Bituminous mixture laying equipment capable of protecting bonding layer and application method thereof

An asphalt mixture and bonding layer technology, which is applied to asphalt mixture paving equipment and application fields that can protect the bonding layer, can solve the problems of bonding layer pollution, waste, crushed stone damage, etc., so as to improve the bonding between layers. quality, reduce interlayer pollution, and improve the effect of stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

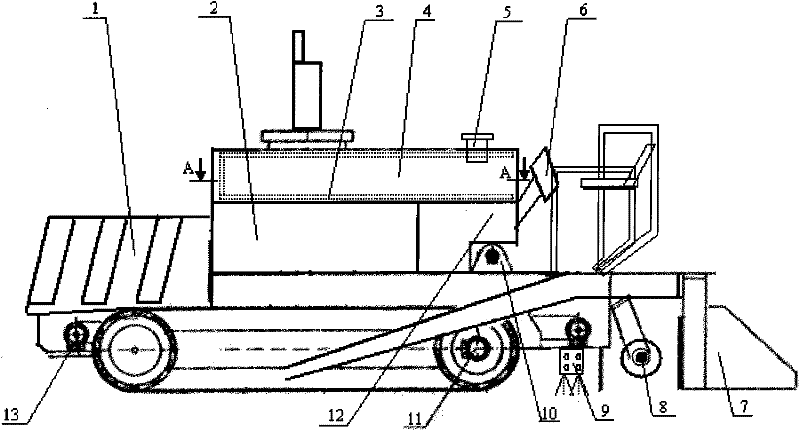

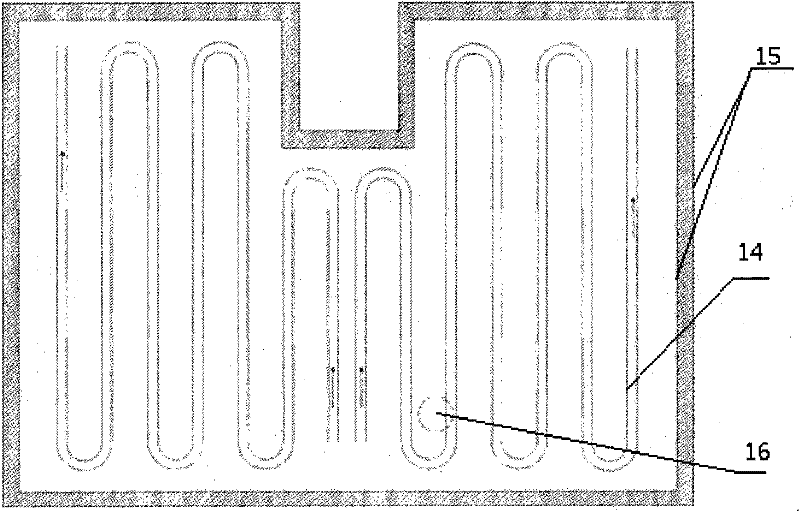

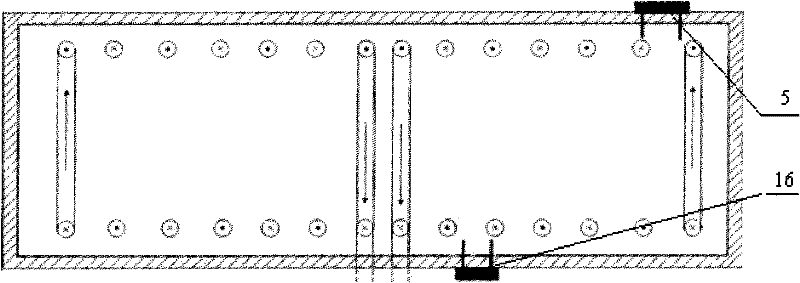

[0015] like figure 1 As shown, a kind of asphalt paving equipment capable of protecting the adhesive layer of the present invention includes an asphalt mixture receiving hopper 1, a power system 2, an adhesive layer material storage tank 4, a console 6, a screed device 7, An asphalt mixture distributor 8 , an adhesive layer material spraying mechanism 9 , an adhesive layer material pumping mechanism 10 , a traveling mechanism 11 , a heater 12 and an asphalt mixture conveyor 13 . The asphalt mixture conveyor 13 is preferably a chain plate conveyor. Asphalt mixture distributor 8 is preferably auger distributor. The bonding layer material spraying mechanism 9 is preferably a retractable spraying mechanism. The bonding layer material spraying mechanism 9 is connected with the console 6, its nozzles can be opened or closed independently, and any combination can be realized, and the height from the ground and the lateral position of the spraying bar can be adjusted. In this way, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com