Patents

Literature

32 results about "Porcelain Veneer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A restoration consisting of a layer of tooth-colored porcelain material cemented to the surface of a tooth.

Dental cleaning and polishing composition comprising diamond particles

InactiveUS20100254915A1High glossReduce wearCosmetic preparationsImpression capsNatural toothPorcelain Veneer

A new whitening dentifrice suitable for use with porcelain veneers and dental work as well as with natural tooth enamel comprising diamond particles is disclosed.

Owner:KAO LISA MARIE

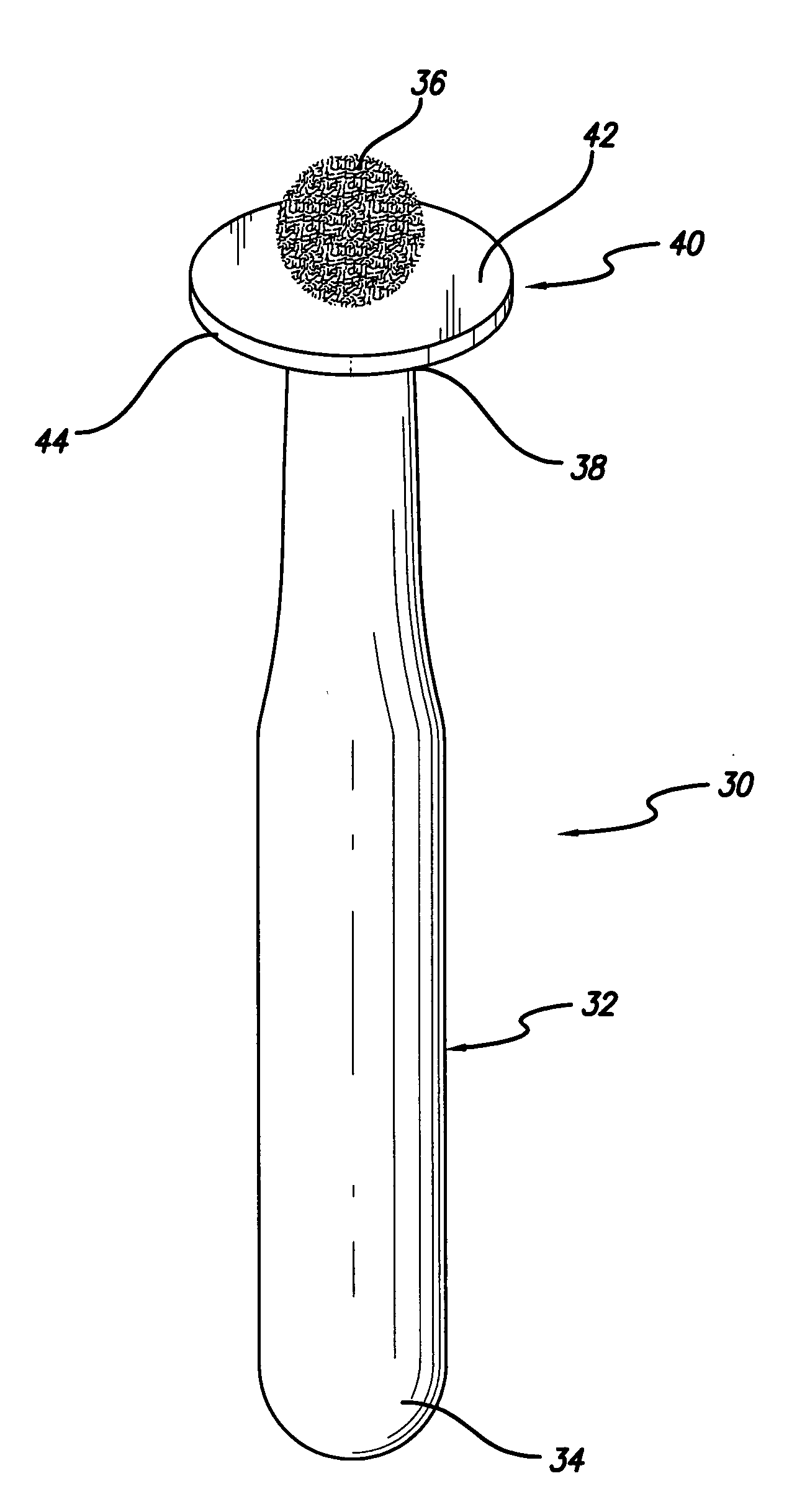

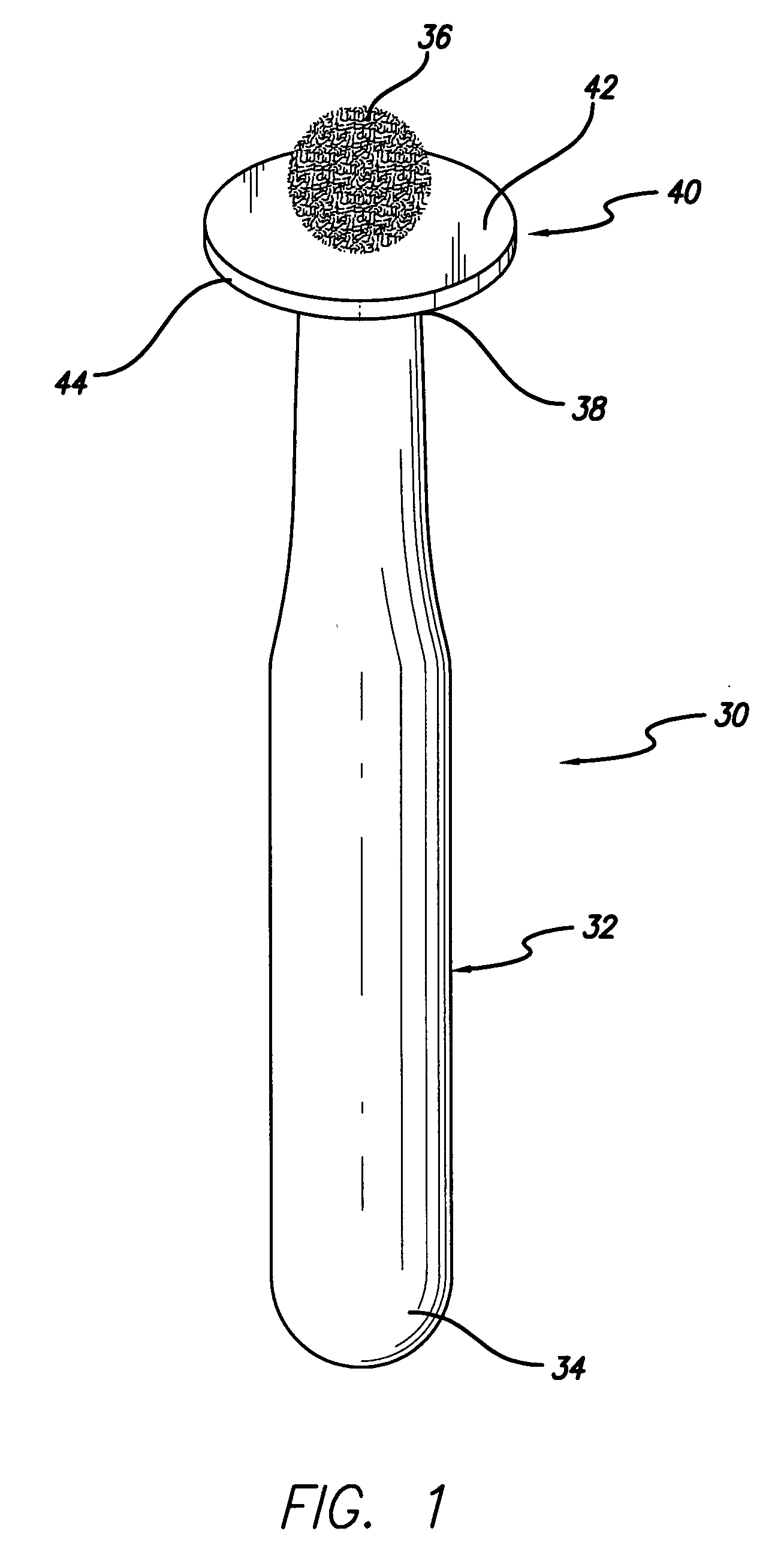

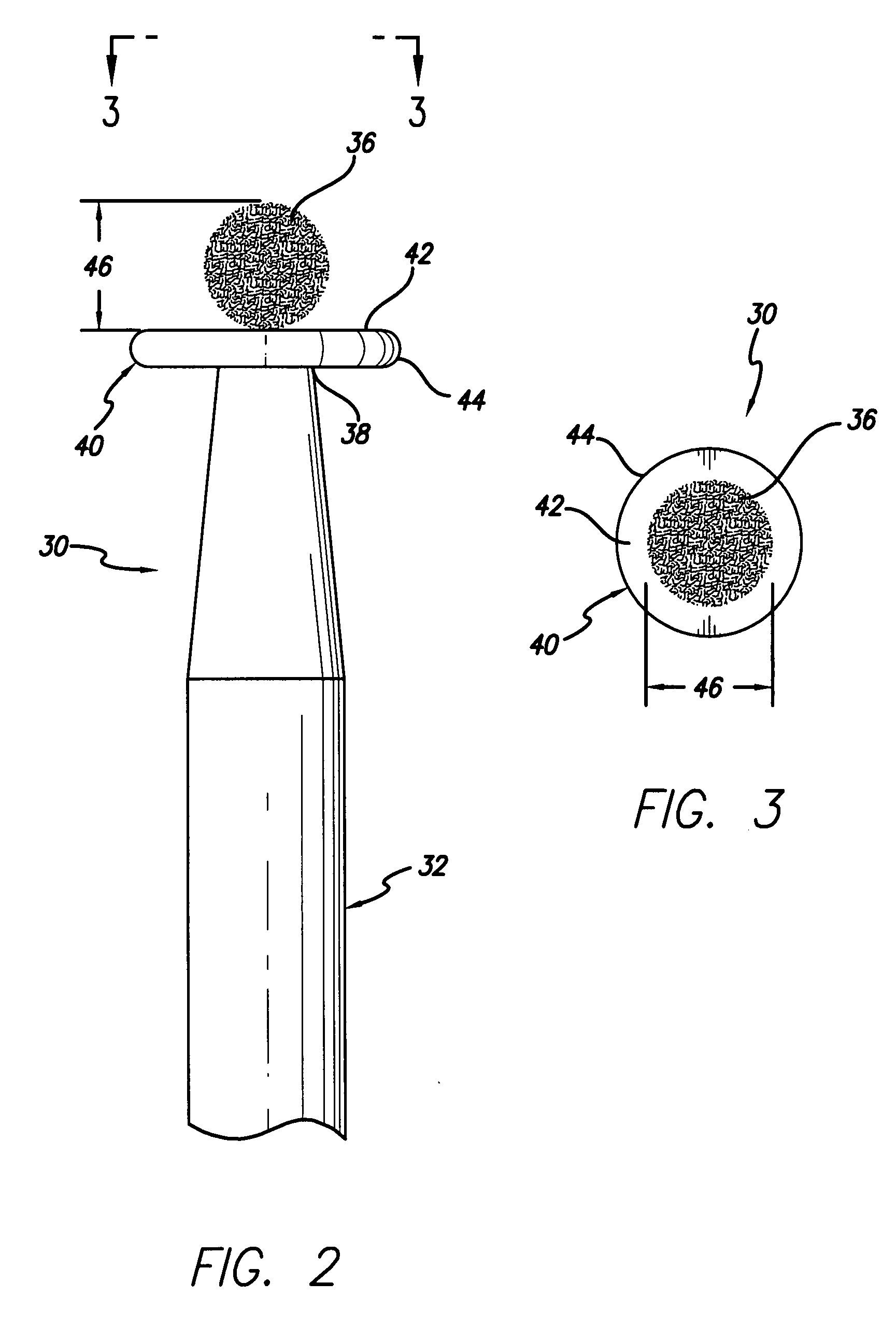

Self-limiting depth gauge spherical dental burr and method of use

A burr (30) includes a spherical cutting element (36) and a shield (40) integrally placed behind the burr. The shield is circularly configured, has a rounded periphery and is provided with a smooth tooth-engaging surface. The shield thus insures that the depth of the penetration—into the tooth is precise, as predetermined, without inflicting deleterious harm to the tooth. The present invention further relates to a method, utilizing the shield, for precise tooth preparation of porcelain veneers and porcelain crowns.

Owner:COMFORTES ISAAC

Method for processing ultra-thin cast porcelain laminate veneer capable of preventing tooth grinding

The invention relates to the field of dental prosthesis, in particular to a method for processing ultra-thin cast porcelain laminate veneer capable of preventing tooth grinding. The method comprises the following steps: a three-dimensional scanner is adopted to scan a dental cast, a three-dimensional stereoscopic image is formed, an ultra-thin veneer with the thickness of less than 0.5 mm is designed on the virtual image, after the ultra-thin veneer is designed, data is output to a 3D (three-dimensional) resin wax forming machine, the ultra-thin veneer is formed in the manners of resin-spraying, irradiation curing and printing, and then the formed resin wax pattern is subjected to embedded casting, grinding adjustment, try-in and glazing. Compared with the prior art, the method adopts a computer to design, and the conventional hand-made wax pattern is replaced by the resin wax pattern processed by the digital resin wax spraying, irradiation curing and printing processing, so that fabrication of porcelain laminate veneer with the thickness of less than 0.5 mm is realized. An aesthetic seeking patient with discolored teeth does not need tooth grinding and can receive tooth-whitening treatment without hurting teeth.

Owner:深圳市金悠然科技有限公司

Veneered colorimetric plate, and preparation method and application method thereof

The invention relates to the field of dentures, and specifically relates to a veneered colorimetric plate, and a preparation method and an application method thereof. The veneered colorimetric plate is composed of ten or more product veneers with different color effects. The veneered colorimetric plate is designed to solve the problem of ultrathin porcelain veneer colorimetry, and pre-makes different standardized porcelain veneers with different colors and thicknesses according to the thickness of the ultrathin porcelain veneers. The veneered colorimetric plate can help doctors and patients see the repaired color improvement results before the repair. The solution employed by the invention is that the product ultrathin veneer is directly put on the teeth of a patient to test colors when a veneering repair for whitening the teeth is carried out, enabling the colorimetry to be easier and the color to satisfy the requirements of the patient.

