Patents

Literature

45results about How to "Good dense" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

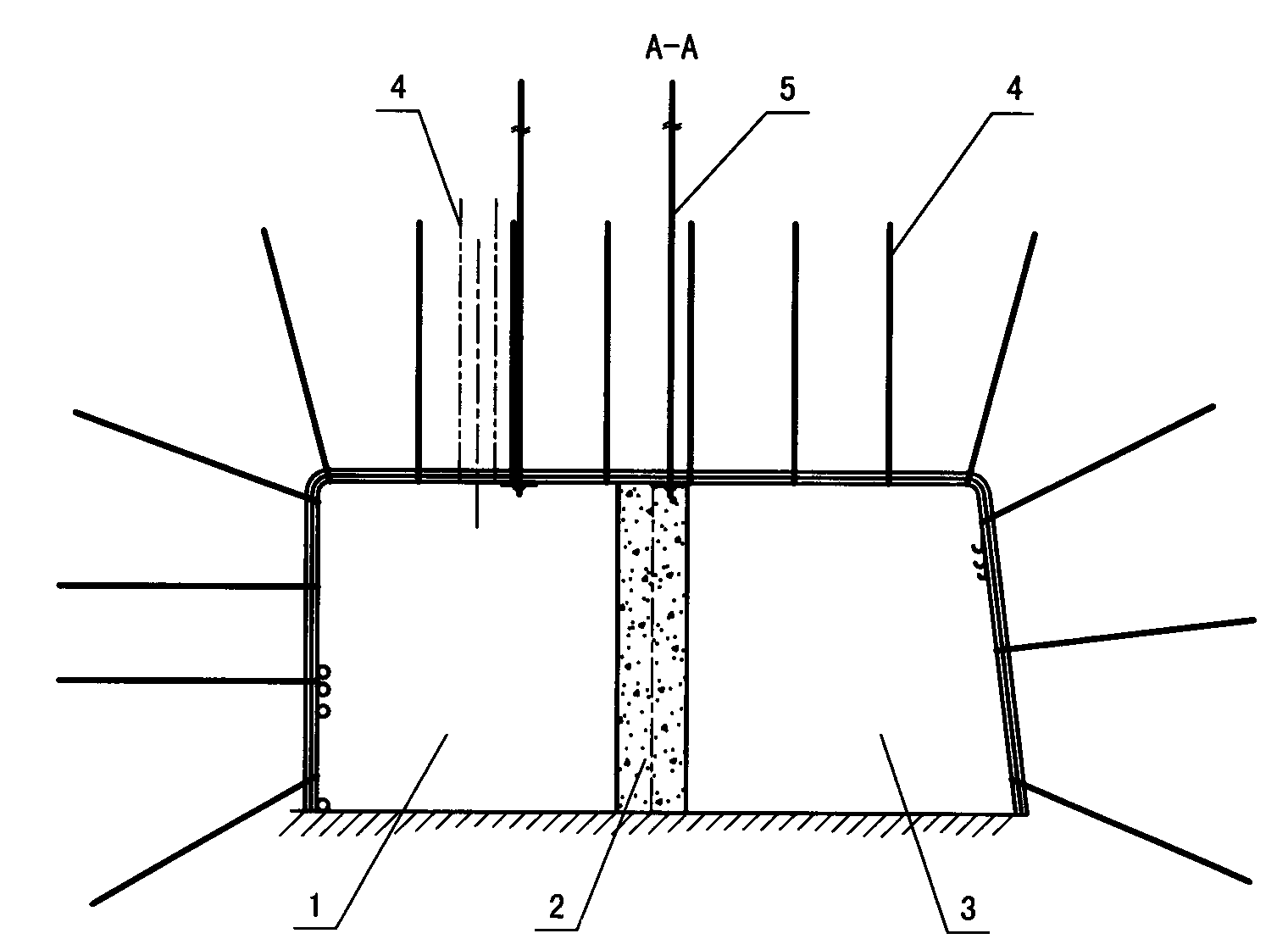

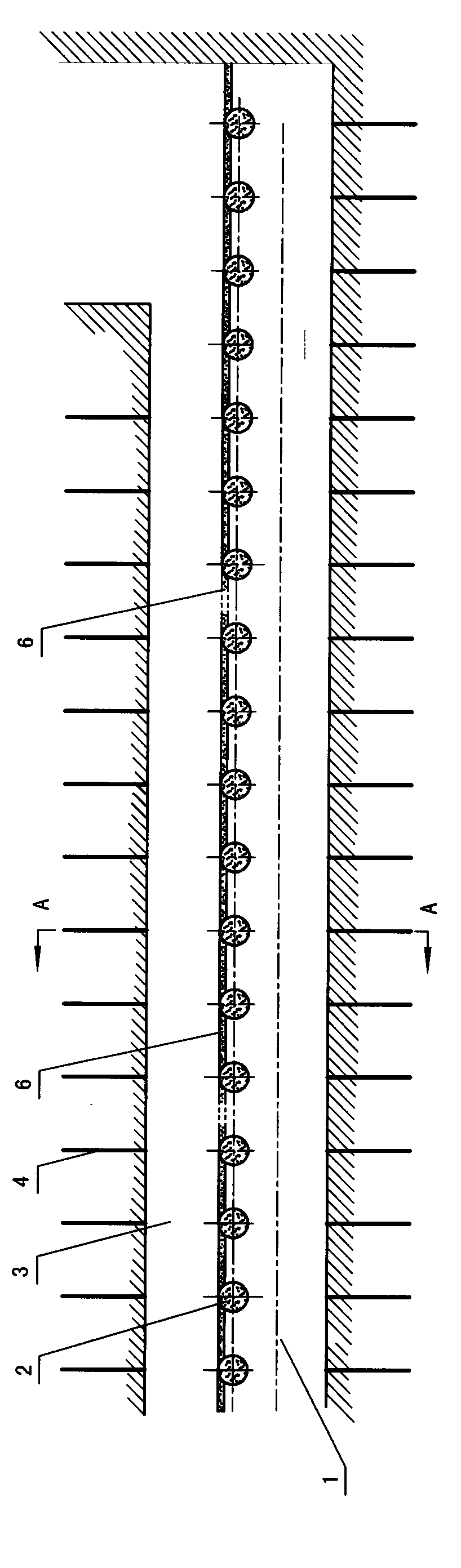

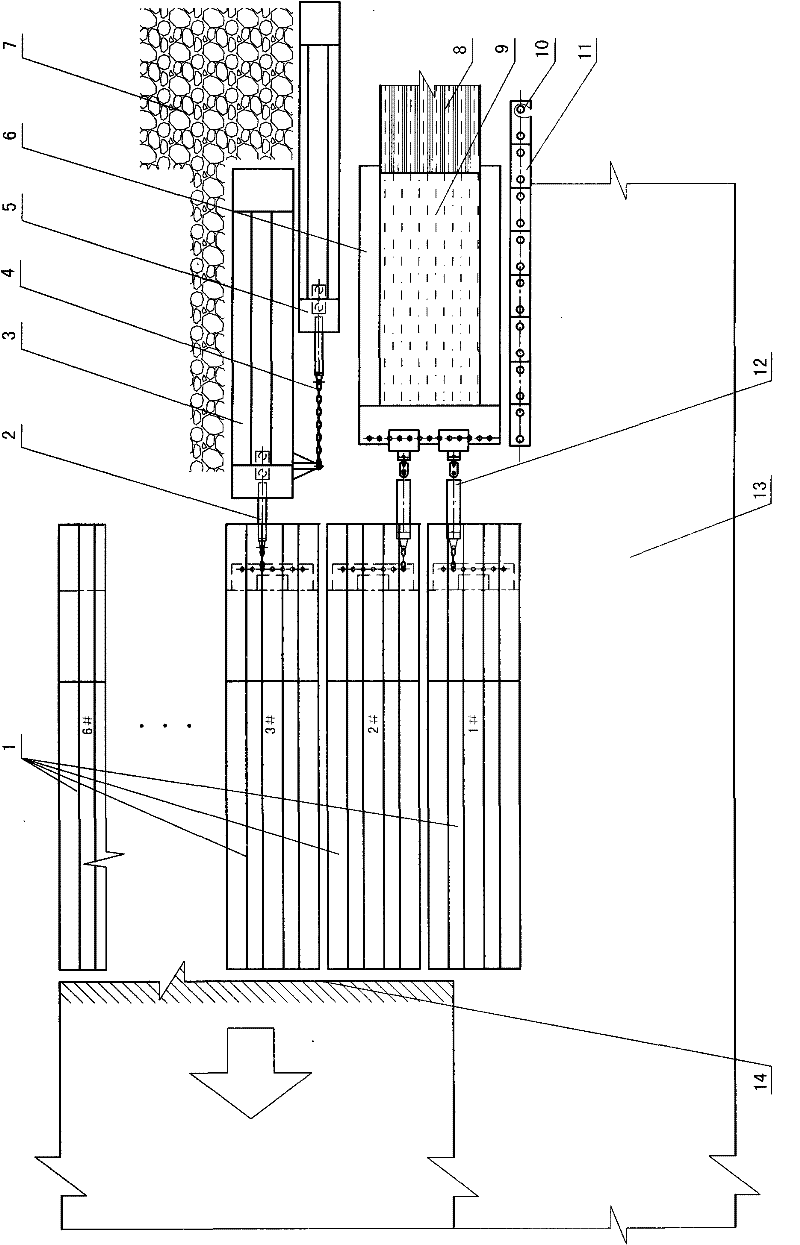

Method for retaining gob-side tunnel

InactiveCN102337904AAchieve miningTake advantage ofMining devicesUnderground chambersEngineeringStructural engineering

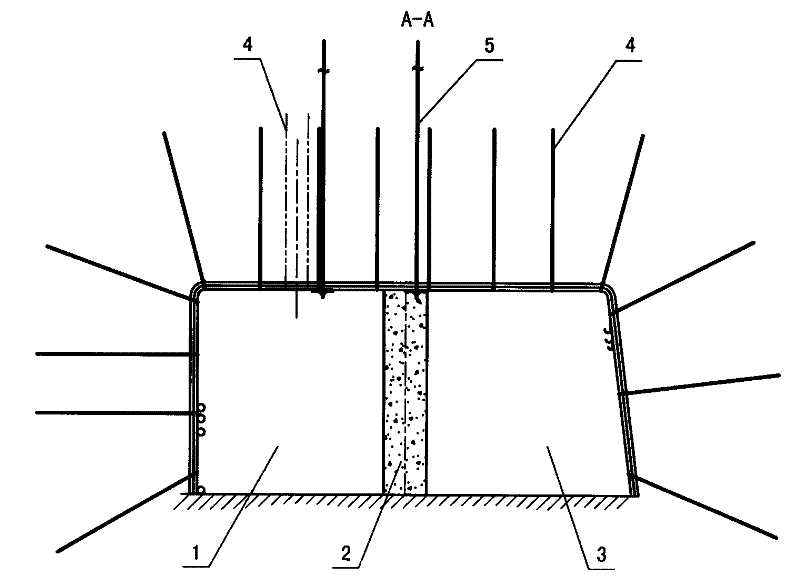

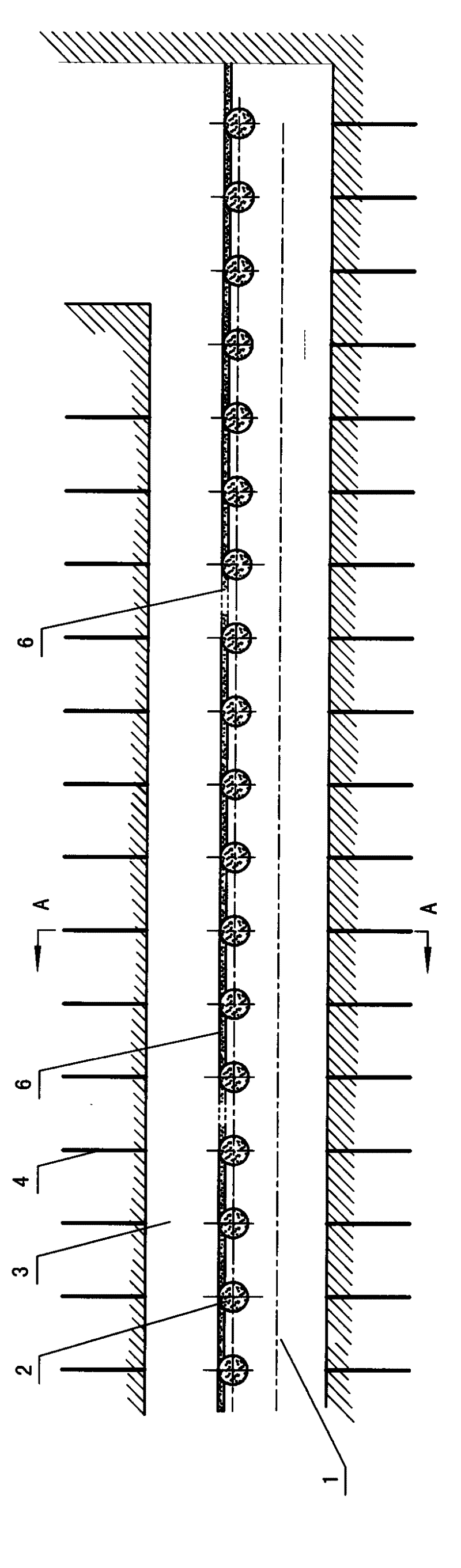

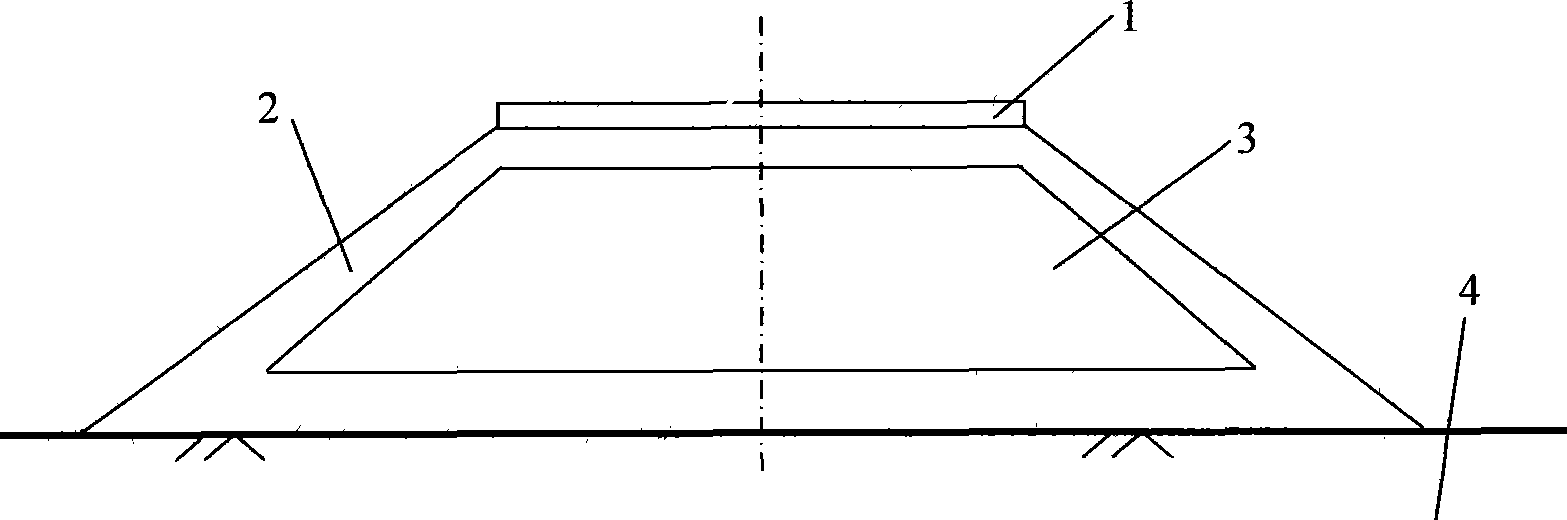

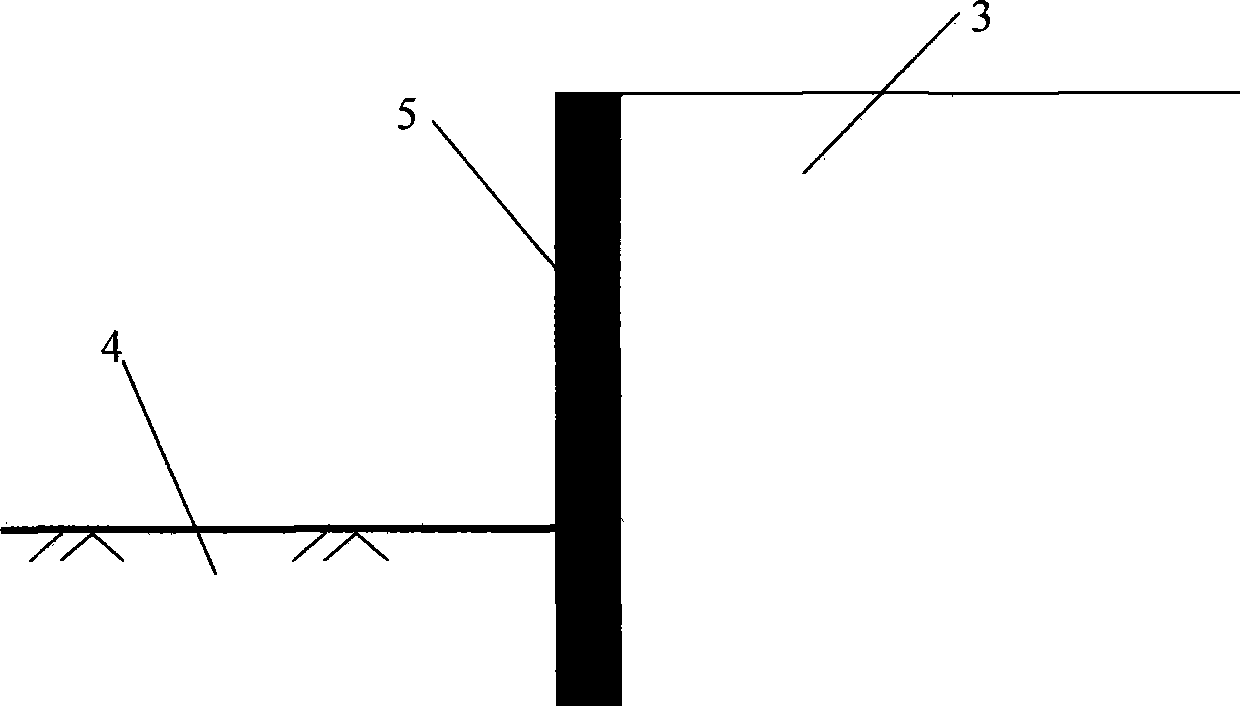

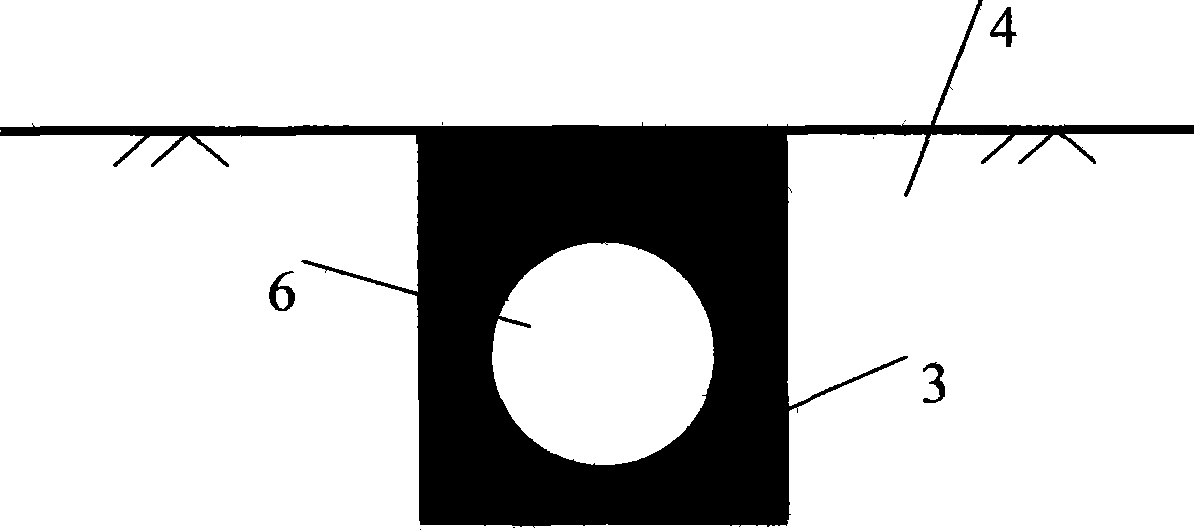

The invention discloses a method for retaining a gob-side tunnel, which overall arranges the retaining of the gob-side tunnel in a stope working face gateway tunneling period, and comprises the steps of: combining the stope working face gateway with the gob-side retained tunnel, namely the next section gateway, together to be served as one tunnel for tunneling; and constructing tunnel concrete pier columns between the stope working face gateway and the gob-side retained tunnel, wherein the tunnel concrete pier columns are served as support in the tunnel and also served as one part of the side support for the gob-side retained tunnel; namely comprising the steps of: widening the section of the tunnel by tunneling, reserving the tunnel section according to the shrinkage factor of the god-side retained tunnel suffering from two times of support pressure, and pouring the reinforcing steel bar concrete pier columns in middle of the transverse direction of the tunnel to match with a cable anchor for supporting. The tunnel concrete pier columns are arranged along the whole length of the tunnel at intervals, and used for dividing the tunnel into two parts. Insulating walls are constructed between two adjacent columns after the columns are constructed. When the stope is starting, the support is needed to be temporarily reinforced at two sides of the columns according to requirements along with the advancing of the stope working face. According to the method for retaining a gob-side tunnel, the retaining of the gob-side tunnel and the tunneling of the stope working face gateway are overall arranged, and the tunnel concrete pier column support is arranged; therefore, the side support intensity and support resistance of the retained tunnel are greatly enhanced, the influence of support pressure in two times of mining is effectively controlled. The method for retaining gob-side tunnel is particularly suitable for using in flexible mining faces of bottom plate and / or top plate.

