Patents

Literature

51results about How to "Suppress the generation of air bubbles" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

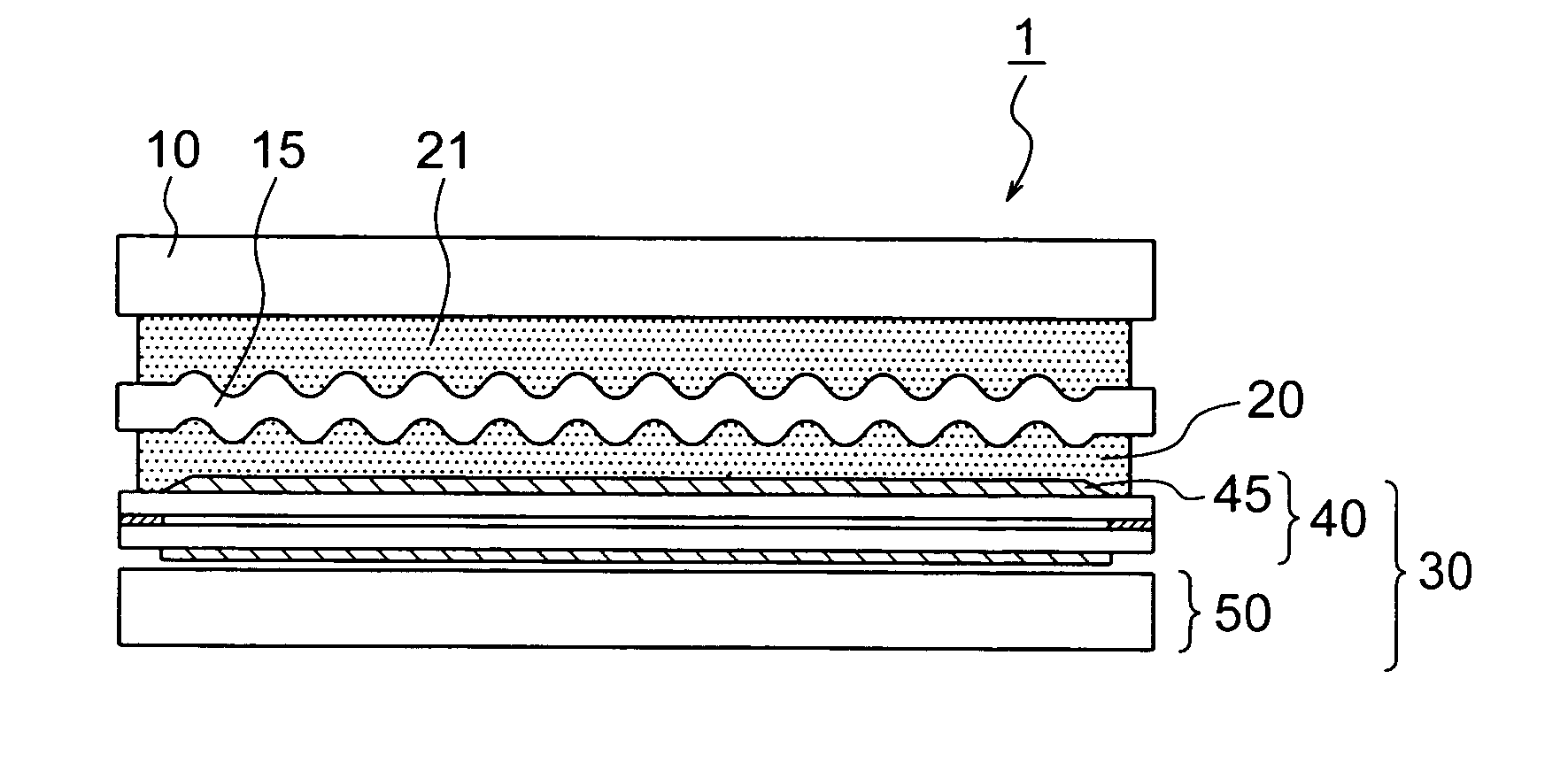

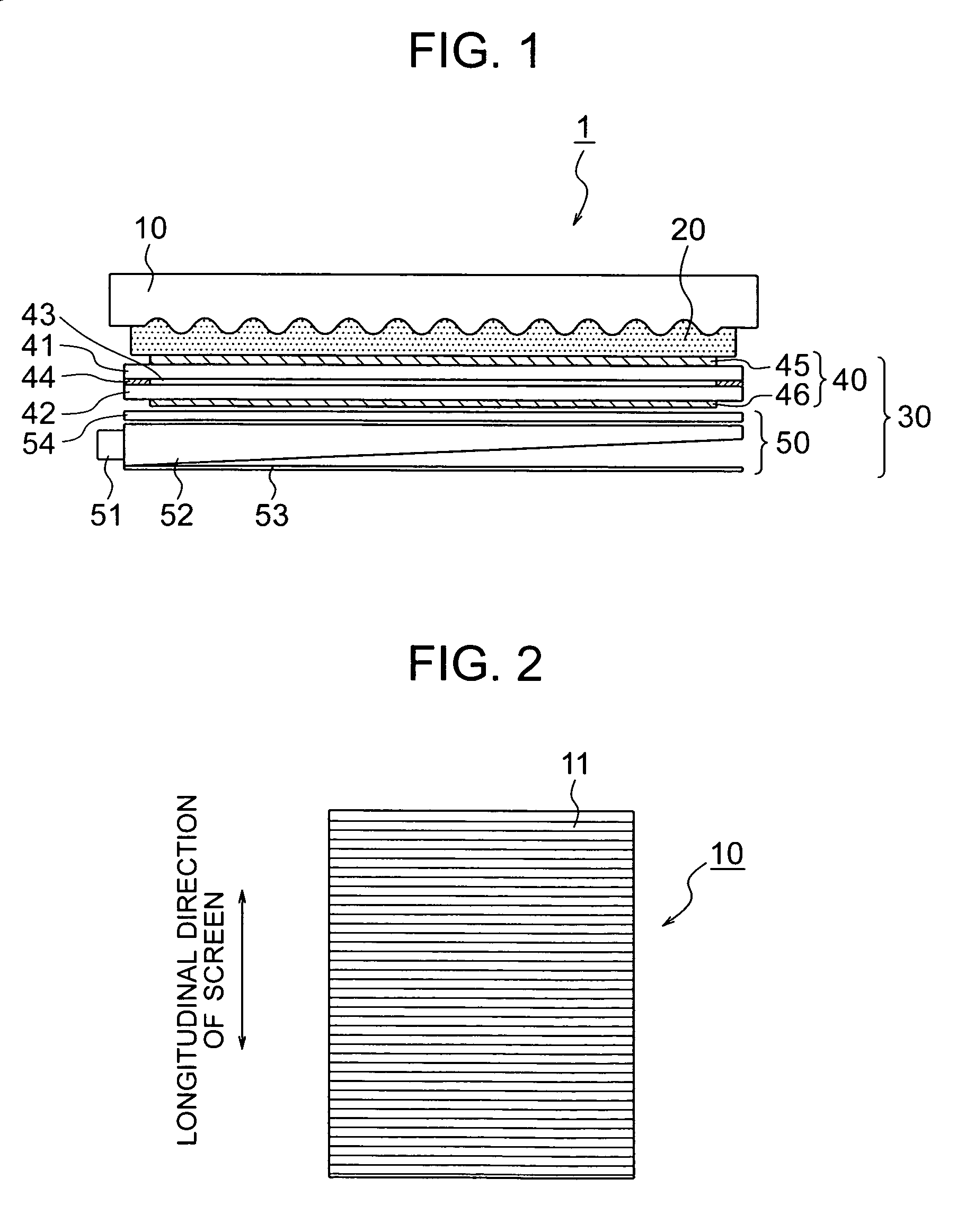

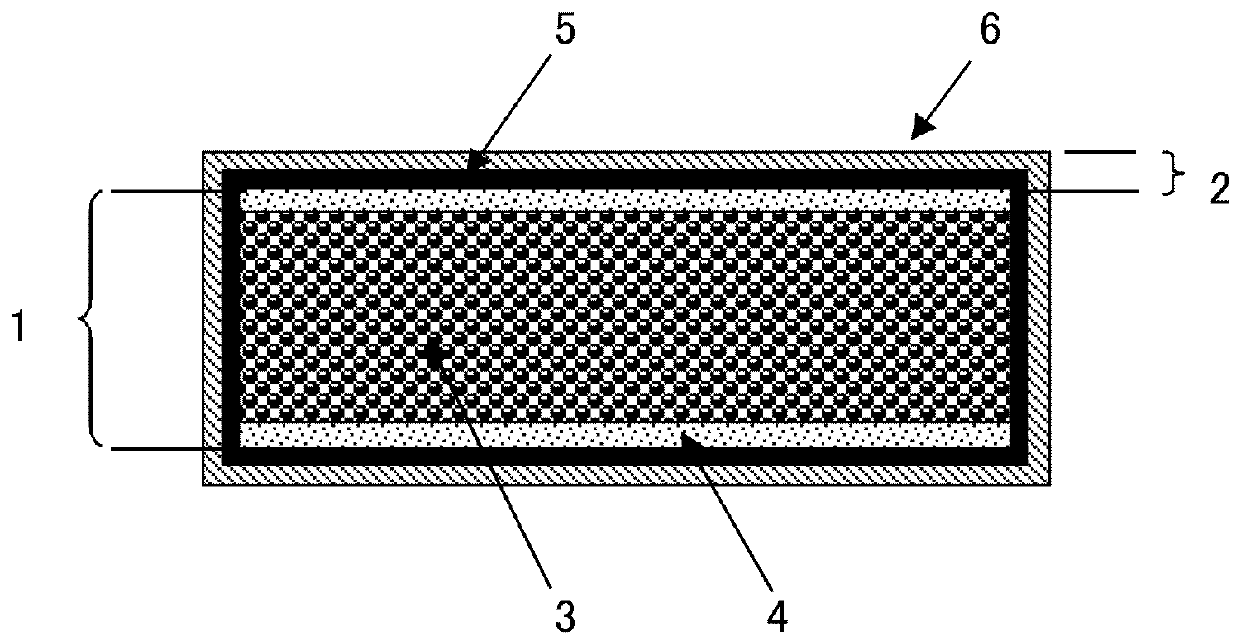

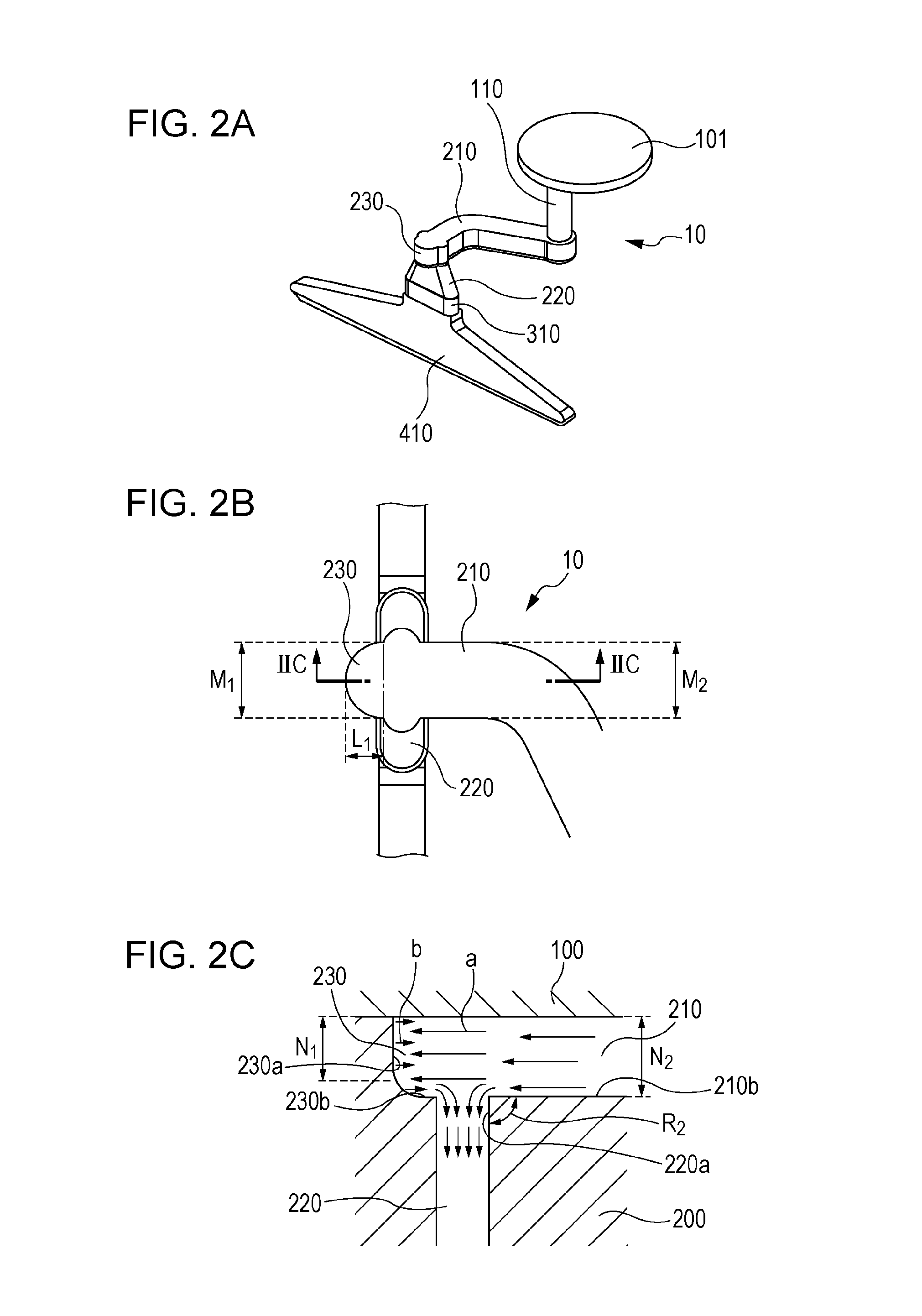

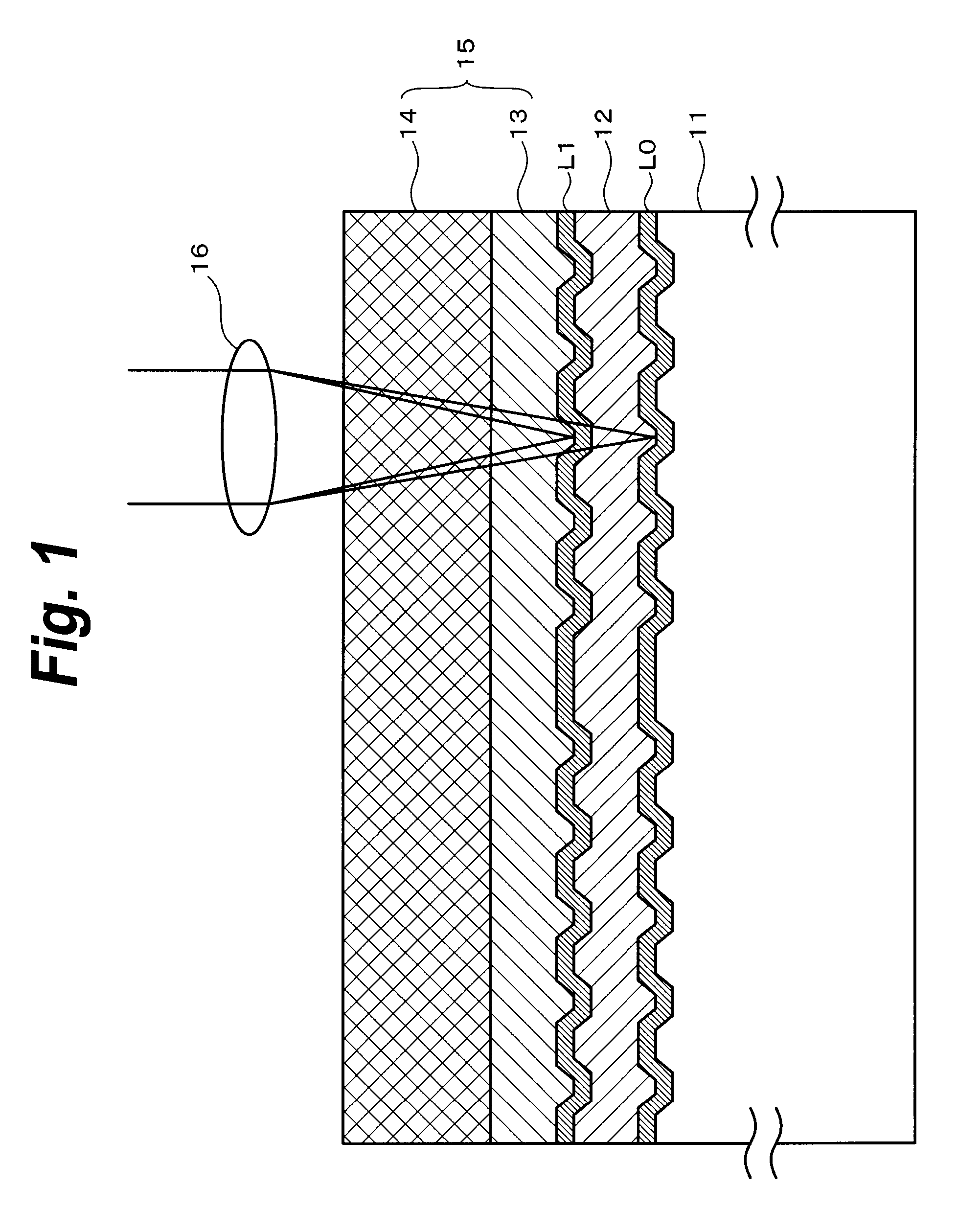

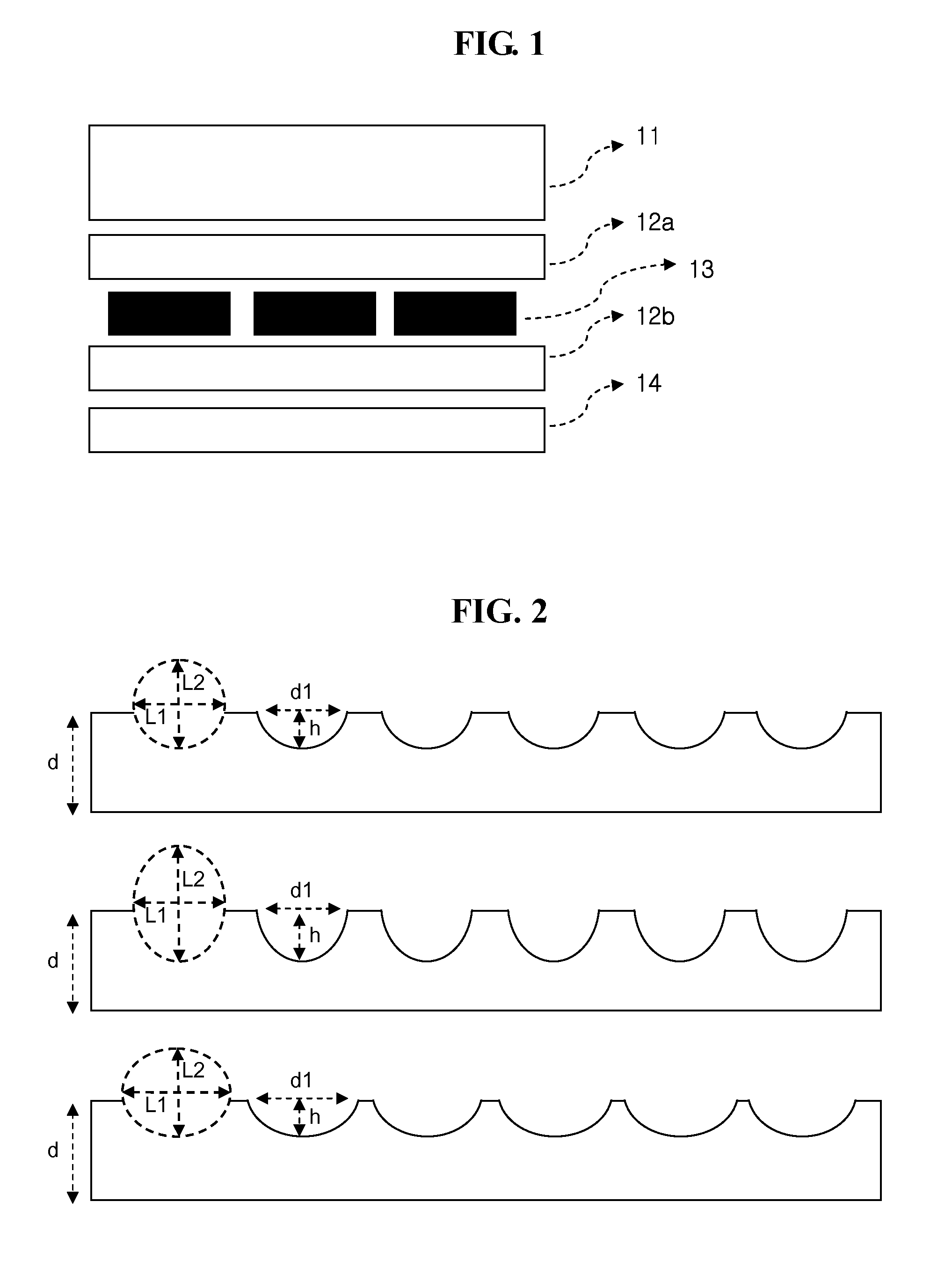

Display device and electrical appliance using the same

InactiveUS20070046874A1Quality improvementDifficult and inconvenientCathode-ray/electron-beam tube vessels/containersNon-linear opticsLiquid-crystal displayDisplay device

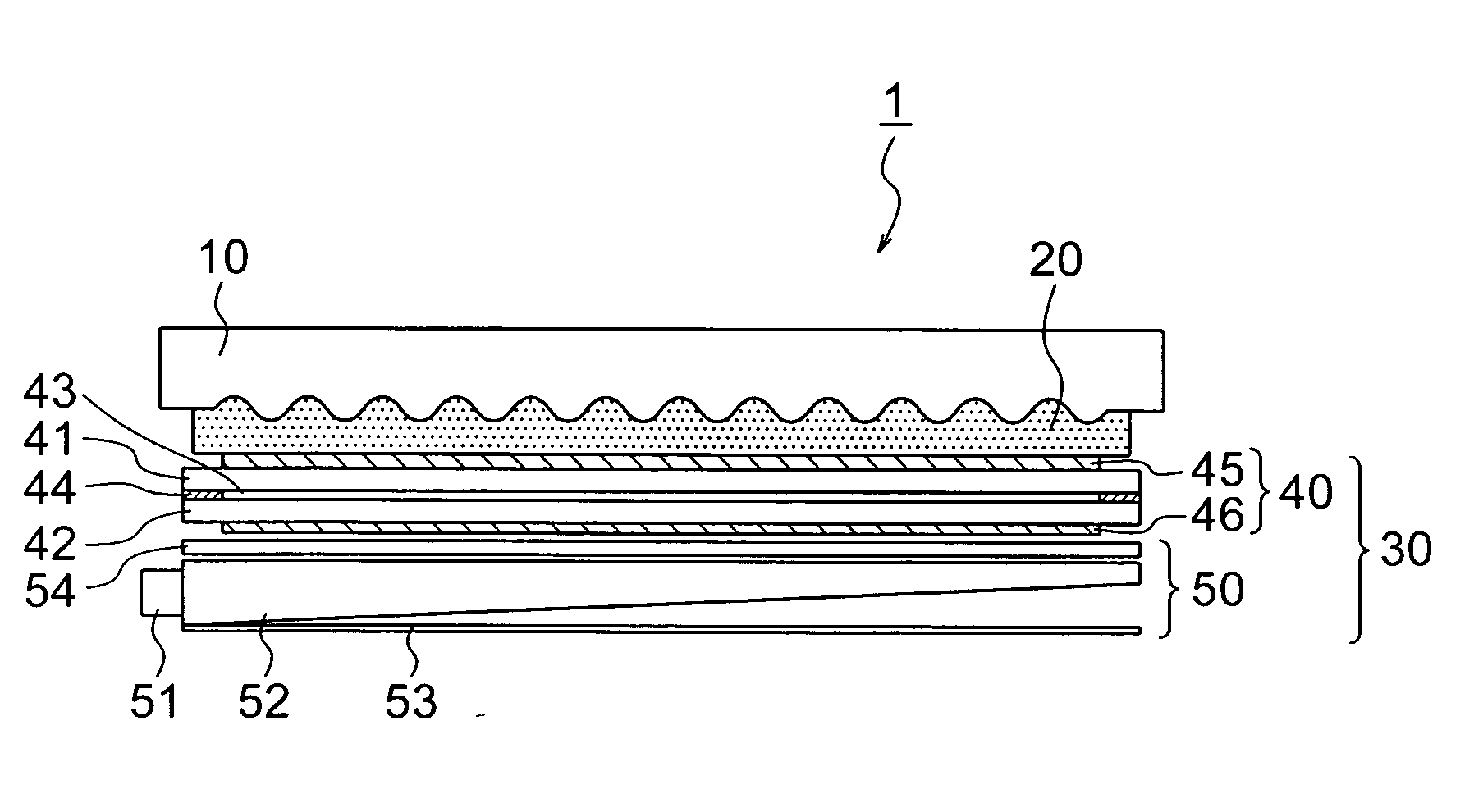

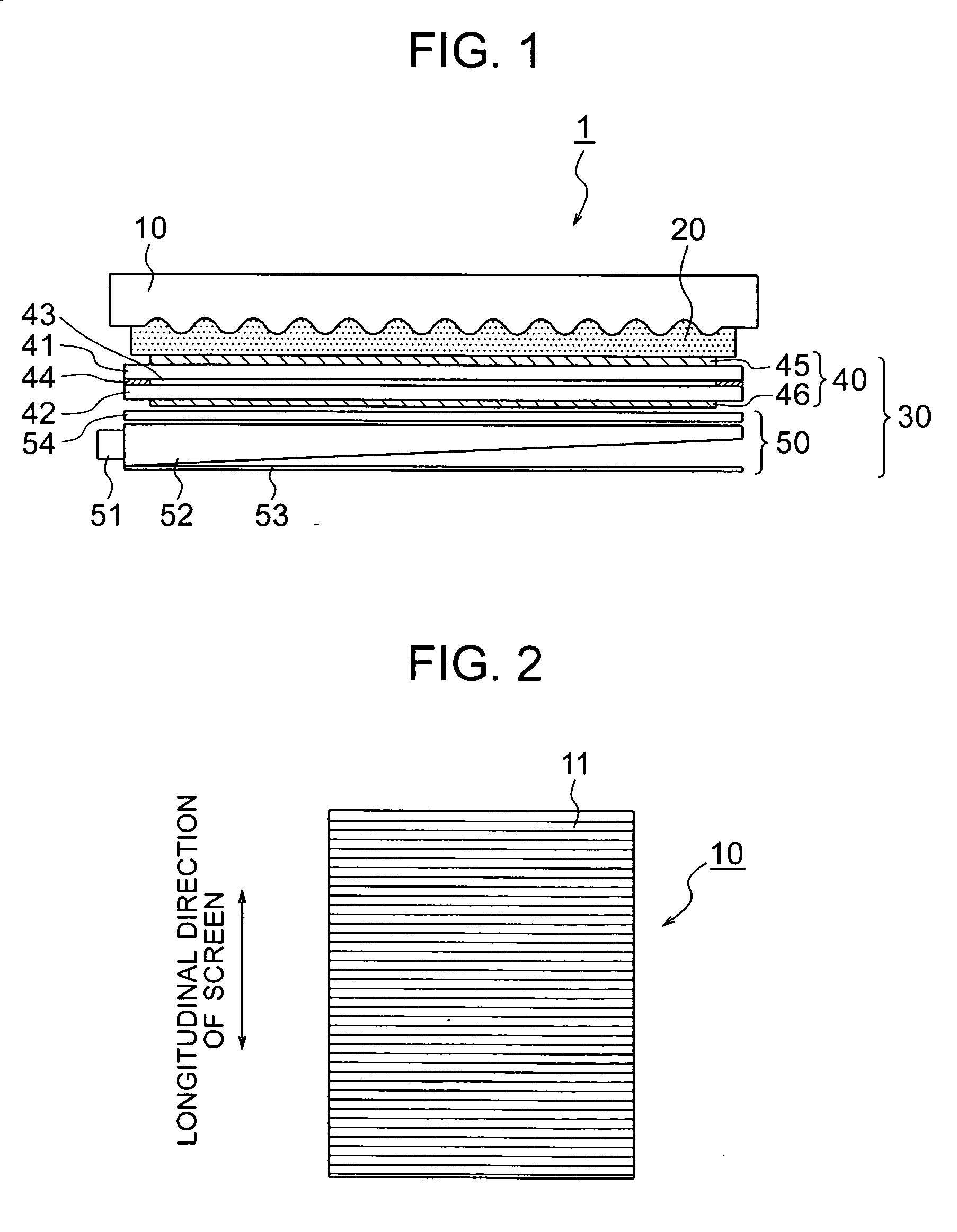

A liquid crystal display device comprising a pair of substrates, a liquid crystal display panel having a liquid crystal layer positioned between the substrates, a transparent protective plate arranged on a front surface side of the display panel, and an optically transparent layer between the display panel and the protective plate, and wherein the protective plate includes fine concavity and convexity configurations on at least a surface thereof toward the display panel.