Owner:深圳市金悠然科技有限公司

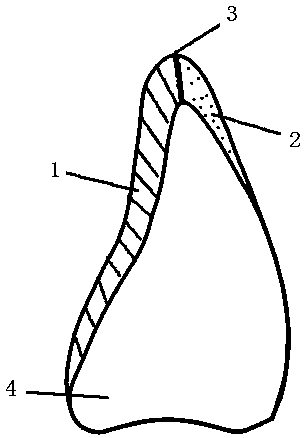

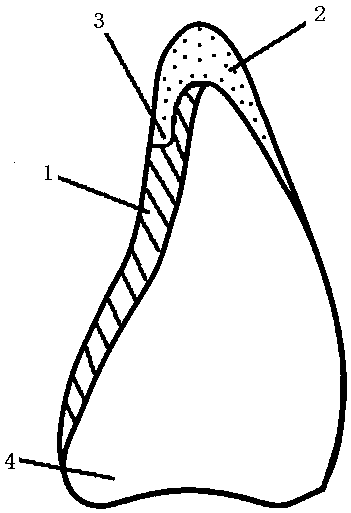

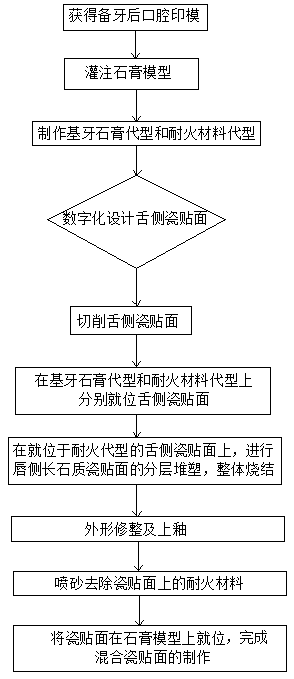

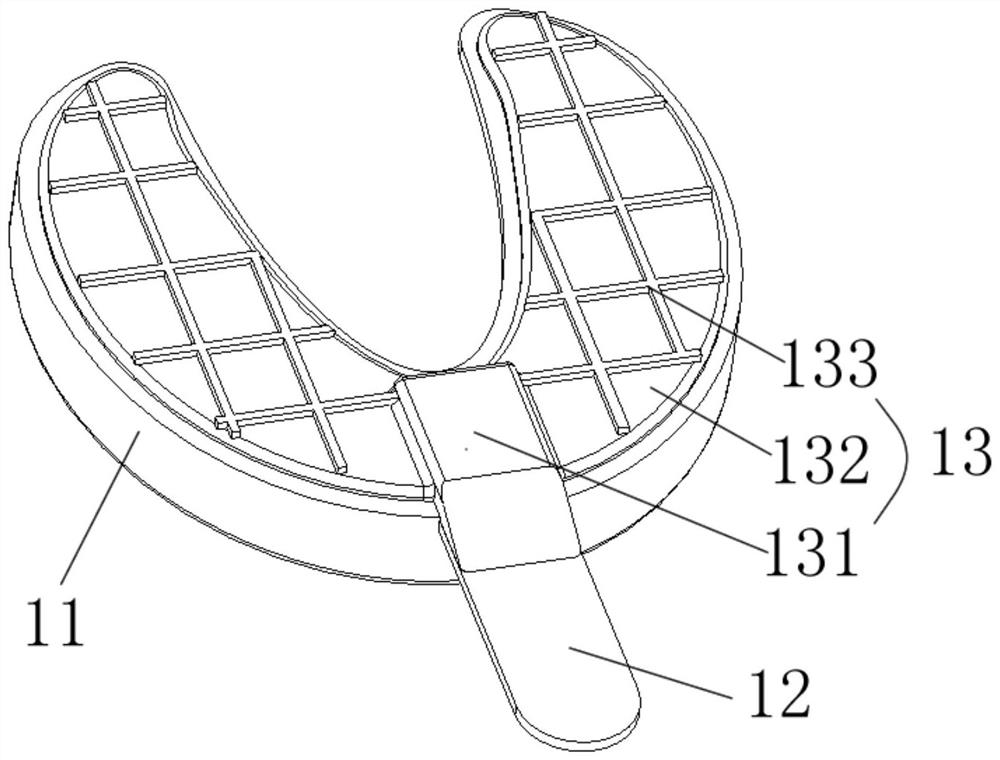

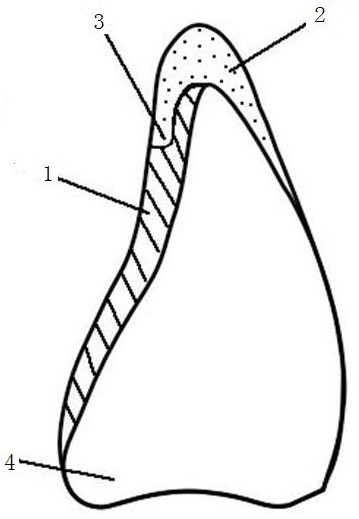

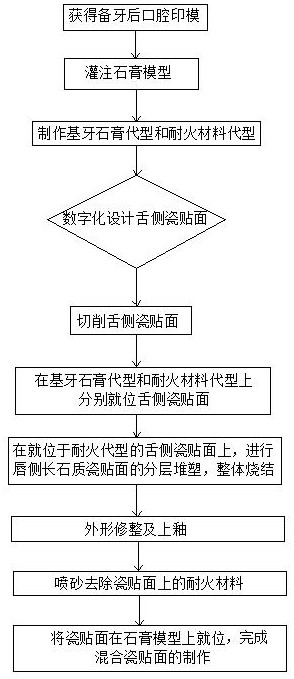

Dental mixed porcelain laminate veneer and manufacturing method

ActiveCN111150502AEasy dockingImprove bindingTeeth fillingSurface layering apparatusNormal tongueTooth Preparations

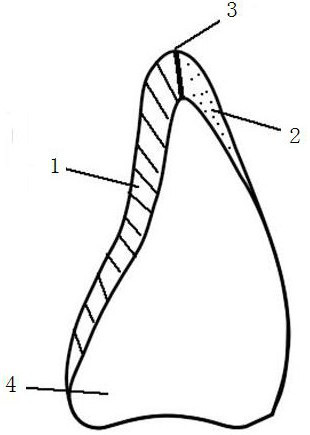

The invention discloses a dental mixed porcelain laminate veneer and belongs to the technical field of dental medical instruments. The dental mixed porcelain laminate veneer is characterized by comprising a tongue side porcelain laminate veneer and a lip side porcelain laminate veneer which cover a tooth body; the tongue side porcelain laminate veneer completely covers the tongue side of the toothbody; the lip side porcelain laminate veneer partially covers the lip side of the tooth body; a boundary line for butt joint and combination is formed between the tongue side porcelain laminate veneer and the lip side porcelain laminate veneer; the boundary line is positioned at the rear cutting end of the tongue side porcelain laminate veneer and avoids for 2mm from an occlusion contact area toform a shoulder of a round right angle or is positioned at 1 / 2 of the tooth body in an incisal edge lip and tongue direction; the tongue side porcelain laminate veneer is made of zirconium oxide or glass ceramic; and the lip side porcelain laminate veneer is made of feldspathic ceramic. The dental mixed porcelain laminate veneer disclosed by the invention has both mechanical and aesthetical properties, is applicable to occlusion reconstruction for a tooth with an occlusion space on the lip side and normal tongue colors and fixing and repairing of a tooth with the occlusion space on the lip side, and is good in practicability, in addition, more tooth body tissue can be maintained, tooth preparation on the tongue side is not needed, and the tooth preparation amount on the lip side is smallerthan 0.5mm or is not needed.

Owner:SICHUAN UNIV

Customized fixed partial denture porcelain veneer

InactiveCN106116547AGood compatibilityStable chemical propertiesImpression capsTeeth fillingNatural toothLeucite

The invention discloses a customized fixed partial denture porcelain veneer. Porcelain powder with leucite as the main ingredient is directly used for paste-on-paste decoration of tooth repair form. The porcelain veneer comprises SiO2, Al2O3, K2O, Na2O, Li2O, BaO, B2O3, CaO, Sb2O3, ZrO2, SnO2, CeO2, F and TiO2. A method for preparing the porcelain veneer comprises the steps of making a high-temperature resistant tooth die, conducting pretreatment and soaking on the die so that porcelain coating and sintering can be conducted, coating combination porcelain, dentin porcelain and cutting porcelain in sequence, conducting sintering in a sintering furnace at different temperatures every time porcelain coating is conducted, conducting form polishing and finishing after sintering, then conducting glazing, conducting sintering in the furnace again, removing the die material, and taking off the veneer with overall thickness of 0.5-0.7 mm. The veneer has high tissue compatibility, stable chemical performance and high breaking strength, the color of the veneer can be adjusted to be matched with natural teeth, and a basis is laid for clinical application of porcelain repair of oral cavity.

Owner:SHANXI MEIYUAN PHARMA TECH

Veneer color matching resin die

The invention discloses a veneer color matching resin die. A production method of the veneer color matching resin die comprises the following steps: production of an impression, clinic color selection, production of a tooth repairing resin die, and production of a veneer working model. Polymer ceramic is selected in the production step of the tooth repairing resin die, the polymer ceramic is a micro-ceramic polymerization system, and contains 73% of a micro-ceramic component, so the good wear resistance of the surface of the produced resin die is ensured, and the resin die has a good polishingeffect, has resistance to dyeing, is not prone to change color, and has dental plaque resistance. The production method of the veneer color matching resin die has the advantages of simple productionprocess, and convenience in operation; the veneer color matching resin die is made by adopting porcelainized resin having the similar color with a practical tooth, so the veneer color is not affected,and the clamping and supporting effects of the veneer are achieved; and the veneer color matching resin die is suitable for the toning and glazing processes of cast porcelain veneers, baked porcelainveneers, glass ceramic veneers and zirconia baked porcelains, and has a wide application range and extremely high market values.

Owner:山西美原齿科器械有限责任公司

Method of making dental prosthesis and ductile alloys for use therein

InactiveUS20130273501A1Avoid crackingAdditive manufacturing apparatusImpression capsMetal alloyDental porcelain material

A dental prosthesis comprising a metal alloy pre-form and a dental porcelain veneer coating the metal alloy, wherein the metal alloy has a composition comprising, in % by weight, about 30-40% Co, 25-40% Ru, 20-40% Cr, and 0-0.1% Ni and wherein a coefficient of thermal expansion of the metal alloy is compatible with that of the dental porcelain to prevent cracking of the porcelain

Owner:ARGEN

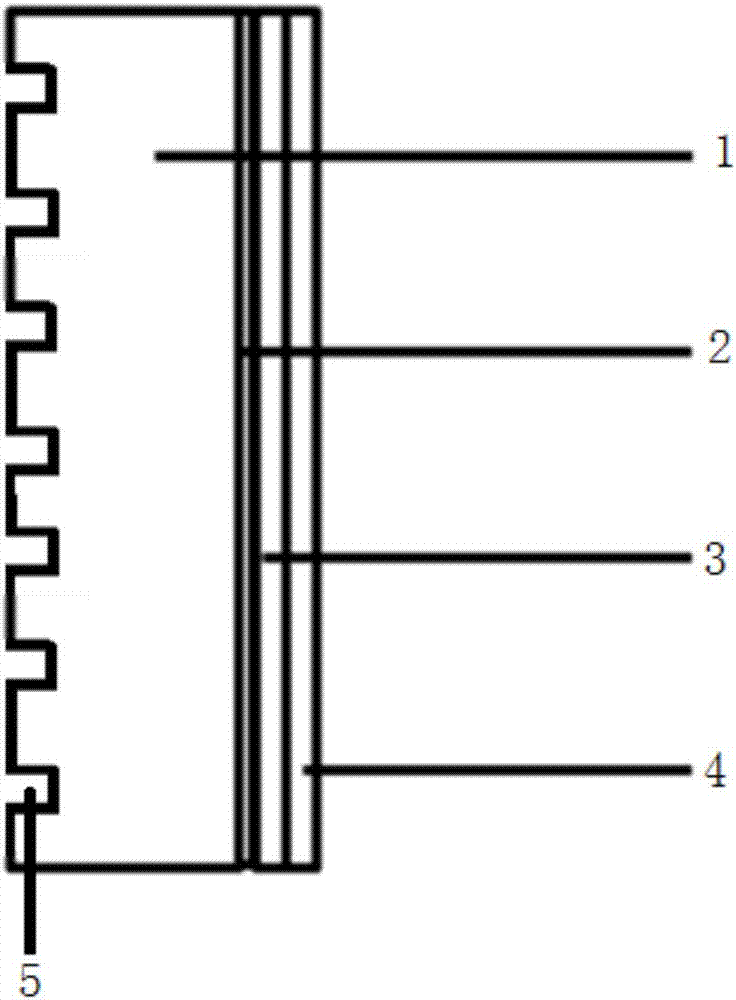

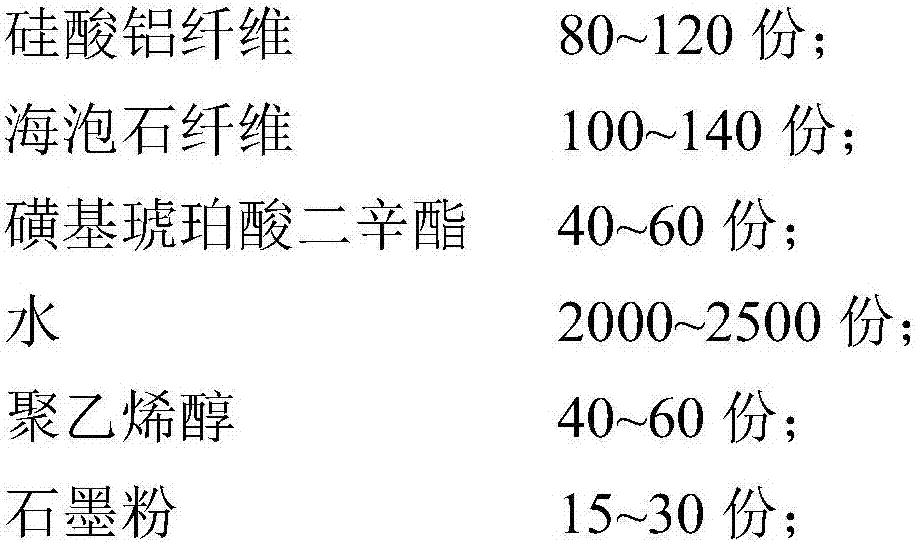

Fireproof thermal insulation decorative board and manufacturing method thereof

ActiveCN106930493AIncrease contact areaLow thermal conductivityCovering/liningsLaminationFiberCalcium silicate

The invention discloses a fireproof thermal insulation decorative board and a manufacturing method thereof. The fireproof thermal insulation decorative board comprises an inorganic fiber modified thermal insulation board, a bonding layer, a calcium silicate board layer and a soft porcelain veneer layer which are sequentially arranged from inside to outside; the inorganic fiber modified thermal insulation board is made of fireproof thermal insulation materials; the fireproof thermal insulation materials comprise the component A and the component B; the component A comprises, by weight, 80-120 parts of aluminum silicate fibers, 100-140 parts of sepiolite fibers, 40-60 parts of dioctyl sulfosuccinate, 2000-2500 parts of water, 40-60 parts of polyvinyl alcohol, and 15-30 parts of graphite powder; and the component B comprises, by weight, 600-800 parts of sulphate aluminum cement and 5-10 parts of water repellents. The fireproof effect is greatly improved, and the fireproof thermal insulation decorative board is suitable for high-rise buildings and thermal insulation structures with cavities. The heat conductivity coefficient of a thermal insulation layer is low, the thermal insulation effect is good, the weight is low, construction operation is easy, and the veneer is made of a soft porcelain material and is good in weather resistance and decoration effect.

