Secondary packing machine of woven bags

A secondary packaging, woven bag technology, applied in packaging and other directions, can solve the problems affecting the normal operation of the machine, low efficiency and safety, poor bag holding stability, etc., to improve work efficiency, safety performance, and work stability. Improved performance and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

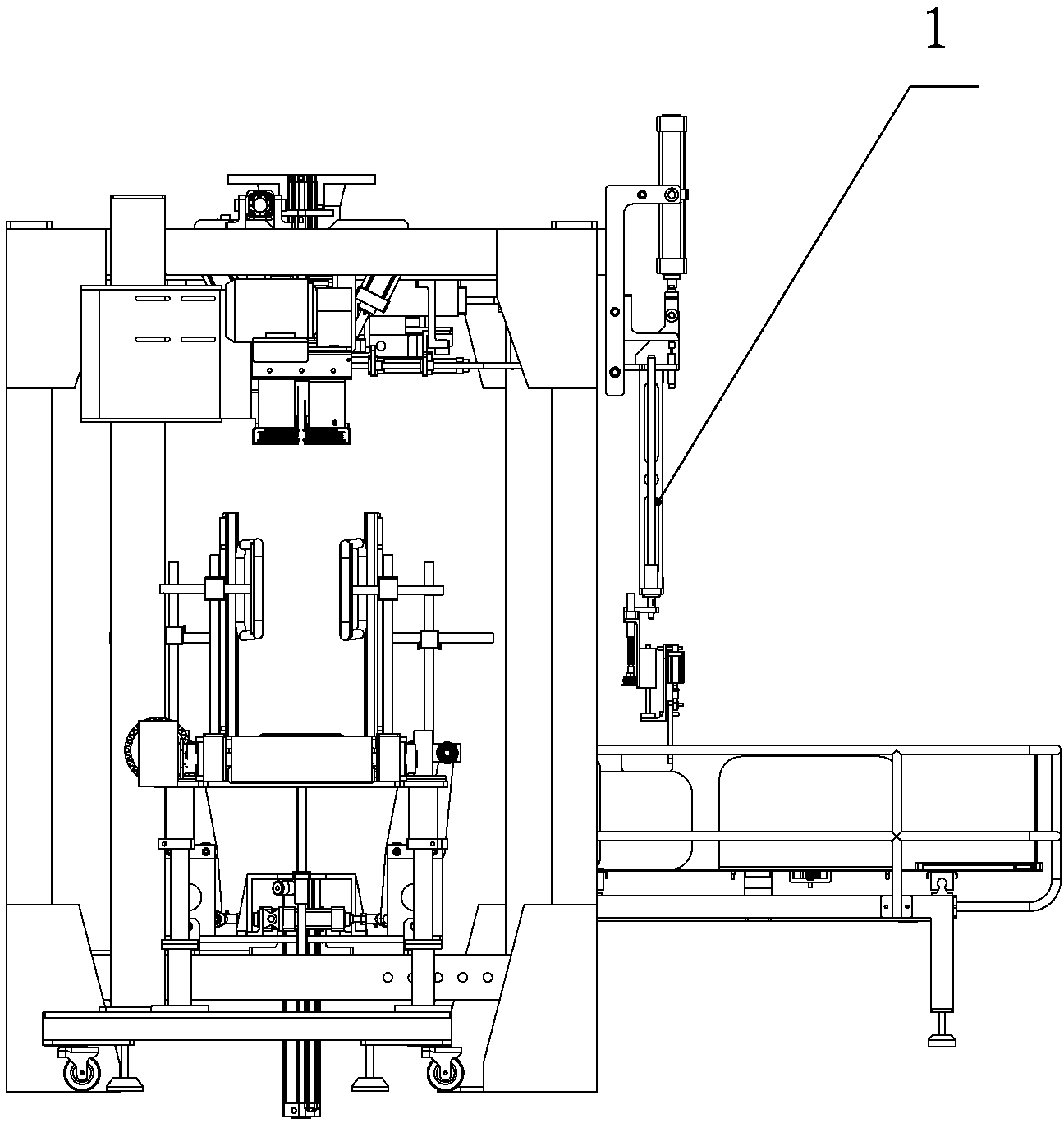

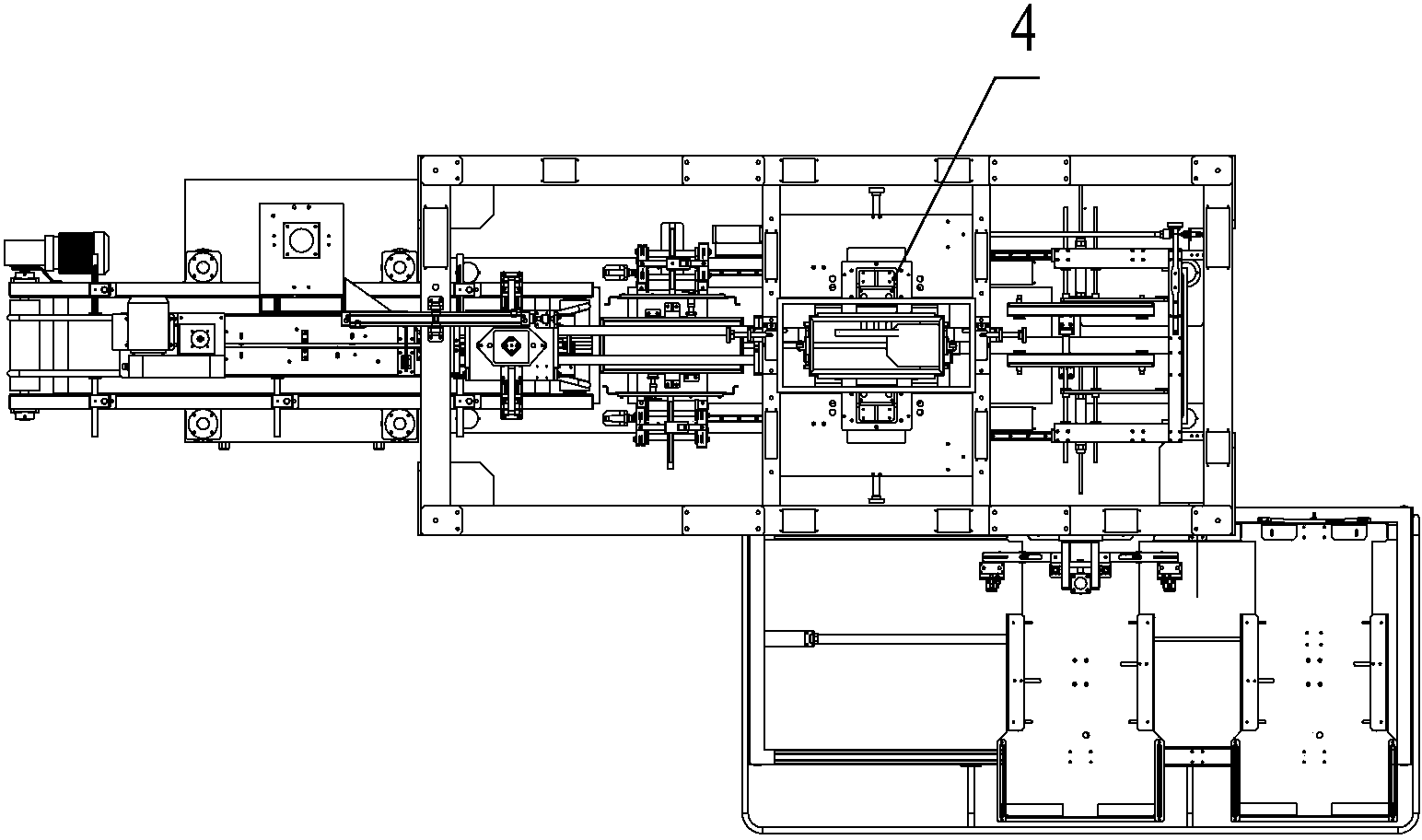

[0023] see Figure 1-3 , as shown in the figure, a secondary packaging machine for woven bags includes a sewing bag conveying line 7, a bag preparation mechanism 2, a bag feeding mechanism 1, a bag clamping mechanism 4, a bag opening mechanism 3, an M side mechanism 6, a bag holding mechanism Agency 5.

