Package bag secondary automatic packaging system

An automatic packaging and bagging technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of random packaging, messy packaging, inconvenient management of enterprises, etc., to reduce labor intensity of workers and enhance installation performance. , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

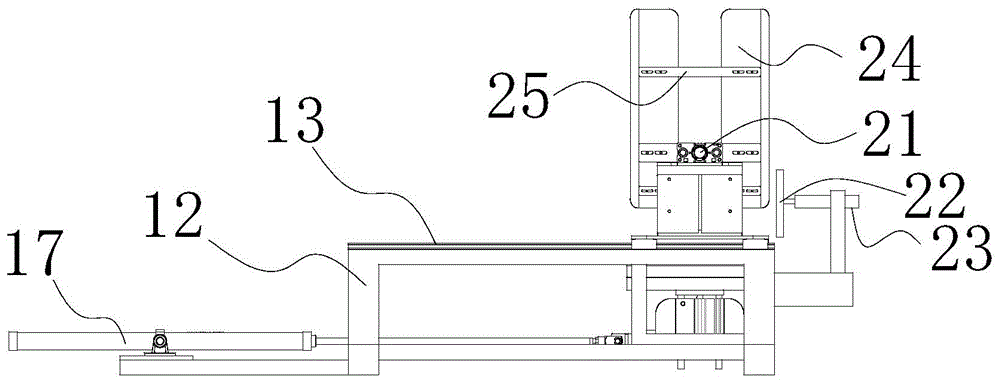

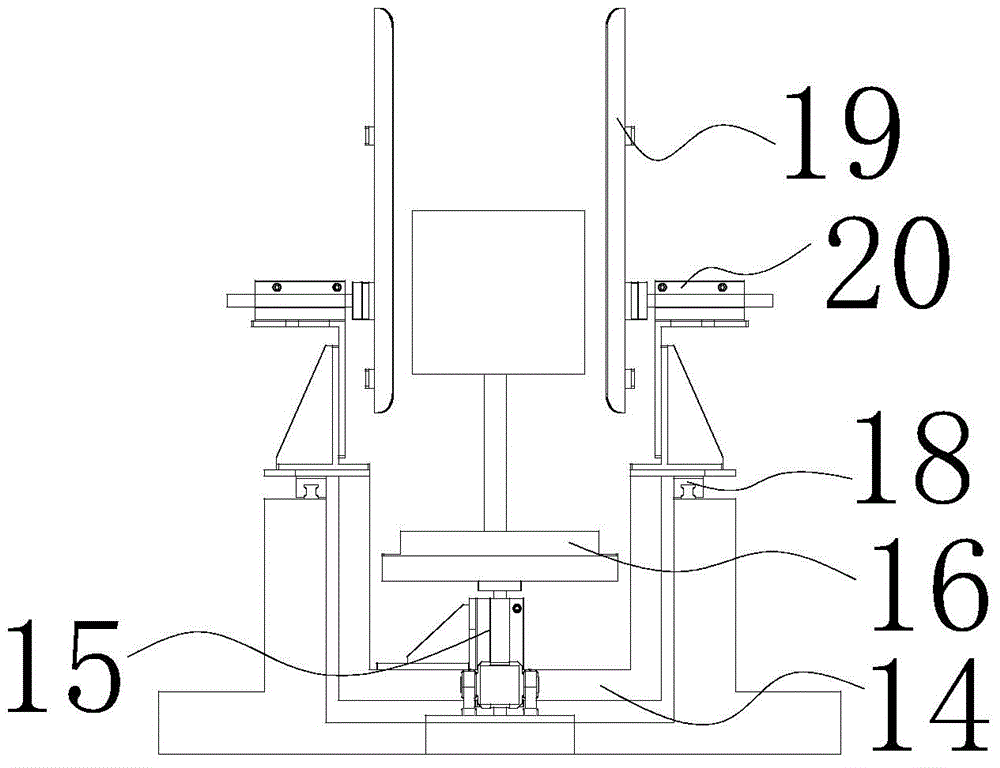

[0035] Secondary automatic packaging system for packaging bags, which includes secondary packaging automatic bag discharge mechanism, secondary packaging machine bag collection warehouse, secondary packaging machine bag taking and bag opening mechanism, secondary packaging machine bag storage mechanism, secondary packaging machine bag support Mechanism, secondary packaging machine bag opening shaping heat sealing mechanism, secondary packaging machine dragging bag bag holding mechanism.

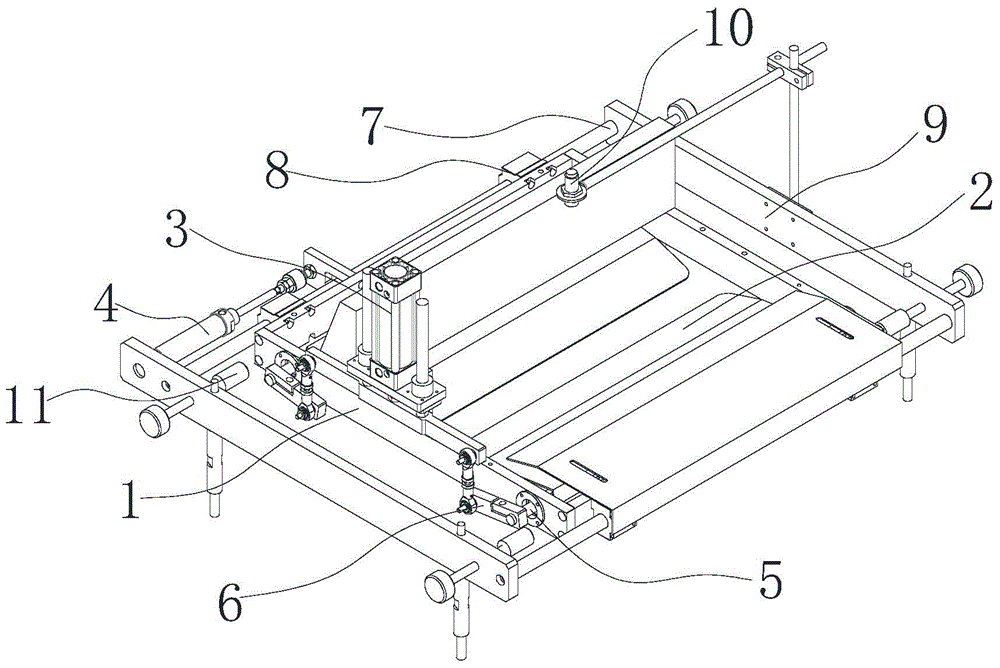

[0036] Such as figure 1 As shown, the automatic bag-discharging mechanism for secondary packaging includes a fixed frame, a bag-drawing plate, a bag-dropping cylinder, and a positioning cylinder. There is a bag-dropping cylinder, a connecting rod connection is provided between the bag-dropping cylinder and the rotating shaft, ranking guide rails are respectively provided on both sides of the fixing frame, and a slider connection is provided between the ranking guide rail and the fixing frame,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com