Lithium-rich manganese-based high-energy-density lithium-ion battery and preparation method thereof

A lithium-ion battery, high energy density technology, applied in electrolyte battery manufacturing, secondary batteries, battery electrodes, etc., can solve the problems that restrict the development and application of silicon materials, and achieve high energy density, high safety factor, and long cycle life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

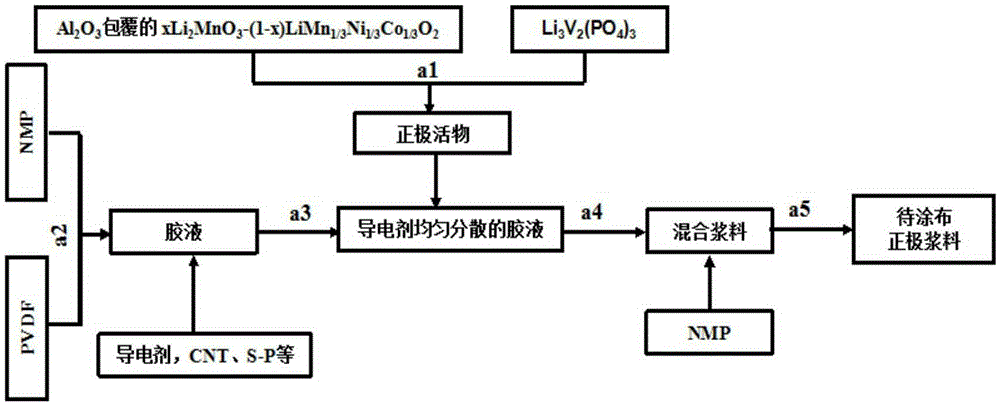

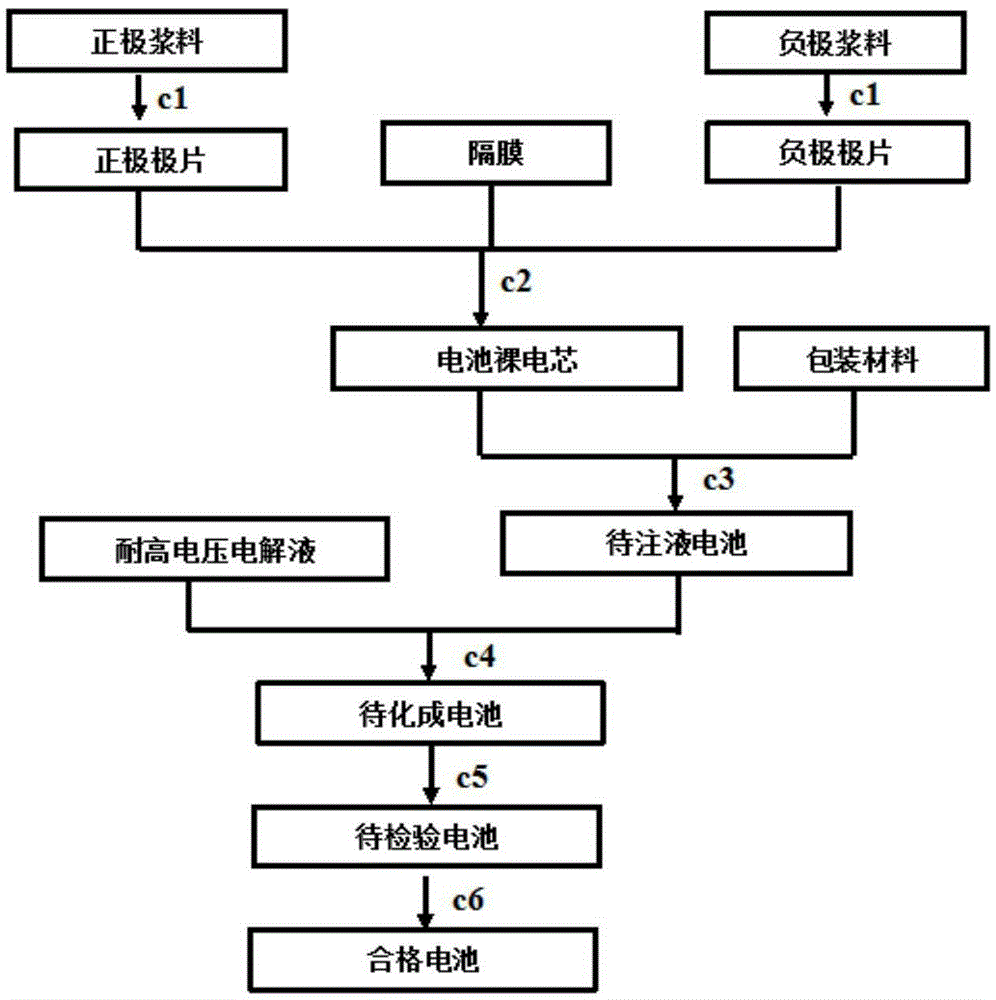

[0052] The preparation of positive and negative electrode slurries is one of the keys to the excellent performance of the patented battery. Here, combined with the attached figure 1 with attached figure 2 Describe in detail.

