Construction process for cement stabilized macadam pavement

A technology of cement stabilizing gravel and construction technology, applied in cement mixing devices, roads, roads, etc., can solve problems such as easy cracks, and achieve the effect of increasing interlayer bonding, ensuring integrity, and increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

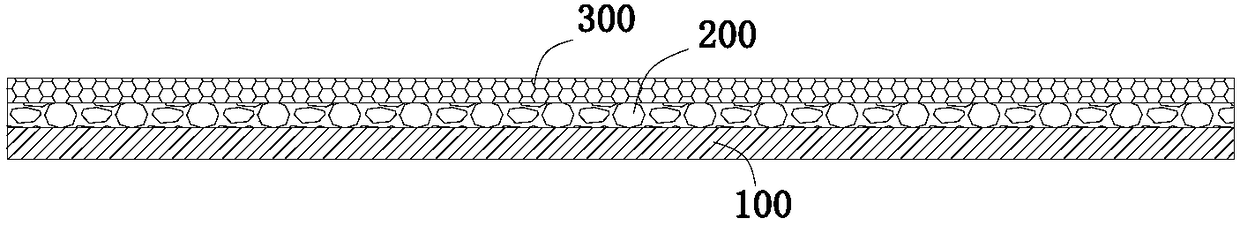

[0041] see figure 1 - Figure 4 , the present embodiment provides a cement-stabilized macadam pavement construction process, the construction process comprising:

[0042] Step 100: Calculate the mixing ratio of the cement-stabilized gravel mixture, and mix the cement-stabilized gravel mixture. After the calculation of the mixing ratio is completed, mix and stir the raw materials, and use the mixing equipment 400 to mix the mixture. The finished product is stored in the finished product warehouse, and the finished product warehouse is transferred to the construction site by using transportation equipment, such as a transport vehicle, and the finished product is laid on the corresponding roadbed 100 .

