Patents

Literature

39 results about "Dental porcelain material" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dental porcelain (also known as dental ceramic) is a dental material used by dental technicians to create biocompatible lifelike dental restorations, such as crowns, bridges, and veneers.

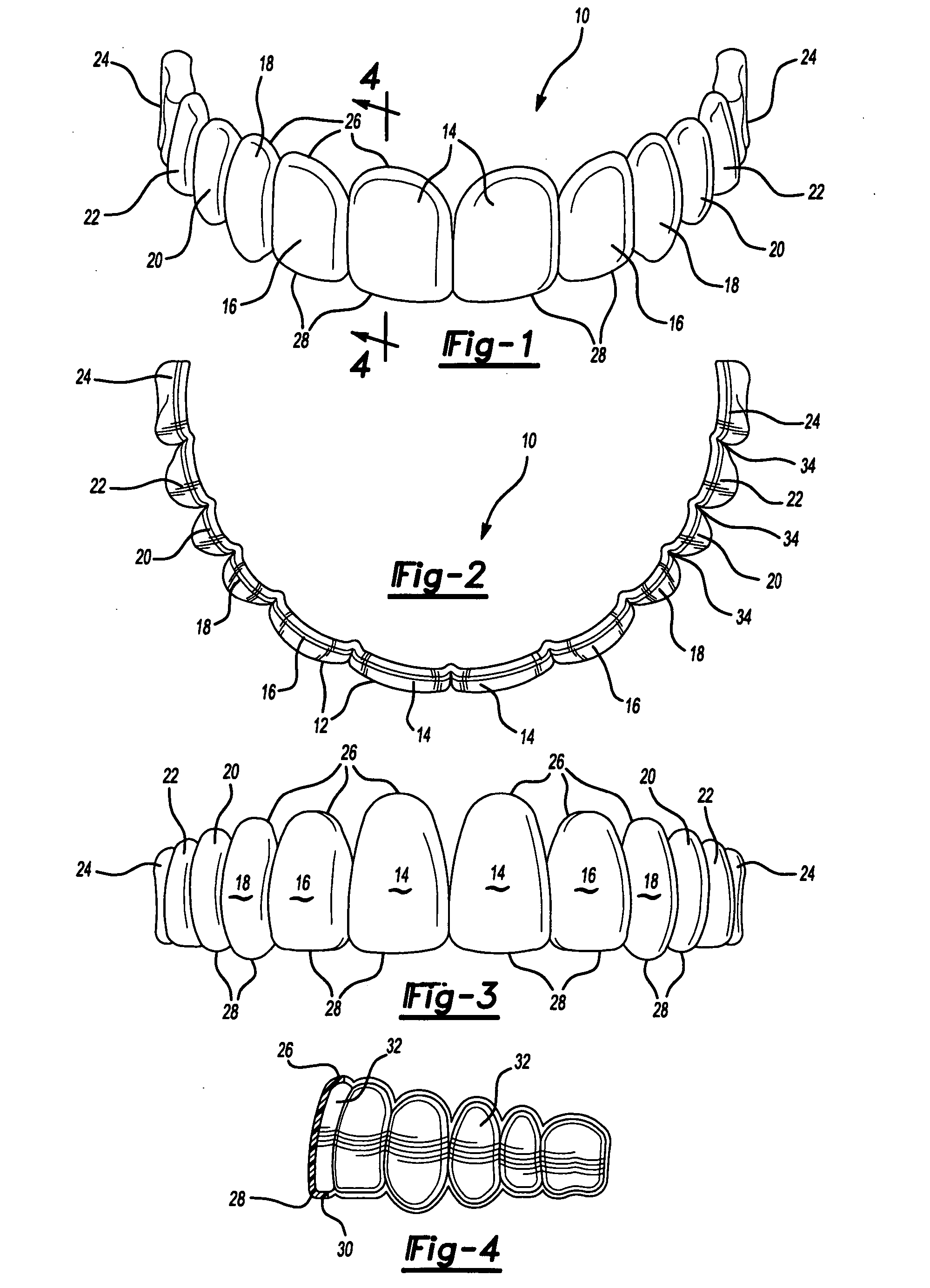

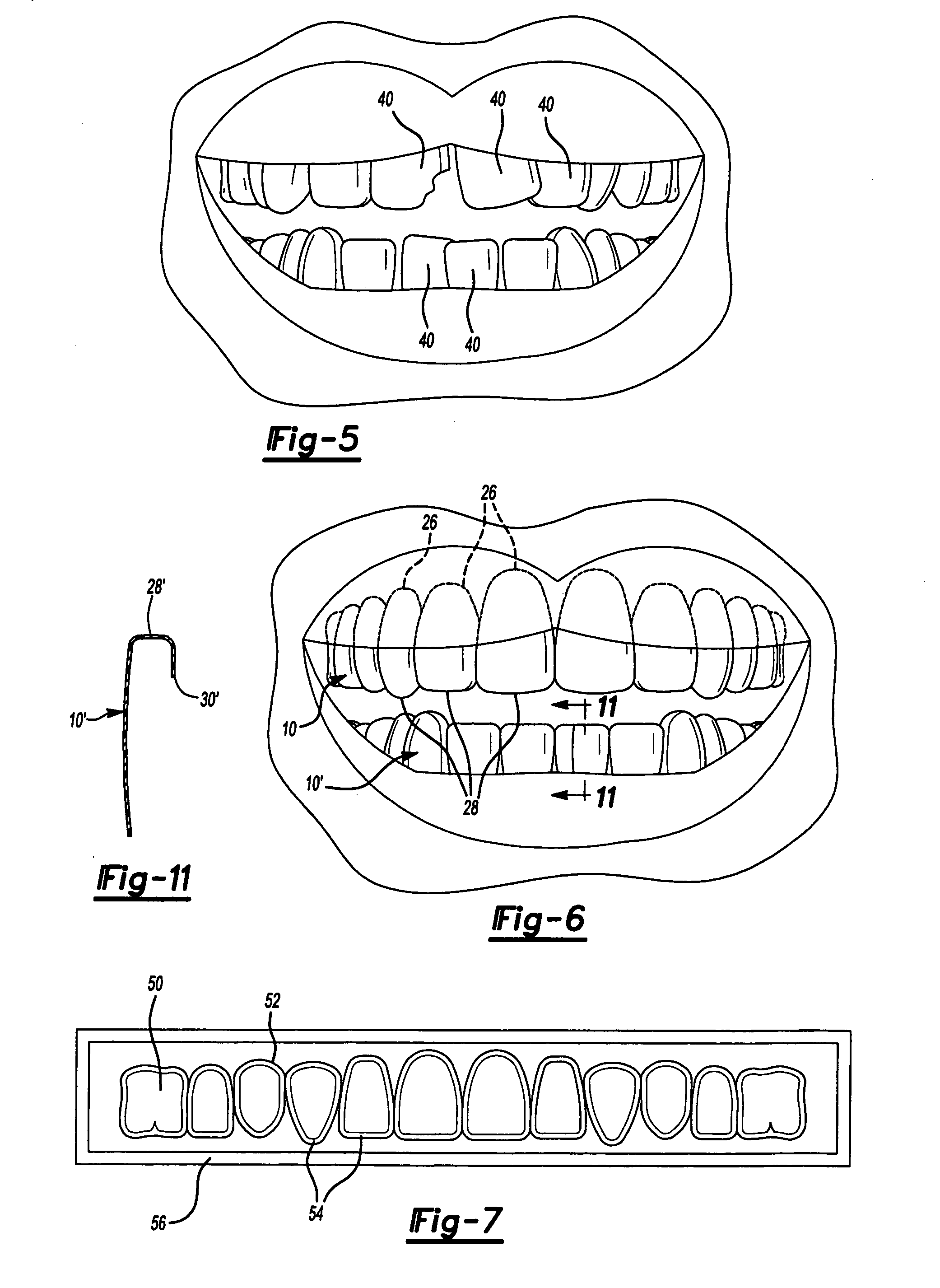