Owner:北京艺高世纪科技股份有限公司

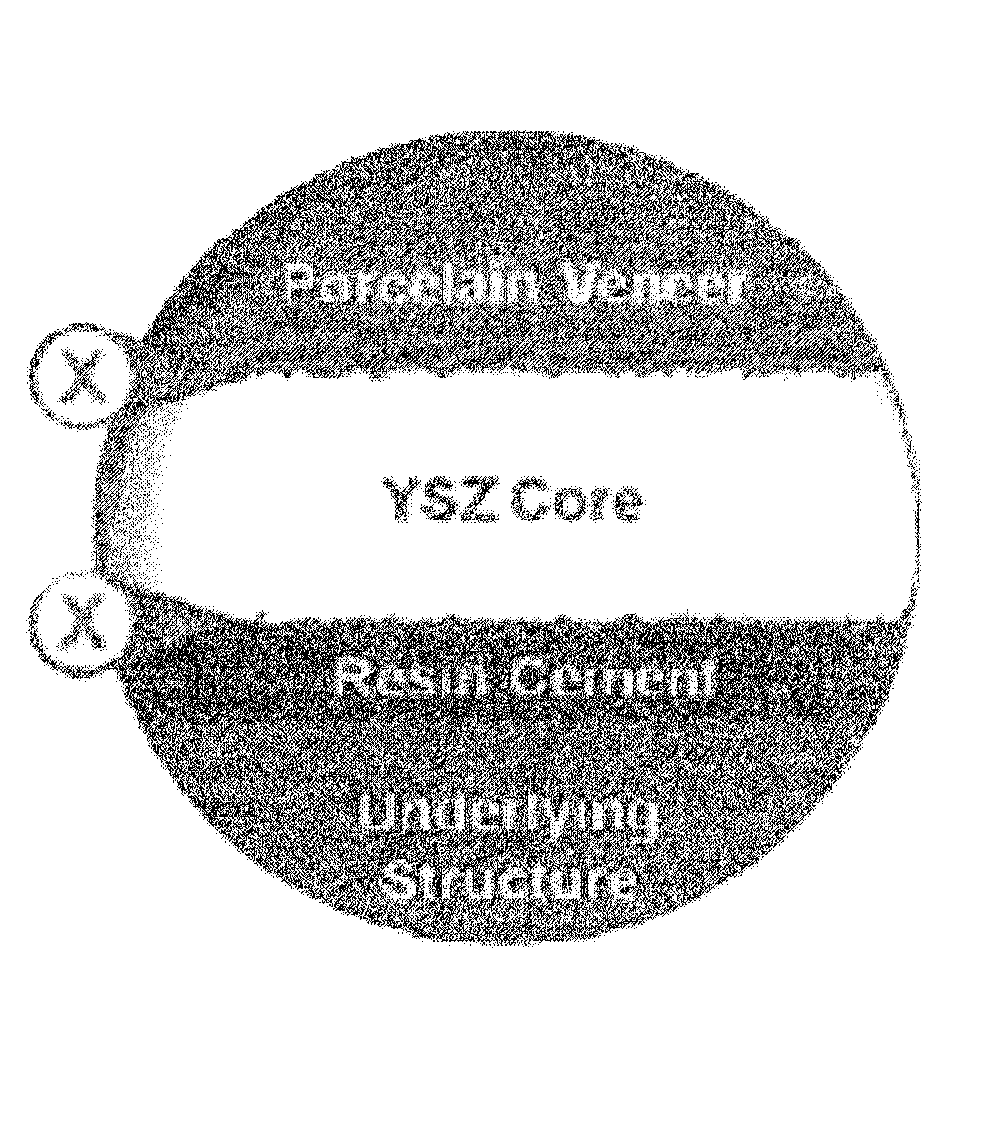

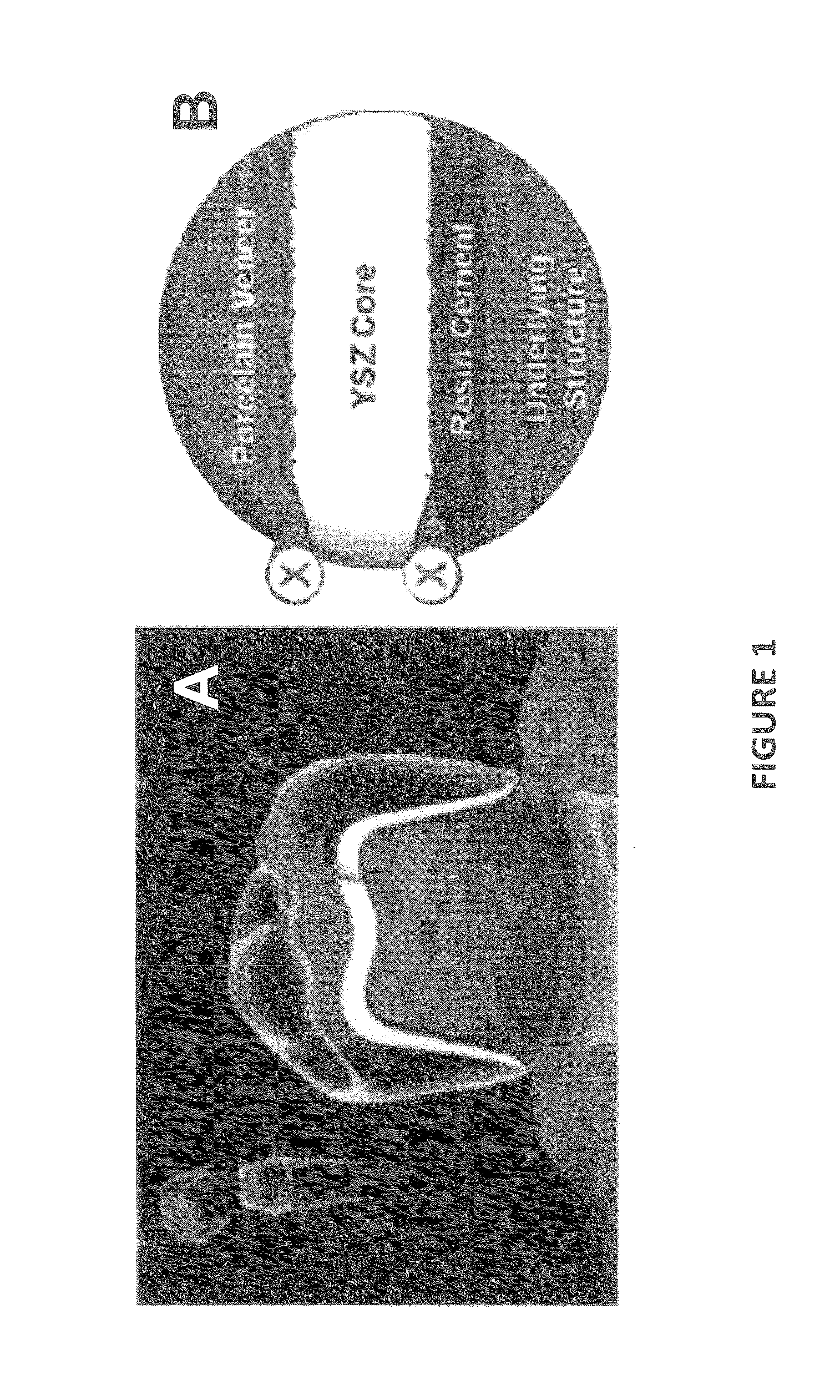

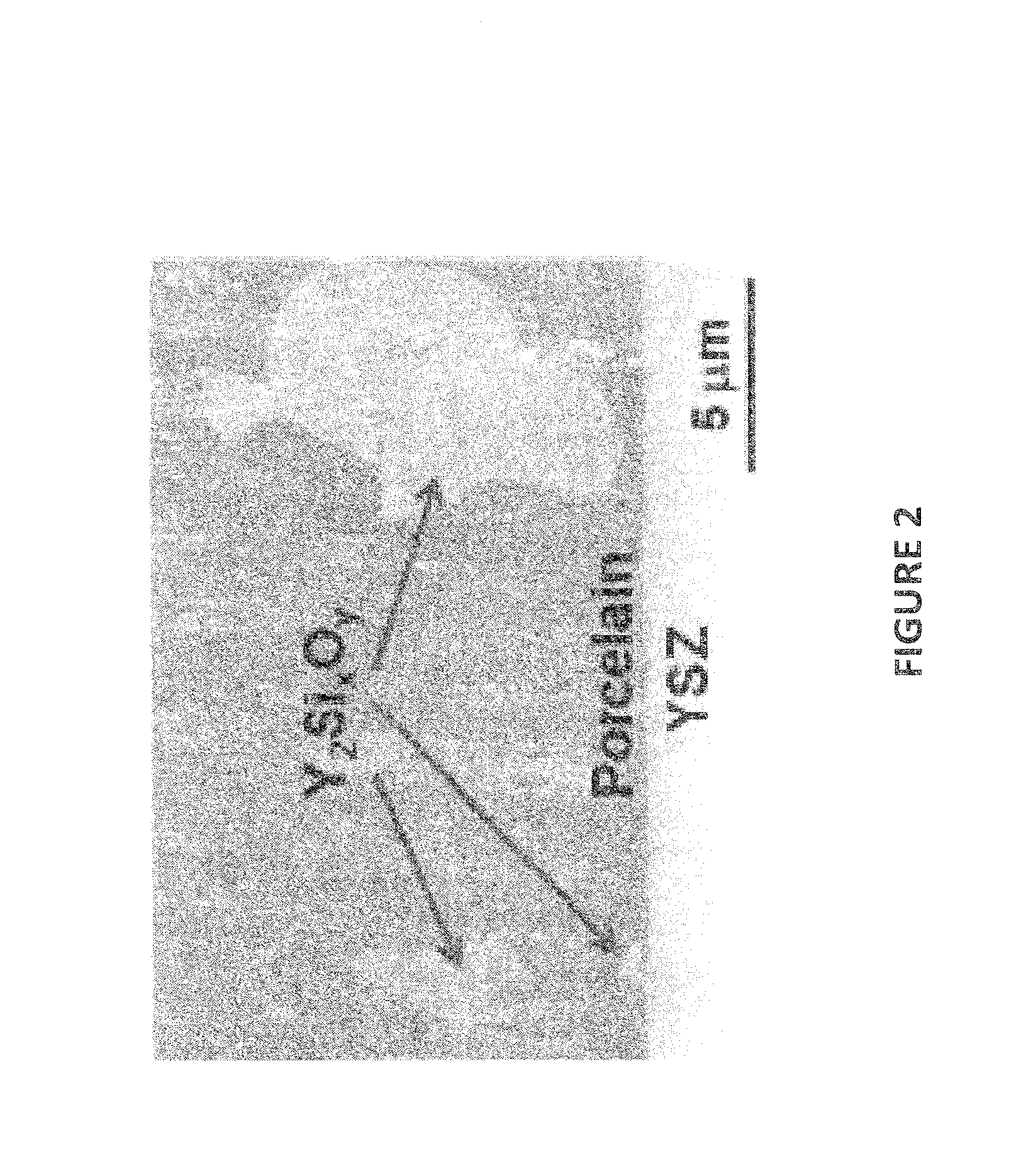

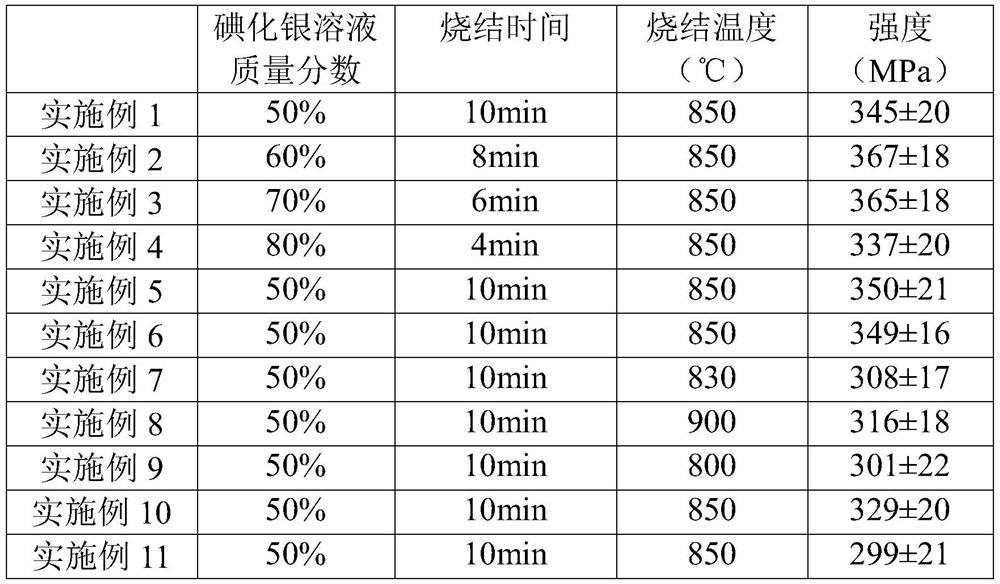

Yttria-treated porcelain veneer

InactiveUS20140272799A1Improve toughnessEasy to prepareDental implantsImpression capsCrystalline inclusionSlurry

A dental component comprising a modified porcelain veneering coating thereon is provided, wherein the porcelain veneering coating can comprise a plurality of crystalline inclusions. The crystalline inclusions can serve to strengthen the porcelain veneering coating and the dental component as a whole. A method for the preparation of such treated implants is also provided, the method involving providing a dental component; applying a porcelain slurry comprising about 5% or more by weight of an additive capable of forming a crystalline silicate phase to at least a portion of the surface of the dental component to give a coated dental component; and firing the porcelain-coated dental component.

Owner:RES TRIANGLE INST

Glass ceramic veneer and processing method thereof

ActiveCN111904638AImprove manufacturing precisionAvoid damageArtificial teethNumerical controlTeeth grinding

The invention relates to a glass ceramic veneer and a processing method thereof. The processing method comprises the following steps: scanning: scanning a tooth model or teeth in the mouth to manufacture a three-dimensional model; designing: carrying out veneering design on the three-dimensional model; cutting: cutting a glass ceramic material according to the veneering design to prepare a veneergreen body; and sintering: sintering the veneer green body to prepare the veneer. According to the processing method, the glass ceramic material is processed in a cutting and sintering combined mode,thickness requirement of an ultrathin veneer can be innovatively met, tooth grinding is not needed during a using process, and damage to teeth of a wearer is avoided. Compared with a traditional tooth-free cast porcelain veneering process, the processing method does not need to prepare wax molds, omits processing steps of numerical control equipment, has simple procedures and short preparation time, and can also improve veneer production accuracy.