Owner:HITACHI LTD

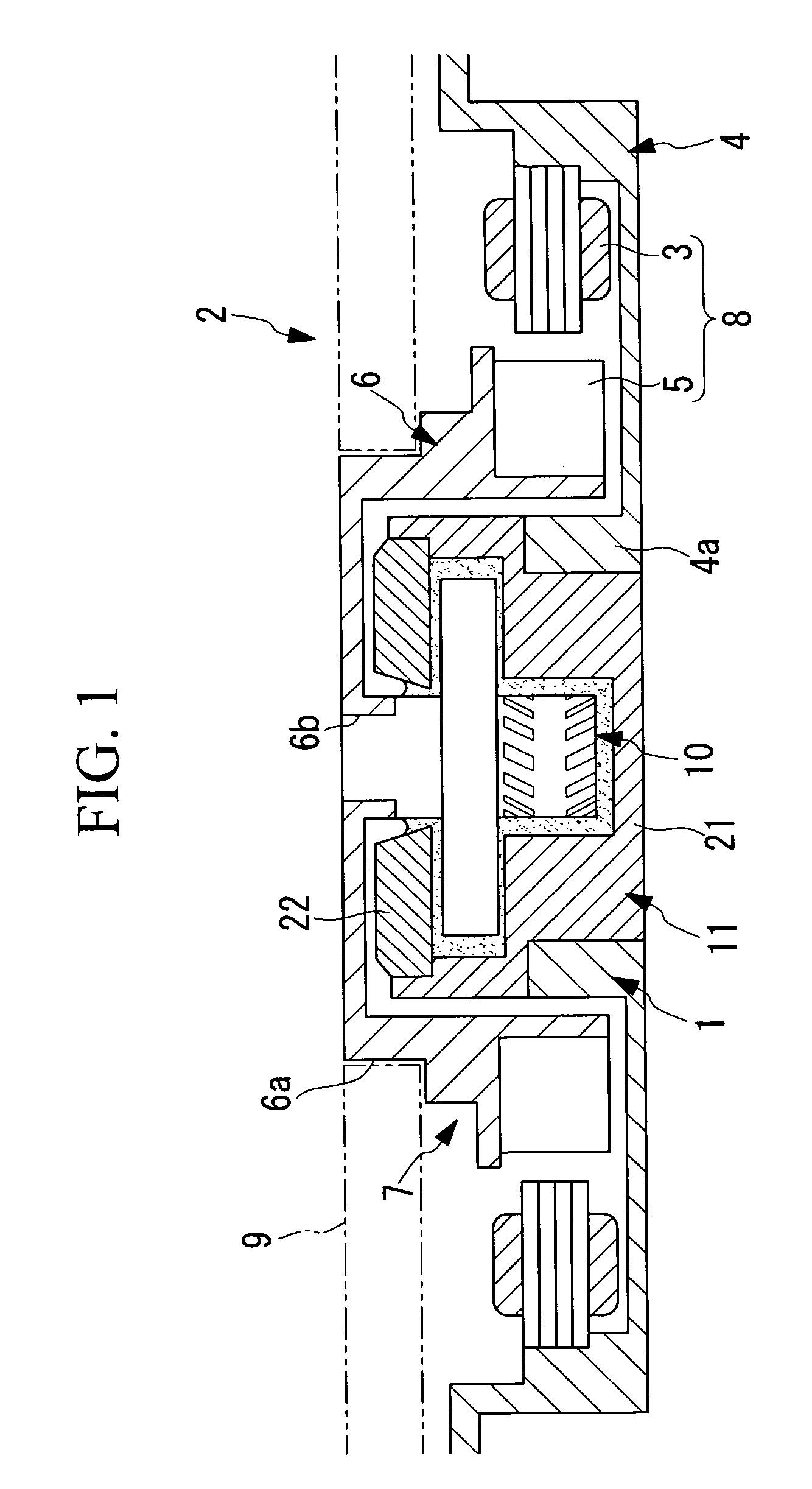

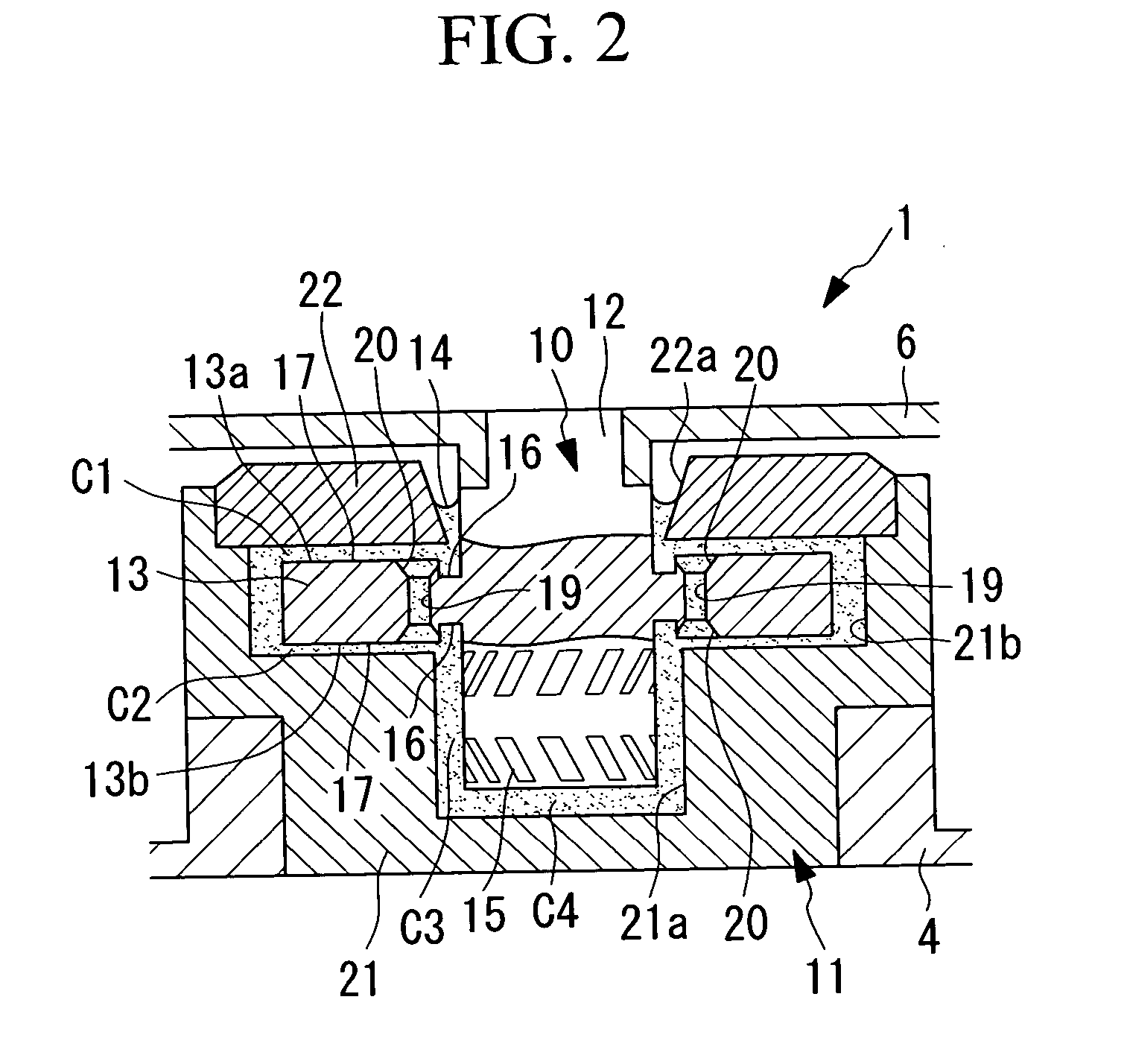

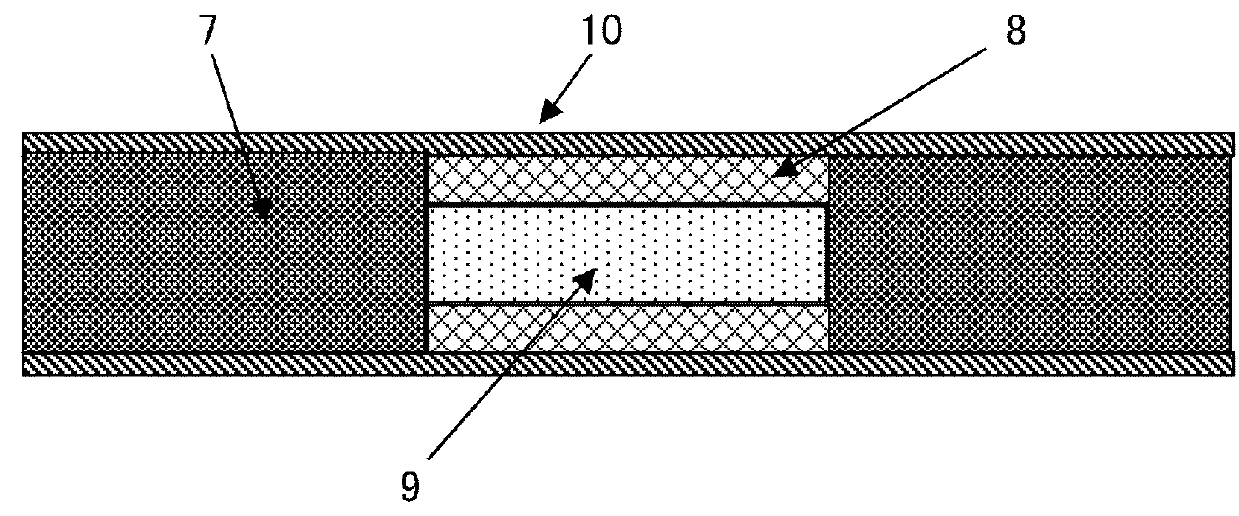

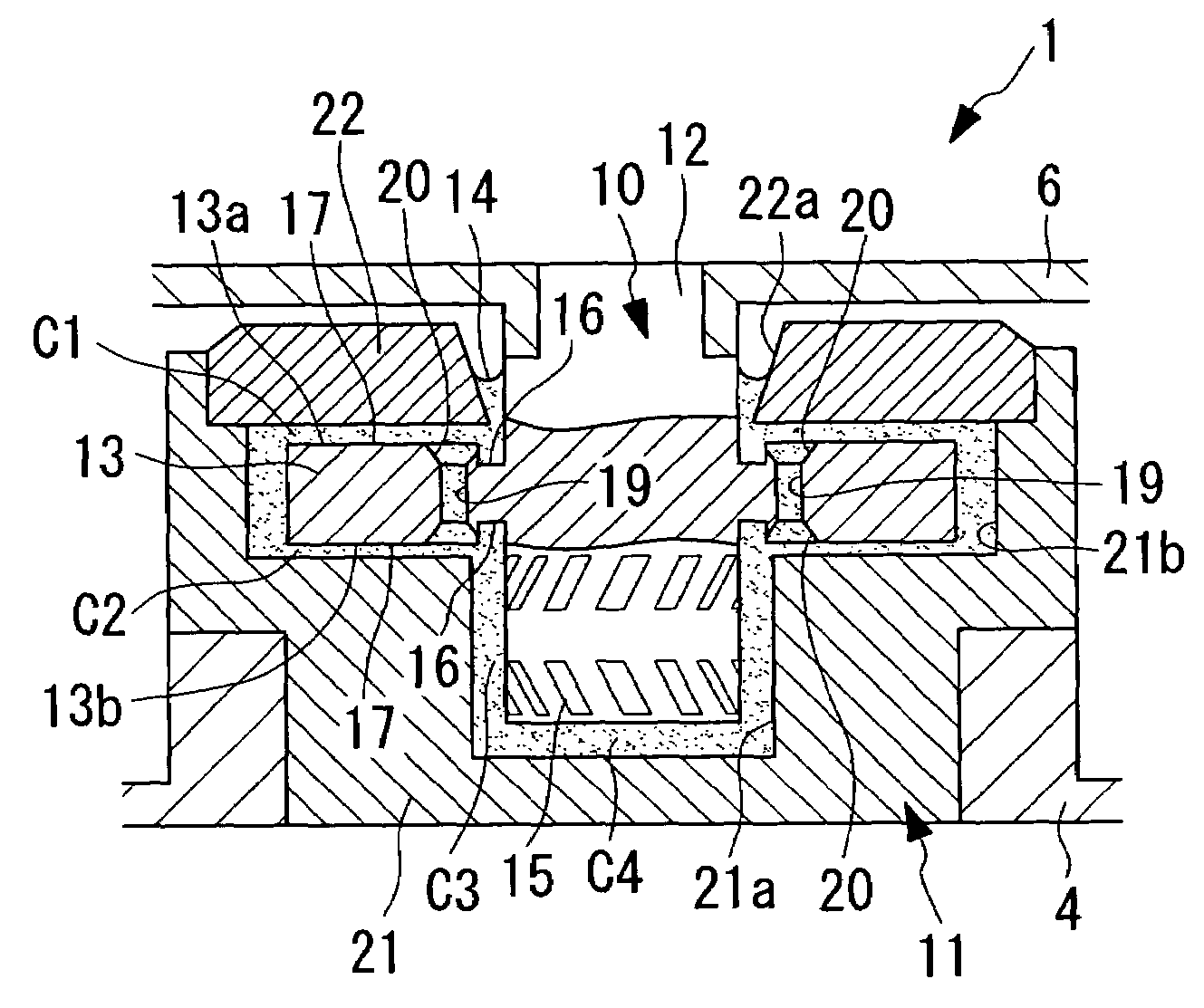

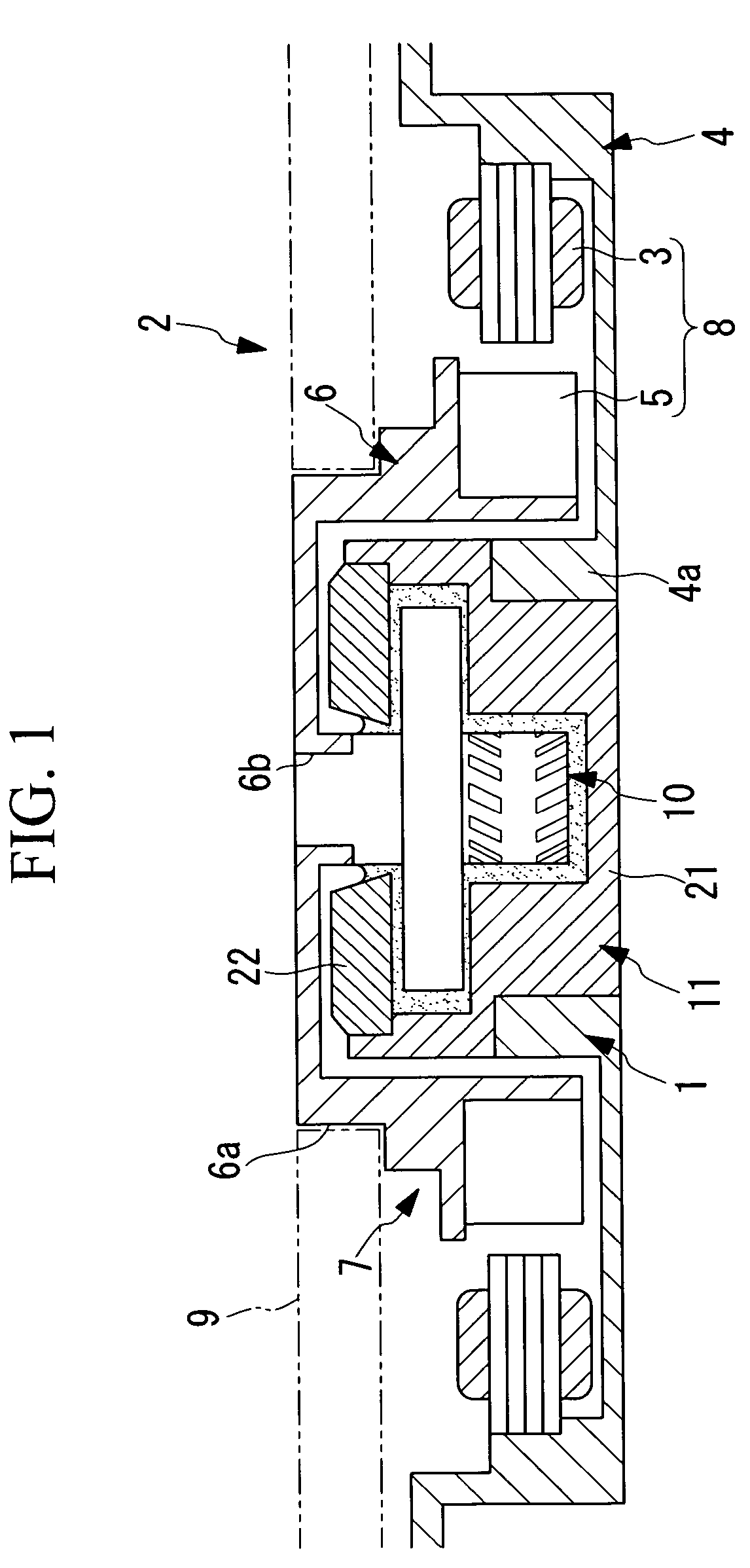

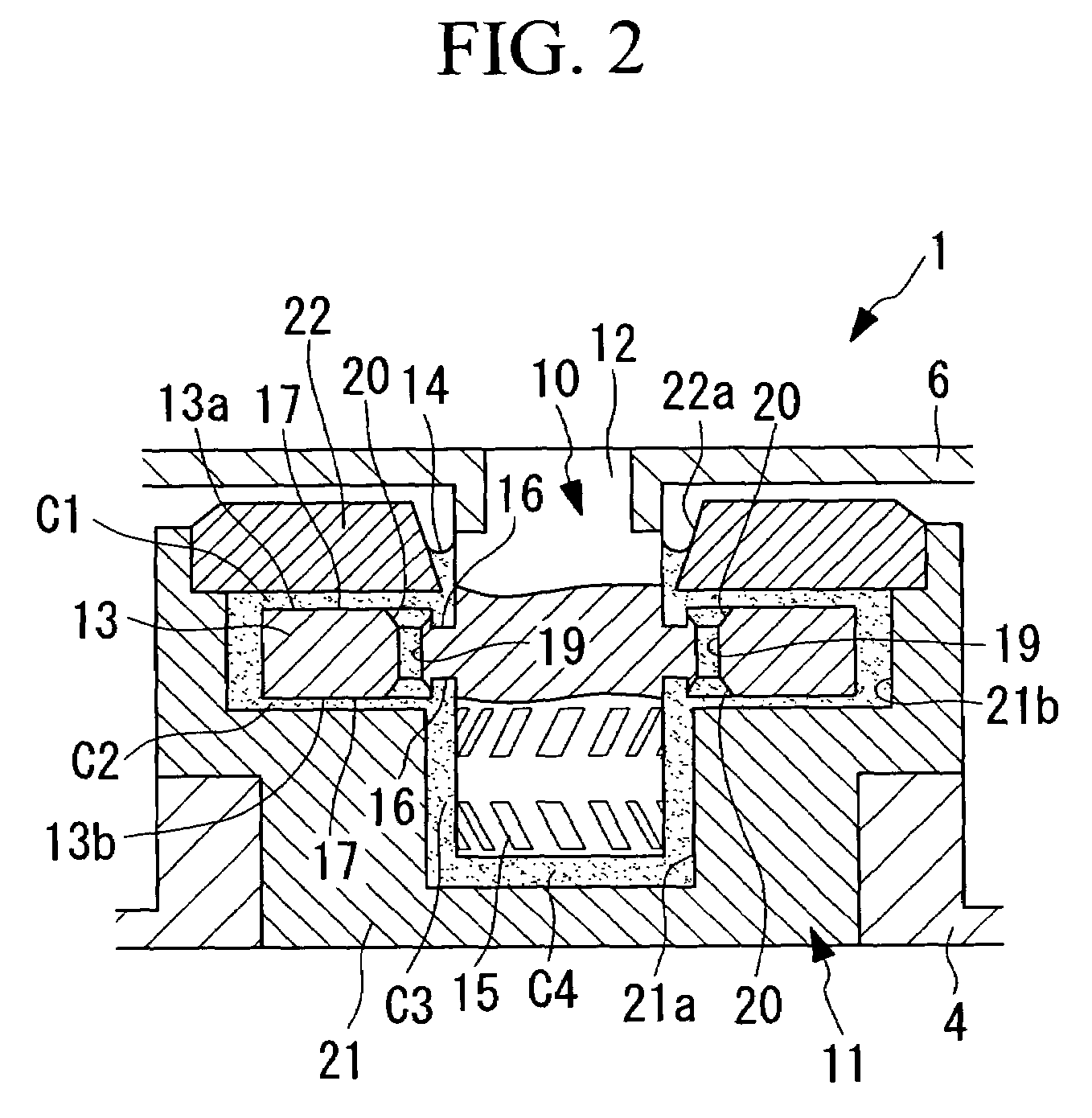

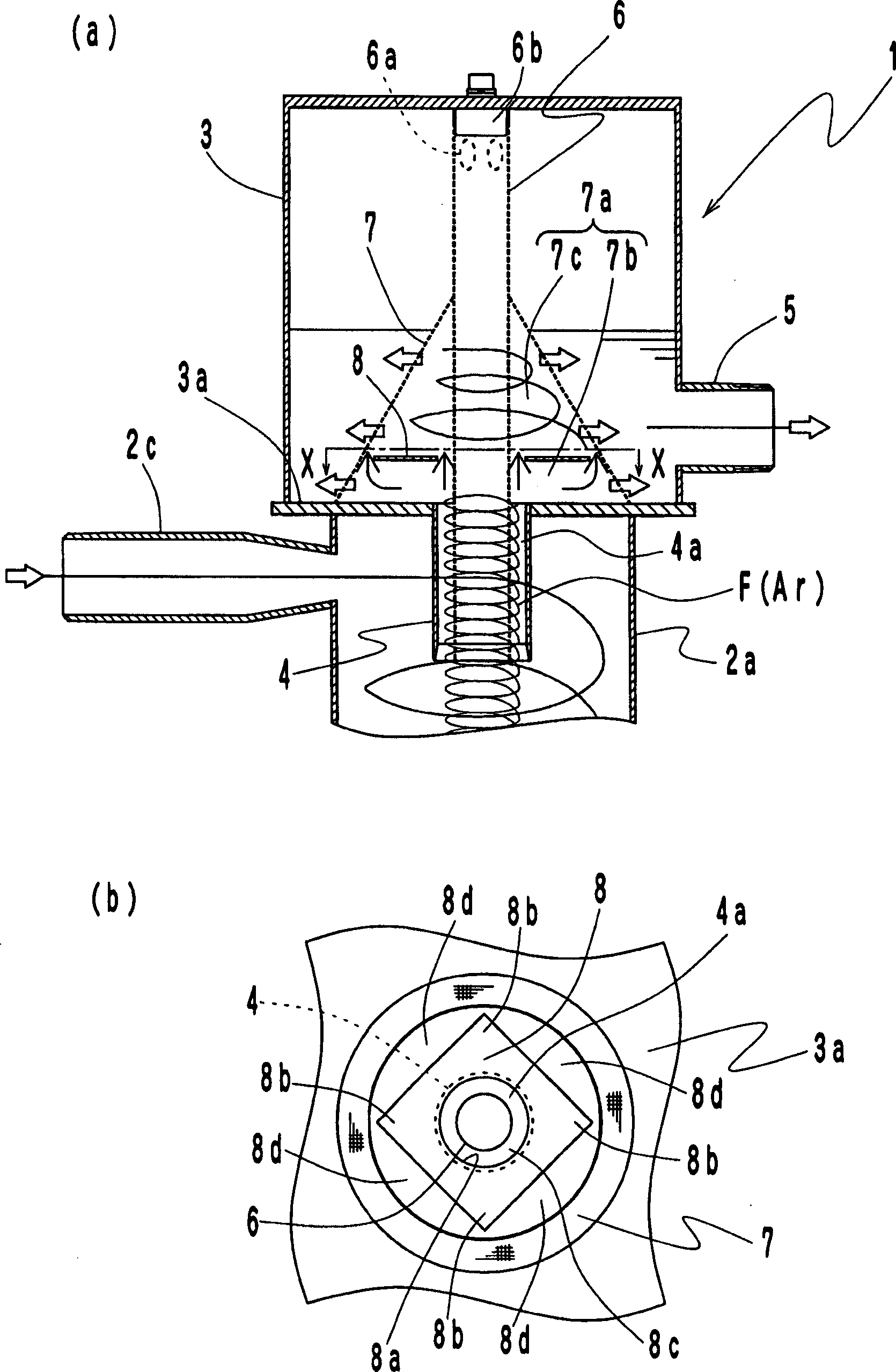

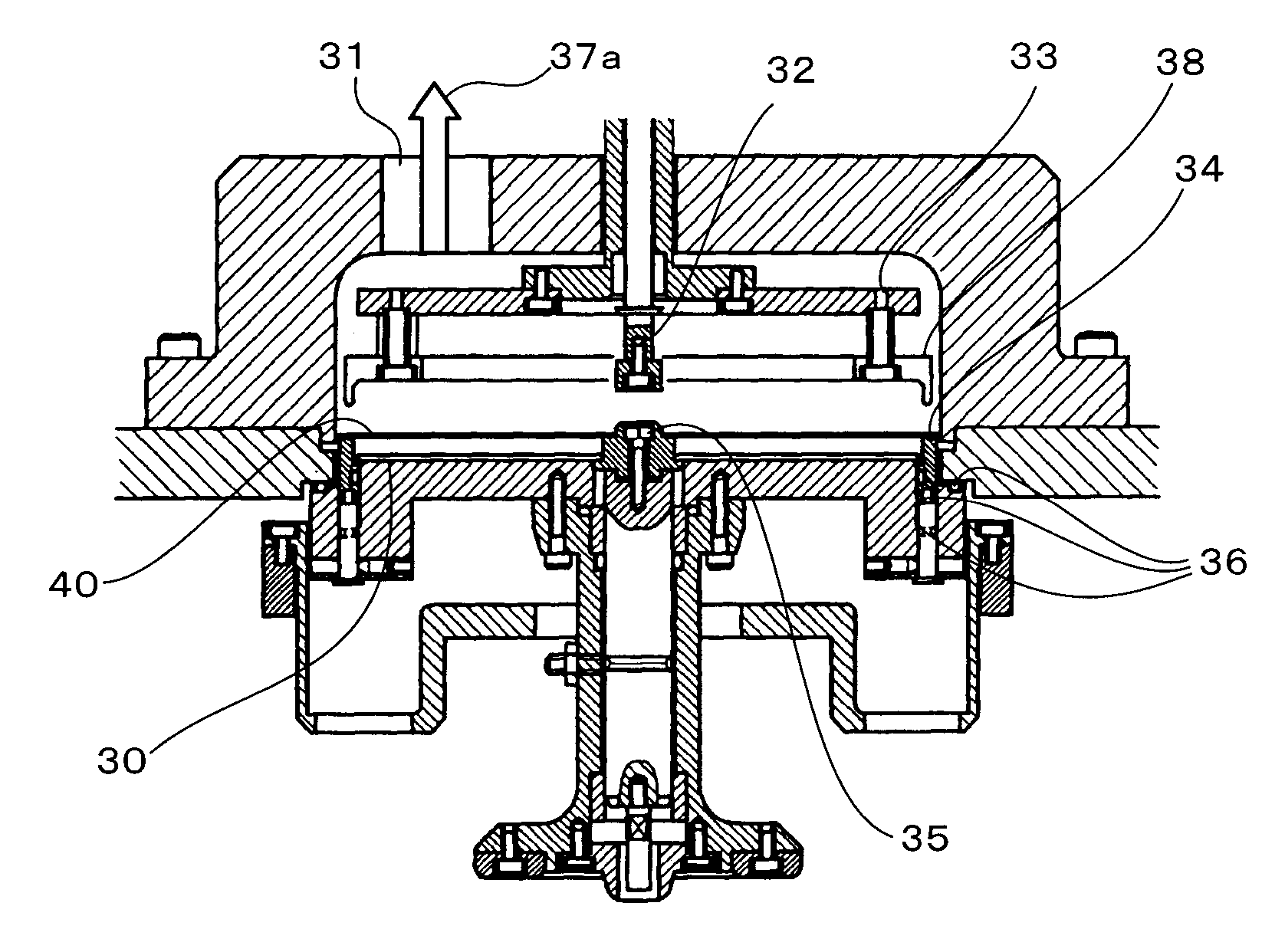

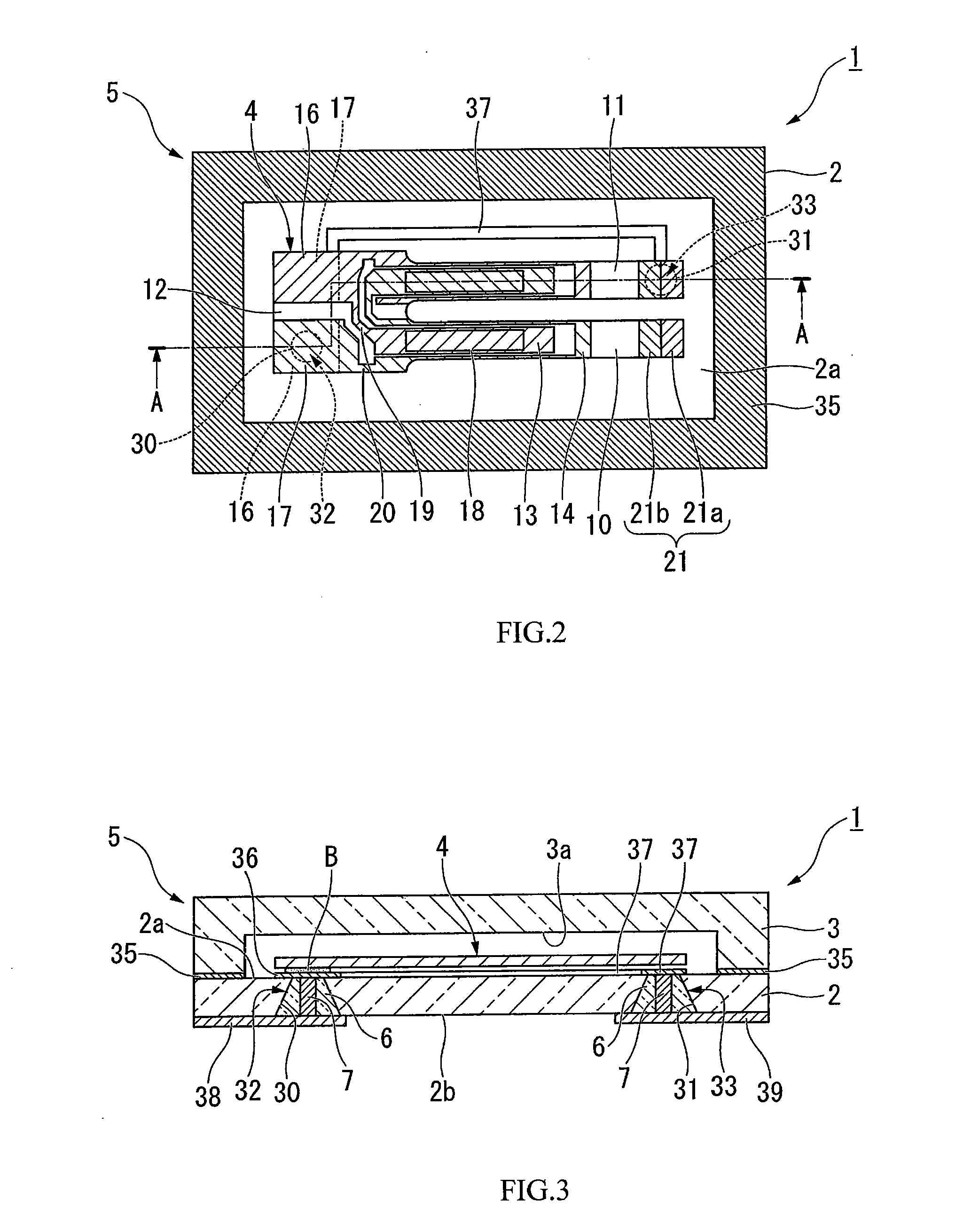

Fluid dynamic pressure bearing, motor, and recording medium driving device

InactiveUS20070177832A1Avoid mistakesAvoid bubblingShaftsRecord information storagePressure generationWorking fluid

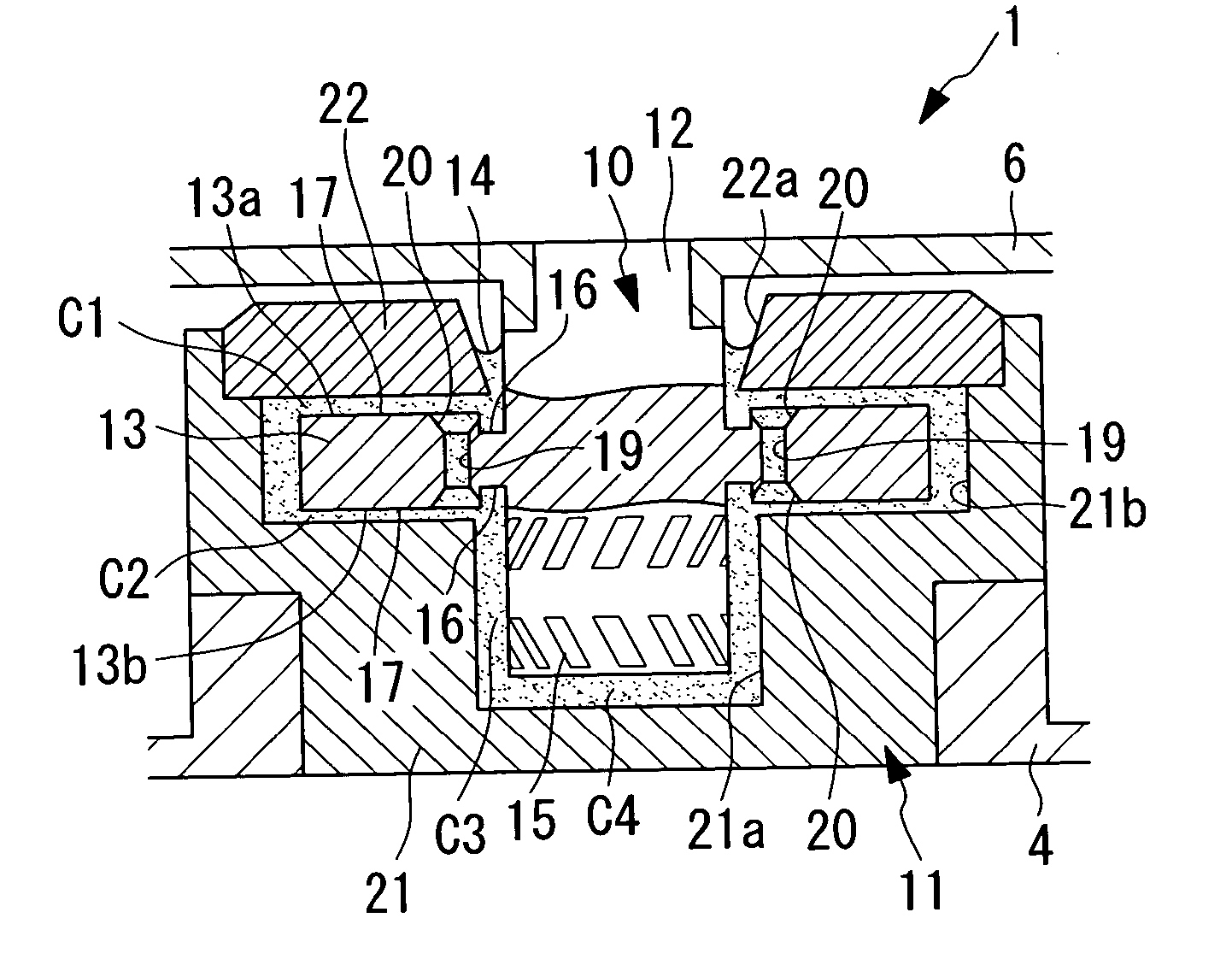

The generation of bubbles can be suppressed by enabling a stable supply of working fluid to a dynamic pressure generating groove, and oscillation at the time of rotation and leakage of working fluid can be prevented effectively by efficiently releasing any bubbles generated. There is provided a fluid dynamic pressure bearing 1 provided with an annular dynamic pressure generating face 17 made by forming a dynamic pressure generating groove, which draws a working fluid 14 toward a midway position in the radial direction from the inside and outside of a thrust bearing plate 13 in the radial direction, when a shaft 10 and a housing 11 are rotated relative to each other about the axis, on thickness direction end faces 13a, 13b of the thrust bearing plate 13, or on an inner surface of the housing 11, and an inner groove section 16, which is located on an inner peripheral side thereof and that is depressed more than the dynamic pressure generating face 17 in the thickness direction, on the end faces 13a, 13b. Moreover there is provided a through hole 19 which passes through the thrust bearing plate 13 in the thickness direction so as to open to the dynamic pressure generating face 17, and there is provided a communicating cavity 20 which connects the opening portion of the through hole 19 and the inner groove section 16.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