Owner:贾民

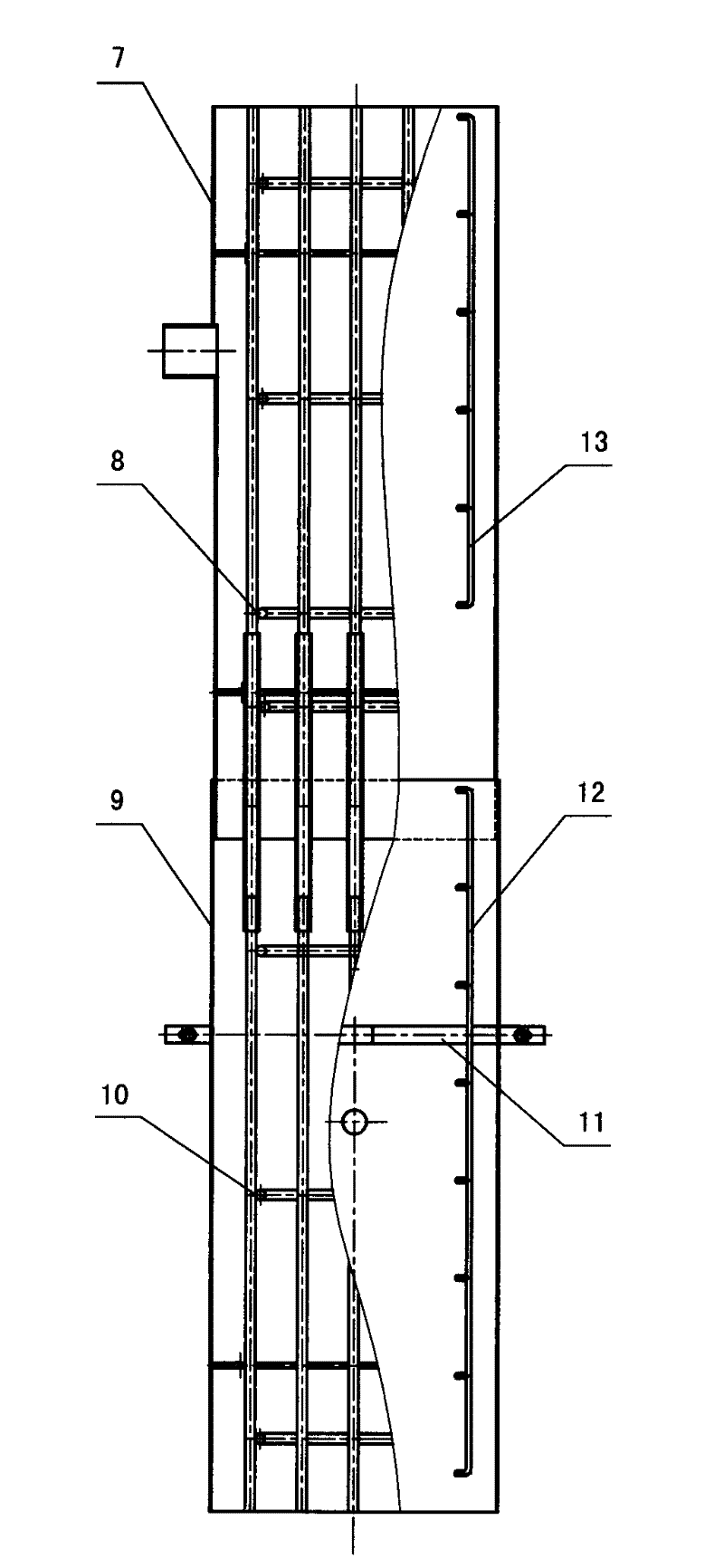

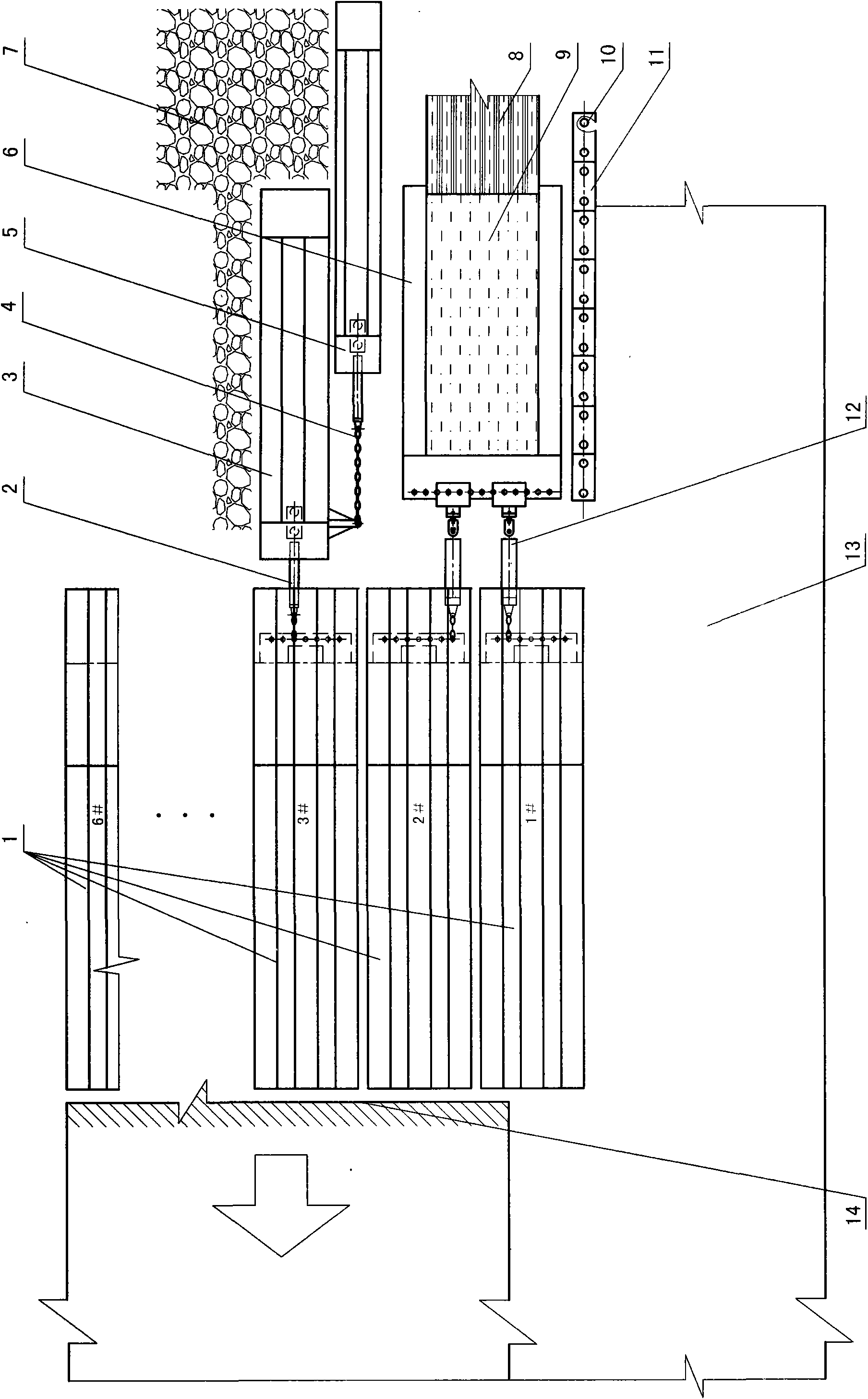

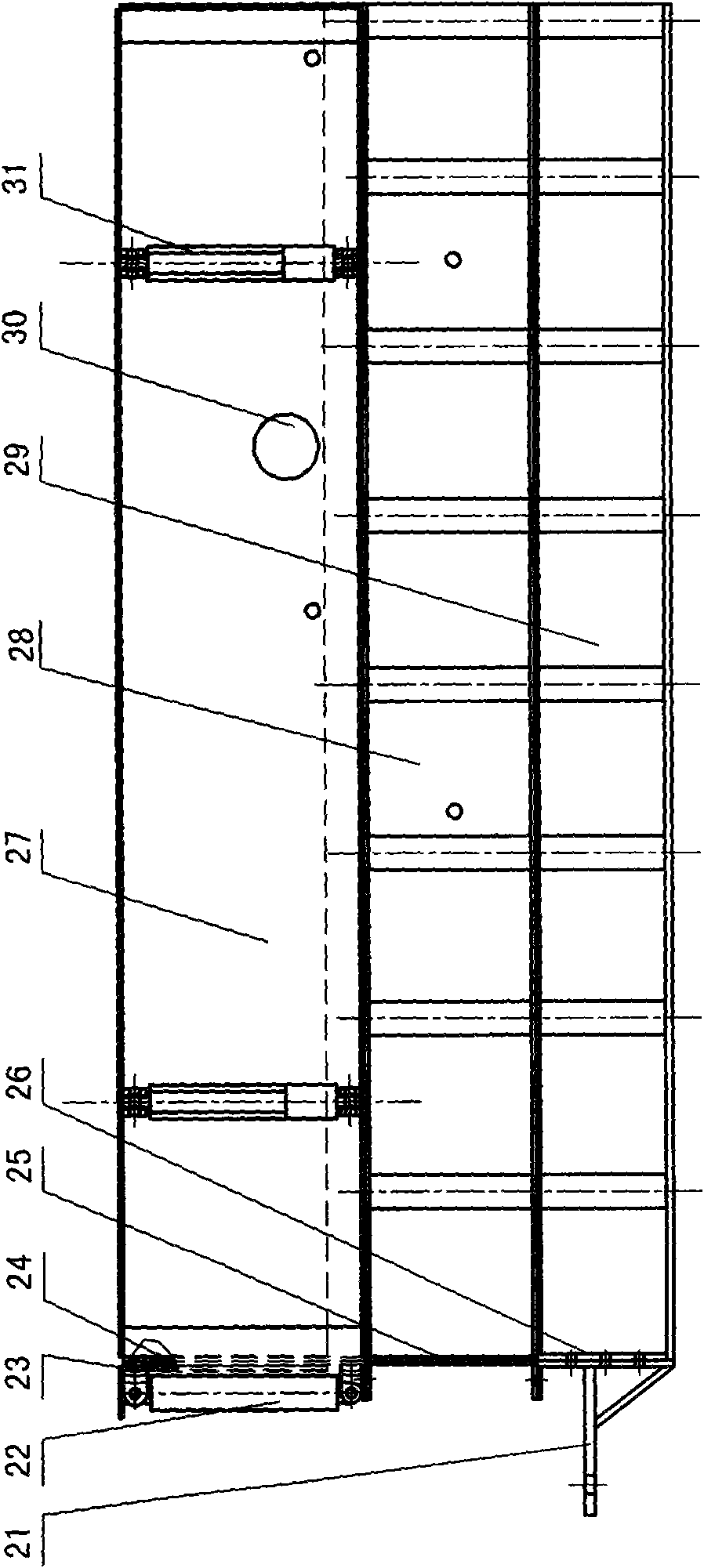

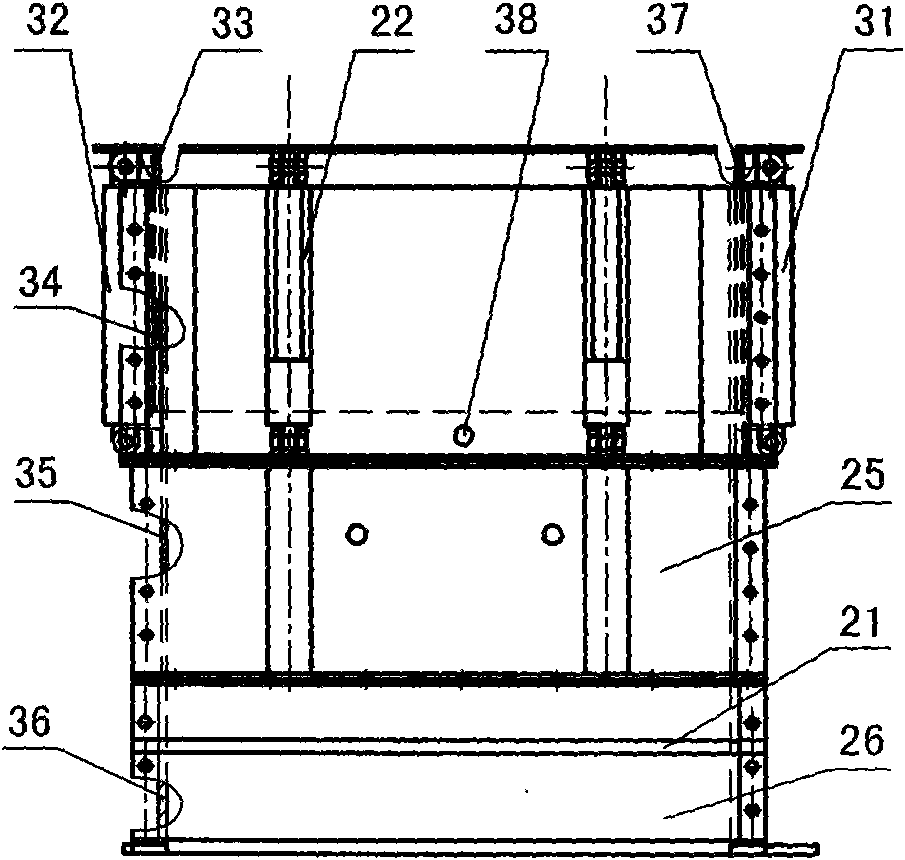

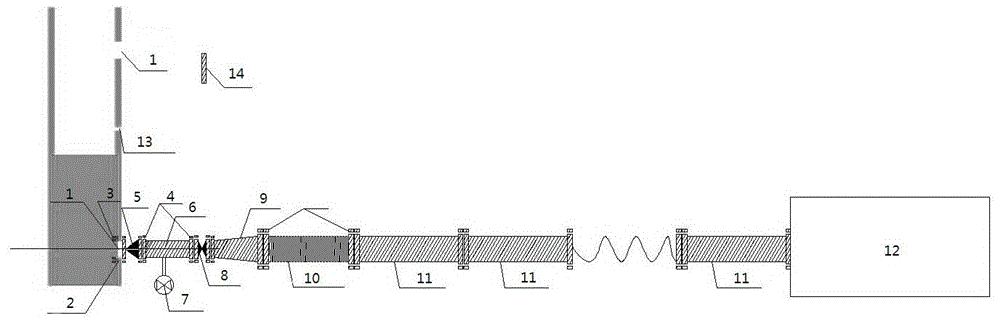

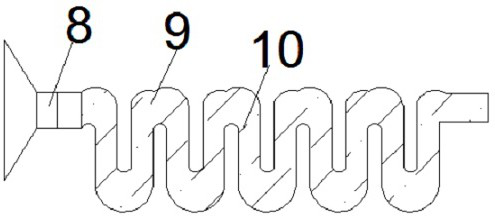

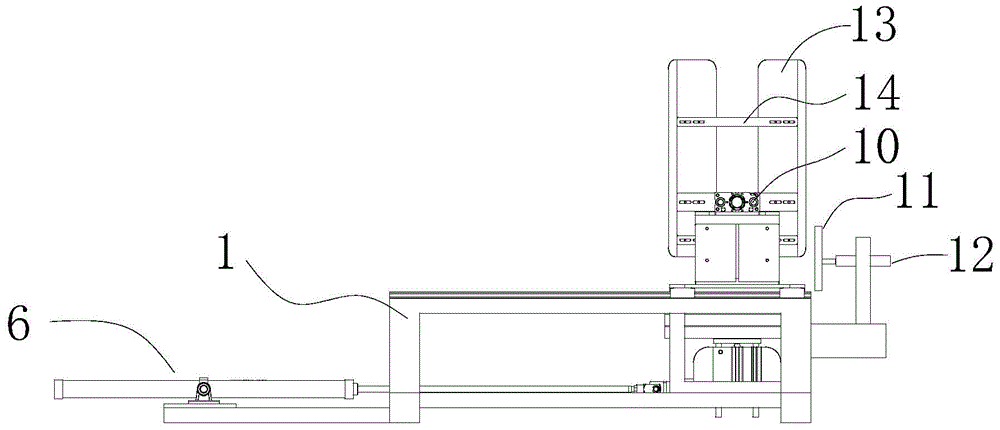

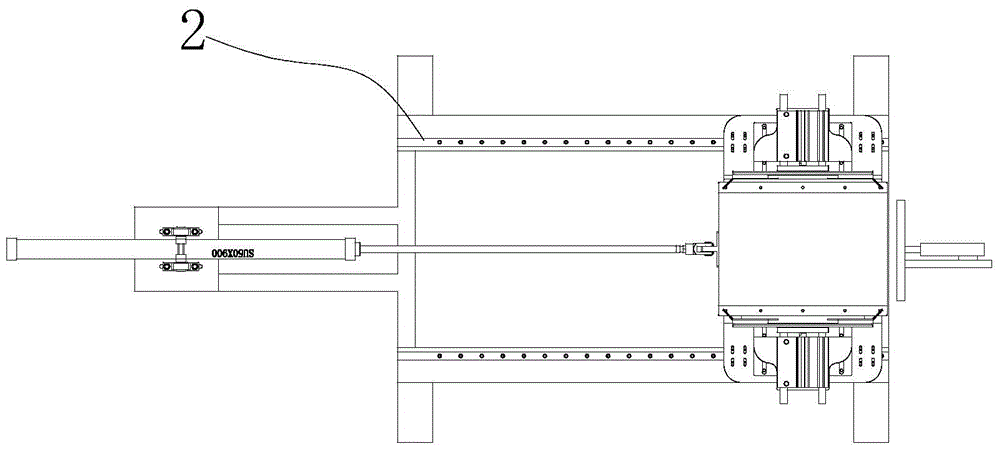

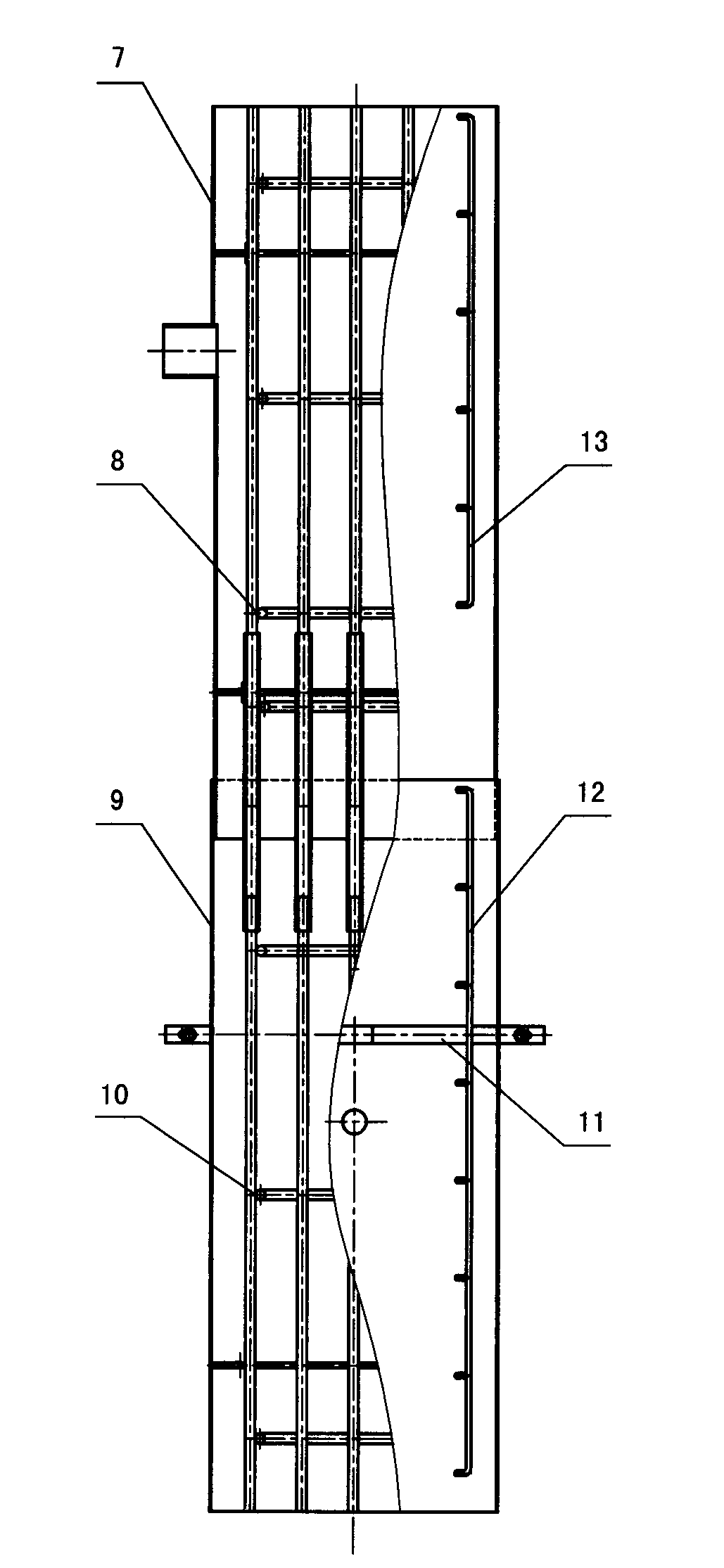

Gob-side road retaining supporting method and road-injecting slip mould

The invention relates to a gob-side road retaining supporting method of mining roadways of coal mines, comprising the following steps of: feeding a concrete to a filling mould by using a pump to pour along the lapse of a working surface on a gob side of the gob-side road retaining, and constructing a roadside backfilling wall 8; supporting top plates arranged above the backfilling wall 8 and outside the backfilling wall 8 by using an anchor cable and constructing in the front side of a leading support 1; adopting a height-adjustable integral pull-shift type road-injecting slip mould 6 by the backfilling mould; using blindage supports 3 and 5 on one side of the gob of the road-injecting slip mould to temporarily support; connecting the road-injecting slip mould and the blindage supports with the leading support 1 through a pull-shift jack to shift; and enabling the blindage supports, the roadside backfilling wall and the top surfaces of each leading support supported by the external anchor cable to be provided with grooves for protecting anchor cables of anchor rods. Besides the advantages of digging less roads, realizing pillarless exploration, releasing the tension of mining drifting and the like, the invention also has the advantages that the height of the road-injecting slip mould is integrally regulated by means of integral pull-shift hydraulic, the road-injecting slip mould is convenient to use and the work efficiency is improved; the supporting of the anchor cable is matched with the supporting of the backfilling wall to effectively control a separation layer of an immediate roof, and the blindage supports and the leading support can protect the anchor cables and the anchor rods from being jacked broken so as to lose efficacy.

