Method for filling hinge joint of fabricated prestressed hollow beam slab

A hollow beam, prestressed technology, used in bridges, buildings, bridge parts, etc., to achieve the effect of reducing pores, solving premature failure of water seepage, and improving compaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

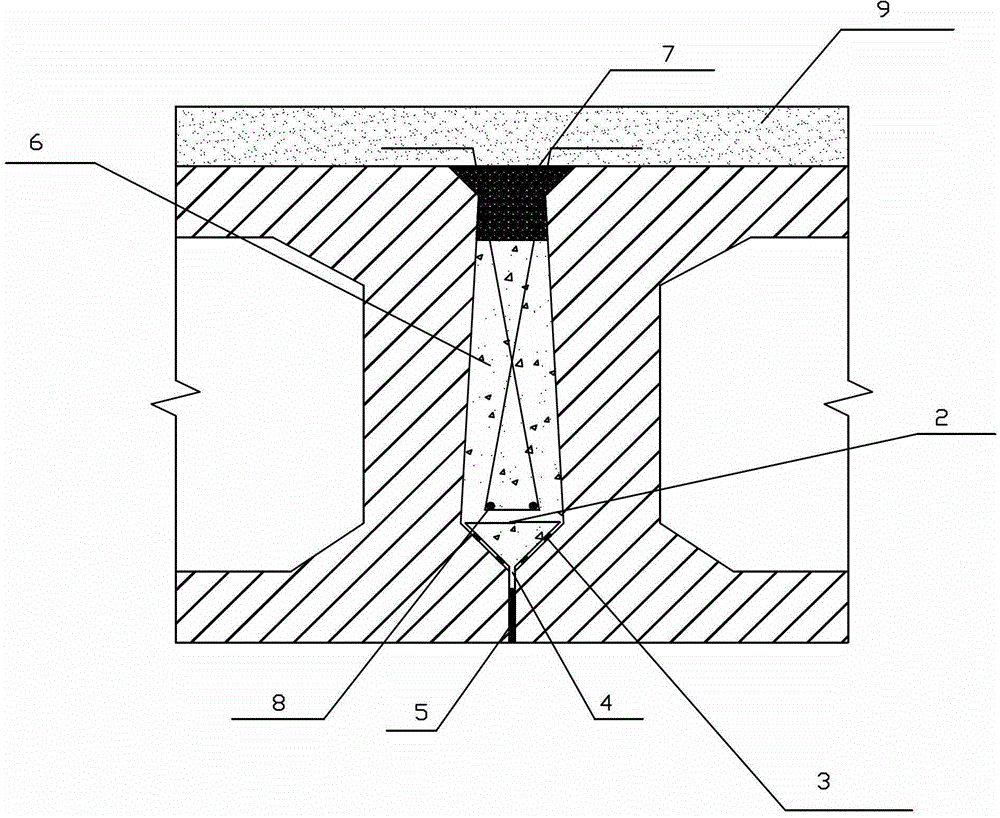

[0020] The present invention provides a method for filling hinged joints of prestressed hollow beam slabs. In order to make the purpose, technical solution and advantages of the present invention clearer and clearer, the present invention will be further described in detail in conjunction with specific examples below.

[0021] A method for filling hinged joints of fabricated prestressed hollow beam slabs, comprising filling the bottom, middle and top of the hinged joints, the method comprising the following steps:

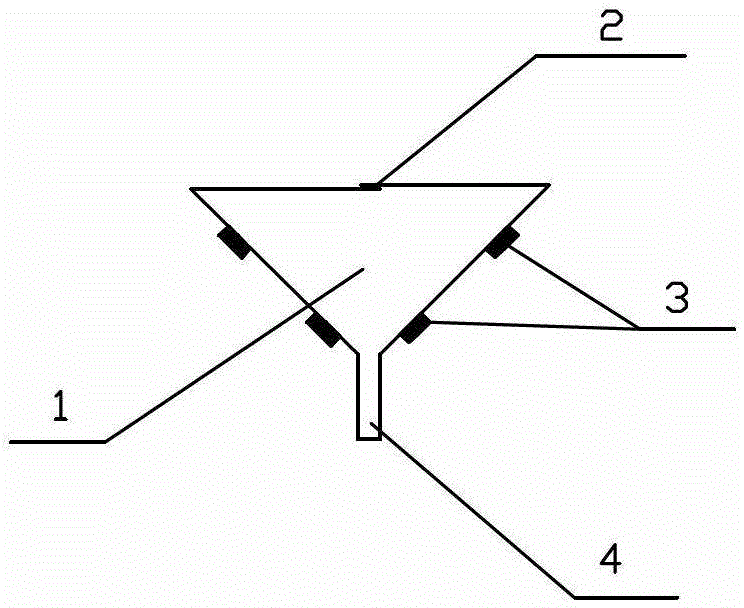

[0022] Step 1: If figure 1 As shown, the nail-shaped tampon 1 is inserted into the bottom gap of the hinge, and the nail-shaped tampon 1 includes a column 4, a top surface 2 of the tampon and two side wings of the tampon, wherein the top surface 2 of the tampon and the two sides of the tampon The side wings form an inverted triangle shape and are located above the column 4. The side wings are left-right symmetrical along the length direction of the column 4. The to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com