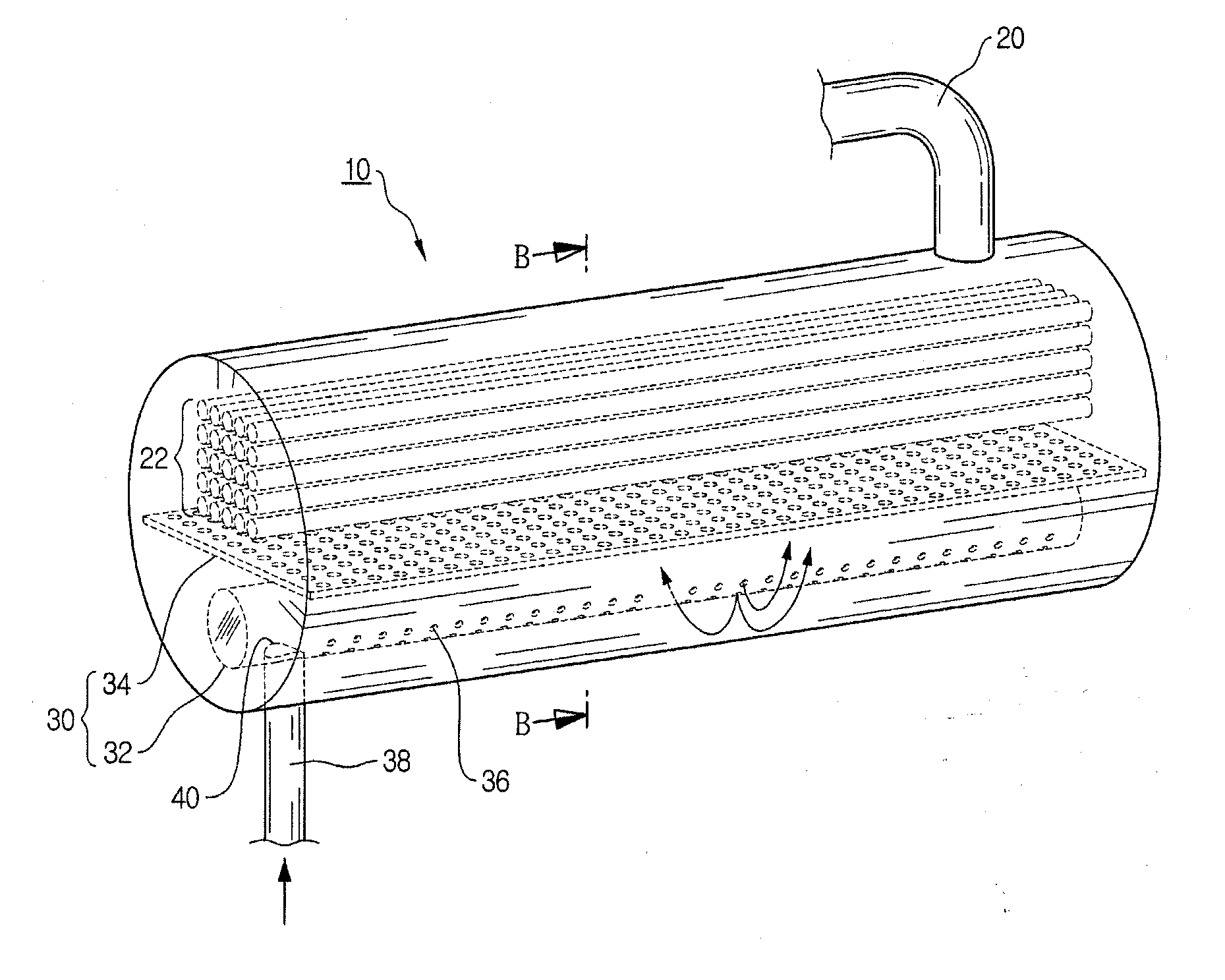

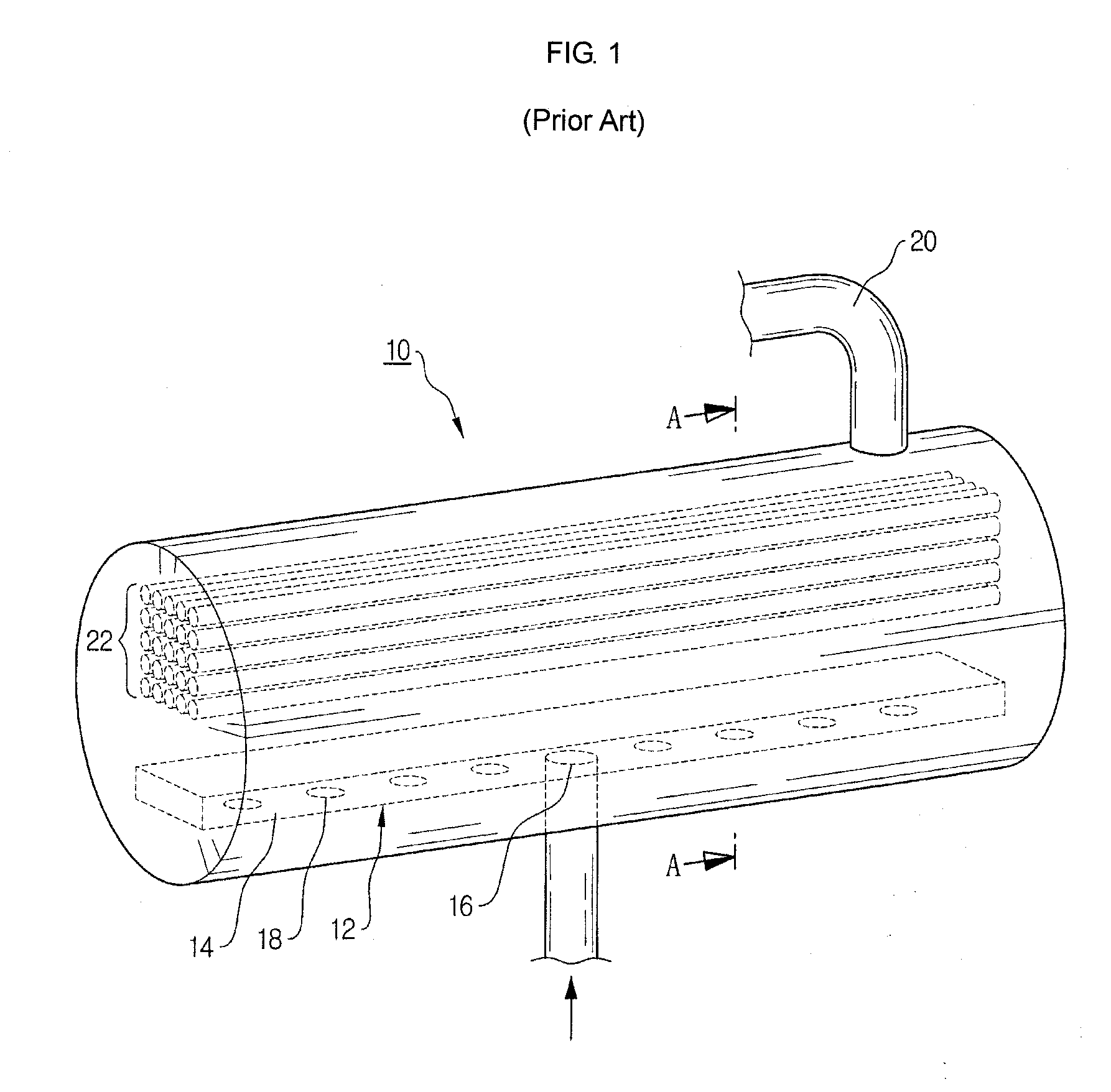

Distributor, and evaporator and refrigerating machine with the same

InactiveUS20110226005A1Lower performance requirementsReduce vibrationCompression machines with non-reversible cycleEvaporators/condensersEngineeringLevel line

Provided are a distributor having a distribution tube having an inner surface formed as a curved surface, a plurality of distribution holes which are formed in a lower semicircular region of the distribution tube with respect to a horizontal line of the distribution tube and are arranged to be symmetrical about a vertical line of the distribution tube and a connection hole provided in the distribution tube so that the distribution tube is connected to a connection tube, an evaporator and a refrigerating machine with the distributor. A perforated plate may be fixed to an inside of the distribution tube so as to block a flow path of a cooling medium.

Owner:LG ELECTRONICS INC

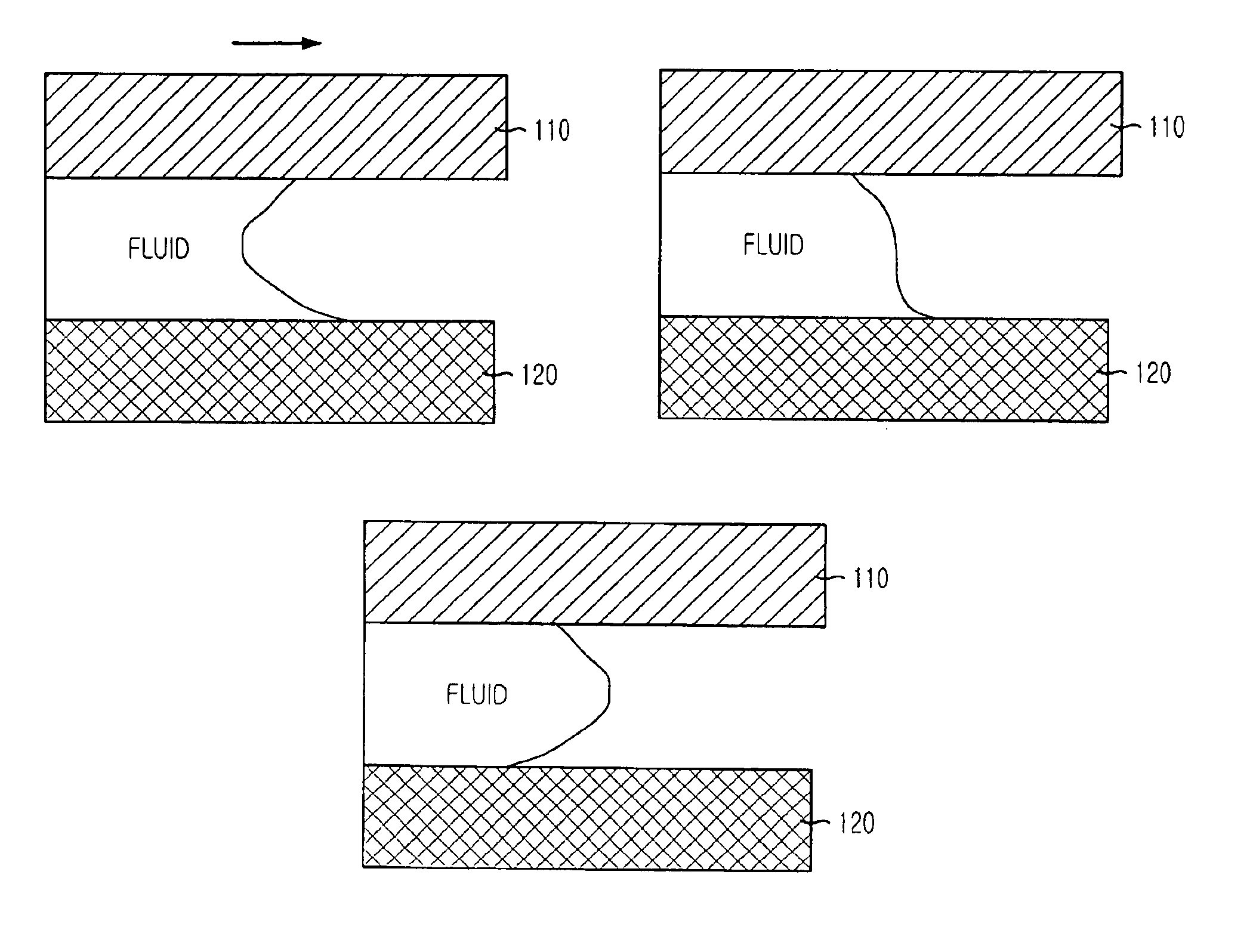

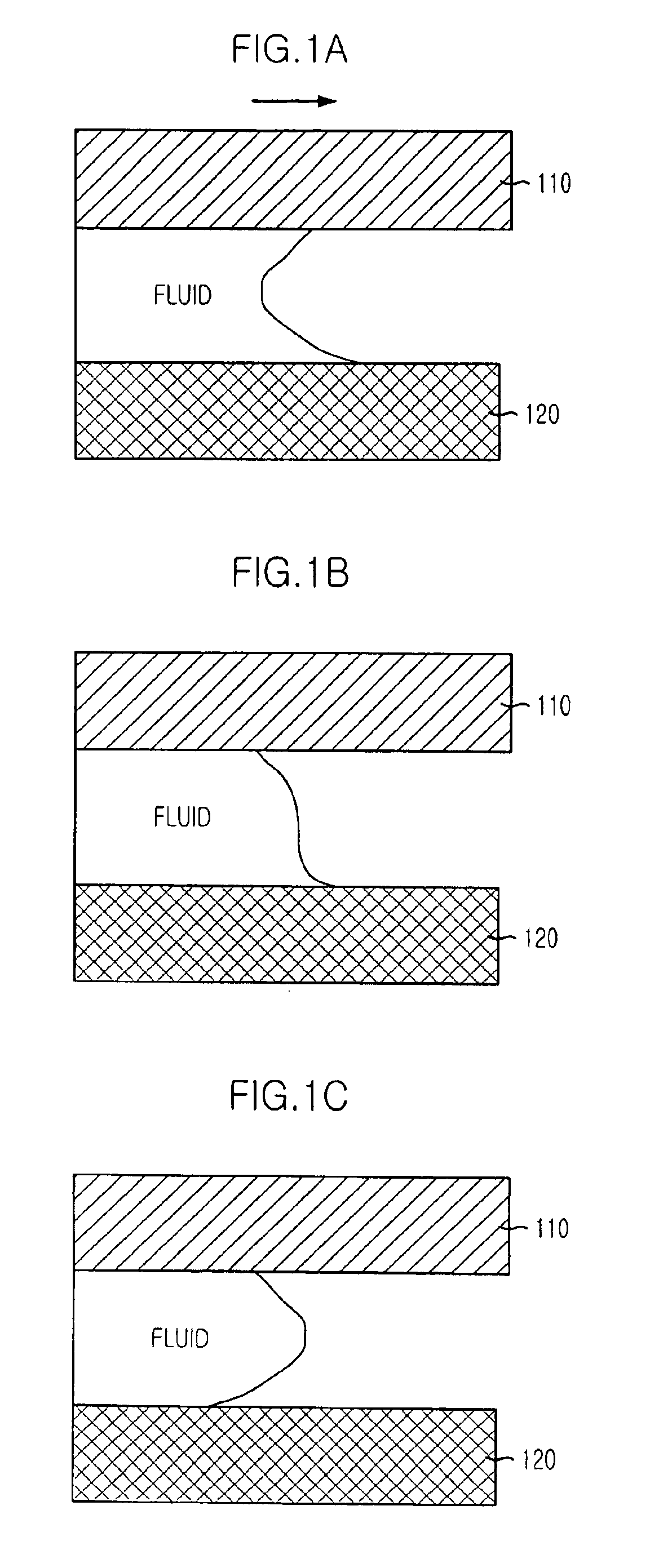

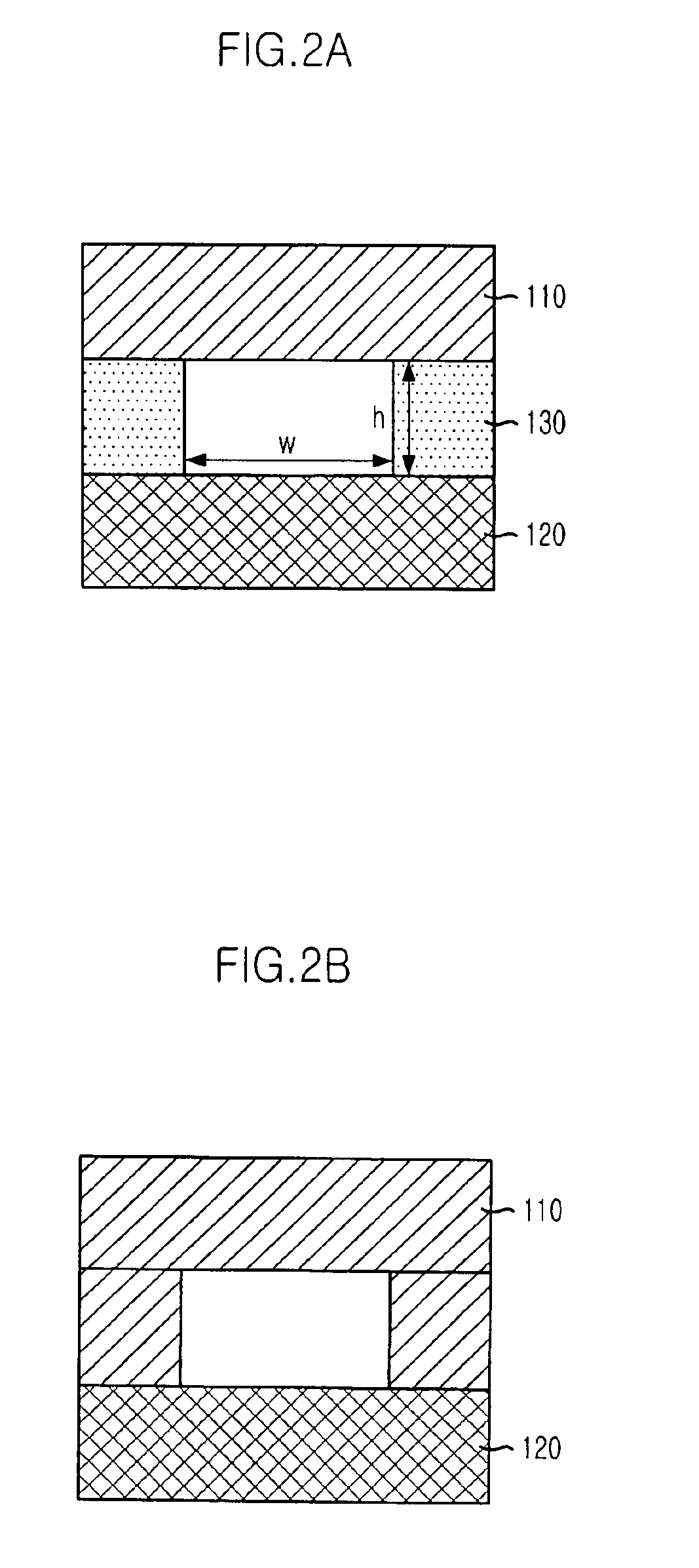

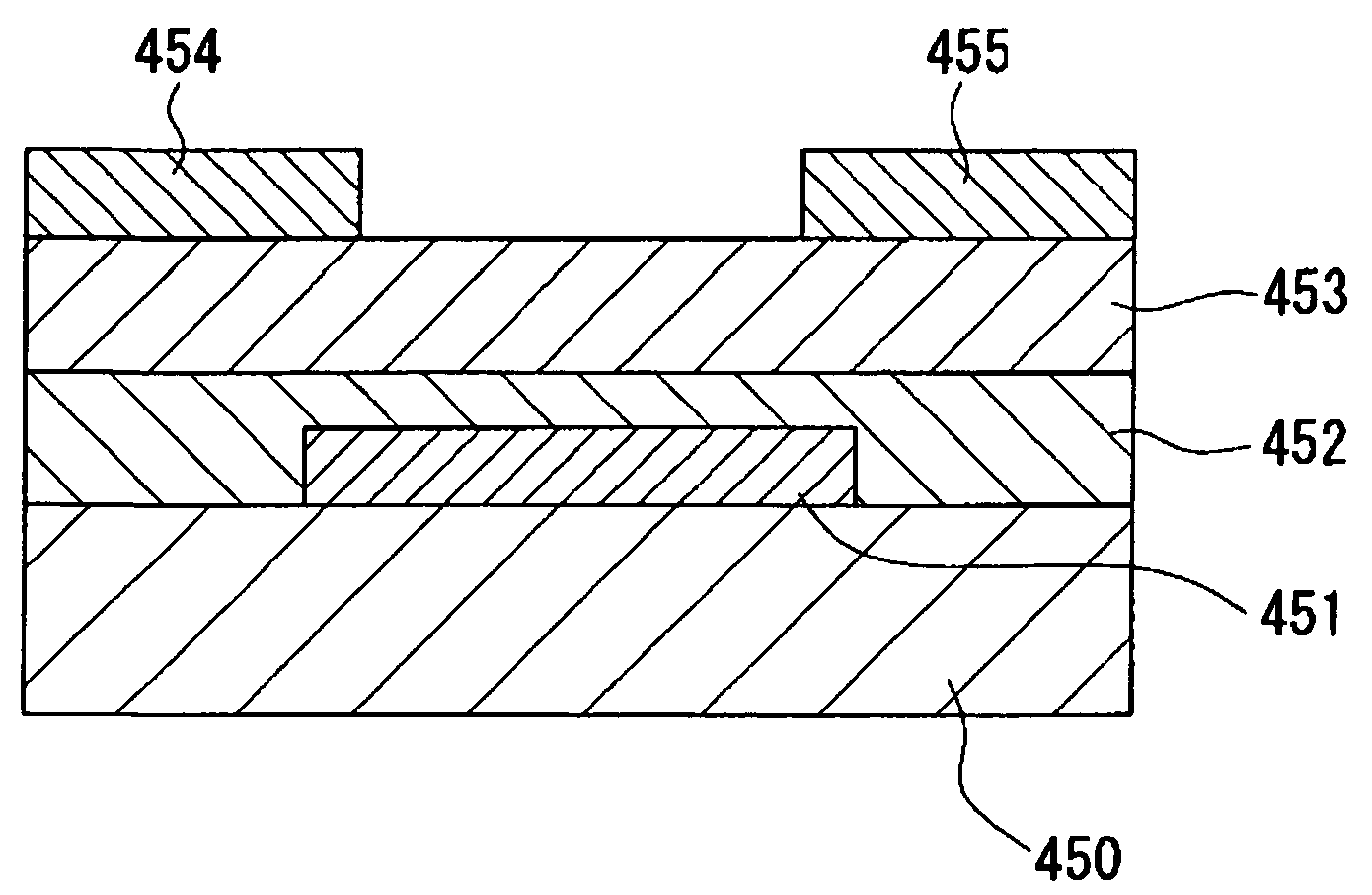

Micro fluidic device for controlling flow time of micro fluid

ActiveUS6901963B2Simple principleSimple structureAmpoule syringesCircuit elementsControl flowEngineering

Provided is a micro fluidic device that can control a flow time of micro fluid by using a capillary phenomenon. The micro fluidic device includes: a flow channel for flowing fluid, the flow channel being formed between a top substrate and a bottom substrate or between a top substrate, a bottom substrate, and a middle substrate; a flow blocking surface for stopping a flow of the fluid in the flow channel temporarily; and a hump for delaying the flow formed in the line of continuity with the flow blocking surface. The micro fluidic device of the present research can control the flow time in a simple manner.

Owner:INTELLECTUAL DISCOVERY CO LTD

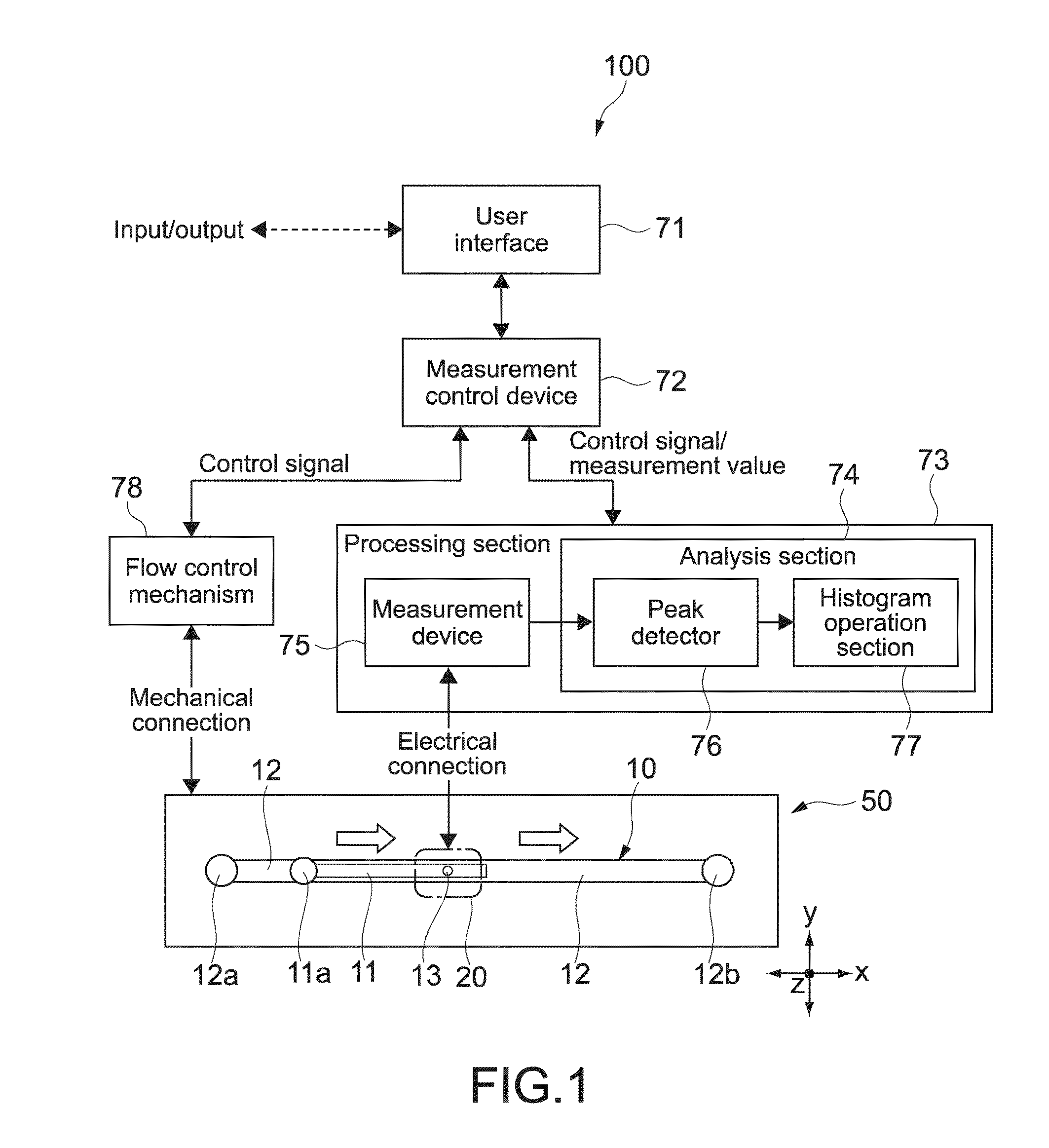

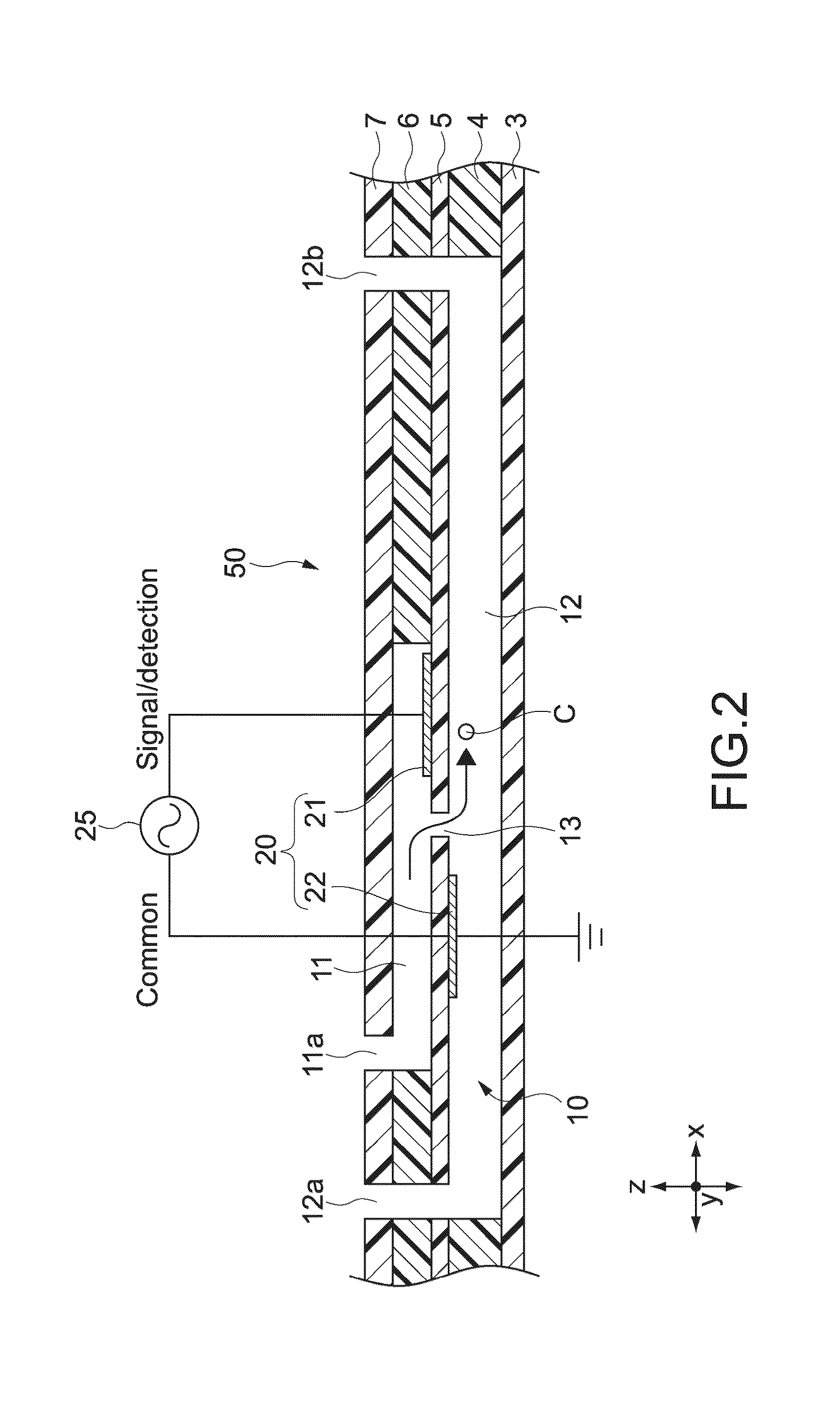

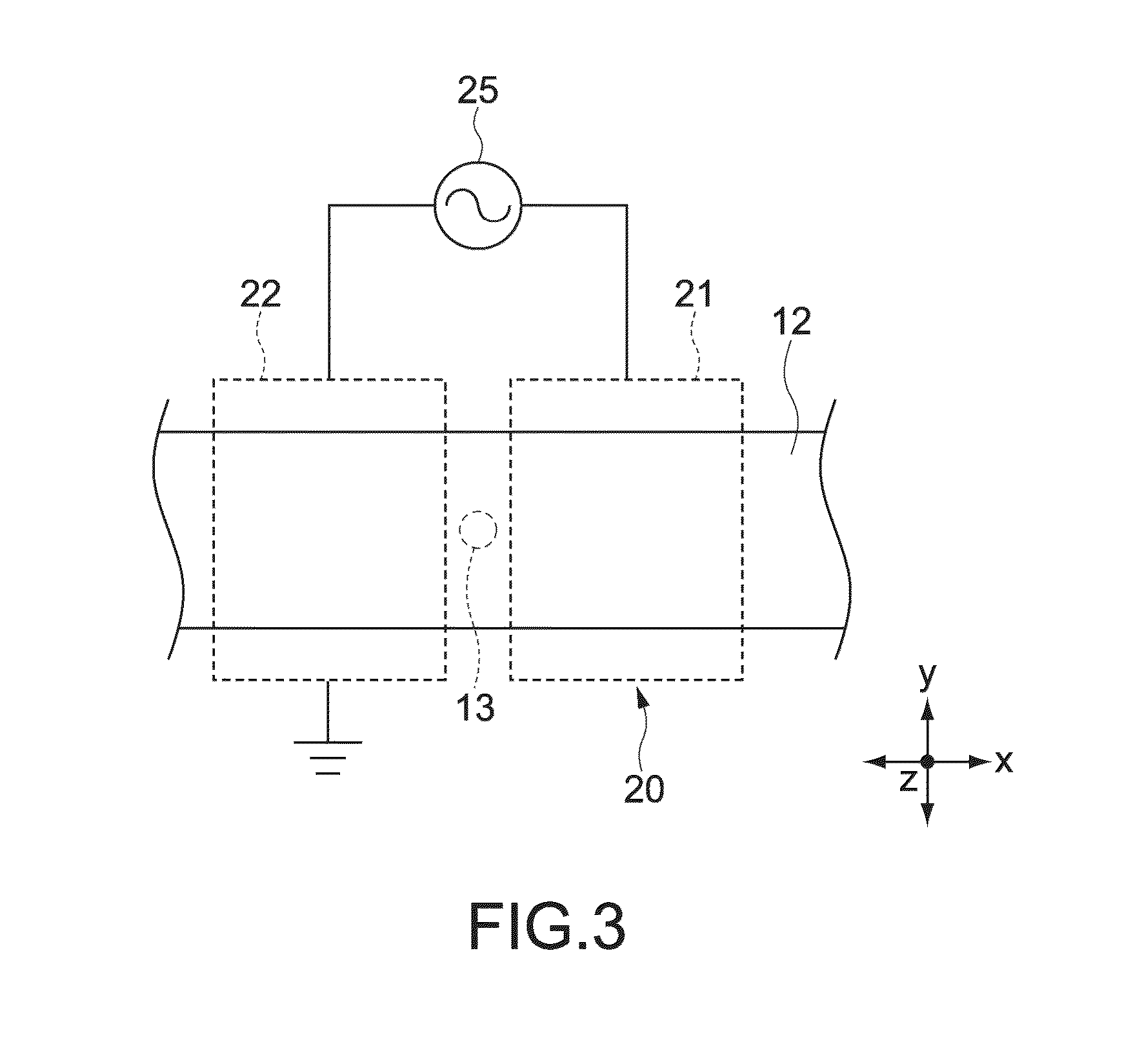

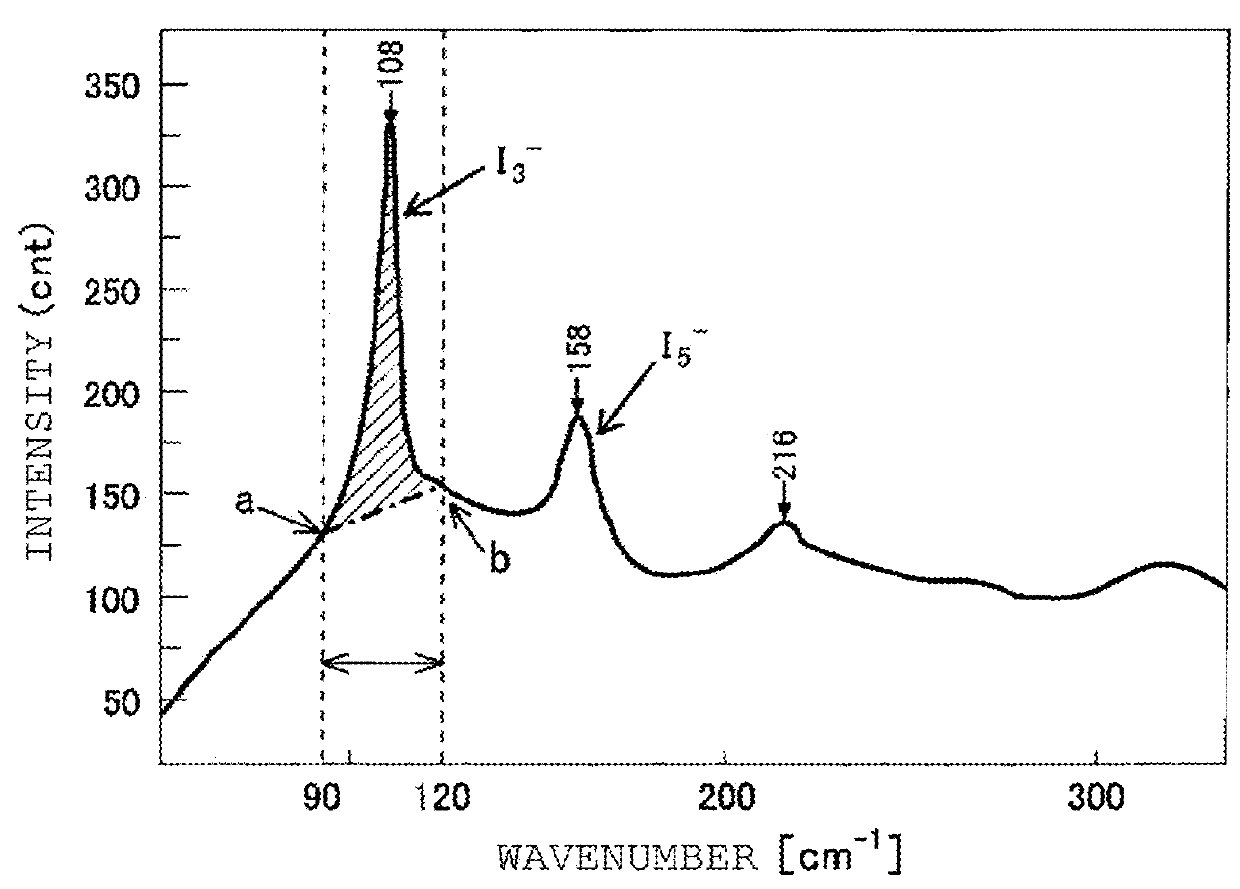

Measurement apparatus and measurement method

InactiveUS20160025610A1Generation of air bubble be suppressSuppress the generation of air bubblesBioreactor/fermenter combinationsBiological substance pretreatmentsDouble-layer capacitanceMeasurement device

A measurement apparatus includes a generation section and a measurement section and performs a predetermined measurement using a flow channel device including a narrow channel through which particles pass by a flow of a fluid and a measurement electrode section provided in the vicinity of the narrow channel. The generation section generates, in the measurement electrode section, an AC voltage that is higher than a characteristic frequency defined by a conductance of the fluid including the particles in the narrow channel and an electrical double layer capacitance formed by the measurement electrode section and has a frequency range indicating a conductance corresponding to a size of the particles. The measurement section measures, while the AC voltage is applied to the measurement electrode section, an electrical amount including at least the conductance obtained when the particles pass through the narrow channel.