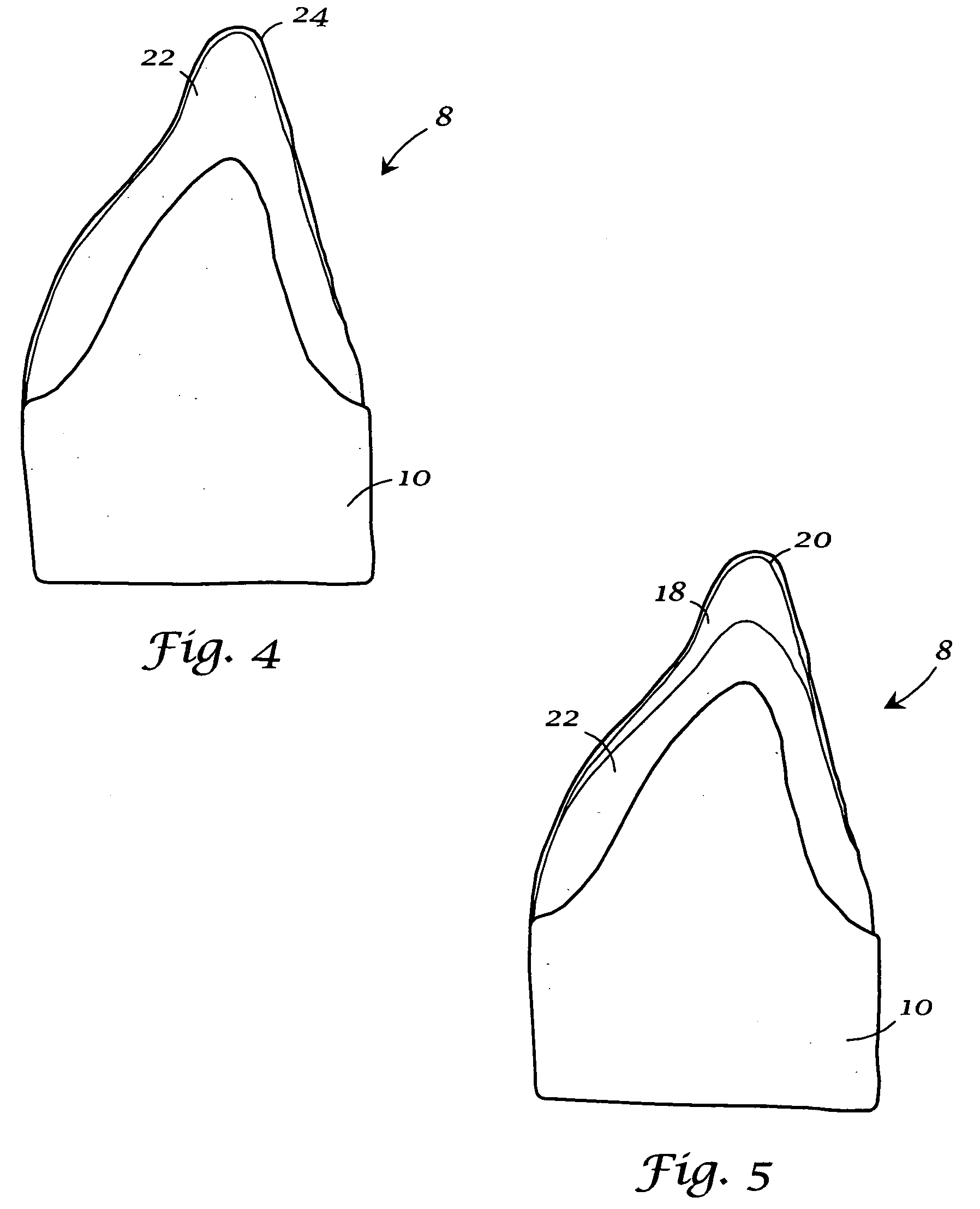

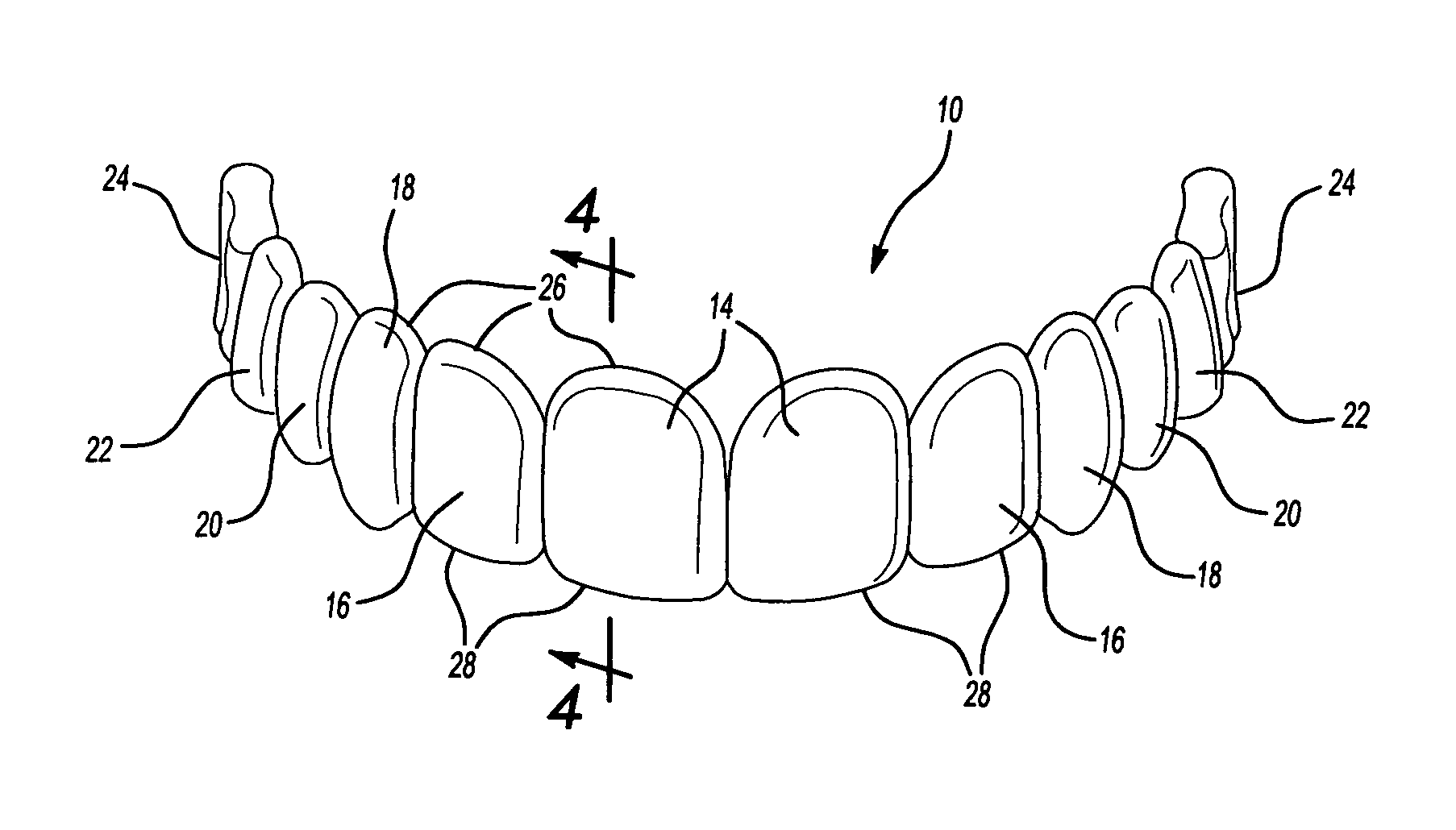

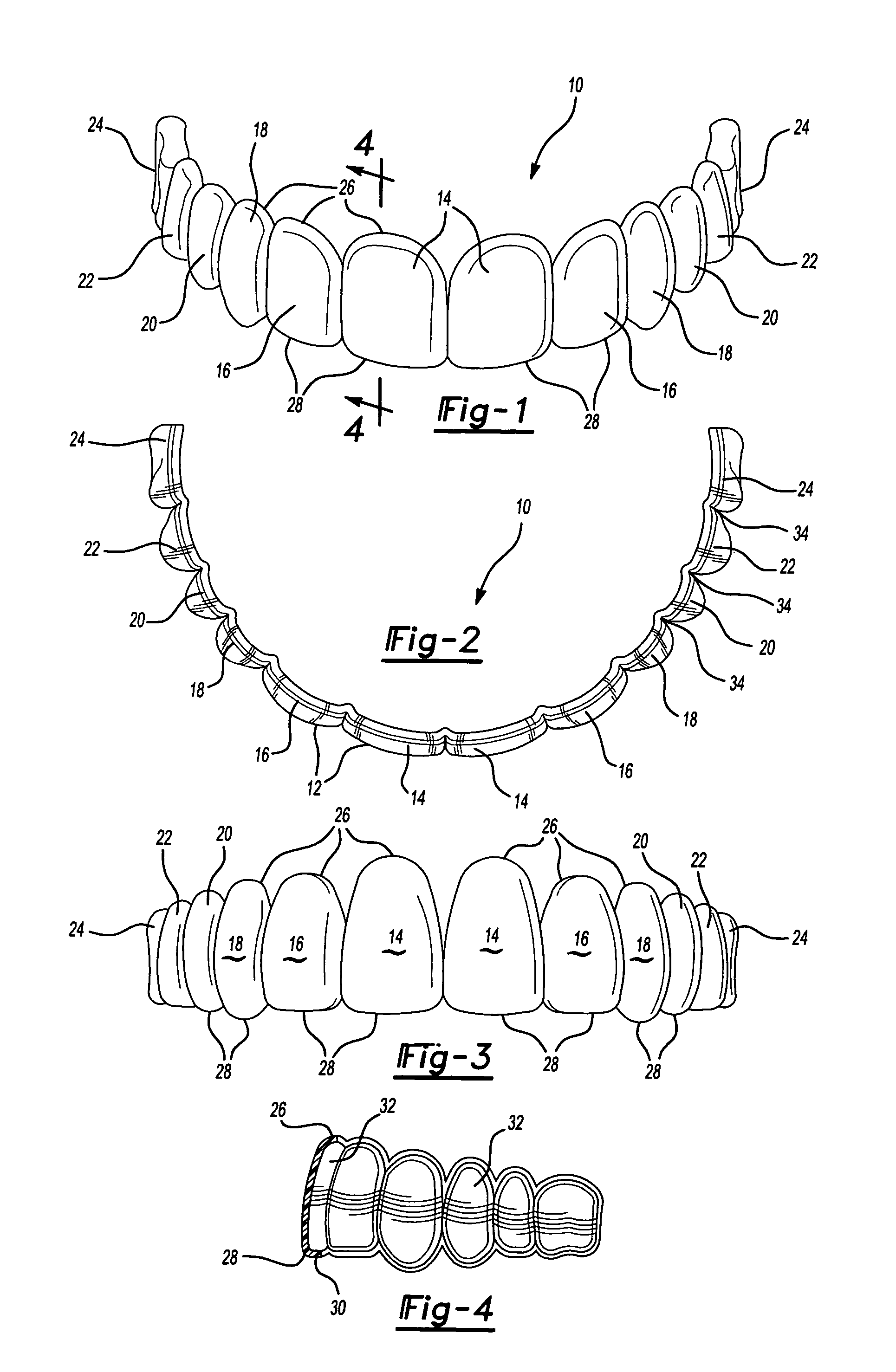

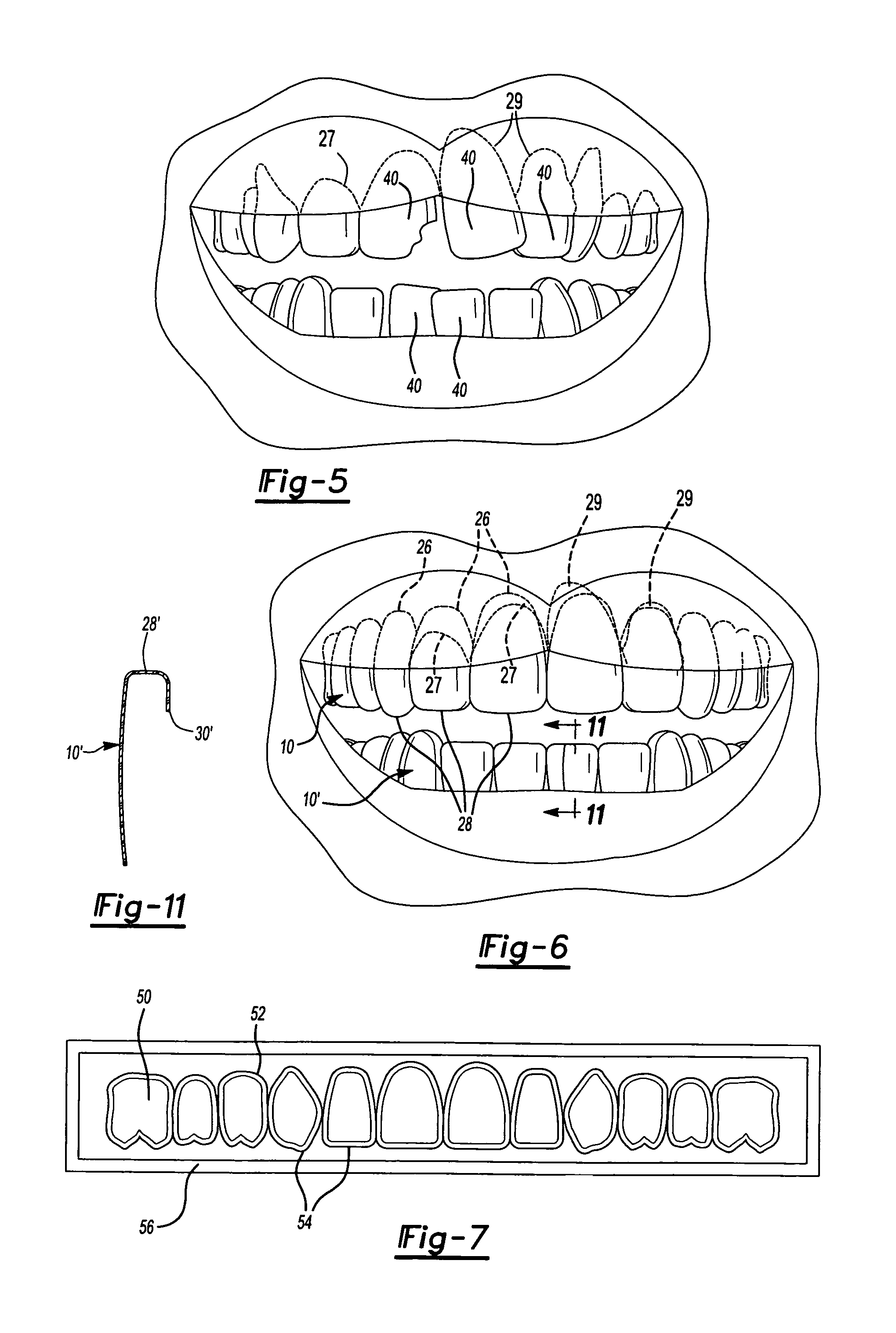

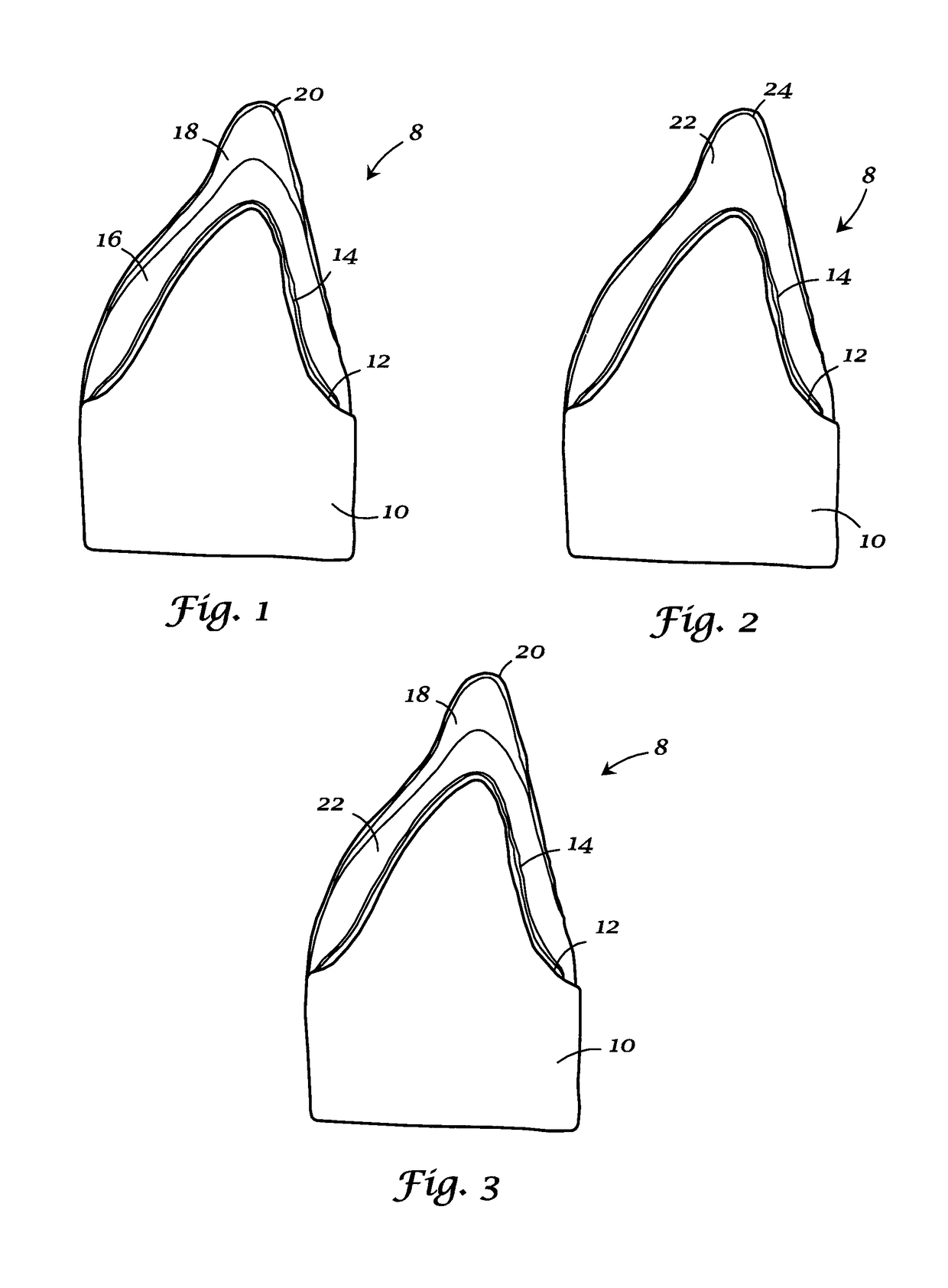

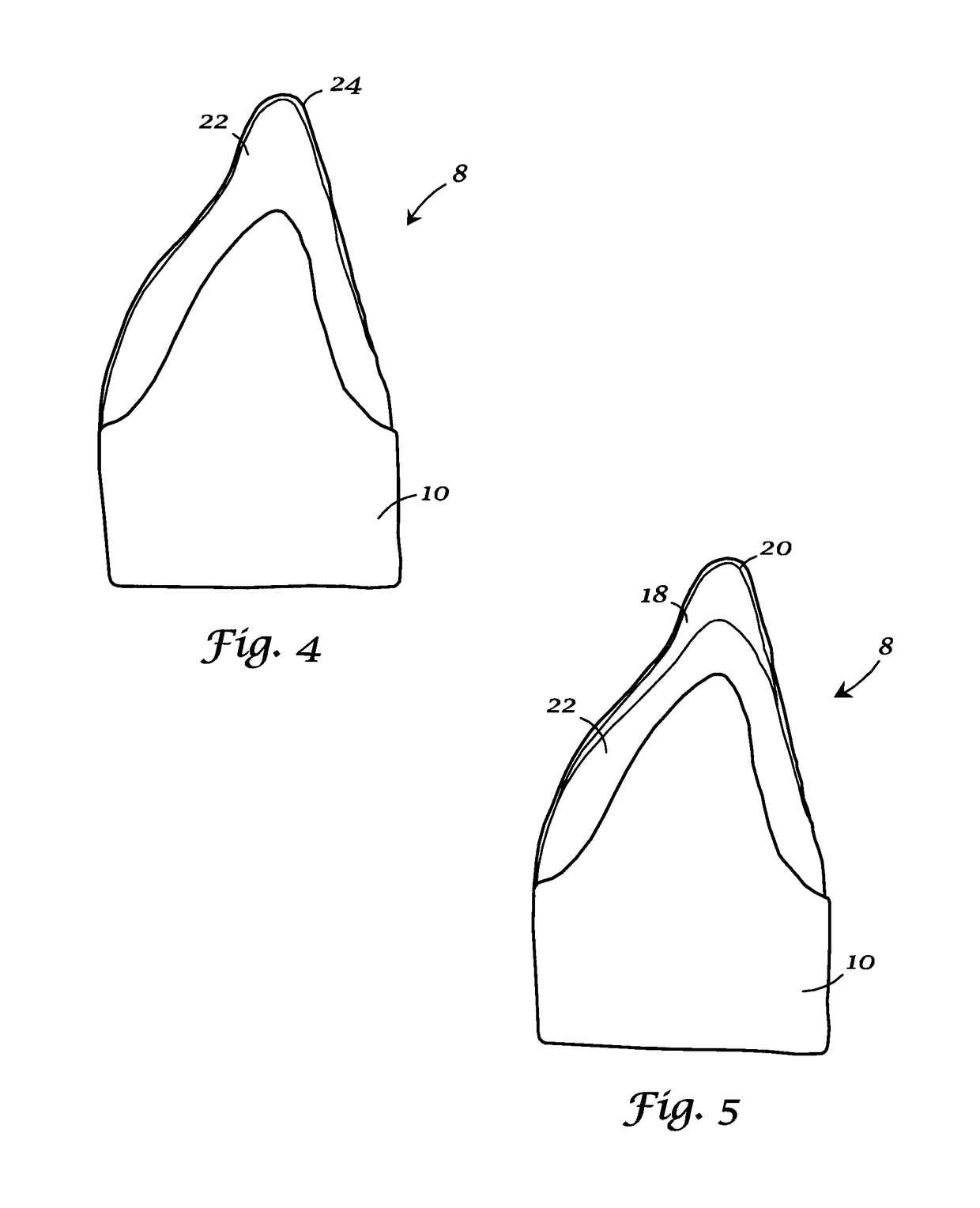

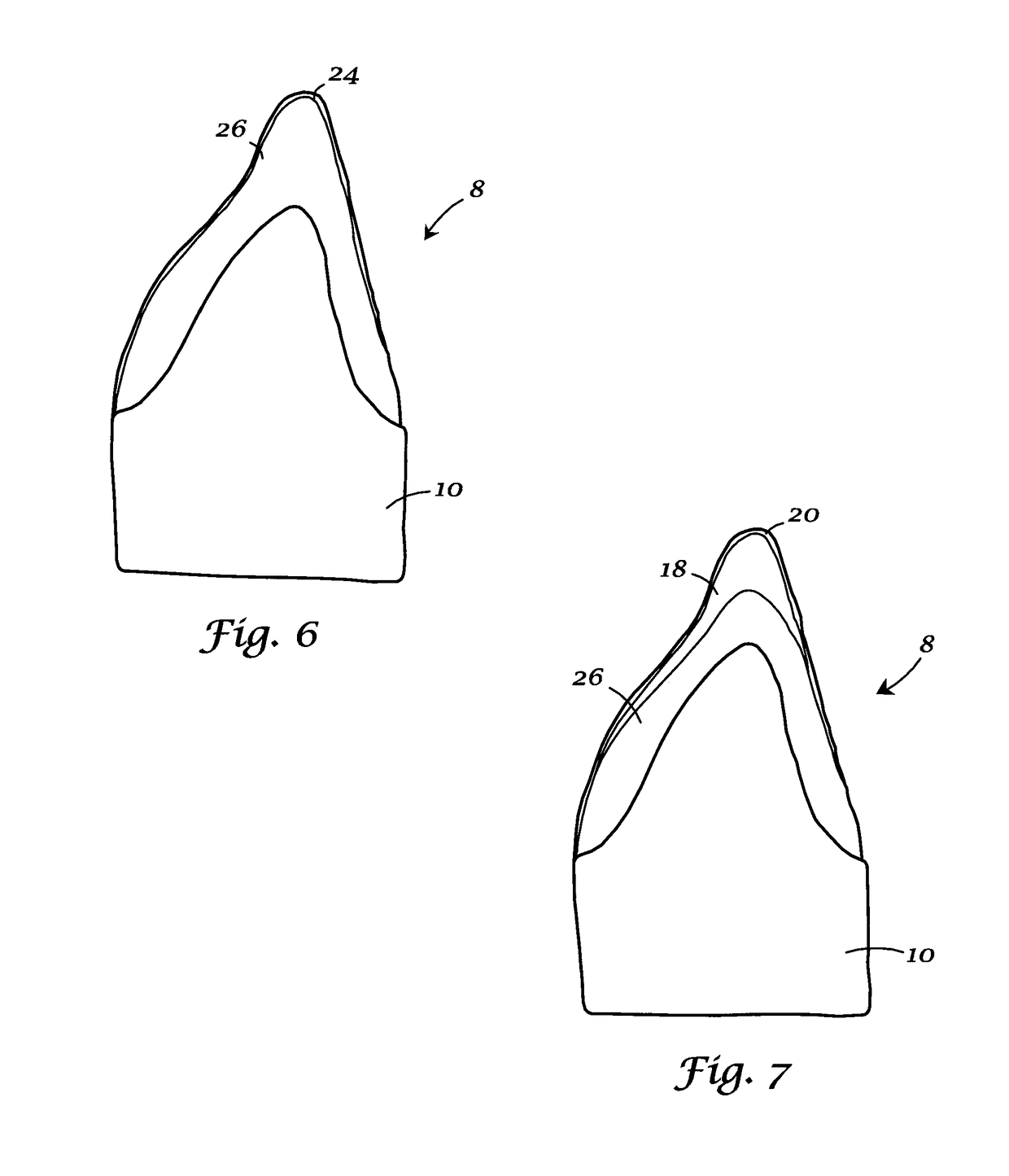

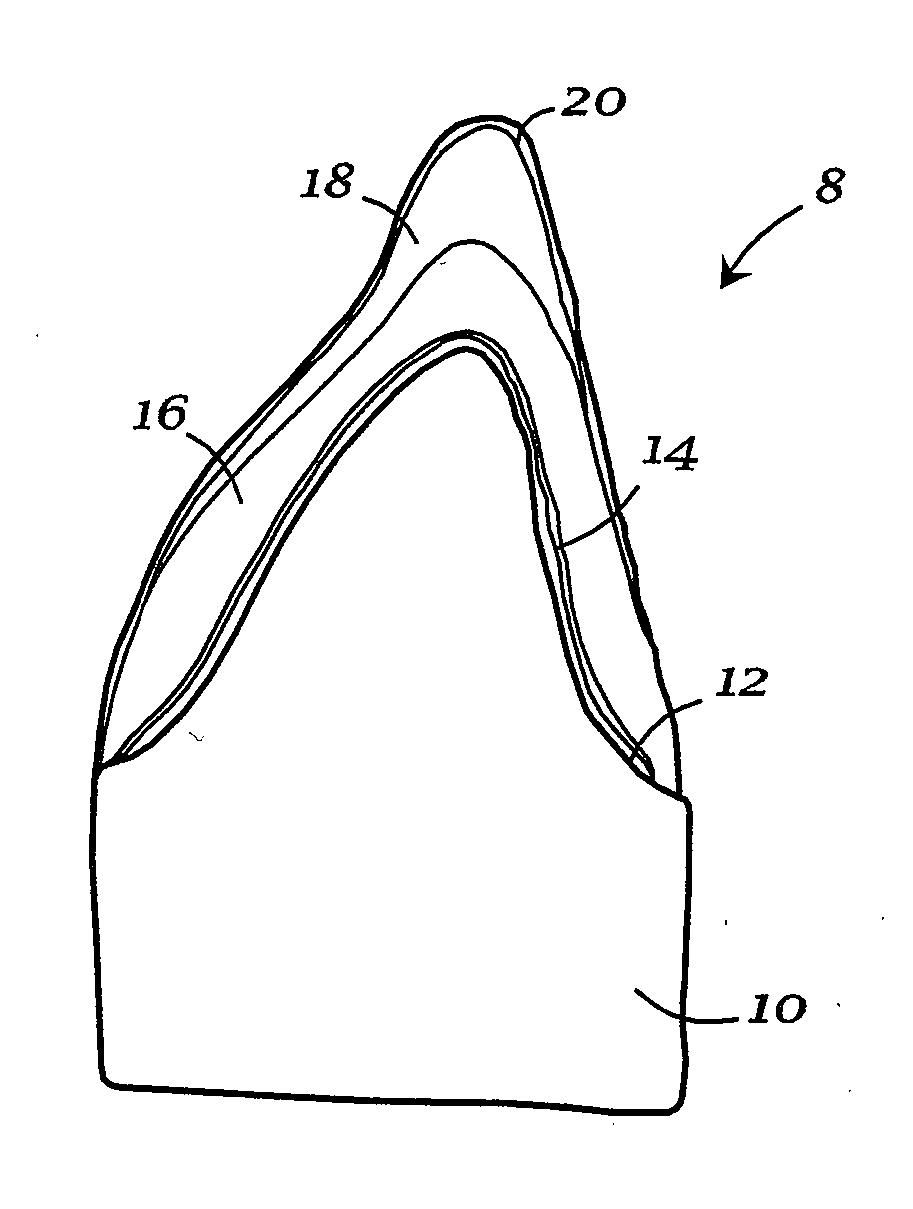

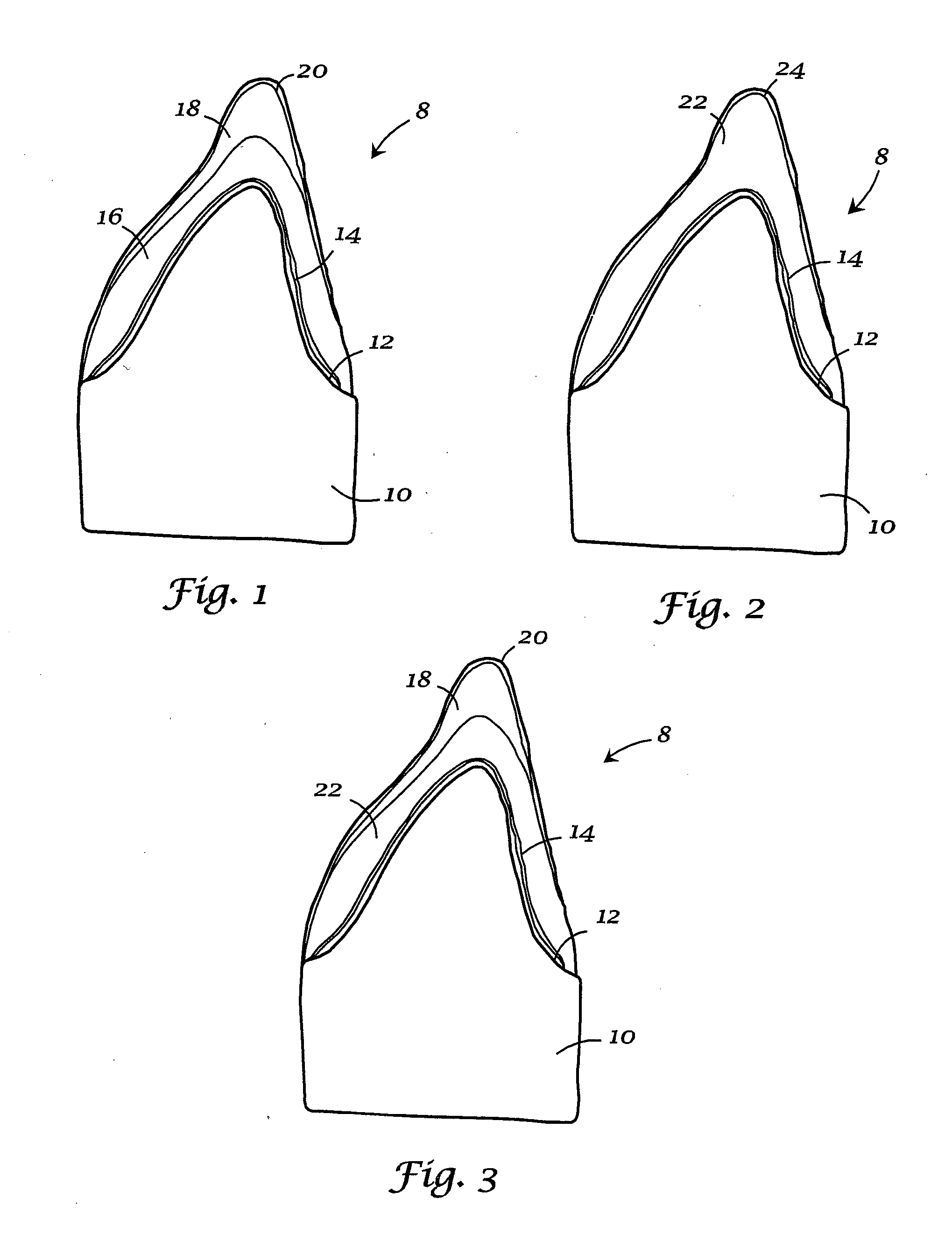

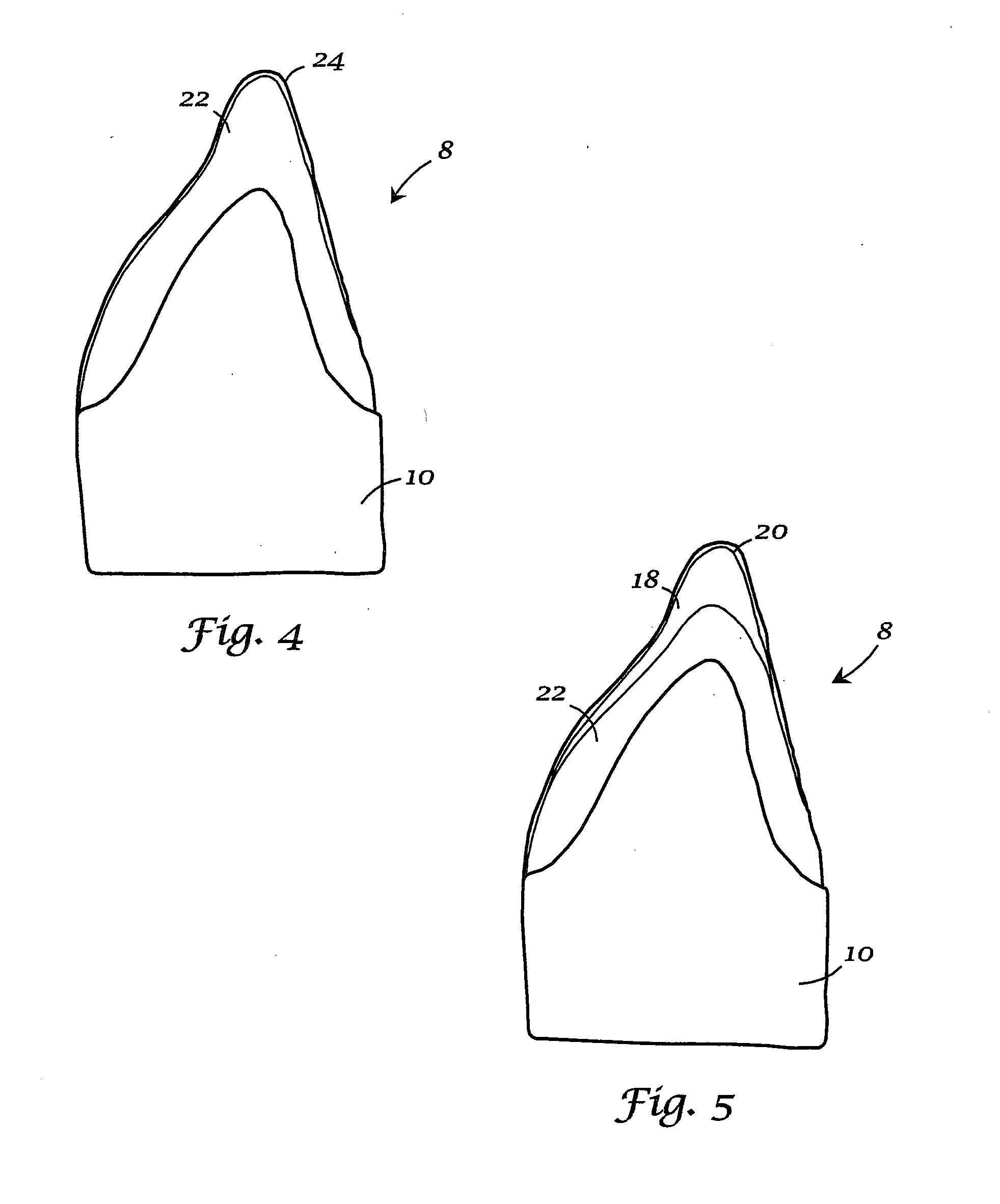