Owner:FUZHOU RUIKE BULANG MEDICAL TECH CO LTD

Composite material for repairing porcelain laminate veneers of teeth

The invention discloses a composite material for repairing porcelain laminate veneers of teeth. A SiC-AlN composite ceramic material is adopted. The composite material specifically comprises, by weight, 65-75% of SiC, 10-15% of AlN, 2-3% of TiO2, 5-8% of SiO2, 1-4% of B2O3, 0.5-3% of MgO, 0.5-3% of CaO, 0.5-3% of ZnO, 0.2-2% of Cr2O3 and 0.2-2% of Co2O3. The bending strength of the prepared porcelain laminate veneers of the teeth is 180-210 MPa, and the thermal expansion coefficient is (12.1-12.5)*10<-6> / DEG C.

Owner:湖南鹏登生物科技股份有限公司

Manufacturing method of whole-wrapped type extra-thin porcelain veneer

PendingCN110269701AImprove stress resistanceNot easy to collapseTeeth fillingTeeth cappingLarge toothOral problems

The invention provides a manufacturing method of a whole-wrapped type extra-thin porcelain veneer. The method comprises specific steps of (1) preparing a tooth model from a tooth body prepared in a minimally invasive manner; (2) preparing a wax pattern of the whole-wrapped type extra-thin porcelain veneer according to the tooth model; (3) according to the wax pattern in the step (2), mounting a sprue on the wax pattern, and performing embedment casting treatment on porcelain blocks so as to obtain a prosthesis, wherein the material of the porcelain blocks in the step (3) is IPS e.max Press porcelain blocks; (4) removing the embedment from the prosthesis, and removing a reaction layer; and (5) polishing the prosthesis, and finally performing glazing and sintering so as to obtain preparation of the porcelain veneer. The thinnest porcelain veneer prepared by the method can reach 0.2mm, the porcelain veneer is high in pressure resistance, is jointed to teeth, is not liable to molder, has good esthetic properties, and can wholly wrap a tooth large in tooth defects, and the problem that conventional tooth crown repair cannot reach minimally invasive esthetics due to large tooth defect quantity can be solved.

Owner:JINAN UNIVERSITY

Cast ceramic veneer manufacturing method and process

InactiveCN111772830AHigh precisionHighly corporatedTeeth fillingTeeth cappingPorcelain VeneerSILICONE DIOXIDE

The invention relates to a cast ceramic veneer manufacturing method and process. The manufacturing method comprises the steps: a), checking an oral cavity model, segmenting a working region model, andprecisely judging an abutment tooth needing a veneer part; b) uniformly coating a separating agent on the surface of the abutment tooth; c) putting the manufactured veneer made of a wax material intoa carrier; f) removing an embedding material after casting the veneer made of a silicon dioxide material, namely spraying the embedding material on the veneer made of the silicon dioxide material byusing a sand-blasting machine, and checking whether the veneer made of the silicon dioxide material is tightly attached to the edge of the abutment tooth or not; g) a modification process: making theveneer made of the silicon dioxide material into a shape meeting the requirements of a patient according to the photo, the gender of the adjacent tooth and the age; and h) glazing: referring to the picture of the teeth of the patient to meet the satisfaction of the patient. The invention provides the manufacturing method and process of the cast ceramic veneer, which improve the precision of the manufactured veneer, improve the fitness of the veneer and the teeth of the user, and improve the comfort and satisfaction of the user in use.

Owner:苏州固锐德医疗器械有限公司

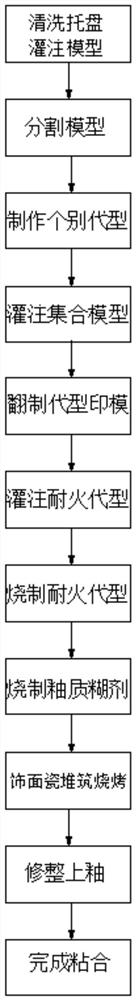

Manufacturing method of baked porcelain veneer

ActiveCN112430074AHigh strengthContribute to stackingTeeth fillingCeramic shaping apparatusNatural toothRefractory

The invention discloses a manufacturing method of a baked porcelain veneer. The manufacturing method comprises the following steps: cleaning a tray, and pouring a model; dividing the model by a separation mechanism, manufacturing an individual generation type, pouring a set model, duplicating an individual generation type silicone rubber impression, pouring a refractory material generation type, firing the refractory generation type at high temperature, and firing the refractory generation type enamel paste; stacking facing porcelain, and roasting the facing porcelain in a porcelain roasting furnace; and after shape finishing and glazing are completed, seding the manufactured baked porcelain veneer to a doctor to be used for being bonded to a patient. Through high-temperature firing fire-resistant molding, the strength is good, the plasticity is high, the fire resistance is high, and the manufacturing efficiency is greatly improved; the piled facing porcelain adopts porcelain powder ofa baked porcelain crown in dental crown repair, the color is attractive, the effect is more similar to that of natural teeth, the appearance requirement of a patient can be met, meanwhile, a baked porcelain patch manufactured through baking of a porcelain oven is small in thickness, good in strength and good in abrasion resistance and corrosion resistance, and the original tooth tissues can be reserved to the maximum extent.

Owner:北京联袂义齿技术有限公司

Manufacturing method of baked porcelain veneer

ActiveCN112089496AHigh precisionHighly corporatedTeeth fillingCeramic shaping apparatusSand blastingEngineering

The invention relates to a manufacturing method of a baked porcelain veneer. The method comprises the following steps of a) firstly checking whether an abutment model has a problem or not, and trimming a root part of the abutment model to be in a shape which is the same as that of the root part of the abutment, wherein the abutment model comprises an upper part and the root part; b) duplicating the gypsum abutment; c) putting the duplicated gypsum abutment into a tray, and smearing high-oil vaseline on the surface of the duplicated gypsum abutment; d) driving the root part of the duplicated gypsum abutment into an artificial gingiva; i) putting a duplicated refractory abutment into water, and applying porcelain on the surface of a neck edge line of the refractory abutment when water absorption reaches a saturated state; and j) polishing off the part, far away from the baked porcelain veneer, of the duplicated refractory abutment subjected to high-temperature treatment, and finally attaching the baked porcelain veneer subjected to sand blasting to the upper part of the duplicated gypsum abutment. According to the manufacturing method of the baked porcelain veneer, the precision of the manufactured veneer is improved, and the use comfort and satisfaction of a user are improved.

Owner:苏州固锐德医疗器械有限公司

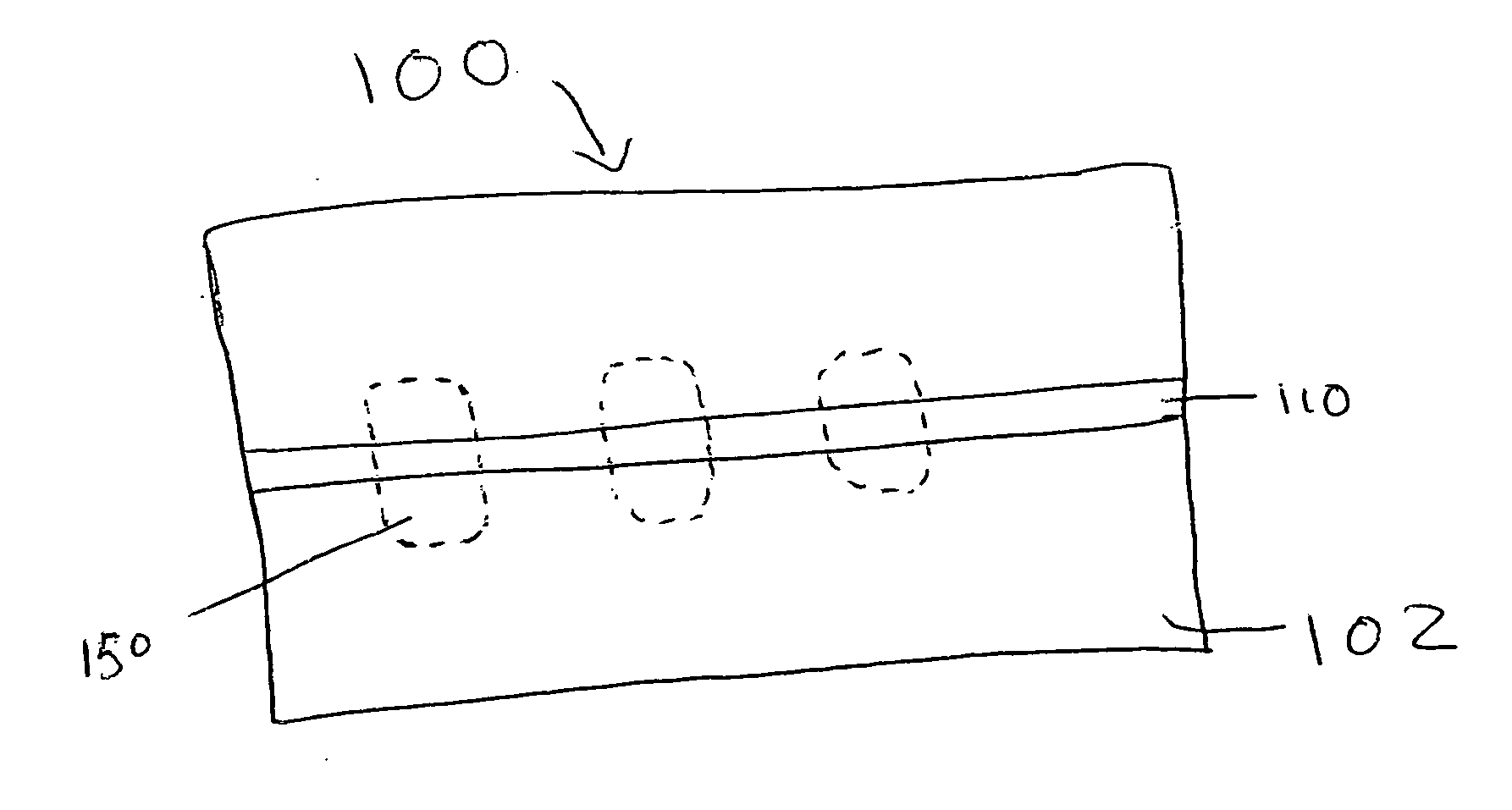

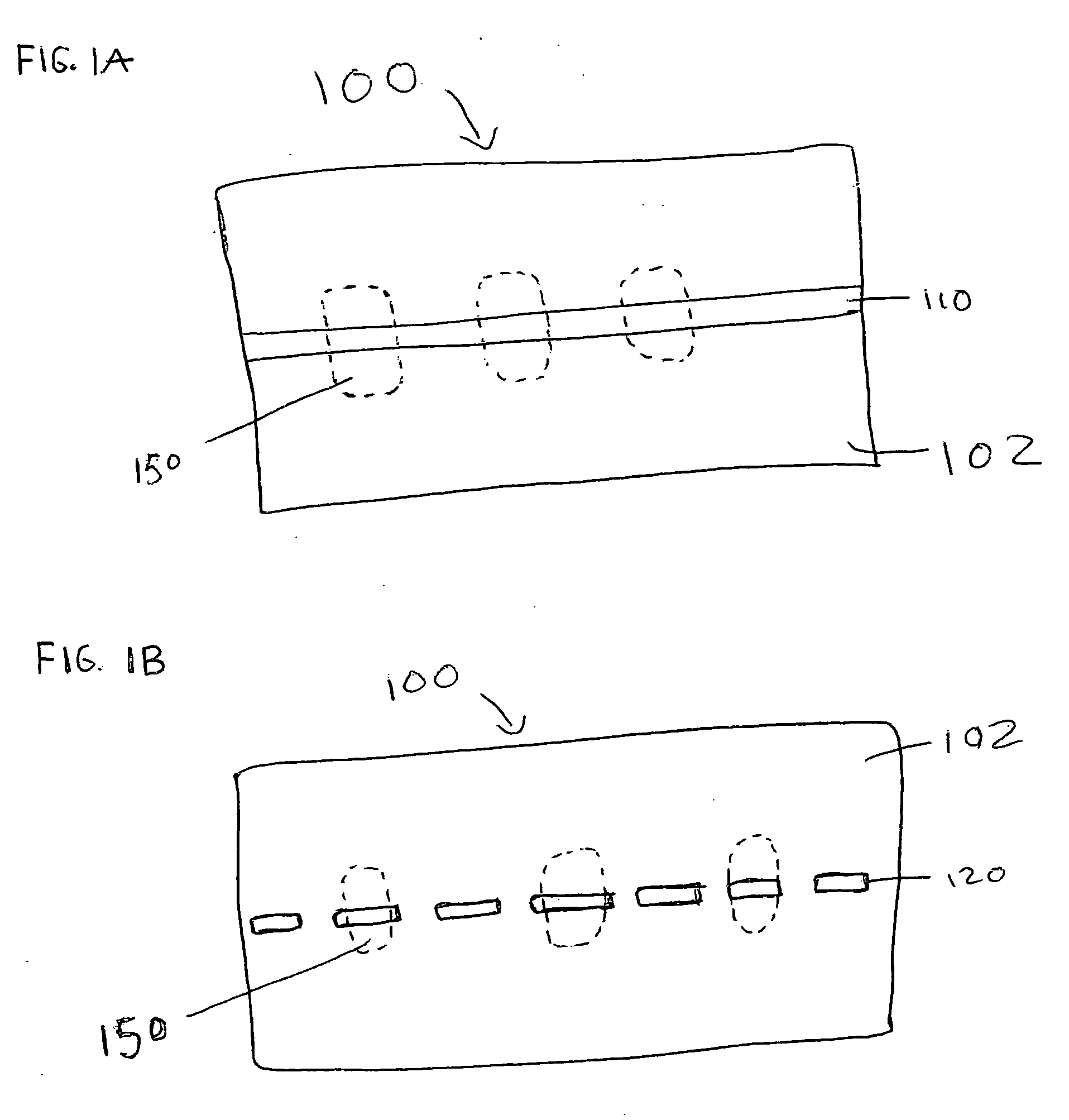

Method and device for simplifying the bonding of porcelain veneers

InactiveUS20060084037A1Easy line up and orientationSecurely holdTeeth fillingDental packagingDental laminatesPorcelain Veneer