Owner:SONY CORP

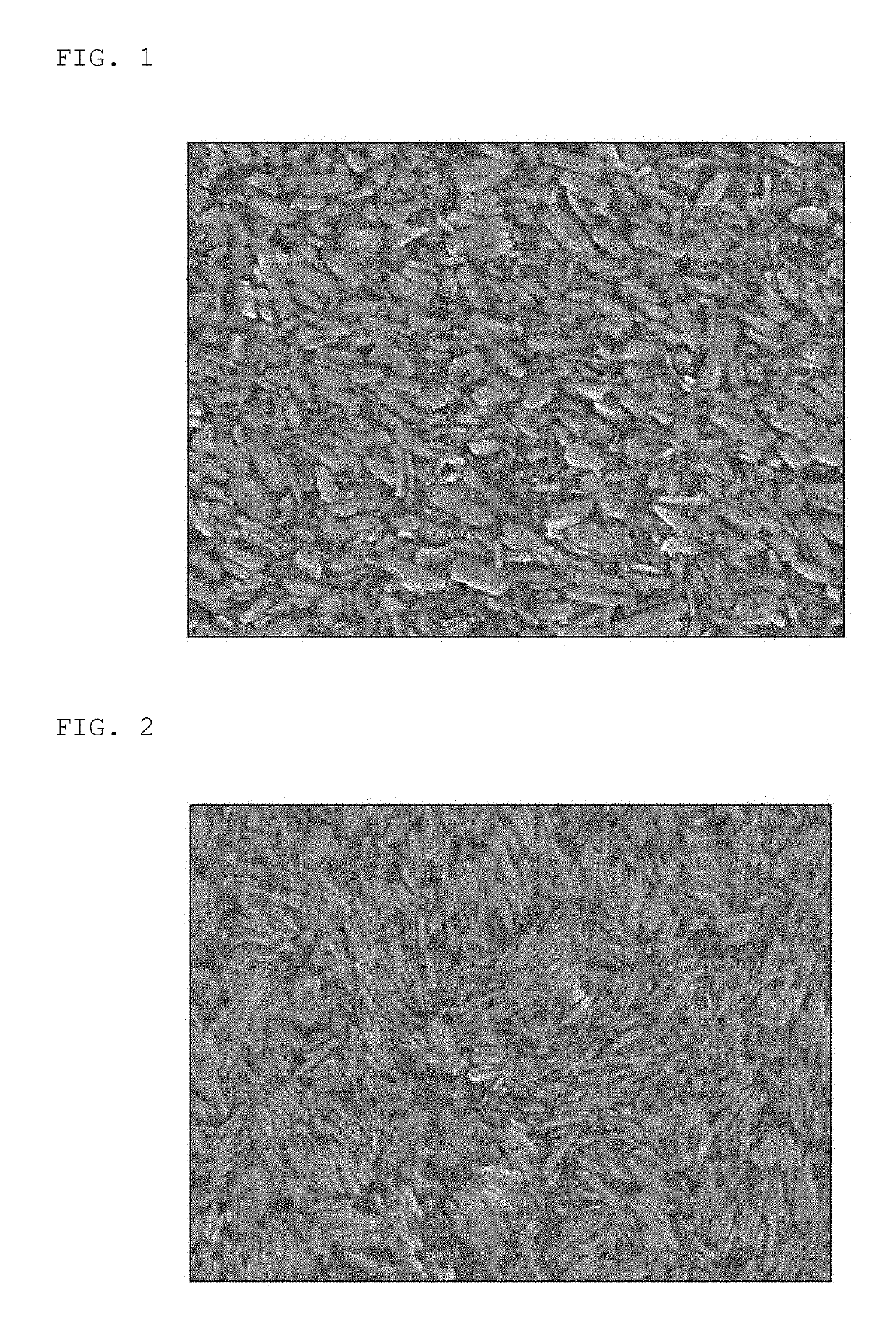

Rubber composition and process for preparing the same

InactiveUS20070015861A1Efficient couplingReduce rolling resistanceSpecial tyresRolling resistance optimizationRolling resistancePolymer science

A rubber composition improving the reaction efficiency of a silane coupling agent in kneading, suppressing generation of air bubbles, improving processability and abrasion resistance and lowering rolling resistance, and a process for preparing the same are provided. A rubber composition comprising silica, wherein 3 to 15 parts by weight of a silane coupling agent based on 100 parts by weight of silica and 0.3 to 1.45 parts by weight of a potassium salt based on 100 parts by weight of silica are contained.

Owner:SUMITOMO RUBBER IND LTD

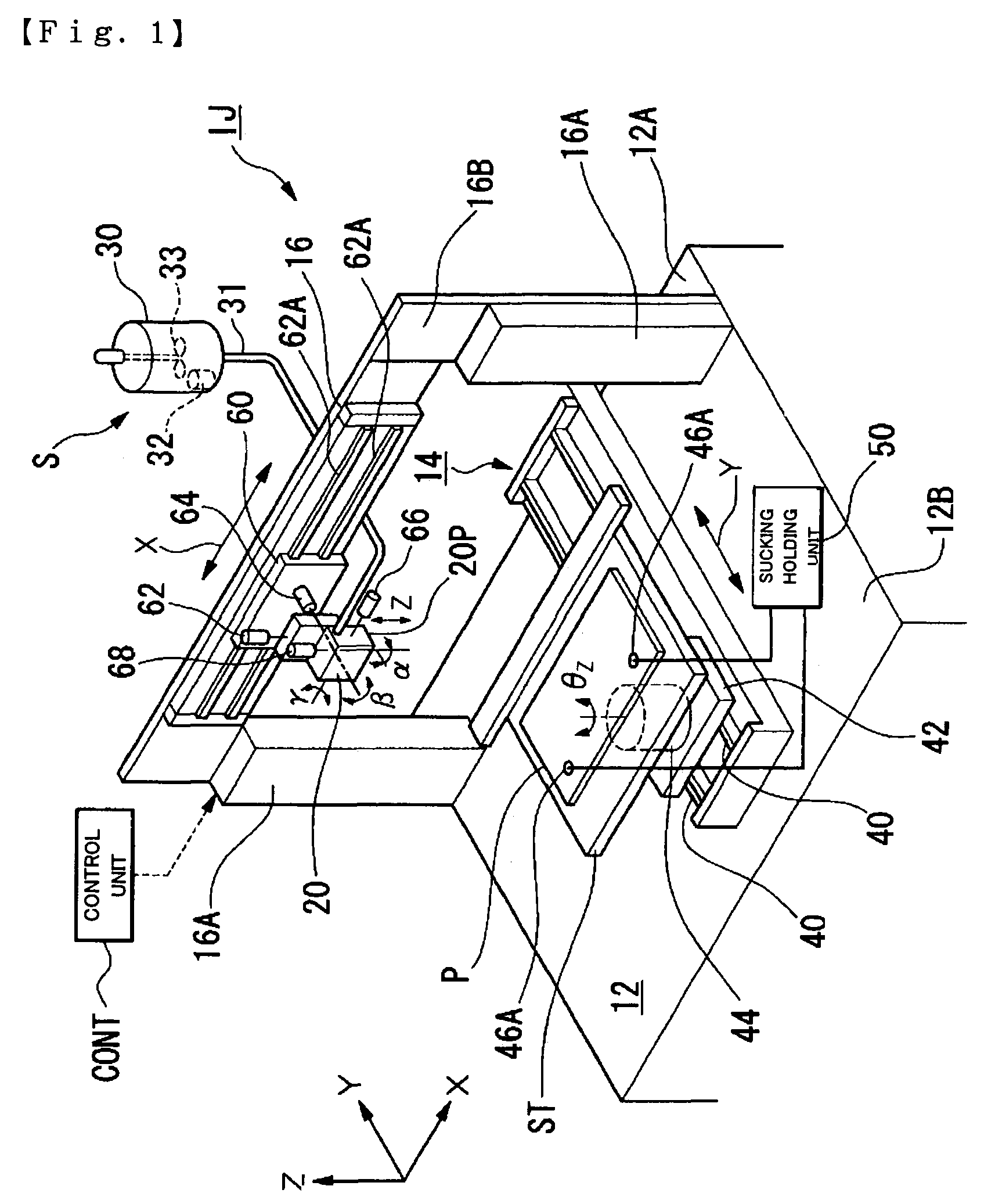

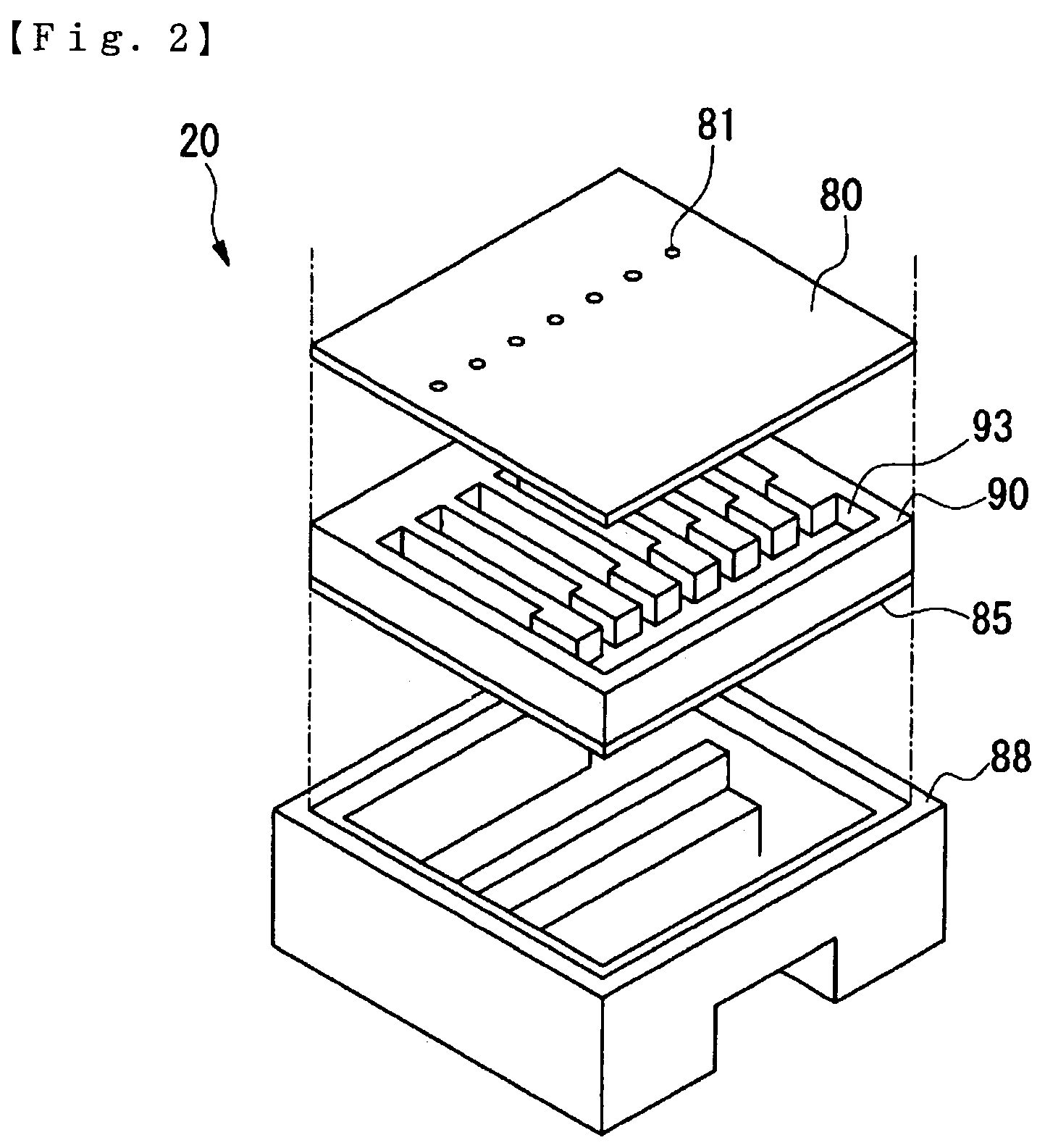

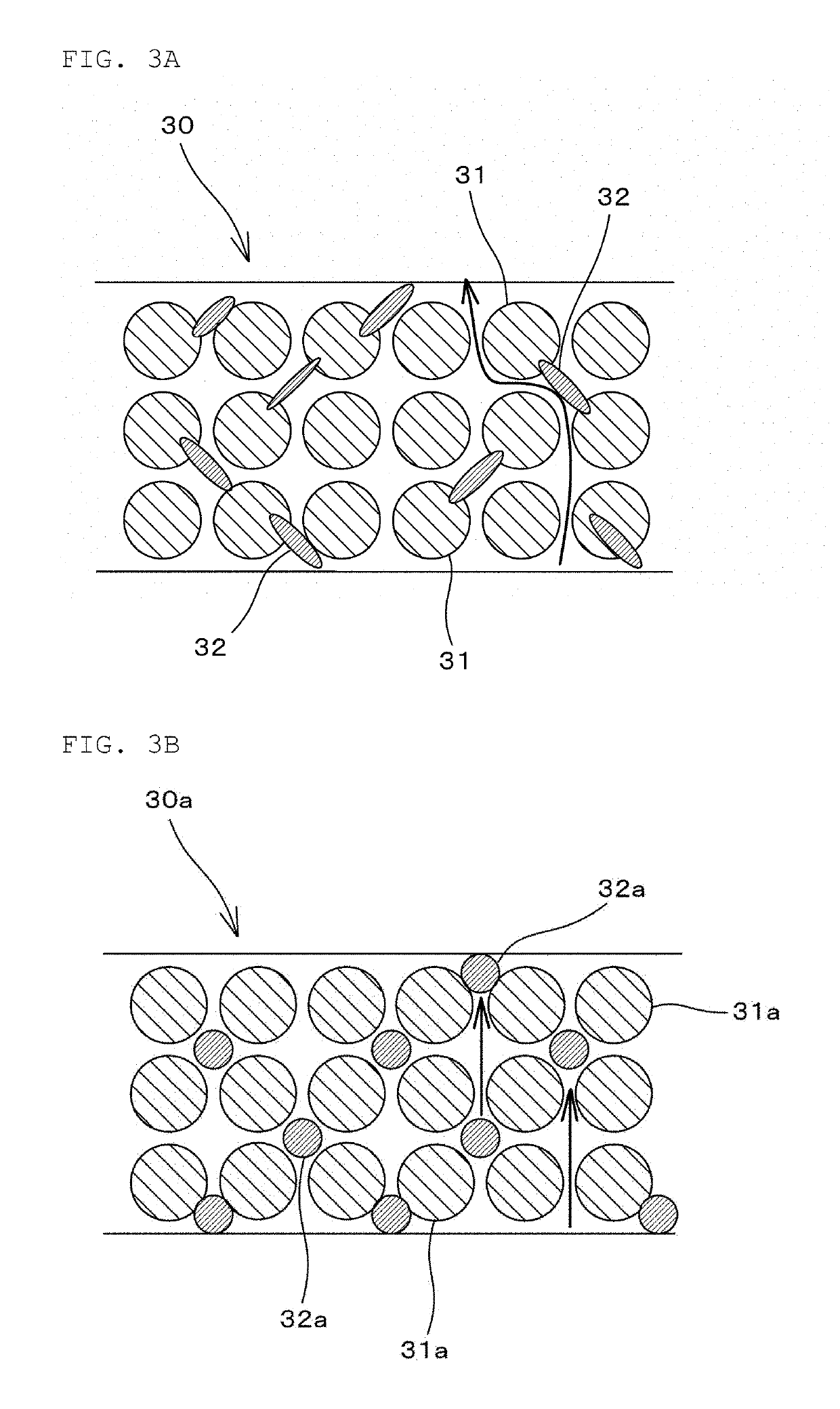

Composition, method of forming film, film formation device, electro-optical device, method of manufacturing the same, organic electroluminescent device, method of manufacturing the same, device and method of manufacturing the same, and electronic apparatus

ActiveUS7176617B2Increase production capacitySuppress the generation of air bubblesDischarge tube luminescnet screensElectroluminescent light sourcesEngineeringSolvent

A film formation device includes a liquid material composition generating device for generating a liquid material composition containing a organic functional material, a solvent, and a surfactant, and a liquid droplet ejecting device for ejecting liquid droplets made therefrom onto a substrate P.

Owner:SEIKO EPSON CORP

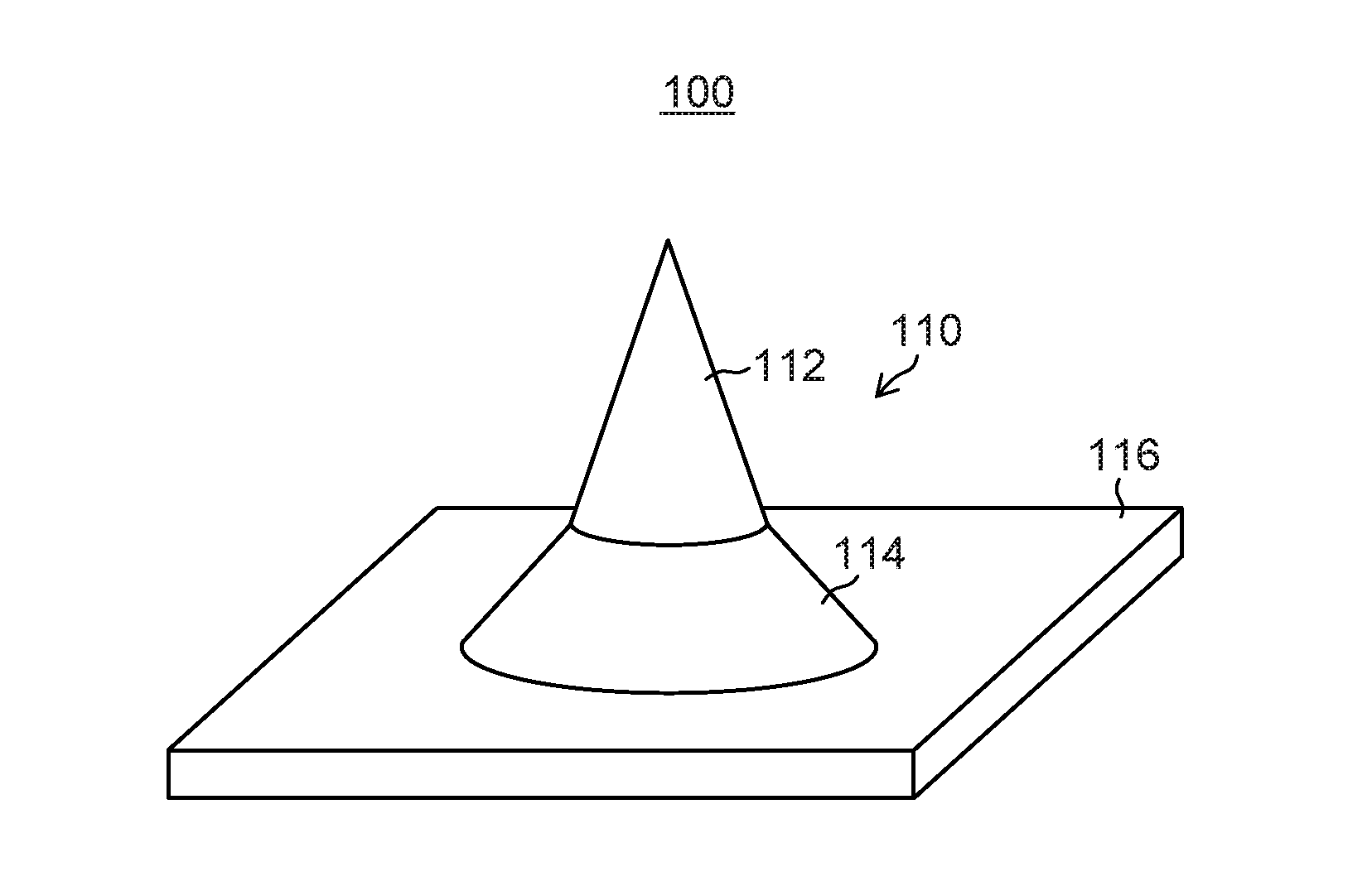

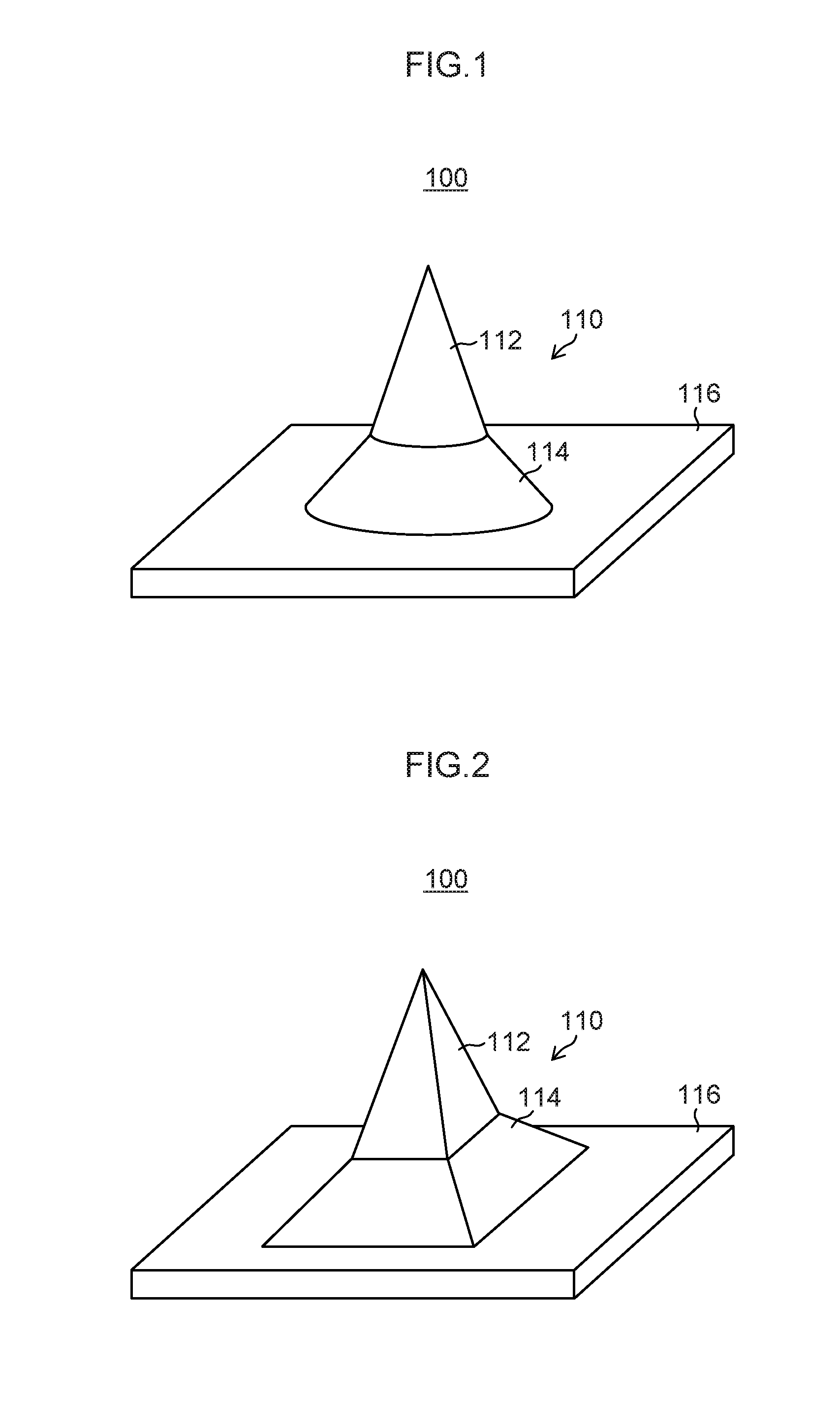

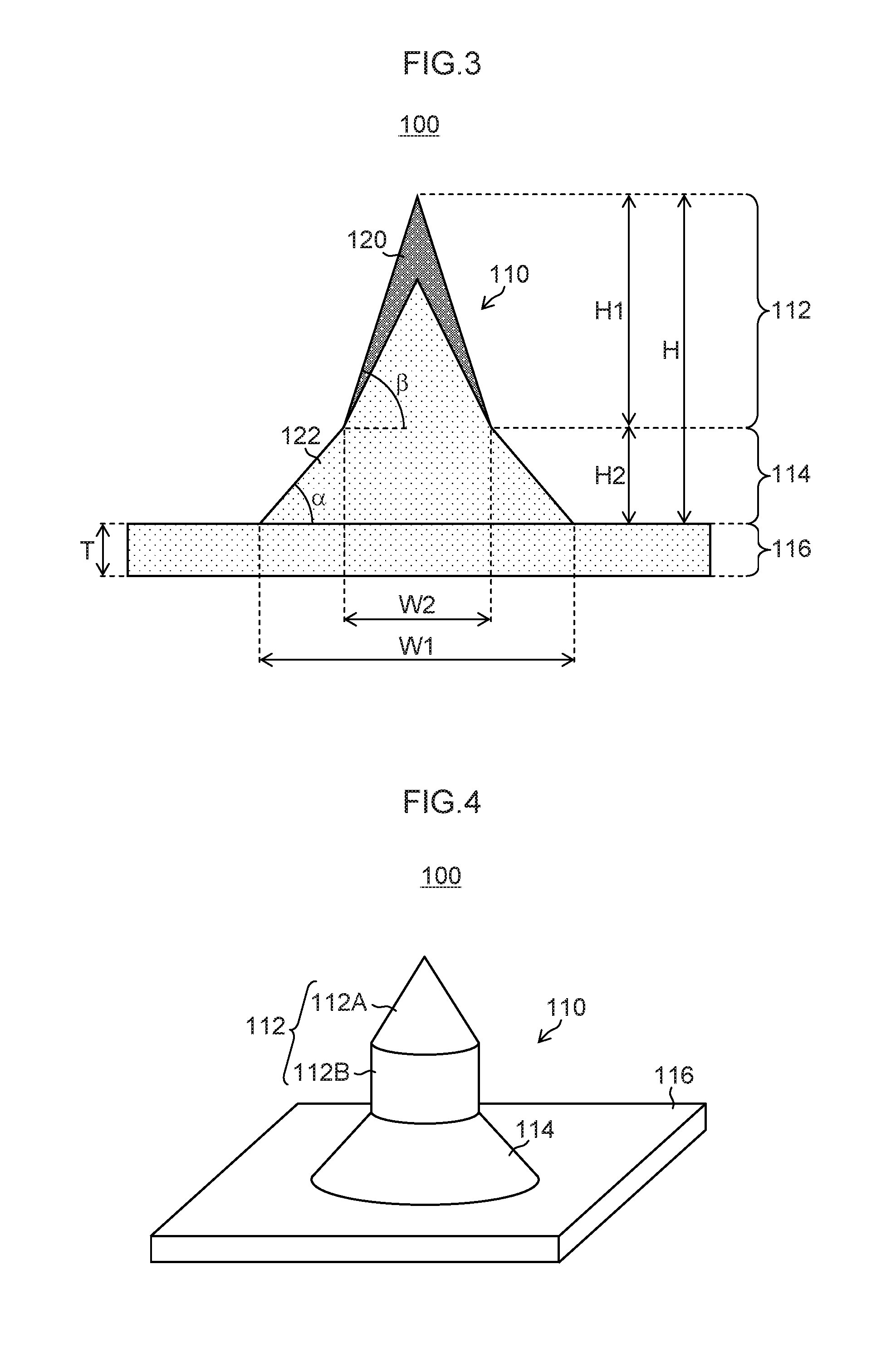

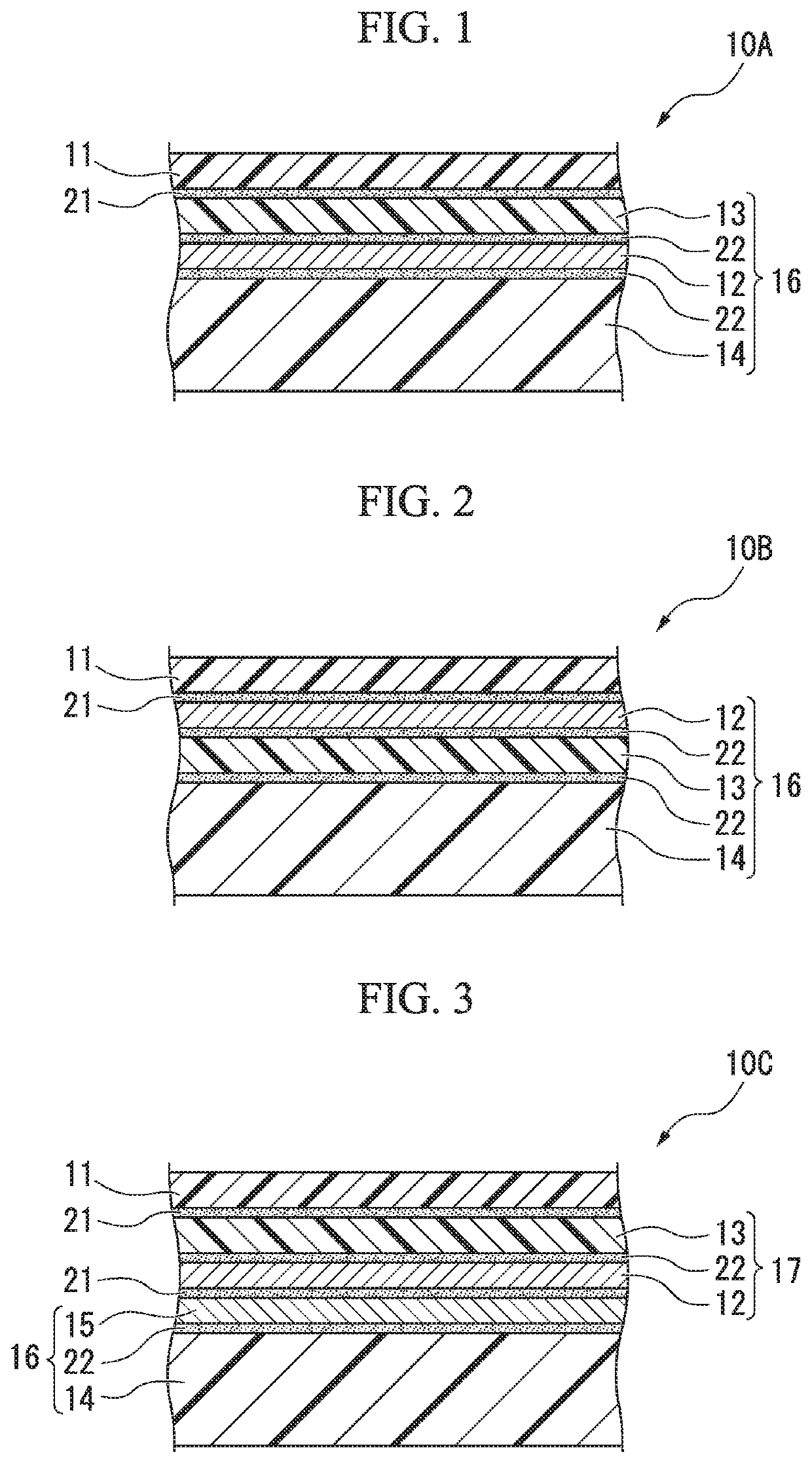

Method of manufacturing transdermal absorption sheet and transdermal absorption sheet

InactiveUS20170057124A1Suppress the generation of air bubblesPeptide/protein ingredientsMicroneedlesTransdermal absorptionAir bubble

An object is to provide a method of manufacturing a transdermal absorption sheet and a transdermal absorption sheet that can suppress generation of air bubbles. In the method of manufacturing the transdermal absorption sheet that includes a drug solution filling step, a drug solution drying step, a base solution filling step, a base solution drying step, and a peeling-off step in that order, each step of at least from the drug solution filling step to the base solution drying step is performed in an environment with a temperature of 1° C. to 10° C.

