Design and transformation method for integrally forming and paving asphalt composite crushed stone sealing layer

A crushed rock seal and asphalt technology, applied in calculation, road repair, road and other directions, can solve problems such as temperature loss, reduce construction efficiency, increase construction period, etc., to reduce temperature loss, achieve leveling and bonding, improve The effect of mechanical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

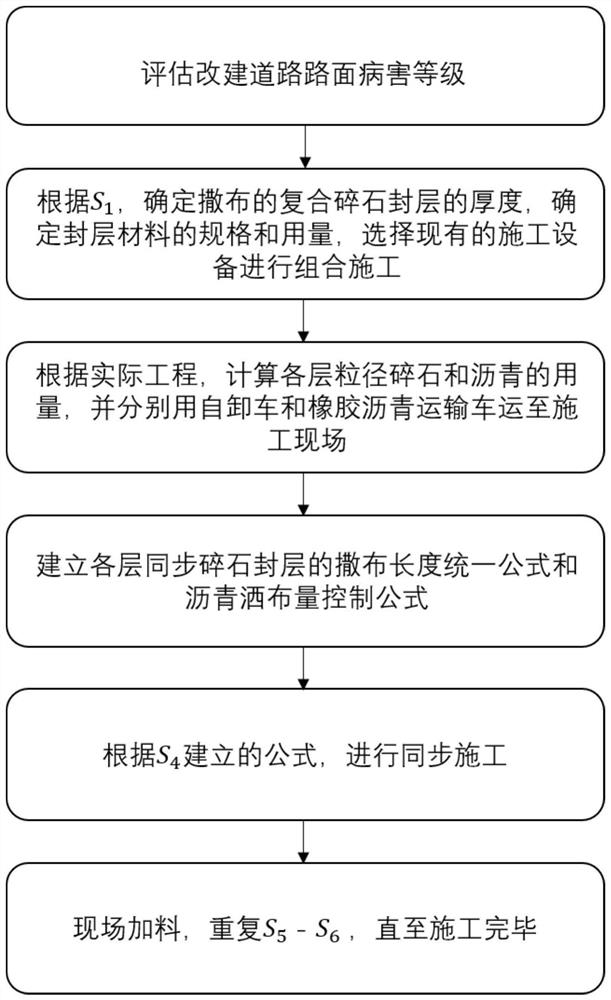

[0051] The asphalt compound crushed stone seal layer overlay design and renovation is being carried out on the Sanya Road (Xiangyu Avenue-Nanjing Road) section of the Economic Development Zone in Huai'an City, Jiangsu Province. The length of this section is 1200m, which is the main road, and the width of the road surface is 15m. The original pavement is cement concrete pavement.

[0052] S 1 : Assess the road surface damage level of the rebuilt road. The original road is a cement concrete road surface, and it is an urban trunk road. According to Table 1, the damage level of the cement concrete road surface is assessed. Based on this, it is determined as a third-level road condition, and the 6cm scheme is selected.

[0053] Table 1 Evaluation of cement concrete pavement damage grade

[0054]

[0055]

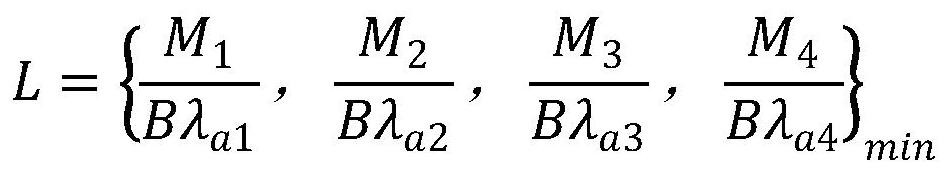

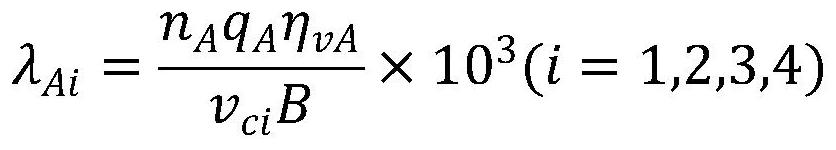

[0056] S 2 : Based on S 1 According to the scheme selected in Table 2, select the specification and dosage of asphalt composite crushed stone seal material for paving; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com