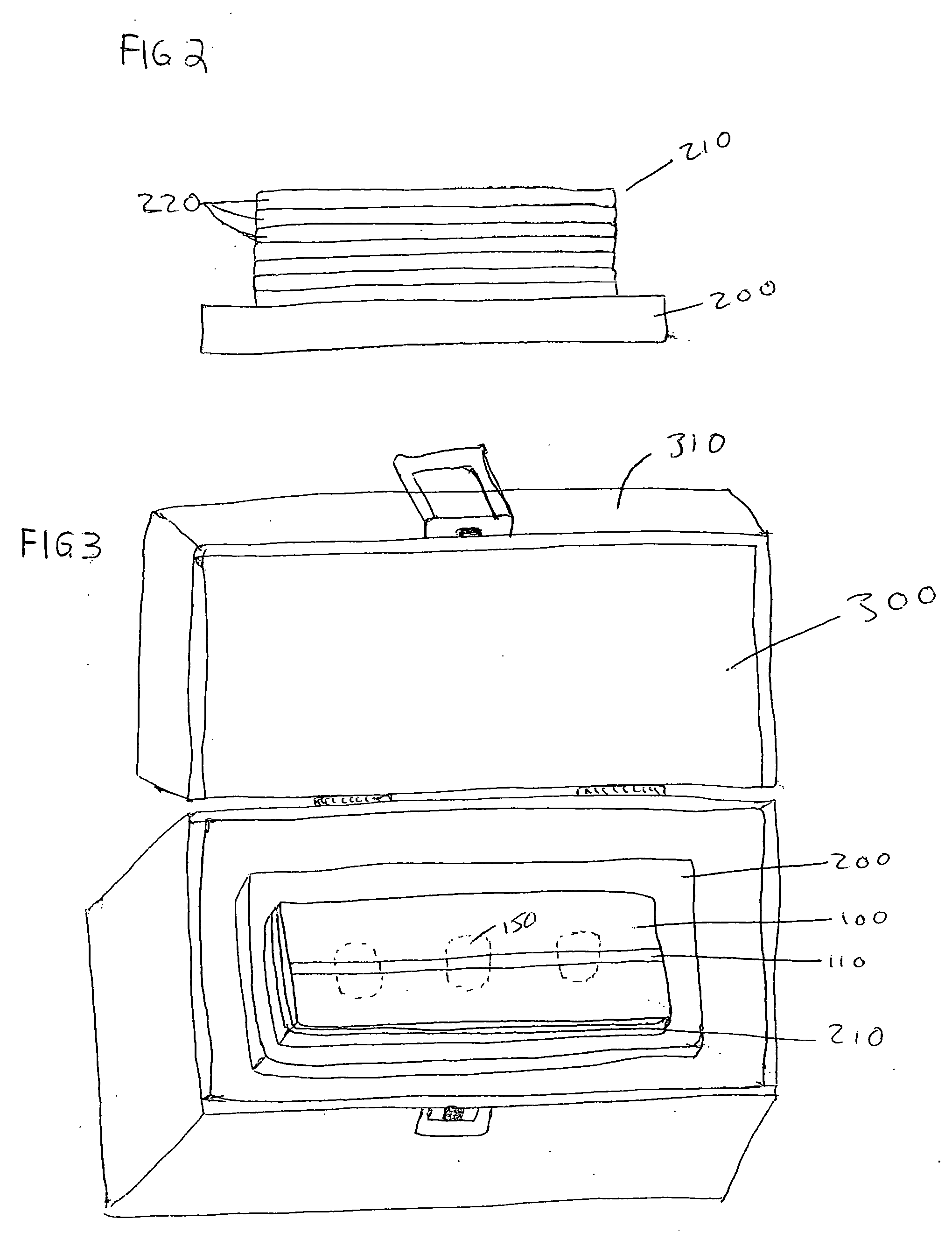

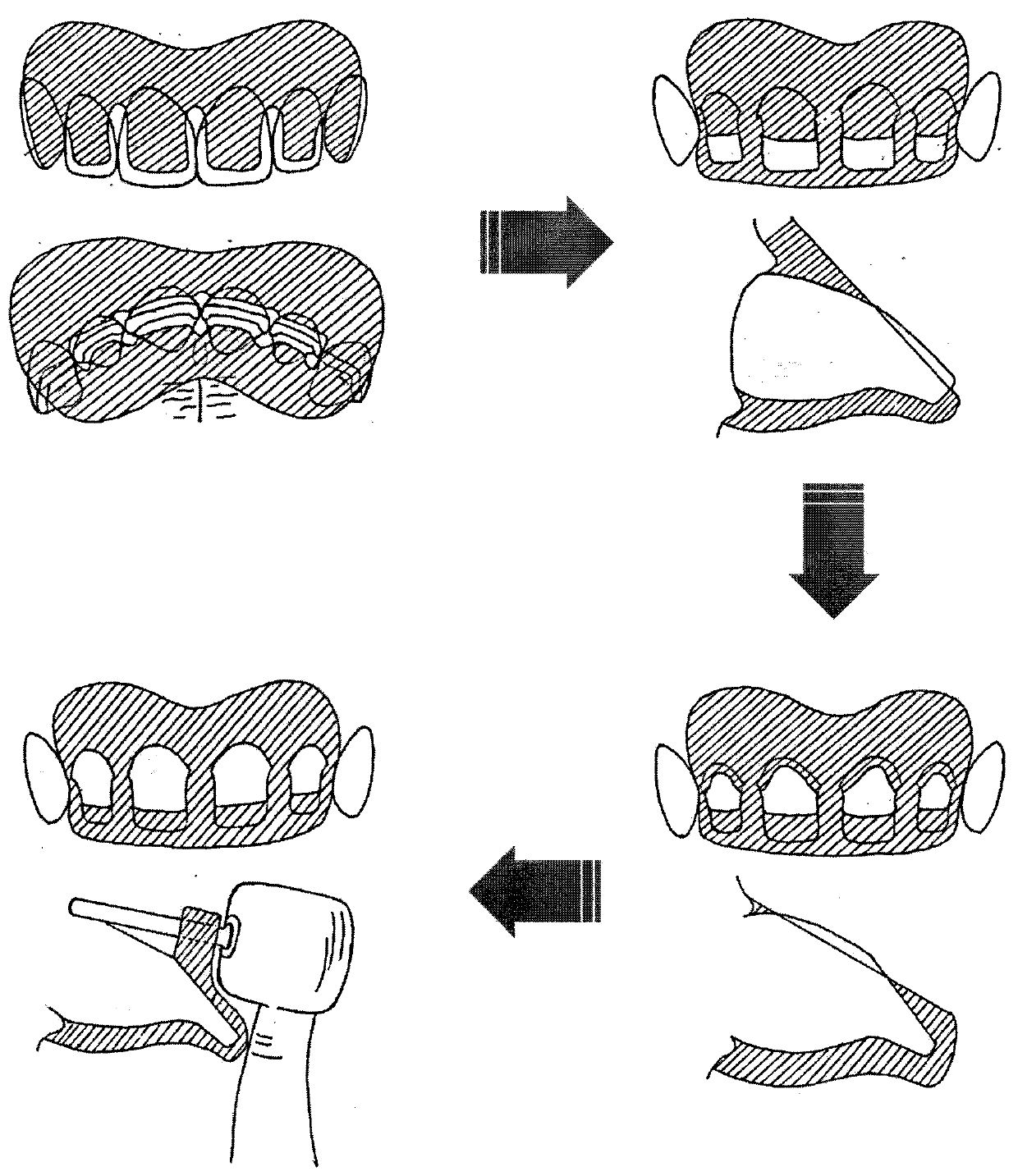

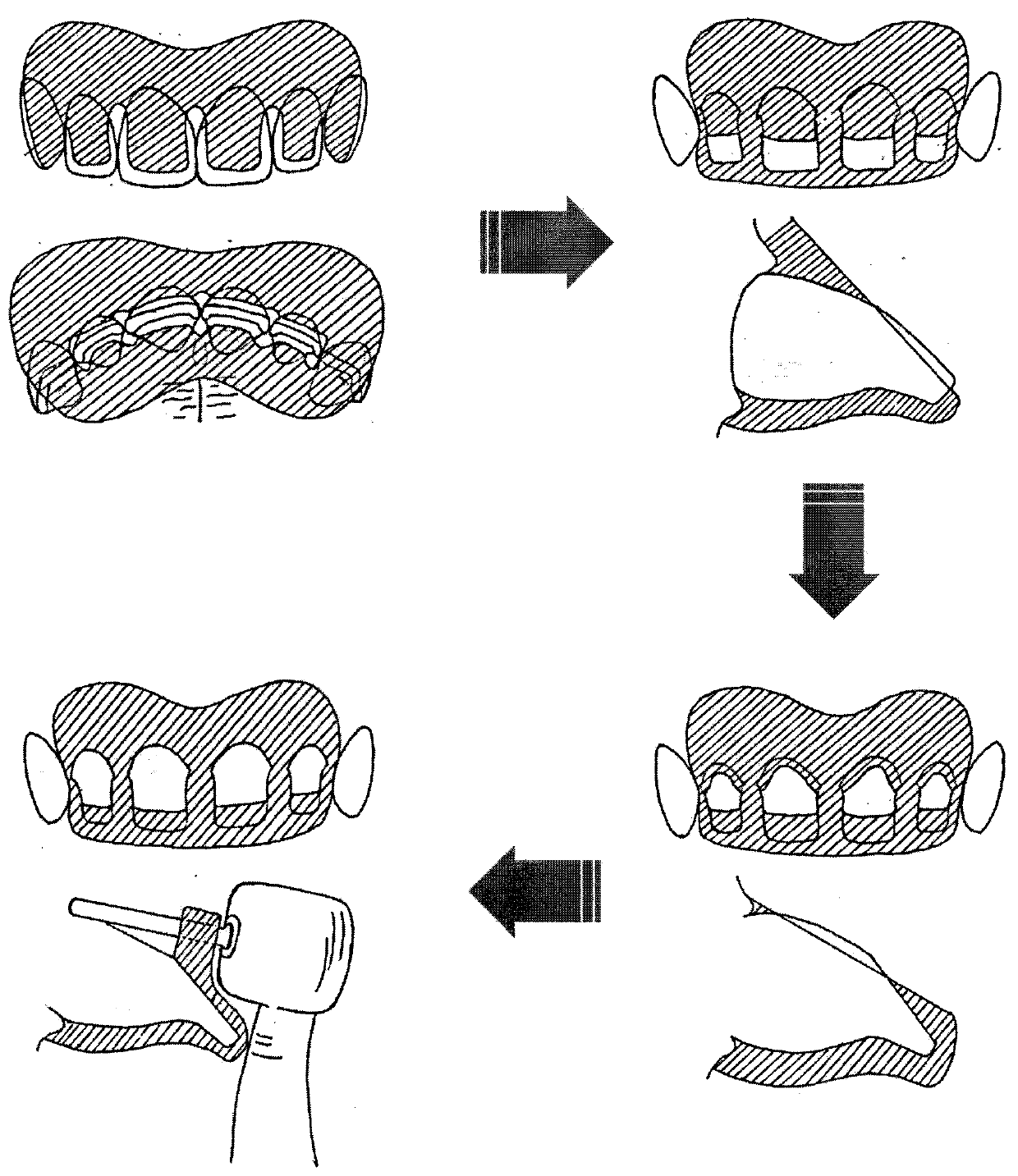

An apparatus and method for holding dental laminates is provided. A sheet is provided with an attachment means running along the center of the sheet that attaches the dental laminates to the sheet. The sheet may be stacked on top of several other similar sheets to form a pad. The pad is placed onto a platform such as a base, and inserted into an opaque box that blocks out the light so the light sensitive resin placed on the dental laminates does not cure until the dentist is ready to place the dental laminates onto a patient's teeth. The dental laminates can be held in the box until the dentist is ready to place the dental laminates onto a patient's teeth.

Owner:GOLD PHILIP

Composite porcelain veneering process

ActiveCN112006789AWear naturalAccurate dataImpression capsTeeth fillingComposite ceramicPorcelain Veneer

The invention discloses a composite porcelain veneering process, and relates to the field of oral cosmetology. The process comprises the following steps of: step 1, measuring: scanning teeth of a userby using a professional scanner to obtain tooth data, performing 3D modeling according to the obtained tooth data, exporting the tooth surface data, and performing designing by using a computer to generate a proper veneering model; and step 2, manufacturing a composite ceramic material for veneering. According to the invention, the teeth are partitioned by using an international dental union system, a tooth position is determined after partitioning; measurement is then made, the professional scanner scans the teeth of the user to obtain the tooth data, 3D modeling is carried out according tothe acquired tooth data, the tooth surface data is exported, and a proper veneering model is designed and generated by the computer, so that the acquired tooth data is accurate, and a user wears the product naturally in the later period. Repeated impression operation of the user is avoided by adopting machine scanning, and the operation trouble and the waiting time are reduced.

Owner:杭州雅齿美口腔科技有限公司

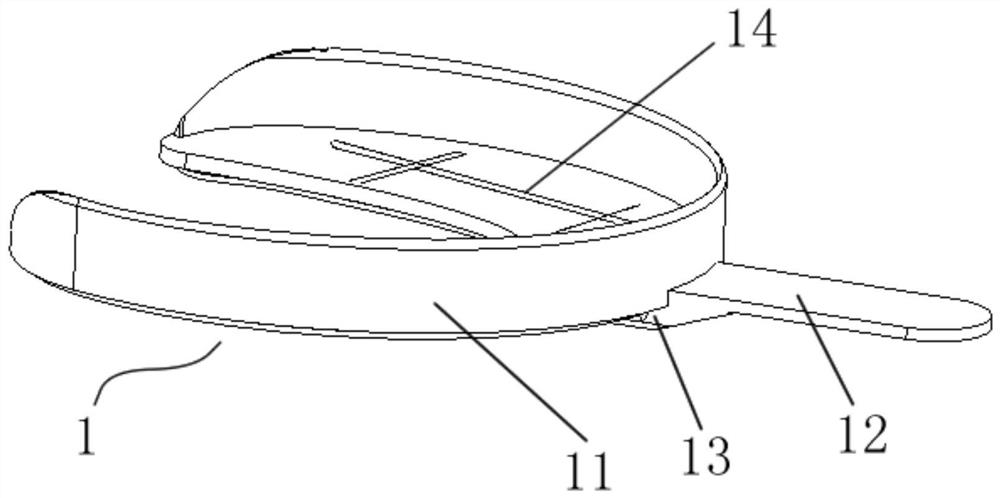

Individualized tooth preparation substep indicating guide plate manufactured by digital design

ActiveCN111166507AImprove satisfactionHigh precisionTeeth fillingDesign optimisation/simulationPulp (tooth)Tooth Preparations

In accordance with the present situations that clinically, the tooth preparation operation of porcelain laminate veneers of anterior teeth is high in difficulty, and tooth tissue is easy to excessively strip to cause dental pulp sensitivity, the invention relates to an individualized tooth preparation substep indicating guide plate manufactured by digital design. The individualized tooth preparation substep indicating guide plate manufactured by digital design is characterized in that the guide plate is designed and manufactured by a digital method, and is used for performing accurate tooth preparation on the porcelain laminate veneers of the anterior teeth, so that accurate dental hard tissue stripping can be realized in a substep manner, and the purpose of being minimally invasive is achieved. The substep guide plate is used for indicating tooth preparation through the three steps of: in a first step, indicating preparation of a cutting end and a neighbor surface with a neighbor surface cutting guide plate; in a second step, indicating labial side preparation with a labial side guide plate; and a third step, indicating gum edge preparation with a gum edge guide plate. According to the individualized tooth preparation substep indicating guide plate manufactured by digital design disclosed by the invention, accurate design is performed by the digital method, and then the toothpreparation is guided in the substep manner, so that the problem that the preparation capacity is insufficient or excessive cannot be generated, the operation difficulty of a clinician can be reduced,the clinical repairing quality and patient satisfactoriness are improved, and the individualized tooth preparation substep indicating guide plate is a beneficial attempt of an idea of accurate medical care in the field of mouth rehabilitation.

