Dental hybrid porcelain veneer and manufacturing method thereof

A production method and technology of porcelain veneer, applied in dentistry, medical science, filling teeth, etc., can solve the problems of multi-tooth tissue, affect the aesthetic effect, poor color of the labial repair, etc., and achieve the effect of strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

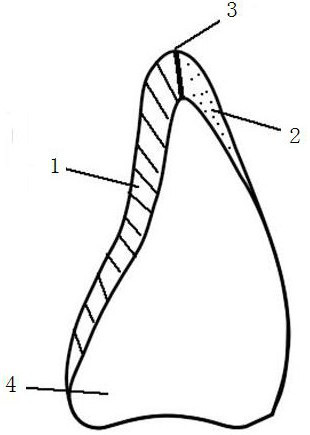

[0031] see figure 1 , a dental hybrid porcelain veneer, comprising a lingual porcelain veneer 1 and a labial porcelain veneer 2 for covering a tooth body 4, the lingual porcelain veneer 1 fully covers the lingual side of the tooth body 4, the The labial porcelain veneer 2 partially covers the labial side of the tooth body 4, and a junction line 3 for docking and bonding is formed between the lingual porcelain veneer 1 and the labial porcelain veneer 2, and the junction line 3 is located at 1 / 2 of the incisal edge of the tooth body to the labial tongue.

[0032] The lingual porcelain veneer 1 is made of zirconia, and the labial porcelain veneer 2 is made of feldspar ceramics.

Embodiment 2

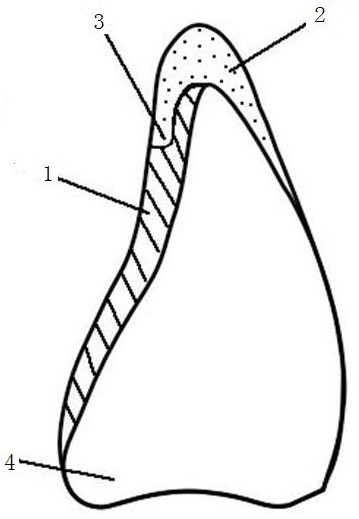

[0034] see figure 2 , a dental hybrid porcelain veneer, comprising a lingual porcelain veneer 1 and a labial porcelain veneer 2 for covering a tooth body 4, the lingual porcelain veneer 1 fully covers the lingual side of the tooth body 4, the The labial porcelain veneer 2 partially covers the labial side of the tooth body 4, and a junction line 3 for docking and bonding is formed between the lingual porcelain veneer 1 and the labial porcelain veneer 2, and the junction line 3 is located on the lingual side. The proximal incisal end of side porcelain veneer 1 avoids the occlusal contact area by 2mm, forming a right-angled shoulder.

[0035] The lingual porcelain veneer 1 is glass ceramics, and the labial porcelain veneer 2 is feldspar ceramics.

[0036]"The lingual porcelain veneer 1 fully covers the lingual side of the tooth 4, the labial porcelain veneer 2 partially covers the labial side of the tooth 4, and the lingual porcelain veneer 1 and the labial porcelain veneer 2 a...

Embodiment 3

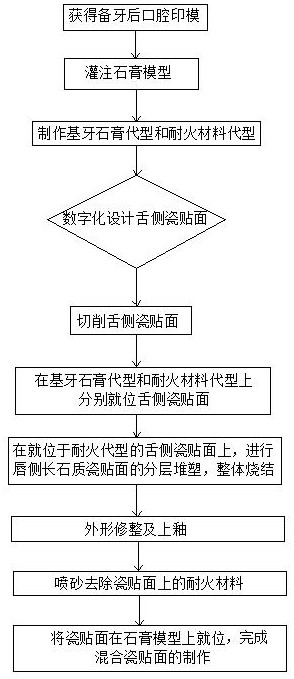

[0038] see image 3 , a method for making a dental hybrid porcelain veneer, comprising the following steps:

[0039] a. After tooth body 4 is prepared, an impression is obtained and a plaster model is poured;

[0040] b. Make the abutment gypsum model and refractory material model for the veneer, and sinter the refractory material model to make it solidify;

[0041] c. Design the lingual porcelain veneer 1 through digital software, digitally cut the lingual zirconia veneer, and sinter the crystalline zirconia lingual porcelain veneer;

[0042] d. Adjust and grind the zirconia lingual porcelain veneer, and put them in place on the abutment gypsum mold and the refractory material mold respectively. The lip side feldspathic veneer is layered and molded, and the whole is sintered;

[0043] e. Trimming and glazing the shape, removing the refractory mold by sand blasting, and putting it in place on the plaster model to obtain a hybrid porcelain veneer.

[0044] When preparing th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com