Low-thermal-bridge vacuum insulated panel

A technology of vacuum insulation panels and thermal bridges, which is applied to heat exchange equipment, pipelines through thermal insulation, thermal insulation, etc., can solve the problems of heat loss and thermal insulation effect, and achieve weight reduction, good fire performance, and reduction of surface thermal bridges. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

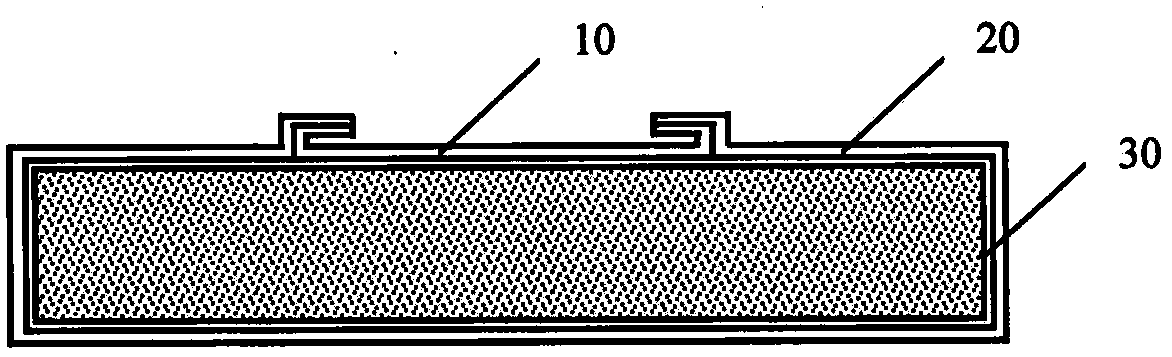

[0020] A vacuum insulation panel with low thermal bridge, which has upper and lower edge sealing structures, and is encapsulated by two high-barrier membrane materials of different materials and sizes, among which the membrane material with a larger area is the main packaging membrane material, wrapping the core material around, and the smaller membrane material is the sub-encapsulation membrane material, which partially covers the upper or lower packaging surface of the vacuum insulation panel.

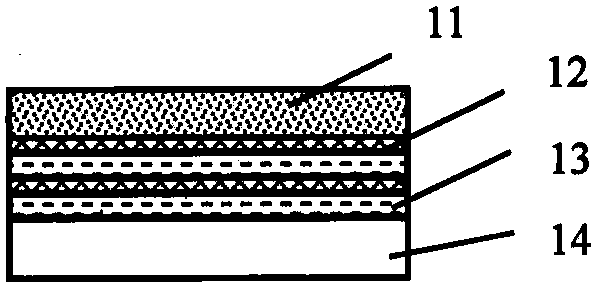

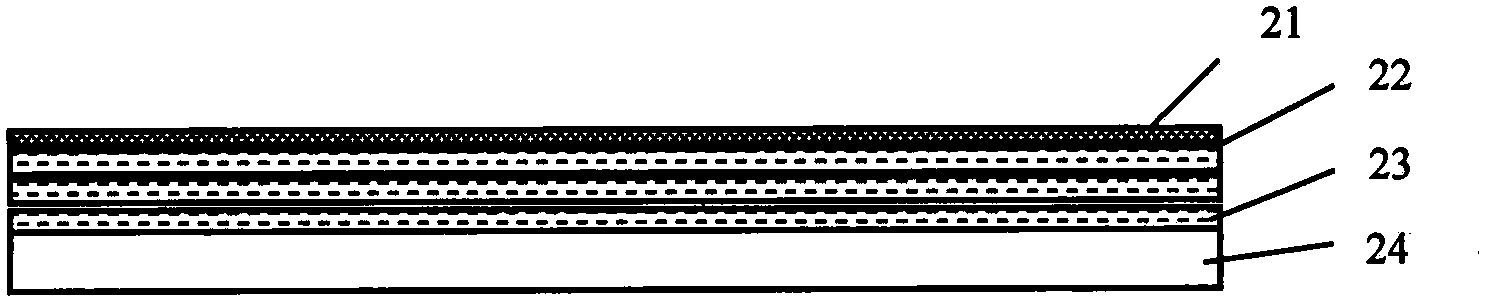

[0021] The main packaging film material contains multiple aluminum film layers, and the thickness of a single aluminum film layer is 20nm; while the secondary packaging film material does not contain a metal layer. The outermost layer of the main packaging film is 15 μm amorphous nylon (PA), the innermost layer is 50 μm polyethylene film (PE), and the middle layer contains 2 layers of polyester (PET) and aluminum film. The polyester (PET) layer has a thickness of 20 μm. The outermos...

Embodiment 2

[0024] A vacuum insulation panel with low thermal bridge, which has upper and lower edge sealing structures, and is encapsulated by two high-barrier membrane materials of different materials and sizes, among which the membrane material with a larger area is the main packaging membrane material, wrapping the core material around, and the smaller membrane material is the sub-encapsulation membrane material, which partially covers the upper or lower packaging surface of the vacuum insulation panel.

[0025] Both the main packaging film and the secondary packaging film are composed of multi-layer film materials, including an outer protective layer, a heat-sealing layer and a barrier layer. It is characterized in that the main packaging film contains multiple aluminum film layers, and the single-layer aluminum The thickness of the film layer is 50nm; and the sub-encapsulation film material does not contain a metal layer. The outermost layer of the main packaging film is a 13 μm car...

Embodiment 3

[0028] A vacuum insulation panel with low thermal bridge, which has upper and lower edge sealing structures, and is encapsulated by two high-barrier membrane materials of different materials and sizes, among which the membrane material with a larger area is the main packaging membrane material, wrapping the core material around, and the smaller membrane material is the sub-encapsulation membrane material, which partially covers the upper or lower packaging surface of the vacuum insulation panel.

[0029] Both the main packaging film and the secondary packaging film are composed of multi-layer film materials, including an outer protective layer, a heat-sealing layer and a barrier layer. It is characterized in that the main packaging film contains multiple aluminum film layers, and the single-layer aluminum The thickness of the film layer is 100nm; and the sub-encapsulation film material does not contain a metal layer. The outermost layer of the main packaging film is 10 μm carb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com