Owner:兖矿能源集团股份有限公司

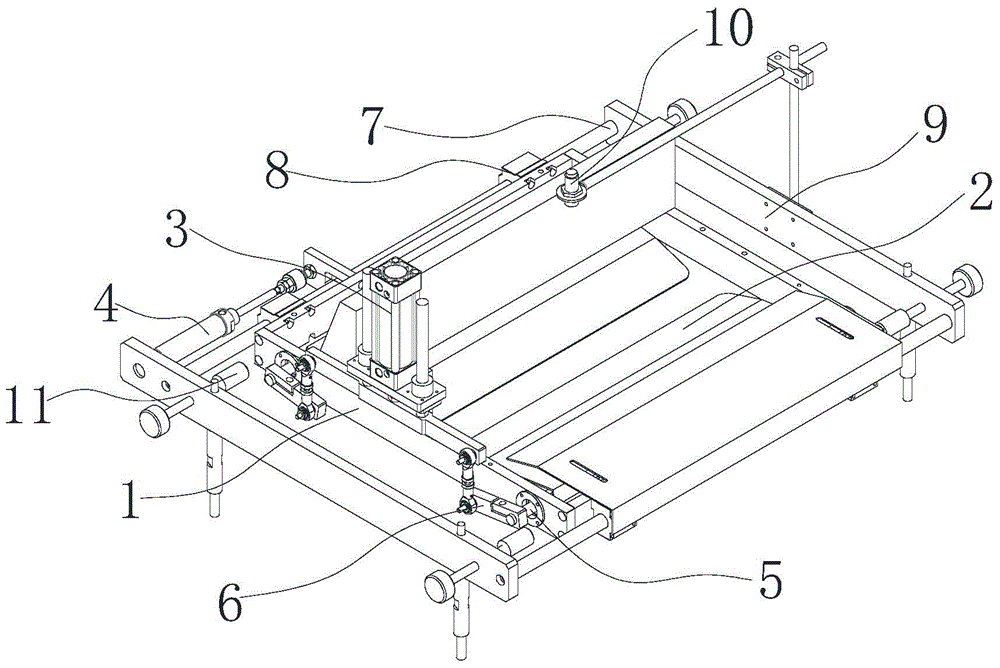

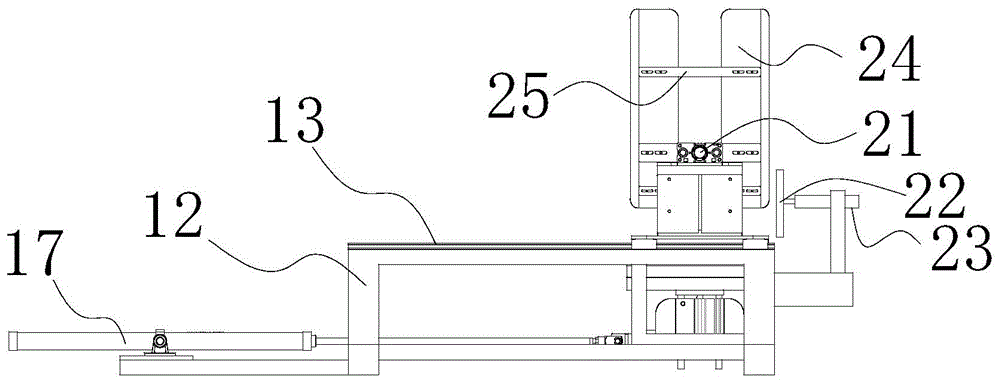

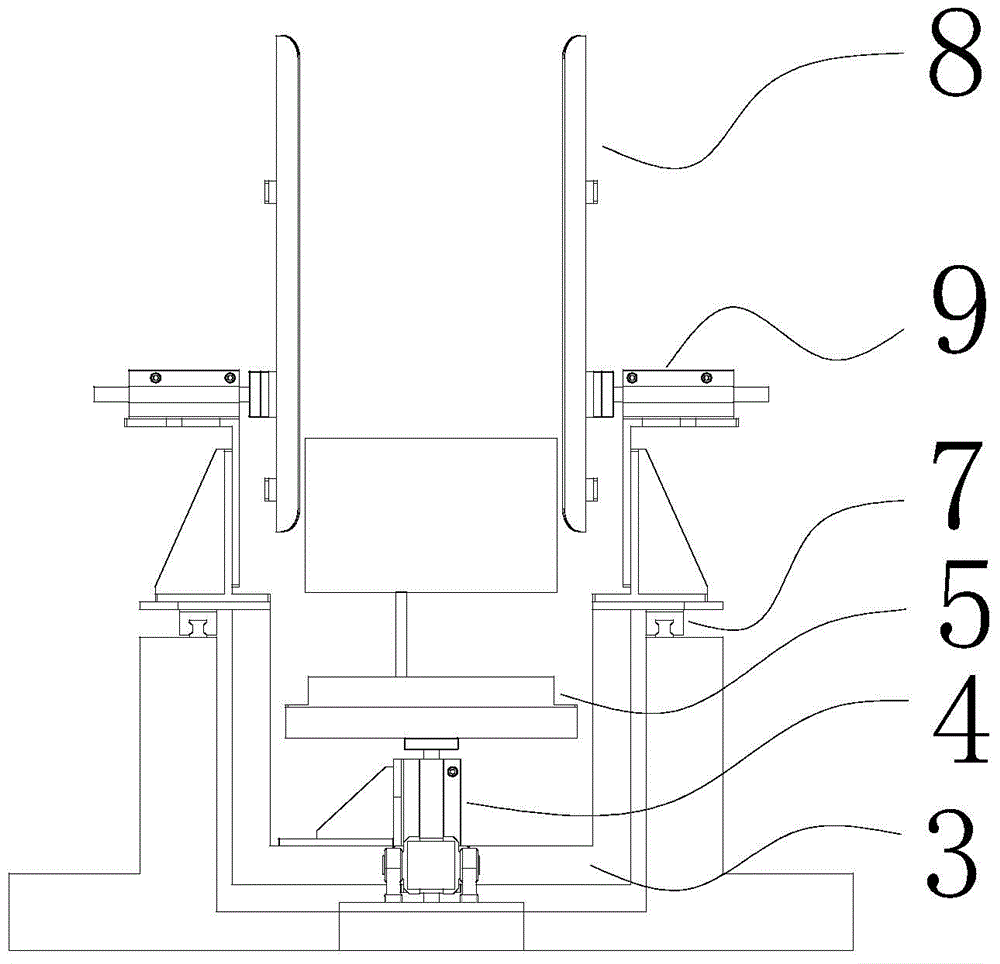

Package bag secondary automatic packaging system

ActiveCN103979144AImprove stabilityReduce labor intensityWrapper twisting/gatheringSecondary PackagingPackaging machine

The invention discloses a package bag secondary automatic packaging system, which comprises a secondary packaging automatic bag arranging mechanism, a secondary packing machine bag collecting cabin, a secondary packaging machine bag taking and bag opening mechanism, a secondary packaging machine bag storing mechanism, a secondary packaging machine bag supporting mechanism, a secondary packaging machine bag opening shaping and hot sealing mechanism and a secondary packaging machine bag dragging and bag holding mechanism. The package bag secondary automatic packaging system has the advantages that the automatic bag arranging, bag taking and bag conveying positions are accurate, the packaging stability is greatly improved, and the whole packaging system adopts a plurality of sensors, so the work efficiency is greatly improved, the work intensity of workers is reduced, and in addition, the installation performance is greatly enhanced.

Owner:HEFEI SANGUAN PACKING SCI & TECH

Method for filling hinge joint of fabricated prestressed hollow beam slab

InactiveCN103147395AImprove crack resistanceReduce porosityBridge structural detailsHollow coreHinge joint

The invention provides a method for filling a hinge joint of a fabricated prestressed hollow beam slab, and belongs to the technical field of bridge engineering. The method comprises the steps as follows: inserting a screw type blocking strip into a bottom gap of the hinge joint, wherein the top surface of the screw type blocking strip comprises two split parts, one part is lapped on the other part, the length of the lapping position is 3-5 cm, and rubber strips are arranged on wing plates on the two sides of the screw type blocking strip; filling the middle of the hinge joint with micro-expansion concrete; when the concrete of the hinge joint reaches enough age period, filling the top of the hinge joint with bituminous grout; and when the bituminous grout reaches the design performance, pouring a pavement layer on the top surface of the hollow beam slab. When the micro-expansion concrete is poured, the top surface of the screw type blocking strip is open, so that the space of a vertical column is communicated with that of the hinge joint and the screw type blocking strip is stabilized by the rubber strips on the wing plates and the self weight of the concrete of the hinge joint; and the middle of the hinge joint is filled with the micro-expansion concrete, so that the space of the hinge joint is closed for a long time and the problem of water seepage due to premature failure of the hinge joint is solved.

Owner:山东畅通路桥科技股份有限公司 +3

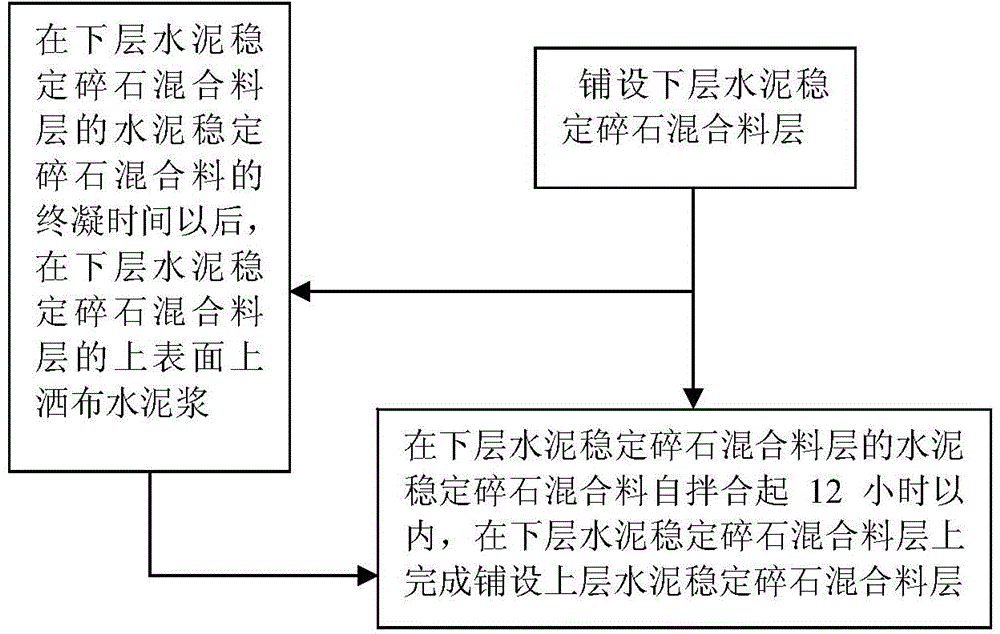

Upper-layer and lower-layer joined-paving construction method of cement stabilized macadam

The invention provides an upper-layer and lower-layer joined-paving construction method of cement stabilized macadam. The upper-layer and lower-layer joined-paving construction method comprises the following steps: (a) paving a lower layer, namely, paving a lower-layer cement stabilized macadam mixture layer on a pavement, grinding the lower-layer cement stabilized macadam mixture layer; and (b) paving an upper layer, namely, within 12 hours since mixing of a cement stabilized macadam mixture of the lower-layer cement stabilized macadam mixture layer, paying an upper-layer cement stabilized macadam mixture layer on the upper surface of the lower-layer cement stabilized macadam mixture layer formed by rolling, and rolling the upper-layer cement stabilized macadam mixture layer. According to the upper-layer and lower-layer joined-paving construction method of the cement stabilized macadam, provided by the invention, the interlayer bonding strength is ensured, the interlayer construction time can be relatively prolonged, and the construction efficiency is improved.

Owner:CHINA FIRST HIGHWAY ENG +1

Construction process for cement stabilized macadam pavement

ActiveCN108486979AIncrease interlayer bondingReduce interlayer pollutionIn situ pavingsCement mixing apparatusMaterials scienceCrushed stone

The invention discloses a construction process for a cement stabilized macadam pavement. The construction process comprises the following steps: calculating a mix proportion of a cement stabilized macadam mixture, and blending the cement stabilized macadam mixture; laying a first cement stabilized macadam mixture layer on the pavement, laminating the first cement stabilized macadam mixture layer,laying a second cement stabilized macadam mixture layer on the upper surface of the laminated first cement stabilized macadam mixture layer, laminating the second cement stabilized macadam mixture layer, and maintaining the pavement until the strength of the pavement is not less than 3MPa. The pavement laid by the construction process difficultly causes cracks, and is long in service life and safeand reliable to use.

Owner:CHINA FIRST HIGHWAY ENG +1

Multifunctional foaming system used in air foam flooding

The invention discloses a multifunctional foaming system used in air foam flooding, relates to the technical field of oilfield development and is used for increasing oil recovery efficiency. The multifunctional foaming system is composed of following components, by weight: 0.1-0.5% of fatty alcohol polyoxyethylene ether sodium sulphate, 0.05-0.2% of silicon resin polyether emulsion, 0.05-0.2% of anionic polyacrylamide, 0.5-2% of molasses, 0.01-0.1% of yeast extraction, 0.0005-0.005% of ferrous sulfate, 0.00005-0.0002% of manganese sulfate, 0.05-0.5% of sodium nitrate and the balanced being water. The sum of weight percentages of all components is 100%. The multifunctional foaming system can solve a problem of requirements of a ground oxygen reducing apparatus and the profile control for plugging gas passages during conventional air foam flooding construction, and can enable the air foam flooding to be safe, more high-efficient and more low-cost.

Owner:SOUTHWEST PETROLEUM UNIV

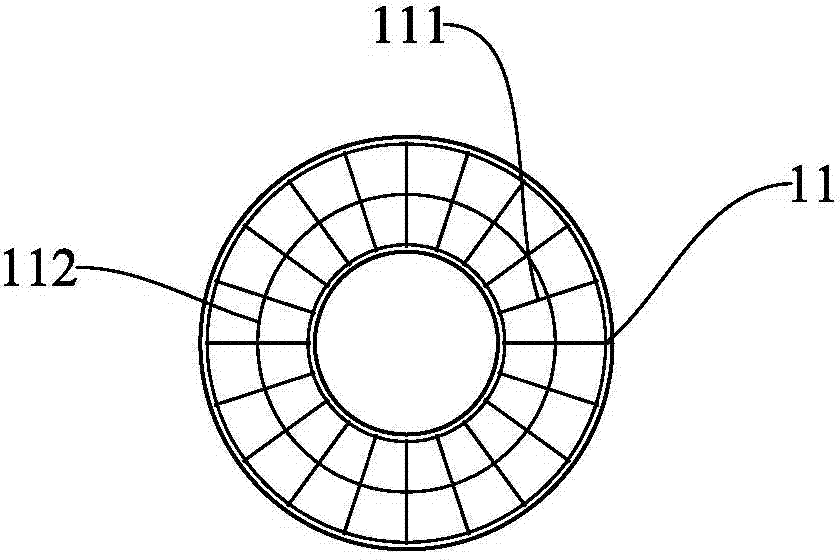

Half-through bracket haunching type multibarrel tube-confined concrete column-steel beam node

InactiveCN105507426AIncrease stiffnessHigh strengthBridge structural detailsBuilding constructionsBridge engineeringUltimate tensile strength

The invention discloses a half-through bracket haunching type multibarrel tube-confined concrete column-steel beam node, relates to a node connecting form of a multibarrel tube-confined concrete column and a steel beam, and belongs to the technical field of constructional engineering and bridge engineering. The node comprises the multibarrel tube-confined concrete column, the steel beam and a force-transmission component. The multibarrel tube-confined concrete column comprises an inner steel pipe, an outer steel pipe and poured concrete. The steel beam comprises upper and lower flanges and a web. The force-transmission component comprises a steel bracket and an oblique haunching plate. The steel bracket comprises upper and lower flanges and a web. One end of the steel bracket penetrates the outer steel pipe to be welded to the wall of the inner steel pipe, and the other end of the steel bracket is in bolt-weld connection with the steel beam. Meanwhile, the oblique haunching plate is welded between the steel beam and the multibarrel tube-confined concrete column. The half-through bracket haunching type multibarrel tube-confined concrete column-steel beam node is simple in structure, convenient in construction, high in rigidity and strength, good in anti-seismic property, clear in force transmission path, and the like. By the node, effective force transmission between the multibarrel tube-confined concrete column and the steel beam can be achieved.