Owner:FUJIFILM CORP

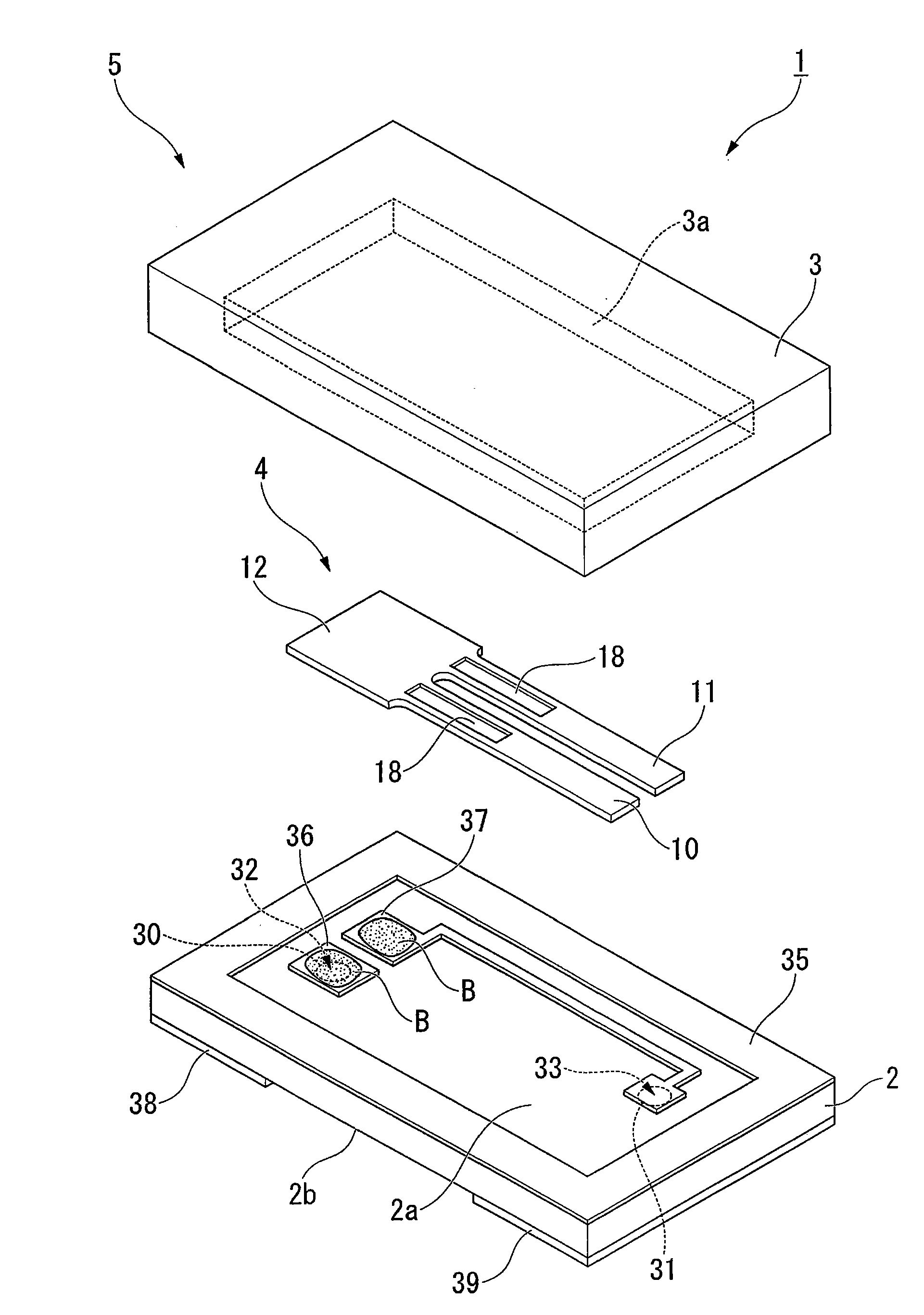

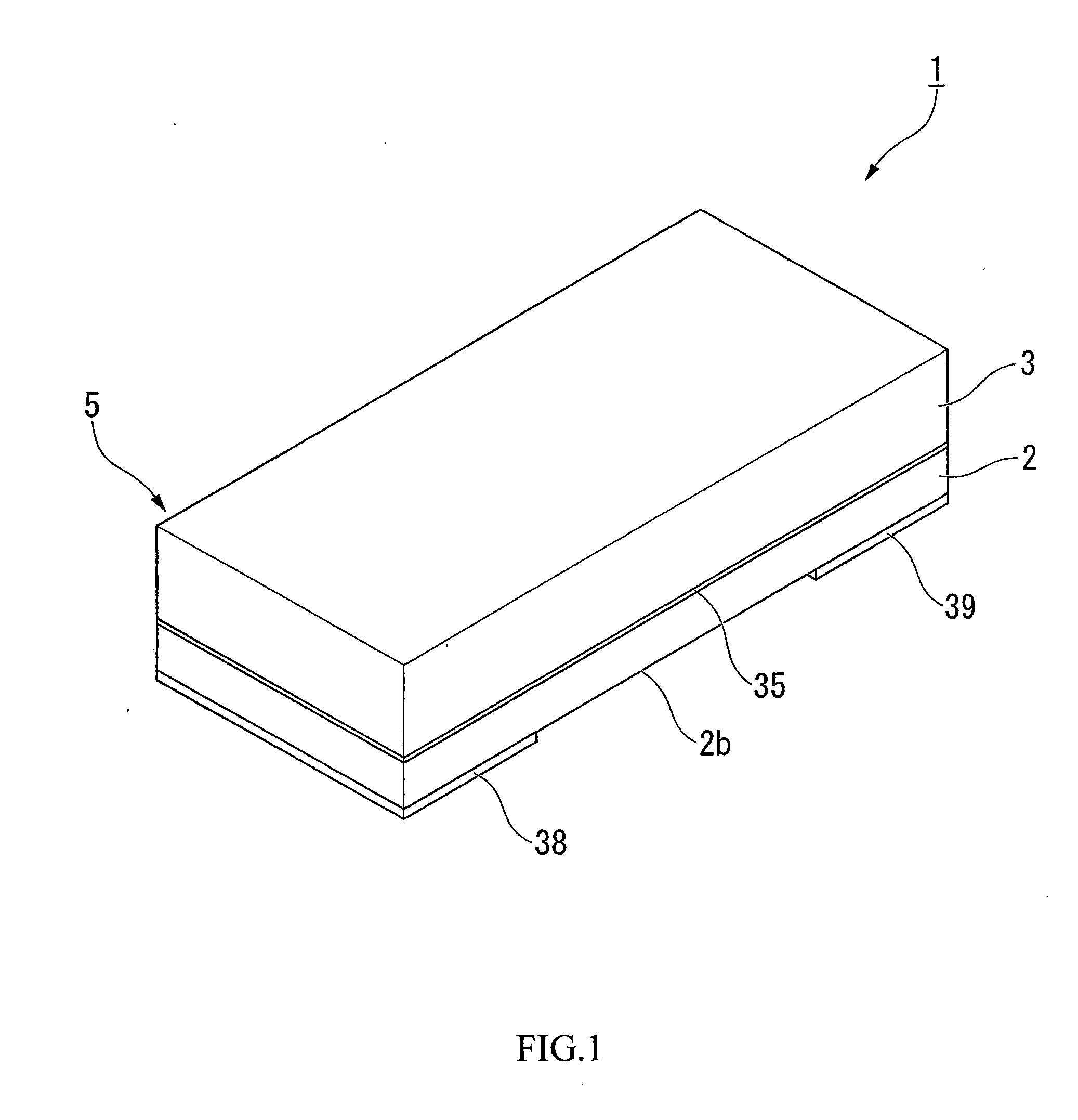

Display device and electrical appliance using the same

InactiveUS7742137B2Reduce deflectionForce is limitedCathode-ray/electron-beam tube vessels/containersNon-linear opticsLiquid-crystal displayDisplay device

A liquid crystal display device comprising a pair of substrates, a liquid crystal display panel having a liquid crystal layer positioned between the substrates, a transparent protective plate arranged on a front surface side of the display panel, and an optically transparent layer between the display panel and the protective plate, and wherein the protective plate includes fine concavity and convexity configurations on at least a surface thereof toward the display panel.

Owner:HITACHI LTD

Heat dissipation component for semiconductor element

ActiveUS20170268834A1High thermal conductivitySuppress generation of blister , crackSemiconductor/solid-state device detailsSolid-state devicesAluminiumSemiconductor components

A heat dissipation component for a semiconductor element includes: a composite part containing 50-80 vol % diamond powder with the remainder having metal including aluminum, the diamond powder having a particle diameter volume distribution first peak at 5-25 μm and a second peak at 55-195 μm. A ratio between a volume distribution area at particle diameters of 1-35 μm and a volume distribution area at particle diameters of 45-205 μm is 1:9 to 4:6; surface layers on both composite part principal surfaces, each of the surface layers containing 80 vol % or more metal including aluminum and having a film thickness of 0.03-0.2 mm; and a crystalline Ni layer and an Au layer on at least one of the surface layers, the crystalline Ni layer having a film thickness of 0.5-6.5 μm, and the Au layer having a film thickness of 0.05 μm or larger.

Owner:DENKA CO LTD

Fluid dynamic pressure bearing, motor, and recording medium driving device

InactiveUS7568839B2Guaranteed work efficiencySuppress the generation of air bubblesShaftsRecord information storageWorking fluidThrust bearing

A fluid dynamic pressure bearing has an annular dynamic pressure generating face having a dynamic pressure generating groove, which draws a working fluid toward a midway position in the radial direction from the inside and outside of a thrust bearing plate in the radial direction when a shaft and a housing are rotated relative to each other. The dynamic pressure generating groove is provided on thickness direction end faces of the thrust bearing plate or on an inner surface of the housing, and an inner groove section is located on an inner peripheral side of the dynamic pressure generating face on the end faces and is recessed more than the dynamic pressure generating face in the thickness direction. A through-hole extends through the thrust bearing plate in the thickness direction so as to open to the dynamic pressure generating face, and a communicating cavity connects the opening portion of the through-hole and the inner groove section.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Conductive paste for external electrode and method for manufacturing electronic component including the conductive paste for external electrode

ActiveUS10529486B2Suppress generation of blisterIncrease in amountFixed capacitor electrodesTransportation and packagingElectrically conductiveElectronic component

A conductive paste for an external electrode that includes a conductive metal powder; a glass frit having an average particle diameter D50 of not more than 0.8 μm and having a flat shape with an average flatness of 1.5 to 5.5; and a binder resin. A method of manufacturing an electronic component includes preparing an electronic component element; applying the conductive paste for an external electrode onto an outer surface of the electronic component element; and baking the applied conductive paste to form an external electrode.

Owner:MURATA MFG CO LTD

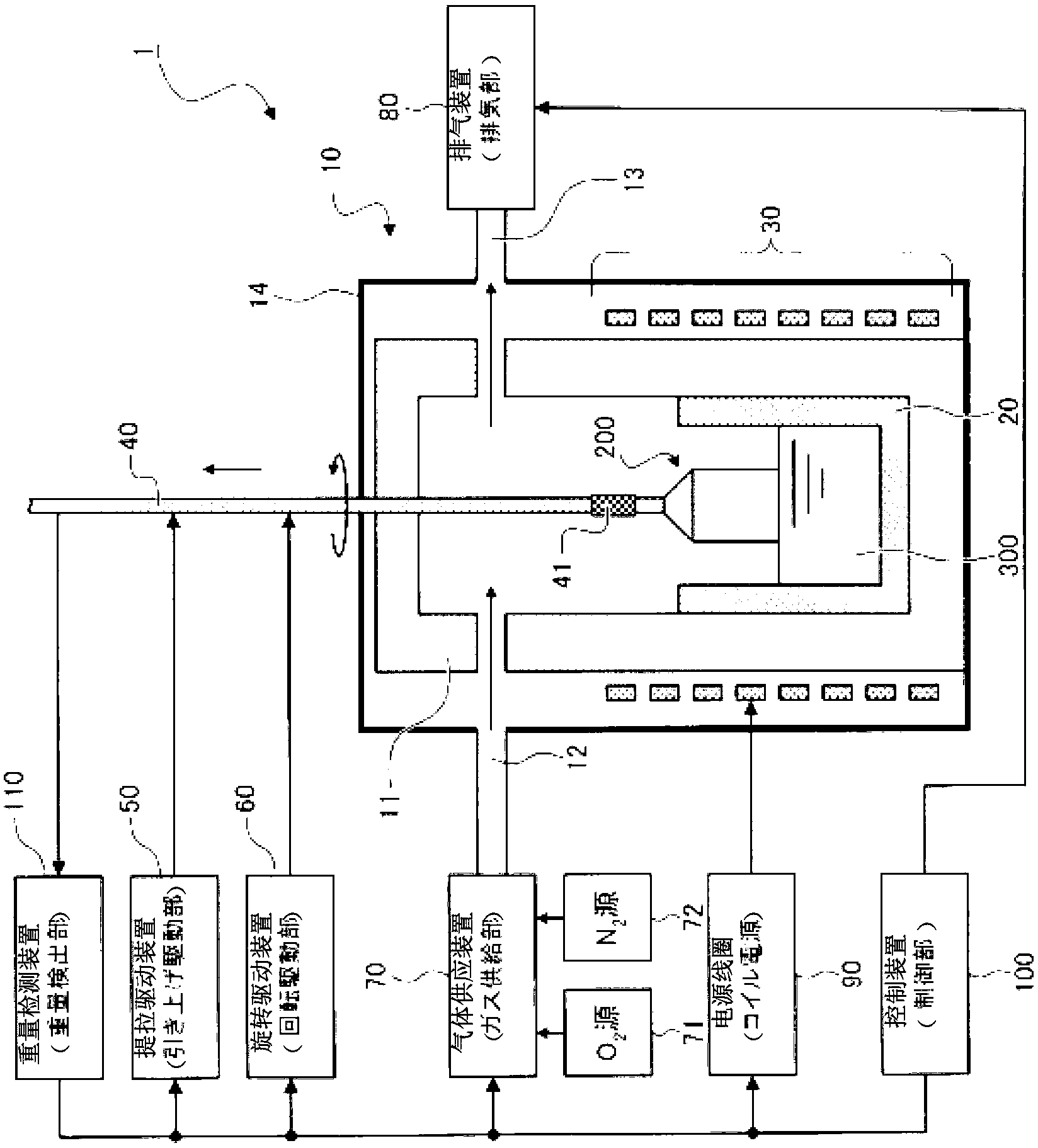

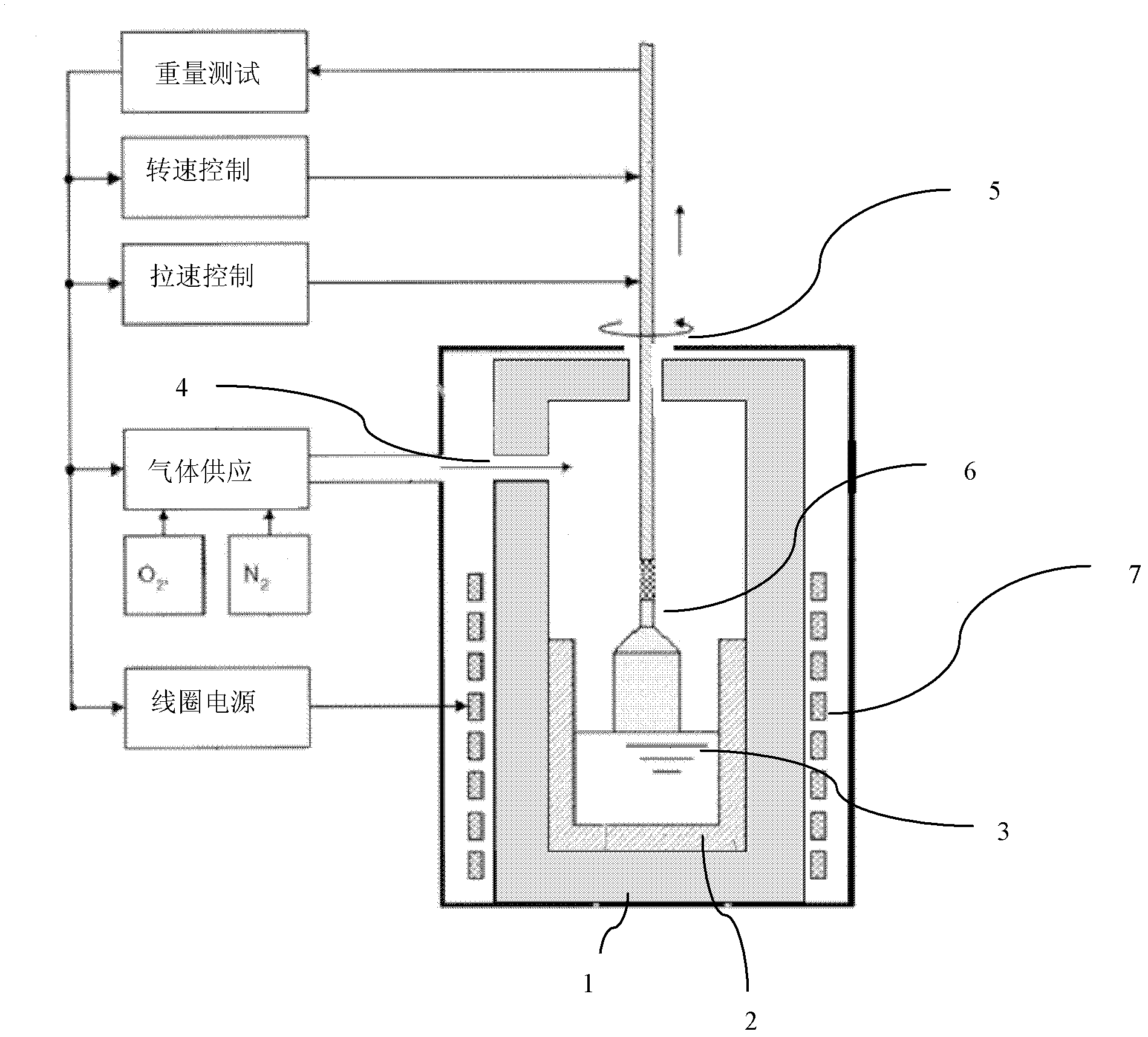

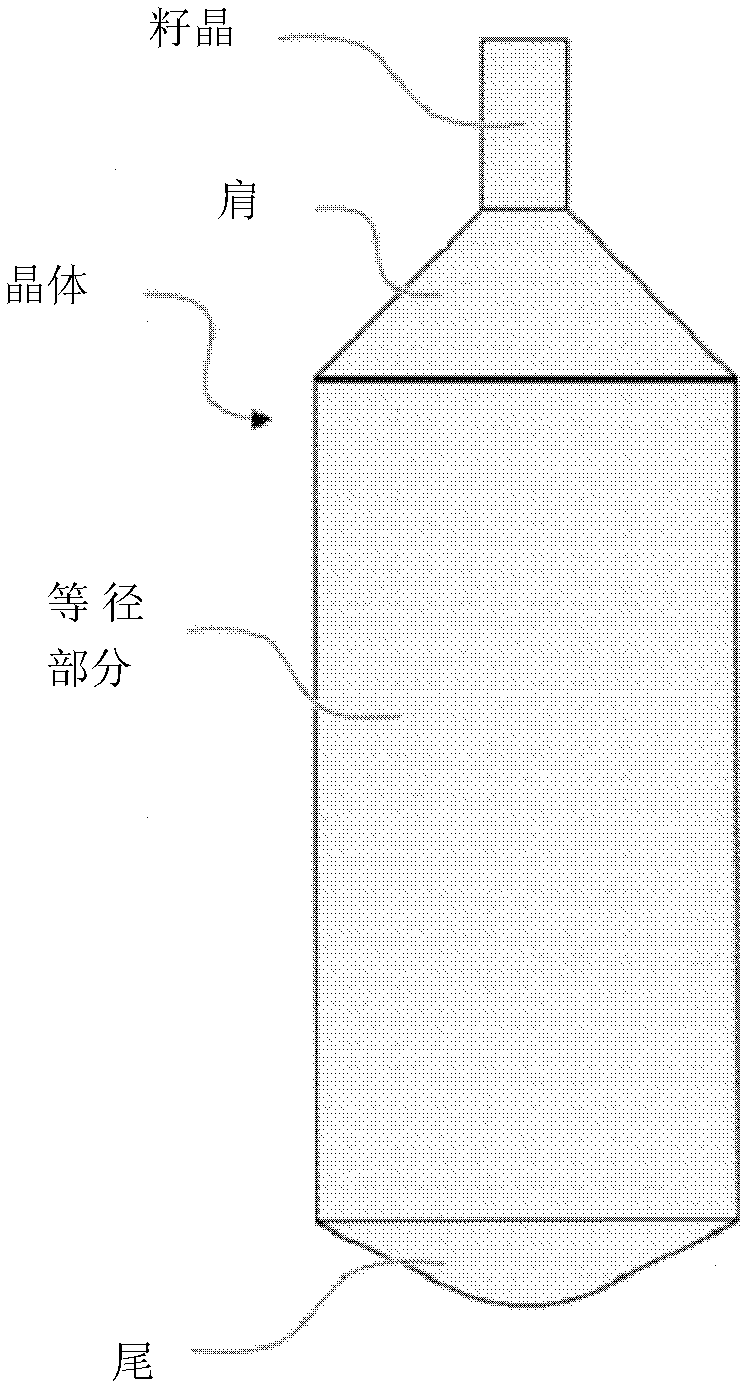

Improvement on structure of crystal growing furnace for pulling alumina single crystal and method for growing alumina single crystal

ActiveCN103255478ASuppress the generation of air bubblesGood effectPolycrystalline material growthBy pulling from meltSeed crystalVacuum pumping

The invention relates to an improvement on structure of crystal growing furnace for pulling alumina single crystal and method for growing alumina single crystal, and the structure improvement is that a cylinder cavity body is in a thermal insulator, the cylinder type cavity is placed with a crucible, and the external part of the thermal insulator is provided with a heating wire. The structure improvement is characterized in that the upper side part of the thermal insulator has at least one opening, and the middle part of the upper part of the thermal insulator is provided with an opening, and oxygen and inactive gas flow into the cavity from the opening, and the gas flows out from the opening, and the opening is the port for the seed crystal to arrive at the solution. The mixing gas composed of oxygen and inactive gas is used in the growing process, and the concentrations of oxygen in the mixing gas at different steps are different; and a purifying process is added. The invention can effectively inhibit bubble generation in the crystal, and service life of the crucible is long without vacuum-pumping, and not only c-plane alumina single crystal, but also r-plane, m-plane or n-plane white alumina single crystal can be pulled.

Owner:SHANGHAI ADVANCED SILICON TECH CO LTD

Liquid discharge head and liquid discharge apparatus

ActiveUS20140043395A1Suppress the generation of air bubblesSuppress generationPrintingEngineeringHead parts

A liquid discharge head includes a liquid discharge substrate configured to discharge liquid; a flow channel configured to supply the liquid to the liquid discharge substrate and including a first flow channel portion, a second flow channel portion communicating with the first flow channel portion and extending in a direction intersecting a predetermined direction in which the first flow channel portion extends, and a third flow channel portion provided on a downstream side of a position of communication between the first and second flow channel portion with respect to a flow of liquid flowing in the first flow channel portion and communicating with the first flow and second flow channel portion, the third flow channel portion including a first wall defining an end portion of a flow channel and a second wall having an inclined surface inclining toward a wall which defines the second flow channel portion.

Owner:CANON KK

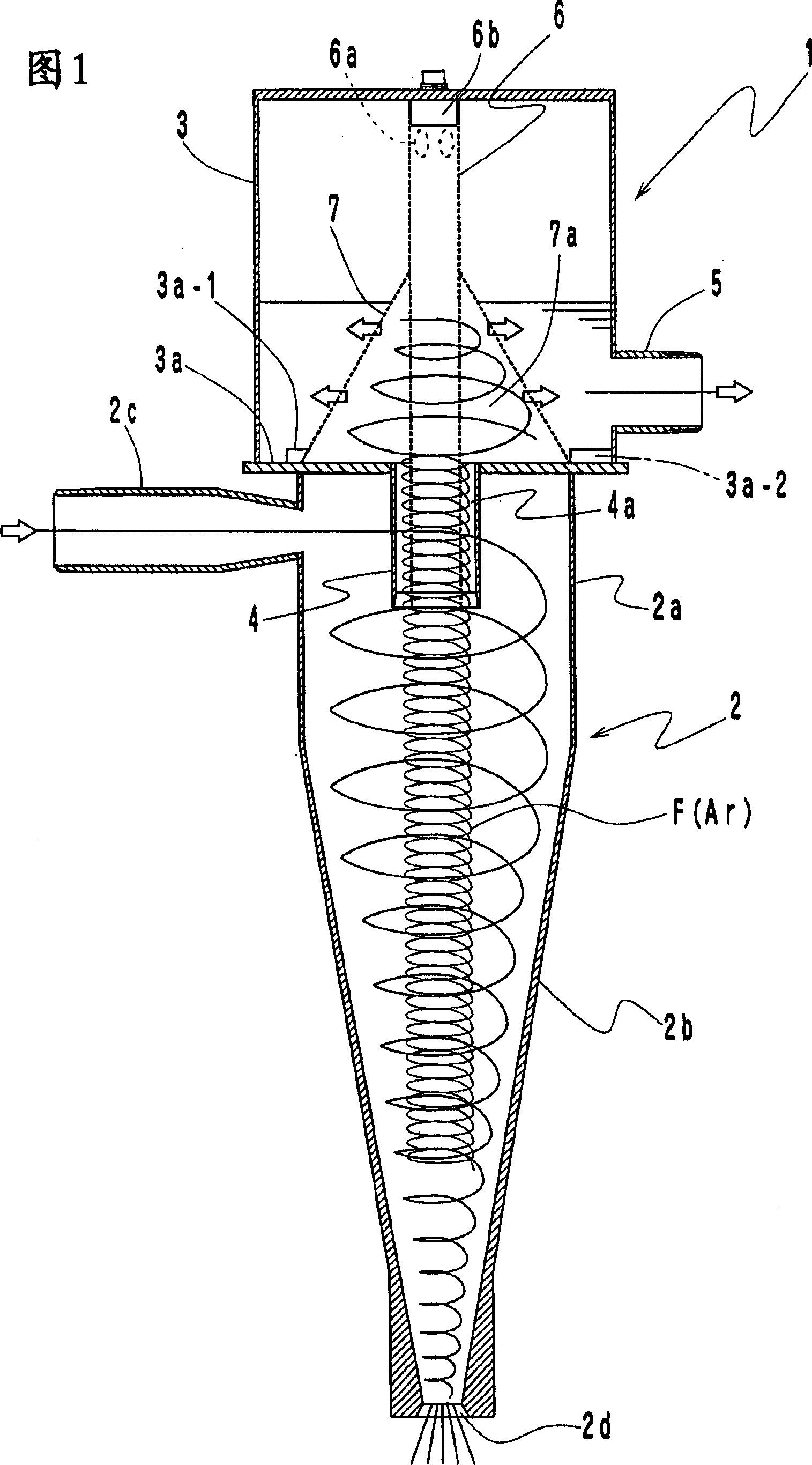

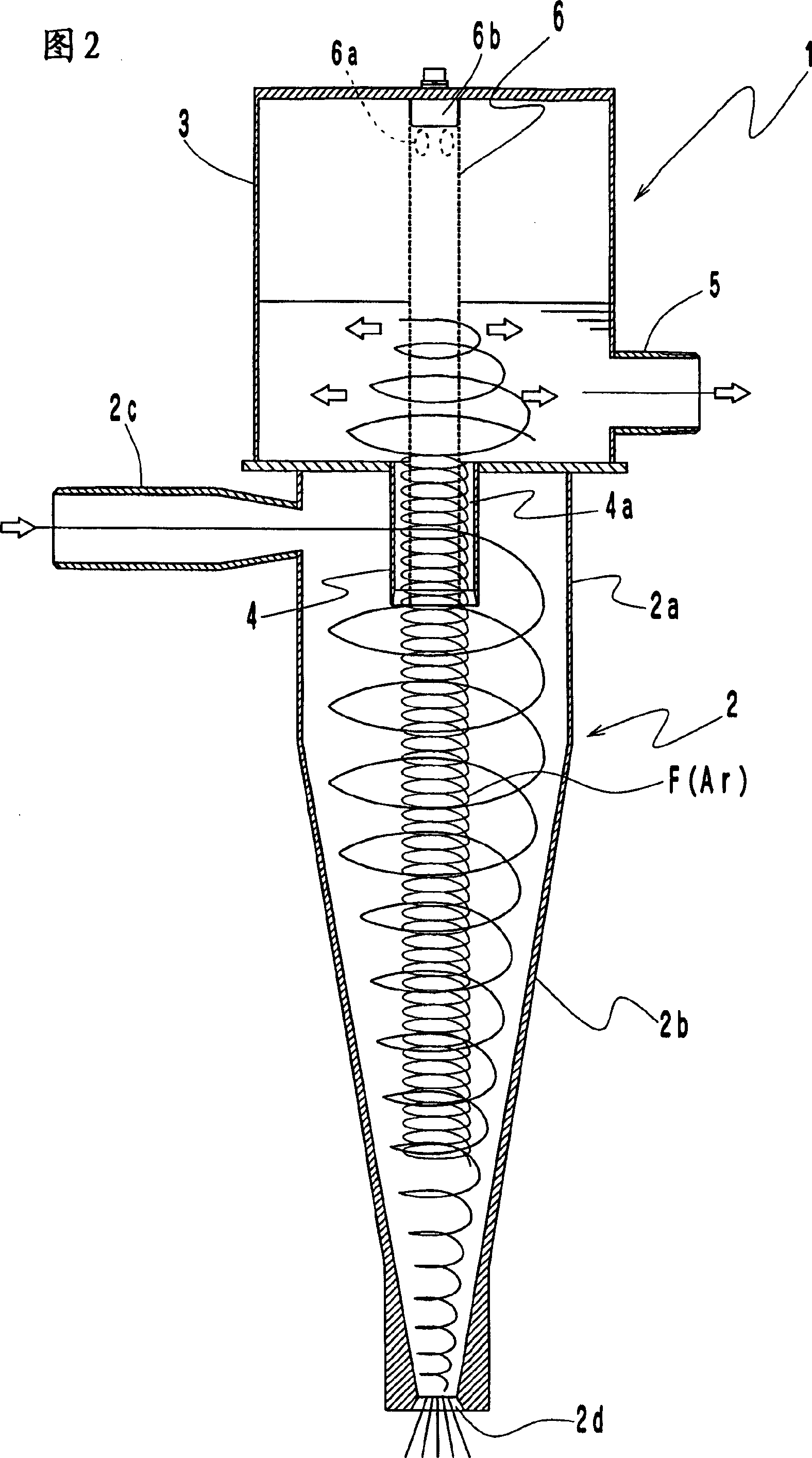

Liquid cyclone

ActiveCN1891344AAvoid mixingSuppress the generation of air bubblesLiquid degasificationReversed direction vortexForeign matterEngineering

The hydrocyclone 1 comprises a body 2 comprising a cylindrical part 2a and a conical part 2b with its diameter gradually reduced from the lower part of the cylindrical part 2a; a treating object liquid introducing port 2c connected to the cylindrical part 2a; a foreign matter discharge port 2d formed by opening the lower part of the conical part 2b; an upper casing 3 temporarily storing clean water; and an outlet pipe 4 concentric with the body 2 and connected to the upper casing 3 disposed above the body 2. A cylindrical body 6 with a mesh-like peripheral face is inserted into the outlet pipe4 keeping a space from the inner face thereof through the upper casing 3, and a flow-out control part 7a is formed at the outlet in the upper casing 3 of the outlet pipe 4 by an annular body 7 surrounding a protruded part in the upper casing 3 of the cylindrical body 6.