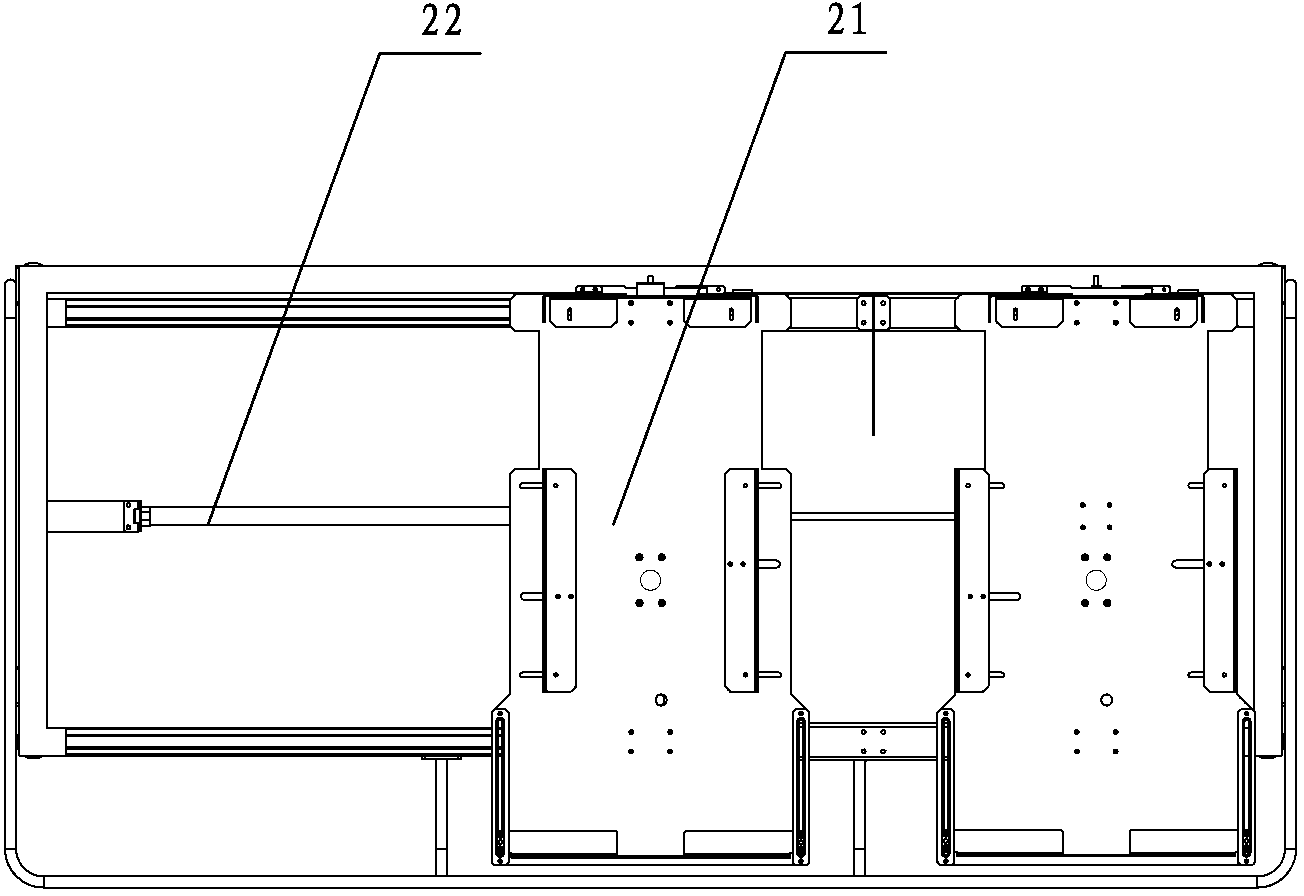

[0024] see Figure 4 , prepare bag mechanism 2, comprise frame, be provided with prepare bag storehouse 21 on the frame, prepare bag storehouse 21 one sides and push the push rod connection of bag cylinder 22.

[0025] see Figure 5 , the bag-opening mechanism 3 includes a bag-pushing cylinder 33 fixedly installed on the lifting plate of the bag-clamping device, the front end of the piston rod of the bag-pushing cylinder 33 is connected with a horizontal connecting plate, and a sliding connecting plate is fixed on the connecting plate, and the sliding connecting plate Sliding plates are fixed on both sides of the sliding plate, and the outer side of the sliding plate is sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com