Owner:HEBEI UNIV OF TECH

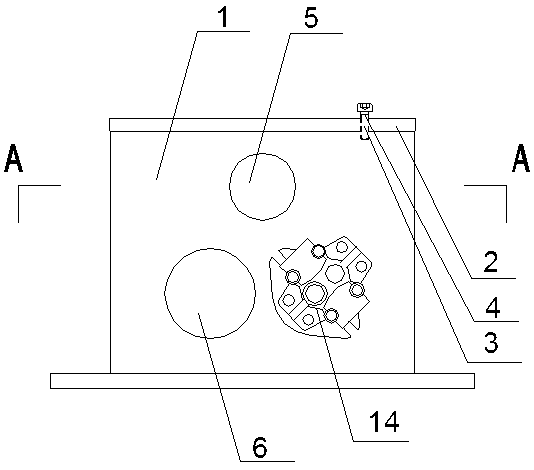

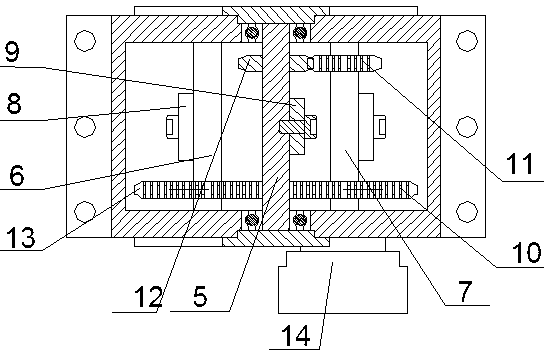

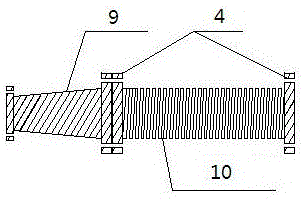

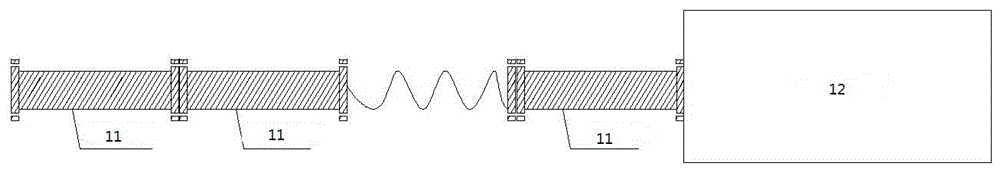

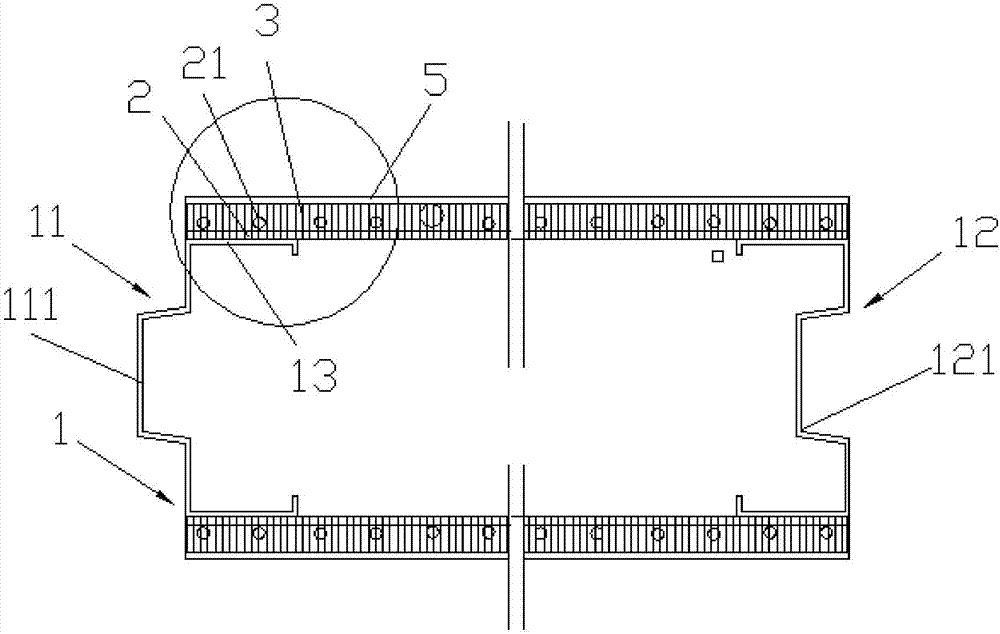

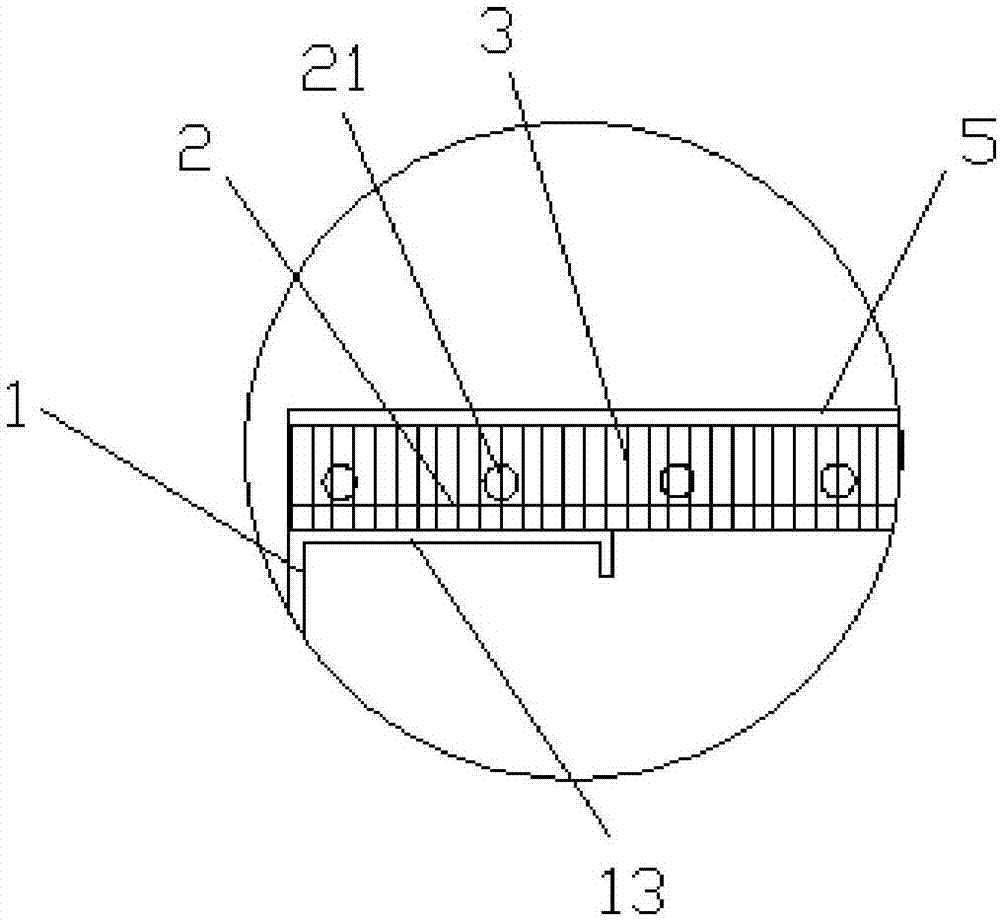

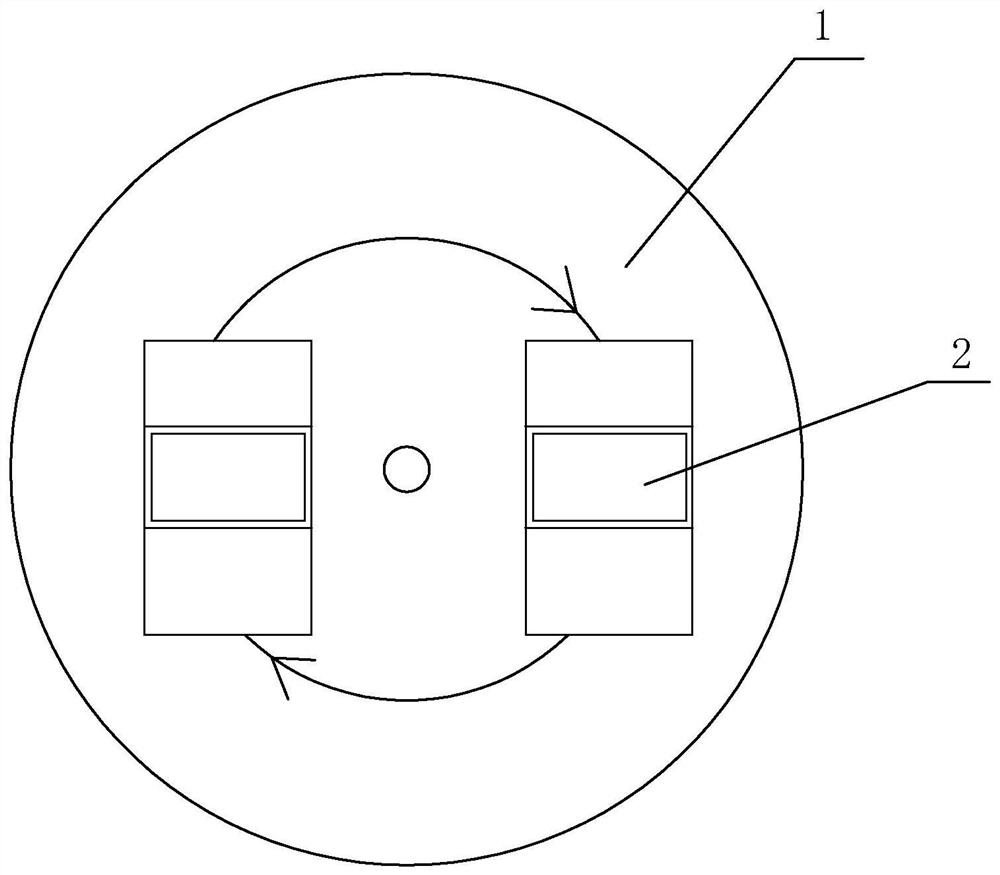

Slipform paver concrete compaction vibrator

The invention relates to a cement concrete compaction external vibrator, especially to a slipform paver external vibrator for compulsive compaction of cement concrete during continuous pouring of kerbs, side ditches and other structures. The concrete compaction vibrator comprises a box body. A longitudinally arranged high speed shaft is disposed at a central position inside the box body. A low speed shaft and a drive shaft are arranged on two sides of the high speed shaft symmetrically. The middle parts of the low speed shaft and the drive shaft are respectively in fixed connection with a first eccentric block. The middle part of the high speed shaft is in fixed connection with a second eccentric block. The low speed shaft, the high speed shaft and the drive shaft are provided with transmission gears. One side of the box body is equipped with a driving hydraulic motor that drives the drive shaft to rotate. With a stable structure, the slipform paver concrete compaction vibrator provided in the invention can remove the concrete adhered to a template lower surface so as to ensure a smooth surface of a concrete structure.

Owner:JIANGSU SIMING ENG MACHINERY

Geotechnical filling for use in cold area

InactiveCN101386500AIncrease contact areaIncrease frictionSolid waste managementPolystyrene particlePollution

The invention provides an earthwork filling material for use in cold area, which is formed by waste casting sand, fly ash, cement, polystyrene particles and water according to certain weight percentages. According to the test measurement, the density of the earth work filling material reaches between 0.97 and 1.35x10<3>kg / m<3>, the compression strength reaches between 60 and 292kPa / 7 days, and the compression strength reaches between 116 and 664kPa / 28 days; meanwhile, the earth work filling material also improve the freeze-thaw resistance, the coefficient of thermal conductivity reaches between 0.40 and 0.74W / (m.K) / 7 days, and the coefficient of thermal conductivity reaches between 0.350 and 0.53W / (m.K) / 28 days. The earthwork filling material can reduce the breakdown of an earth filling project caused by frozen expansion in the cold areas and recycle the waste casting sand and fly ash, which cause pollutions on environment, as earthwork filling materials in the earth filling project; moreover, the filling materials, which are secondary industrial wastes, are widely available and low in price, thereby reducing cost.