Owner:NIHON SPINDLE MFG CO LTD

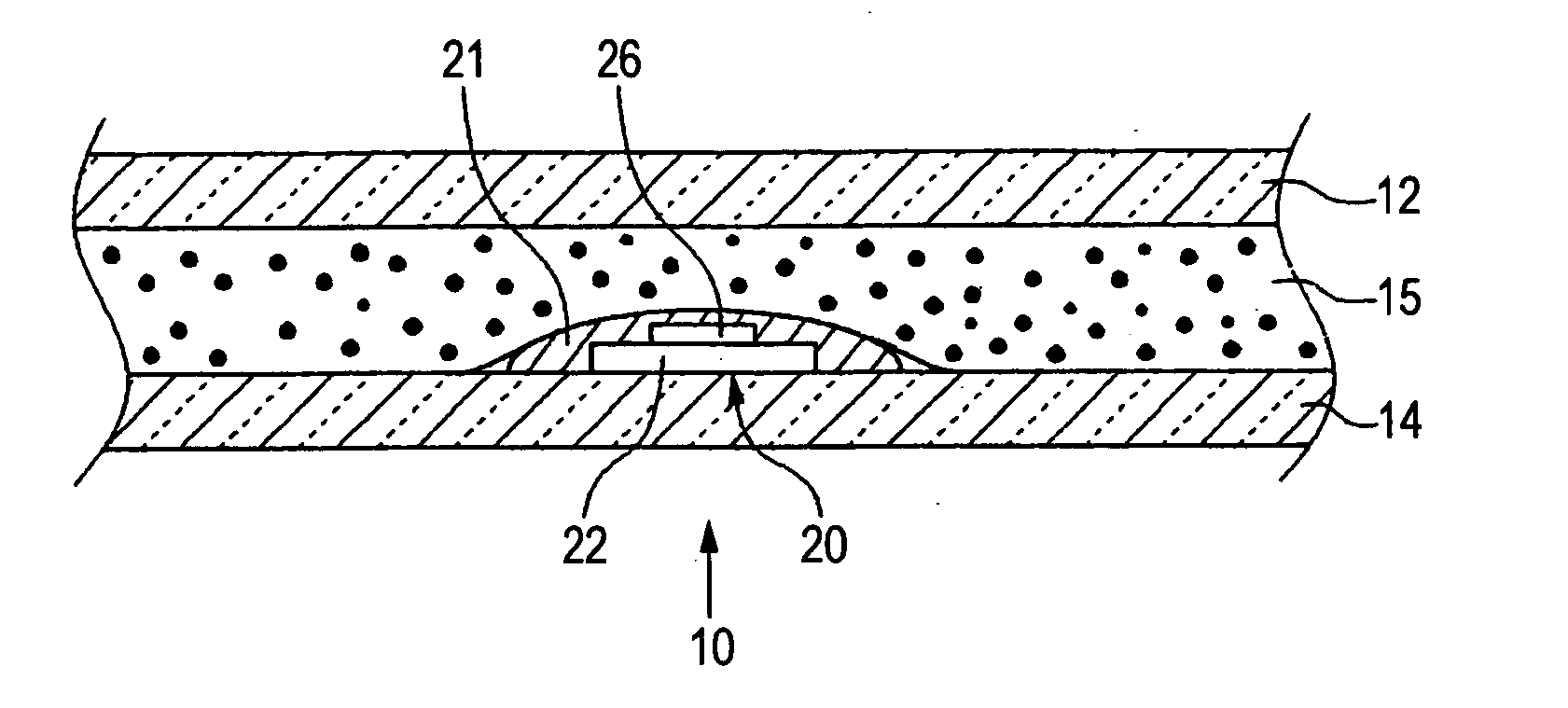

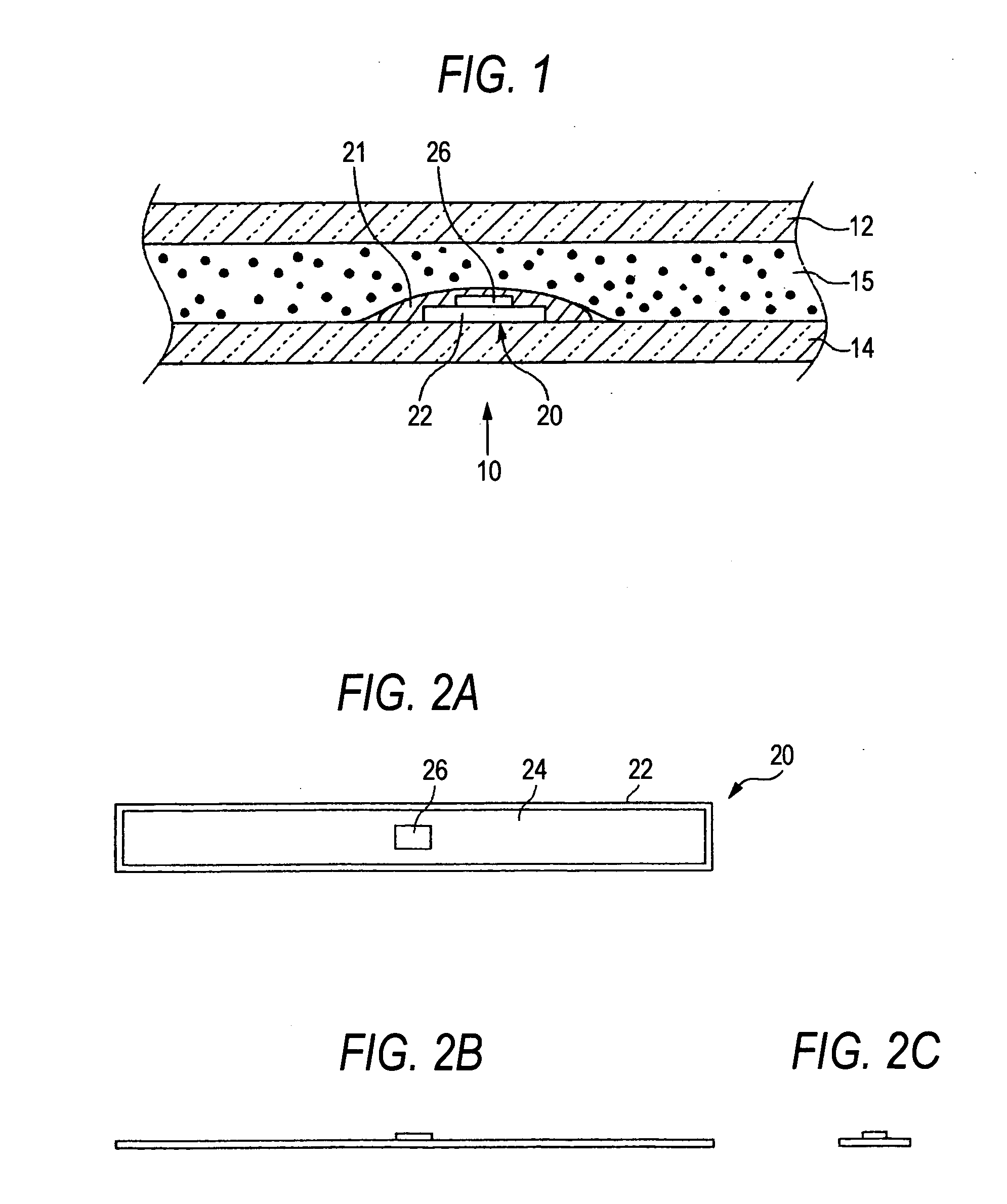

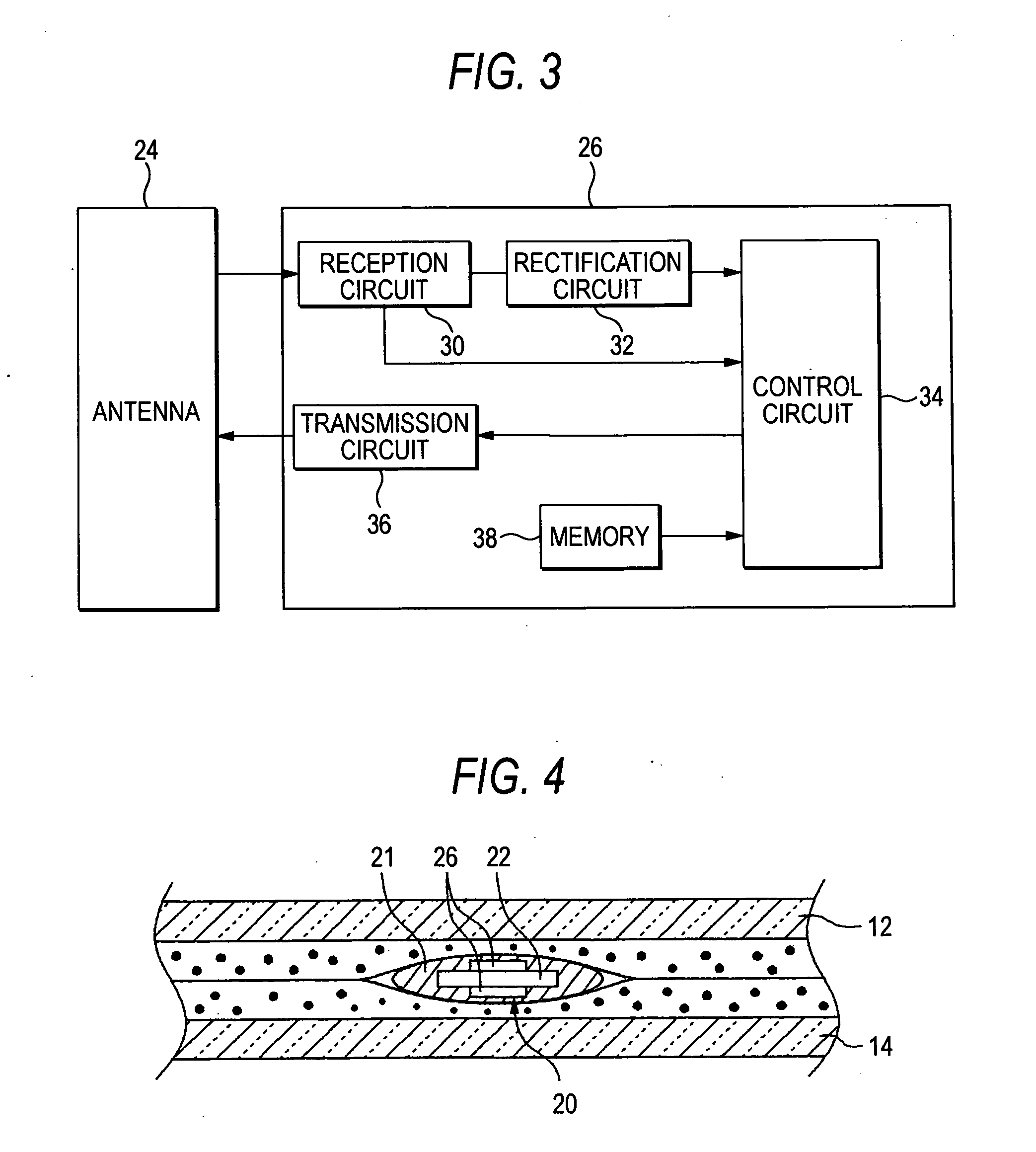

Interlayer film member for panel, panel and electronic tag

InactiveUS20060208906A1Easy to useNot easily brokenRecord carriersAntenna adaptation in movable bodiesEngineeringSurface plate

An electronic tag is coated with a coating material so that an upper portion of an insulation film is embedded in the coating material on the periphery of a semiconductor chip. This electronic tag is applied to a target object to be controlled such as a laminated glass which is fabricated by joining base materials together. A glass panel, which is a laminated glass, has a first sheet glass and a second sheet glass which are disposed so that main surfaces thereof are made to face each other and an interlayer film member which is disposed between the first sheet glass and the second sheet glass. In addition, the electronic tag coated with the coating material is disposed between the interlayer film member and the second sheet glass.

Owner:NIPPON SHEET GLASS CO LTD

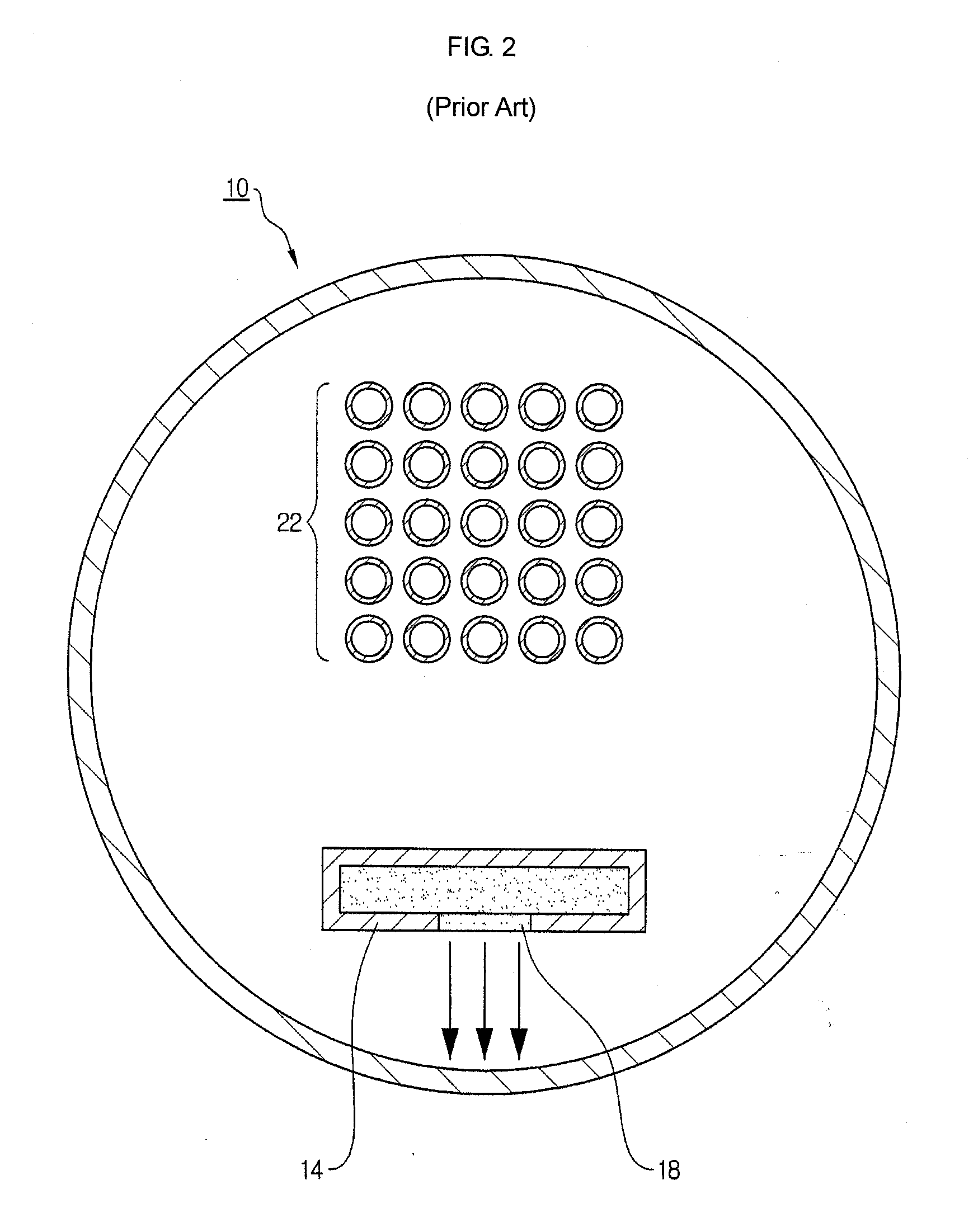

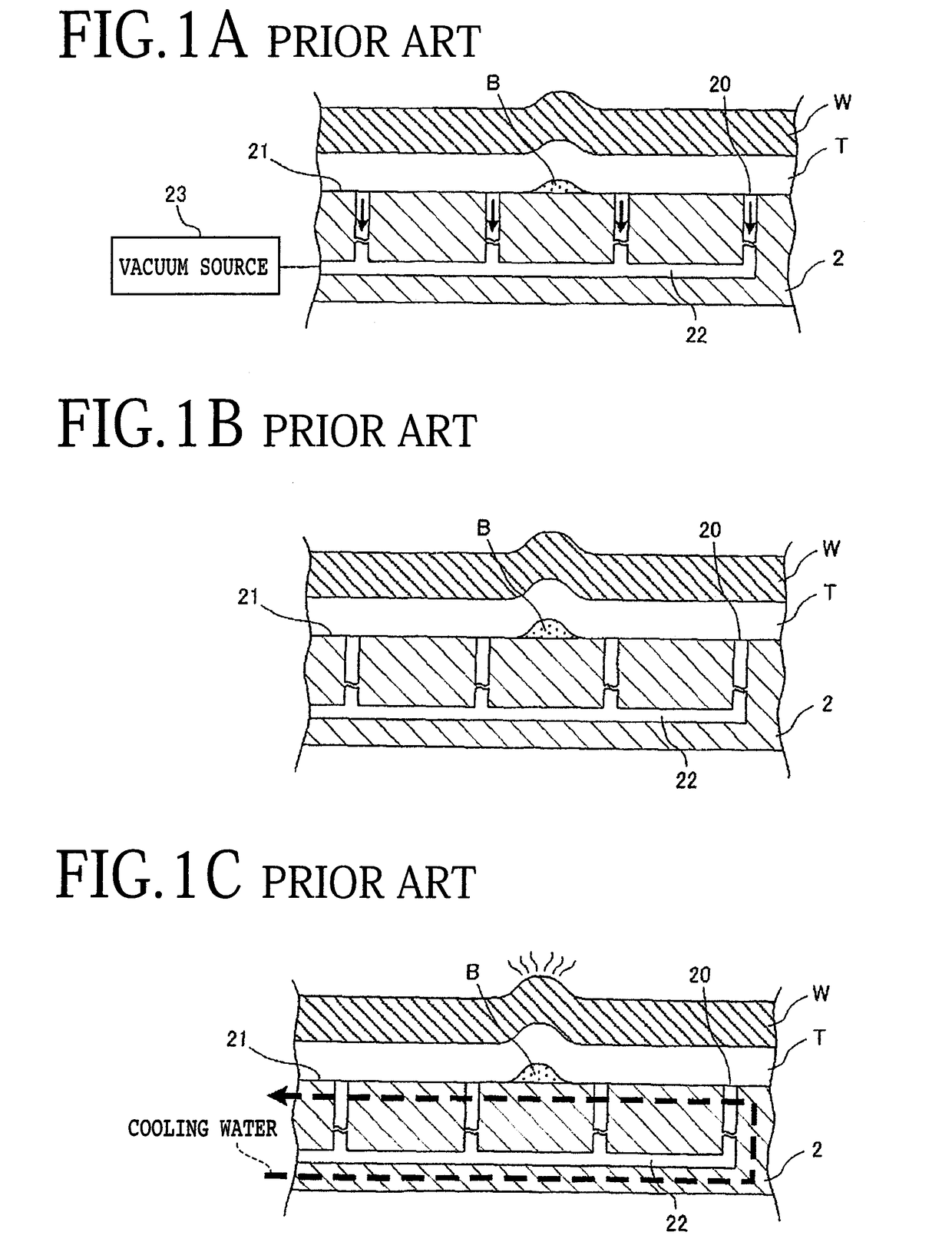

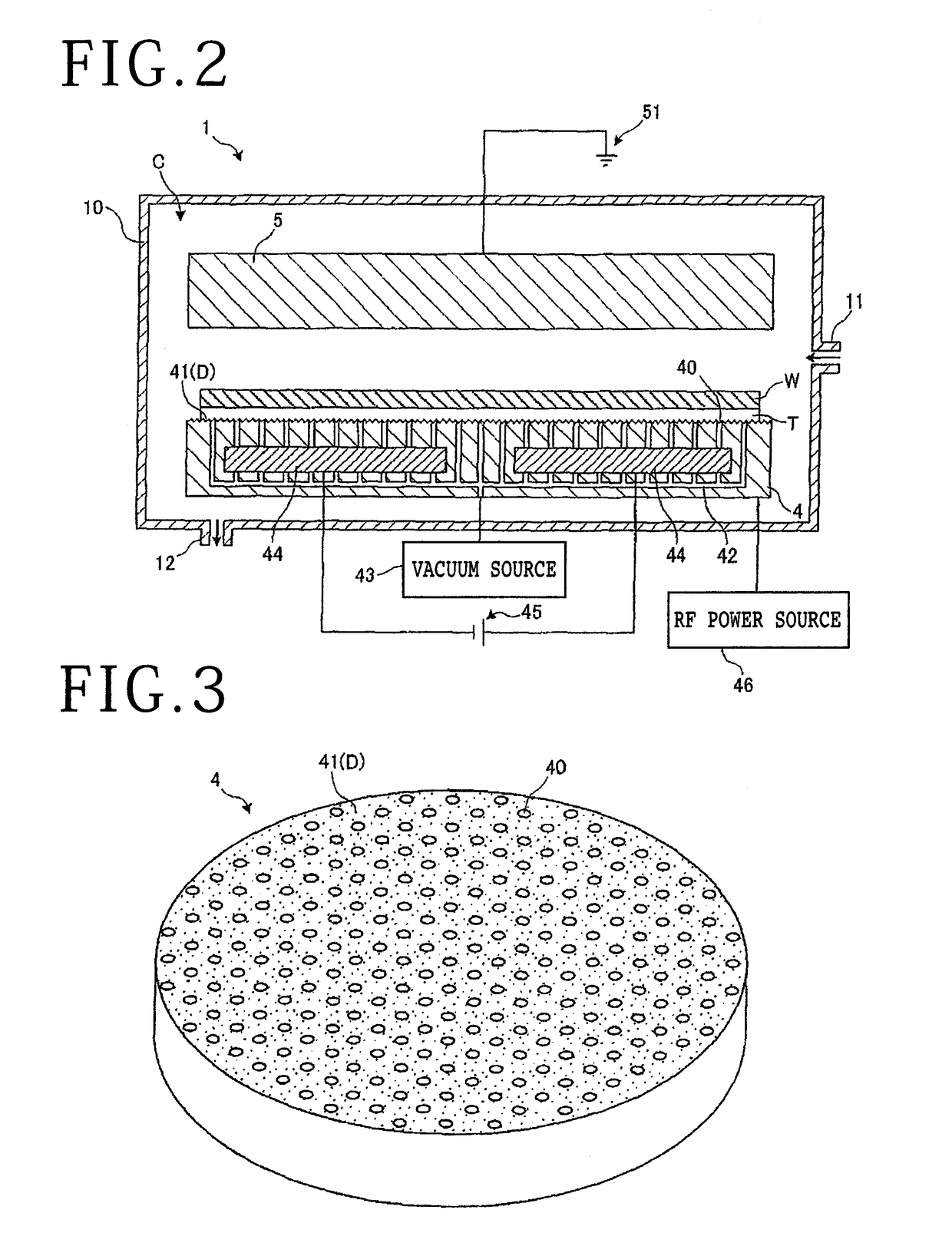

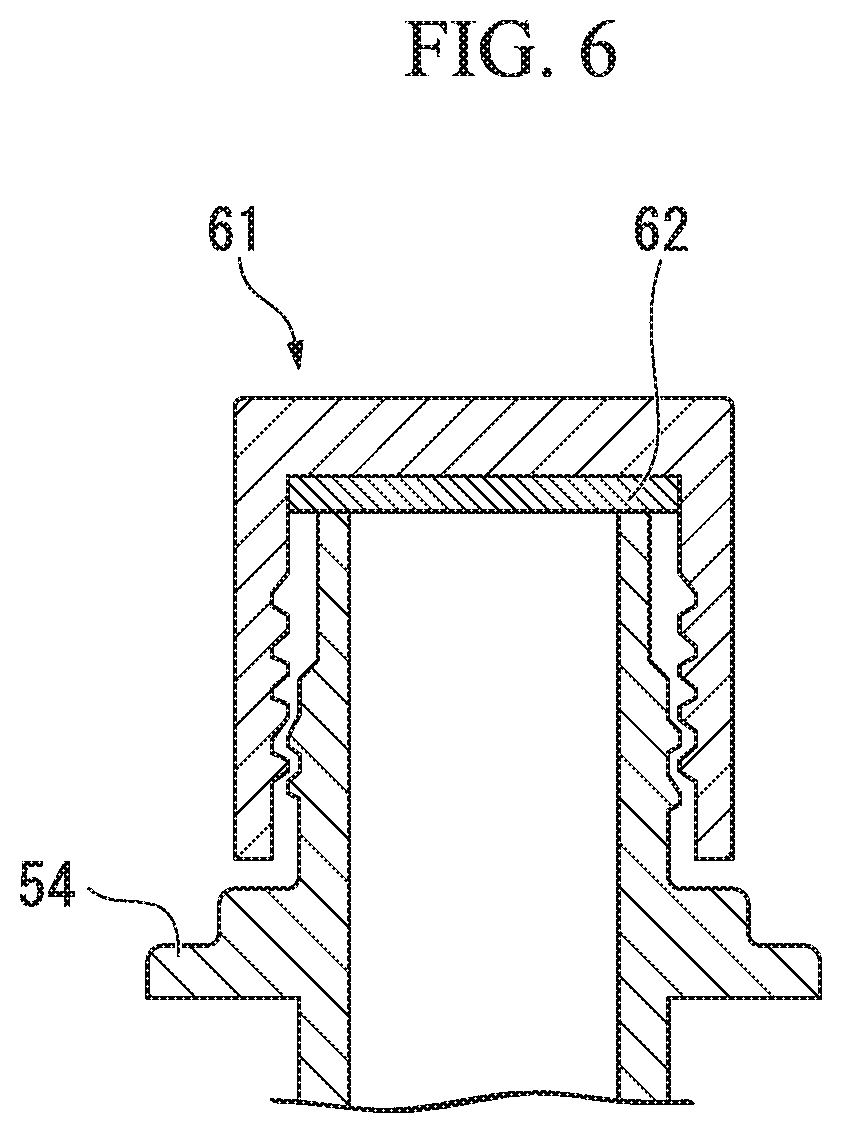

Electrostatic chuck

ActiveUS20190019712A1Generation of bubbleSuppress generationSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringElectrical and Electronics engineering

Disclosed herein is an electrostatic chuck having a holding surface for holding a wafer with a tape attached to one side of the wafer in the condition where the tape is in contact with the holding surface. The electrostatic chuck includes a disk-shaped member having a plurality of fine holes communicating with a vacuum source, the fine holes being exposed to the holding surface, a plurality of asperities formed on the holding surface and connected to the fine holes, and an electrode embedded in the disk-shaped member. When the vacuum source is operated to produce a vacuum on the holding surface through the fine holes and thereby hold the wafer through the tape on the holding surface under suction, the asperities formed on the holding surface function as a suction passage communicating with the fine holes.