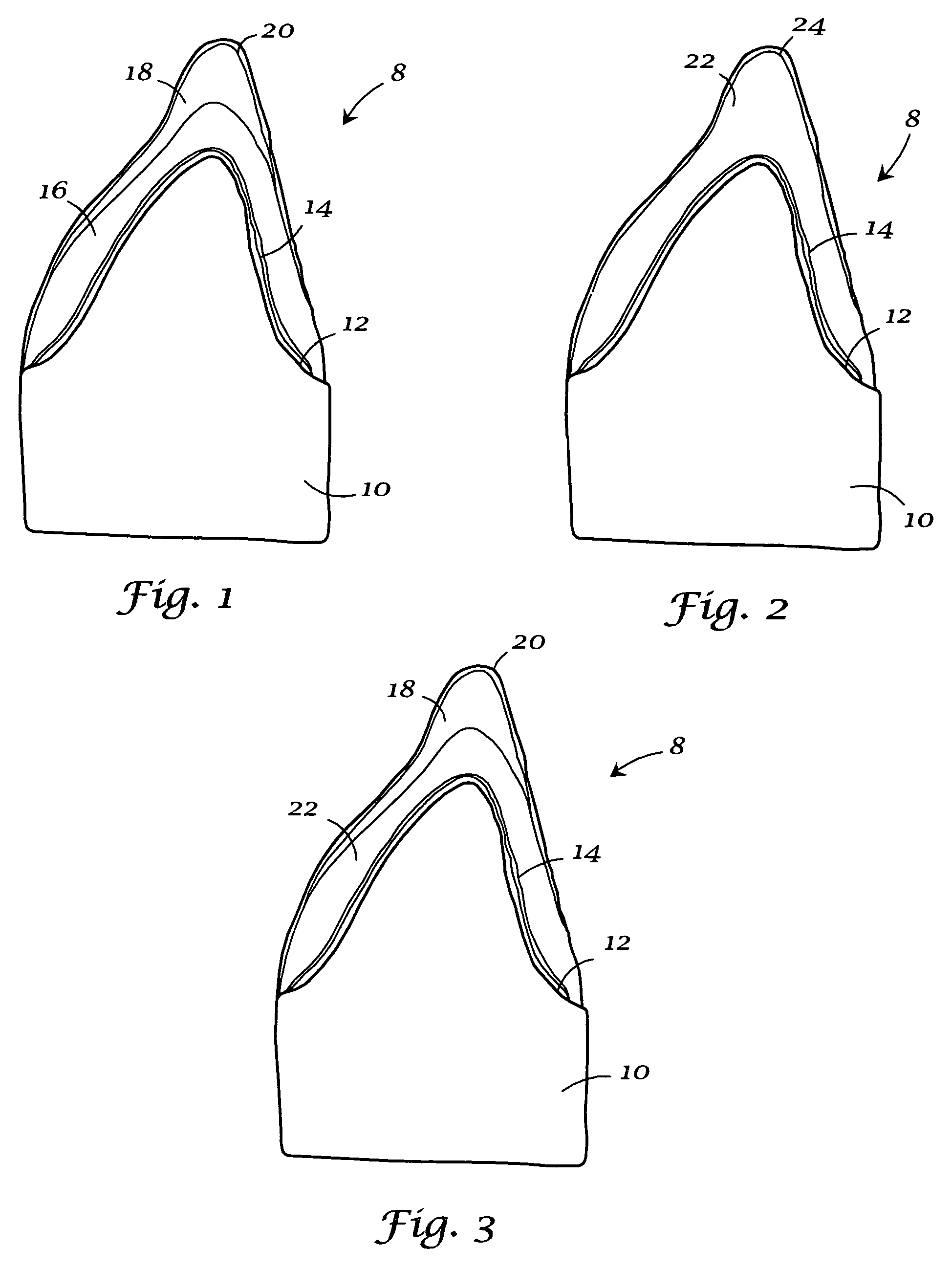

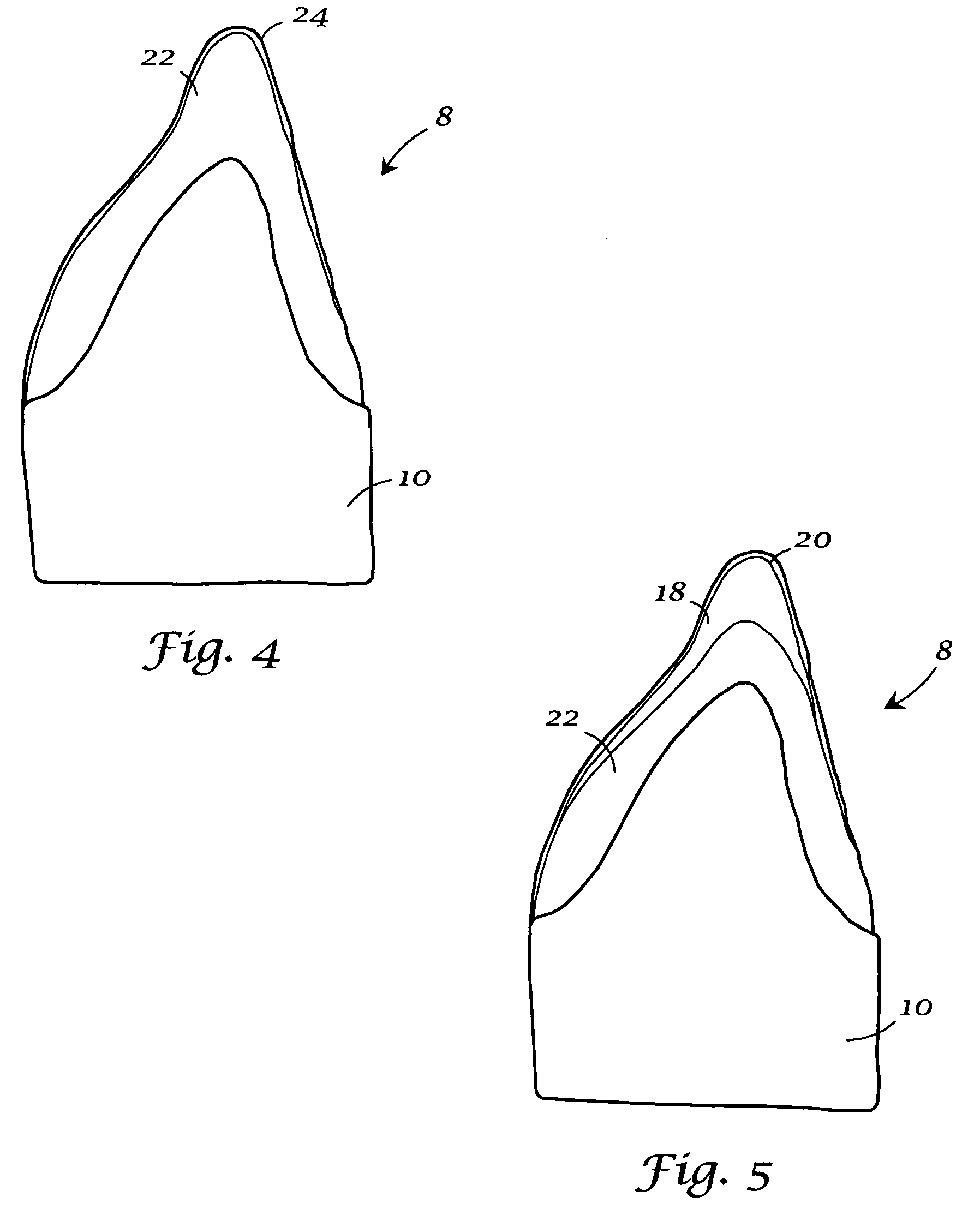

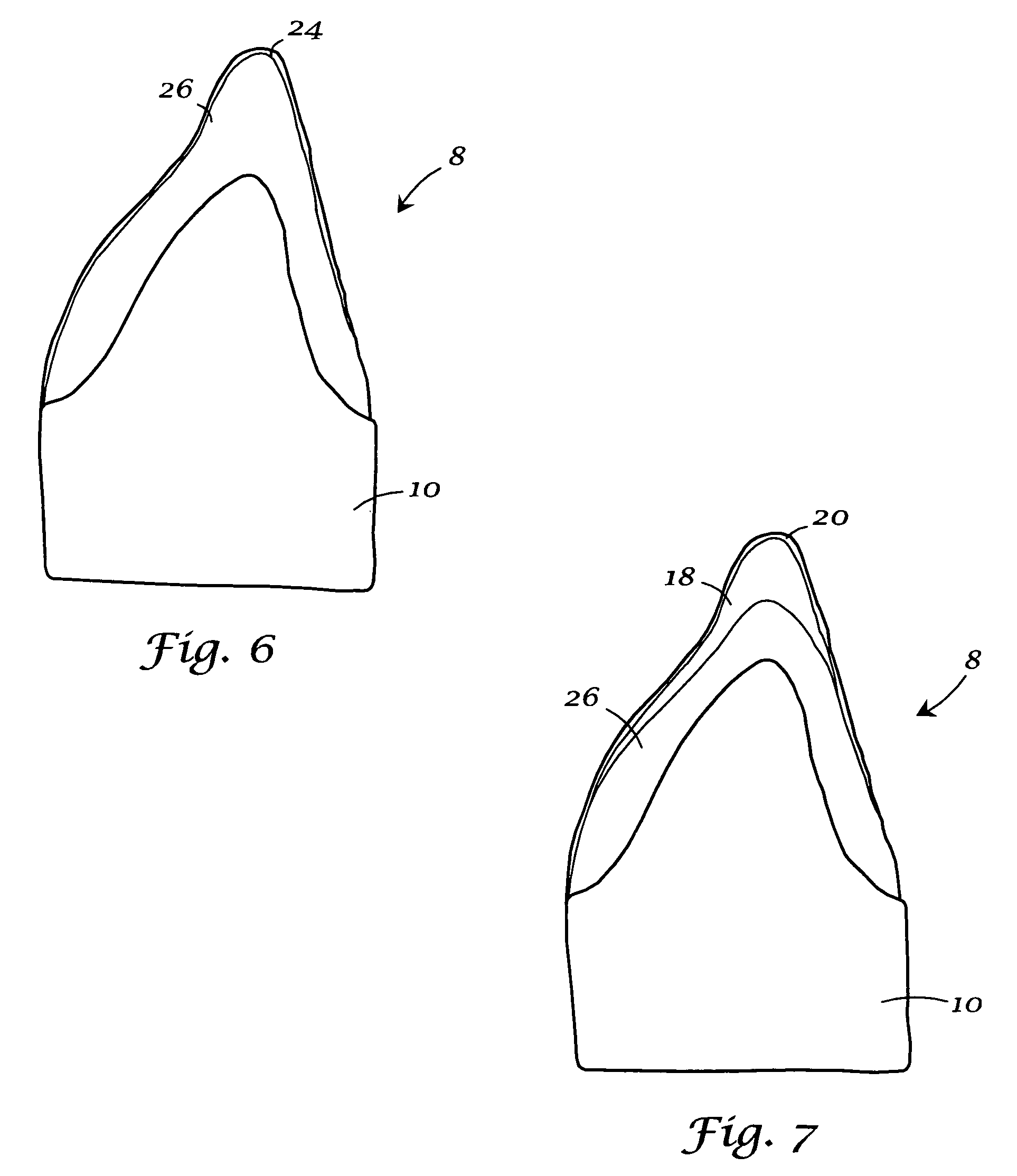

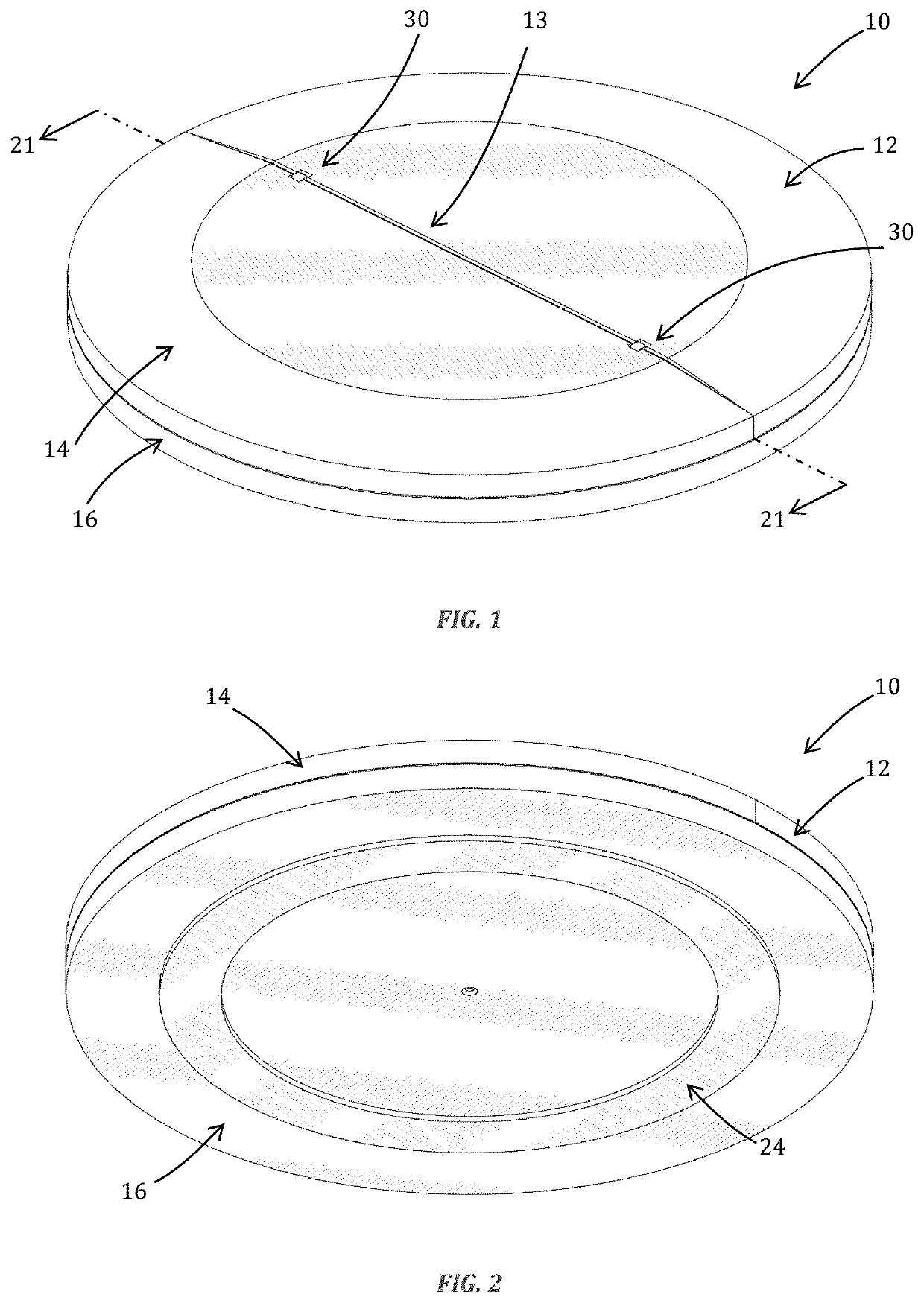

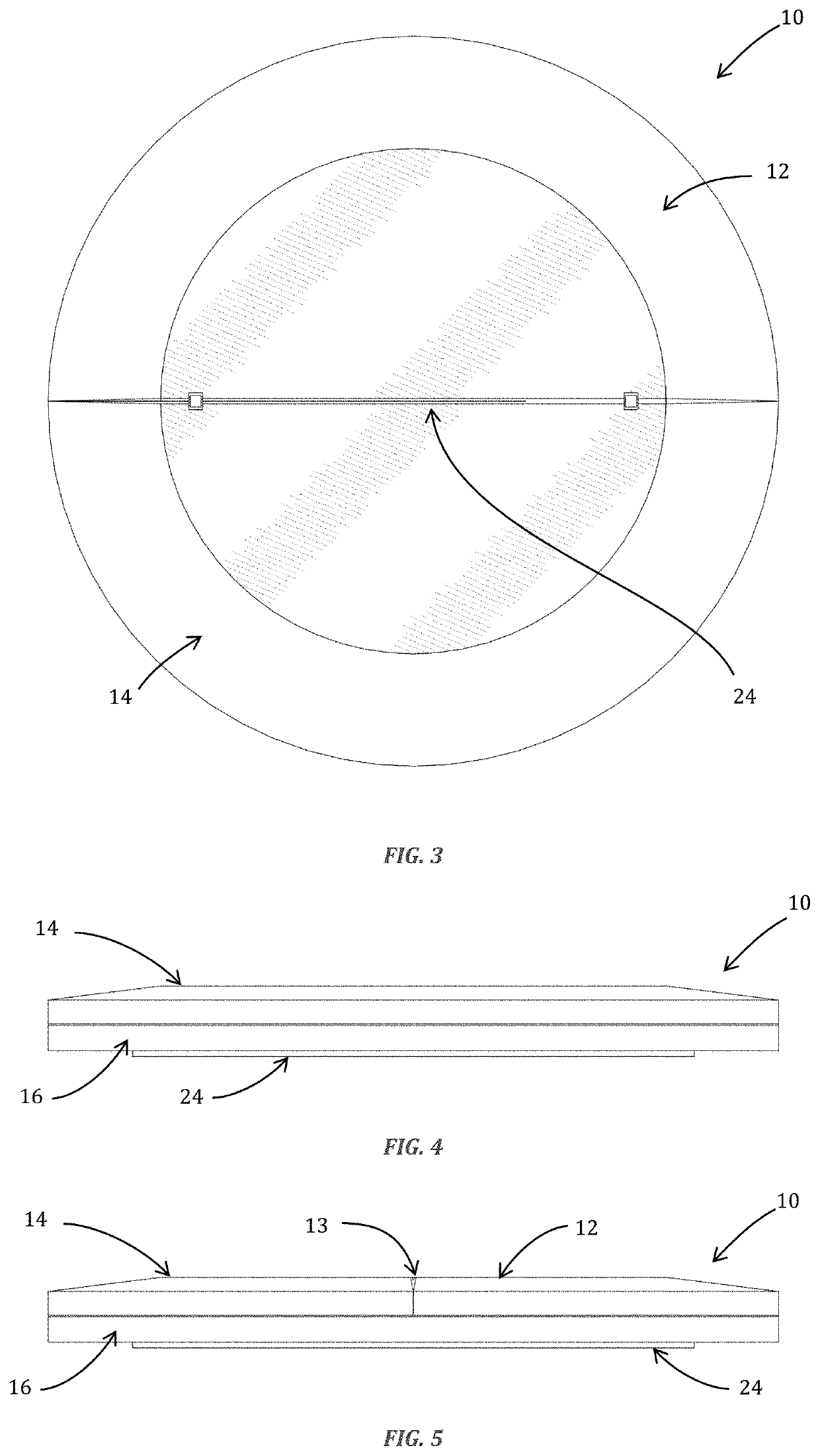

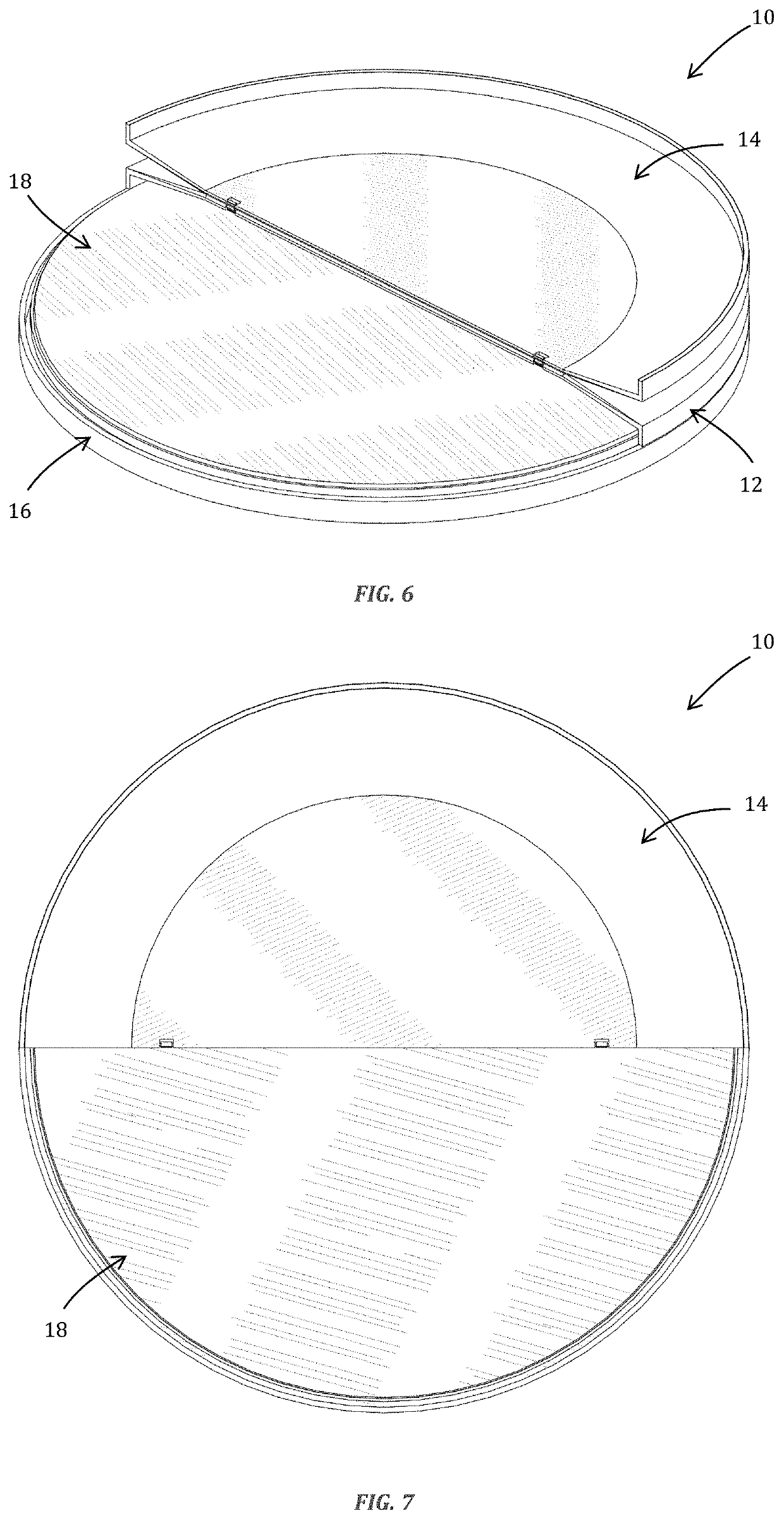

Dental template and method of visually demonstrating an overlay for a dental patient and setting the horizontal plane with an overlay