Owner:HOHAI UNIV

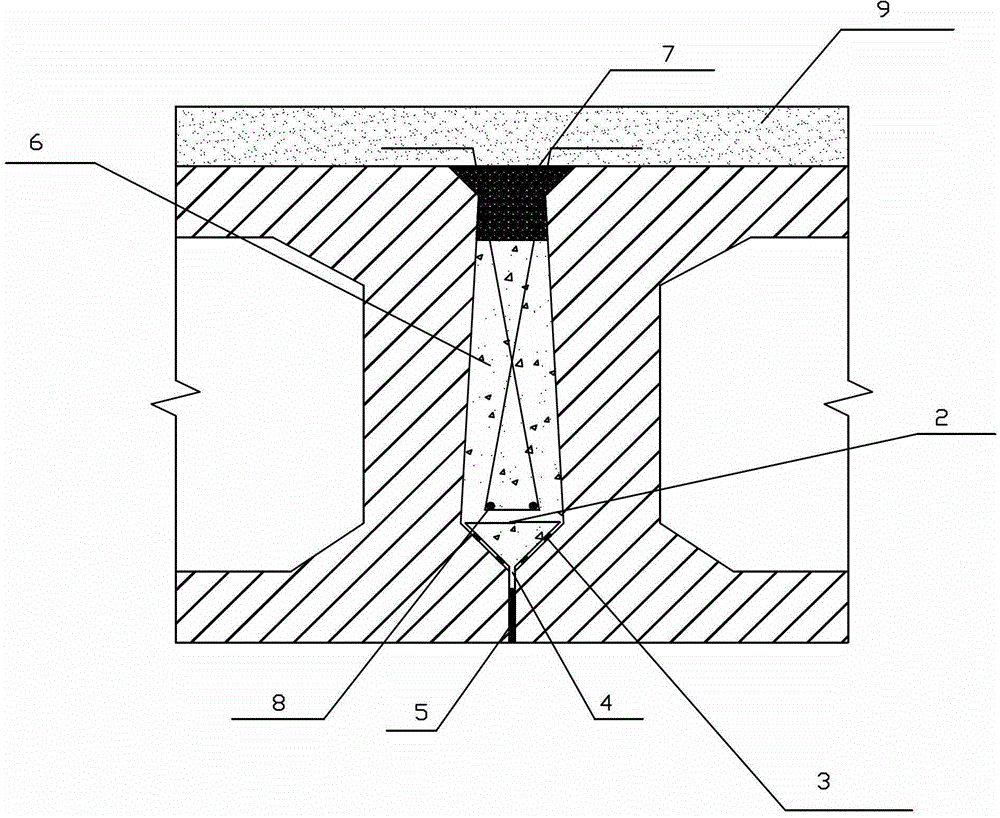

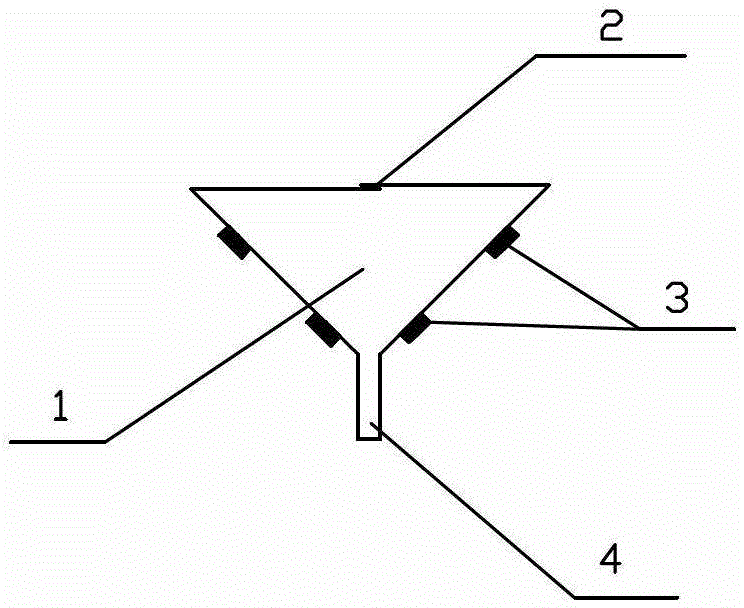

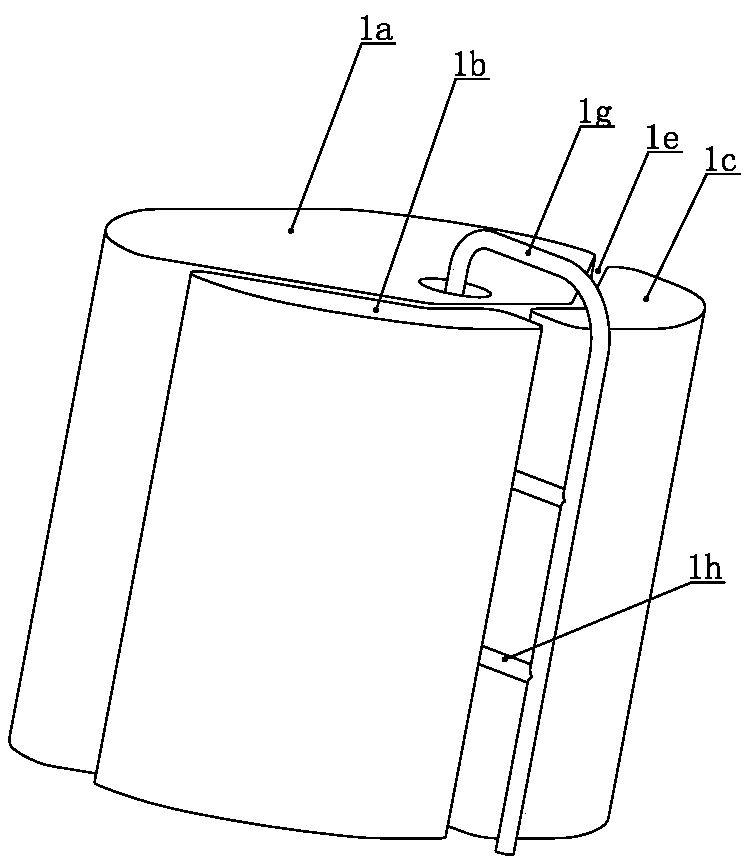

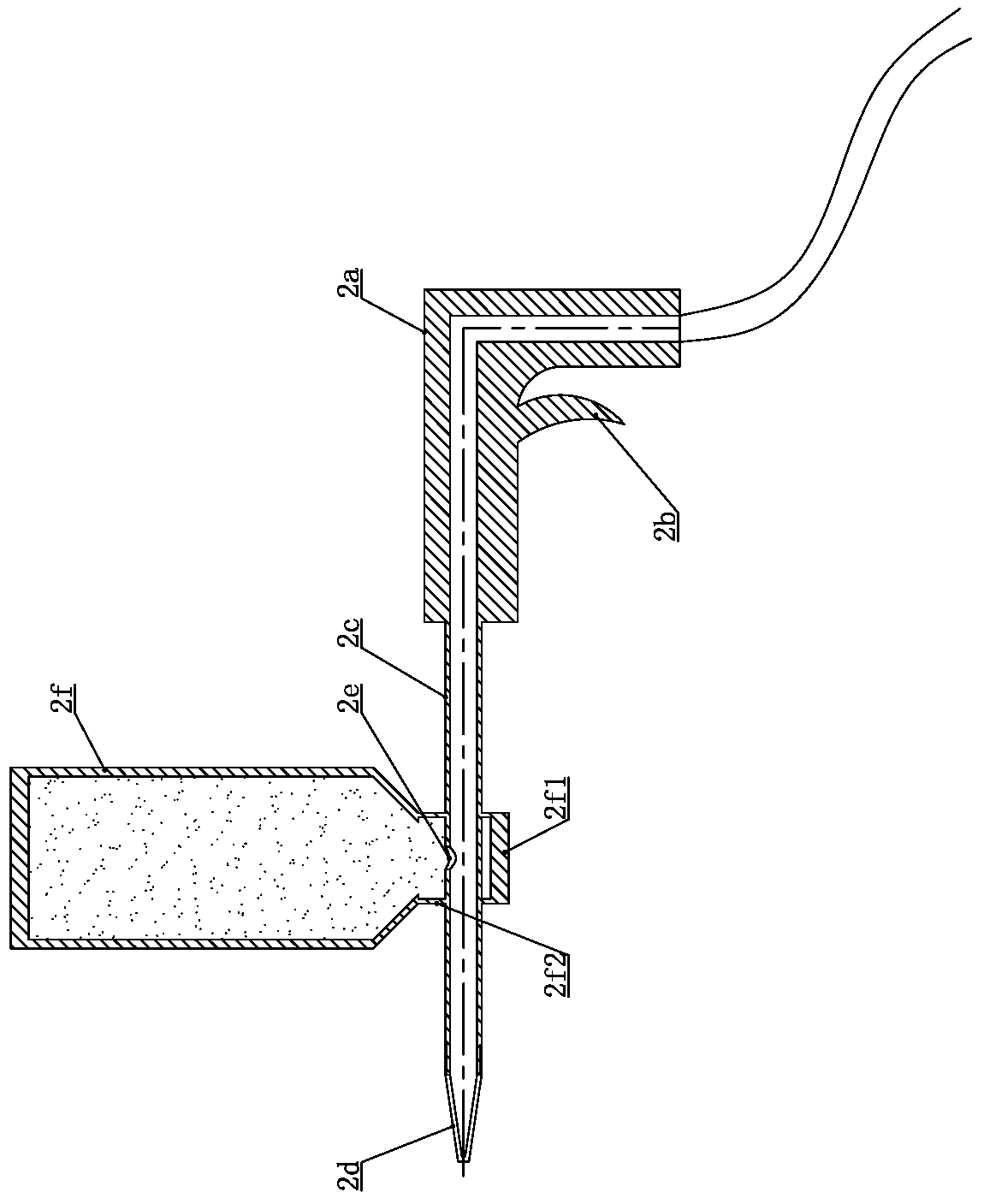

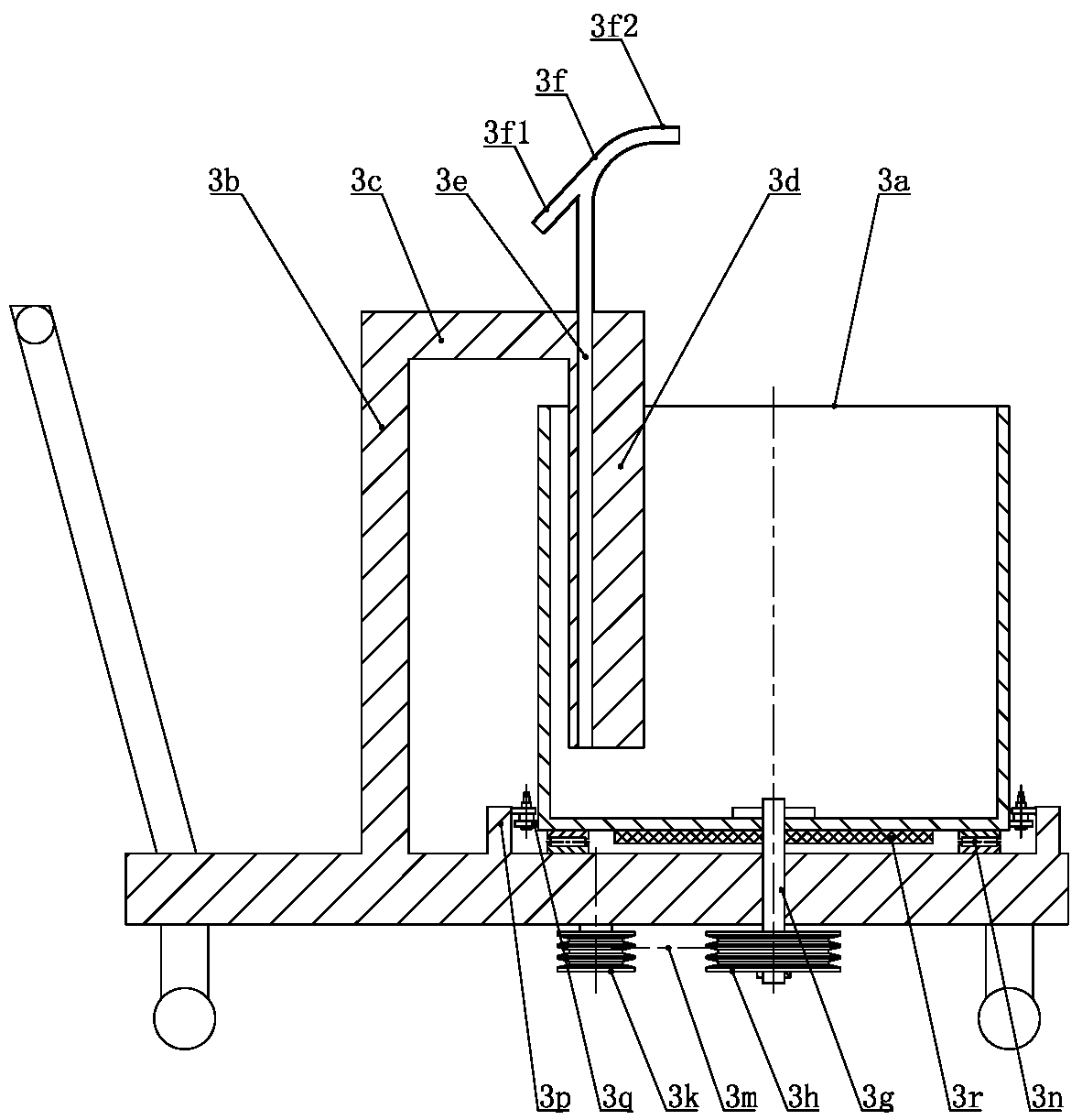

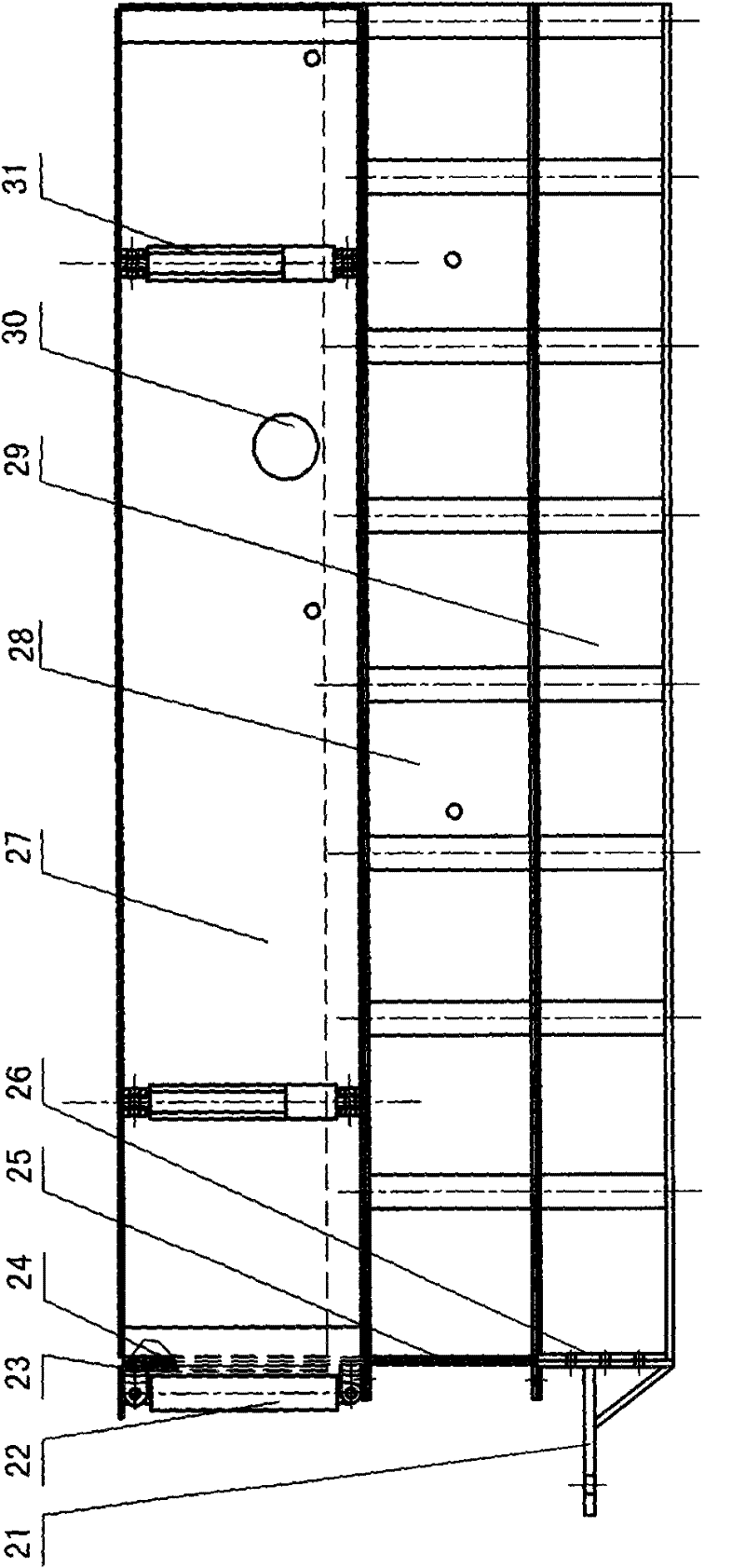

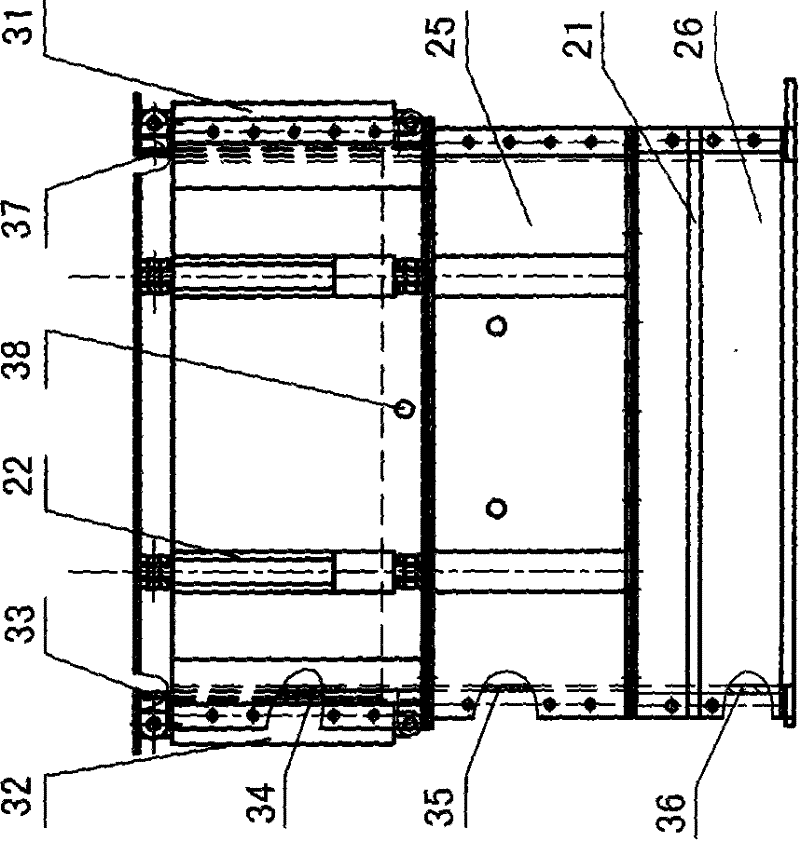

Apparatus and method for lifting up, compacting and forming concrete in steel-pipe column (wall)

InactiveCN106065690AImprove performanceImprove good performanceStrutsWallsEngineeringCounter current

The invention provides an apparatus and a method for lifting up, compacting and forming concrete in a steel-pipe column (wall). The apparatus comprises the following components: a material pressing structure node, a counter current preventing apparatus, a pressure regulating apparatus, and a pumping system; the material pressing structure node is arranged at the side surface of the bottom of the steel-pipe column (wall), and the material pressing structure node is connected to the counter current preventing apparatus, the pressure regulating apparatus, and the pumping system in order. The pumping system is used, a pressure conveying principle is used in order to lift concrete from the bottom of the steel-pipe column (wall) to the top of the column (wall), and the concrete is compacted and formed in the steel-pipe column (wall) by pressure. The apparatus and the method for lifting up, compacting and forming concrete in the steel-pipe column (wall) use local materials for processing and producing, pressure in a transfer pump is used for carrying out the lifting-up work for the concrete, so that the common concrete reaches effects of self-compaction concrete, and the apparatus and the method have the advantages of substantially reduced construction cost, simple operation, good quality, low cost, and substantial economic effects; the apparatus and the method can be applied to concrete construction of various steel-pipe columns (walls) with application and promotion values.

Owner:NANTONG CONSTR PROJECT GENERAL CONTRACTING

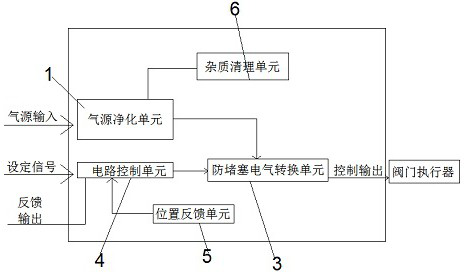

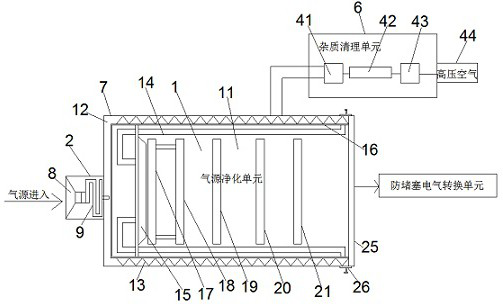

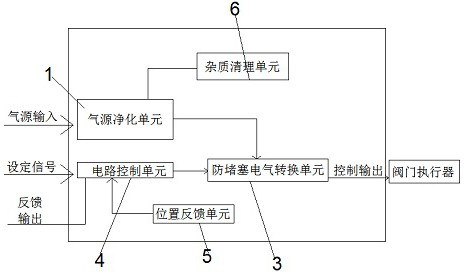

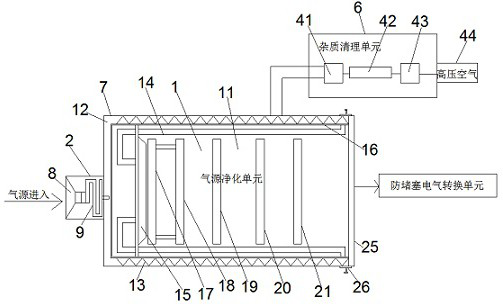

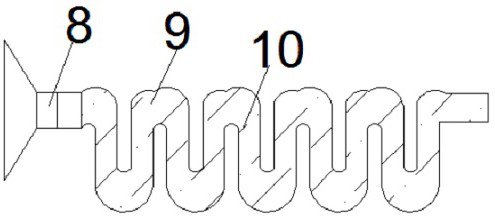

Valve with intelligent positioning and anti-blocking functions

ActiveCN112483709AAvoid cloggingAvoid getting smallerCombination devicesOperating means/releasing devices for valvesValve actuatorControl signal

The invention discloses a valve with intelligent positioning and anti-blocking functions. The valve comprises a positioner and a valve actuator, wherein the positioner comprises an air source purification unit, an air inlet for inputting an air source is formed in the air source purification unit, the air source purification unit is connected with an anti-blocking electrical conversion unit used for controlling the valve actuator, the anti-blocking electrical conversion unit is connected with a circuit control unit through a control signal, and the circuit control unit is connected with a position feedback unit. The valve has the advantages that a drying indicator is wrapped inside water-absorbing cotton cloth so that moisture in airflow can be absorbed, then the inside of a purification shell is kept dry, and the valve positioner is prevented from being damaged; and during cleaning, a heating mechanism is arranged, so that hot air enters the purification shell, the water-absorbing cotton, the drying indicator and the water-absorbing cotton cloth are heated and dried, then the water-absorbing cotton, the drying indicator and the water-absorbing cotton cloth are in a dry working state, and the long-term moisture absorption and use of parts such as the water-absorbing cotton are guaranteed.

Owner:江苏博特威流体科技有限公司

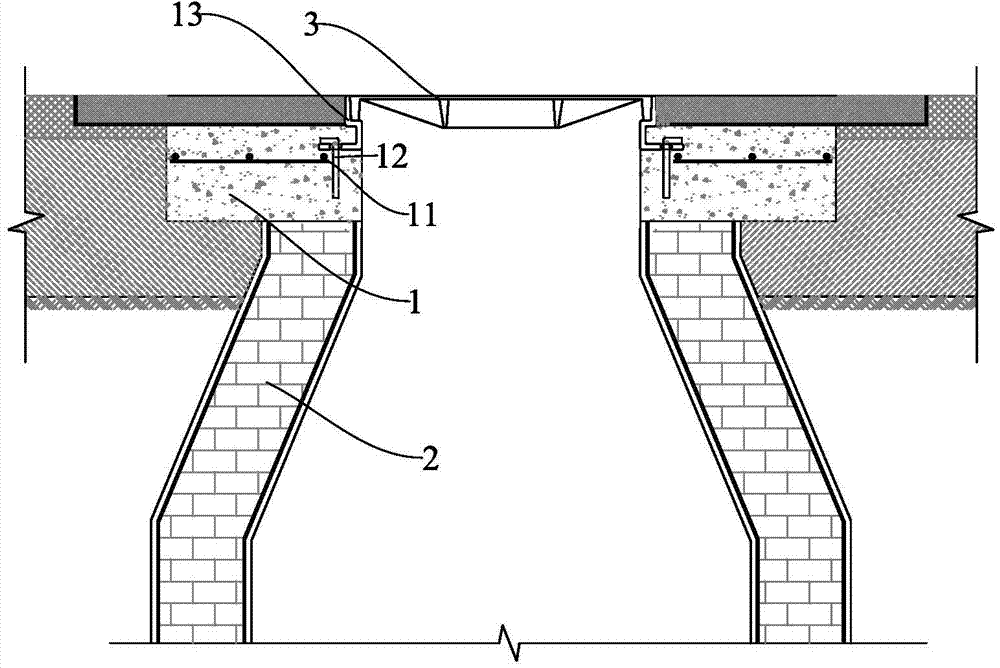

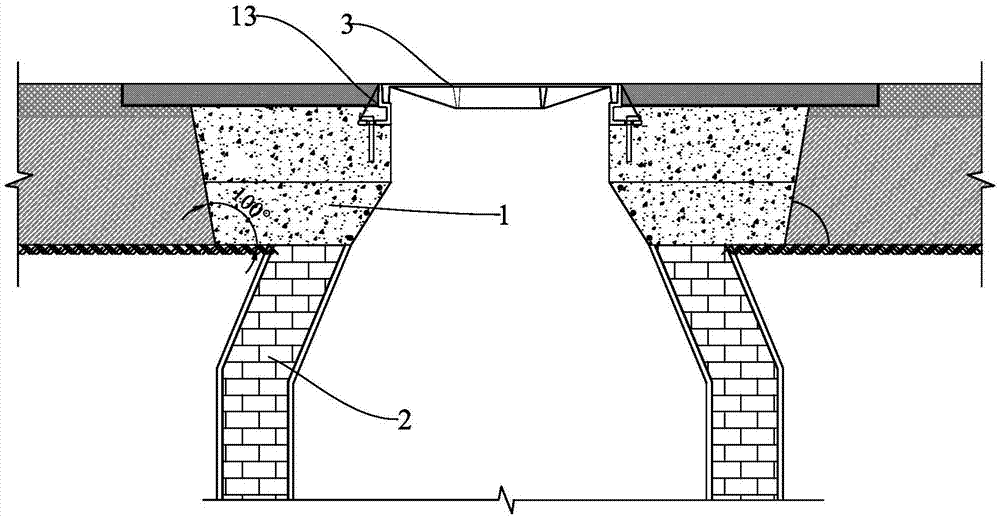

Sinking-prevention structural body of well peripheral composite material

InactiveCN104775450ATime benefit is obviousStrong crack resistanceArtificial islandsSewerage structuresBrickStructure of the Earth

The invention discloses a sinking-prevention structural body of a well peripheral composite material. The structural body comprises a base and a well lid seat. The base is a table body, wherein the center of the table body is provided with a through hole matched with the well lid, and the base is embedded on the roadbed on the periphery of a well hole of an inspection well. The well lid seat is arranged on the base and is flushed with the road surface. The base is made of concrete composite materials and comprises, by weight, 300 parts to 500 parts of cement, 30 parts to 50 parts of expanding agents, 1500 parts to 2000 parts of aggregate and 8 parts to 10 parts of water reducing agents. According to the sinking-prevention structural body of the well peripheral composite material, the load diffusion area is increased so as to obviously reduce shaft stress, and the phenomena of well periphery sinking and the like caused by damage of a brick body of the shaft are avoided.

Owner:青岛市城乡建设委员会 +3

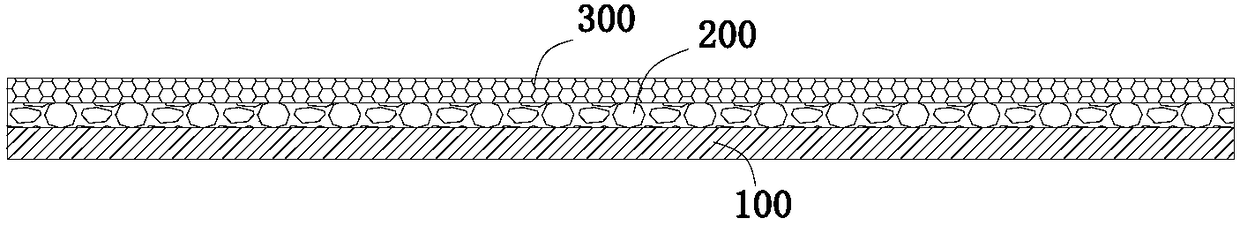

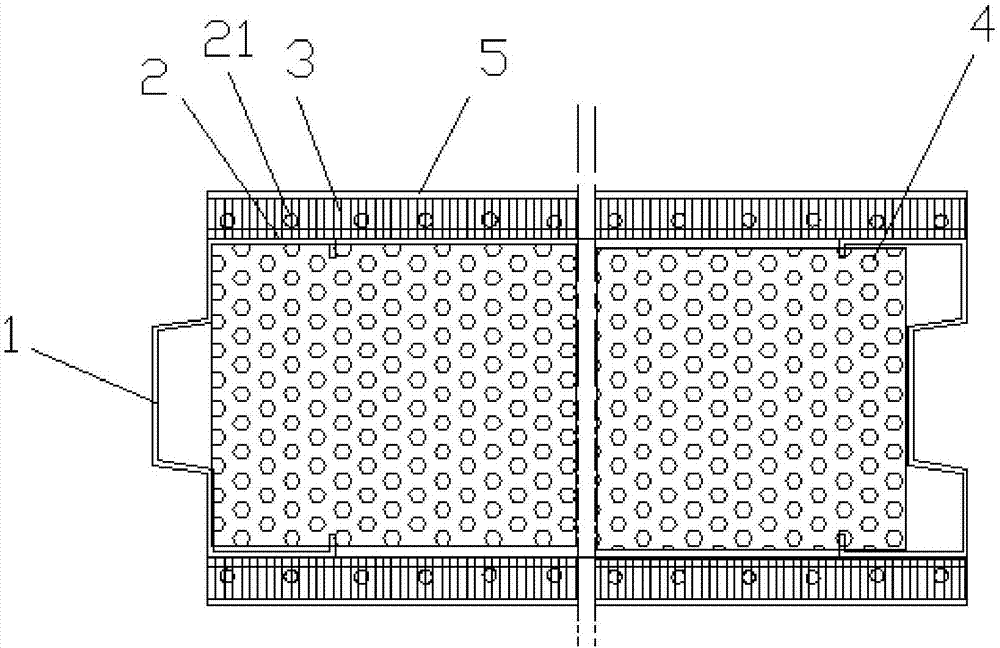

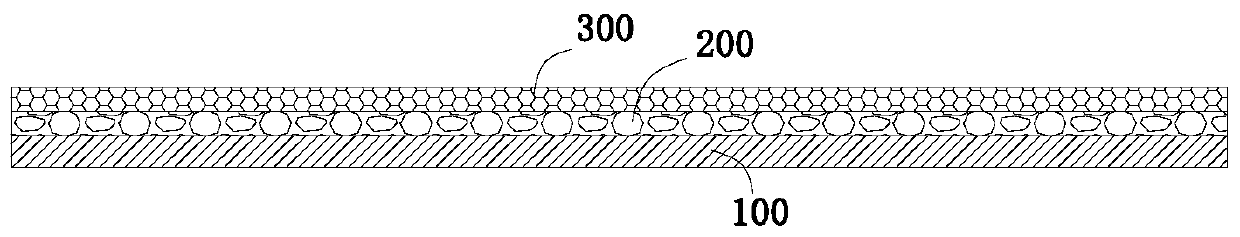

Composite air-drying hardened wallboard and manufacturing method and using method thereof

The invention provides a composite air-drying hardened wallboard and a manufacturing method and using method thereof. The wallboard comprises a rectangular frame, a rebar combination net and an air-drying face layer, and the rebar combination net and the air-drying face layer are sequentially located on the front side and the rear side of the frame from inside to outside. The air-drying face layercomprises a honeycomb weave layer and light dry-mixed mortar, the honeycomb weave layer is attached to or mounted on the rebar combination net, the honeycomb weave layer is provided with densely-covered honeycomb holes, the honeycomb holes of the honeycomb weave layer are filled with the light dry-mixed mortar, and paster is attached to the outer side of the air-drying face layer. The wallboard is low in weight and convenient to transport, the transporting cost is reduced, the labor intensity of workers in the mounting process is relieved, the mounting efficiency is improved, and the mountingmanpower cost is decreased. After the wallboard is mounted and hardened with water, the wallboard has the advantages that compactness and strength are good, and a wall face layer is not prone to cracking. Mechanized, standardized and large-scale production of the wallboard can be achieved in a factory, the production efficiency is improved, and the production cost is lowered.