[0053] For the preparation of positive electrode slurry, see attached figure 1 . Operation a1, Al by mass ratio 95:5 2 o 3 Coated 0.3Li 2 MnO 3 -0.7LiMn 1 / 3 Ni 1 / 3 co 1 / 3 o 2 with Li 3 V 2 (PO 4 ) 3 Mixing ball milling for 4-24 hours; process a2, dissolving PVDF in NMP to make a glue solution with a mass fraction of 10%; process a3, adding CNT slurry, after high-speed dispersion for 1 hour, adding S-P high-speed stirring for 1-2 hours; process a4, Add the mixed active material prepared in step a1 in 3-5 times, and stir for 3-6 hours; step a5, add a small amount of NMP, adjust the viscosity to 6000-12000cp, and obtain the positive electrode slurry to be coated. The ratio of the positive electrode slurry active material, CNT, S-P, and PVDF ...

Embodiment 2

[0062] For the preparation of positive electrode slurry, see attached figure 1 . Operation a1, Al by mass ratio 98:2 2 o 3 Coated 0.3Li 2 MnO 3 -0.7LiMn 1 / 3 Ni 1 / 3 co 1 / 3 o 2 with Li 3 V 2 (PO 4 ) 3 Mixing ball milling for 4-24 hours; process a2, dissolving PVDF in NMP to make a glue solution with a mass fraction of 10%; process a3, adding CNT slurry, after high-speed dispersion for 1 hour, adding S-P high-speed stirring for 1-2 hours; process a4, Add the mixed active material prepared in step a1 in 3-5 times, and stir for 3-6 hours; step a5, add a small amount of NMP, adjust the viscosity to 6000-12000cp, and obtain the positive electrode slurry to be coated. The ratio of the positive electrode slurry active material, CNT, S-P, and PVDF is 94:1:2:3.

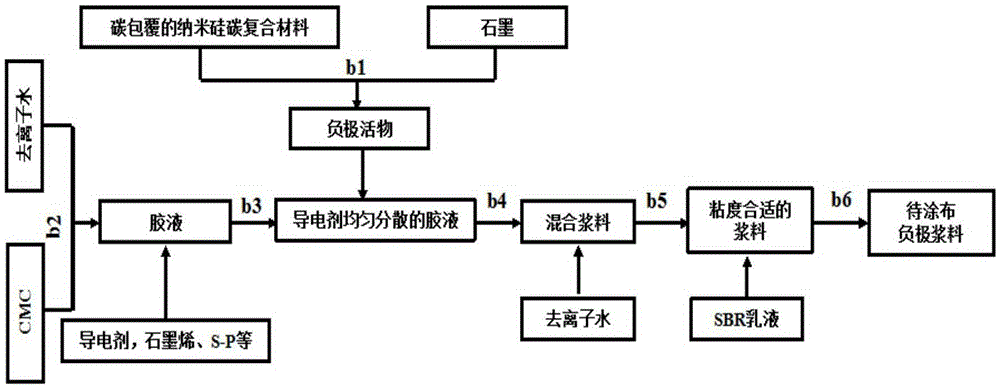

[0063] For the preparation of negative electrode slurry, see attached figure 2 . Process b1, mixing carbon-coated silicon carbide material (80% by mass of silicon carbide) and artificial graphite at a mass ratio ...

Embodiment 3

[0071] For the preparation of positive electrode slurry, see attached figure 1 . Operation a1, Al by mass ratio 95:5 2 o 3 Coated

[0072] 0.5Li 2 MnO 3 -0.5LiMn 1 / 3 Ni 1 / 3 co 1 / 3 o 2 with Li 3 V 2 (PO 4 ) 3 Mixing ball milling for 4-24 hours; process a2, dissolving PVDF in NMP to make a glue solution with a mass fraction of 10%; process a3, adding CNT slurry, after high-speed dispersion for 1 hour, adding S-P high-speed stirring for 1-2 hours; process a4, Add the mixed active material prepared in step a1 in 3-5 times, and stir for 3-6 hours; step a5, add a small amount of NMP, adjust the viscosity to 6000-12000cp, and obtain the positive electrode slurry to be coated. The ratio of the positive electrode slurry active material, CNT, S-P, and PVDF is 94:1:2:3.

[0073] For the preparation of negative electrode slurry, see attached figure 2 . Process b1, mixing carbon-coated silicon carbide material (80% by mass of silicon carbide) and artificial graphite at a m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com