Owner:STONISCH MARY SUE

Dental template and method of visually demonstrating an overlay for a dental patient and setting the horizontal plane with an overlay

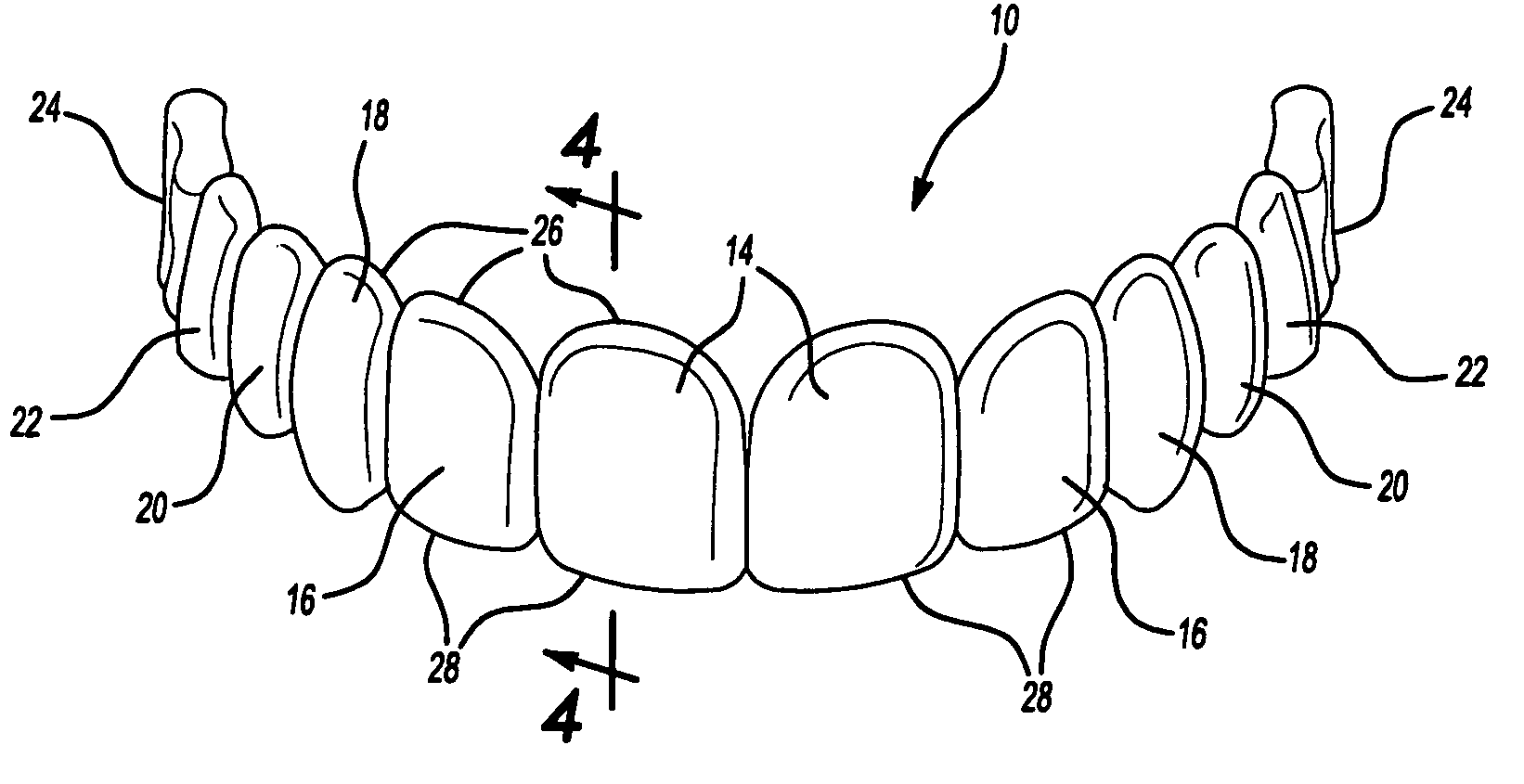

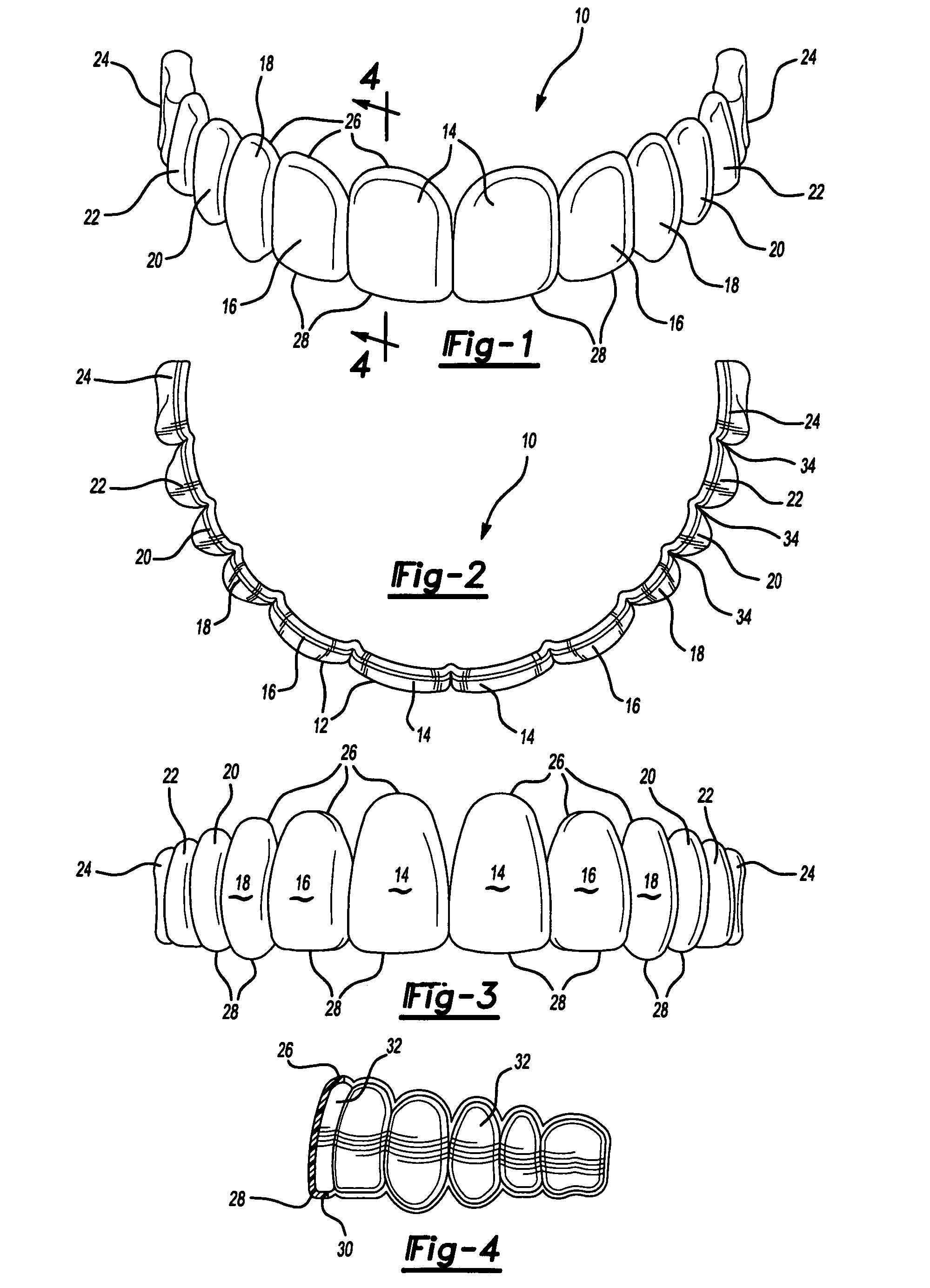

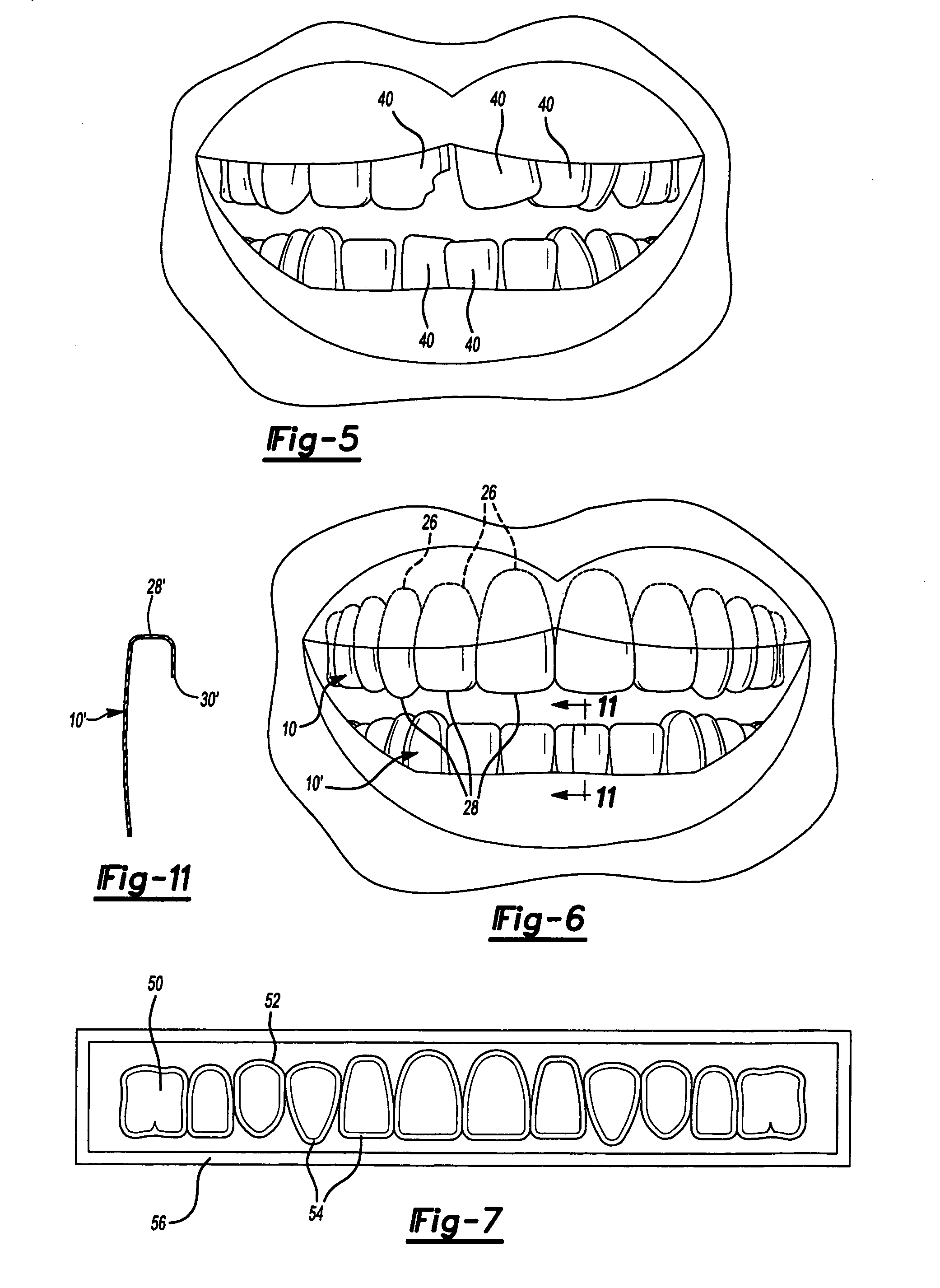

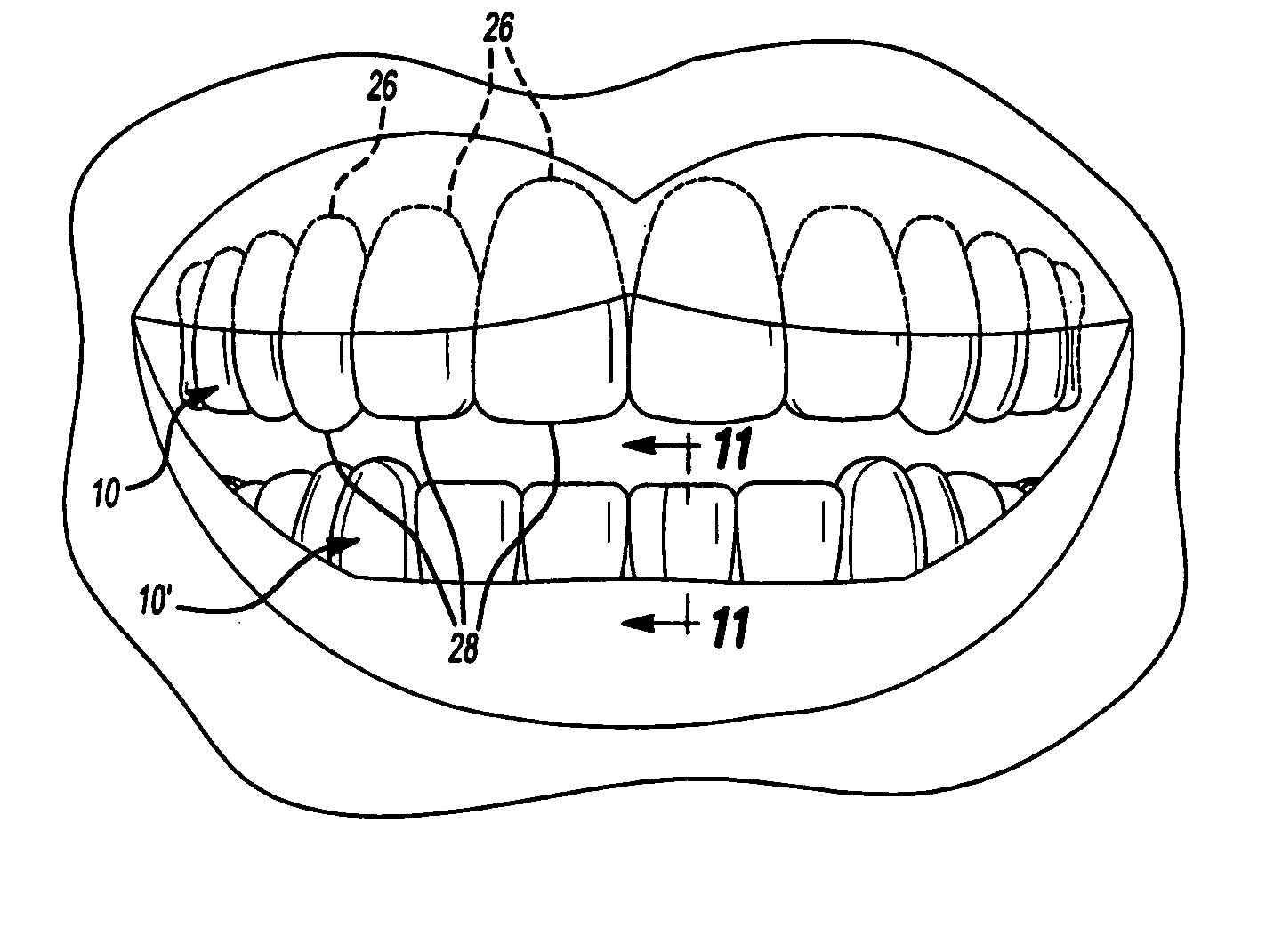

A dental prosthesis or template (10) simulates the front surfaces of a patient's teeth and is overlayed over a patient's natural teeth (40) to provide an indication of what a dental porcelain overlay may look like once applied to the patient's teeth. The dental template preferably is made from a flexible urethane or sanaprene material to allow the template to be applied against the person's natural teeth and temporarily adhere the template to his teeth provide for the visual demonstration of potential improvement to the patient's smile. The dental template (10) can be adhered to a set gel or registration paste to set the facial plane (75) at which the overlay should lie relative to the tooth plane (73) of the natural teeth (40) to establish a final restoration with an ideal and naturally appearing aesthetic result as it relates to horizontal facial planes and facial appearances.

Owner:STONISCH MARY SUE

Integrated porcelain system for a dental prosthesis

An integrated dental porcelain system for making dental prostheses and restorations is provided. The system includes three universal major components: a) opaque porcelain composition; b) pressable dentin ingot; and c) veneering porcelain composition that can be used interchangeably for making restorations. Techniques for making the prostheses and restorations include porcelain fused-to-metal (PFM), press-to-metal (PTM), and either pressed and / or machined all-ceramic methods. The system uses both a hand-layering of veneering porcelain (PFM technique) and a hot-pressing process (PTM and all-ceramic technique) to fabricate the prostheses and restorations.

