Slipform paver concrete compaction vibrator

A slipform paver and concrete technology, which is applied to roads, road repairs, roads, etc., can solve the problems of slump deformation of structures, uniform and compact vibrating rods, and low slump, so as to eliminate damage and stabilize the mold mechanism. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

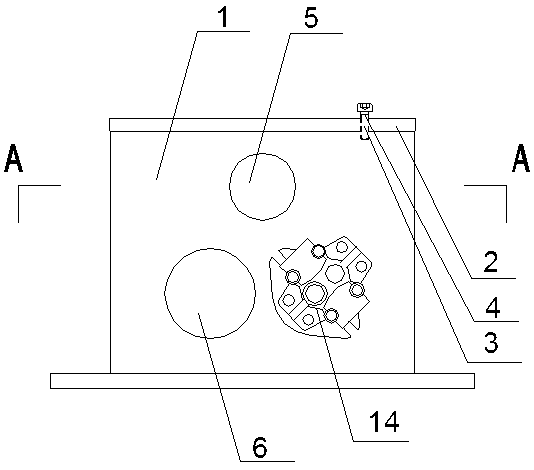

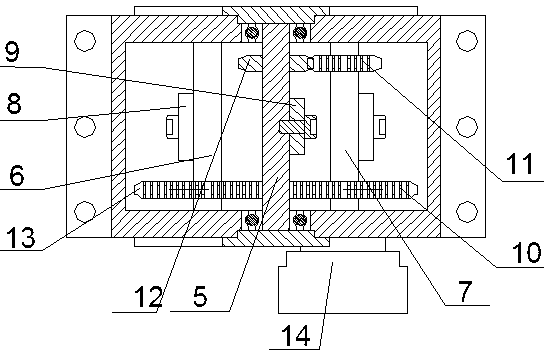

[0013] Such as figure 1 , 2 As shown, the present invention comprises box body 1, and the upper end of box body 1 is an opening, and the opening of box body 1 upper end is provided with cover plate 2, and described cover plate 2 is provided with vent hole 3, and the vent hole 3 is threadedly connected with Vent screw 4.

[0014] A high-speed shaft 5 arranged longitudinally is arranged in the center of the box body 1, a low-speed shaft 6 arranged longitudinally is arranged in the box body 1 below the left side of the high-speed shaft 5, and a low-speed shaft 6 arranged longitudinally is arranged in the box body below the right side of the high-speed shaft 5. 1 is provided with a longitudinally arranged drive shaft 7, the low-speed shaft 6 and the drive shaft 7 are symmetrically arranged with the high-speed shaft 5 as the center of symmetry, and the middle parts of the low-speed shaft 6 and the drive shaft 7 are respectively fixedly connected with a first eccentric block 8, Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com