Owner:唐方方

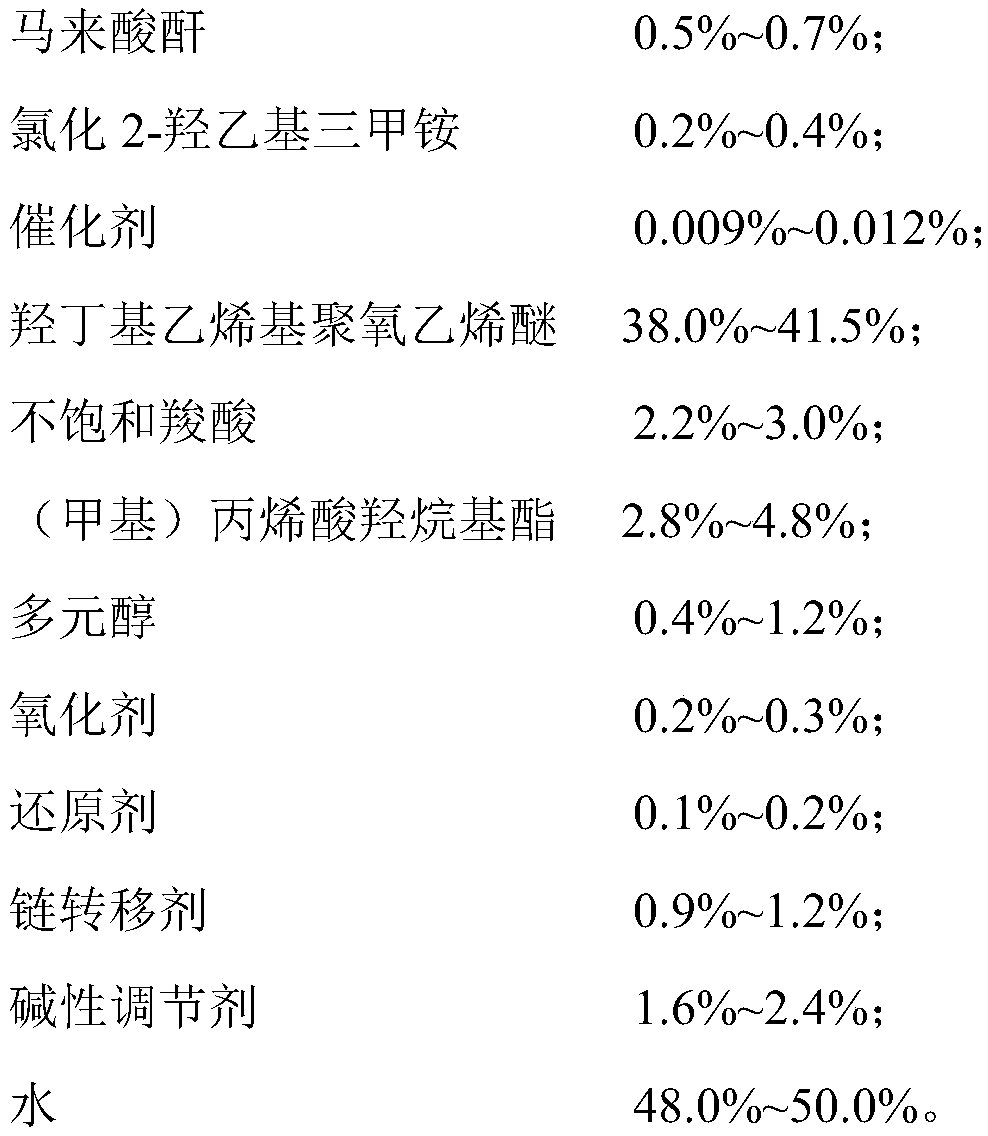

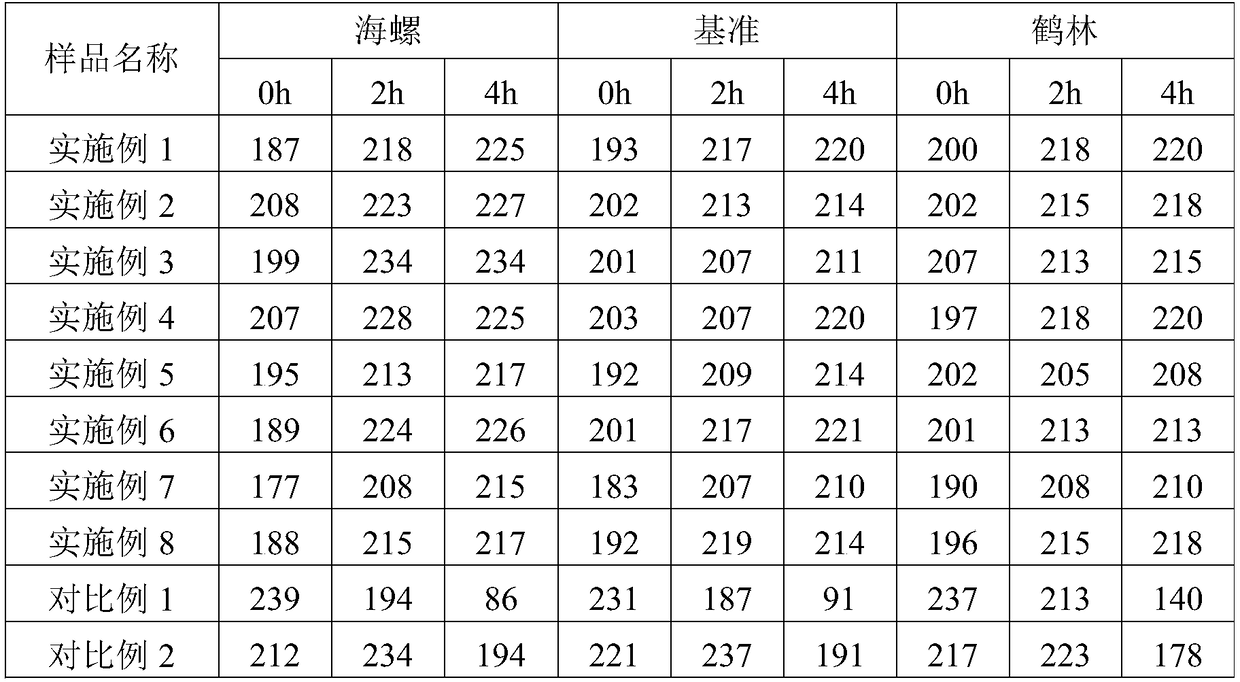

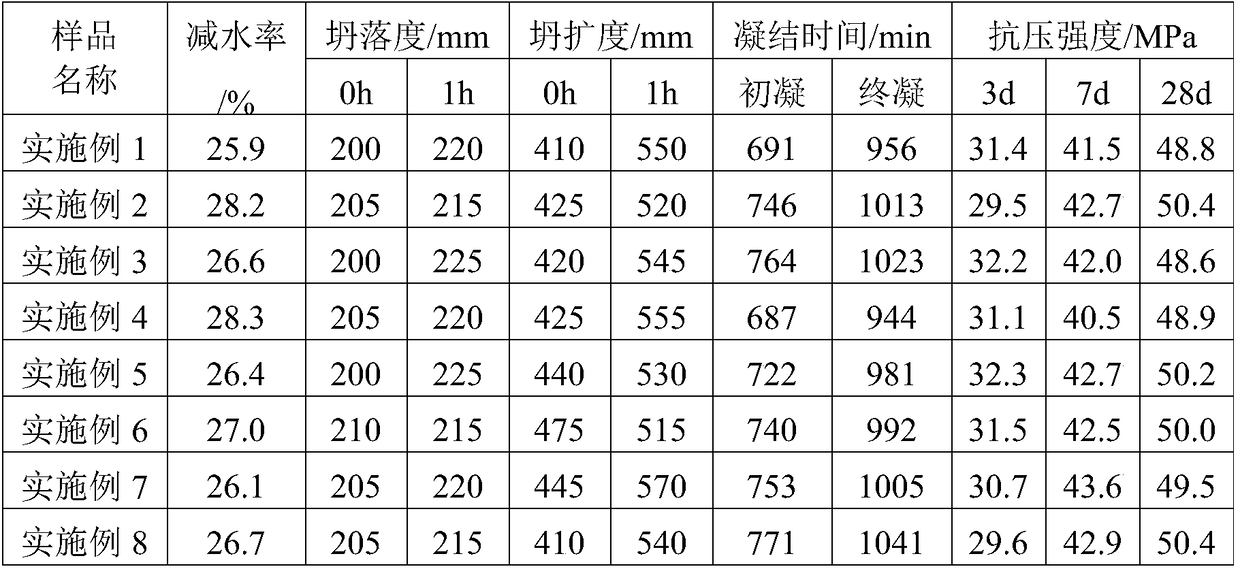

Super-retarding polycarboxylic acid type water-reducer as well as preparation method and application thereof

InactiveCN109306038AAvoid clotting time anomaliesReduce process2-hydroxyethyl-trimethyl-ammoniumCompound a

Owner:安徽瑞和新材料有限公司 +1

Chloride-free early-strength water-reducing agent capable of improving concrete workability

Owner:滁州京安工贸有限责任公司

Quick-dry self-flow casting material for ladle permanent layer

The invention discloses a quick-dry self-flow casting material for a ladle permanent layer. The quick-dry self-flow casting material is prepared from the following raw materials in percentage by mass:56-75% of a pyrophyllite and fused mullite composite material of which the particle size is 1-9mm, 14-22% of a pyrophyllite and fused mullite composite material of which the particle size is 0-1mm, 2-8% of silicon nitride of which the particle size is less than or equal to 1mm, 0.5-1.5% of a water reduction agent, 0.8-1.5% of an anti-explosion agent, 1-3% of a combination agent, 1-3% of silicon dioxide micro powder of which the particle size is less than or equal to 60mu m, 1-4% of an active aluminum oxide micro powder of which the particle size is less than or equal to 60mu m, and 2-5% of asilica powder of which the particle size is less than or equal to 50mu m. By adopting the quick-dry self-flow casting material, the ladle permanent layer is good in thermal insulation, good in thermalshock resistance, good in peeling resistance and easy to construct, has the characteristics of excellent self flowing, spreading, filling and the like, can be rapidly baked without cracking, achievesthe purposes of self flowing and quick drying, in addition is free of iron slag adhesion, and is long in service life.

Owner:YANSHI ZHONGYUE REFRACTORY MATERIALS

Quick-drying self-flowing castable for reclaimed ladle permanent layer

The invention discloses a self-flowing castable for a reclaimed ladle permanent layer. The castable is prepared from raw materials in percentage by mass as follows: 46%-56% of a waste ladle permanentlayer reclaimed material with granularity being 1-9 mm, 13%-20% of a pyrophyllite and fused mullite compound with granularity being 1-9 mm, 14%-22% of a pyrophyllite and fused mullite compound with granularity being 0-1 mm, 2%-6% of silicon nitride with granularity being smaller than or equal to 1 mm, 0.5%-1.5% of a water reducer, 0.5%-1.5% of an antiknock agent, 2%-5% of a binder, 1%-3% of silicafine powder with granularity being smaller than or equal to 60 mu m, 2%-5% of activated alumina powder with granularity being 60 mu m and 1%-4% of silica powder with granularity being smaller than orequal to 50 mu m. The self-flowing castable has good heat insulation, good thermal shock resistance and high stripping resistance, has excellent characteristics of self-flowing, leveling and filling,is easy to construct and can be quickly baked without bursting, and purposes of self-flowing and quick drying are achieved.

Owner:YANSHI ZHONGYUE REFRACTORY MATERIALS

Casting method for aluminum alloy engine shell

The invention relates to a casting method for an aluminum alloy engine shell. The casting method sequentially includes the following steps that firstly, red copper pipes are manufactured to be in a shape the same with that of shell oil ways, and the red copper pipes are sealed after being filled with precoated sand; secondly, cores are manufactured; thirdly, the red copper pipes and the cores arecombined and fixed; fourthly, the cores are subjected to pulp dipping and then sand pouring, then pulp dipping is conducted again and sand pouring is conducted again, the operation is conducted repeatedly by multiple layers, inner die shells are obtained, dewaxing is conducted after the inner die shell is subjected to air drying, and high-temperature roasting sizing is conducted; fifthly, sand molds are manufactured in sand boxes, cavities coincide with the outer wall of the engine shell in shape, and casting systems are arranged in the sand molds; sixthly, the inner die shells are put into the cavities of the sand molds, then mold assembling is conducted; seventhly, aluminum alloy liquid is injected into the cavities till mold filling is completed; eighthly, after cooling forming, the engine shell is obtained, spare parts are removed, and the precoated sand in all the red copper pipes is removed; ninth, the shell engine is immersed in a dilute nitric acid solution, and the red copperpipes are corroded and form oil ways. By means of the casting method, the manufacturing cost is low, consumption of raw materials is low, the product quality is good, manufactured hole ways are smoothand reliable, and the yield is high.

Owner:YANGZHOU FENG MING METAL PROD

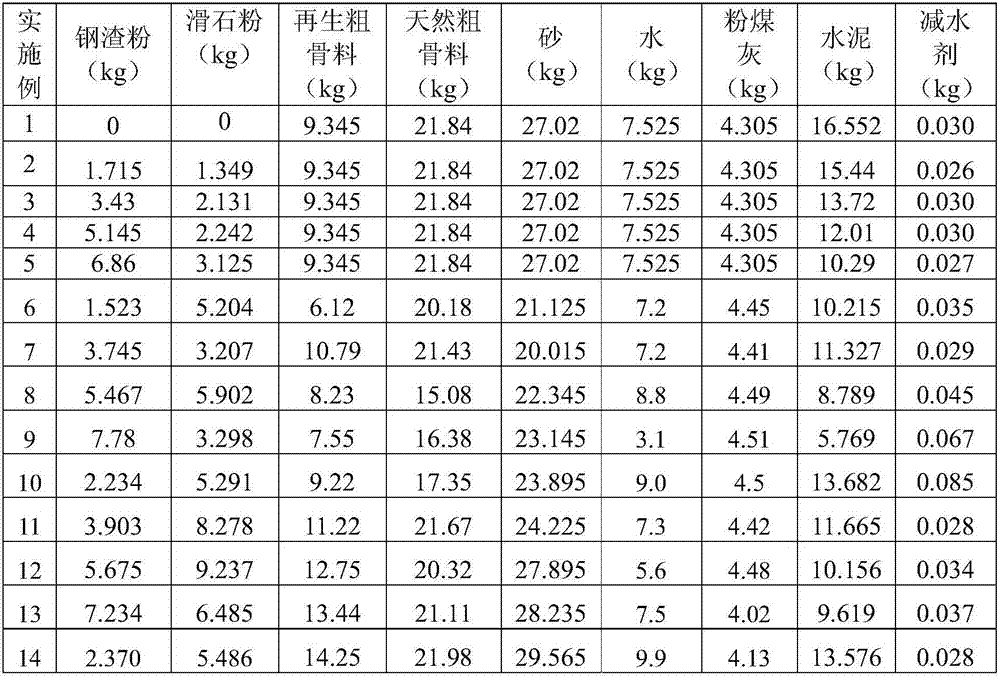

C30 grade steel slag powder self-consolidating concrete, preparation method and prefabricated component thereof

The invention provides a C30 grade steel slag powder self-consolidating concrete with a water-binder ratio controlled at 0.3-0.7. The C30 grade steel slag powder self-consolidating concrete comprises the following raw materials by weight: 1-10 parts of steel slag powder; 1-10 parts of talcum powder; 5-15 parts of cement; 20-30 parts of natural coarse aggregate; 6-15 parts of recycled coarse aggregate; 20-30 parts of sand; 1.5-3.5 parts of fly ash; 2-10 parts of water; and 0.001-0.1 part of a water reducing agent. The obtained self-consolidating concrete has good fluidity, gap passing ability, and segregation resistance, and meets the strength requirement. The concrete is convenient for construction, simultaneously the concrete production cost is lowered, and the preparation method is simple, and is suitable for industrial production.

Owner:张家港市华诚混凝土构件有限公司

Bag supporting and bag holding mechanism of secondary packaging machine

InactiveCN103979156AImprove stabilityPlay the role of exhaust limitPackagingEngineeringSecondary Packaging

The invention discloses a bag supporting and bag holding mechanism of a secondary packaging machine. The bag supporting and bag holding mechanism comprises a mechanism base, a horizontal guide rail, a bag supporting bottom plate support frame and a bottom plate air cylinder, wherein a bag supporting bottom plate and a bag moving air cylinder are arranged on the bottom plate air cylinder, a clamp groove is formed in the bag supporting bottom plate support frame, a clamp plate air cylinder is respectively arranged on the clamp groove, in addition, a bag holding clamp plate is fixedly arranged on the plate clamping air cylinder, a sensor is arranged at the inner side of the bag holding clamp plate, one end, in the direction along the horizontal guide rail, of the bag supporting bottom plate is provided with a material pushing plate, and the outer side of the material pushing plate is connected with a push plate air cylinder. The bag supporting and bag holding mechanism of the secondary packaging machine has the advantages that the bag holding clamp plate is directly connected with the plate clamping air cylinder, and the bag holding speed is accelerated, so the work efficiency is greatly improved, the bag holding stability is improved, the bag holding clamp plate is provided with the sensor, the stroke of the clamp plate air cylinder can be regulated, the proper clamping force is ensured, the push plate pushing conveyance is used for replacing clamping conveyance, the bag holding clamp plate only realizes an exhaust position limitation effect, and the deformation and the damage of packaged articles are prevented.

Owner:合肥三冠机电设备有限公司

Method for retaining gob-side tunnel

InactiveCN102337904BAchieve miningTake advantage ofMining devicesUnderground chambersArchitectural engineeringRebar

The invention discloses a method for retaining a gob-side tunnel, which overall arranges the retaining of the gob-side tunnel in a stope working face gateway tunneling period, and comprises the steps of: combining the stope working face gateway with the gob-side retained tunnel, namely the next section gateway, together to be served as one tunnel for tunneling; and constructing tunnel concrete pier columns between the stope working face gateway and the gob-side retained tunnel, wherein the tunnel concrete pier columns are served as support in the tunnel and also served as one part of the side support for the gob-side retained tunnel; namely comprising the steps of: widening the section of the tunnel by tunneling, reserving the tunnel section according to the shrinkage factor of the god-side retained tunnel suffering from two times of support pressure, and pouring the reinforcing steel bar concrete pier columns in middle of the transverse direction of the tunnel to match with a cable anchor for supporting. The tunnel concrete pier columns are arranged along the whole length of the tunnel at intervals, and used for dividing the tunnel into two parts. Insulating walls are constructed between two adjacent columns after the columns are constructed. When the stope is starting, the support is needed to be temporarily reinforced at two sides of the columns according to requirements along with the advancing of the stope working face. According to the method for retaining a gob-side tunnel, the retaining of the gob-side tunnel and the tunneling of the stope working face gateway are overall arranged, and the tunnel concrete pier column support is arranged; therefore, the side support intensity and support resistance of the retained tunnel are greatly enhanced, the influence of support pressure in two times of mining is effectively controlled. The method for retaining gob-side tunnel is particularly suitable for using in flexible mining faces of bottom plate and / or top plate.

Owner:贾民

Supporting method for gob-side entry retaining and its sliding form for injection entry

ActiveCN101906979BAchieve miningTake advantage ofUnderground chambersMaterial fill-upArchitectural engineeringBunker

A method for supporting a gob-side entry of a coal mine recovery roadway. With the progress of the working face, concrete is pumped to the filling mold for pouring on the side of the goaf of the gob-side entry along with the progress of the working face, and the filling wall 8 beside the roadway is constructed; the top of the filling wall 8 and the The outer roof is supported by anchor net cables and constructed on the front side of the head support 1; the filling form adopts the height-adjustable integral pull-type slip form 6 for the entry lane; the bunker support 3 is used on the side of the goaf of the slip form and 5 temporary support; the sliding form of the injection lane and the bunker bracket are connected and moved by the pulling jack and the head bracket 1; the bunker bracket, the filling wall beside the lane and the top surface of each head bracket supported by the outer anchor net cable are provided with protective anchors Grooves for rod anchors. In addition to the advantages of less digging of roadways, realization of coal pillar-free mining, and relief of continuous tension in mining, the sliding form of the injection roadway of the present invention can be moved as a whole by hydraulic pressure adjustment, which is convenient to use and improves work efficiency; anchor net cable support cooperates with filling wall support , to more effectively control the separation layer of the direct roof; the bunker support and the head support can protect the anchor cable and anchor rod from being damaged by the roof.