Owner:DENTSPLY SIRONA INC

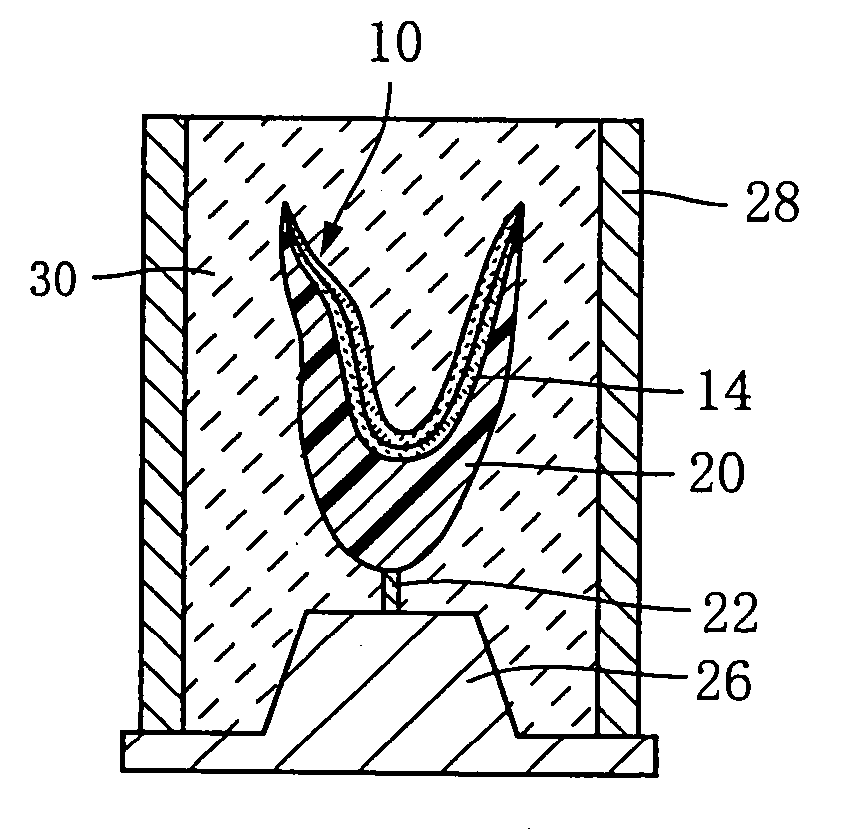

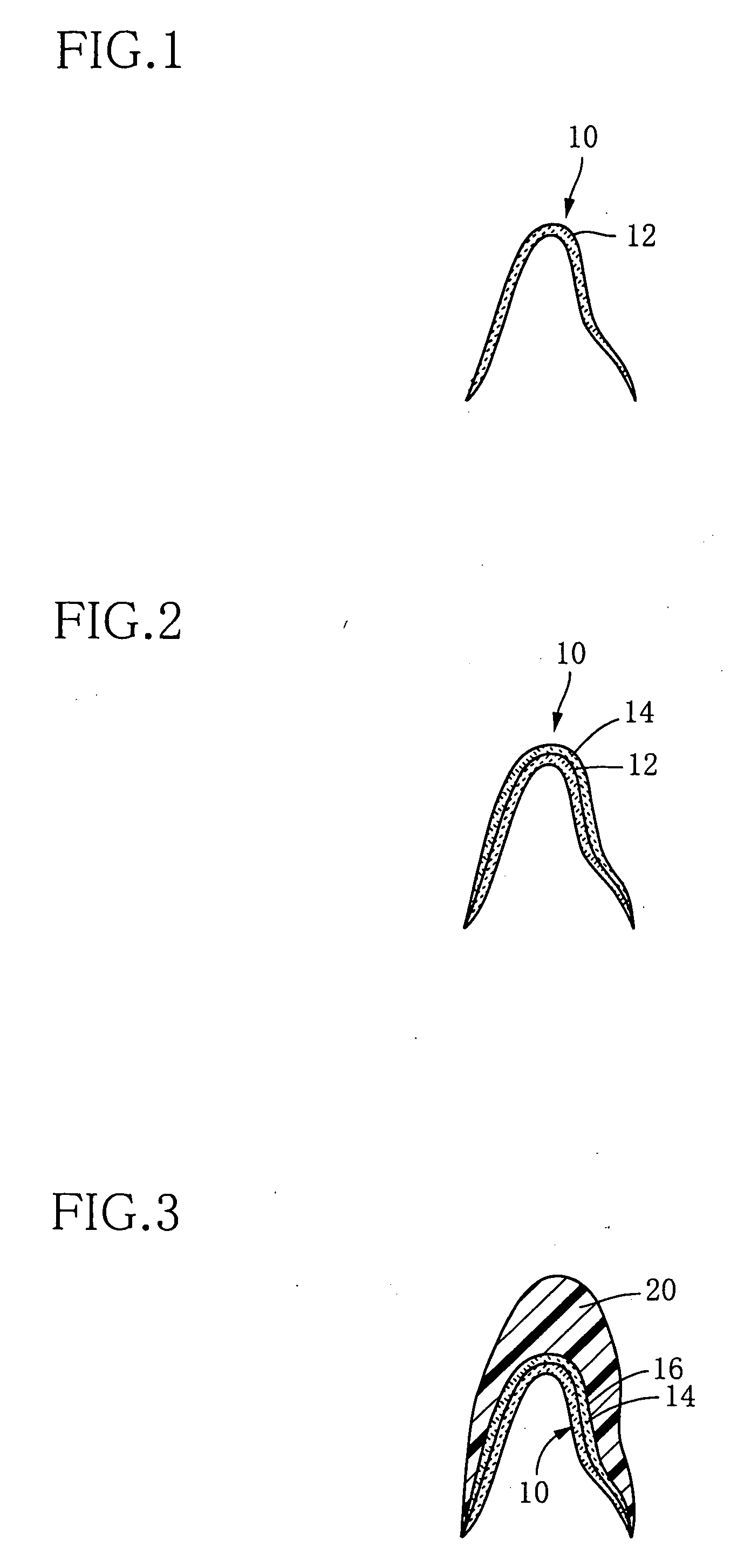

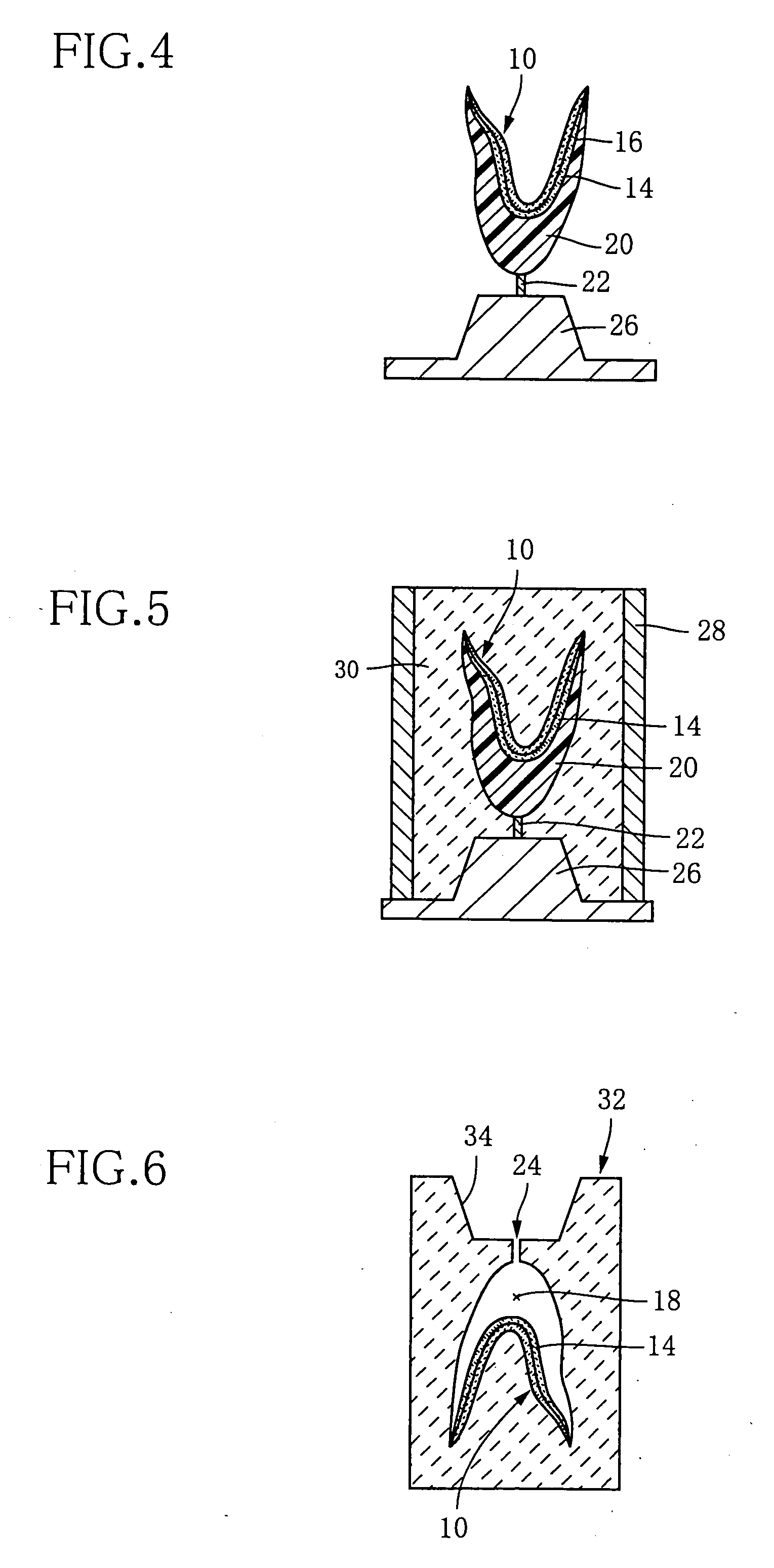

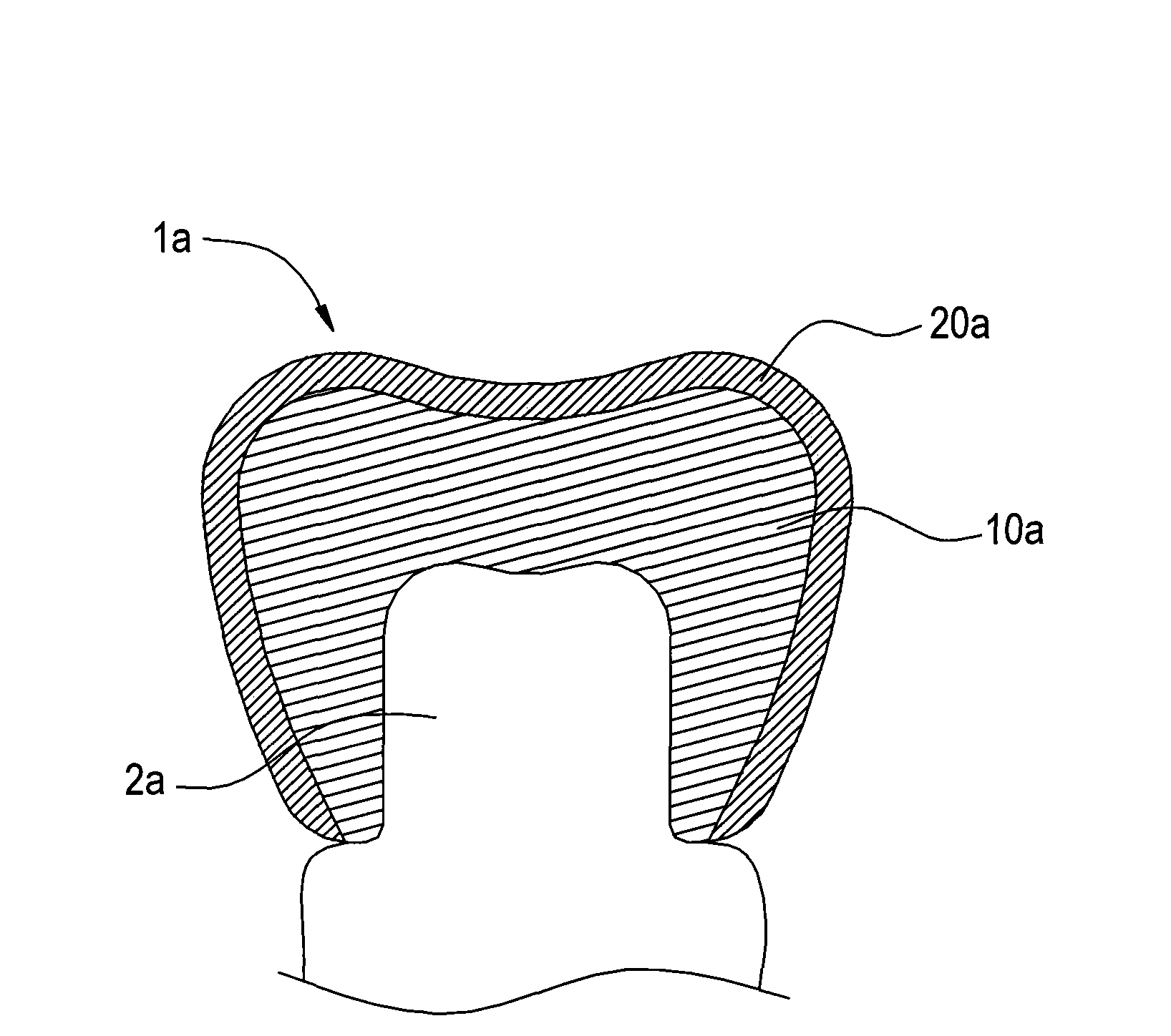

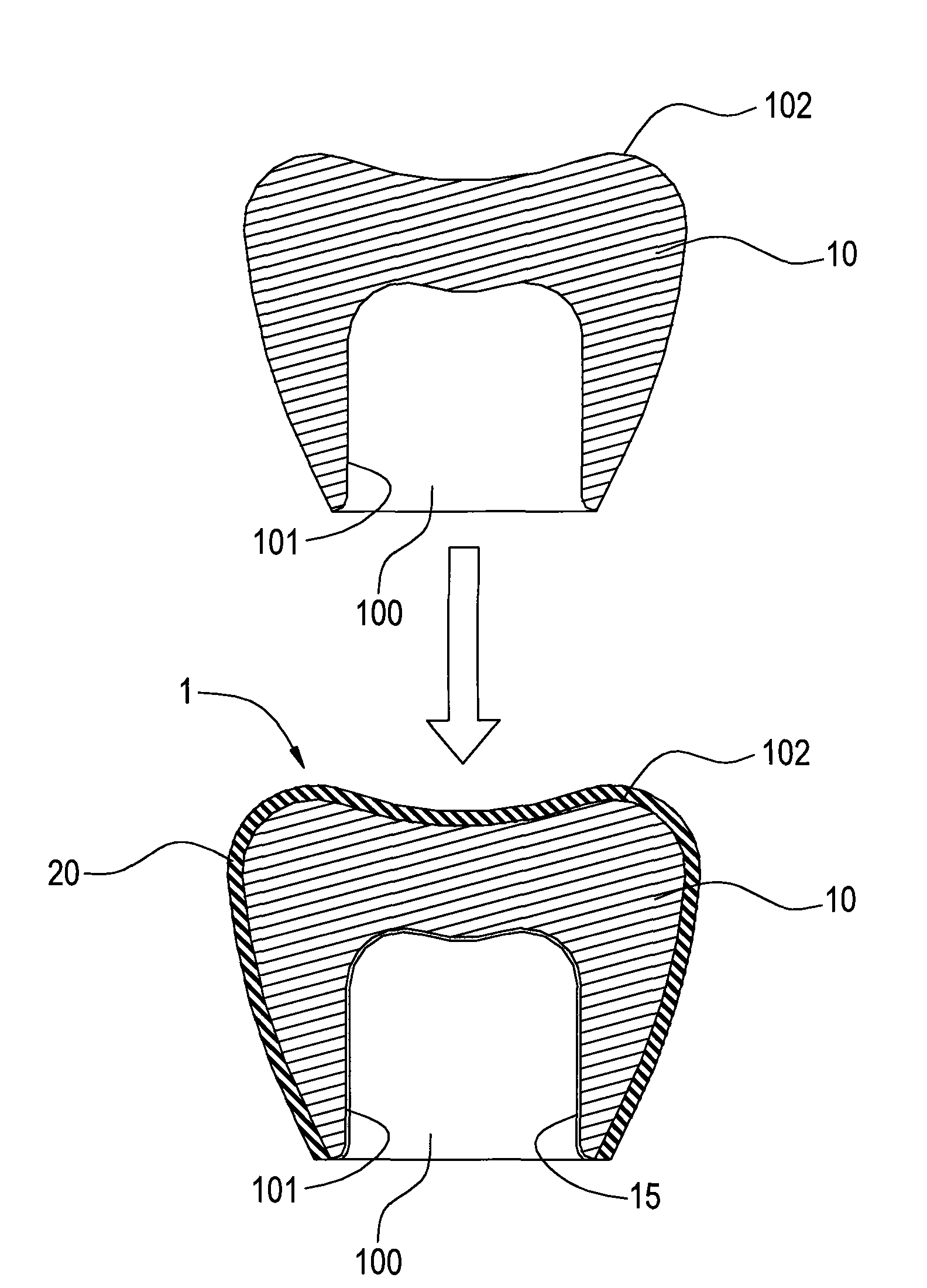

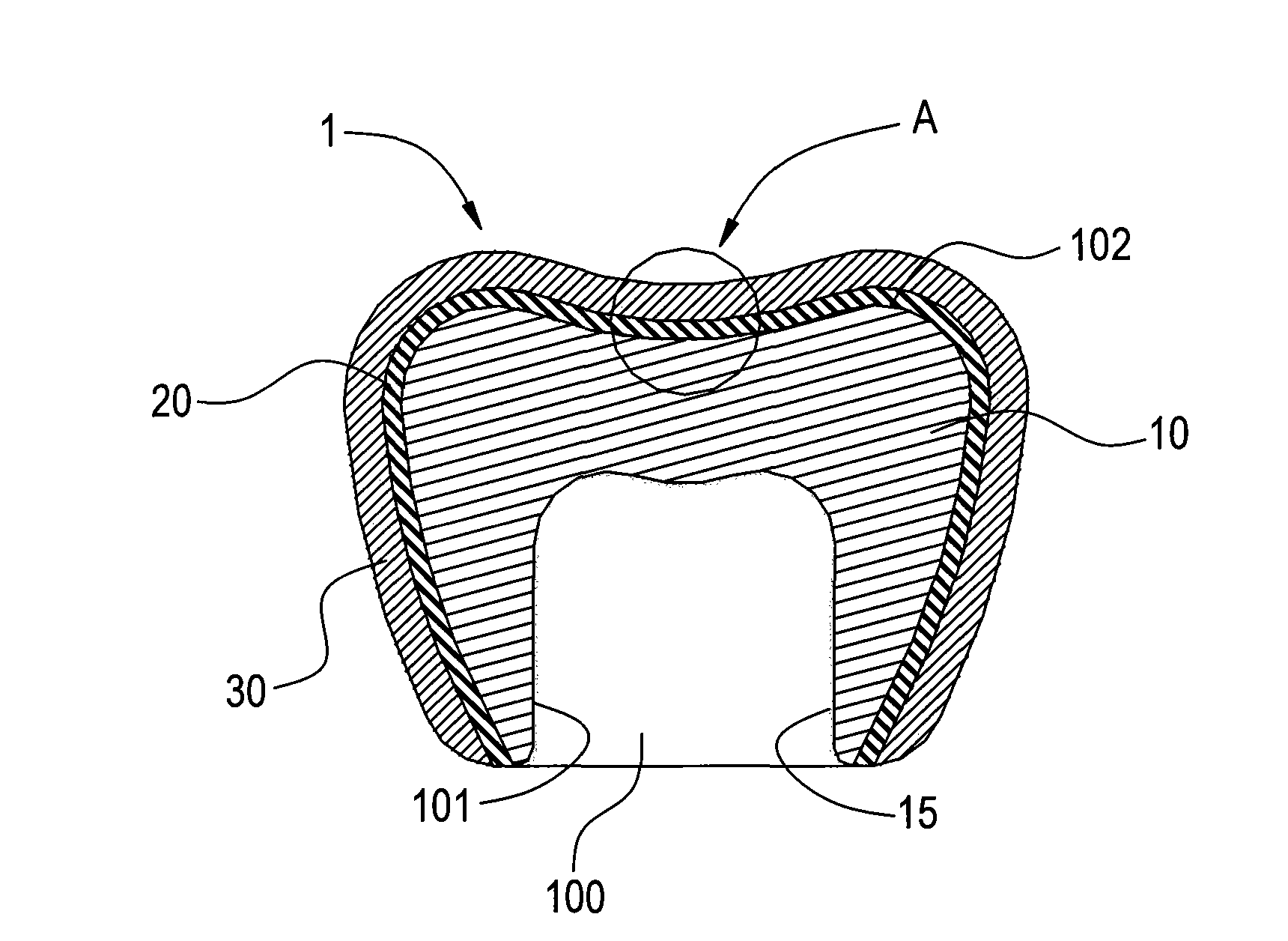

Process for producing dental prosthesis and kit for use for therein

InactiveUS20060261503A1Prevent movementImprove liquidityOther chemical processesPharmaceutical containersDenturesDental porcelain material

