Valve with intelligent positioning and anti-blocking functions

An intelligent positioning and anti-blocking technology, applied in valve device, valve details, valve operation/release device, etc., can solve the problems of piezoelectric valve air inlet or exhaust port blockage, abnormal work, moisture and other problems, to avoid The effect of blockage or reduction of air path, simple cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

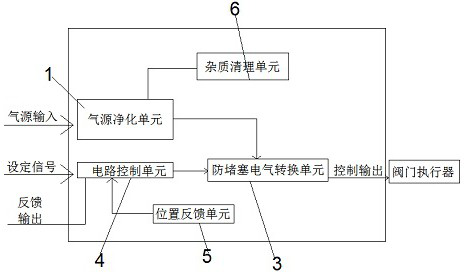

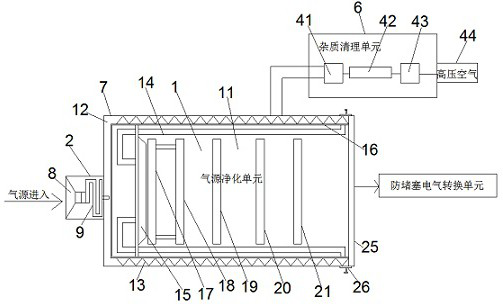

[0034] see Figure 1-8 , a valve with intelligent positioning and anti-clogging according to an embodiment of the present invention, including a positioner and a valve actuator, the positioner includes an air source purification unit 1, and the air source purification unit 1 is provided with an input air source The gas source purification unit 1 is connected to an anti-clogging electrical conversion unit 3 for controlling the valve actuator, and the anti-clogging electrical conversion unit 3 is connected to a circuit control unit 4 through a control signal. The circuit control unit 4 is connected to the position feedback unit 5, the impurity cleaning unit 6 is connected to the air source purification unit 1, the air source purification unit 1 includes a purification shell 7, and the material of the air inlet 2 is plastic air intake shell, the purification housing 7 is detachably connected to the air inlet 2, and the inner wall of the air inlet 2 near the opening is provided wi...

Embodiment 2

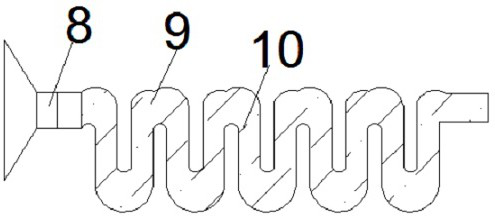

[0036] see Figure 4 , for the purification housing 7 , one end of the purification housing 7 is provided with an internal thread groove 45 , and the air inlet 2 is helically inserted into the internal thread groove 45 .

[0037] Through the above scheme of the present invention, the beneficial effect is that the air inlet 2 is helically inserted in the internal thread groove 45, so that the air inlet 2 and the purification shell 7 are helically connected, which is convenient for installation and easy to disassemble.

Embodiment 3

[0039] see Figure 6 , for the air pressure input passage 28, the joints of the air pressure input passage 28, the air pressure output passage 29, the exhaust passage 30 and the working channel 27 are all connected by arc surfaces.

[0040] Through the above scheme of the present invention, the beneficial effect is that the joints of the air pressure input passage 28, the air pressure output passage 29, the exhaust passage 30 and the working channel 27 are all connected by arc surfaces to avoid impurities inside the air passage. The corners are deposited, and the air pressure input channel 28 is equipped with a filter dustproof net 34, which can block the dust and effectively prevent the dust from entering.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com