Owner:PEKING UNIV SCHOOL OF STOMATOLOGY

A kind of manufacturing method of porcelain veneer

ActiveCN112089496BHigh precisionHighly corporatedTeeth fillingCeramic shaping apparatusRefractoryEngineering

The invention relates to a method for making a porcelain veneer. The making method includes the following steps: a) firstly checking whether there is a problem with an abutment model, which includes an upper part and a root part, and trimming the root part of the abutment model to be the same as the one to be affixed. The same shape as the root of the tooth; b) Reconstructed gypsum abutment; c) Put the reproduced gypsum abutment into the tray, and apply high oil Vaseline on the surface of the reproduced gypsum abutment; d) Put the The root of the gypsum abutment is driven into the artificial gums; i) The refractory abutment is put into water, and when the water absorption reaches a saturated state, porcelain is applied on the surface of the neck line; j) After high temperature treatment The part of the remanufactured refractory abutment away from the porcelain veneer is polished off, and finally the sandblasted porcelain veneer is attached to the upper part of the remanufactured gypsum abutment. The invention provides a method for manufacturing a porcelain veneer, which improves the precision of the manufactured veneer and improves the comfort and satisfaction of users.

Owner:苏州固锐德医疗器械有限公司

Dental hybrid porcelain veneer and manufacturing method thereof

ActiveCN111150502BEasy dockingImprove bindingTeeth fillingSurface layering apparatusMedical equipmentApparatus instruments

The invention discloses a dental hybrid porcelain veneer, which belongs to the technical field of dental medical devices, and is characterized in that it includes a lingual porcelain veneer and a labial porcelain veneer for covering teeth, and the lingual porcelain veneer is completely Covering the lingual side of the tooth body, the labial porcelain veneer partially covers the labial side of the tooth body, a junction line for butt joint and combination is formed between the lingual side porcelain veneer and the labial side porcelain veneer, the junction The line is located at the proximal incisal end of the lingual porcelain veneer and avoids the occlusal contact area by 2mm, forming a right-angled shoulder or at the 1 / 2 of the lip-lingual direction of the incisal edge of the tooth. The lingual porcelain veneer is made of zirconia or glass ceramics. The labial porcelain veneer is feldspathic ceramic. The hybrid porcelain veneer prepared by the invention has both mechanical and aesthetic properties, and retains more tooth tissue. There are no teeth on the lingual side, and the amount of teeth on the labial side is less than 0.5mm or no teeth. It is suitable for people with teeth on the lingual side. The occlusal space, occlusal reconstruction with normal lip color and fixed repair with occlusal space on the lingual side have strong applicability.

Owner:SICHUAN UNIV

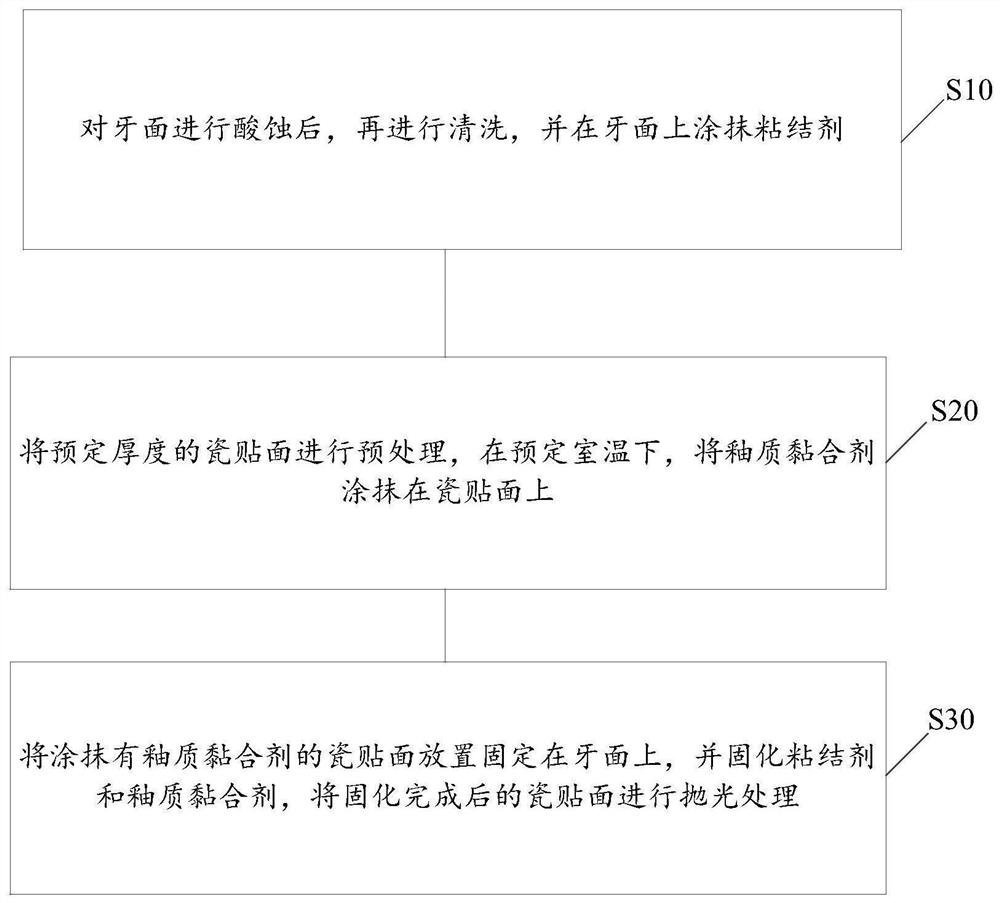

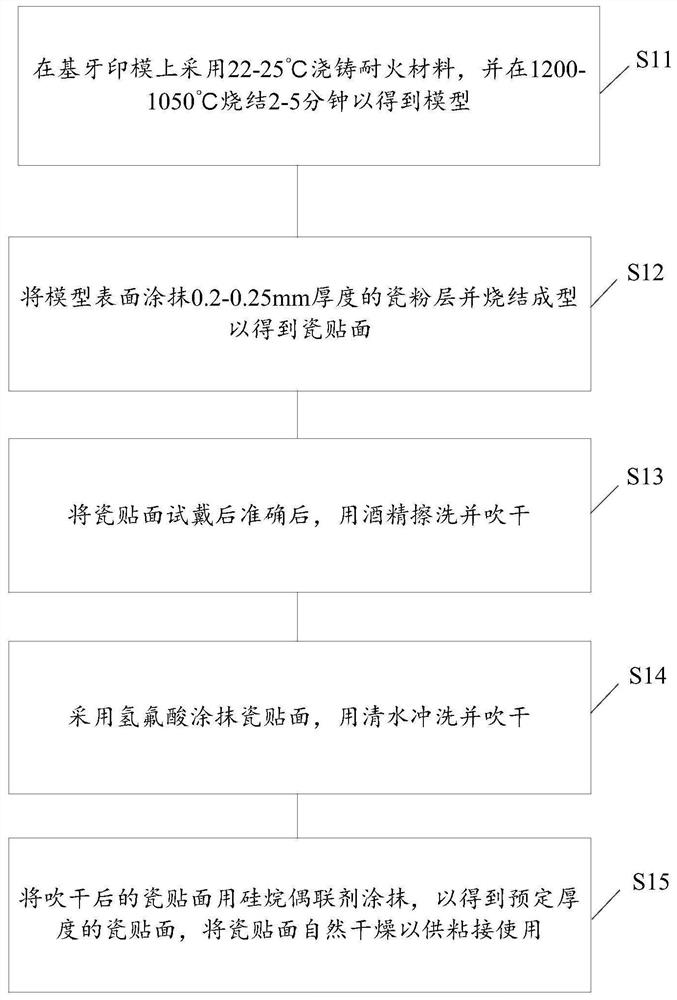

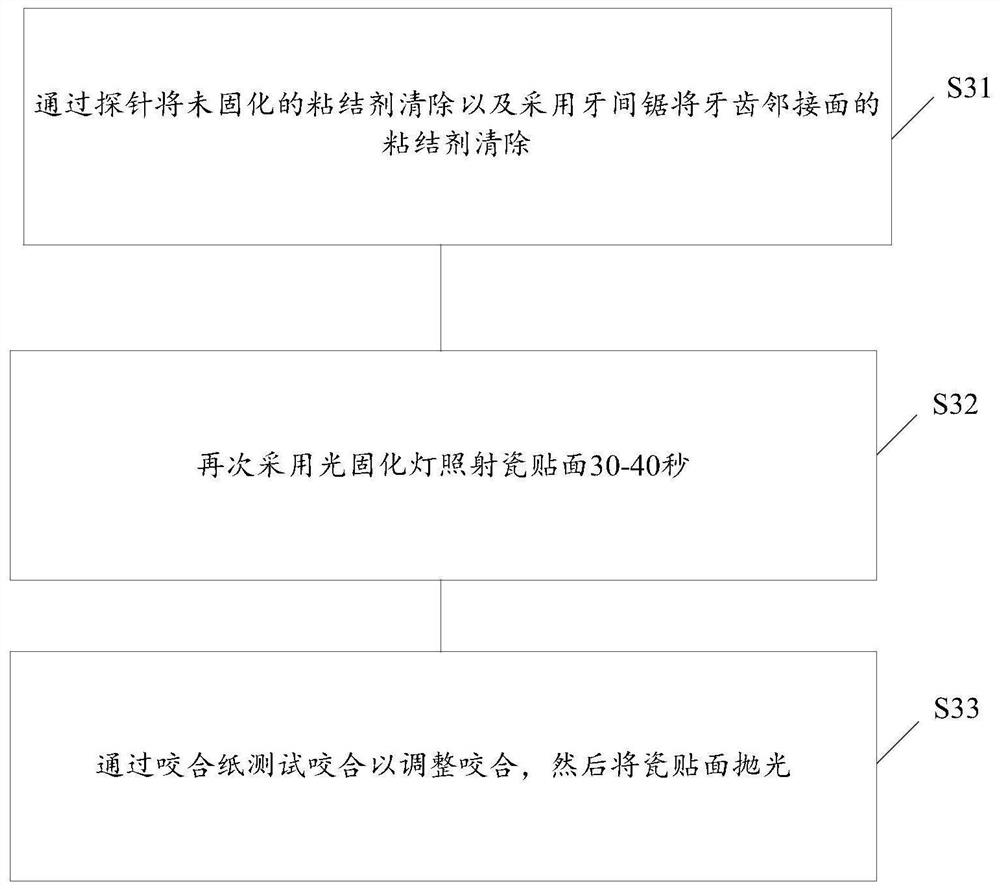

Tooth porcelain veneer bonding method

The invention discloses a tooth porcelain veneer bonding method, which comprises the following steps: carrying out acid etching on a tooth surface, cleaning, and smearing a binder on the tooth surface; then pretreating a porcelain veneer with a predetermined thickness, and smearing an enamel adhesive on the porcelain veneer at a predetermined room temperature; and placing and fixing the porcelain veneer coated with the enamel adhesive on the tooth surface, curing the adhesive and the enamel adhesive, and polishing the cured porcelain veneer. According to the tooth beautifying device, teeth do not need to be polished and then pasted, so that the teeth are prevented from being damaged, and the tooth beautifying efficiency is improved.