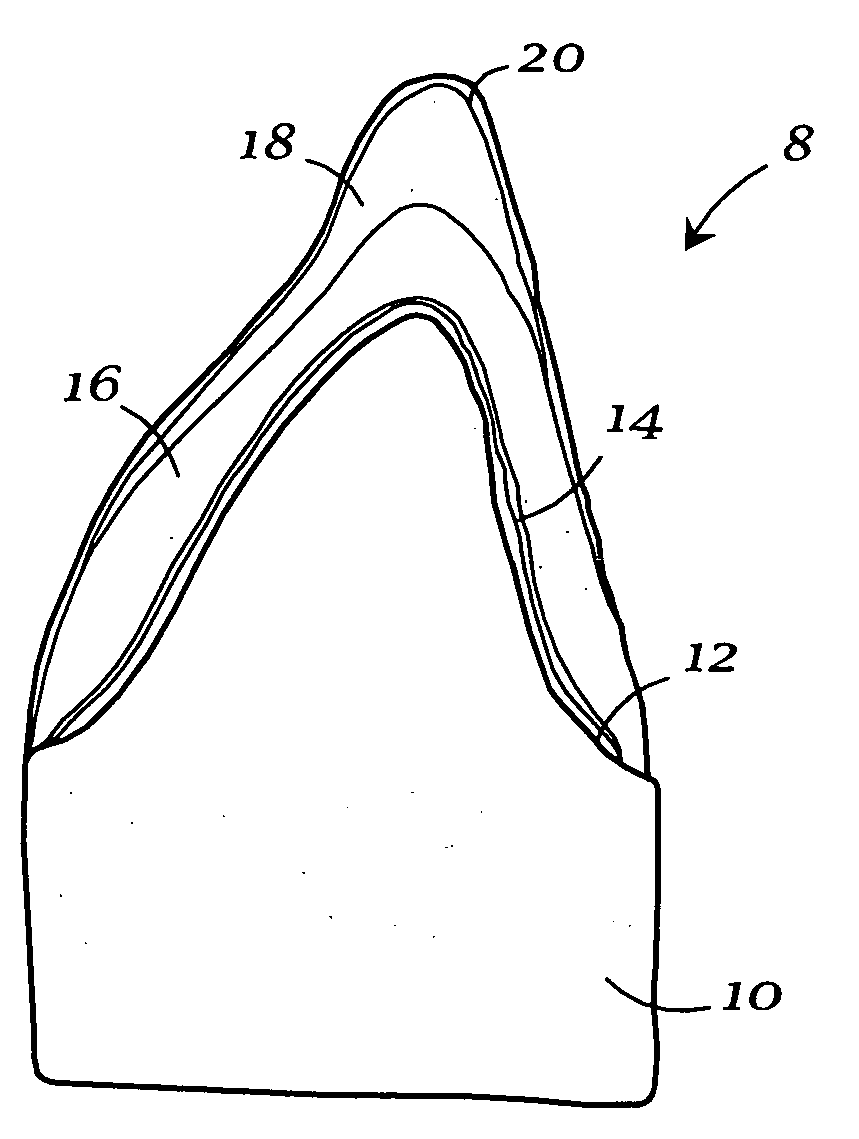

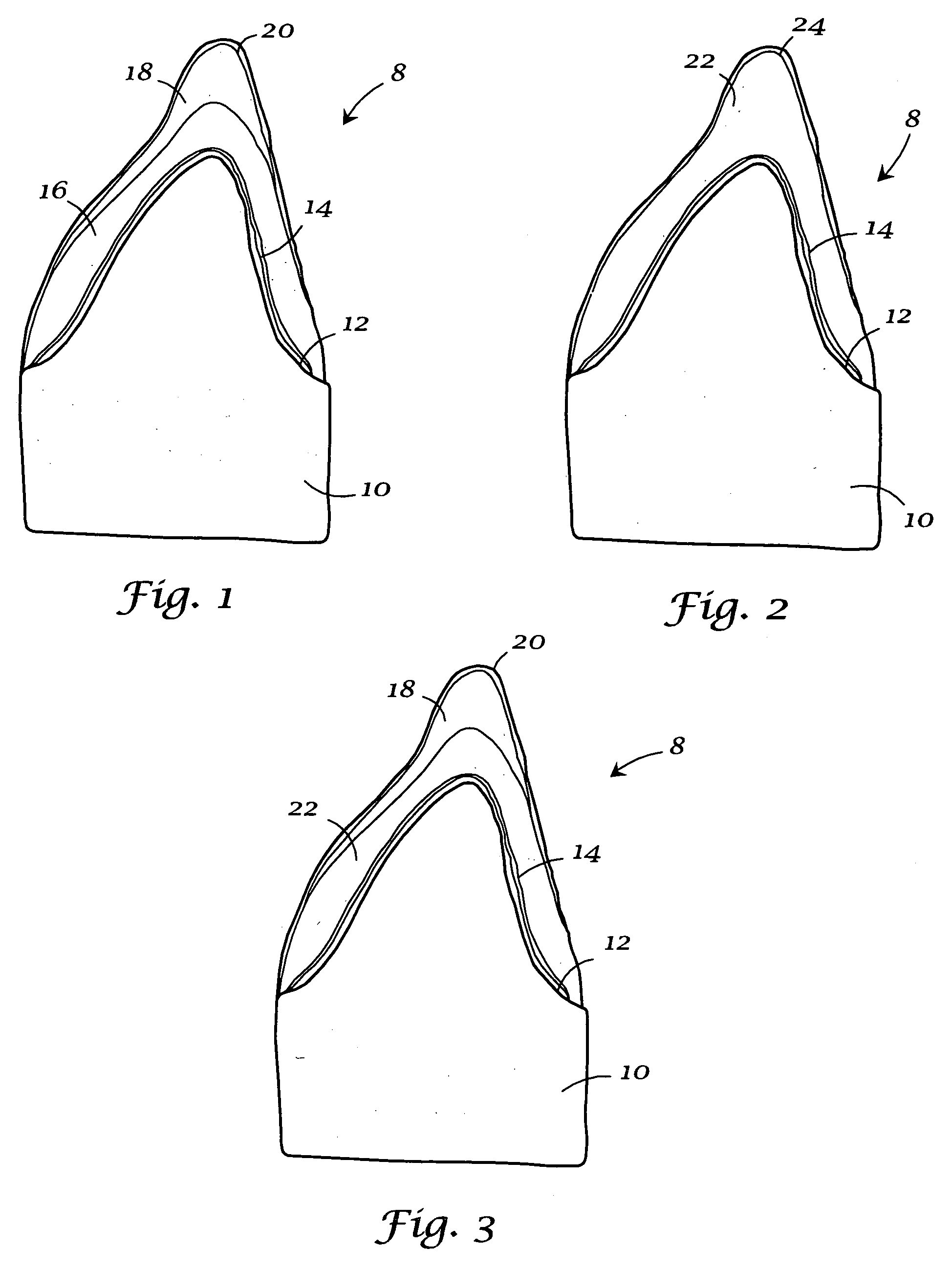

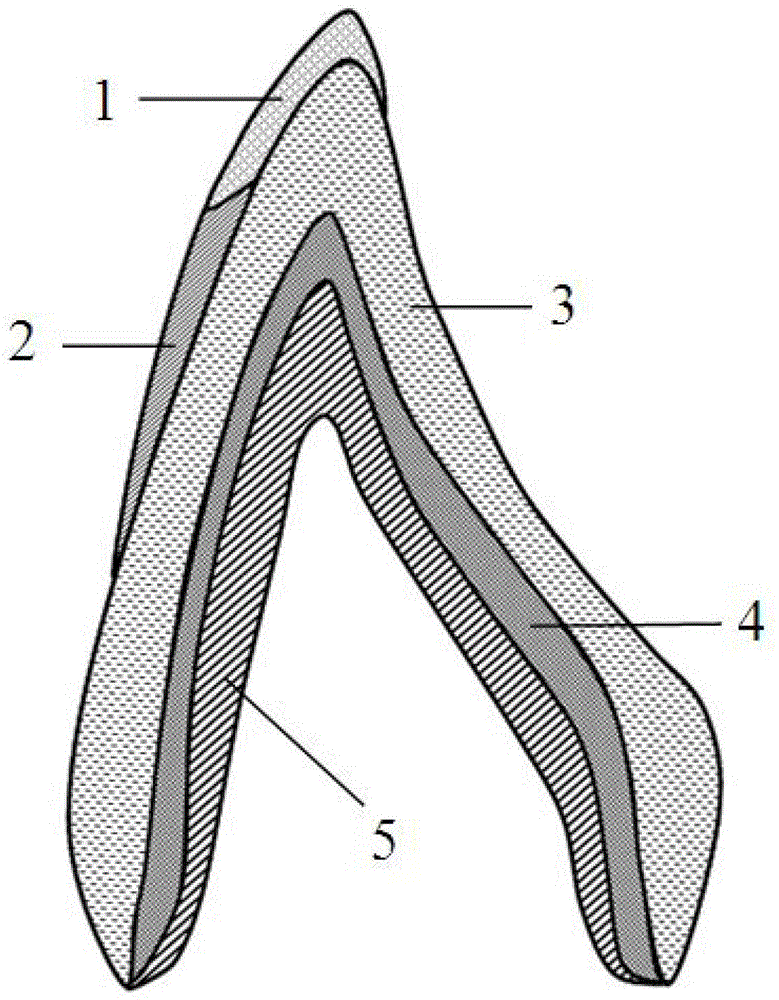

A method of manufacturing a dental prosthesis, including: (a) a step of preparing a substrate of the dental prosthesis that is constituted by a dental molding material; (b) a step of forming a back coating layer on at least a part of a surface of the substrate, by using a first porcelain that is constituted principally by ceramic; (c) a step of forming a casting mold such that the substrate is disposed in the casting mold and such that a void is provided on a surface of the back coating layer; and (d) a step of forming a cast coating layer on at least a part of a surface of the back coating layer, by pouring a second porcelain into the void at a casting temperature. The second porcelain is constituted principally by ceramic whose composition is different from that of the ceramic of the first porcelain that viscosity of the second porcelain at the casting temperature is lower than that of the first porcelain. Also disclosed are a kit and a dental porcelain set that are used for manufacturing the dental prosthesis.

Owner:NORITAKE CO LTD

Dental alloys

InactiveUS20050158693A1High yield strengthImprove polishing effectImpression capsArtificial teethDenturesDental porcelain material

A dental alloy that comprises little or no amounts of noble metals. The alloys herein are designed to be a substitute for gold alloys in the fabrication of prosthetic dental appliances employing porcelain to metal bonds. The alloys are based on a combination of iron and chromium with a lesser inclusion of other elements to provide a high yield strength and to provide a durable impact resistant bond with dental porcelain.

Owner:PRASAD ARUN +1

Demonstration dental template and matching temporary overlay

Owner:STONISCH MARY SUE

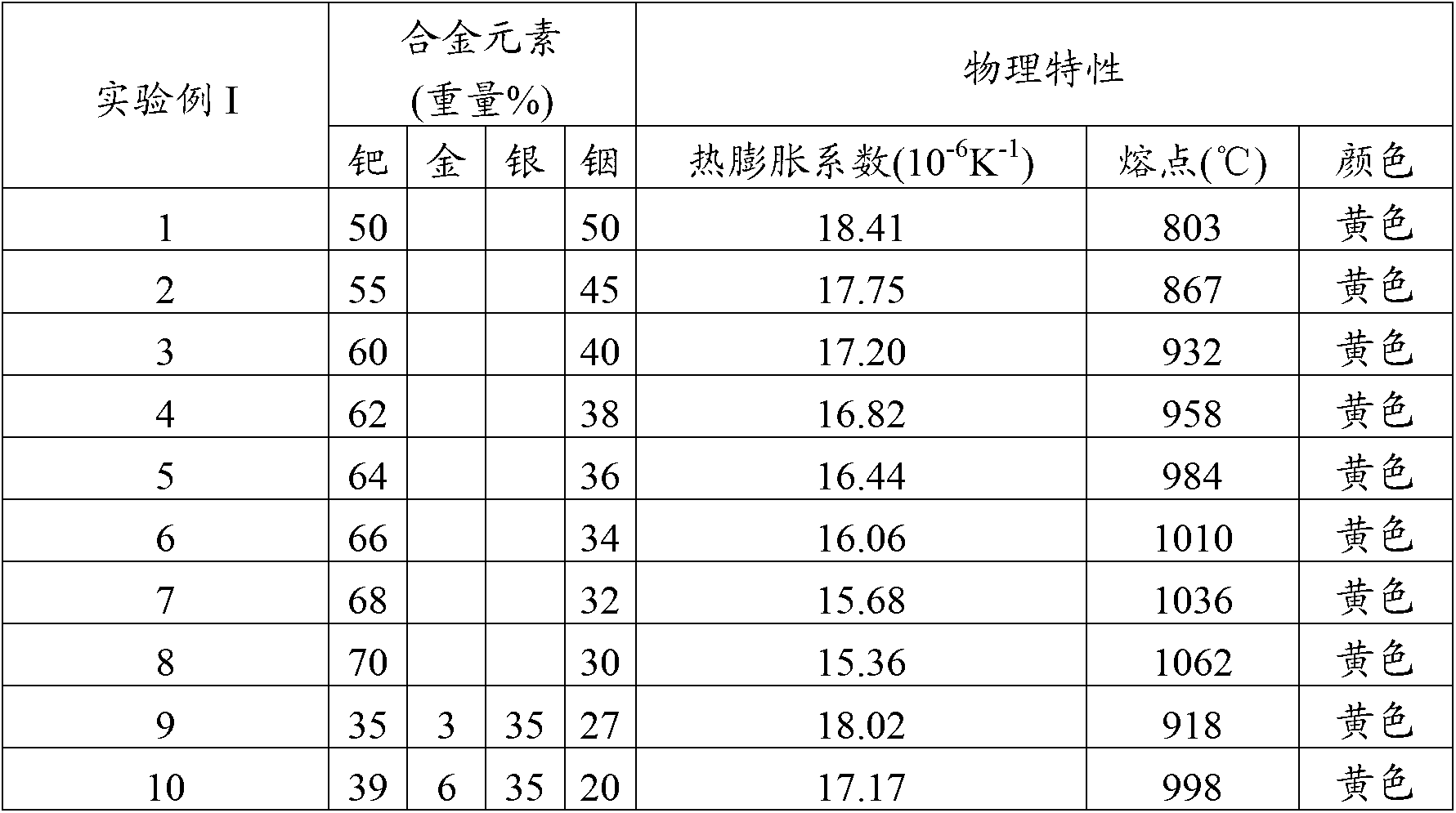

Metal alloy for fusion of dental ceramics, and dental prosthesis

InactiveCN103002858AImprove economyImprove mechanical propertiesDental implantsImpression capsDental ceramicsIndium

Metal alloys for dental porcelain fusing and dental prosthetic appliances are provided. The metal alloy includes: gold (Au) in an amount that is greater than 0 and equal to or smaller than 35 weight %; silver (Ag) in an amount of 5 to 35 weight %; indium (In) in an amount of 6 to 40 weight %; palladium (Pd) in an amount of 30 to 70 weight %; and at least one element selected from the group consisting of boron (B), germanium (Ge), zirconium (Zr), silicon (Si) and iron (Fe) in a total amount that is greater than 0 and equal to or smaller than 5.0 weight %.

Owner:朴炯奭

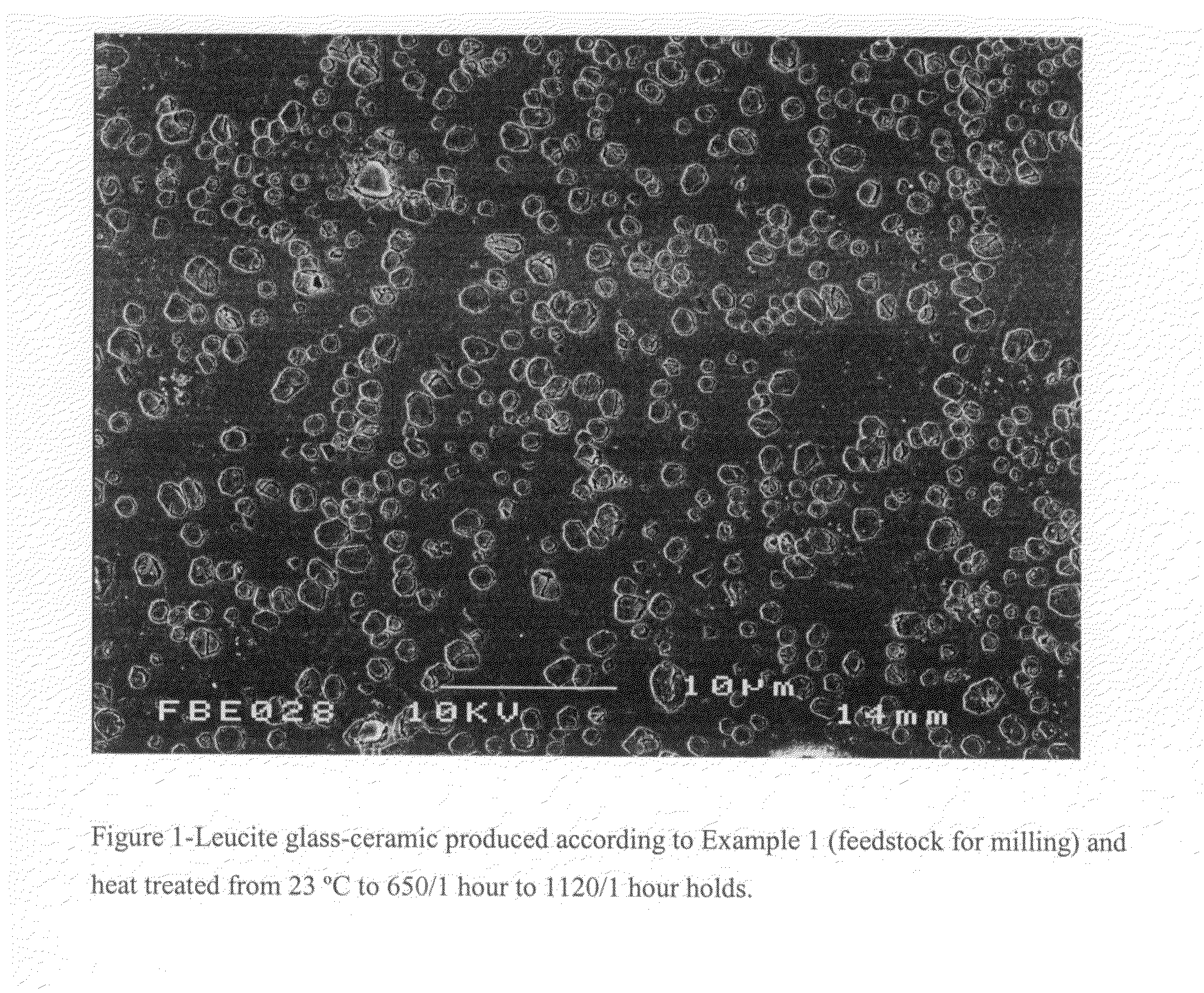

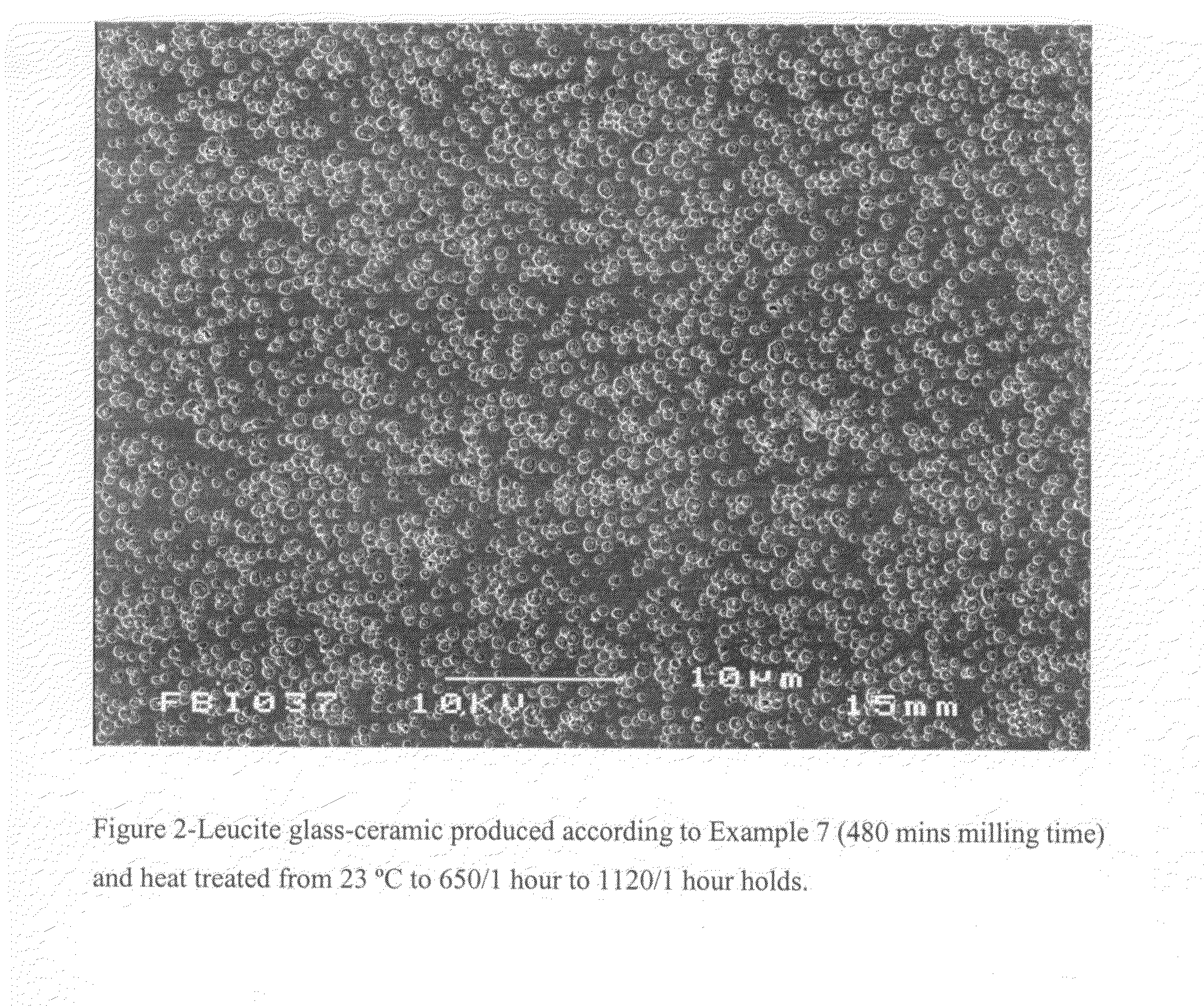

Control of ceramic microstructure

The present invention provides for the production of a single frit, dental porcelain, glass-ceramic containing small, uniformly dispersed, single leucite crystals of ellipsoidal habit and very uniform size.

Owner:DEN MAT HLDG

Aluminosilicate glass and color adapting composition for ceramics

InactiveUS20090227438A1Improvement factorReduction factorTooth crownsDentistry preparationsCeramic crownFrit

The present invention relates to a color adapting composition used for coloring and color adapting porcelain for ceramic crown such as dental restorations and prosthetics, and aluminosilicate glass appropriate for using in a color adapting composition. More specifically, a color adapting composition for dental porcelains are prepared by blending two or more kinds of glass frits having different sintering temperatures from each other and an inorganic pigment or a colored glass obtained by previously dispersing inorganic pigments in glass.

Owner:SHOFU INC

Integrated porcelain system for a dental prosthesis

An integrated dental porcelain system for making dental prostheses and restorations is provided. The system includes three universal major components: a) opaque porcelain composition; b) pressable dentin ingot; and c) veneering porcelain composition that can be used interchangeably for making restorations. Techniques for making the prostheses and restorations include porcelain fused-to-metal (PFM), press-to-metal (PTM), and either pressed and / or machined all-ceramic methods. The system uses both a hand-layering of veneering porcelain (PFM technique) and a hot-pressing process (PTM and all-ceramic technique) to fabricate the prostheses and restorations.

Owner:DENTSPLY SIRONA INC

Method of making dental prosthesis and ductile alloys for use therein

InactiveUS20130273501A1Avoid crackingAdditive manufacturing apparatusImpression capsMetal alloyDental porcelain material

A dental prosthesis comprising a metal alloy pre-form and a dental porcelain veneer coating the metal alloy, wherein the metal alloy has a composition comprising, in % by weight, about 30-40% Co, 25-40% Ru, 20-40% Cr, and 0-0.1% Ni and wherein a coefficient of thermal expansion of the metal alloy is compatible with that of the dental porcelain to prevent cracking of the porcelain

Owner:ARGEN

Ceramic product provided with china decorative accessory on strengthened dental porcelain and manufacturing method of ceramic product

ActiveCN102173278AOvercome consistencyOvercoming problems that are prone to burstingSpecial ornamental structuresFree coolingDental porcelain material

The invention provides a ceramic product provided with a china decorative accessory on the strengthened dental porcelain and a manufacturing method of the ceramic product. The ceramic product comprises a strengthened dental porcelain basal body, wherein a china decorative accessory is bonded on the basal body; and the manufacturing method of the ceramic product comprises the steps of: (1) manufacturing the strengthened dental porcelain basal body; (2) manufacturing the china decorative accessory; (3) bonding the china decorative accessory on the dental porcelain basal body, and drying naturally; (4) bisque-firing a green body at a low temperature, and cooling naturally; and (5) detecting, finishing, polishing, and glazing and glaze-firing after watering. By applying the manufacturing method disclosed by the invention, the china decorative accessory is bonded on the strengthened dental porcelain, thus the strength of the main body, the light-transmitting property and crystal-clear property of the decorative accessory, and the three-dimensional relief decoration effect are reflected; a special bonding material is adopted for bonding, thus the problem of crack easily caused by non-uniform coefficients of thermal expansion of two kinds of perform bodies are solved, and the yield of the product is improved; and the daily-use property and the artistic quality are organically combined, and the grade and the additional value of the product are improved.

