Sinking-prevention structural body of well peripheral composite material

A composite material and structure technology, used in underwater structures, infrastructure engineering, drainage structures, etc., can solve the problems of cracking around inspection wells, difficulty in mechanical rolling, and damage to the integrity of masonry, so as to improve concrete resistance. Crack performance and impact resistance, time benefit is obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solution of the present invention will be described in further detail below in conjunction with the accompanying drawings.

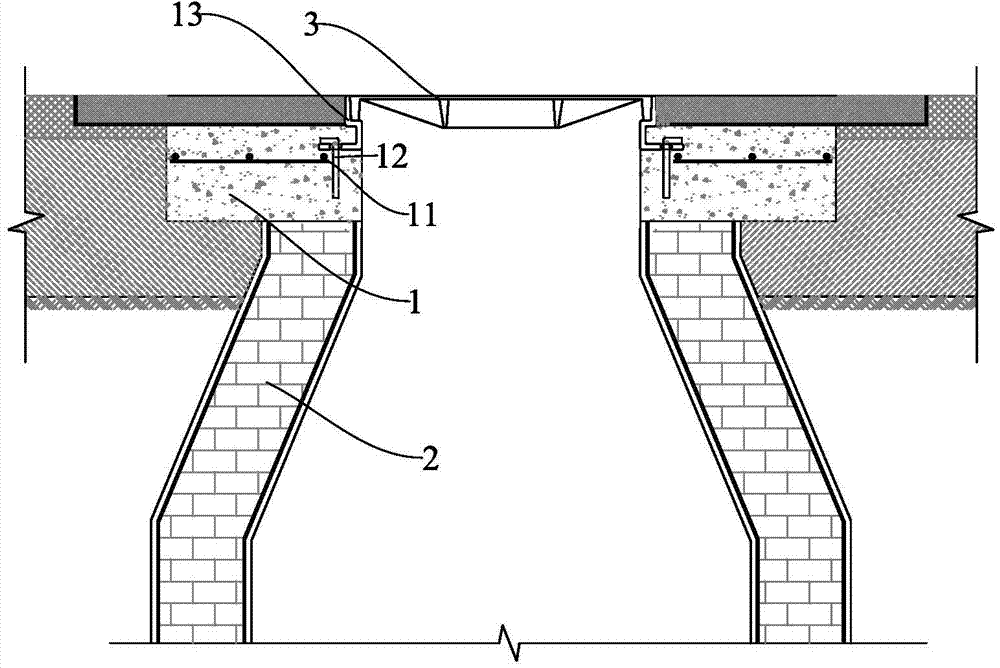

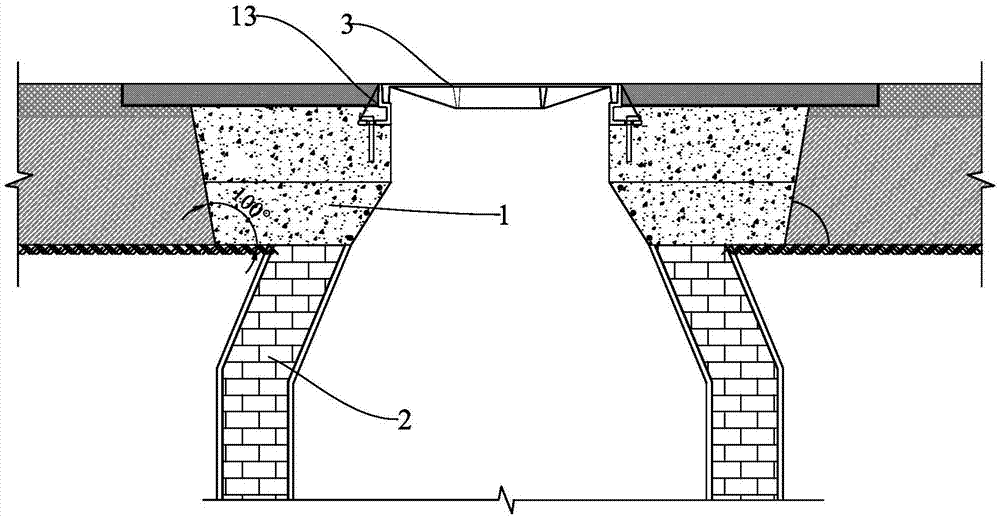

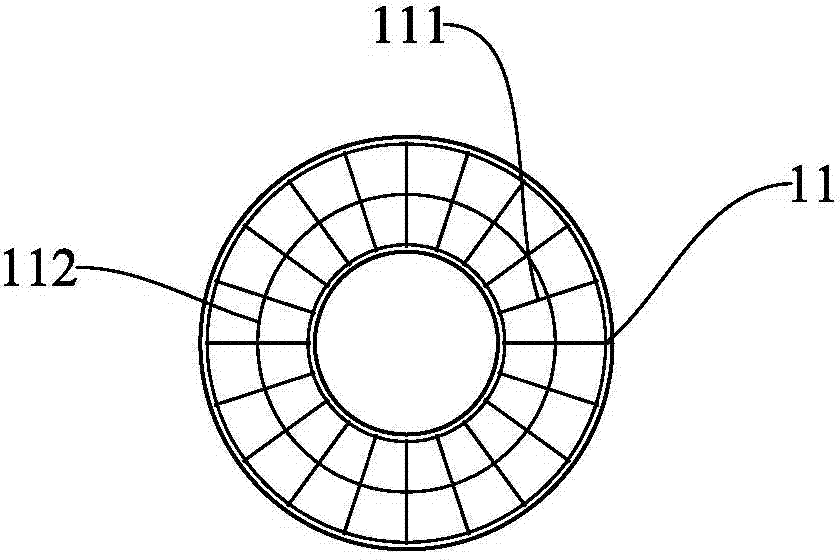

[0028] Such as figure 1 As shown, the present invention provides a composite material anti-subsidence structure around a well, including a base 1 and a well cover seat 13. Set on the subgrade around the wellhead of the inspection well, the manhole cover seat 13 is arranged on the base 1 and is flat with the road surface; in the present invention, the base 1 is made of concrete composite material, and its composition is in parts by weight It includes: 300-500 parts by weight of cement, 30-50 parts by weight of expansion agent, 1500-2000 parts by weight of aggregate and 8-10 parts by weight of water reducing agent. The swelling agent and the water reducer are commercially available conventional products. But preferably, the aggregates include fine aggregates and coarse aggregates, and the weight ratio of the fine aggregates to the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com