Owner:郑程元

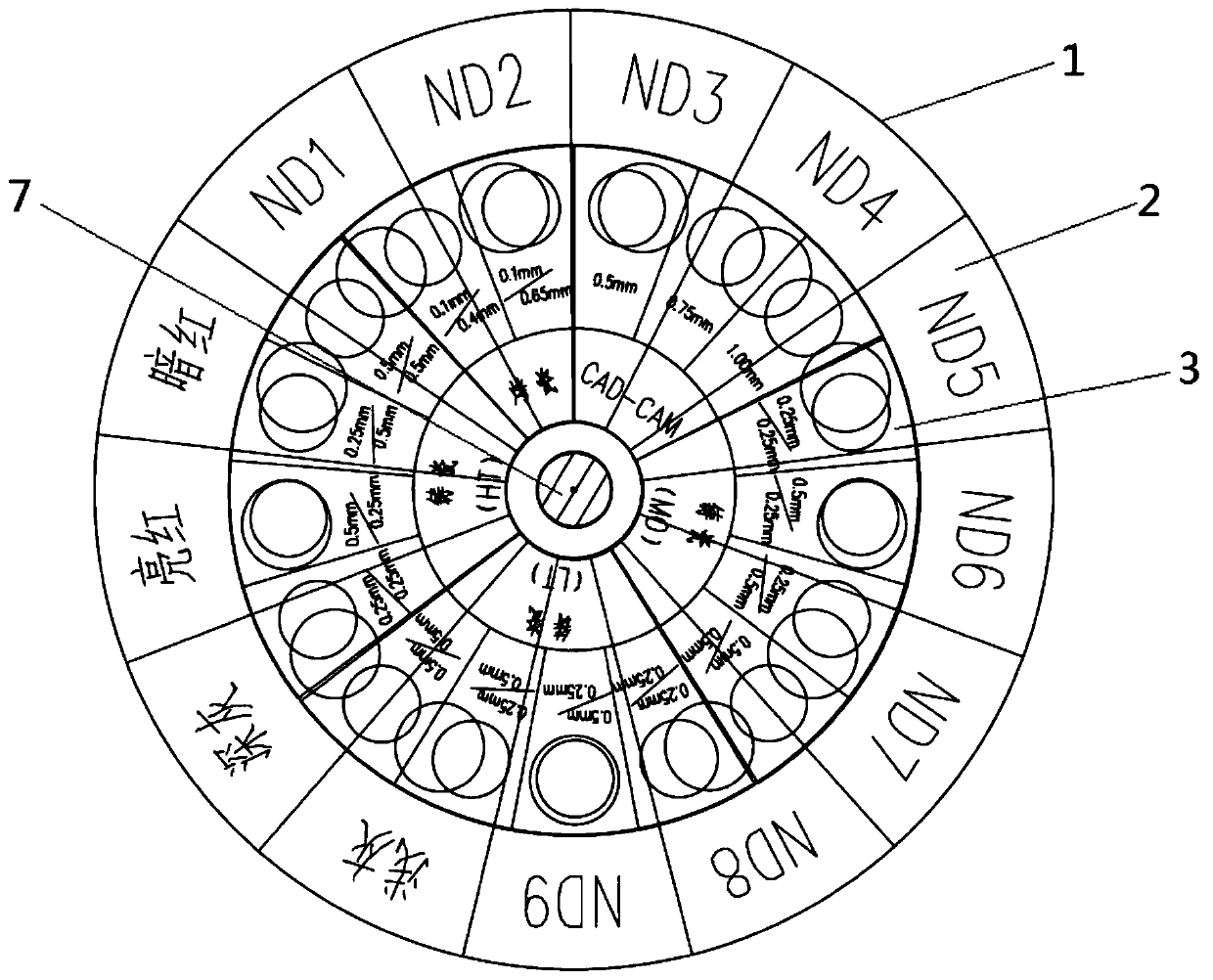

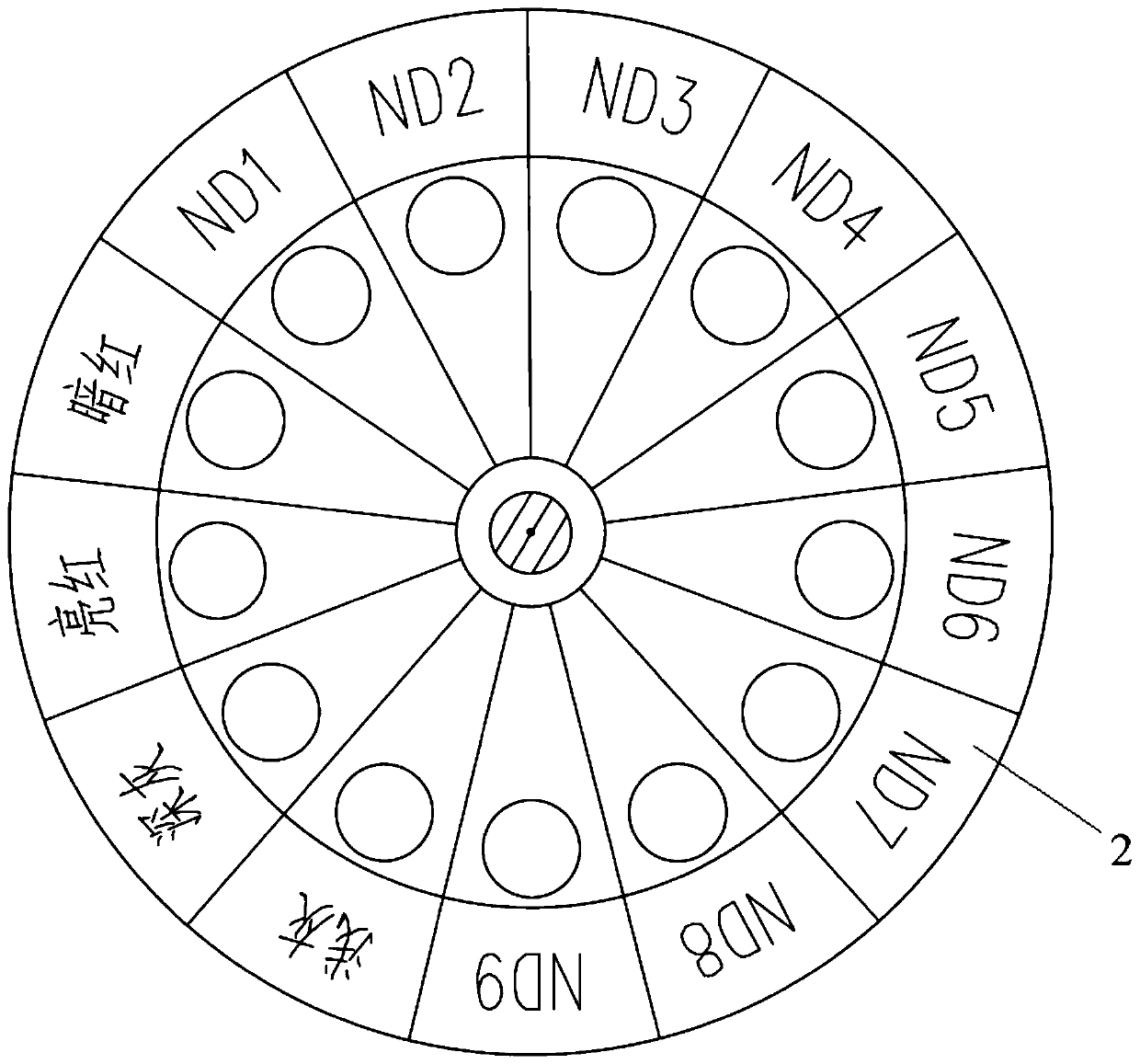

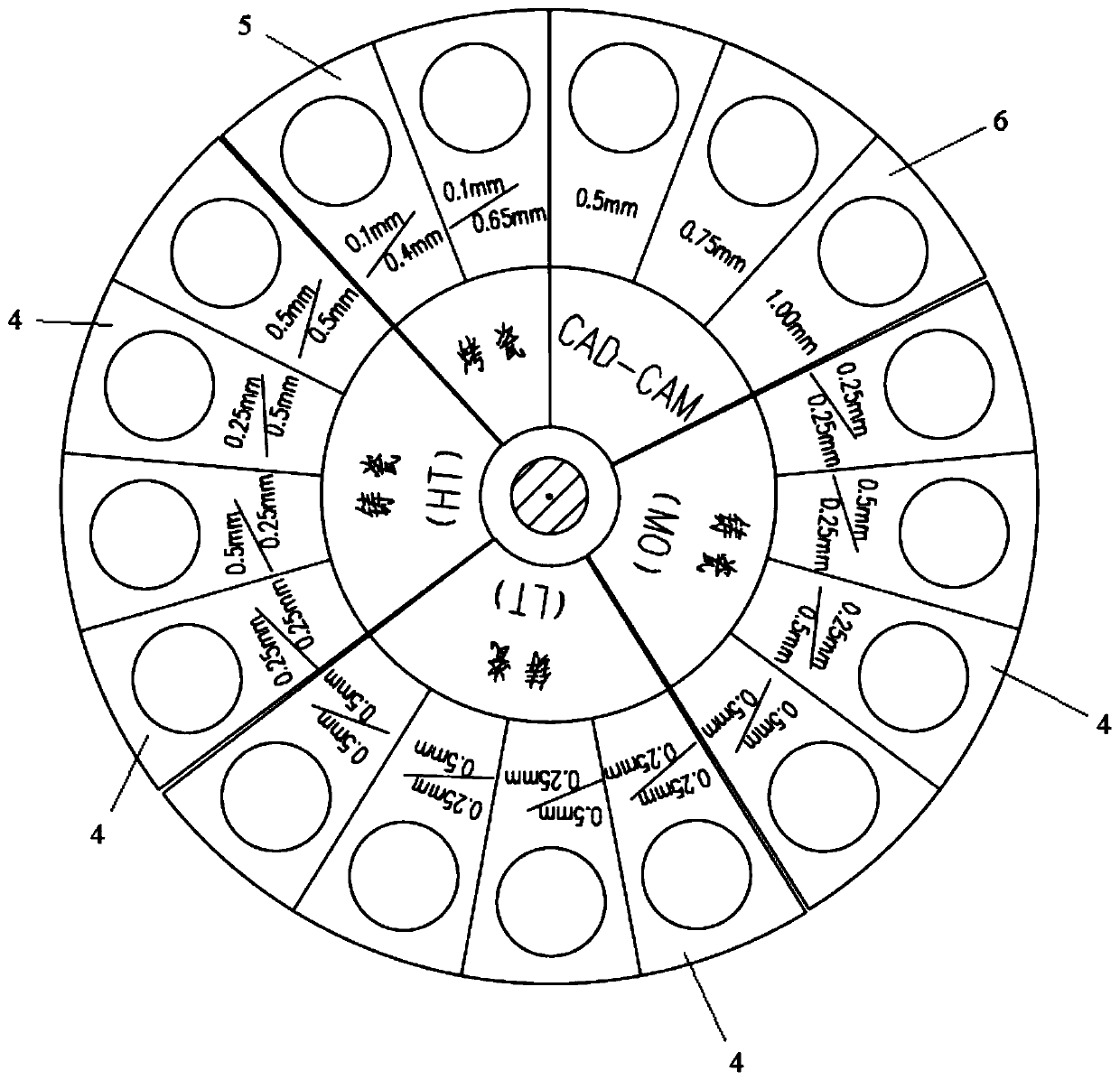

Aesthetic effect display swatch for porcelain veneer repaired discolored teeth with different technologies and manufacturing method

PendingCN110433005AAccurately reproduce color informationImprove satisfactionDentistryCeramic shaping apparatusStaining teethStain tooth

The invention belongs to the technical field of auxiliary equipment for stomatology, and discloses an aesthetic effect display swatch for porcelain veneer repaired discolored teeth with different technologies and a manufacturing method. By analyzing the effects of different manufacturing processes and different process parameters on the chromatographic properties and semi-permeability of porcelainveneer repaired discolored teeth, the special aesthetic effect display swatch for the porcelain veneer repaired discolored teeth is designed, the chromaticity information of the swatch can be enteredinto a computer, and the computer simulation of the aesthetic effect can be realized through programming. The swatch enables patients to clearly see the affected teeth under a certain degree of discoloration, different tooth grinding amounts require different porcelain materials and manufacturing processes, and differences in aesthetic effects after repair helps the patients to make reasonable choices and establish reasonable aesthetics expectation. The special display swatch for the porcelain veneer can not only improve the aesthetic effect prediction of the porcelain veneer restoration of deep-stained teeth by a doctor before an operation, facilitates the communication between the doctor and the patient before the aesthetic restoration, and helps improve the patient's satisfaction withthe restoration effect.

Owner:昆明医科大学附属口腔医院

Veneered colorimetric plate, and preparation method and application method thereof

The invention relates to the field of dentures, and specifically relates to a veneered colorimetric plate, and a preparation method and an application method thereof. The veneered colorimetric plate is composed of ten or more product veneers with different color effects. The veneered colorimetric plate is designed to solve the problem of ultrathin porcelain veneer colorimetry, and pre-makes different standardized porcelain veneers with different colors and thicknesses according to the thickness of the ultrathin porcelain veneers. The veneered colorimetric plate can help doctors and patients see the repaired color improvement results before the repair. The solution employed by the invention is that the product ultrathin veneer is directly put on the teeth of a patient to test colors when a veneering repair for whitening the teeth is carried out, enabling the colorimetry to be easier and the color to satisfy the requirements of the patient.

Owner:深圳市金悠然科技有限公司

Glass-ceramic veneer and its processing method

ActiveCN111904638BImprove manufacturing precisionAvoid damageArtificial teethNumerical controlTeeth grinding

The invention relates to a glass ceramic veneer and a processing method thereof. The processing method of the glass-ceramic veneer includes the following steps: scanning: scanning the tooth model or the teeth in the mouth to make a three-dimensional model; designing: performing veneer design on the three-dimensional model; cutting: according to the veneer Cutting of glass-ceramic materials is designed to prepare veneer body; sintering: sintering the veneer body to prepare veneer. The processing method of the glass-ceramic veneer provided by the present invention adopts cutting combined with sintering to process the glass-ceramic material, and innovatively finds that it can meet the thickness requirement of the ultra-thin veneer. When using it, there is no need to grind the teeth, which avoids wearing damage to the teeth. At the same time, compared with the traditional unprepared tooth casting porcelain veneer process, there is no need to prepare a wax pattern, and the processing steps of numerical control equipment are omitted. The process is simple, the preparation time is short, and the production accuracy of the veneer can also be improved.

Owner:FUZHOU RUIKE BULANG MEDICAL TECH CO LTD

Method for processing ultra-thin cast porcelain laminate veneer capable of preventing tooth grinding

The invention relates to the field of dental prosthesis, in particular to a method for processing ultra-thin cast porcelain laminate veneer capable of preventing tooth grinding. The method comprises the following steps: a three-dimensional scanner is adopted to scan a dental cast, a three-dimensional stereoscopic image is formed, an ultra-thin veneer with the thickness of less than 0.5 mm is designed on the virtual image, after the ultra-thin veneer is designed, data is output to a 3D (three-dimensional) resin wax forming machine, the ultra-thin veneer is formed in the manners of resin-spraying, irradiation curing and printing, and then the formed resin wax pattern is subjected to embedded casting, grinding adjustment, try-in and glazing. Compared with the prior art, the method adopts a computer to design, and the conventional hand-made wax pattern is replaced by the resin wax pattern processed by the digital resin wax spraying, irradiation curing and printing processing, so that fabrication of porcelain laminate veneer with the thickness of less than 0.5 mm is realized. An aesthetic seeking patient with discolored teeth does not need tooth grinding and can receive tooth-whitening treatment without hurting teeth.