Owner:兖矿能源集团股份有限公司

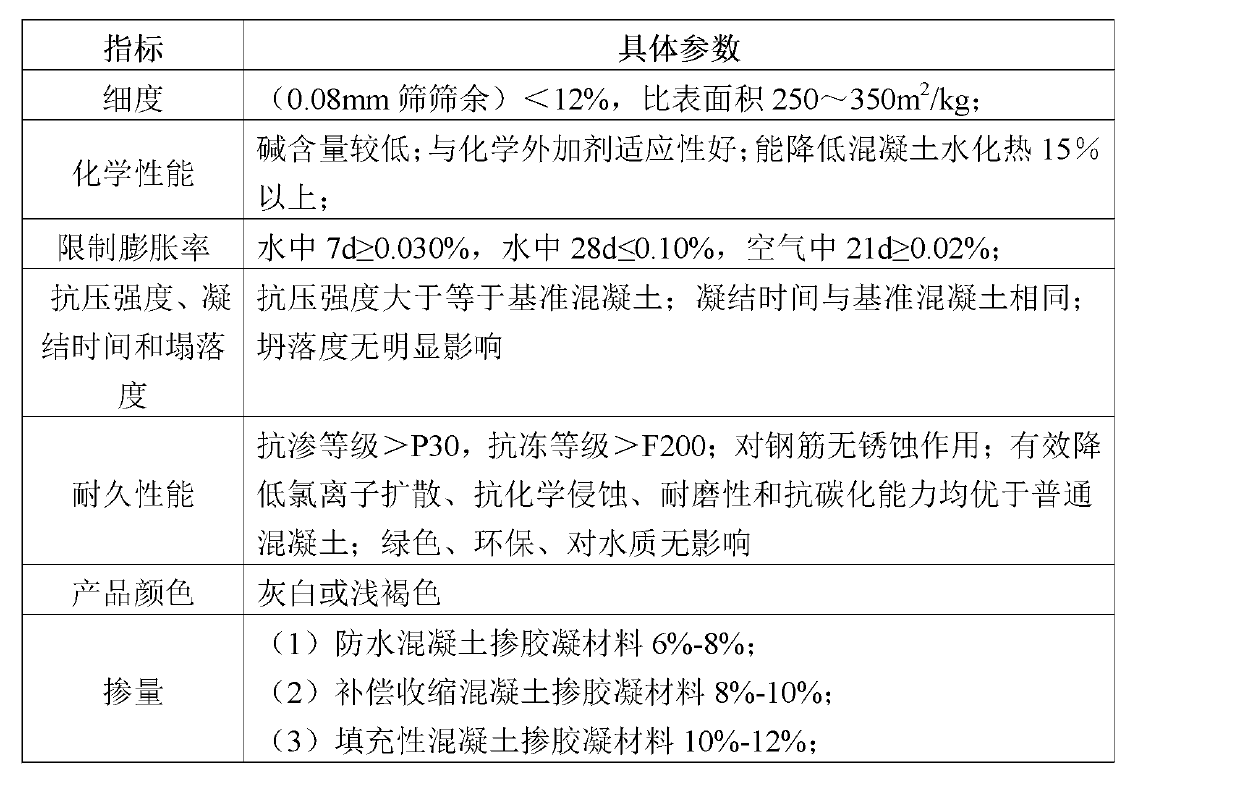

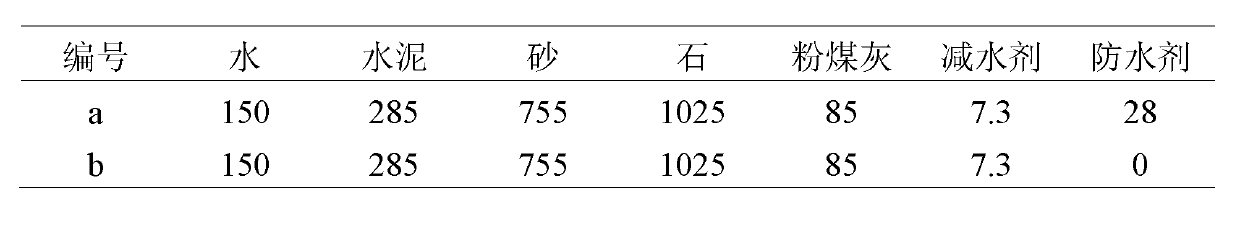

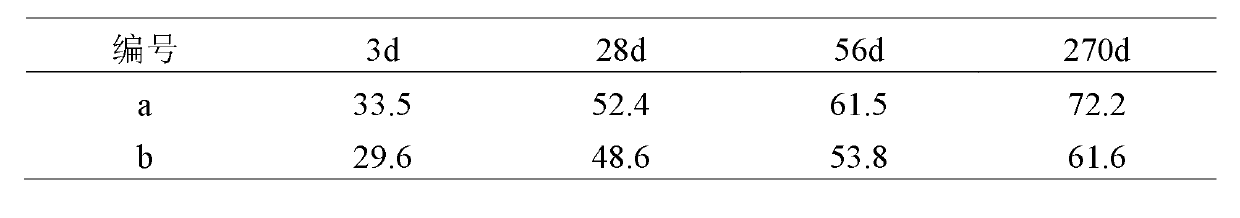

Nanometer composite type expansion anti-cracking waterproofing agent

The invention relates to a nanometer composite type expansion anti-cracking waterproofing agent. The nanometer composite type expansion anti-cracking waterproofing agent comprises the following components and contents: 9.2%-27.5% of calcium sulphoaluminate, 6.8%-11.2% of calcium aluminate, 7.1%-15.4% of calcium hydroxide, 4.8%-13.6% of PSP organic silicon powder, 3.6%-7.5% of sodium silicate, 0.1%-3.2% of ethanediamine sodium phosphate, 0.5%-2.5% of iron powder, 1.0-3.3% of borate, 0.1%-0.5% of manganese dioxide, 0.1%-2.4% of polypropylene fiber, 0.1%-0.8% of disodium ethylene diamine tetraacetate, 1.8%-4.3% of sodium tripolyphosphate, 15.2%-22.5% of pulverized fuel ash, 5.3%-11.6% of aminophenoxy naphthalene sulfonate and 5.1-8.5% of FP nanometer polymer. The expansion generated by the nanometer composite type expansion anti-cracking waterproofing agent and the contraction of concrete synchronously develop; and fillers generated by the nanometer composite type expansion anti-crackingwaterproofing agent can be used for effectively filling apertures of the concrete at different periods and different quantity values and under different action mechanisms of different crystal minerals. When the nanometer composite type expansion anti-cracking waterproofing agent is restrained by steel bars and adjacent positions, the 0.38MPa-0.8MPa prestressing stress can be generated; and different expansion mineral phases are generated at different ages of the concrete, thereby very effectively controlling the generation and development of non-structural cracks such as the early-stage plastic shrinkage and air shrinkage of the concrete and the cement plaster.

Owner:QINGDAO BRANCH TIANJIN TAIKE BUILDING TECHCO

Construction Technology of Cement Stabilized Crushed Stone Pavement

ActiveCN108486979BHigh strengthImprove integrityIn situ pavingsCement mixing apparatusCrushed stoneStructural engineering

The invention discloses a construction process for a cement stabilized macadam pavement. The construction process comprises the following steps: calculating a mix proportion of a cement stabilized macadam mixture, and blending the cement stabilized macadam mixture; laying a first cement stabilized macadam mixture layer on the pavement, laminating the first cement stabilized macadam mixture layer,laying a second cement stabilized macadam mixture layer on the upper surface of the laminated first cement stabilized macadam mixture layer, laminating the second cement stabilized macadam mixture layer, and maintaining the pavement until the strength of the pavement is not less than 3MPa. The pavement laid by the construction process difficultly causes cracks, and is long in service life and safeand reliable to use.

Owner:CHINA FIRST HIGHWAY ENG +1

Steel fiber self-compacting concrete and preparation method thereof, and prefabricated member

ActiveCN107032695BEquivalent compressive strengthHigh tensile strengthStructural engineeringMetal fibers

The invention provides a steel fiber self-compacting concrete, wherein the water-binder ratio of the concrete is controlled to be 0.3-0.7. The concrete is prepared from, by weight, 1-5 parts of 3-20 mm short steel fiber, 0.5-3 parts of magnetic beads, 1-4 parts of non-metallic fiber, 23-27 parts of natural coarse aggregate, 20-22.5 parts of sand, 10-14 parts of cement, 1.5-3.5 parts of fly ash, 4-8 parts of water, and 0.001-0.160 part of water reducing agent. The obtained high performance self-compacting concrete not only has simple production processes, but also can meet requirements on compressive strength and tensile performance.

Owner:苏州港松建材有限公司

A kind of centrifuge dense anti-overflow prevention device and process of porcelain stacking for dental restoration

ActiveCN109925072BPrevent overflowAvoid pollutionTeeth fillingArtificial teethCentrifugationEngineering

The invention discloses a dental prosthesis decorative porcelain stacking centrifugal compact anti-overflow device and process, and relates to the technical field of dental prosthesis preparation. The device includes a dental mold arranged on a centrifuge for containing decorative porcelain slurry The model module is characterized in that the dental model model module is detachably provided with a seal for sealing the dental model model module, and the seal is provided with a hole for discharging the moisture in the ceramic paste. For the micro-holes, seals are used to cover the upper surface of the dental mold model module containing the piled slurry to seal the decorative porcelain slurry from overflowing. After the decorative porcelain slurry is centrifugally shaken, the sealed seal is peeled off Components, adopting the above scheme, can completely prevent the ceramic paste from overflowing, and can avoid the loss of raw materials and equipment pollution. By setting the micropores, it is beneficial to the dehydration treatment of the ceramic slurry in the centrifugation process.

Owner:SHANGHAI JADE DIGITAL DENTAL LAB CO LTD +1

A valve with intelligent positioning and anti-clogging

ActiveCN112483709BAvoid cloggingIntegrity guaranteedCombination devicesOperating means/releasing devices for valvesValve actuatorControl signal

The invention discloses a valve with intelligent positioning and anti-clogging, comprising a positioner and a valve actuator, the positioner includes an air source purification unit, and an air inlet for inputting an air source is arranged on the air source purification unit, The air source purification unit is connected to an anti-clogging electrical conversion unit for controlling the valve actuator, the anti-clogging electrical conversion unit is connected to a circuit control unit through a control signal, and the circuit control unit is connected to a position feedback unit. Beneficial effect: The drying indicator wrapped inside the absorbent cotton can absorb the moisture in the air flow, so as to keep the interior of the purification shell dry and avoid damage to the valve positioner, and during cleaning, the heating mechanism is provided to make the hot air enter the interior of the purification shell , Heat and dry the absorbent cotton, the drying indicator and the absorbent cotton, so that the absorbent cotton, the drying indicator and the absorbent cotton are in a dry working state, which ensures that the absorbent cotton and other parts can absorb moisture for a long time.

Owner:JIANGSU BOTWAY FLUID TECH CO LTD

A kind of quick-drying self-flowing castable for permanent layer of ladle

The invention discloses a quick-dry self-flow casting material for a ladle permanent layer. The quick-dry self-flow casting material is prepared from the following raw materials in percentage by mass:56-75% of a pyrophyllite and fused mullite composite material of which the particle size is 1-9mm, 14-22% of a pyrophyllite and fused mullite composite material of which the particle size is 0-1mm, 2-8% of silicon nitride of which the particle size is less than or equal to 1mm, 0.5-1.5% of a water reduction agent, 0.8-1.5% of an anti-explosion agent, 1-3% of a combination agent, 1-3% of silicon dioxide micro powder of which the particle size is less than or equal to 60mu m, 1-4% of an active aluminum oxide micro powder of which the particle size is less than or equal to 60mu m, and 2-5% of asilica powder of which the particle size is less than or equal to 50mu m. By adopting the quick-dry self-flow casting material, the ladle permanent layer is good in thermal insulation, good in thermalshock resistance, good in peeling resistance and easy to construct, has the characteristics of excellent self flowing, spreading, filling and the like, can be rapidly baked without cracking, achievesthe purposes of self flowing and quick drying, in addition is free of iron slag adhesion, and is long in service life.