Owner:DISCO CORP

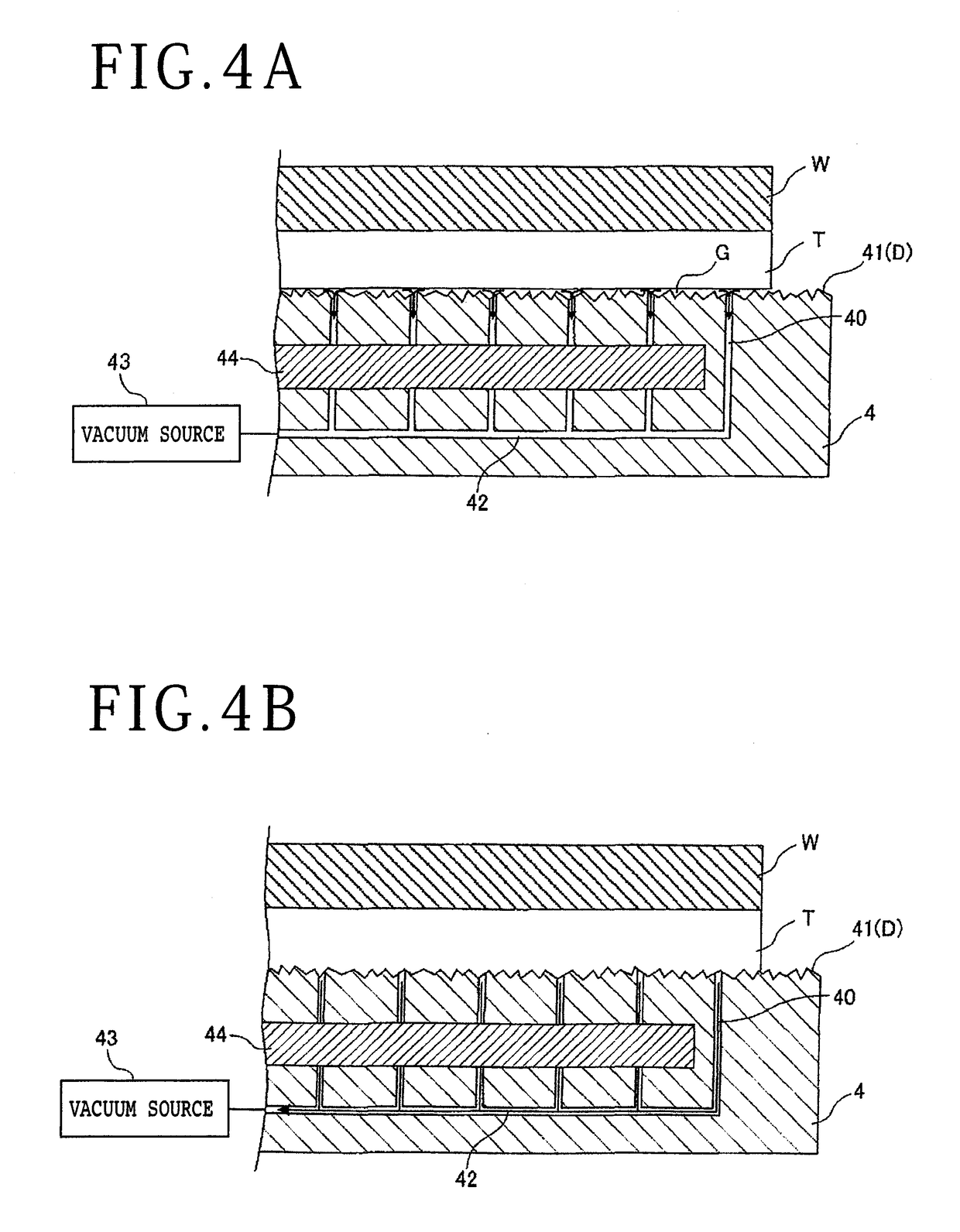

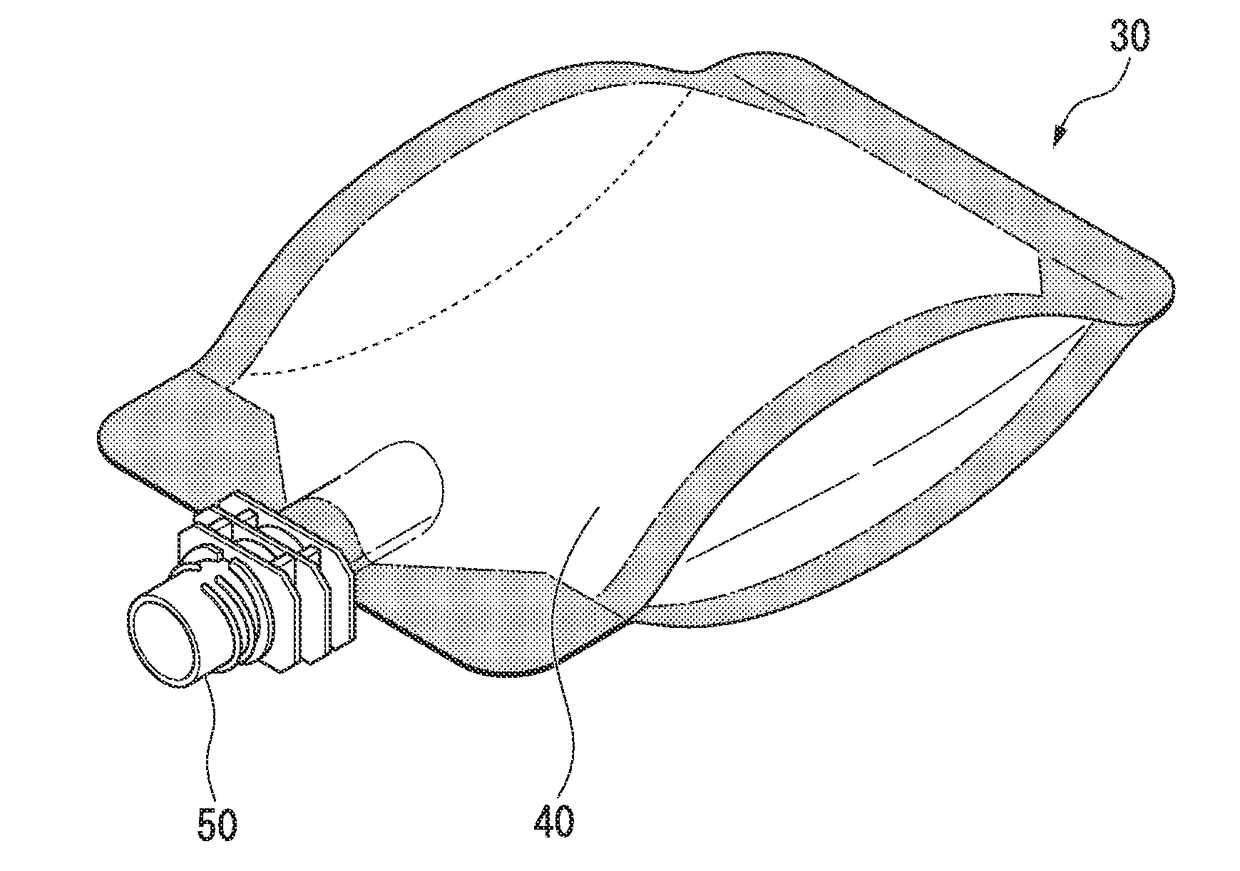

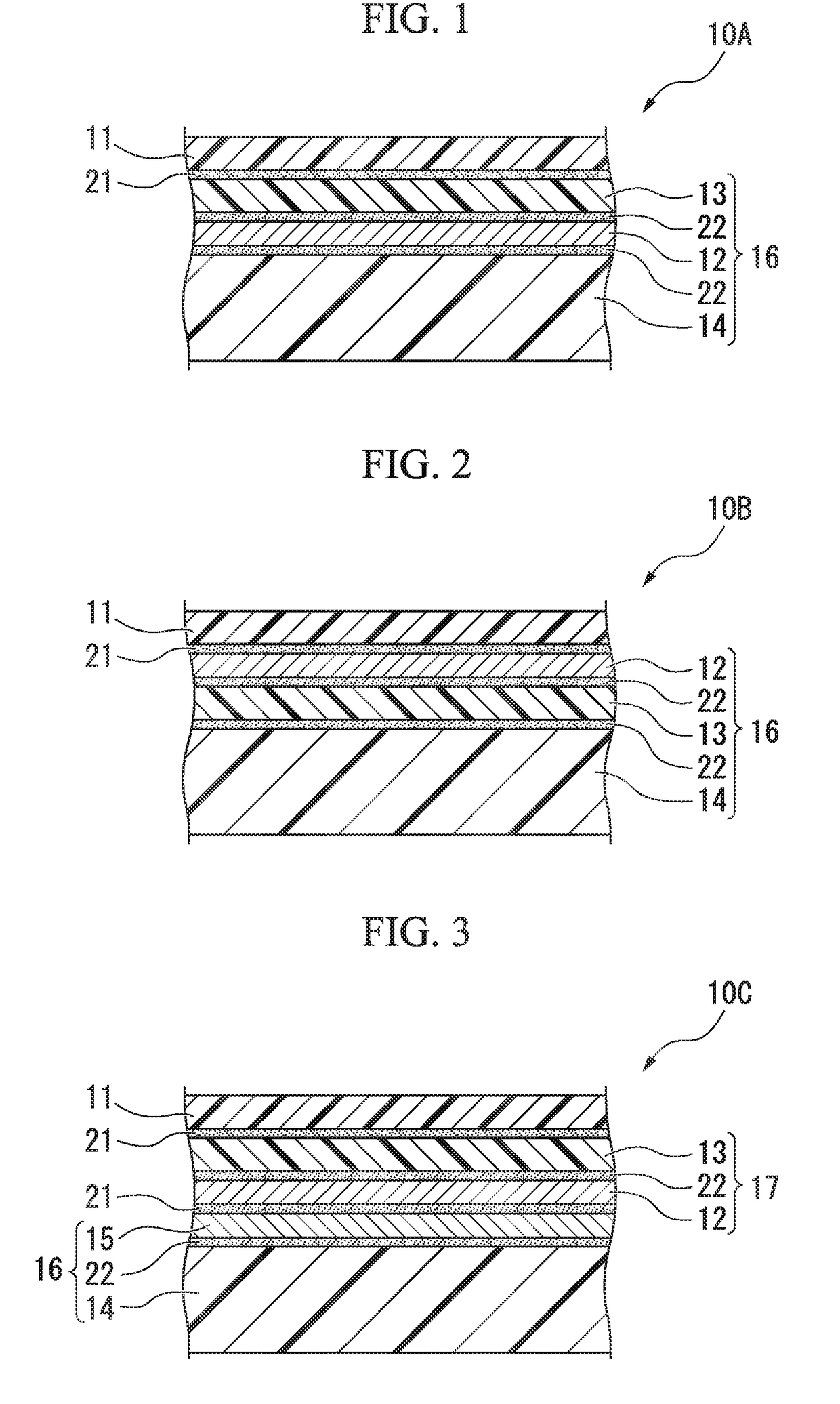

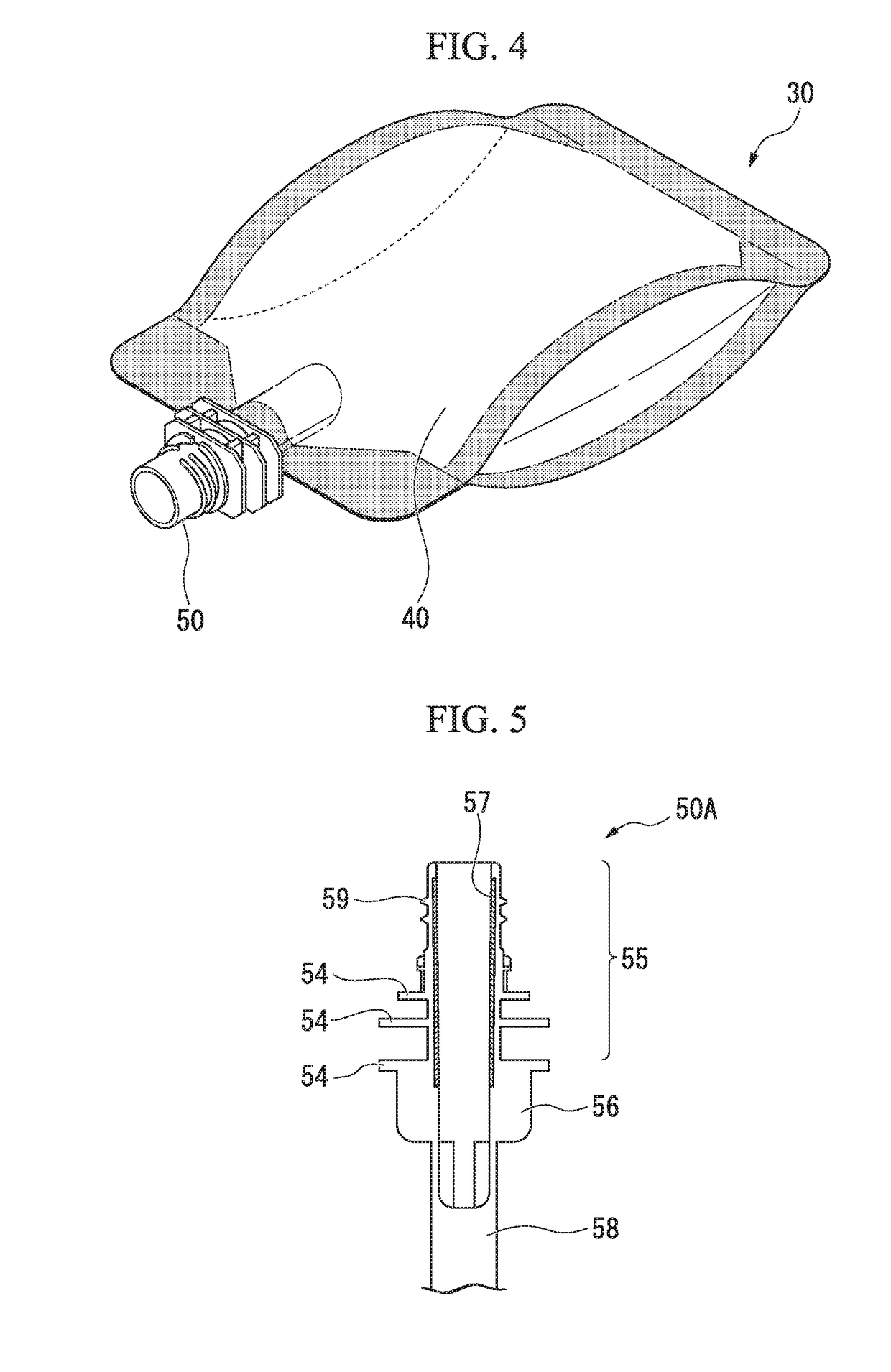

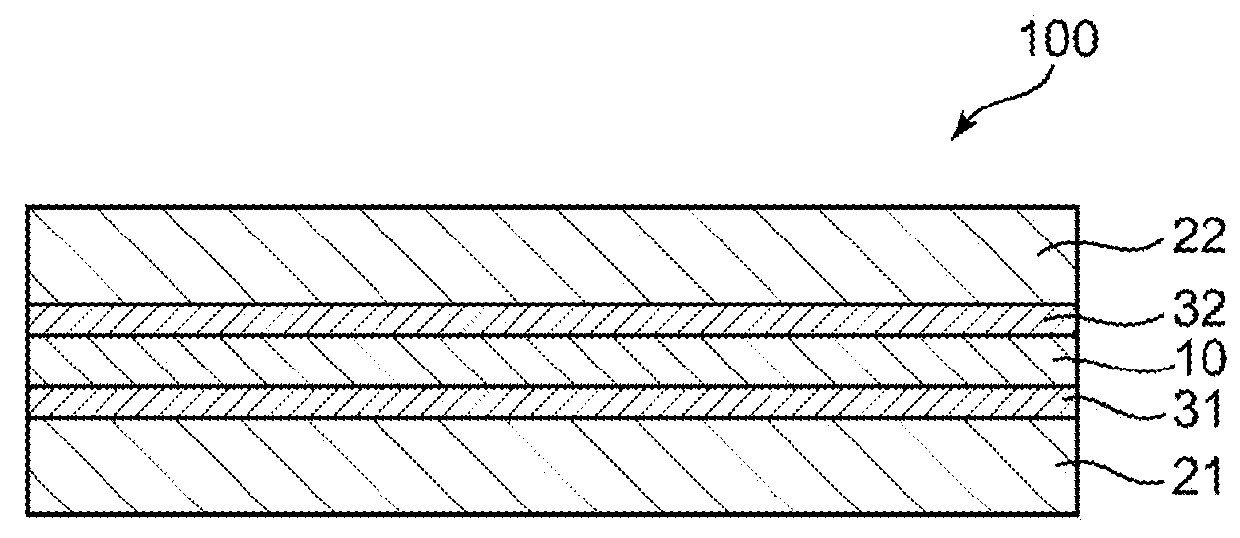

Laminate, packaging bag, packaging bag with plug, and packaging bag with plug with hydrogenous-water

ActiveUS10773491B2Excellent gas barrier performanceSuppress the generation of air bubblesWrappersNon-macromolecular adhesive additivesMetallic foilPolymer science

The present invention provides a laminate (10A) having a first gas barrier layer (11) formed of a gas barrier transparent resin film and a second gas barrier layer (12) formed of a metal foil, in which at least one adhesive layer (X) (21) formed of an adhesive (x) including a polyepoxy resin as a main ingredient and a polyamine resin as a curing agent is provided between the first gas barrier layer (11) and the second gas barrier layer (12).

Owner:HOSOKAWA YOKO CO LTD

Laminate, packaging bag, packaging bag with plug, and packaging bag with plug with hydrogenous-water

ActiveUS20180147814A1Excellent gas barrier propertySuppress bubble generationWrappersNon-macromolecular adhesive additivesMetal foilAdhesive

The present invention provides a laminate (10A) having a first gas barrier layer (11) formed of a gas barrier transparent resin film and a second gas barrier layer (12) formed of a metal foil, in which at least one adhesive layer (X) (21) formed of an adhesive (x) including a polyepoxy resin as a main ingredient and a polyamine resin as a curing agent is provided between the first gas barrier layer (11) and the second gas barrier layer (12).

Owner:HOSOKAWA YOKO CO LTD

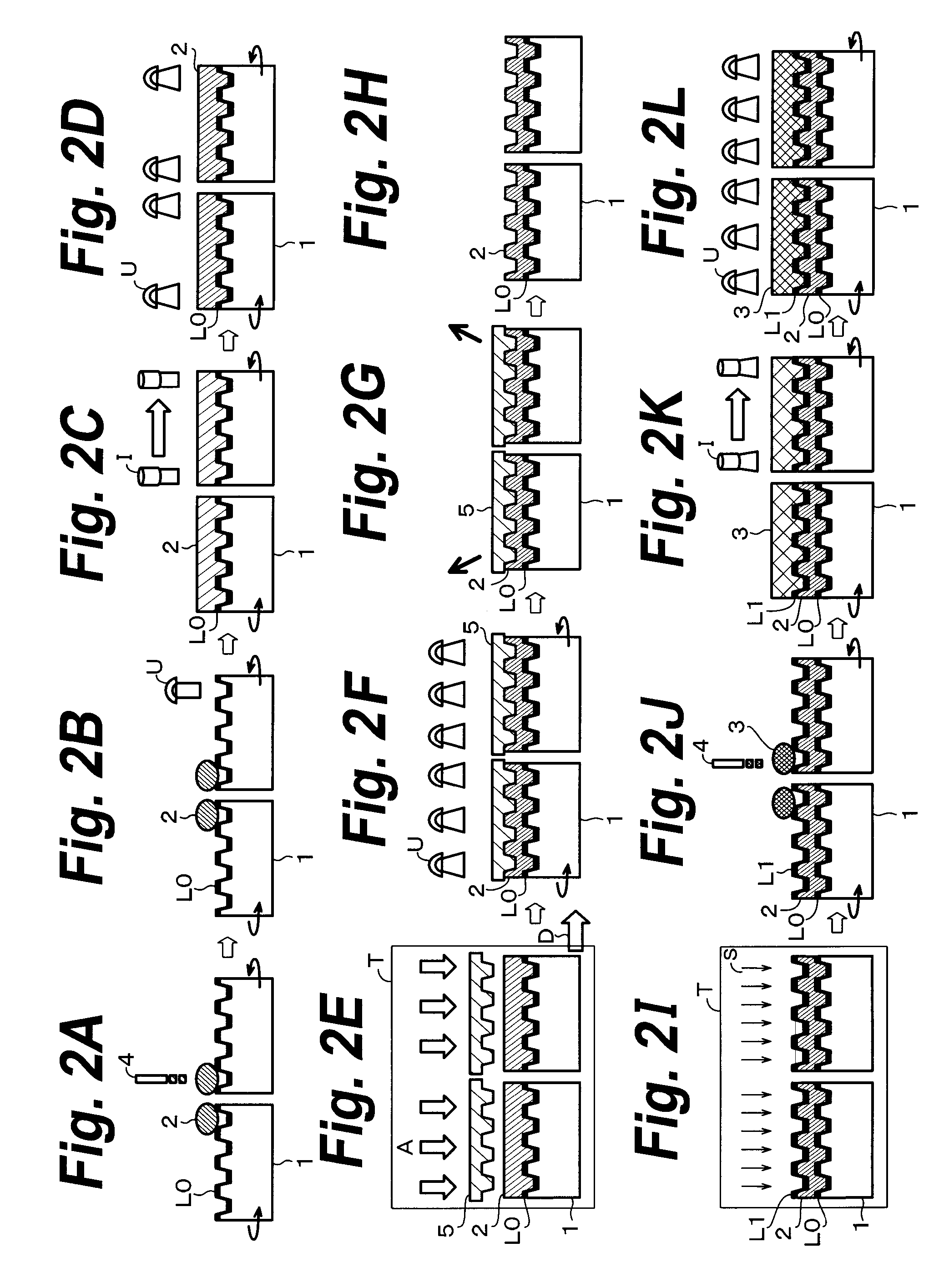

Manufacturing method of optical disk and its manufacturing apparatus

InactiveUS20070048444A1Suppress the generation of air bubblesQuality improvementRecord carriersVacuum evaporation coatingCompact discVacuum pressure

A manufacturing method of an optical disk in which information recording layers are formed onto a resin layer laminated on a substrate surface. The substrate surface is coated with the resin layer. The substrate and a stamper are arranged into a vacuum chamber so that the resin layer surface and the stamper surface with concave / convex portions face almost in parallel. The chamber is set into an almost vacuum state while holding the facing state of the substrate and the stamper. The chamber is changed from the almost vacuum state to an atmospheric pressure or higher. The substrate and the stamper are overlaid. The stamper is pressed by a differential pressure between the almost vacuum pressure and the atmospheric pressure or higher, thereby adhering the substrate and the stamper and transferring the concave / convex portions to the resin layer. The resin layer with the transferred concave / convex portions is hardened.

Owner:SONY CORP

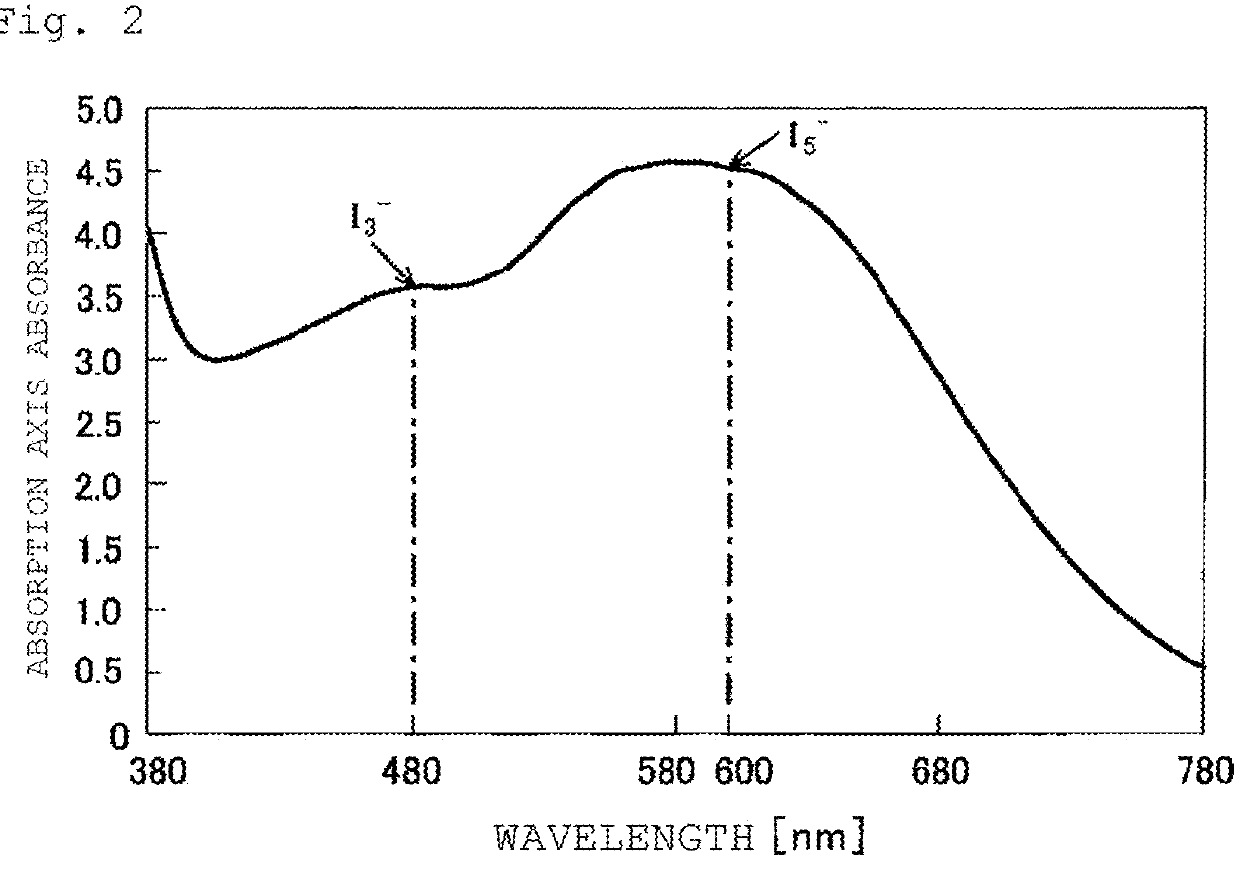

Polarizing plate

InactiveUS20160033699A1Good lookingSuppress the generation of air bubblesPolarising elementsNon-linear opticsBulk waterComposite material

A polarizing plate according to an embodiment of the present invention includes a polarizing film having a thickness of 10 μm or less and a protective layer provided on at least one side of the polarizing film through intermediation of an adhesion layer. The adhesion layer has a thickness of 0.7 μm or more, and the adhesion layer has a percentage of bulk water absorption of 10 wt % or less.

Owner:NITTO DENKO CORP

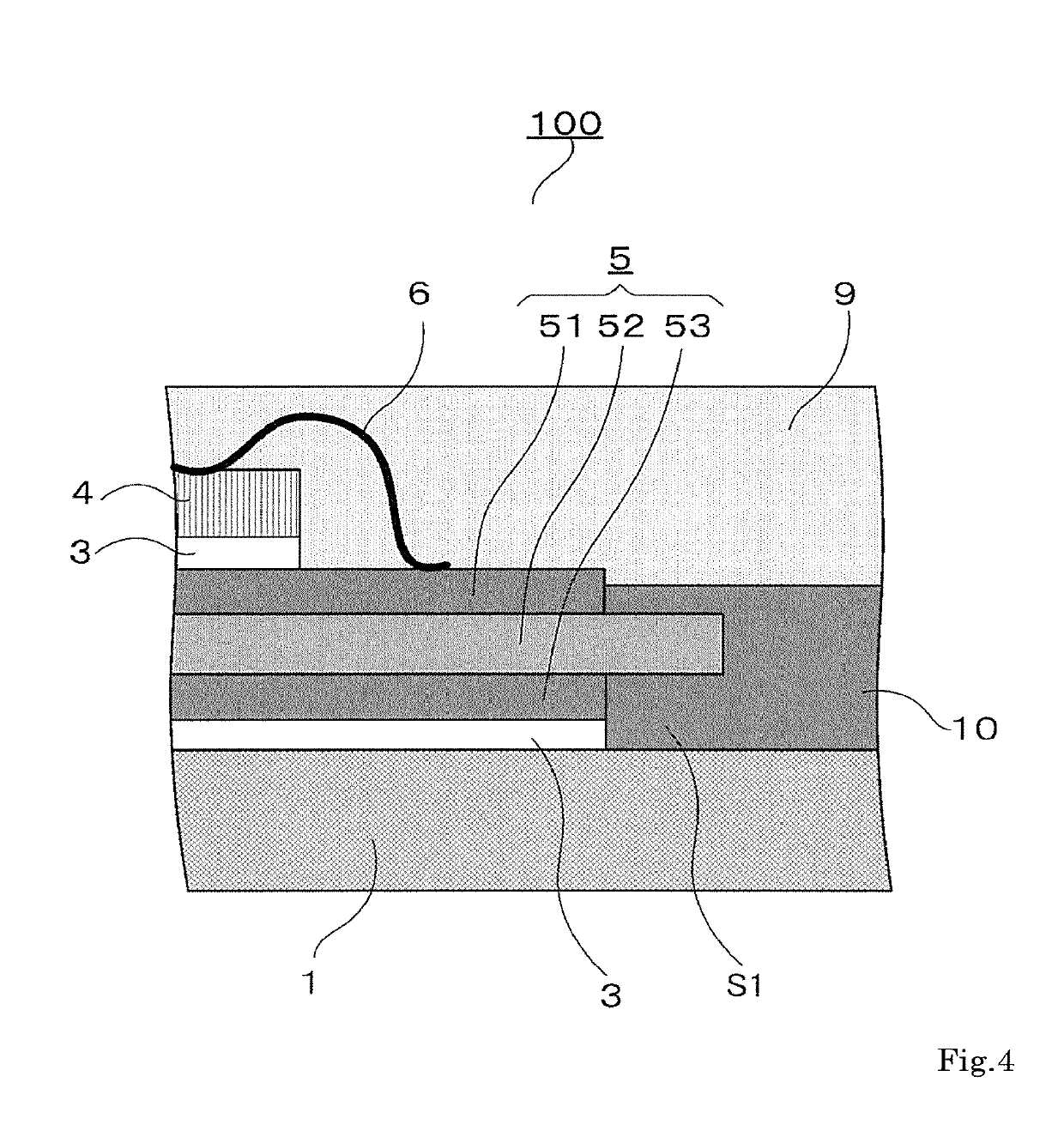

Semiconductor device and electric power converter

ActiveUS20190206751A1Suppress the generation of air bubblesImprove insulation reliabilityAC motor controlSemiconductor/solid-state device detailsElectrical conductorEngineering

A semiconductor device including: an insulating substrate having a conductor layer on the upper face and the lower face and a semiconductor element mounted on the upper conductor layer; a base plate bonded to the lower conductor layer; a case member surrounding the insulating substrate and bonded to the surface of the base plate to which the conductor layer bonded to the lower face; a first filler being a silicone composition filled in a region surrounded by the base plate and the case member; and a second filler being injected into a region below the first filler and surrounding a peripheral edge portion of the insulating substrate, whose height from the base plate is higher than the upper face and is lower than a bonding face between the semiconductor element and the upper conductor layer.

Owner:MITSUBISHI ELECTRIC CORP

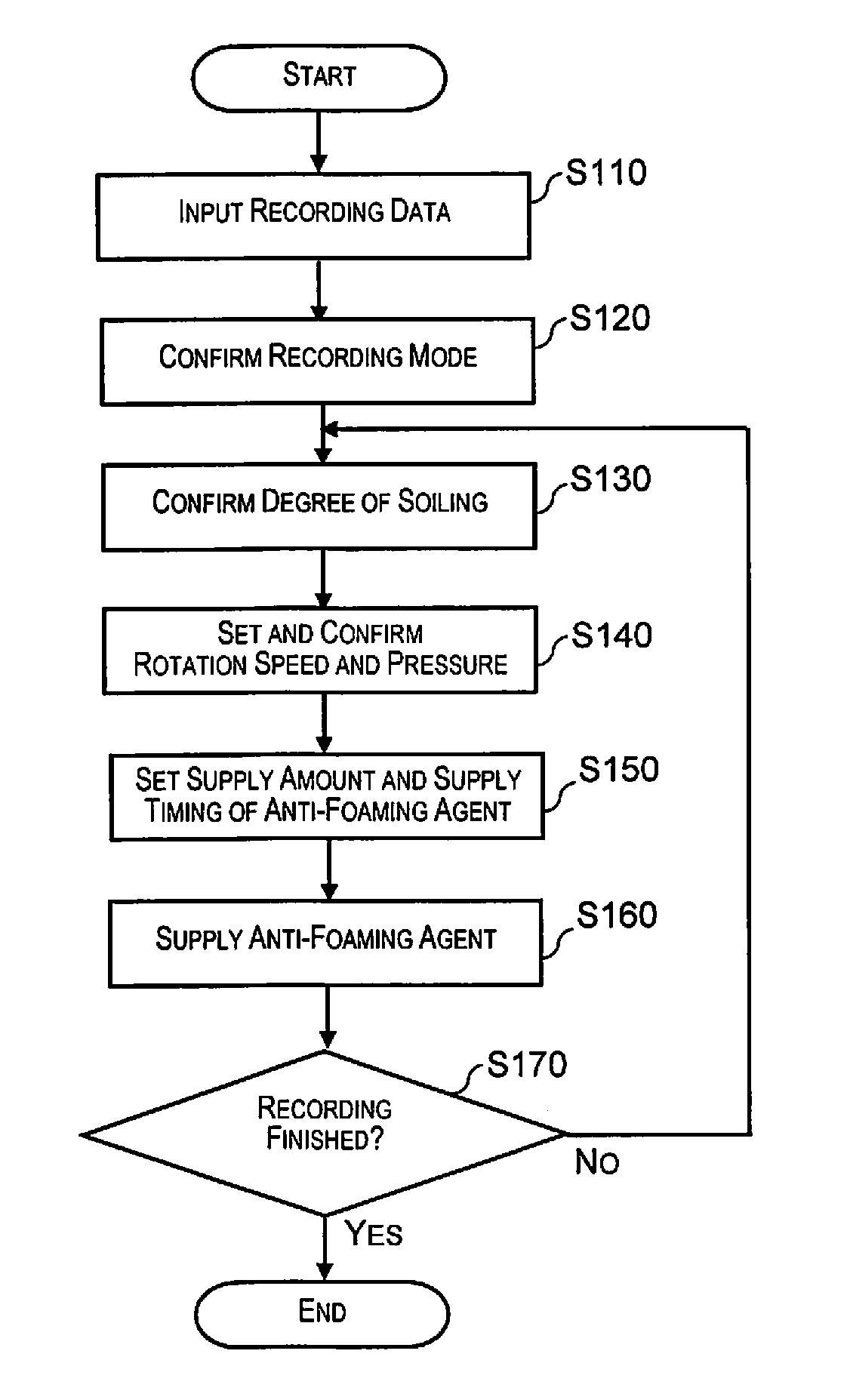

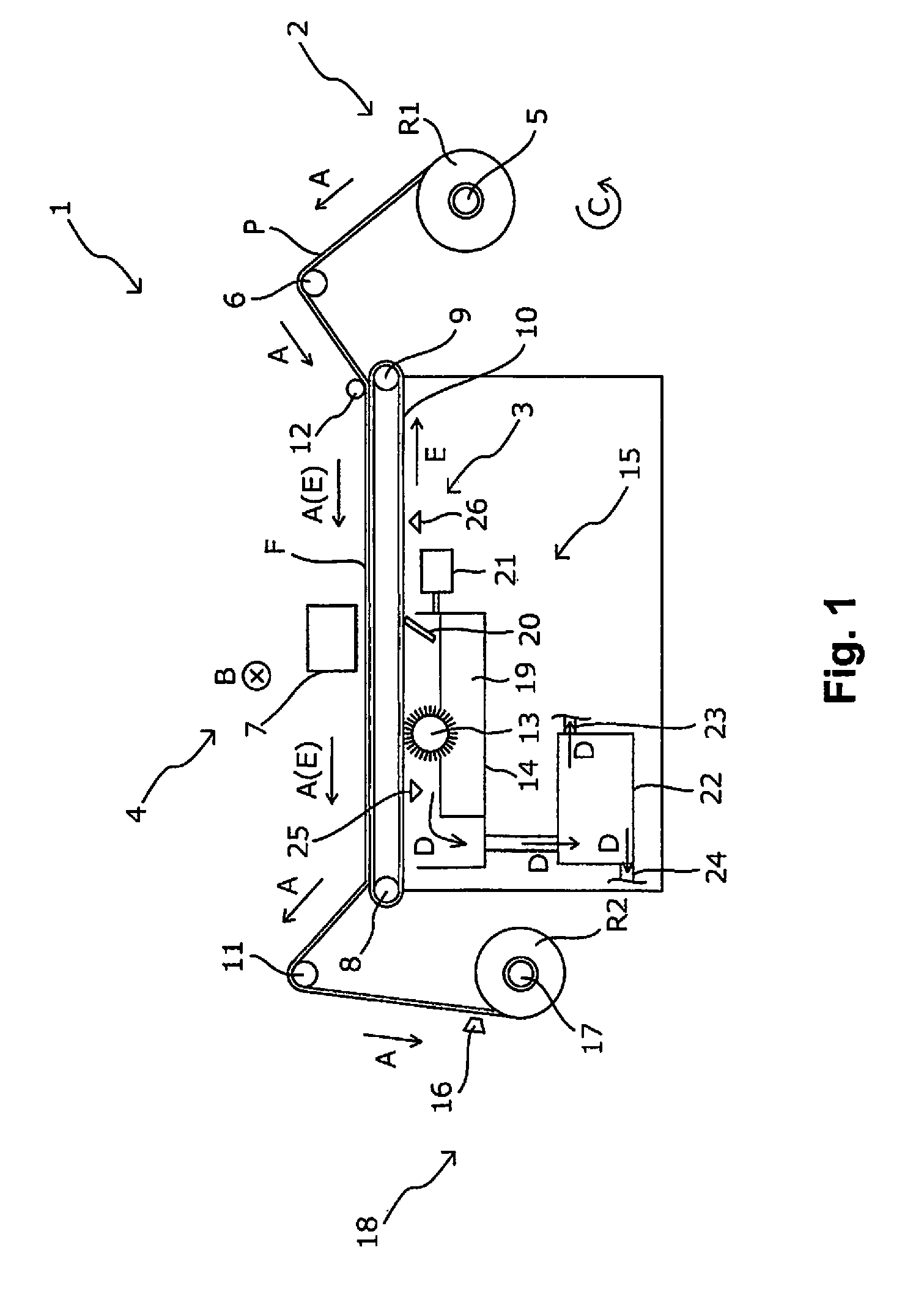

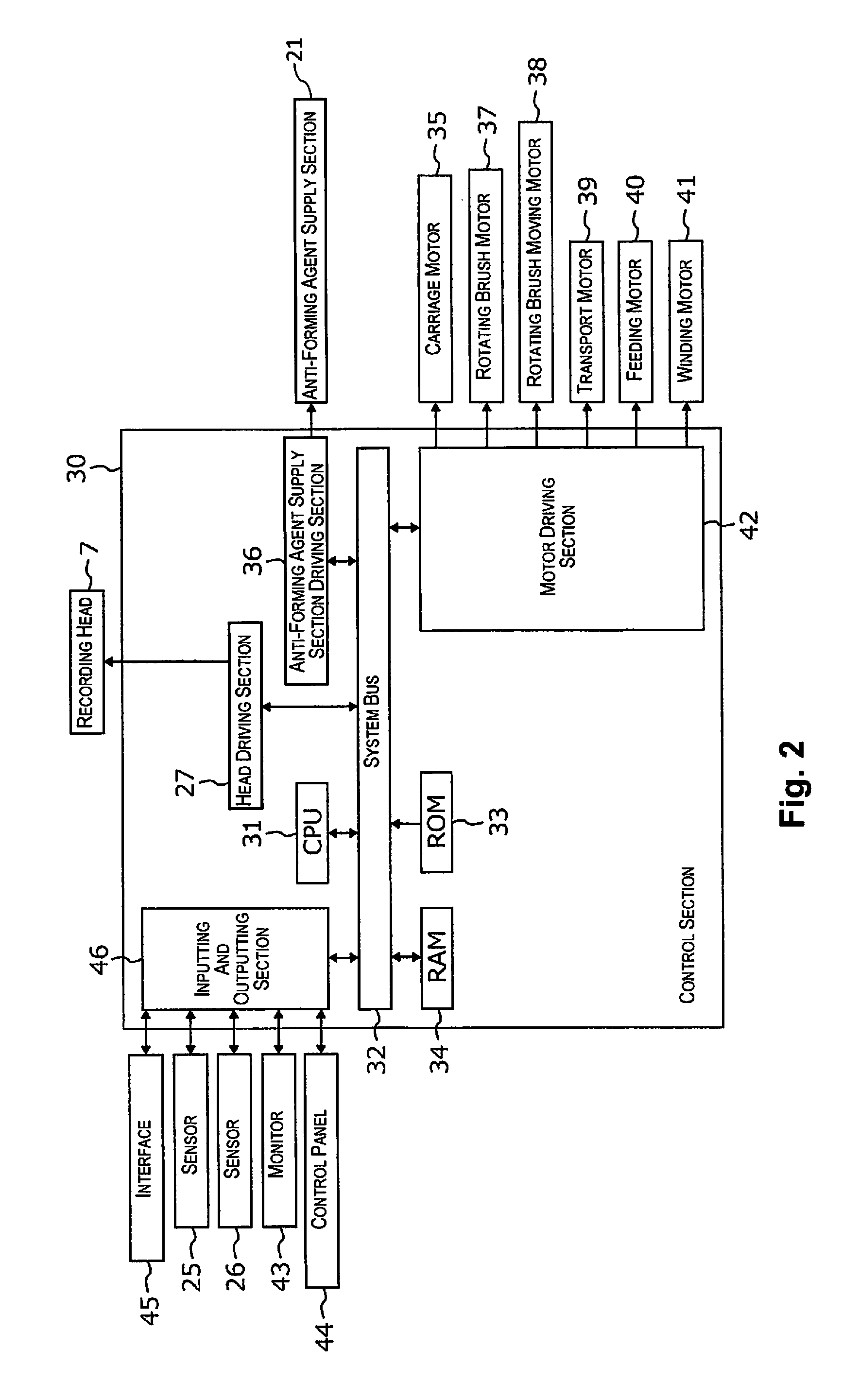

Recording apparatus and recording method

InactiveUS8985737B2Suppress the generation of air bubblesOther printing apparatusArticle feedersFoaming agentAdhesive belt

There is provided an adhesive belt which is configured to support and transport a recording medium, a recording head which is configured to record by discharging ink onto the recording medium which is supported by the adhesive belt, and a cleaning mechanism which is configured to clean the adhesive belt. The cleaning mechanism has a cleaning liquid tank which is configured to have a cleaning liquid, a contact section which is configured to come into contact with the adhesive belt to apply the cleaning liquid and clean off ink which is attached to the adhesive belt, and an anti-foaming agent supply section which is configured to supply an anti-foaming agent for ink to the adhesive belt directly or via another member, and the anti-foaming agent remains on the adhesive belt.

