A kind of centrifuge dense anti-overflow prevention device and process of porcelain stacking for dental restoration

A dental restoration and anti-spill technology, applied in dentistry, medical science, tooth filling, etc., can solve the problems of time-consuming and material-consuming, and achieve the effects of avoiding pollution, reducing usage, and saving porcelain paste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

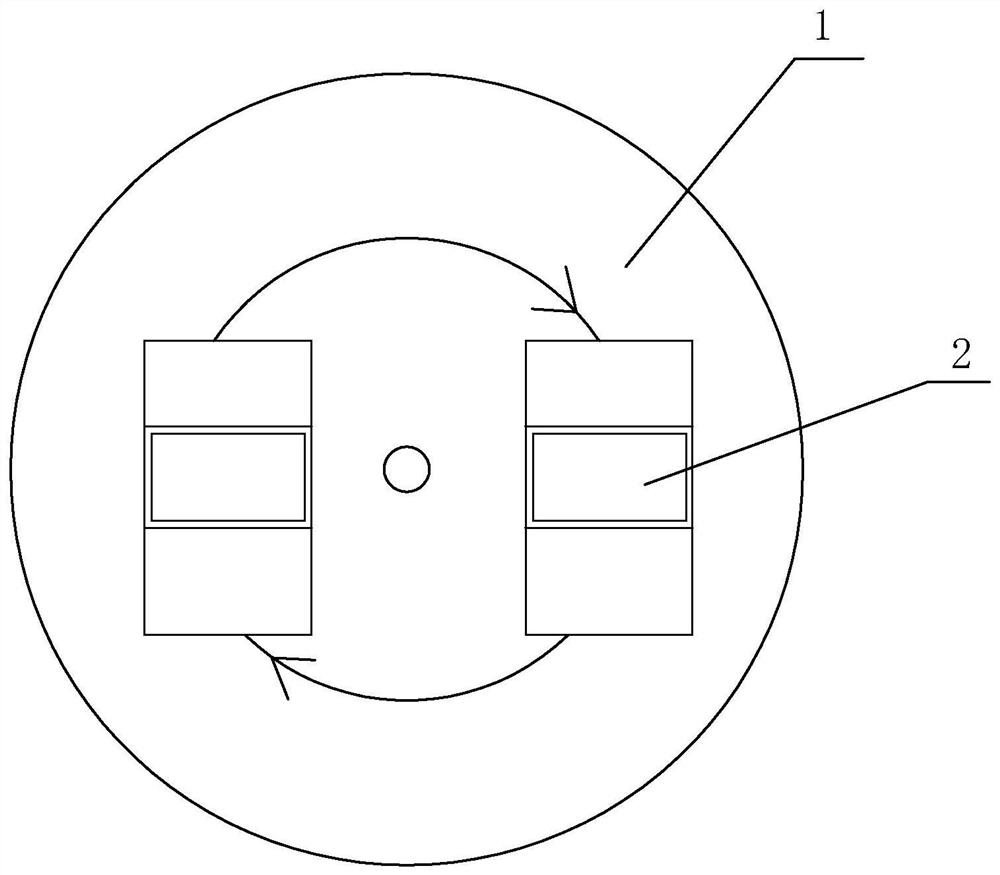

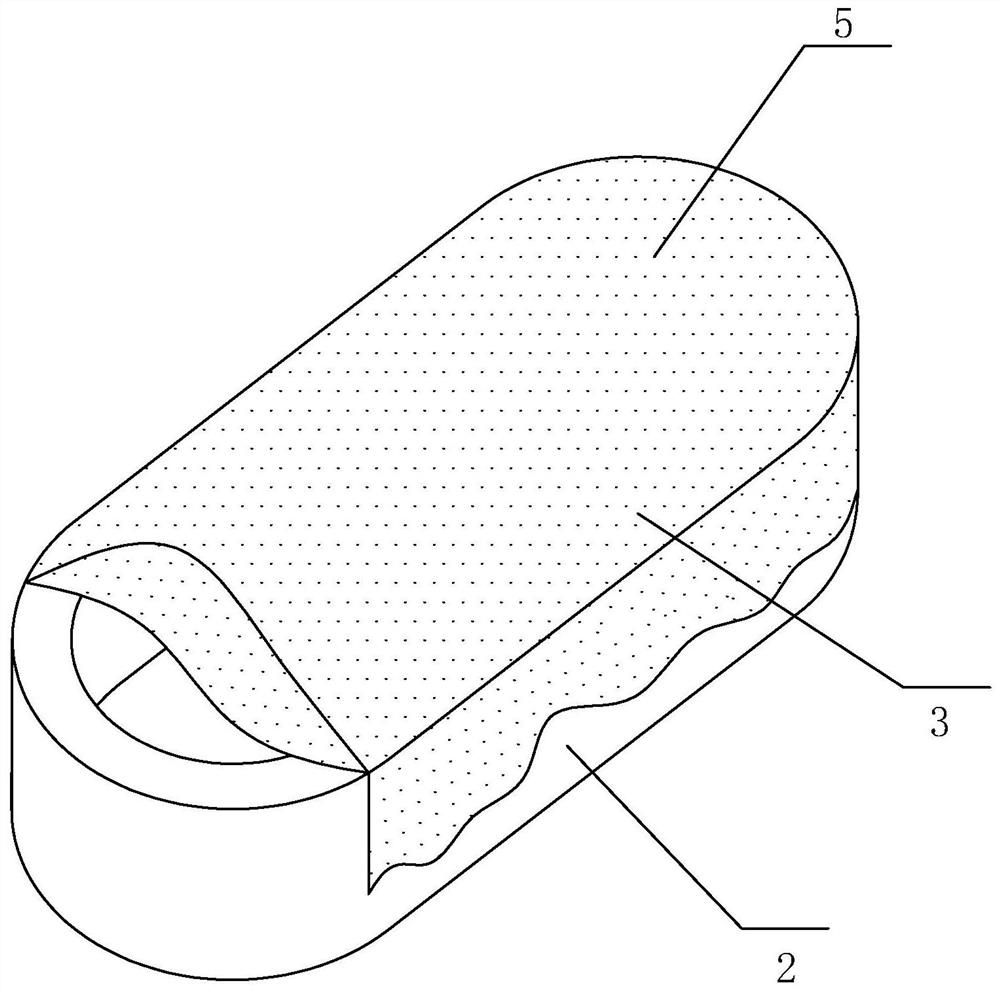

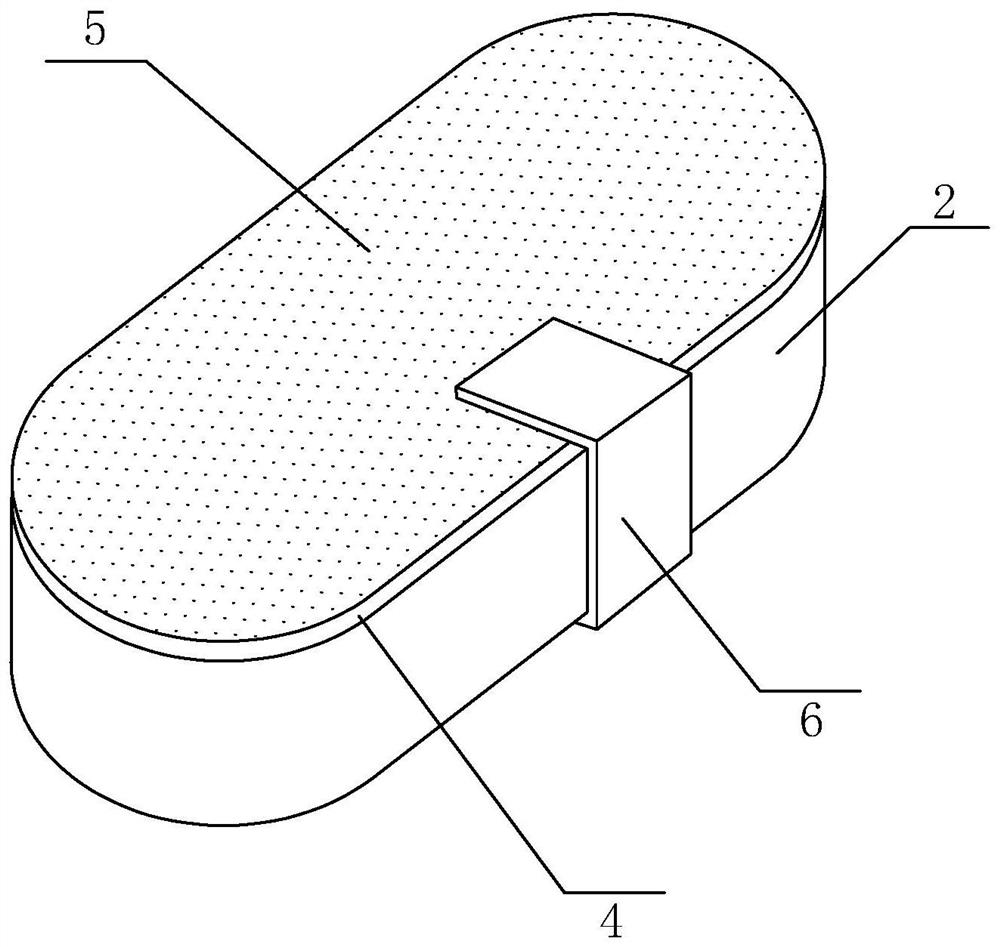

[0027] In dental restorations, of course, the technical solution of the present invention can also be used to make other restorations with surface-decorated porcelain materials. The base of dental restorations will be covered with a layer of porcelain-decorated materials. The above-mentioned porcelain-decorated materials The layer is often made of porcelain material sintered at high temperature. During the manufacturing process of the above-mentioned decorative porcelain material layer, it is necessary to place the fluid decorative porcelain slurry into the dental mold model module 2, and use the centrifuge 1 to centrifuge and compact it. During the compacting process, the porcelain paste is prone to overflow, which not only wastes the porcelain material, but also pollutes the above-mentioned centrifugal equipment. In order to solve the above-mentioned problems, the present invention proposes a centrifuge dense anti-overflow process of porcelain stacking for dental restoration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com