Owner:深圳市金悠然科技有限公司

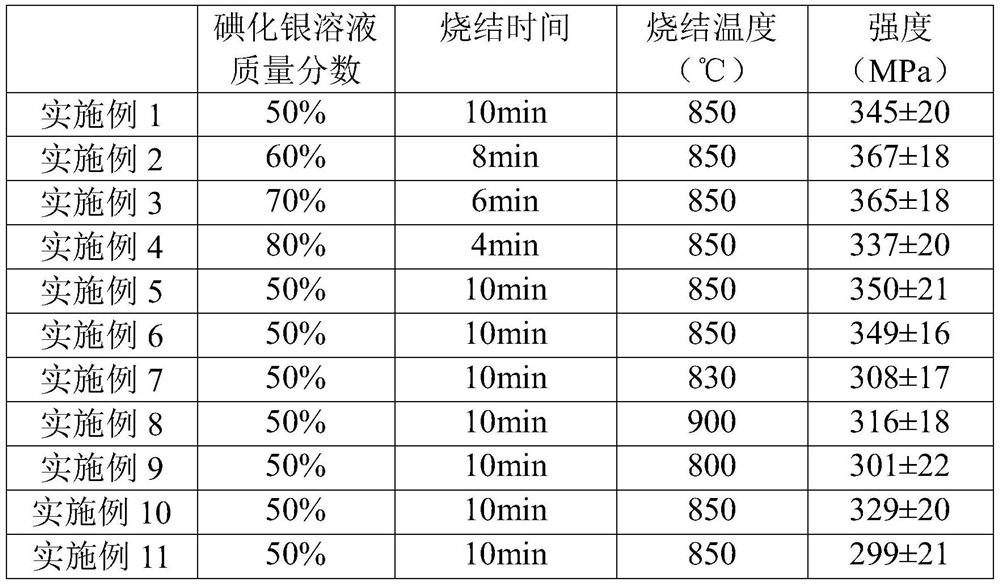

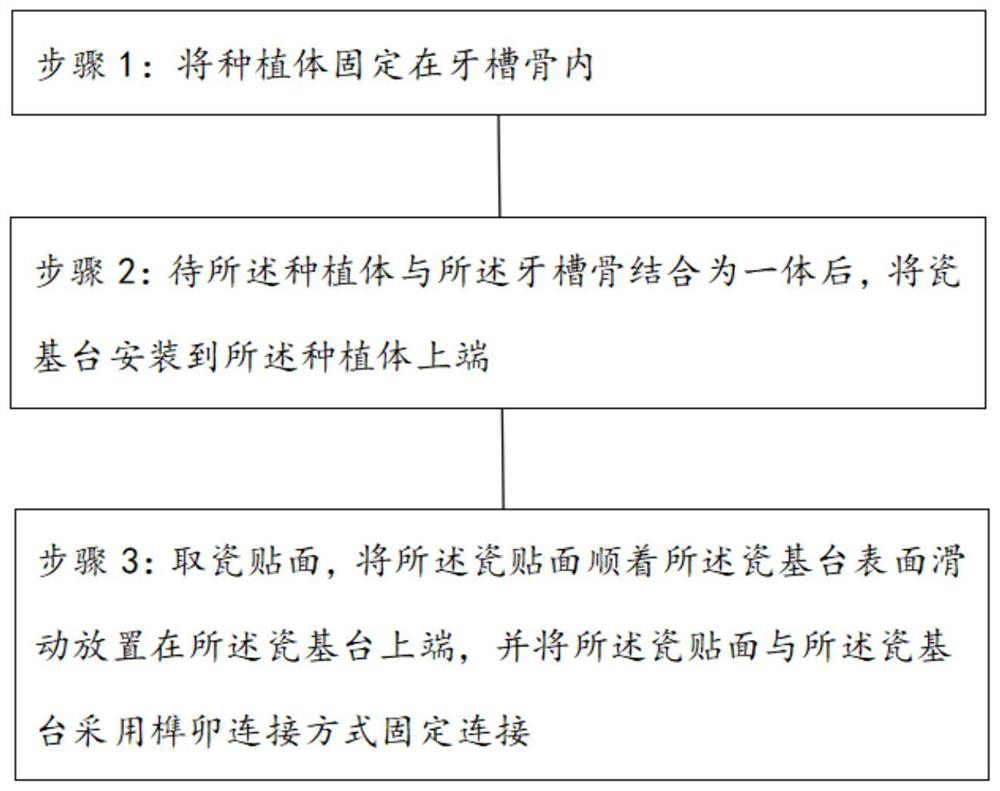

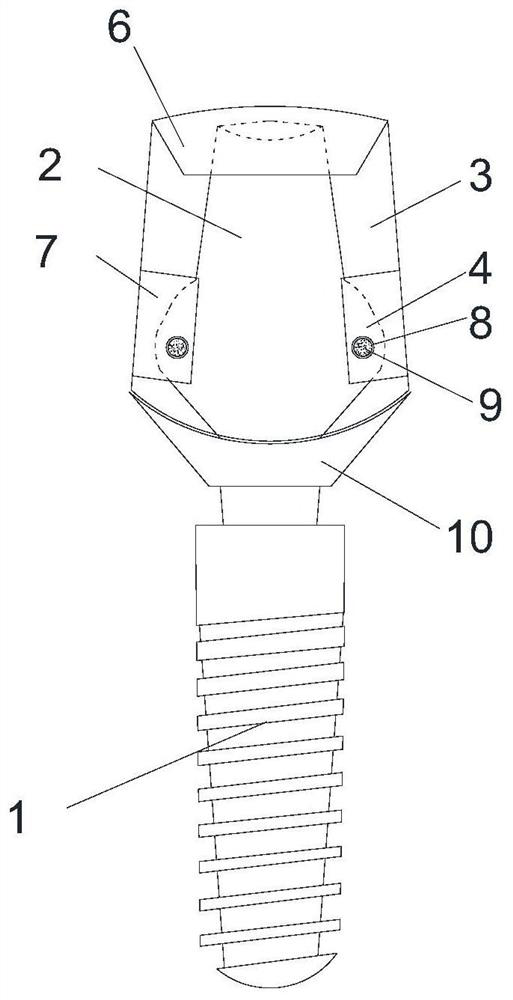

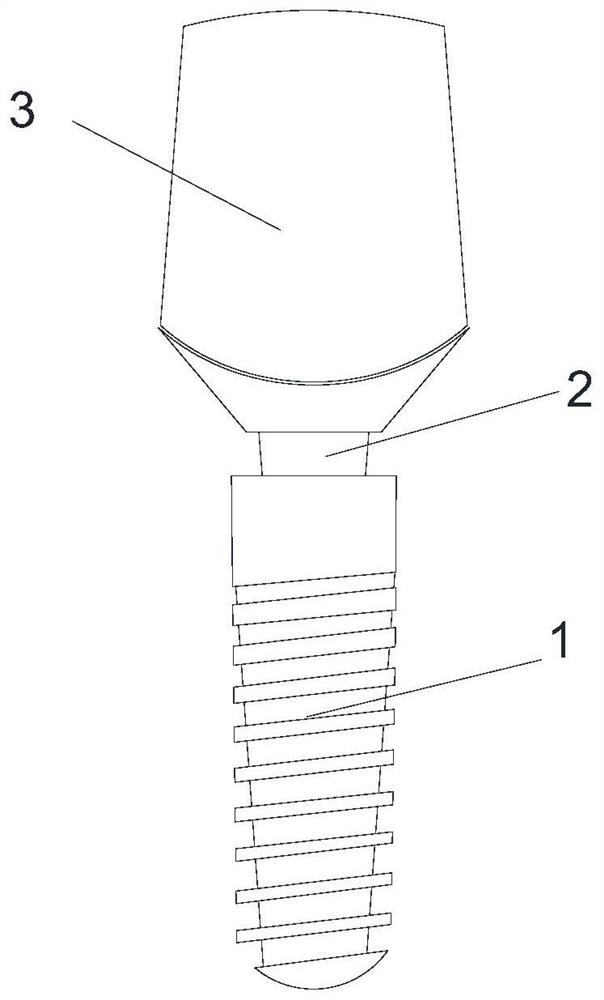

Mortise and tenon joint-type repair design method applied to dental crown implantation in feature-beautifying area

ActiveCN113558802AAvoid the problem of the occurrence of peripheral inflammationSolve the problem of aesthetic defects in openingsDental implantsDental prostheticsMortise and tenonAdhesive

The invention provides a mortise and tenon joint-type repair design method applied to dental crown implantation in a feature-beautifying area. The method comprises the following steps: fixing an implant in an alveolar bone; after the implant and the alveolar bone are combined into a whole, arranging a porcelain abutment at an upper end of the implant; and taking a porcelain veneer, placing the porcelain veneer at an upper end of the porcelain abutment in a sliding manner along a surface of the porcelain abutment, and fixedly connecting the ceramic veneer with the porcelain abutment in a mortise and tenon joint manner. A full dental crown is changed into an improved porcelain veneer, the personalized porcelain abutment matched with the porcelain veneer is designed, the porcelain veneer and the porcelain abutment are fixedly connected in the mortise and tenon joint manner, such that an adhesive is not needed, a problem of inflammation around the implant caused by the residual adhesive is avoided, a success rate of implantation is increased, the porcelain veneer is arranged and a problem of aesthetic defects of a dental crown lip side opening caused by screw retention is effectively solved.

Owner:SUZHOU KOWLOON HOSPITAL

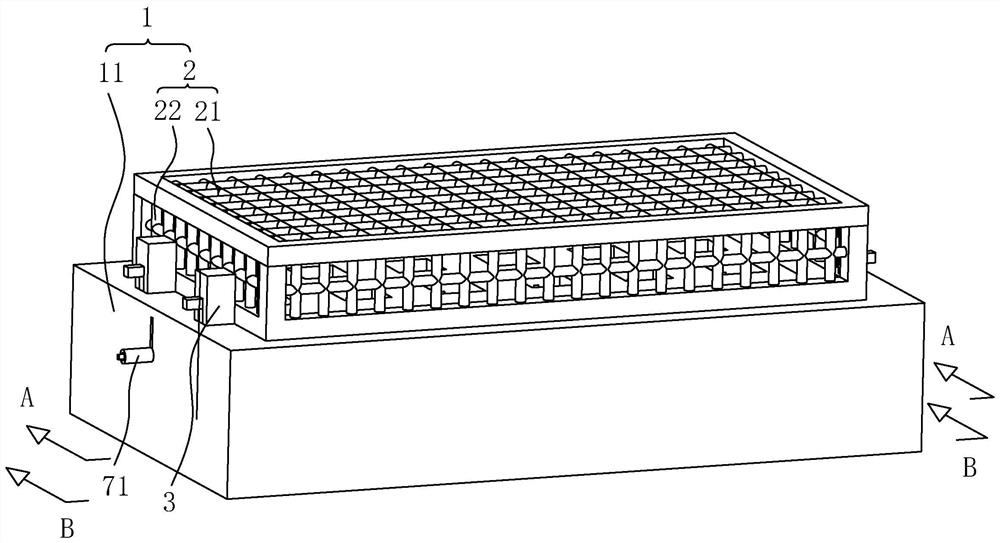

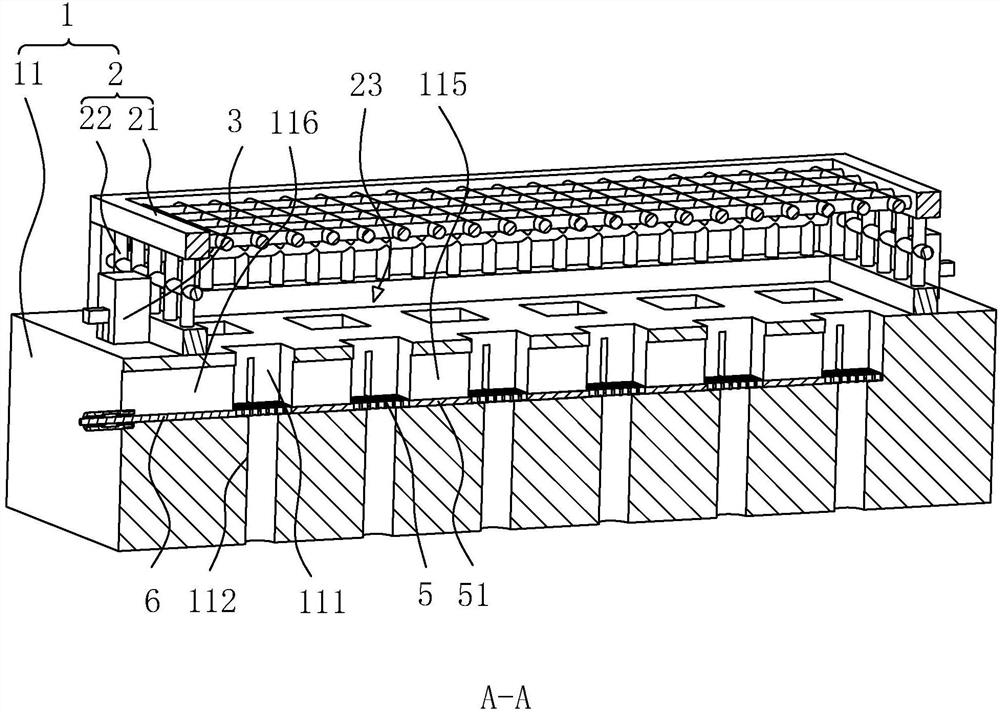

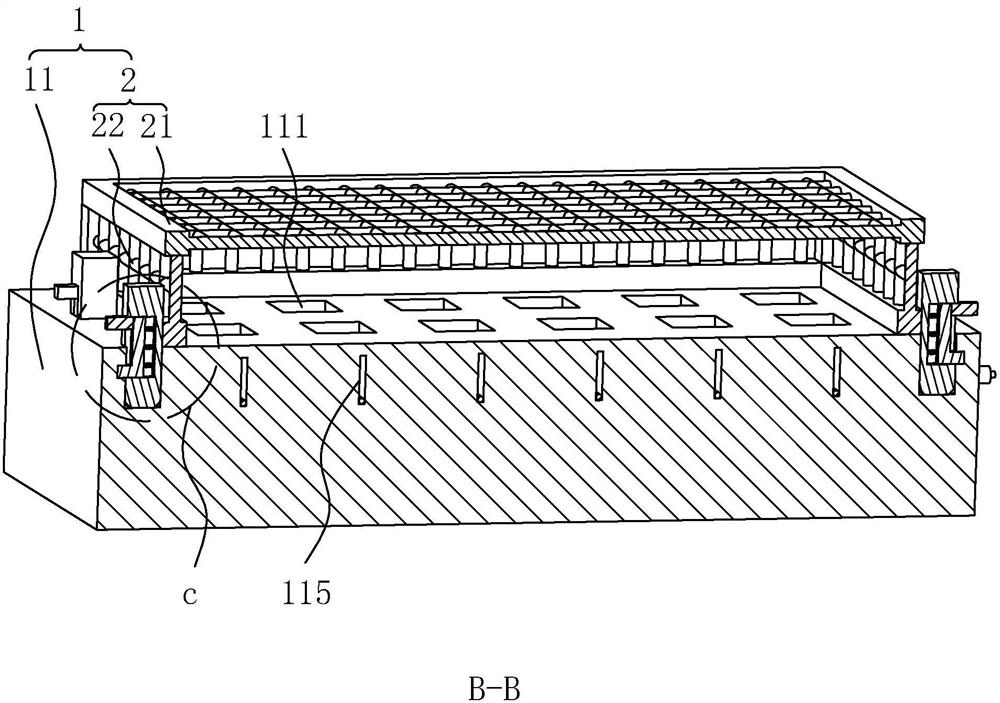

Dental processing technology and processing device thereof

ActiveCN113648085ASave time at workImprove work efficiencyImpression capsTeeth fillingPlaster CastsSand blasting

The invention relates to a dental processing technology and a processing device thereof, and relates to the technical field of dental aesthetic repair. The method comprises the following steps: cleaning a silica gel tray, and filling a superhard gypsum model; dividing the plaster model to manufacture a removable independent model, manufacturing a retention groove on the near-far middle side of the root of the removable independent model, and manufacturing a T shape at the root tip to form a retention model; coating the removable root with a gap agent; duplicating a removable model impression by using silica gel; pouring a refractory material into a refractory material removable model; carrying out heat treatment on the removable refractory material mold through heat treatment equipment, and after heat treatment is completed, putting the removable refractory material mold back into the model for in-place inspection; carrying out water saturation treatment before porcelain coating until the water is fully absorbed; carrying out porcelain sintering for multiple times; carrying out shape finishing, glazing and sand blasting to remove a refractory material substrate; completing in-place polishing to form the baked porcelain veneer; and cleaning the manufactured baked porcelain veneer by using a cleaning device. The method has the effect of improving the working efficiency of workers.

Owner:上海睿齿工贸有限公司

A composite porcelain veneer process

The invention discloses a composite porcelain veneer process, which relates to the field of oral beauty, including: step 1: measuring, using a professional scanner to scan the user's teeth to obtain tooth data, and perform 3D modeling according to the obtained tooth data, and Export the data on the tooth surface, and design it by computer to generate a suitable veneer model; Step 2: Make composite porcelain materials for veneer. In the present invention, the teeth are partitioned by using the International Dental Federation system, and then the tooth position is determined after partitioning, and then the measurement is performed, and the professional scanner scans the user's teeth to obtain tooth data, and performs 3D modeling according to the obtained tooth data , and export the data on the surface of the teeth, designed by the computer to generate a suitable veneer model, the tooth data obtained in this way are accurate, and the user will wear it naturally later, and the use of machine scanning will not allow the user to repeat the impression operation, reducing operational trouble and waiting. time.

Owner:杭州雅齿美口腔科技有限公司

Dental cleaning and polishing composition comprising diamond particles

InactiveUS9724541B2High glossReduce wearCosmetic preparationsImpression capsNatural toothPorcelain Veneer

A new whitening dentifrice suitable for use with porcelain veneers and dental work as well as with natural tooth enamel comprising diamond particles is disclosed.

Owner:KAO LISA MARIE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com