Owner:潮州市煜日陶瓷制作有限公司

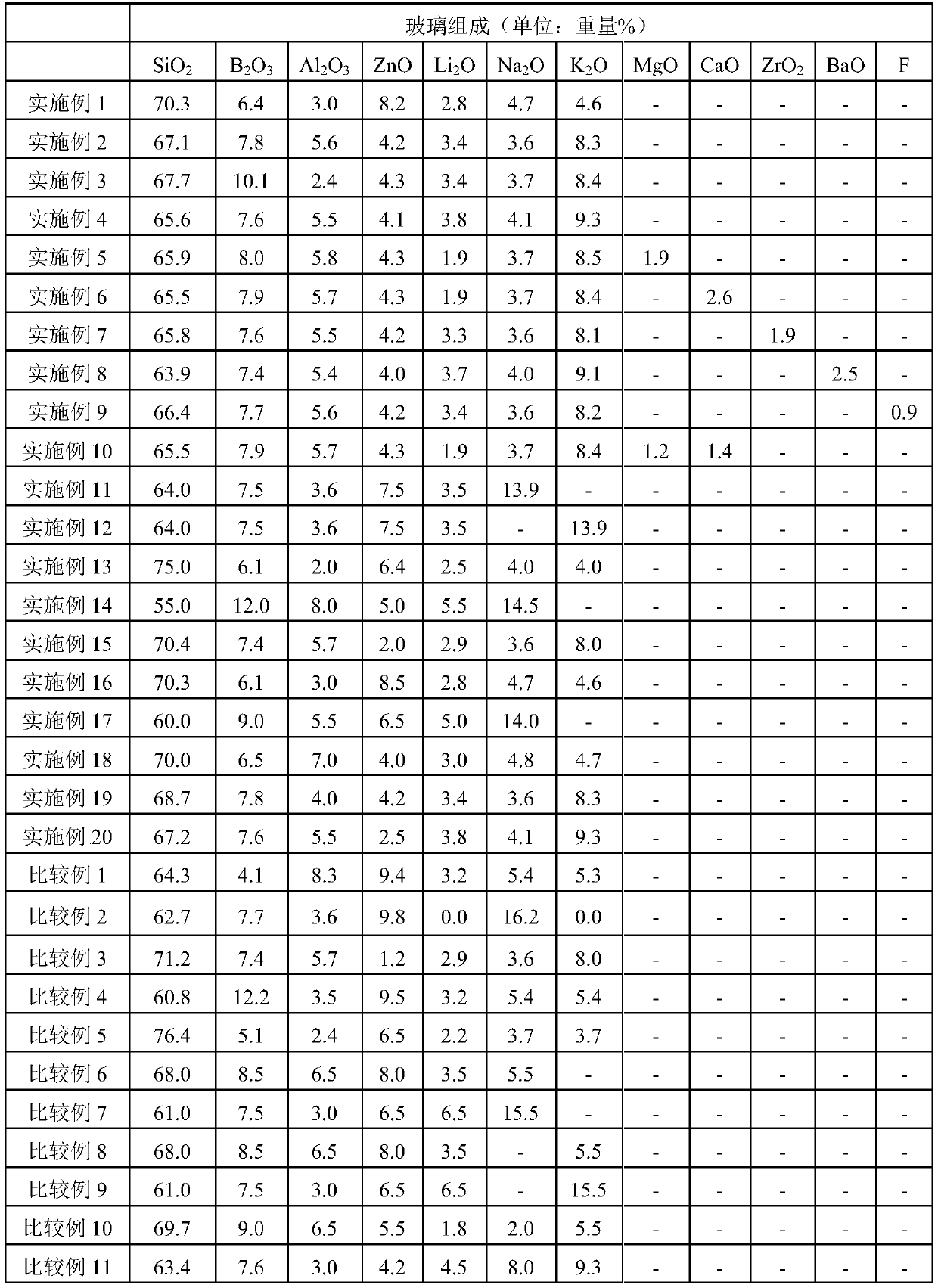

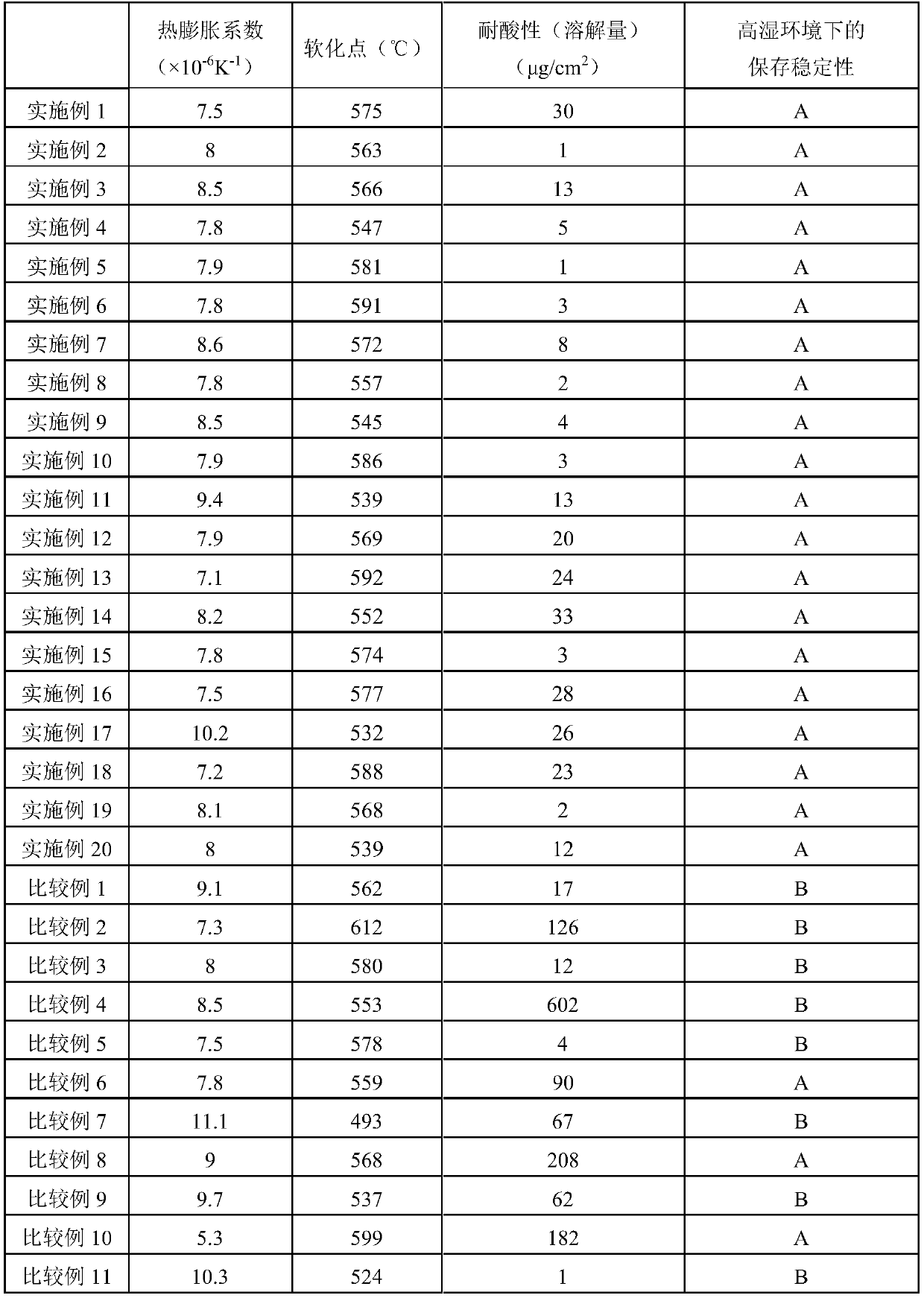

Low melting point glass composition excellent in water resistance

ActiveCN110078371ALower sintering temperatureLower firing temperatureDental implantsPigmenting treatmentDental ceramicsAlkali metal oxide

The invention provides a glass composition which can be used for a dental porcelain or a dental ceramics coloring material, and has low temperature meltability, acid resistance and preservation stability under the humid environment which are required for a dental porcelain or a dental ceramics coloring material, and a dental porcelain and dental ceramics coloring material which contain the glass composition powder. The invention provides a low melting glass composition with softening point (Ts) less than 600 degrees centigrade comprising, as a component; SiO2: 55.0 to 75.0 wt.%, B2O3: 6.1 to 12.0 wt.%, Al2O3: 2.0 to 8.0 wt.%, ZnO: 2.0 to 85 wt.% and two or more kinds of alkali metal oxide: 10.5 to 20.0 wt.%.

Owner:SHOFU INC

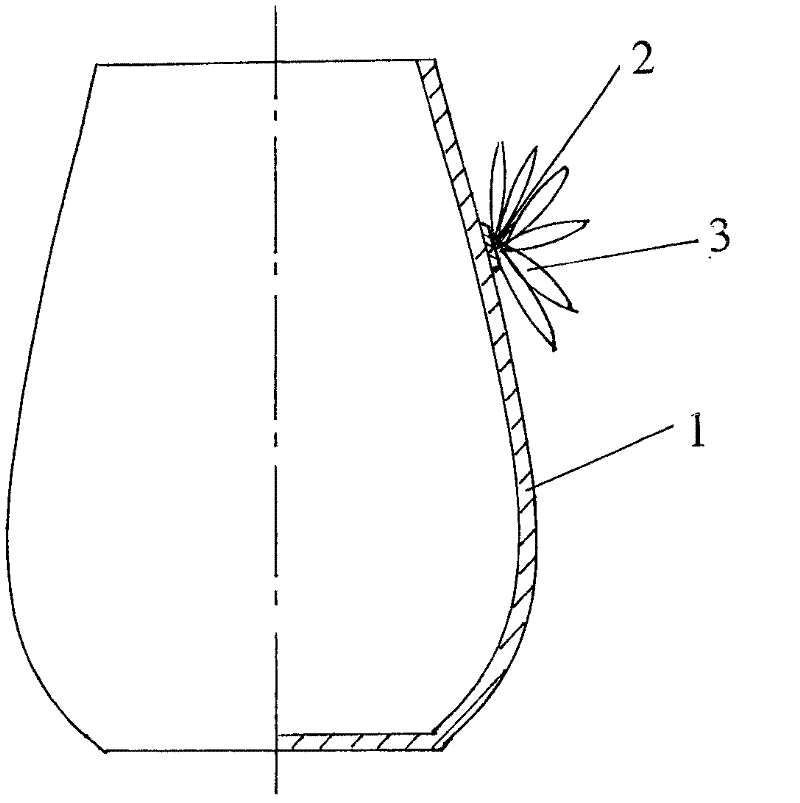

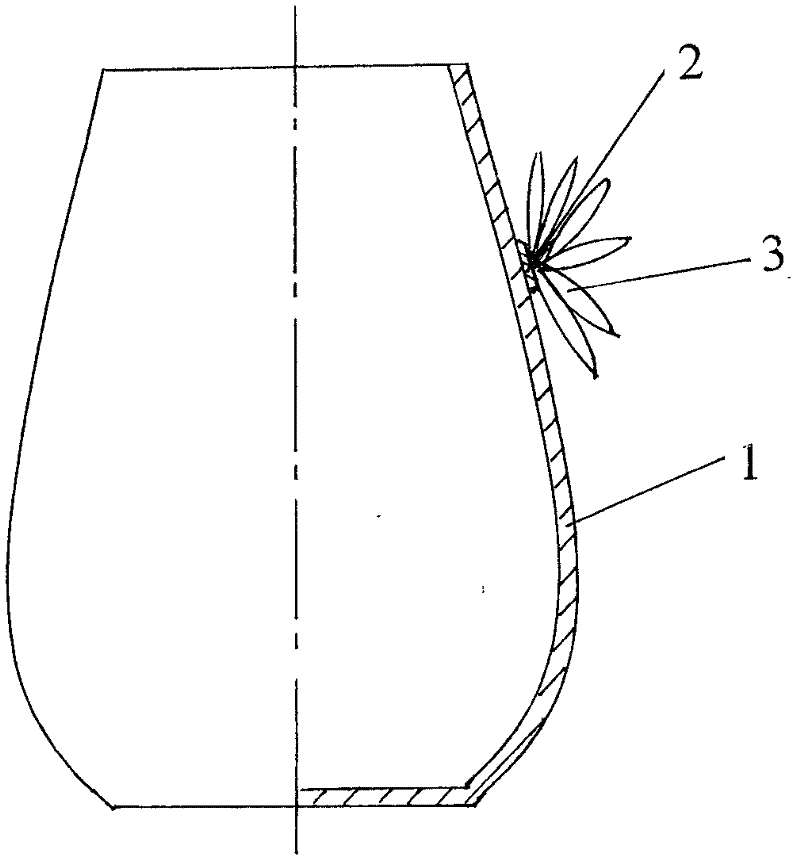

Oral dental material structure with high chaining force

InactiveCN102755198AReduce oxidationAffect aestheticsDental prostheticsDental porcelain materialIon release

The invention relates to an oral dental material structure with high chaining force. The oral dental material structure is used for being combined on a gum and comprises a metal base, a ceramic membrane layer and a dental porcelain layer, the ceramic membrane layer is melted by atmospheric plasma, the metal base is sleeved on the gum, the ceramic membrane layer is plated on the surface of the metal base in a spraying manner, the dental porcelain layer is sintered on the ceramic membrane layer, so that the chaining force between the metal base and the dental porcelain layer is increased, and problems that the metal base is exposed and metal ions release are avoided.

Owner:SMILDEN BIOTECH

Integrated Porcelain System for a Dental Prosthesis

InactiveUS20120111227A1Impression capsOther chemical processesPorcelain fused to metalDental porcelain

An integrated dental porcelain system for making dental prostheses and restorations is provided. The system includes three universal major components: a) opaque porcelain composition; b) pressable dentin ingot; and c) veneering porcelain composition that can be used interchangeably for making restorations. Techniques for making the prostheses and restorations include porcelain fused-to-metal (PFM), press-to-metal (PTM), and either pressed and / or machined all-ceramic methods. The system uses both a hand-layering of veneering porcelain (PFM technique) and a hot-pressing process (PTM and all-ceramic technique) to fabricate the prostheses and restorations.

Owner:DENTSPLY SIRONA INC

Integrated porcelain system for a dental prosthesis

Owner:DENTSPLY SIRONA INC

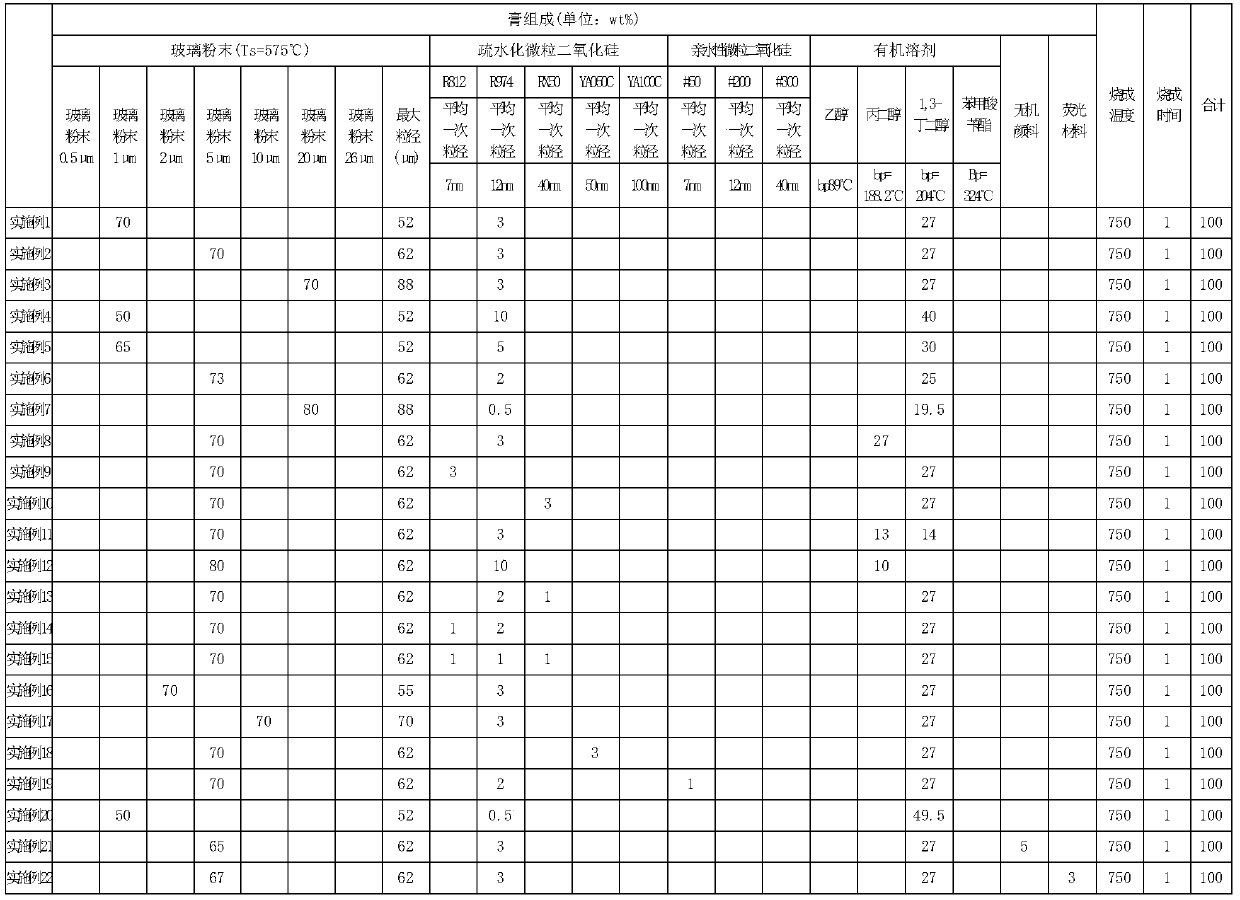

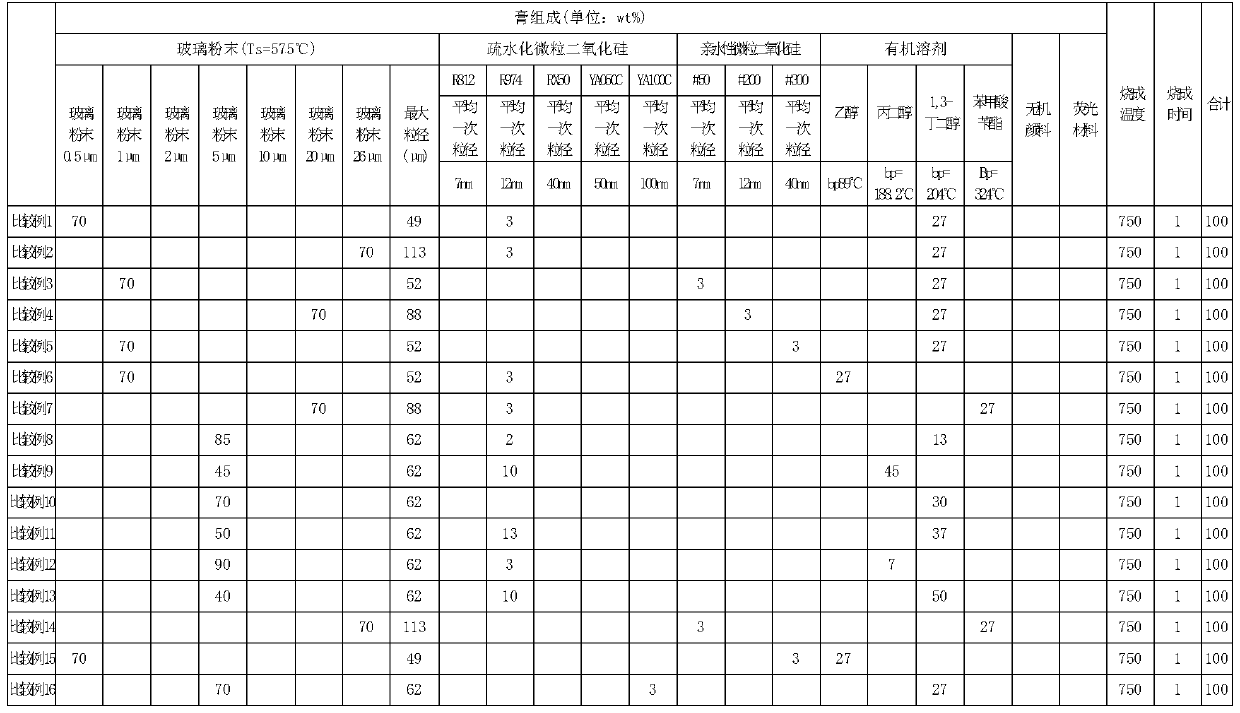

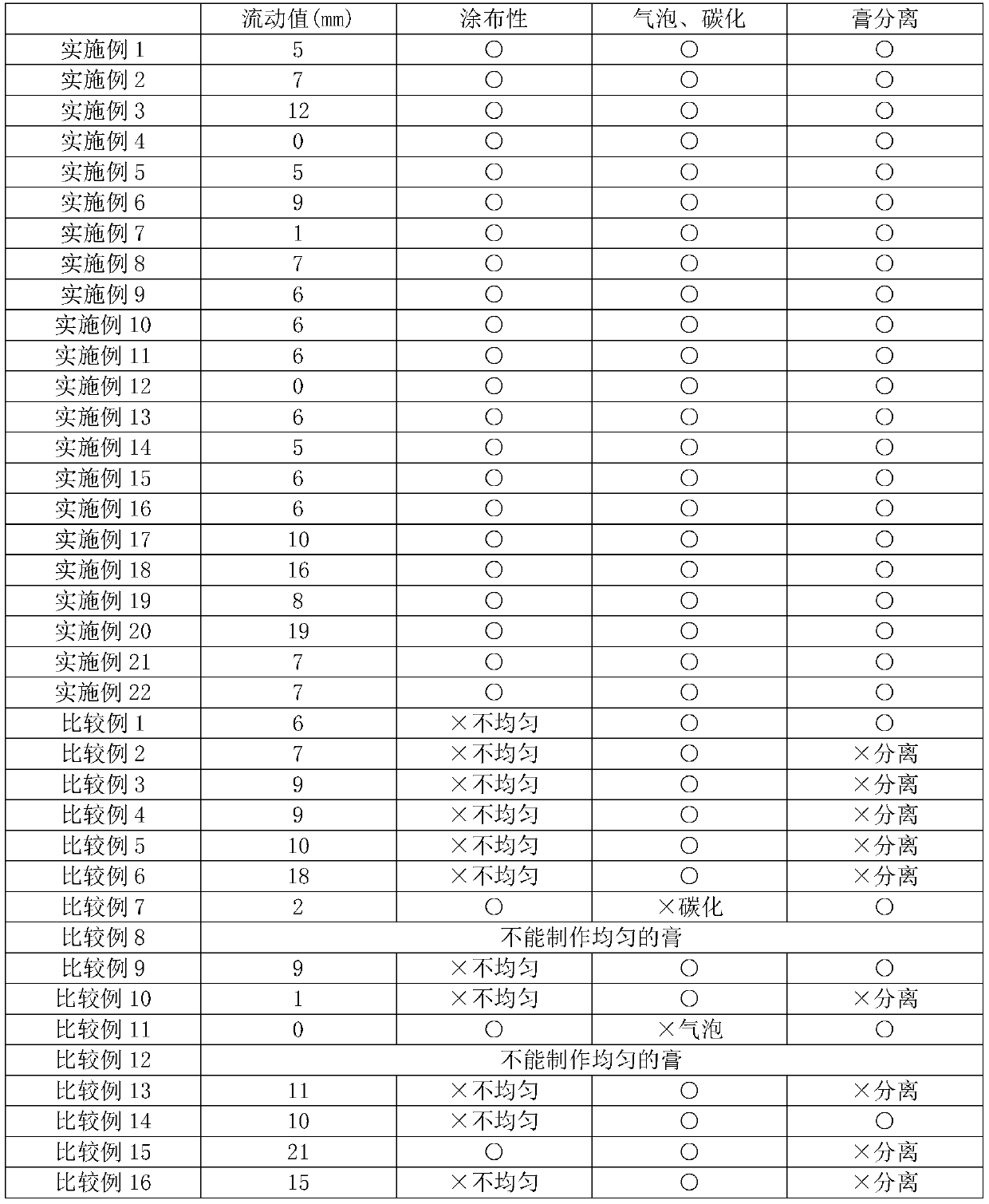

Dental porcelain paste

PendingCN111467246AUniform coatingInhibitionImpression capsArtificial teethOrganic solventCarbonization

Provided is a dental ceramic paste which is capable of maintaining a paste state over a long period of time, has excellent coatability, and hardly causes carbonization and air bubbles due to the influence of an organic component or a polymer component during firing. The dental ceramic paste according to the present invention is used in the production of a dental prosthetic device, and is characterized by comprising: 50.0-80.0 wt% of a glass powder (a) having a maximum particle diameter of 100 [mu] m or less and an average particle diameter of 1-20 [mu] m; 0.5 wt% to 10.0 wt% of hydrophobized particulate silica (b) having an average primary particle diameter of 1 nm to 50 nm; and 10.0 wt% to 49.5 wt% of an organic solvent (c) having a boiling point (bp) of 100 DEG C to 300 DEG C.

