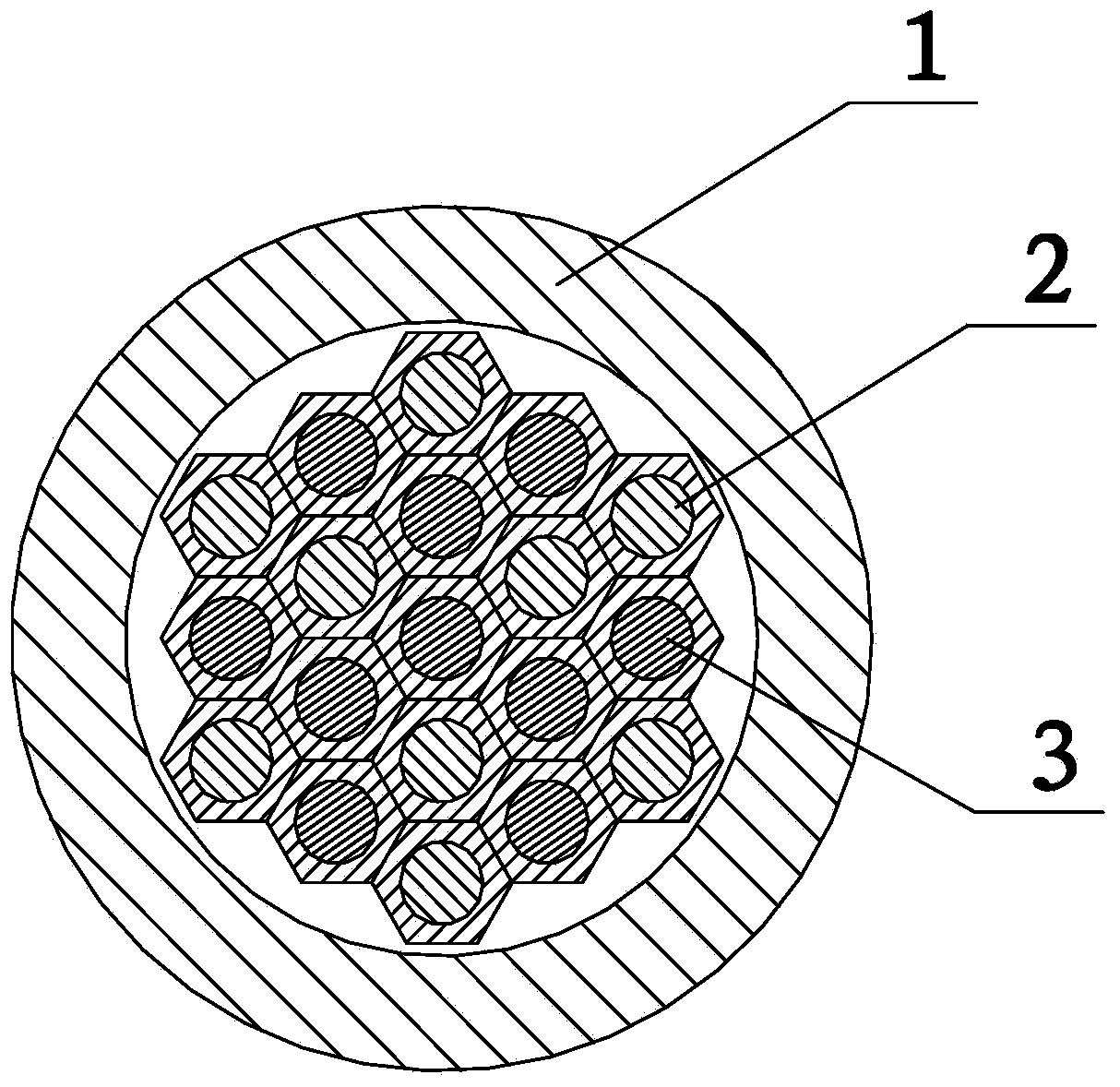

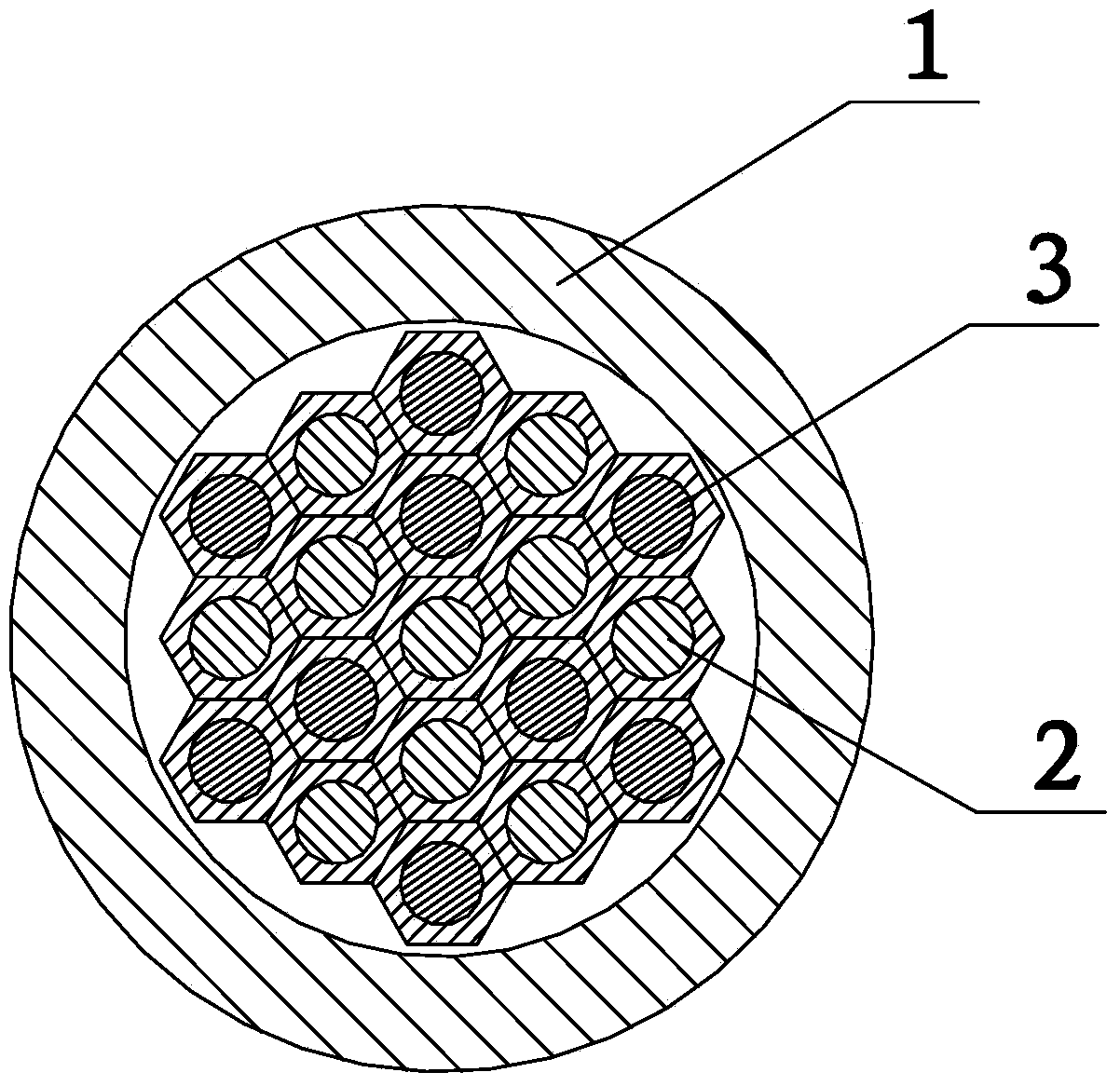

Preparation method of rectangular multicore composite superconductive strip

A technology of superconducting strips and composite strips, applied in the usage of superconducting elements, superconducting devices, superconducting/high-conducting conductors, etc., can solve the problems of mechanical system energy difference, quenching, etc., and achieve wide temperature use Range, high C activity, and uniform core wire size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Step 1, mixing amorphous boron powder and magnesium powder according to the atomic ratio of Mg:B=1:2, mixing evenly, then adding malic acid ethanol solution to the mixture, stirring at 200r / min for 90min to obtain a mixed slurry; The quality of malic acid in the described malic acid ethanol solution is 10% of the total mass of amorphous boron powder and magnesium powder; the mass percentage concentration of malic acid in the described malic acid ethanol solution is 15%;

[0034] Step 2. Pour the mixed slurry described in step 1 into a petri dish, put it in a vacuum oven, dry it in a vacuum at 50°C, and grind it to obtain a powder; put the powder in a tube furnace, Under protection, the temperature was raised to 180°C at a rate of 0.5°C / min, and then the temperature was kept at a constant temperature for 2 hours for low-temperature decomposition treatment. After cooling with the furnace, it was ground evenly to obtain the tube-filled precursor powder;

[0035] Step 3, pa...

Embodiment 2

[0042] Step 1, mix amorphous boron powder and magnesium powder according to the atomic ratio of Mg:B=1:2, mix evenly, then add malic acid ethanol solution to the mixture, and stir at 400r / min for 30min to obtain a mixed slurry; The quality of malic acid in the described malic acid ethanol solution is 30% of the total mass of amorphous boron powder and magnesium powder; the mass percent concentration of malic acid in the described malic acid ethanol solution is 25%;