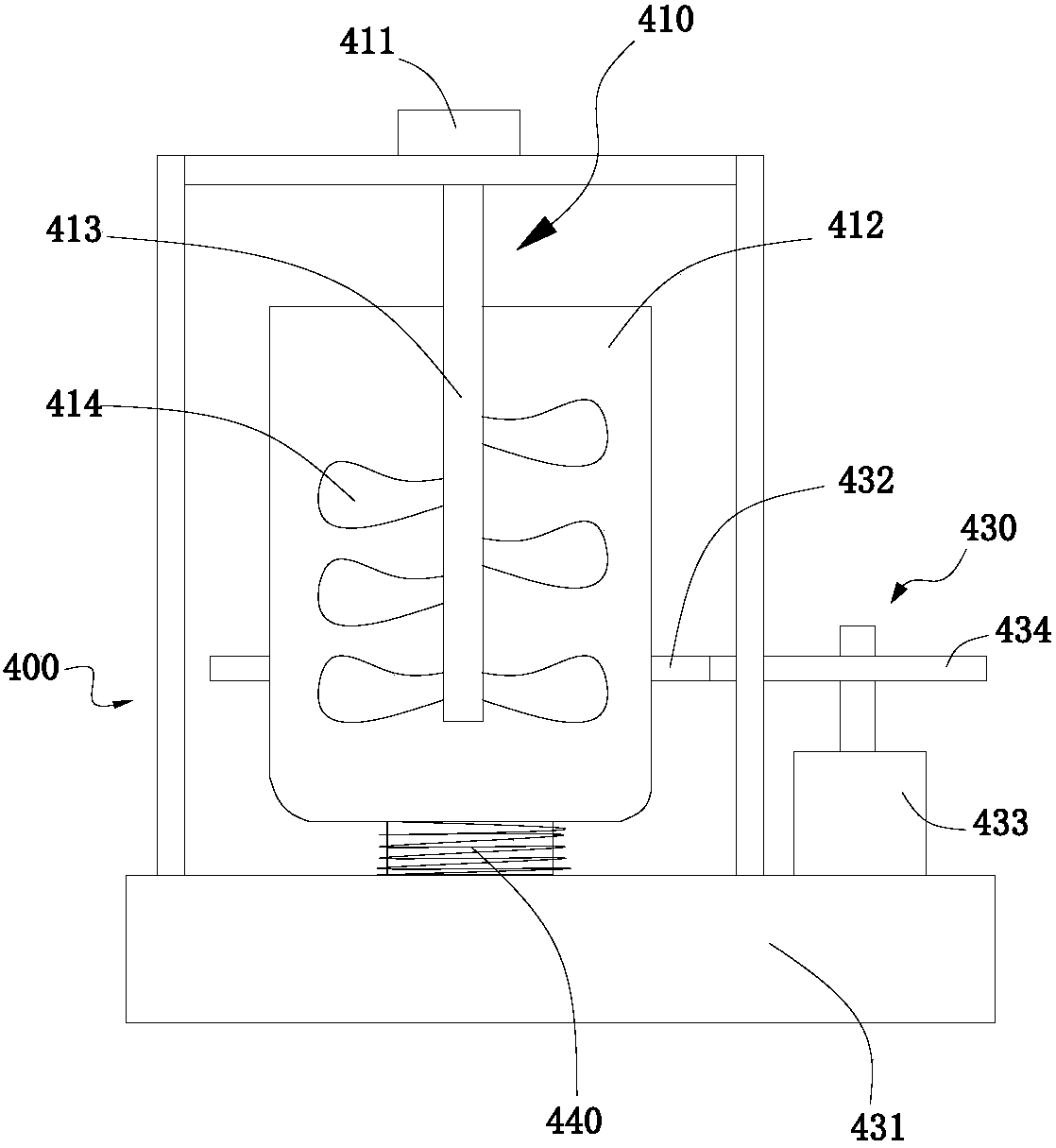

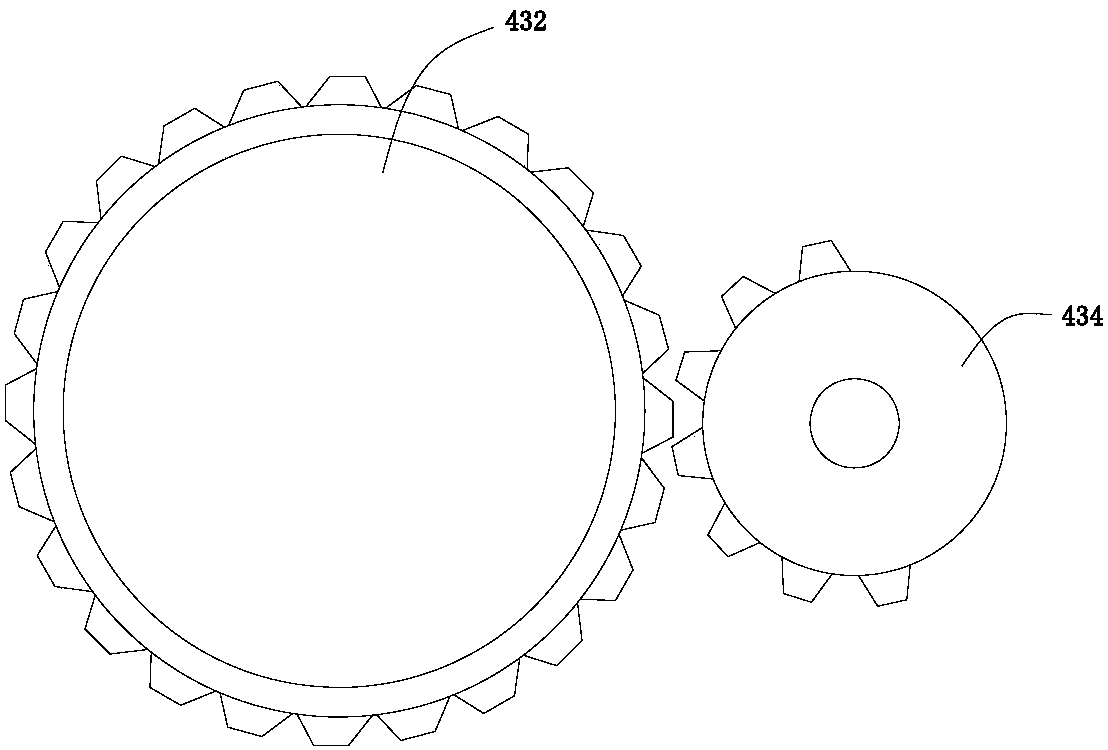

[0043] Optionally in this embodiment, the stirring device 400 includes a stirring assembly 410 and a conveying assembly, and the stirring assembly 410 includes a first motor 411, a mixing bucket 412, a stirring shaft 413, a stirring blade 414 and a transmission mechanism 430, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com