Oral dental material structure with high chaining force

An oral cavity and high-chain technology, applied in dentistry, dental prosthesis, medical science, etc., can solve problems such as unsightly appearance, impact strength, poor link strength, etc., to increase practicability and safety, and avoid harm to human health , The overall structure is light and thin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The detailed description and technical content of the present invention are described below with the drawings, but the drawings are only for reference and illustration, and are not intended to limit the present invention.

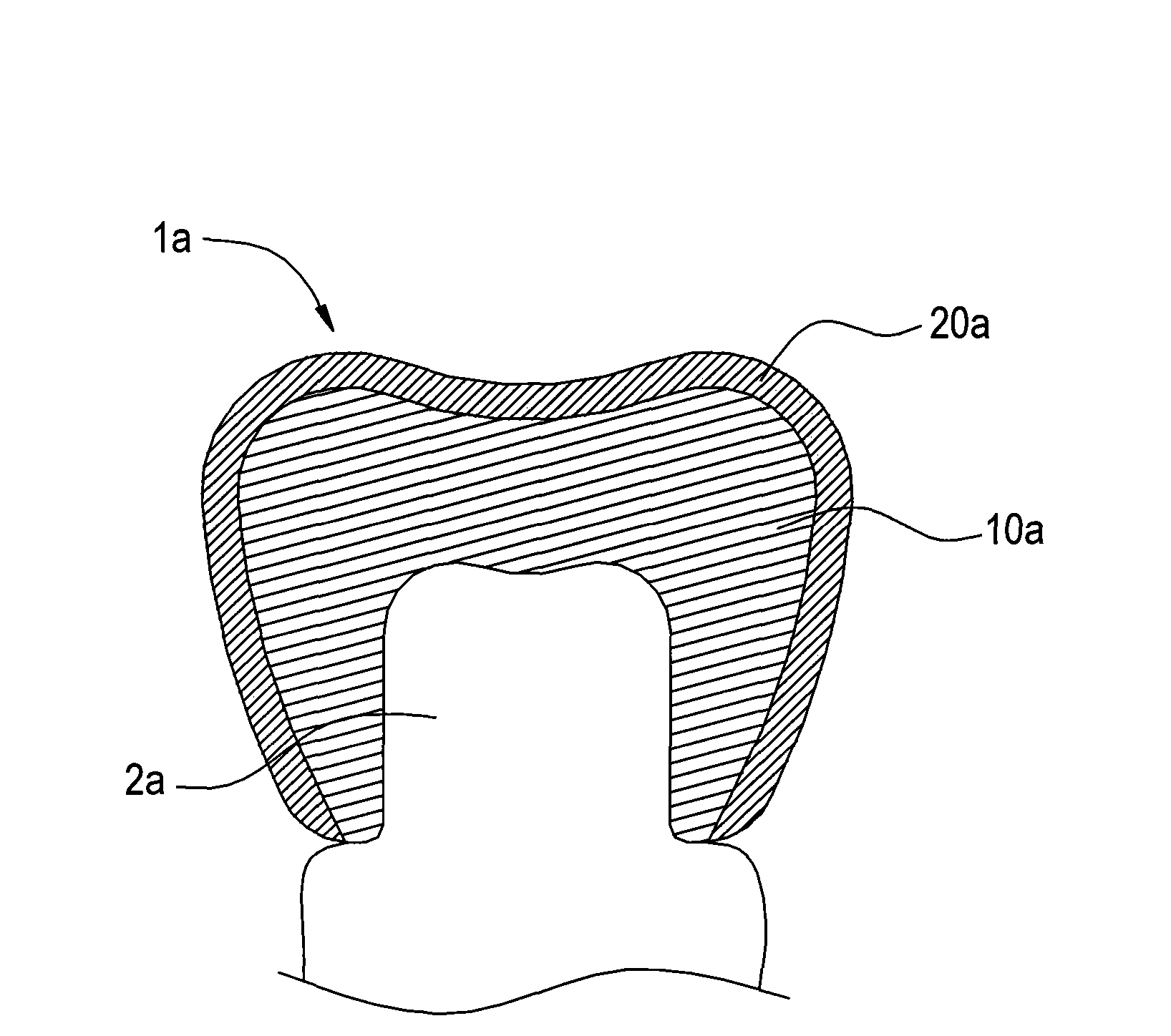

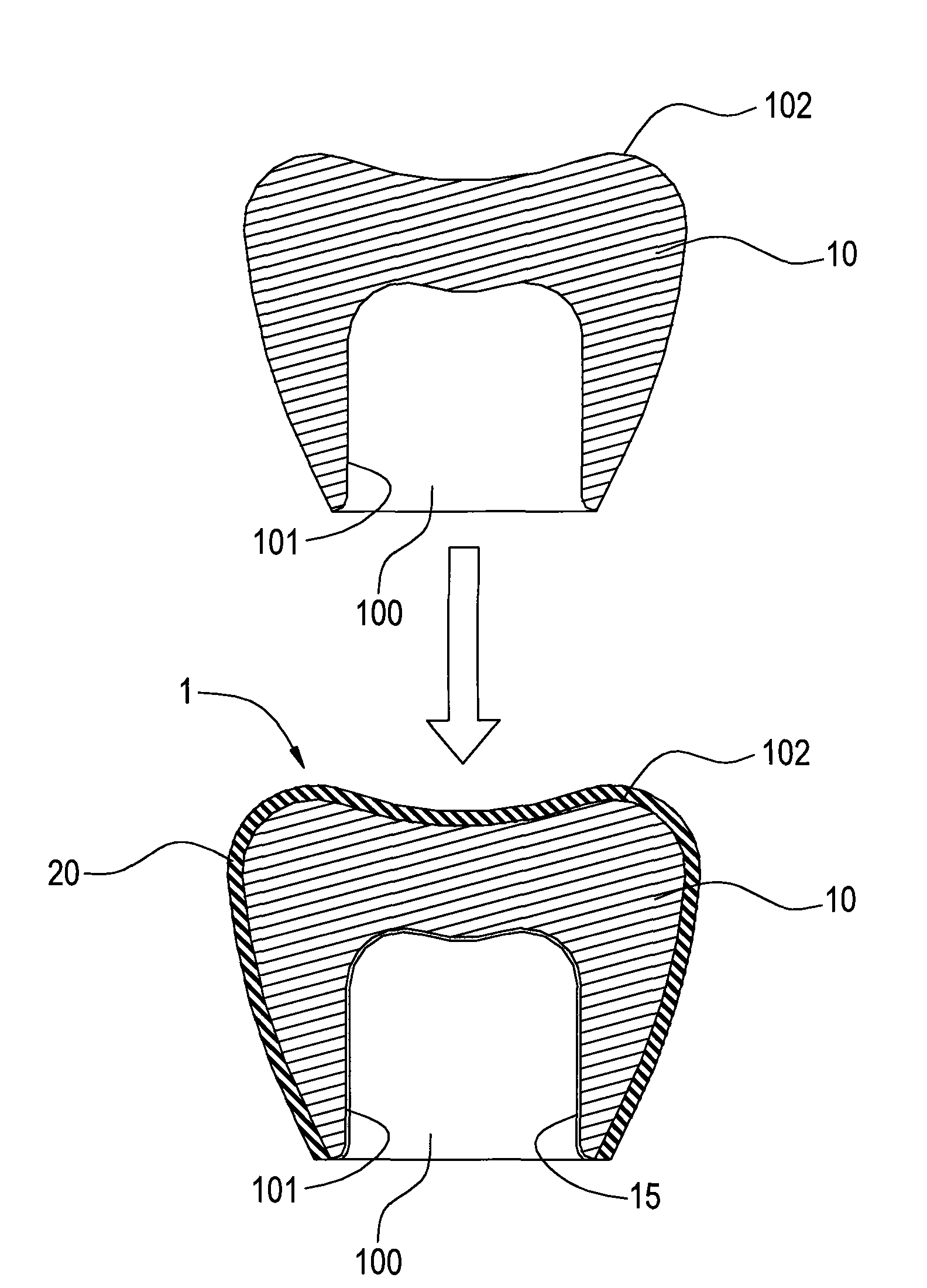

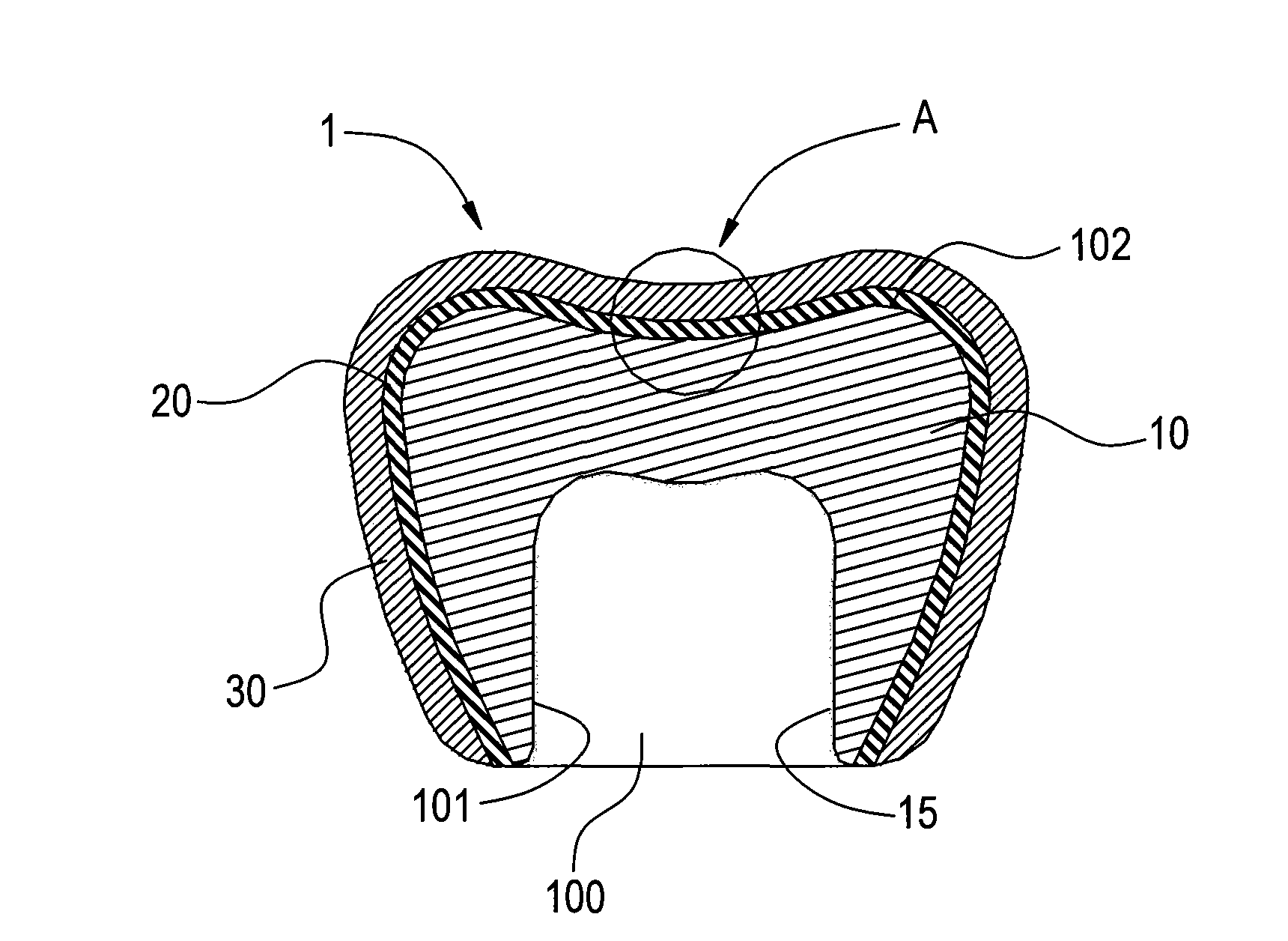

[0028] Please refer to Figure 2 to Figure 4 , are the schematic diagram, cross-sectional view and schematic view of the oral cavity tooth material structure with high link force of the present invention; the oral tooth material structure 1 with high link force of the present invention is used to be combined on a gum 2, and the high link force The dental structure of the oral cavity includes a metal base 10 and a ceramic film layer 20 sprayed by atmospheric plasma.

[0029] The material of the metal base 10 is a metal generally used for dental materials in the oral cavity, which may be composed of nickel, chromium, titanium, platinum, palladium, copper, zinc, gold, silver or other metals or combinations (alloys). The metal base 10 is formed with a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com