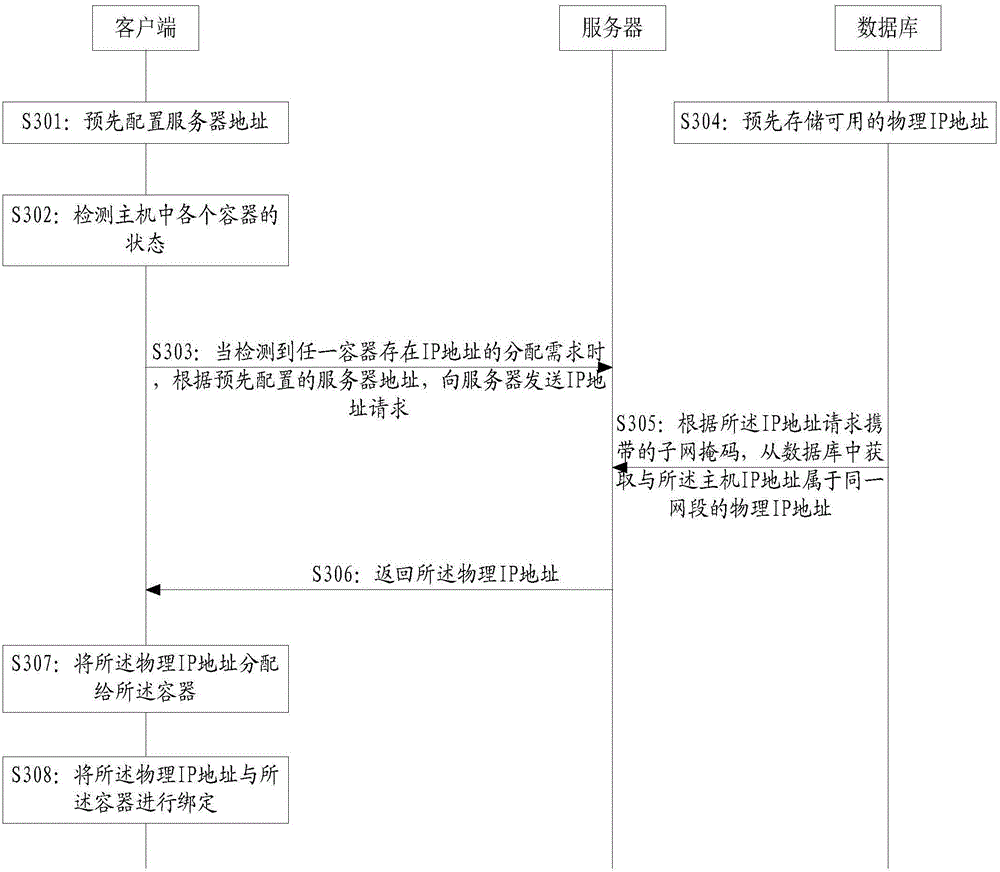

Method and device for allocating IP address to container

ActiveCN105763670AImprove efficiencyShorten the timeData switching networksDistributed computingPacket routing

The invention discloses a method for allocating an IP address to a container.The method includes the steps that when an IP address allocation request of any container is detected, an IP address request is sent to a server according to the pre-configured address of the server, wherein the IP address of a host and a subnet mask are carried in the IP address request; a physical IP address form the server is received and allocated to the container, wherein the physical IP address is determined by the server according to the subnet mask, and the physical IP address and the IP address of the host belong to one network segment; the physical IP address and the container are bound.According to the method, the physical IP address is allocated to the container; when the container of the host sends data, it is not needed that secondary packaging is carried out to meet the requirement a target visual IP address; meanwhile, a data packet does not need to be unpacked when being received, and the data packet is directly routed to the container corresponding to the physical IP address according to the physical IP address of the data packet.By means of the method, in the data communication process, packing time and unpacking time can be saved, and data communication efficiency can be improved.

Owner:BEIJING SOHU NEW MEDIA INFORMATION TECH

Rotary static pressure type undisturbed soil sampling device suitable for shallow strata and sampling method

ActiveCN108344595AIntegrity guaranteedSimple structureWithdrawing sample devicesEngineeringFoot type