[0043] Step 2. Pour the mixed slurry described in step 1 into a petri dish, put it in a vacuum oven, dry it in a vacuum at 60°C, and grind it to obtain a powder; put the powder in a tube furnace, Under protection, the temperature was raised to 200°C at a rate of 1°C / min, and then the temperature was kept at a constant temperature for 1 hour for low-temperature decomposition treatment. After cooling in the furnace, it was ground evenly to obtain the tube-filled precursor powder;

[0044] Step 3, packing the tube-pa...

Embodiment 3

[0051] Step 1, mixing amorphous boron powder and magnesium powder according to the atomic ratio of Mg:B=1:2, mixing evenly, then adding malic acid ethanol solution to the mixture, stirring at 300r / min for 60min, to obtain a mixed slurry; The quality of malic acid in the described malic acid ethanol solution is 20% of the total mass of amorphous boron powder and magnesium powder; the mass percentage concentration of malic acid in the described malic acid ethanol solution is 20%;

[0052]Step 2. Pour the mixed slurry described in step 1 into a petri dish, put it in a vacuum oven, dry it in a vacuum at 55°C, and grind it to obtain a powder; put the powder in a tube furnace, Under protection, the temperature was raised to 200°C at a rate of 1°C / min, and then the temperature was kept at a constant temperature for 1 hour for low-temperature decomposition treatment. After cooling in the furnace, it was ground evenly to obtain the tube-filled precursor powder;

[0053] Step 3, packing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com