Lithium battery packaging, testing, sorting and edge-folding full automatic production line

A packaging and testing, fully automatic technology, applied in the direction of lithium battery, battery assembly machine, secondary battery manufacturing, etc., can solve problems such as gaps, achieve high production efficiency, high degree of automation, and improve consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to enable those skilled in the art to better understand the technical solution of the present invention, the product of the present invention will be further described in detail below in conjunction with the embodiments and accompanying drawings.

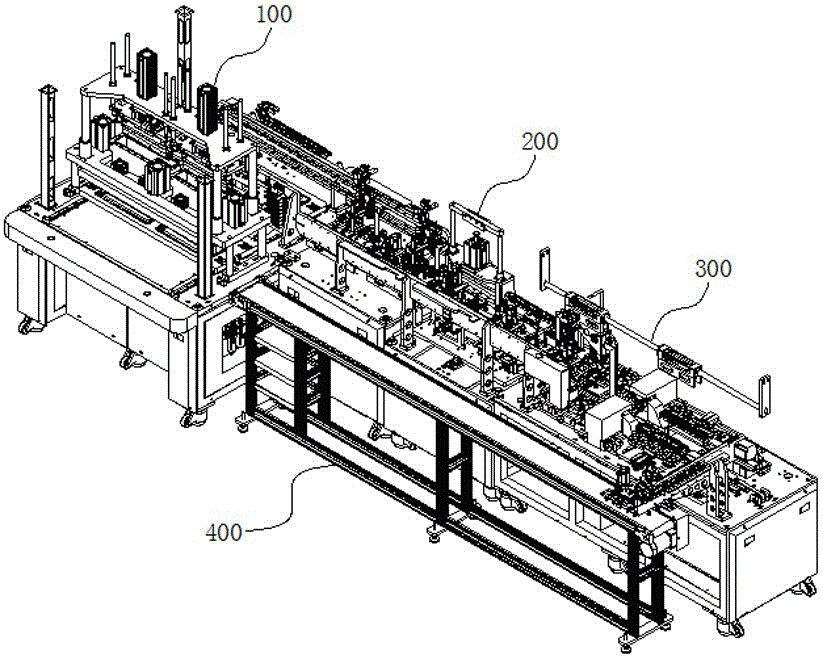

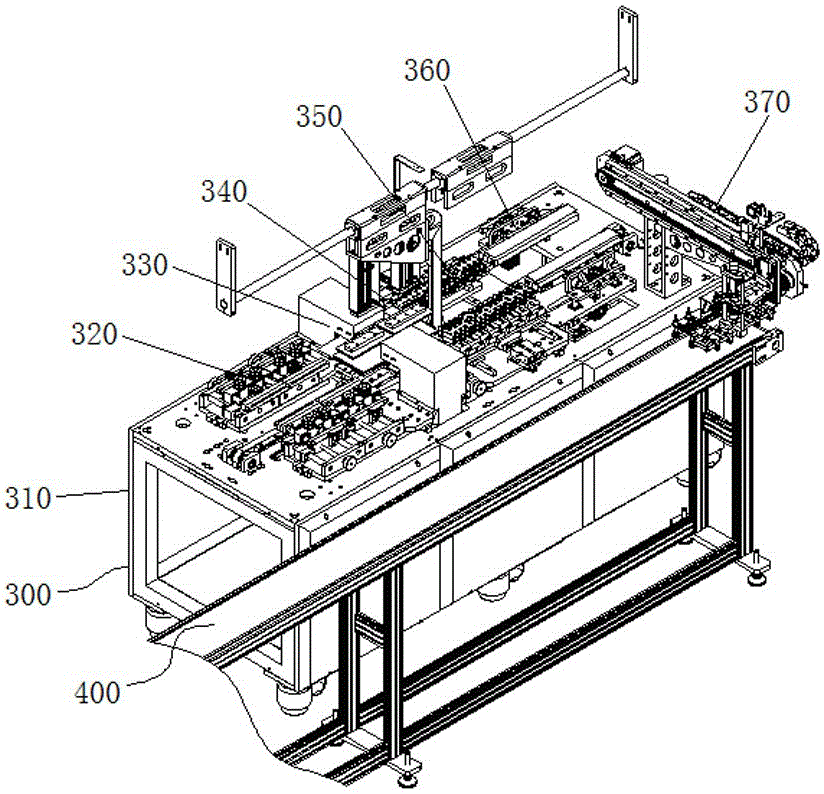

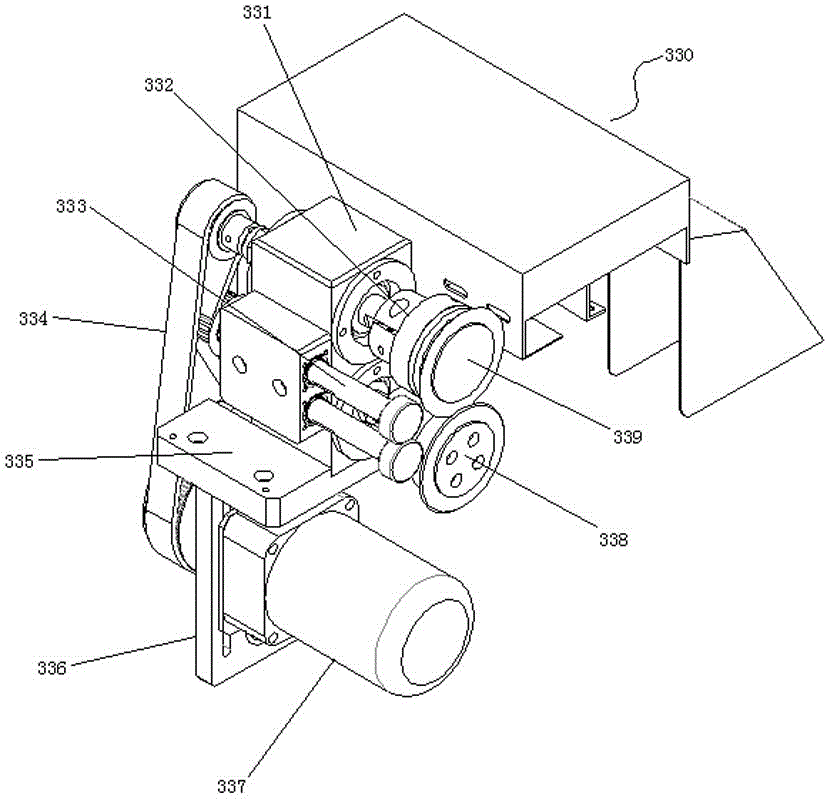

[0037] Such as figure 1 , figure 2 , Figure 9 with Figure 10 As shown, a fully automatic production line for packaging, testing, sorting and folding of lithium batteries includes a two-sealing part 100, a sealing test part 200, a cutting, folding and ironing part 300 and a control system. The cutting, folding and ironing part 300 is arranged in turn from one side to the other side, and the pneumatic or electric devices in the two sealing parts 100, the sealing test part 200 and the cutting, folding and ironing part 300 are connected to the control system, and the sealing and sealing test The part 200 and the front of the cutting, folding and ironing part 300 are provided with a discharge pull wire 400, the two-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com