Owner:SHOFU INC

Low melting point glass composition excellent in water resistance

ActiveUS20190322567A1Lower temperature of calcinationCalcination temperature is lowDental implantsPigmenting treatmentDental ceramicsAlkali metal oxide

To provide a a glass composition which can be used for a dental porcelain or a dental ceramics coloring material, and has low temperature meltability, acid resistance and preservation stability under the humid environment which are required for a dental porcelain or a dental ceramics coloring material, and a dental porcelain and dental ceramics coloring material which contain the glass composition of the present disclosure. To provide a low melting glass composition with softening point (Ts) less than 600° C. comprising as a component; SiO2: 55.0 to 75.0 wt. %, B2O3: 6.1 to 12.0 wt. %, Al2O3: 2.0 to 8.0 wt. %, ZnO: 2.0 to 8.5 wt. % and two or more kinds of alkali metal oxide: 10.5 to 20.0 wt. %.

Owner:SHOFU INC

Dental mixing palette

InactiveUS20200060795A1Easy to separateAccurate moisture contentTeeth fillingTransportation and packagingDental porcelain materialDentistry

A dental mixing palette for ceramic materials such as dental porcelain. The dental mixing palette has a base body, a bearing member mounted on the base body, a rotary platter mounted on the bearing member for undergoing rotational movement relative to the base body, a mixing part disposed on the rotary platter, and a cover configured to selectively, removably covering the mixing part.

Owner:PAPASTAMOS MICHALIS +1

High gold alloy for porcelain fused to metal dental restorations

An alloy is provided for dental porcelain fused to metal restorations, having a rich gold color and light oxide coating for bonding the porcelain to the cast alloy substrate. The alloy has suitable mechanical properties for the support of the porcelain and is readily polished to a bright sheen. The alloy includes from 96 to 98 weight % Au with up to 3 weight % Pt, Pd, Ru, Ir, or combinations thereof and 0 to 1.5 wt % In, Sn, Fe, Mn, Cu, B, or combinations thereof.

Owner:IVOCLAR VIVADENT INC

Metal alloy for fusion of dental ceramics, and dental prosthesis

InactiveUS20130071285A1High propertyImprove mechanical propertiesDental implantsTooth crownsDental ceramicsIndium

Metal alloys for dental porcelain fusing and dental prosthetic appliances are provided. The metal alloy includes: gold (Au) in an amount that is greater than 0 and equal to or smaller than 35 weight %; silver (Ag) in an amount of 5 to 35 weight %; indium (In) in an amount of 6 to 40 weight %; palladium (Pd) in an amount of 30 to 70 weight %; and at least one element selected from the group consisting of boron (B), germanium (Ge), zirconium (Zr), silicon (Si) and iron (Fe) in a total amount that is greater than 0 and equal to or smaller than 5.0 weight %.

Owner:PARK HYUNG SEOK

3D printed cobalt-chromium alloy for dental porcelain repair and preparation method thereof

ActiveCN112159907AHigh bonding strengthHigh sphericityAdditive manufacturing apparatusArtificial teethStress relief3d printed

The invention provides a 3D printed cobalt-chromium alloy for dental porcelain repair and a preparation method thereof, and belongs to the field of dental porcelain repair. A Ta element is added, so that the thermal expansion coefficient is reduced, the metal ceramic bonding strength is improved, the surface active energy is reduced, solid solution strengthening is caused, and the strength is improved; the content of a Cr element is increased, the content of a Co element is reduced, the content of a hcp phase is increased, metal and ceramic bonding is facilitated, after the content of the Co element is reduced, combination of Cr-W, Cr-Mo, Cr-Si and W-Mo is improved, and the strength of the alloy is improved; vacuum stress relief annealing is adopted, and residual stress is completely eliminated, so that microstructure phase change caused by the residual stress in the service process of a cobalt-chromium restoration is avoided, and micro-cracks are prevented from being formed on a metal-ceramic bonding interface; and solid solution and aging are adopted, the composition of a cobalt-chromium alloy phase and precipitation of a second phase are adjusted, so that the alloy has good mechanical properties, meanwhile, the hcp phase is further improved, and the metal-ceramic bonding strength is improved.

Owner:CHENGDU KENINGDA MATERIALS

Aluminosilicate glass and color adapting composition for ceramics

The present invention relates to a color adapting composition used for coloring and color adapting porcelain for ceramic crown such as dental restorations and prosthetics, and aluminosilicate glass appropriate for using in a color adapting composition. More specifically, a color adapting composition for dental porcelains are prepared by blending two or more kinds of glass frits having different sintering temperatures from each other and an inorganic pigment or a colored glass obtained by previously dispersing inorganic pigments in glass.

Owner:SHOFU INC

Nickel base alloy for dental porcelain

InactiveCN101435040AImprove antioxidant capacityAccelerated corrosionImpression capsDentistry preparationsRare-earth elementCerium

The invention relates to a nickel base alloy used for dental porcelain, which is characterized by comprising rare earth elements; the chemical compositions (weight percentage) are as follows: 20 to 25 percent of chromium, 5 to 8 percent of molybdenum, 1 to 5 percent of cerium, 0.5 to 1 percent of manganese, 0.3 to 0.5 percent of rhodium, 1 to 5 percent of tungsten, 1 to 2 percent of silicon, 0.01 to 0.20 percent of cerium and the balance of nickel. The invention not only has good oxidation resistance and corrosion resistance but also has good casting and cutting performances and can be well matched with the existing porcelain powder for use.

Owner:贾军

Dental porcelain paste superior in application property

ActiveUS20200330331A1Constant propertySuppress the generation of air bubblesImpression capsArtificial teethOrganic solventDentures

To provide a dental porcelain paste which can maintain maintaining the paste state and have excellent application property for a long period of time and hardly causes carbonization or bubbles due to the influence of an organic component or a polymer component during firing. The present invention provides a dental porcelain paste for preparing a dental prosthesis device, comprising: 50.0 to 80.0 wt. % of a glass powder (a) having a maximum particle diameter of 100 μm or less and an average particle diameter of 1 to 20 μm, 0.5 to 10.0 wt. % of a hydrophobized fine particle silica (b) having an average primary particle diameter of 1 to 50 nm, and 10.0 to 49.5 wt. % of an organic solvent (c) having a boiling point it is within (bp) of 100 to 300° C.

Owner:SHOFU INC

A kind of 3D printing cobalt-chromium alloy for dental porcelain restoration and preparation method thereof

ActiveCN112159907BHigh strengthHigh melting pointAdditive manufacturing apparatusArtificial teethStress reliefCobalt chromium alloy

The invention provides a 3D printed cobalt-chromium alloy for dental porcelain restoration and a preparation method thereof, belonging to the field of dental porcelain restoration. The present invention adds Ta element, reduces thermal expansion coefficient, improves metal-ceramic bonding strength, reduces surface active energy, causes solid solution strengthening, improves strength; increases Cr element content, reduces Co element content, increases hcp phase content, is beneficial to metal-ceramic bonding, After the Co element is reduced, the combination of Cr-W, Cr-Mo, Cr-Si, W-Mo is improved, and the strength of the alloy is improved; the vacuum stress relief annealing is used to completely eliminate the residual stress, so that the cobalt-chromium restoration will not be used during service. The microstructure phase transformation will be caused by the residual stress, causing the formation of microcracks at the metal-ceramic bonding interface; solid solution and aging are used to adjust the phase composition of the cobalt-chromium alloy and the precipitation of the second phase, so that the alloy has good mechanical properties, and at the same time The hcp phase is further improved to improve the bonding strength of gold and porcelain.

Owner:CHENGDU KENINGDA MATERIALS

A method for improving the metal-ceramic bonding strength of titanium alloy porcelain-fused-to-metal crowns

InactiveCN108969385BReduced activityHigh bonding strengthImpression capsMedical preparationsDental ceramicsPhysical chemistry

Owner:THE FIRST AFFILIATED HOSPITAL OF ZHENGZHOU UNIV

A kind of glass used as dental veneer porcelain, preparation method and use thereof

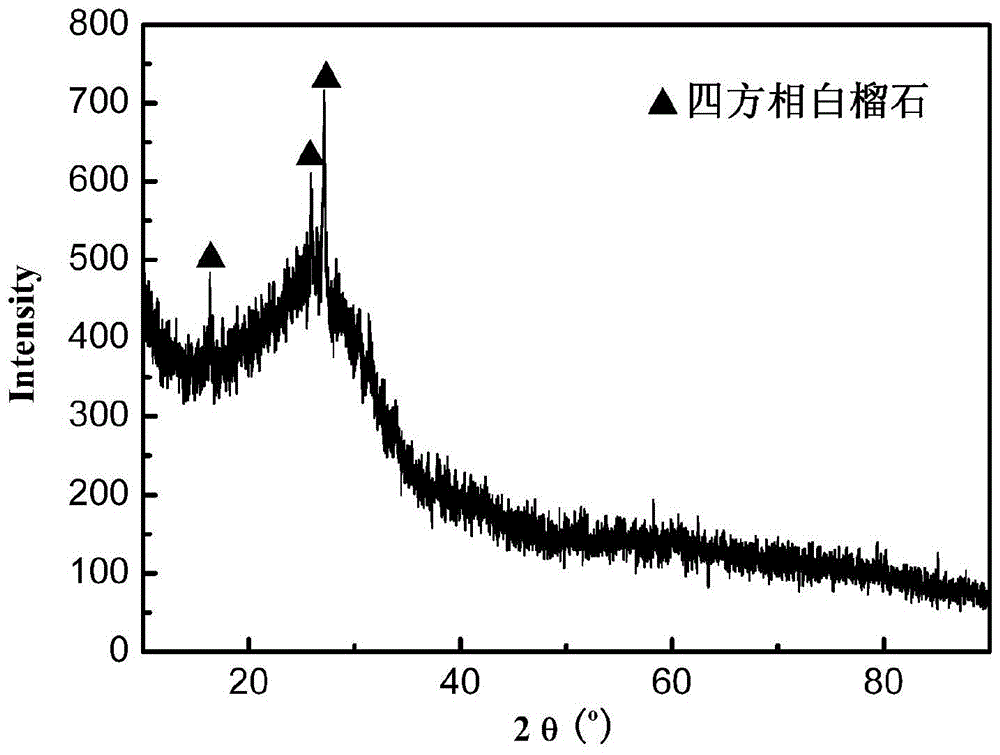

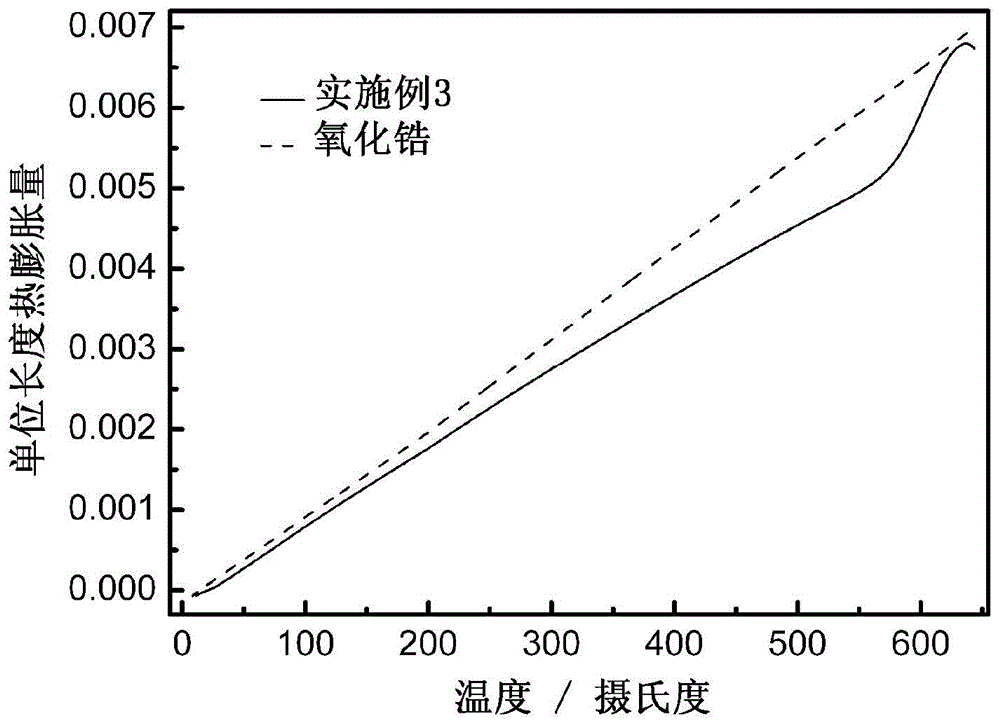

ActiveCN103910489BPorcelain low temperaturePorcelain temperature loweredGlass productionDental Veneer MaterialLeucite

The invention relates to a glass used as a dental veneering porcelain. The glass comprises, by mass, 50%-70% of SiO2, 6%-17% of B2O3, 6%-25% of Al2O3, 1%-10% of Na2O, and 17%-30% of K2O. The glass undergoes heat treatment at 700DEG C-1100DEG C, and leucite microcrystalline glass with different thermal expansion coefficients can be obtained. The microcrystalline glass only contains tetragonal phase leucite crystals, the size of which is less than 4 micrometers. The leucite microcrystalline glass has very good thermal stability, after experiencing a porcelain fusing program 10 times, the thermal expansion coefficient change of the leucite microcrystalline glass is less than 2%, and in a 120min process of heat preservation at a porcelain fusing temperature of 850DEG C, the size and number of the leucite crystals do not have obvious change. The leucite microcrystalline glass can be used as a transparent porcelain and incisal porcelain in the veneering porcelain, and also can be used as a body porcelain if a pigment is added.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

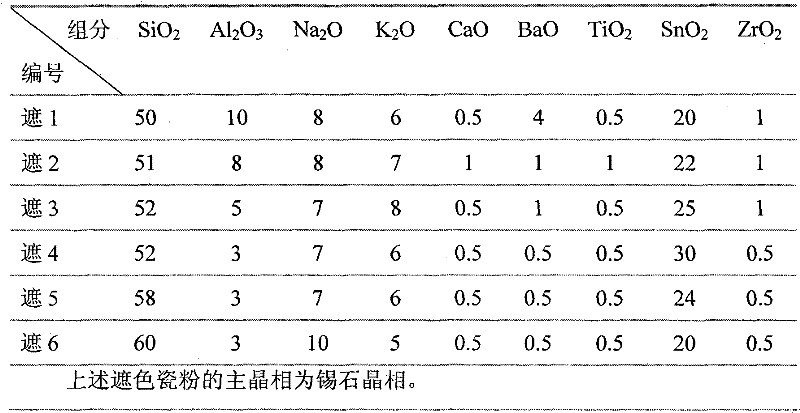

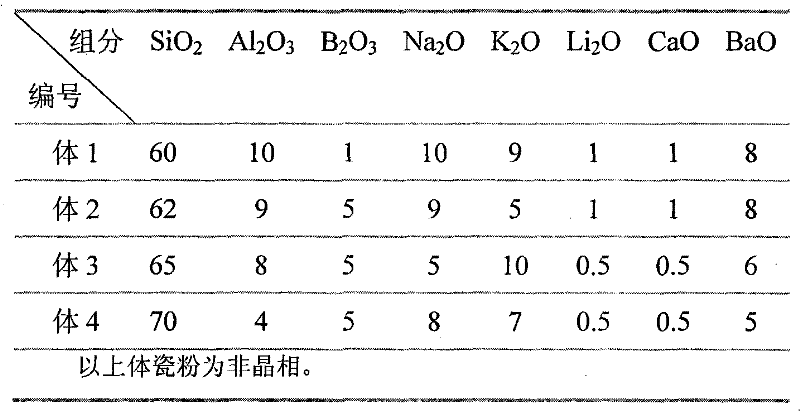

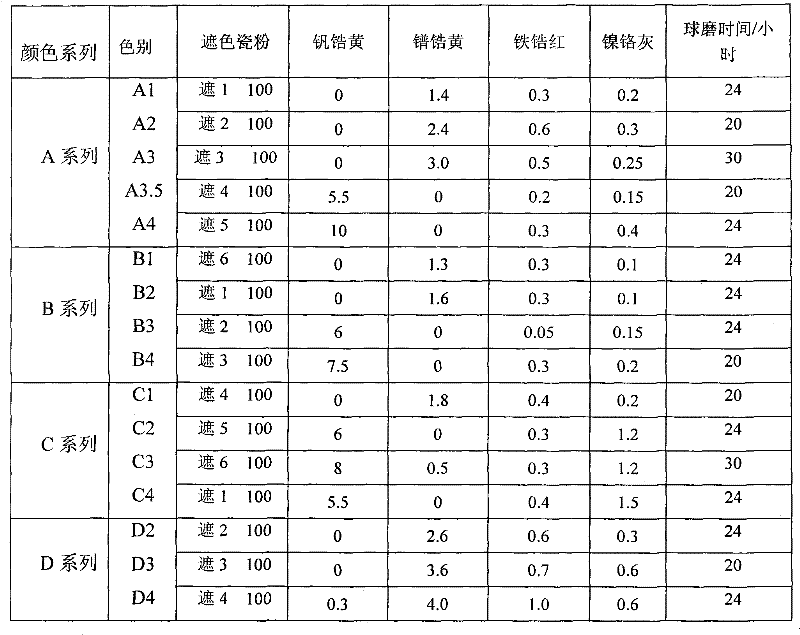

Preparation method of dental titanium porcelain powder with series color matching

InactiveCN101669879BReduce the temperatureAdjust the coefficient of thermal expansionImpression capsDentistry preparationsNatural toothBall mill

The invention discloses a preparation method of a series of color-matched dental titanium porcelain powders, including color-matching of opaque porcelain powders and body-porcelain powders. At least three kinds of ceramic pigments vanadium zirconium yellow, praseodymium zirconium yellow, iron zirconium red and nickel chromium gray; the color matching of the body porcelain powder is based on the mass base of the body porcelain powder, and commercial ceramic pigments vanadium zirconium yellow and praseodymium zirconium are added At least two kinds of yellow, iron zirconium red, iron chrome yellow and nickel chrome gray; the opaque porcelain powder and body porcelain powder after adding color materials are ball milled for 20-30 hours respectively; the opaque porcelain powder and body porcelain powder after ball milling are dried Afterwards, they are bottled separately to prepare for ceramics on the surface of pure titanium substrates. In the present invention, the opaque porcelain powder and the body porcelain powder are prepared according to the current general vita porcelain color card standard, and the colored porcelain powders of 16 colors in four series A, B, C, and D can be respectively selected according to different colors of natural teeth. , to achieve a realistic and beautiful effect.

Owner:FOURTH MILITARY MEDICAL UNIVERSITY

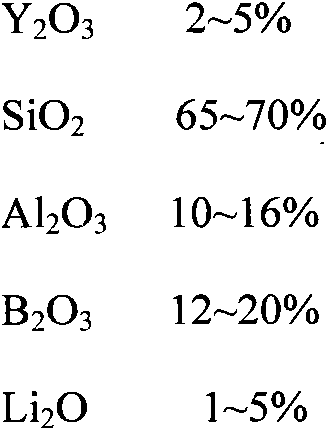

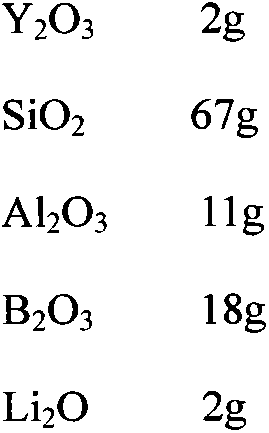

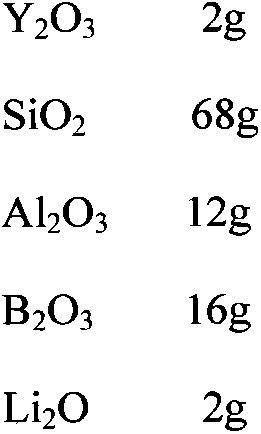

A kind of glass powder for all-ceramic dental porcelain and preparation method thereof

The invention provides a glass powder for all-ceramic dental porcelain and a preparation method thereof. The glass powder is composed of the following components in mass ratio: Y2O32-5%, SiO265-70%, Al2O310-16%, B2O312-20%, Li2O1~5%. The above materials are fully mixed and evenly heated from room temperature to 650-700°C and then held for 20 minutes, then heated to 1350-1450°C and held for 120-180 minutes to fully melt the raw materials into a liquid state, and then quenched with deionized water to form glass particles. The glass particles are ball-milled to 3-5 μm, and the glass powder for all-ceramic teeth can be obtained. The glass powder obtained in the present invention is characterized in that it does not contain K2O, Na2O and other components, and has the advantages of high transparency, good bending resistance, and good acid resistance. The coefficient is 8.8~9.2×10‑6 / ℃.

Owner:FOSHAN BAIRUI NEW MATERIAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com