Preparation method of dental titanium porcelain powder with series color matching

A technology of porcelain powder and porcelain powder, applied in dental preparations, dentistry, dental prostheses, etc., can solve the problems of discoloration, unpublished production technology, and broken porcelain, achieve realistic and beautiful color, improve bonding strength, and reduce porcelain porcelain effect of temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

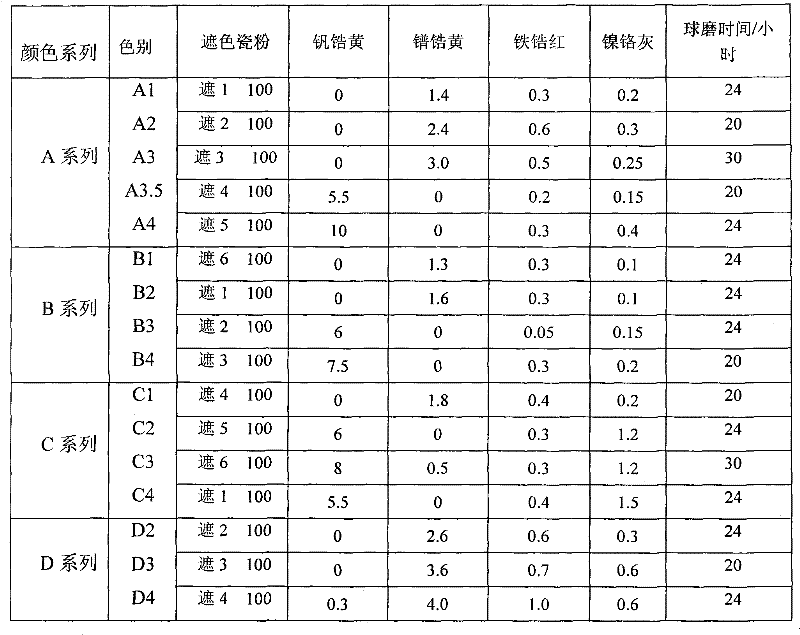

Examples

Embodiment Construction

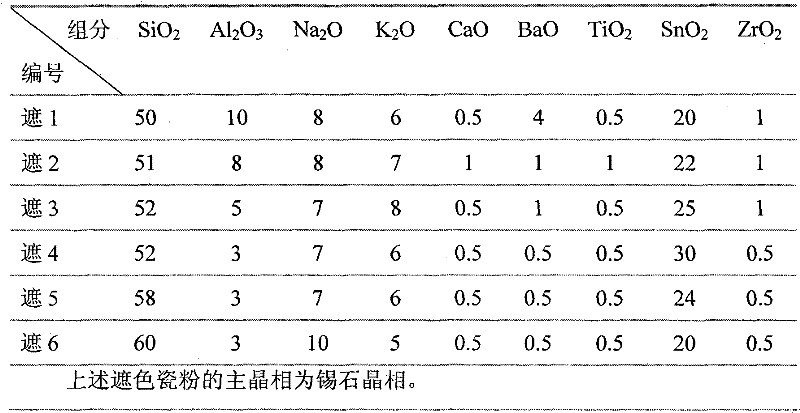

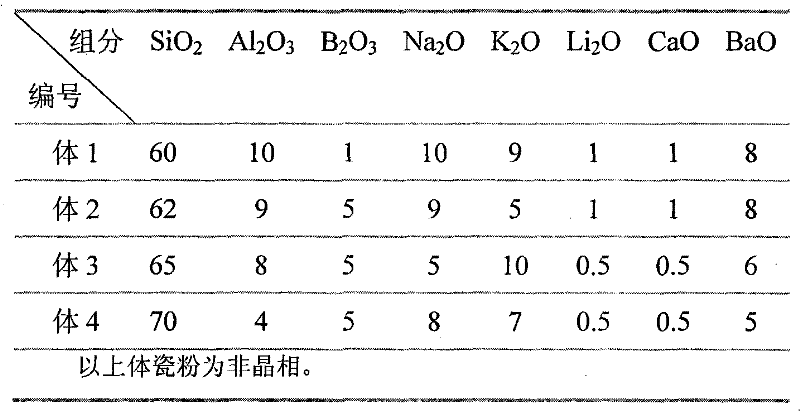

[0019] Preparation method of opaque porcelain powder:

[0020] (1) Calculate and weigh according to the formula of opaque porcelain powder in Table 1, and record the ingredients of opaque porcelain powder as opaque 1 to opaque 6, and mix and ball mill them respectively 0 hours; the component SnO 2 Set aside separately and do not participate in mixed ball milling; where component B 2 o 3 Introduced with boric acid, component Na 2 O, K 2 O. Li 2 O and BaO are introduced with corresponding carbonates, and component F is introduced with corresponding fluorides.

[0021] (2) Put the mixed material after each ball mill into the crucible, at T 1 ℃ melting, heat preservation t 1 Hours, the molten glass is poured into water to quench it.

[0022] (3) wet ball milling of the quenched solid after water quenching 2 hours; after drying, an intermediate powder of opaque porcelain is obtained.

[0023] (4) Add the SnO that was not involved in the mixing and ball milling in step (1)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| sintering temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com