Owner:YANSHI ZHONGYUE REFRACTORY MATERIALS

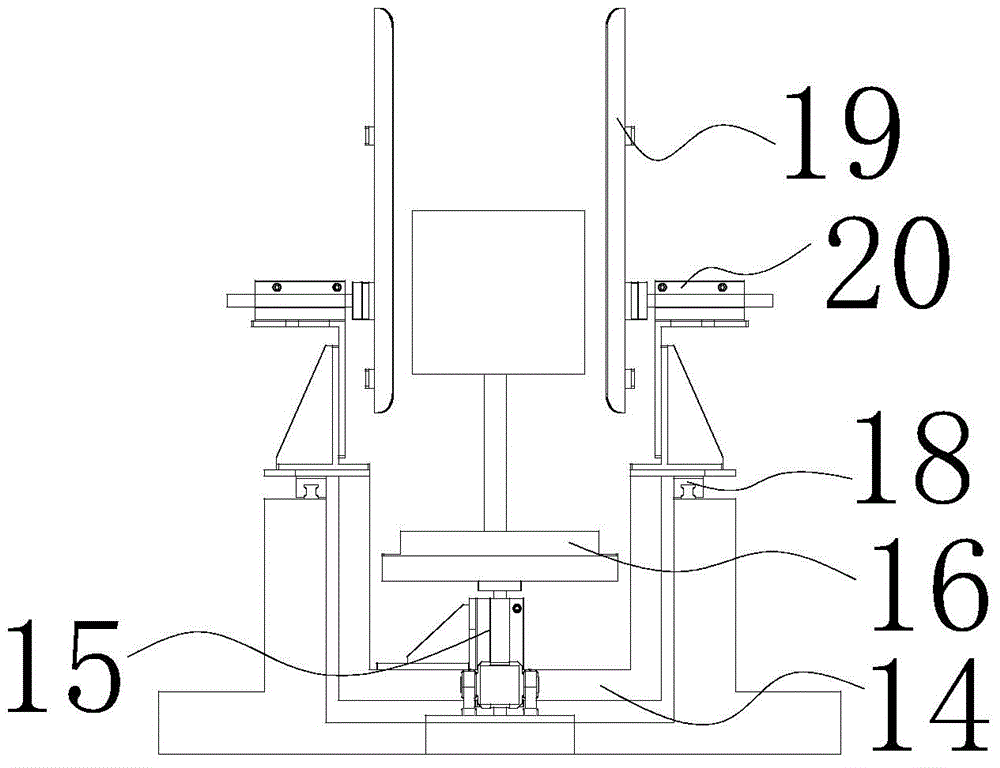

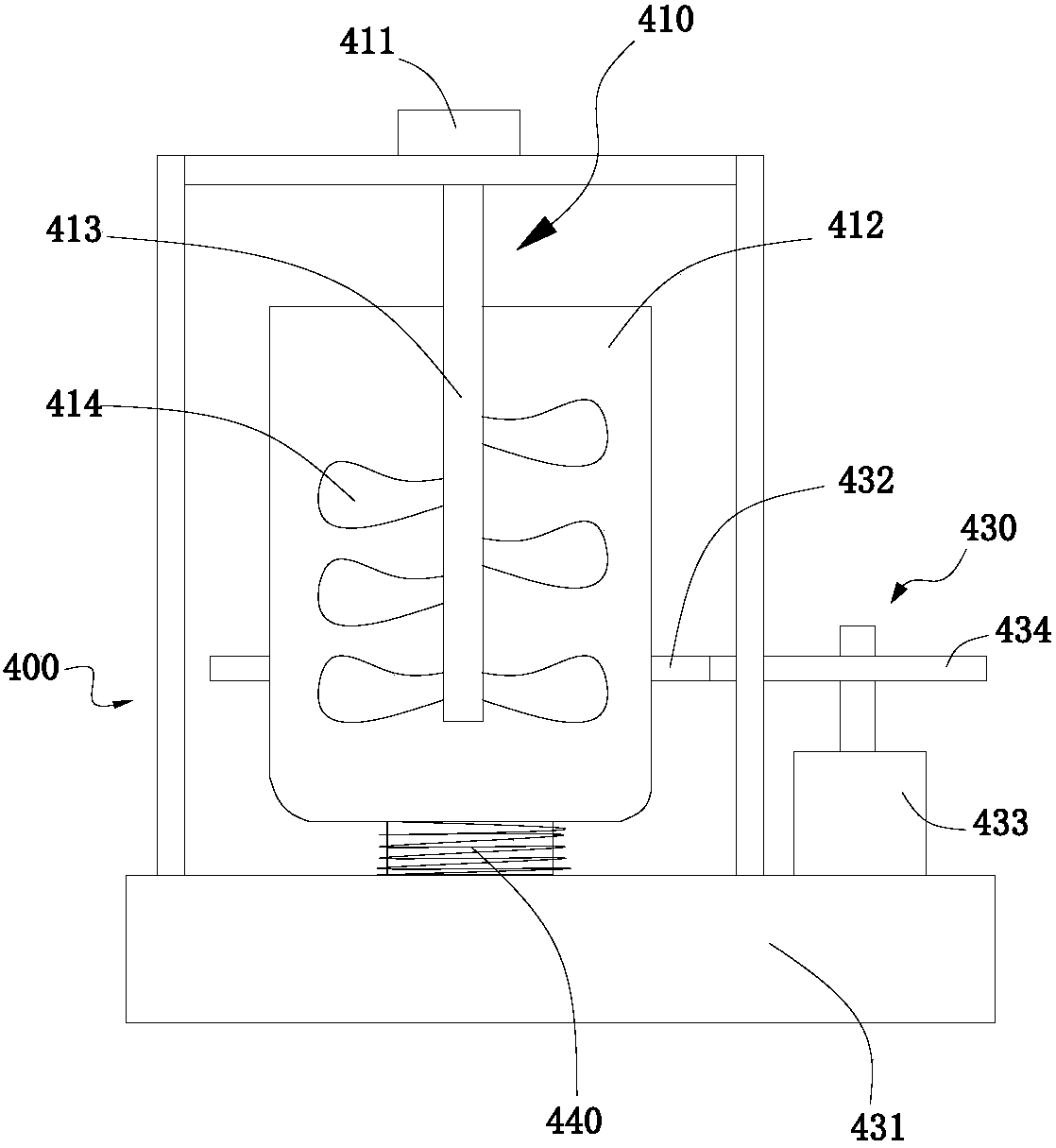

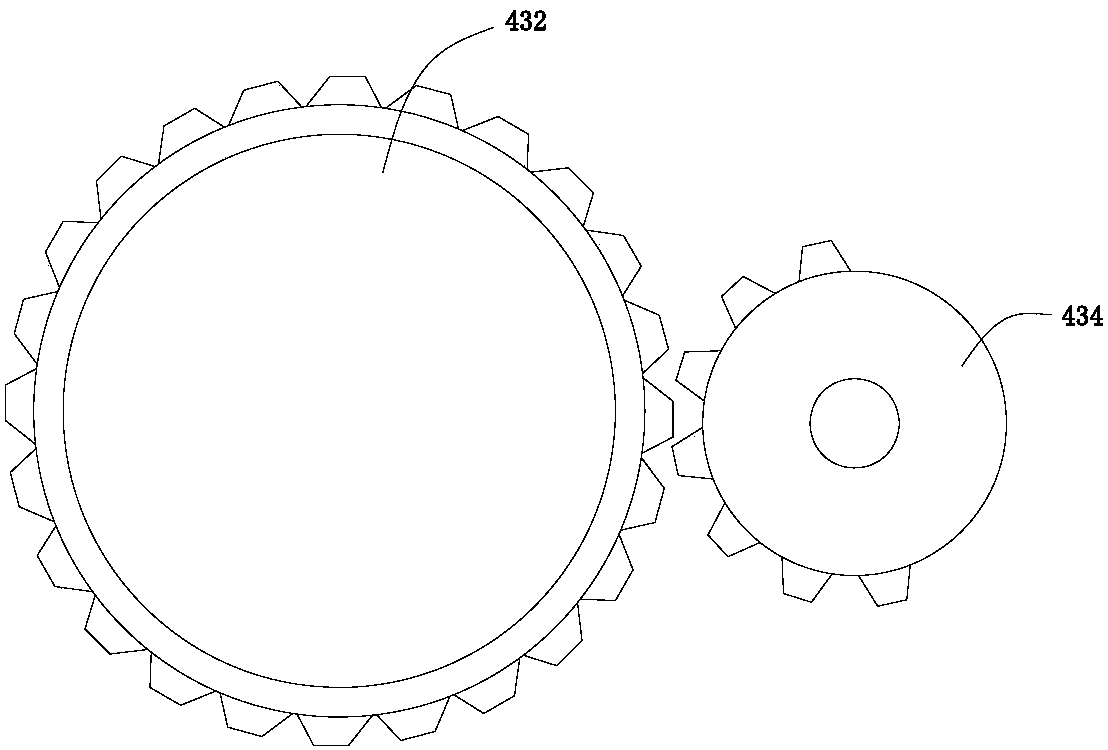

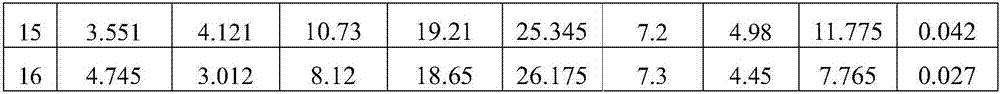

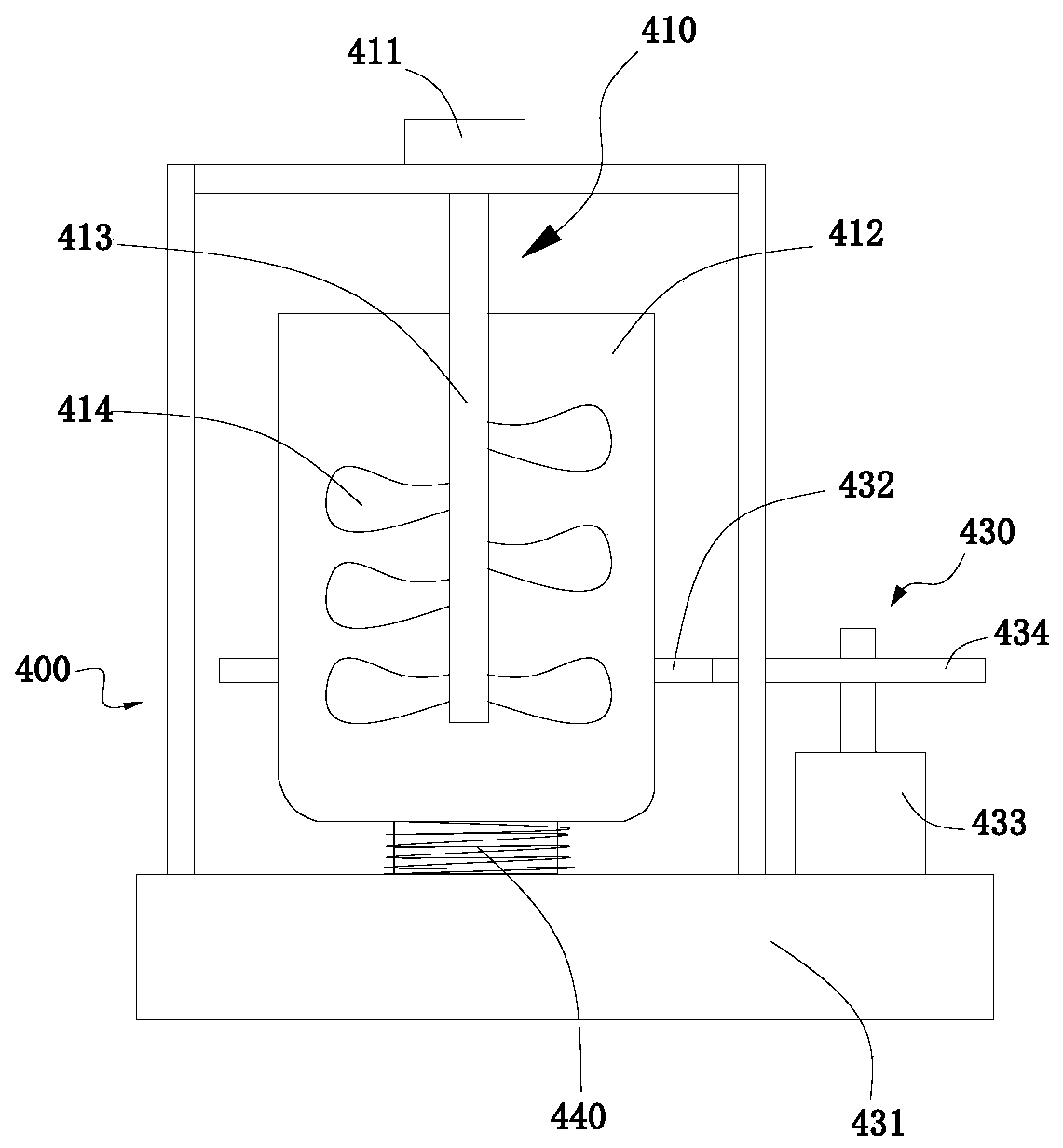

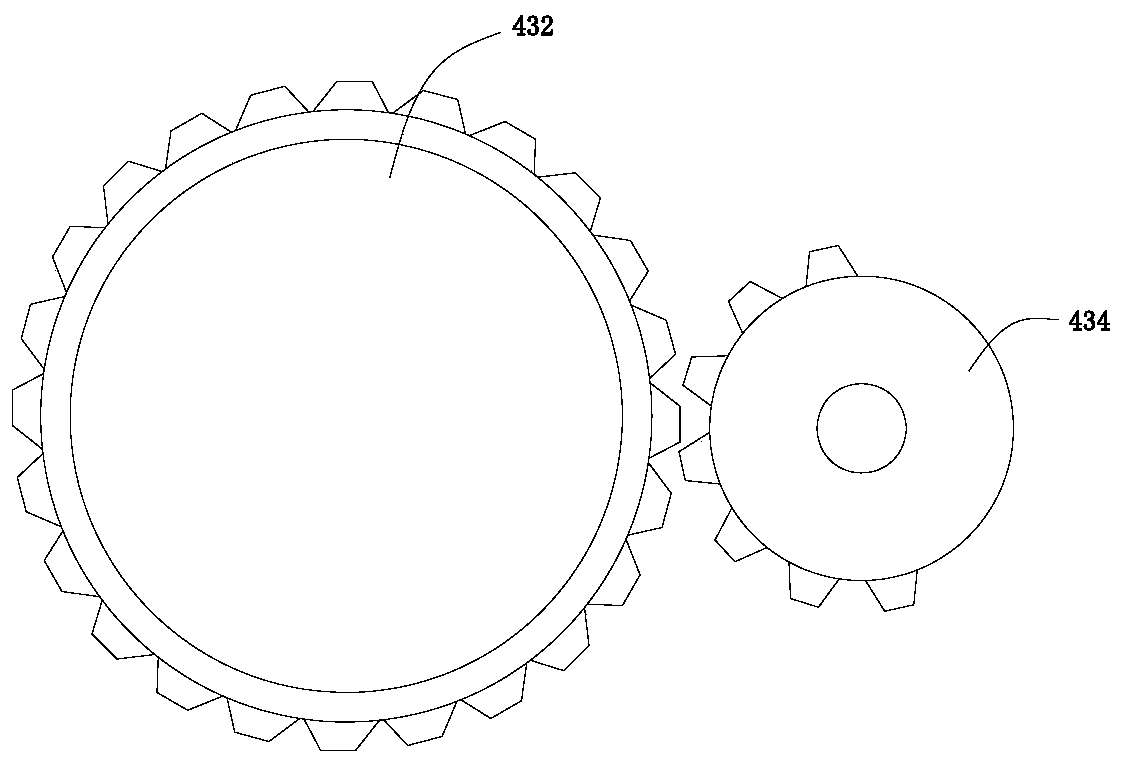

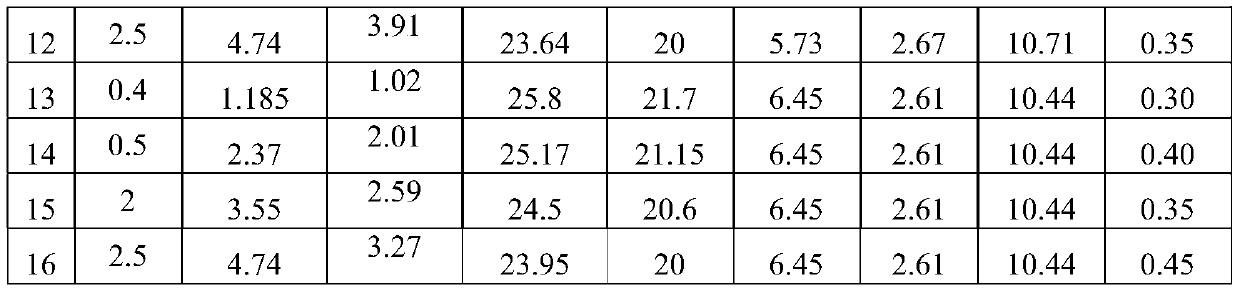

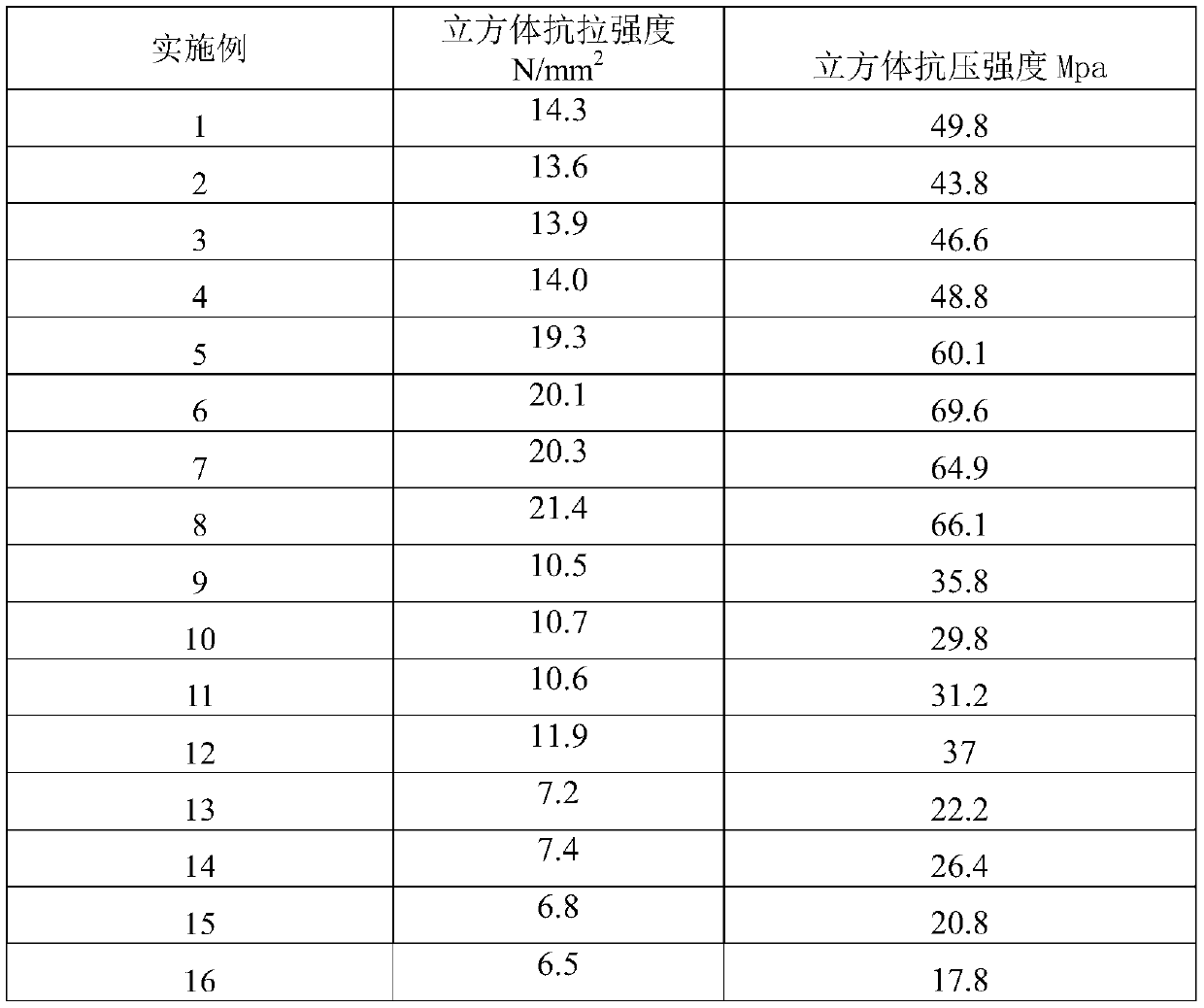

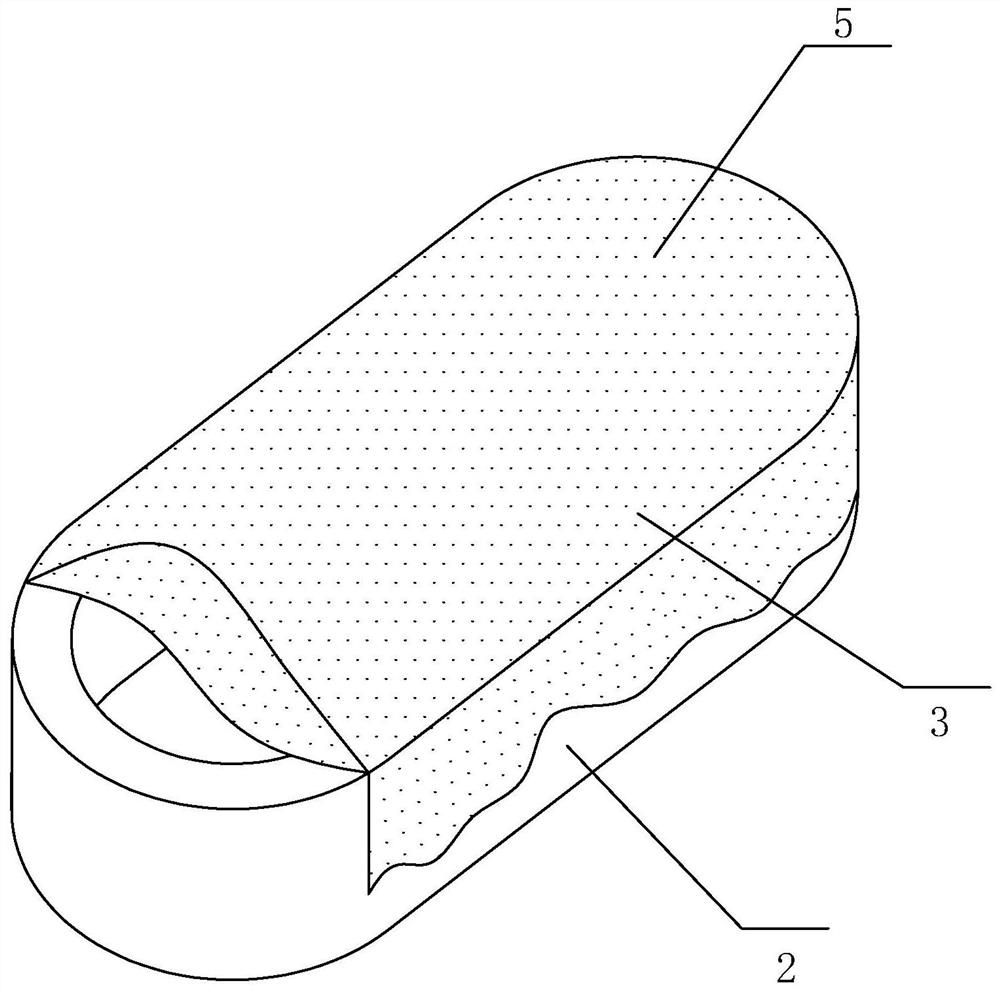

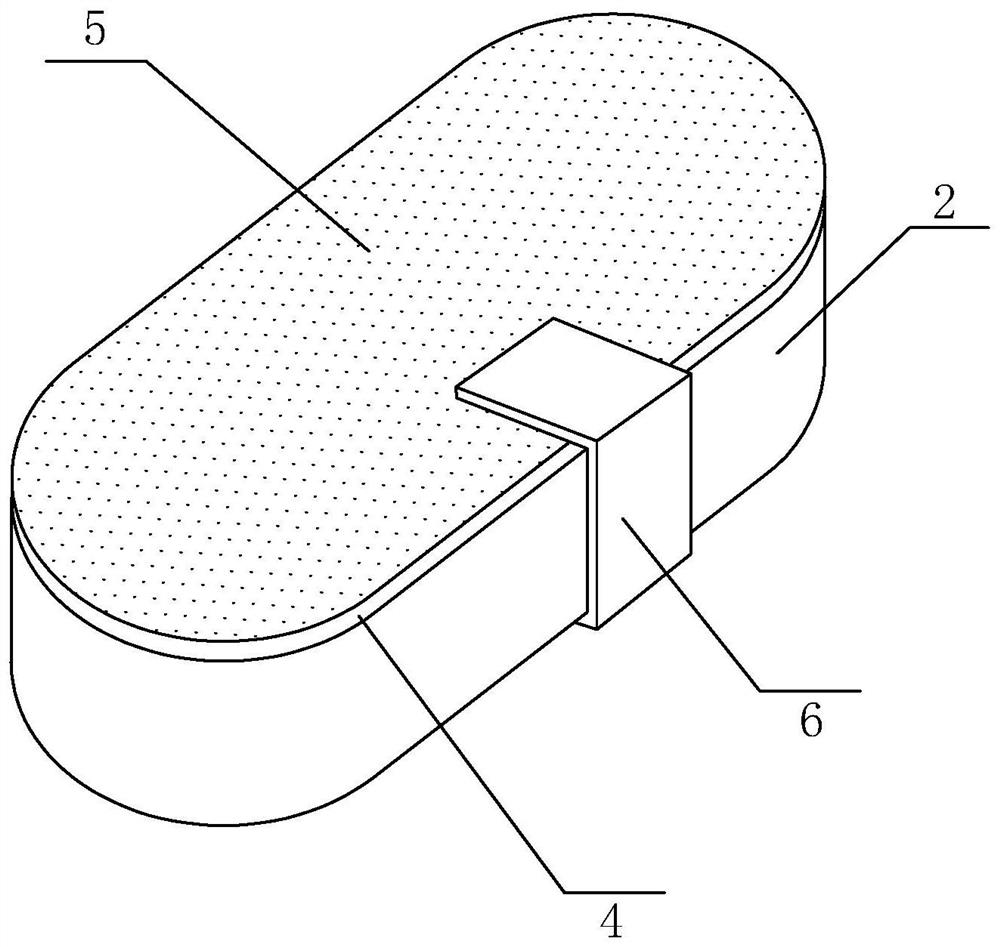

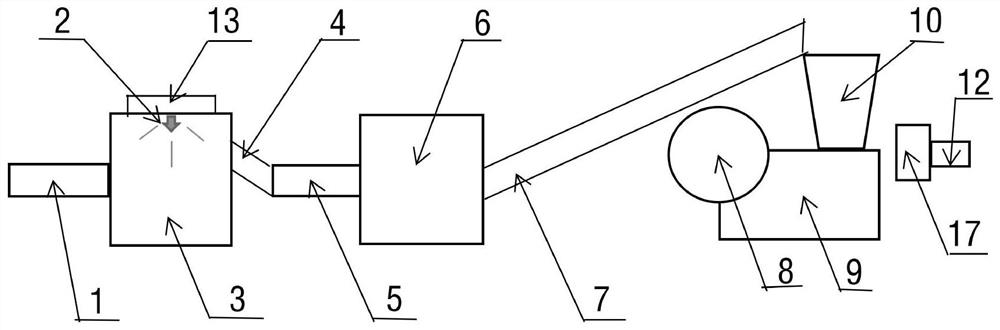

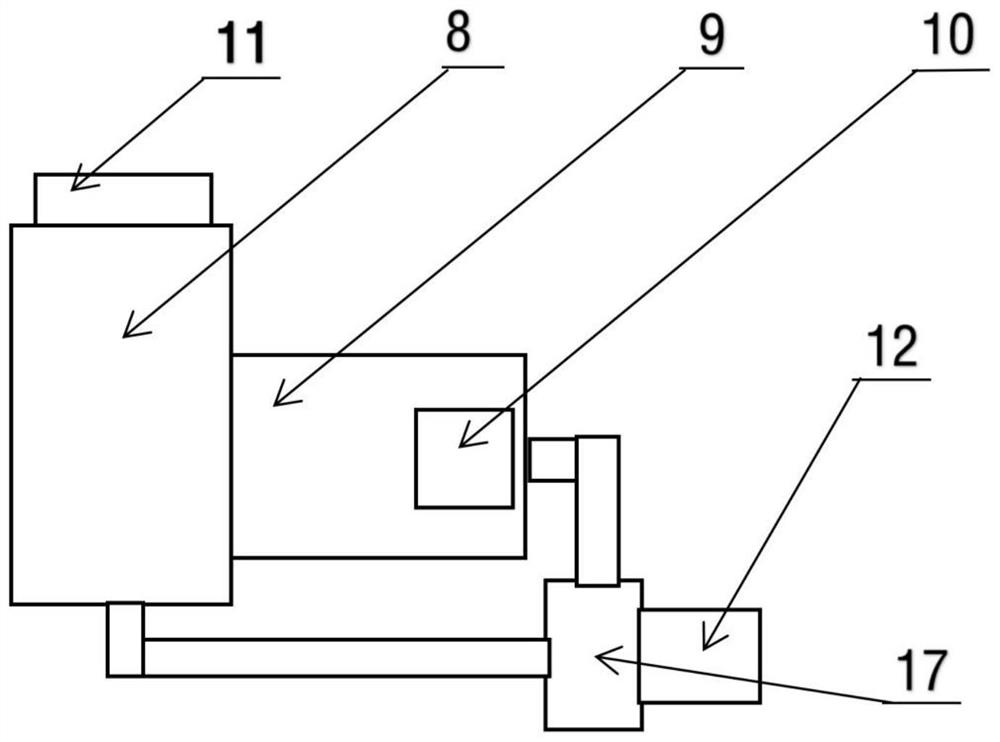

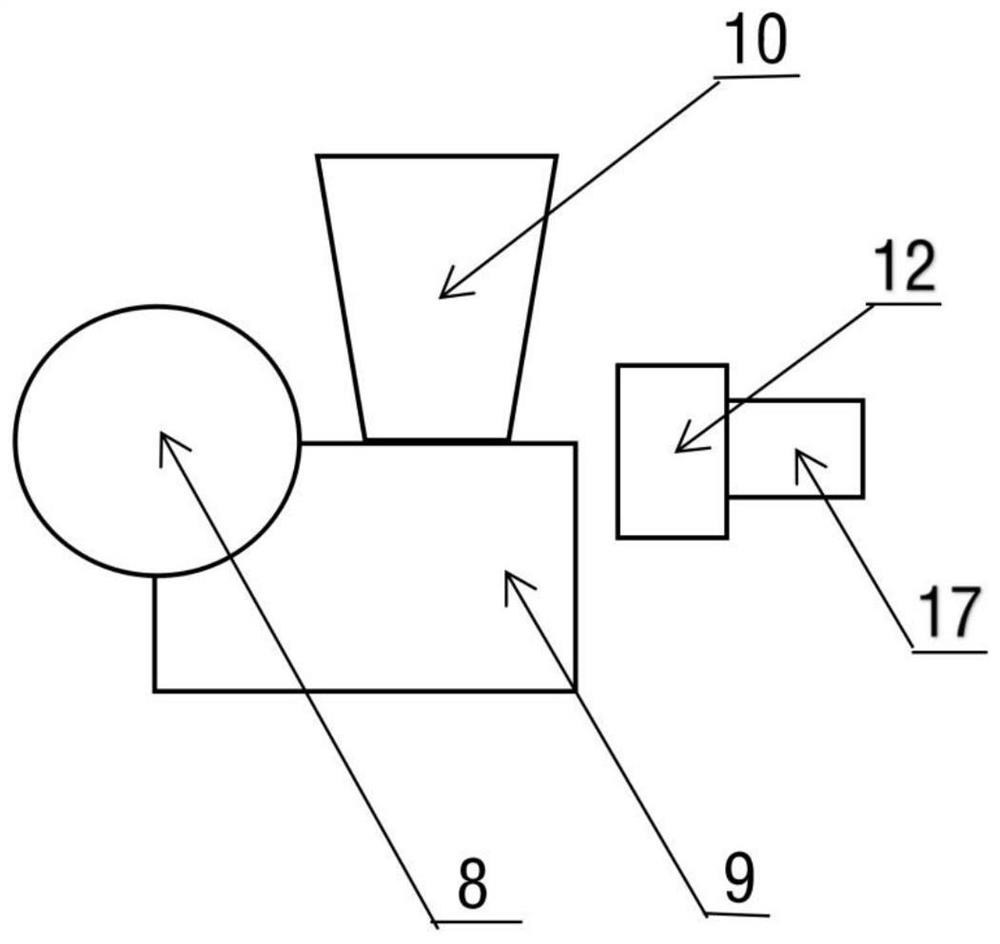

A molding process and molding equipment for biomass derived fuel (rdf)

ActiveCN111229784BStrong draining effectReduce moisture contentTransportation and packagingSolid waste disposalElectric machineProcess engineering

Owner:刘跃伟

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com