The invention discloses a rotary static pressure type undisturbed soil sampling device suitable for a shallow strata. The sampling device comprises a soil sampling device body, the soil sampling device body comprises an outer barrel, the top of the outer barrel is connected with a hand-rotation rod, the hand-rotation rod is in screw joint connection with a three-foot type fixed mount, a pushing and pressing handle is arranged at the top of the outer barrel, an annular drilling tool is rotated and screwed at the bottom of the outer barrel, an annular bearing table with a groove is arranged on the inner wall of the annular drilling tool, a sampling inner barrel is connected to the interior of a cavity of the outer barrel through a bearing, and the lower end of the sampling inner barrel is arranged in the groove of the annular bearing table. The soil sampling device is simple in structure, small in size and convenient to carry and operate. During sampling, under the effect of the three-foot type fixed mount, the outer barrel can stably and evenly rotate and drill in vertically, and meanwhile drives the sampling inner barrel to enter a soil body with static pressure and no disturbance,sampling is finished at a time, and secondary packaging is not needed. In this way, disturbance is sufficiently reduced for a soil sample, the completeness of undisturbed soil is guaranteed, and theefficiency and the economy of soil sampling can be improved.

Owner:YELLOW RIVER ENG CONSULTING

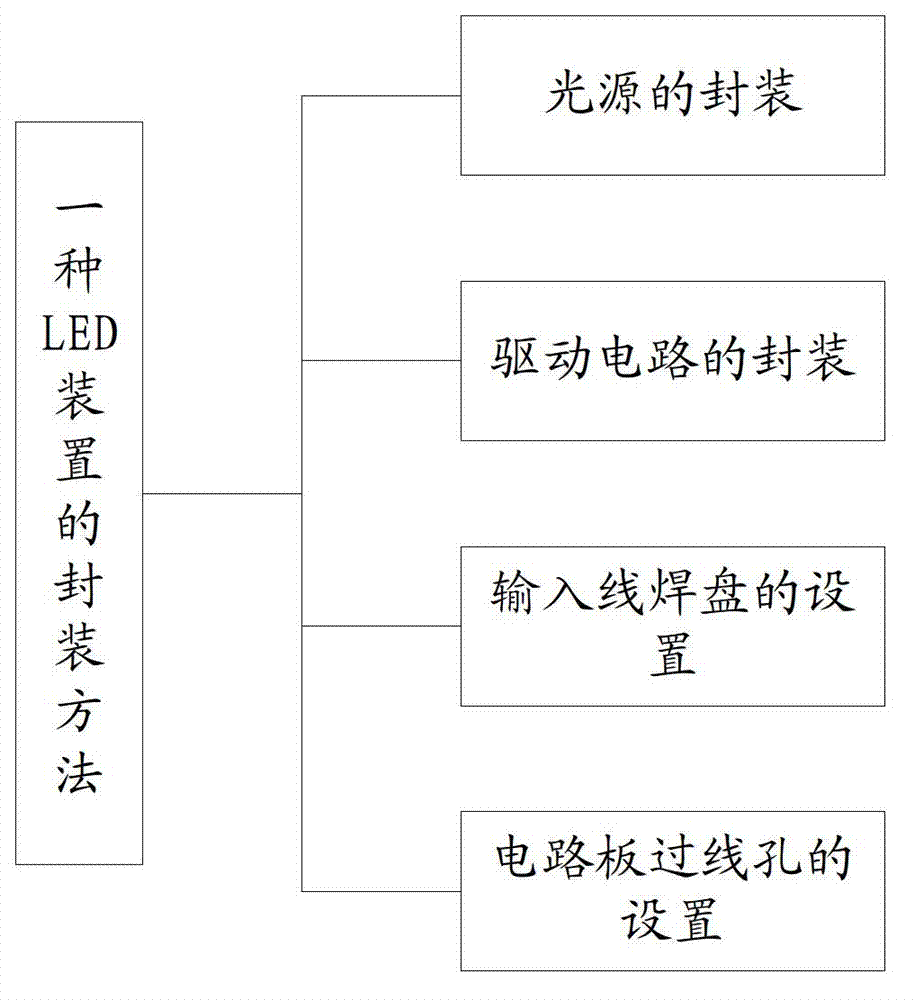

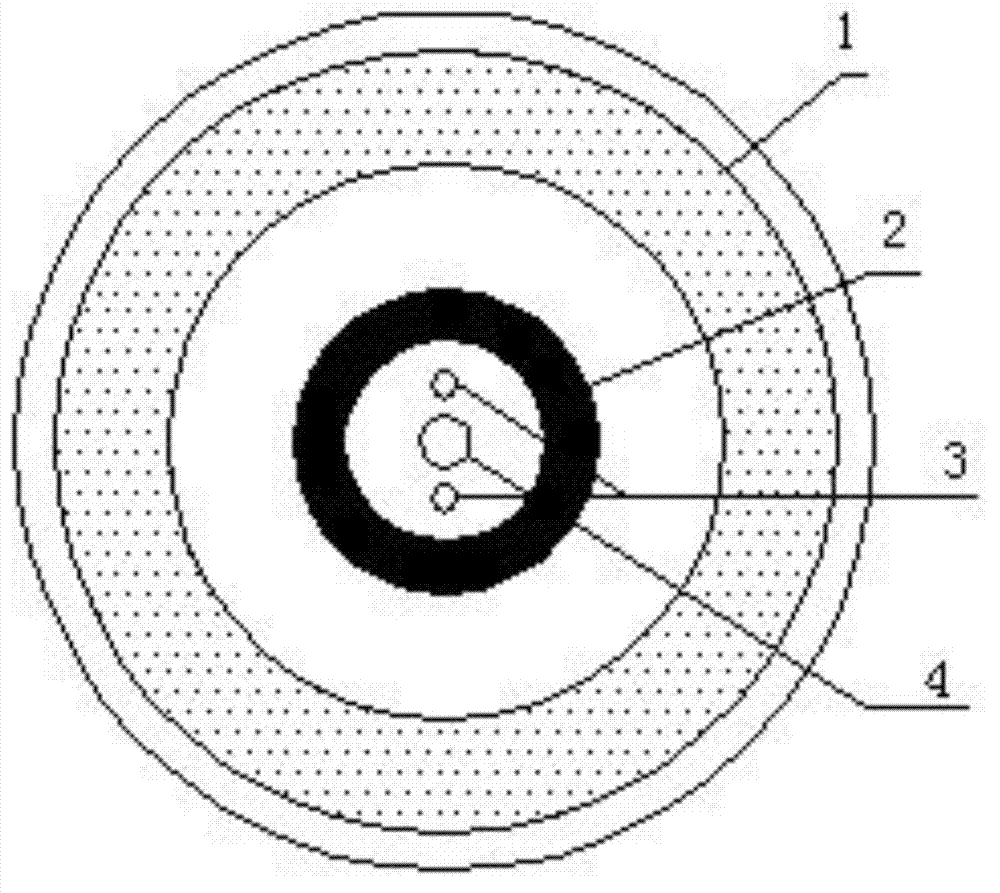

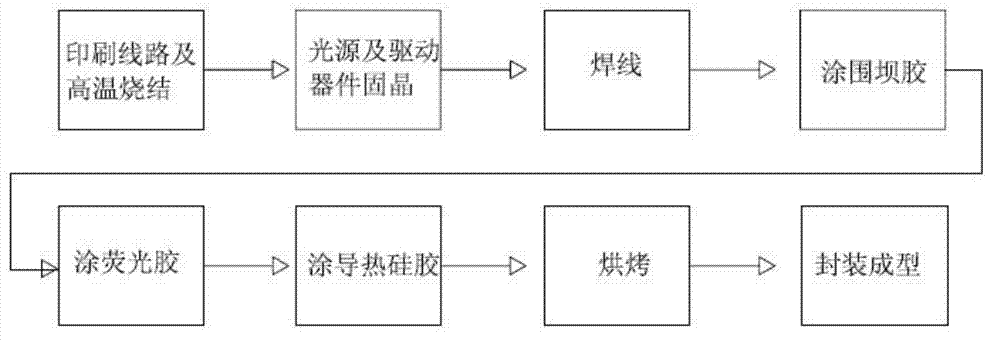

Packaging method of light-emitting diode (LED) device

InactiveCN103094454AHighly integratedSave on installation costsSemiconductor devicesOn boardEngineering

The invention relates to a packaging method of a light-emitting diode (LED) device. The packaging method of the LED device comprises the following steps. A light source is packaged, and the LED light source is packaged in a light source packaging zone by utilizing chip on board (COB) technology. A drive circuit is packaged, and all the elements of the drive circuit are also directly packaged in a drive circuit packaging zone on a light source circuit board. Wire inputting pads are printed at two ends of a wire passing hole so that power wires can be conveniently input in a welding mode. The light source packaging zone and the drive circuit packaging zone are fixed, and the drive circuit packaging zone is fixed on the light source packaging zone to form a LED device main body. According to the packaging method of the Led device, a light and electric integrated module with high integration density is achieved. The COB packaging technology is utilized by the light source in the design method, materials of secondary packaging and a device support frame are removed, and cost is greatly reduced. Packaging procedures are simple and convenient, and size is greatly reduced so that light-emitting efficiency of the LED light source is improved. The design method of integration of the light source and a drive removes a position special for placing the drive in the design of the whole light, installation technology is simplified, and cost in whole light installation and production is greatly reduced, and the method of the LED device is suitable for massive automatic production.

Owner:AD TOYO LIGHTING GUANGZHOU

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com