Owner:SEIKO EPSON CORP

Rubber composition and process for preparing the same

InactiveUS7569632B2Efficient couplingSuppress the generation of air bubblesSpecial tyresRolling resistance optimizationPolymer scienceRolling resistance

A rubber composition which is effective in improving the reaction efficiency of a silane coupling agent in kneading, suppressing generation of air bubbles, improving processability and abrasion resistance and lowering rolling resistance, and a process for preparing the same, wherein the rubber composition includes silica, 3 to 15 parts by weight of a silane coupling agent based on 100 parts by weight of the silica and 0.3 to 1.45 parts by weight of a potassium salt based on 100 parts by weight of silica.

Owner:SUMITOMO RUBBER IND LTD

Package manufacturing method, package, piezoelectric vibrator, oscillator, electronic device and radio timepiece

InactiveUS20110291523A1Quality improvementEnsure overall airtightnessPiezoelectric/electrostrictive device manufacture/assemblyCapsFritGas release

This package manufacturing method is a method for manufacturing a package using a rivet having a flat plate-shaped head portion and a core portion protruding from a rear surface of the head portion. The package includes: a plurality of substrates that are bonded to each other: a cavity that houses an object to be housed in an airtightly sealed state; the core portion which is disposed in a through hole that penetrates a base substrate and which electrically connects the object to be housed with the outside; and a glass frit that is filled between the through hole and the core portion and is fired to form a seal between the through hole and the core portion. The package manufacturing method includes: a rivet disposing step of inserting the core portion into the through hole until the rear surface of the head portion comes into contact with a first surface of the base substrate; a glass frit filling step of filling the glass frit in a paste form between the through hole and the core portion; and a firing step of integrally fixing the through hole, the rivet and the glass frit by firing the filled glass frit, and sealing between the through hole and the core portion. A gas relief passage, which leads from a base end of the core portion to a side surface or a front surface of the head portion, is formed on the rear surface of the head portion of the rivet.

Owner:SEIKO INSTR INC

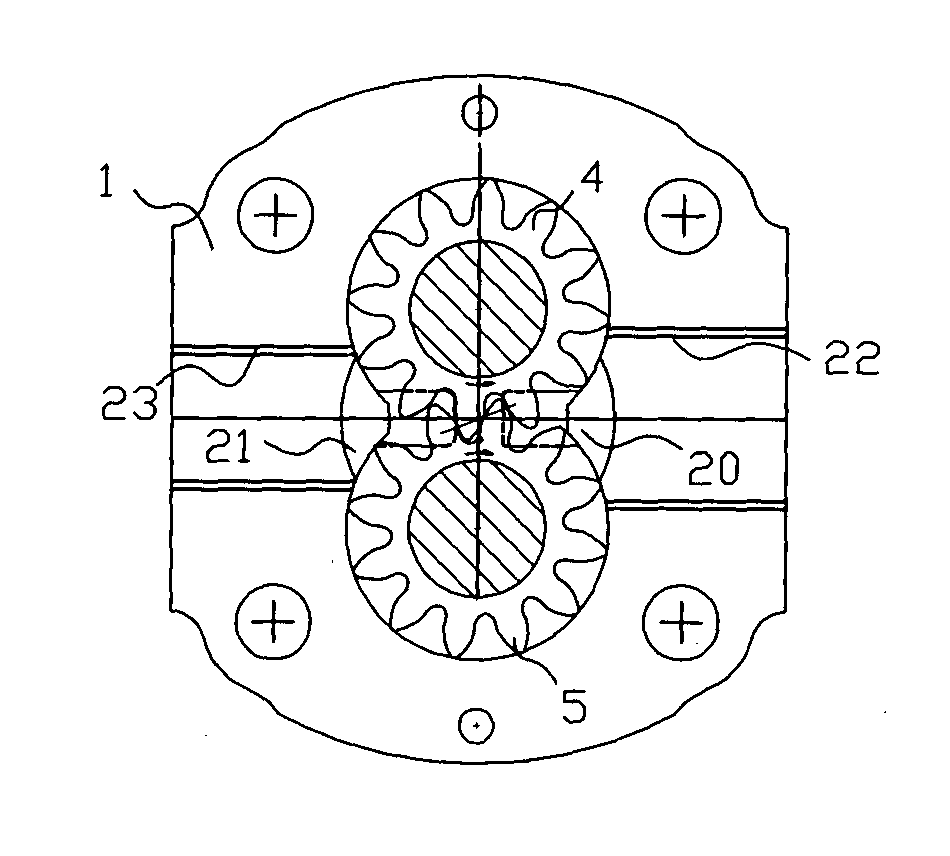

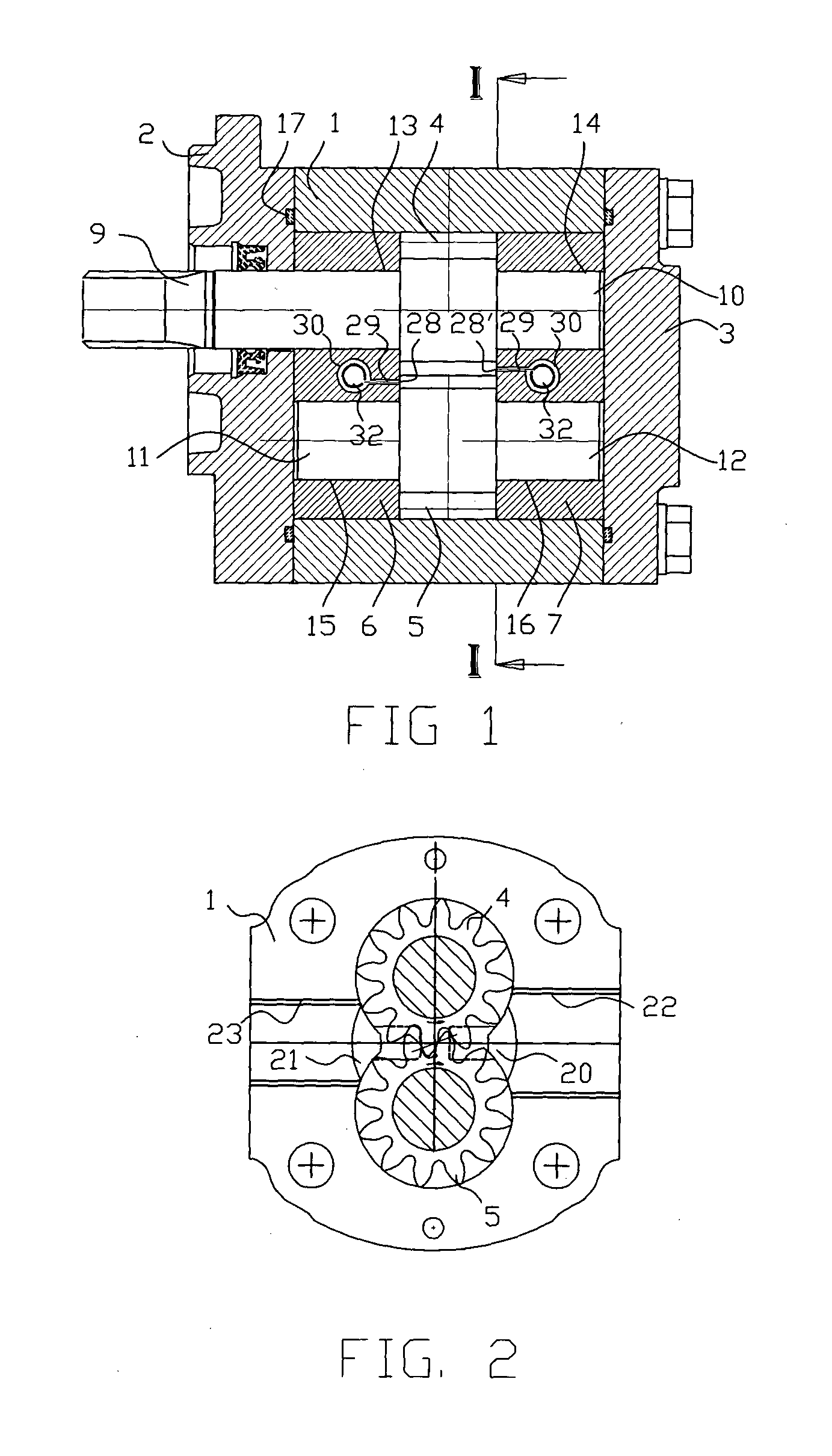

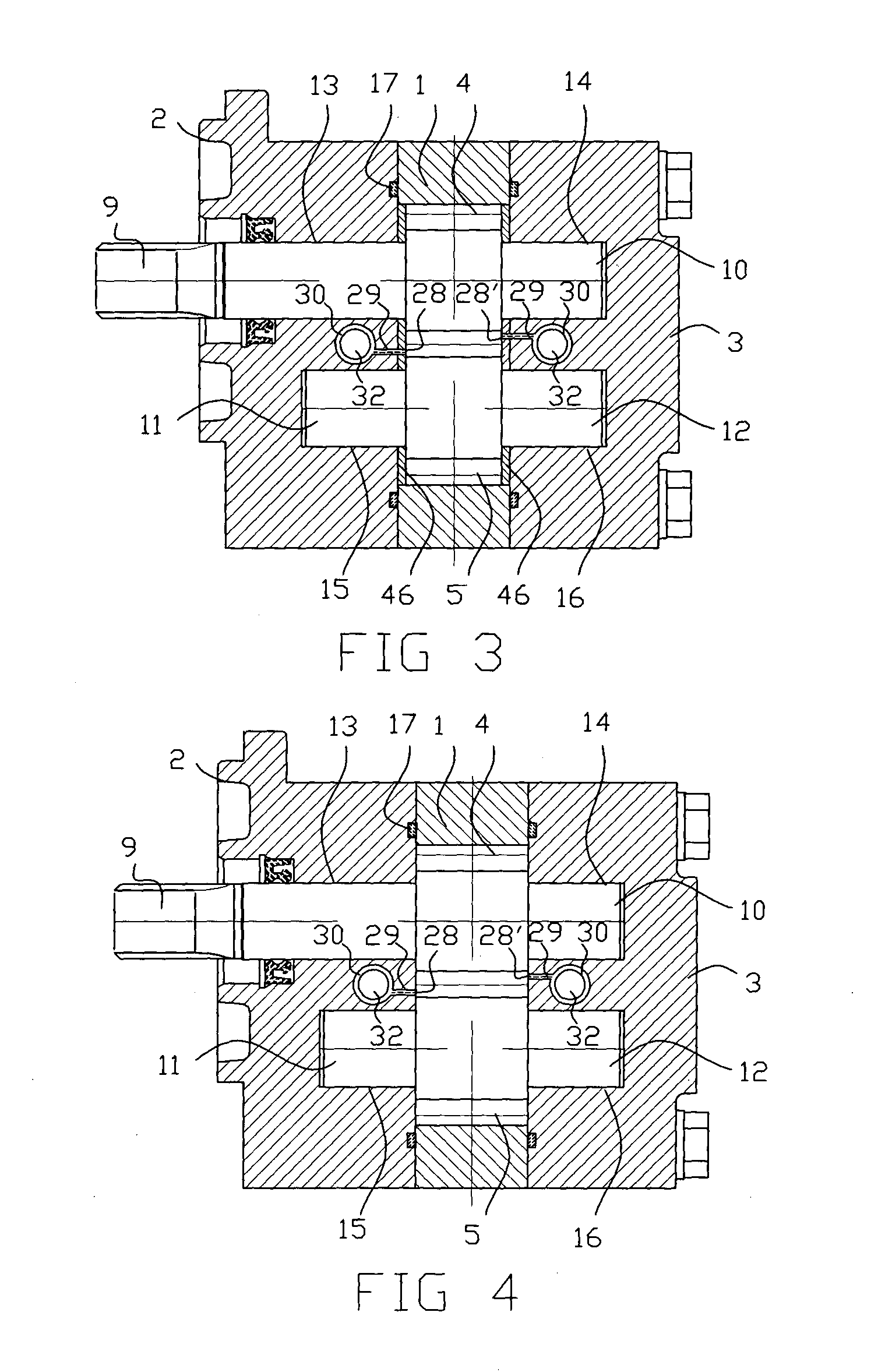

A silent gear pump or motor suppressing troubles of trapping fluid

ActiveUS20160108733A1Increase heightEliminate contactOscillating piston enginesSealing arrangement for pumpsRefrigeration compressorLow noise

Fluid delivery devices using a pair of meshed external gears, in spite of no reciprocating component for fluid delivery enabling low rotational vibration, the high noise due to the trapping phenomenon, and the teeth bouncing contact due to undesired large backlash heretofore afforded in the gear manufacturing process, restrict the employments in the industrial field requiring quiet environment such as electric motor vehicles or room services.Accordingly, a gear pump or motor or a gear refrigerating compressor comprising a shaft gear and a driven gear meshed rotatably within a gear chamber formed with a housing and opposite side walls, which delivers fluids from a inlet chamber to a outlet chamber; a backlash of the meshed gears having fluid-leak-tight clearance; a closed chamber provided in a internal portion of at least a side wall; an opening provided on a side wall from which a communication passage extends to a closed chamber; and at least a elastic disc capsule contained in the closed chamber, comprising a pair of concaved elastic disc plate abutted and sealed against each other with gas inside, of which occupying volume varies elastically subject to the fluid pressure therein enabling to absorb or expel the squeezed fluid in the trapped interstice during the trapping period of the interstice, whereby the fluid entrapped in the interstices isolated by the fluid-leak-tight backlash suppressing the pressure transmission inwardly or outwardly, whereof volumetric variation during the trapping period is compensated by the compression or expansion of the elastic disc capsule, suppressing pressure pulse and air bubble generation and eliminating the teeth bouncing contact, achieving a low noise, low vibration and high efficiency gear pump or motor or refrigerating compressor.

Owner:LIM NAG BOK

Bean product defoaming agent as well as preparation method and use method thereof

PendingCN112772854AImprove qualityAvoid wastingMilk substitutesFood scienceBiotechnologyFood additive

The invention belongs to the technical field of food additives, and particularly relates to a bean product defoaming agent as well as a preparation method and use method thereof. The defoaming agent comprises the following components in parts by weight of 10-15 parts of polysiloxane, 30-45 parts of rice bran oil, 10-13 parts of calcium carbonate, 5-8 parts of calcium bicarbonate, 15-18 parts of polyoxypropyl polyoxyethyl glyceryl ether, 5-7 parts of an emulsifying agent, 0.5-0.6 part of a dispersing agent, 1-2 parts of sorbitan fatty acid ester and 0.005-0.012 part of tert-butylhydroquinone. The generation of bubbles in bean product processing is effectively inhibited.

Owner:JIANGSU HUANYU KANGLI TECH

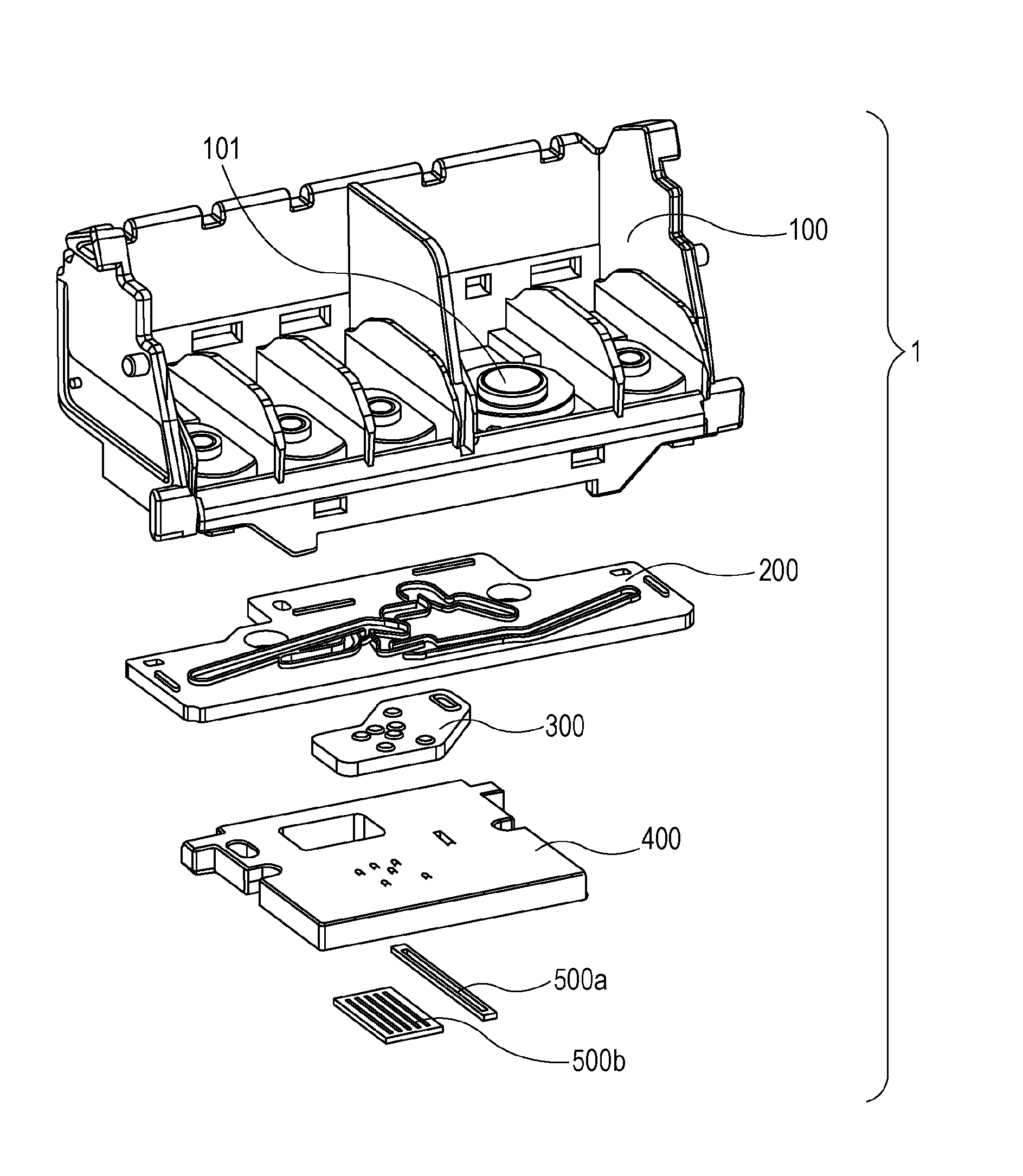

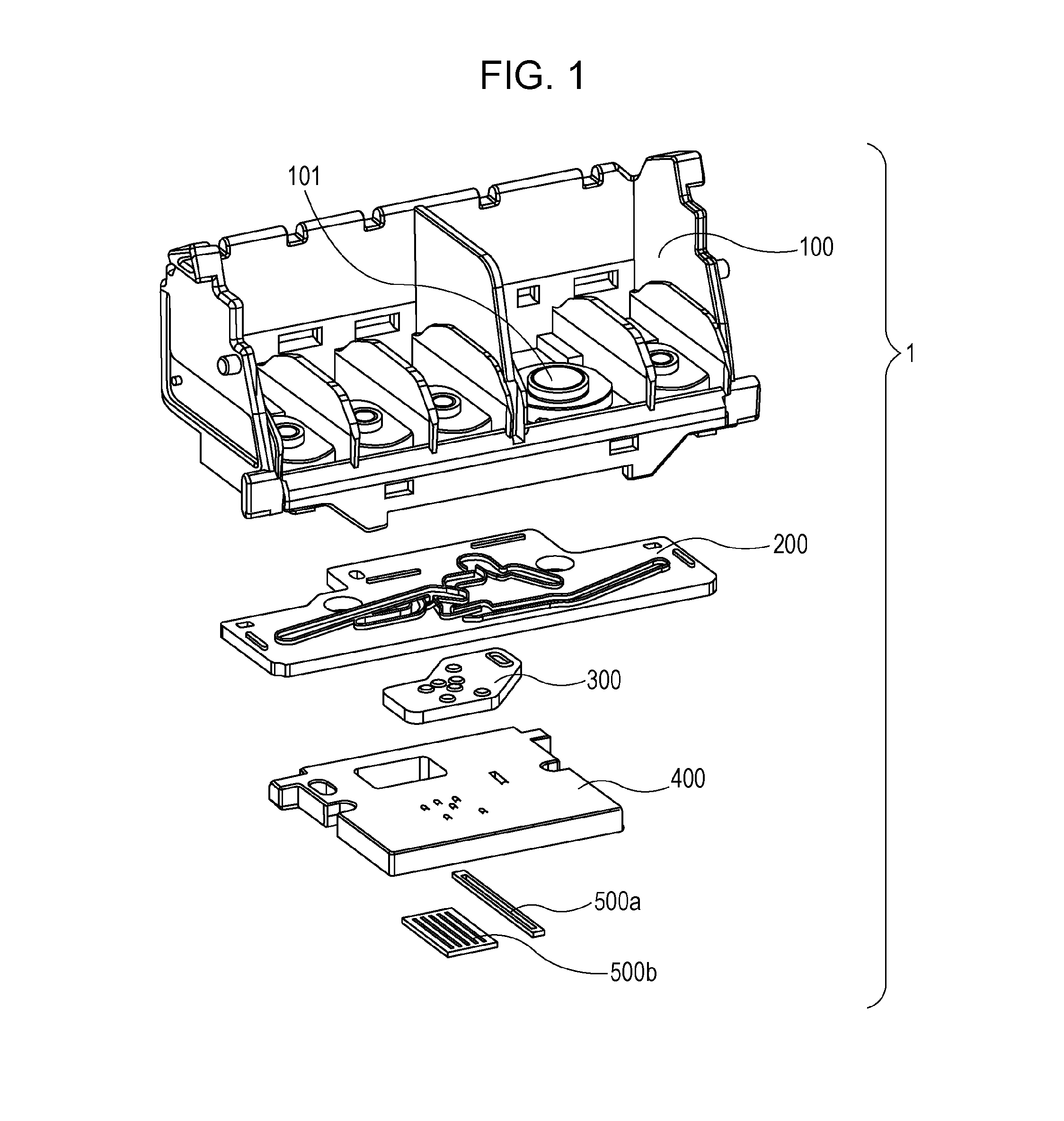

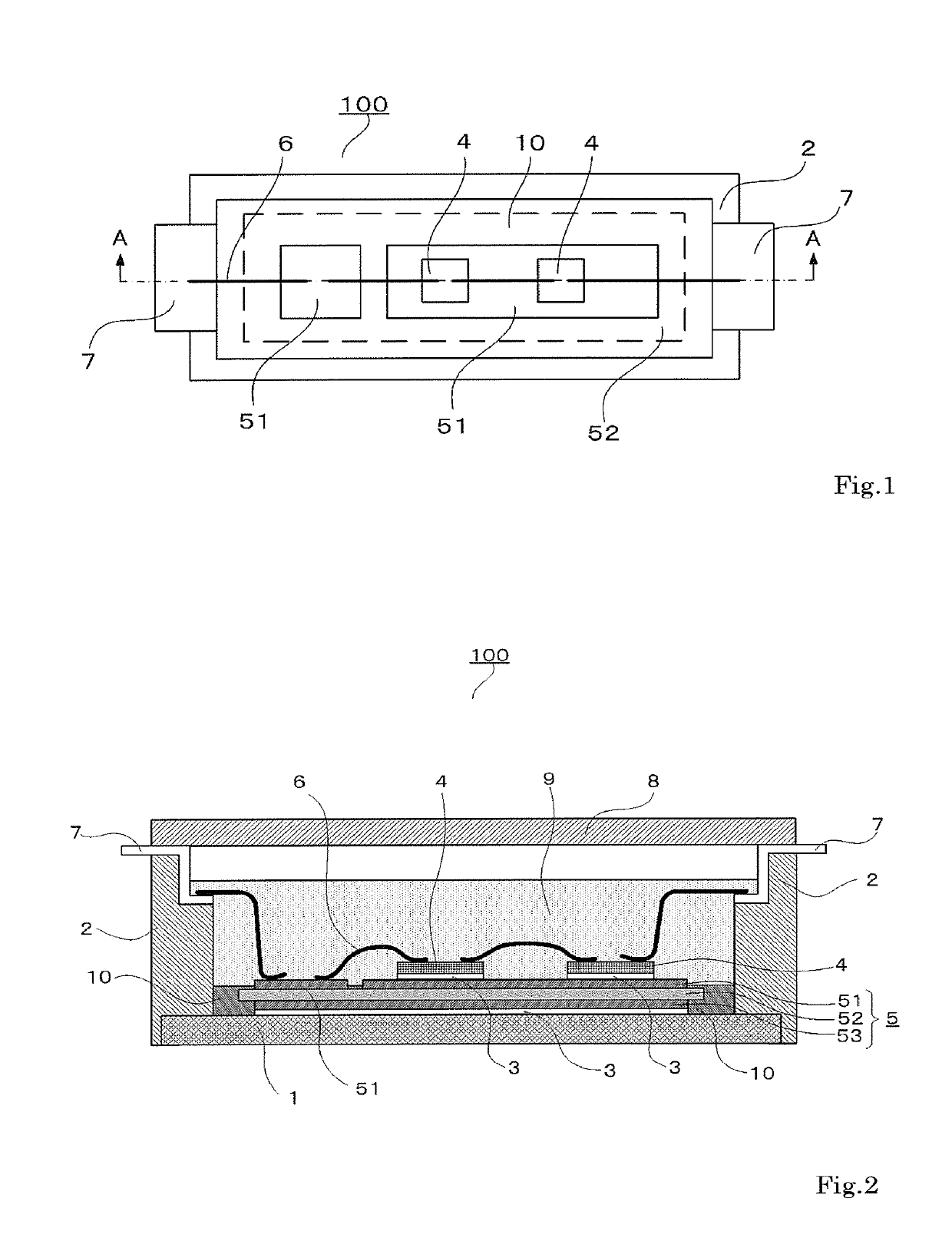

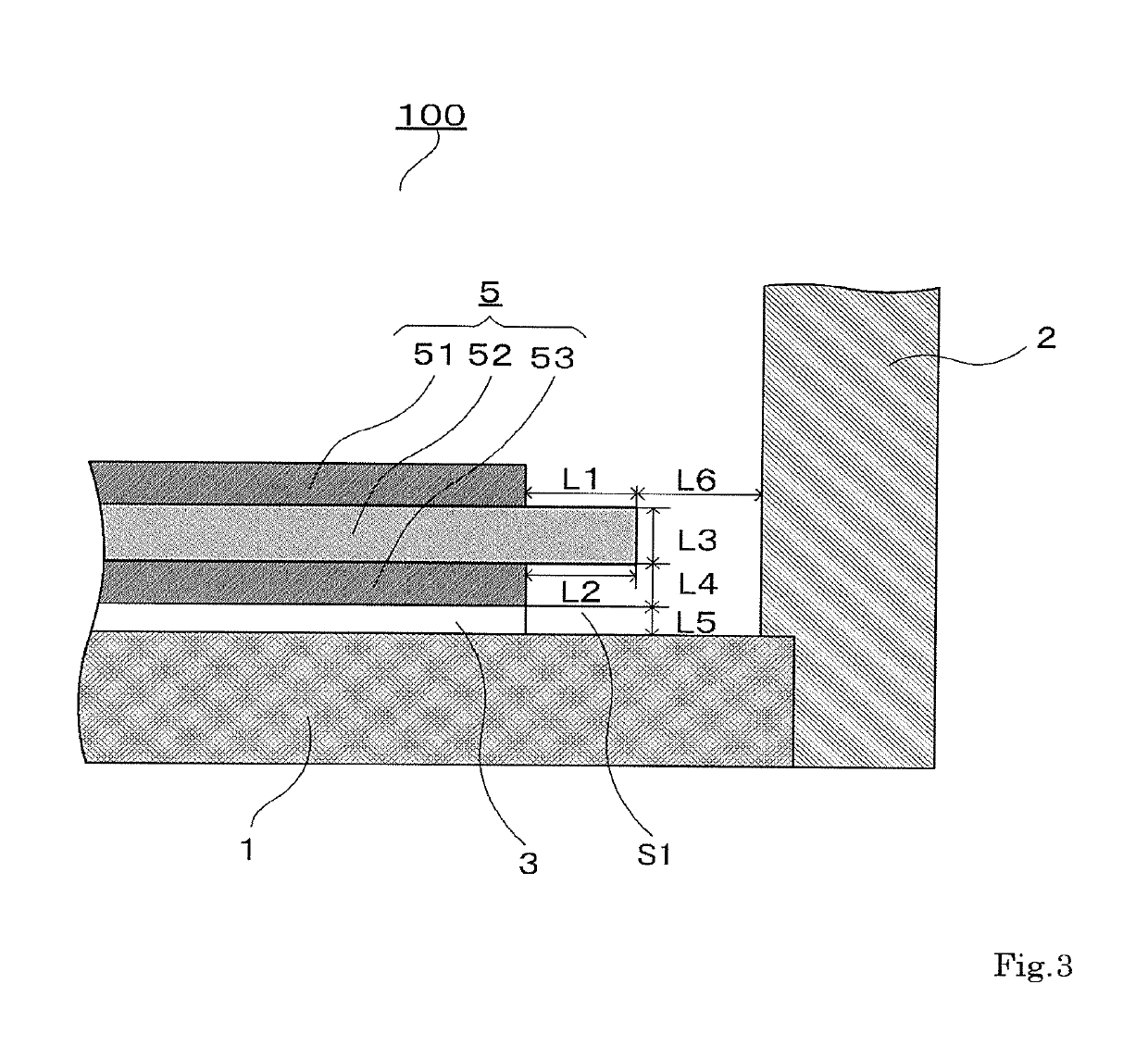

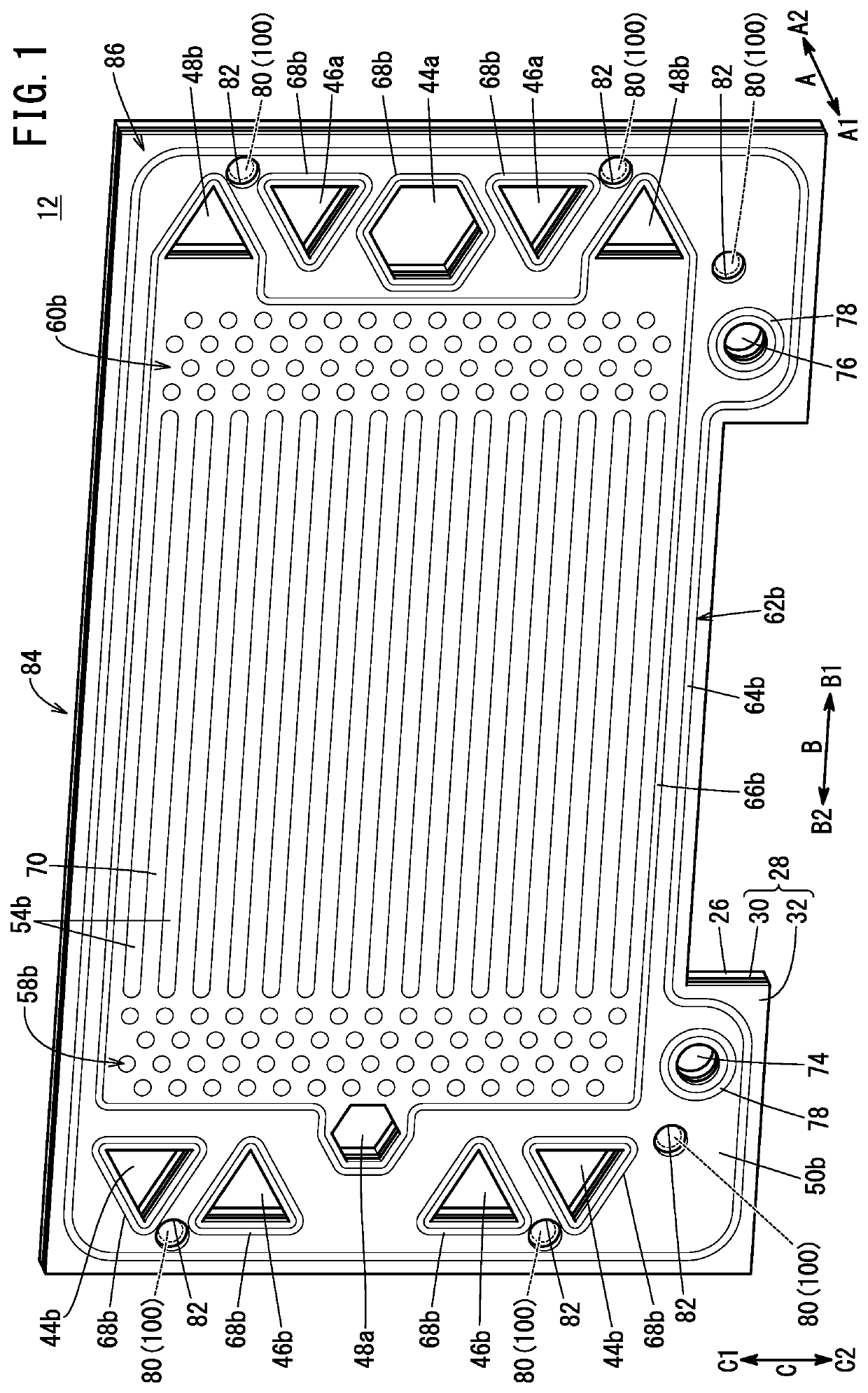

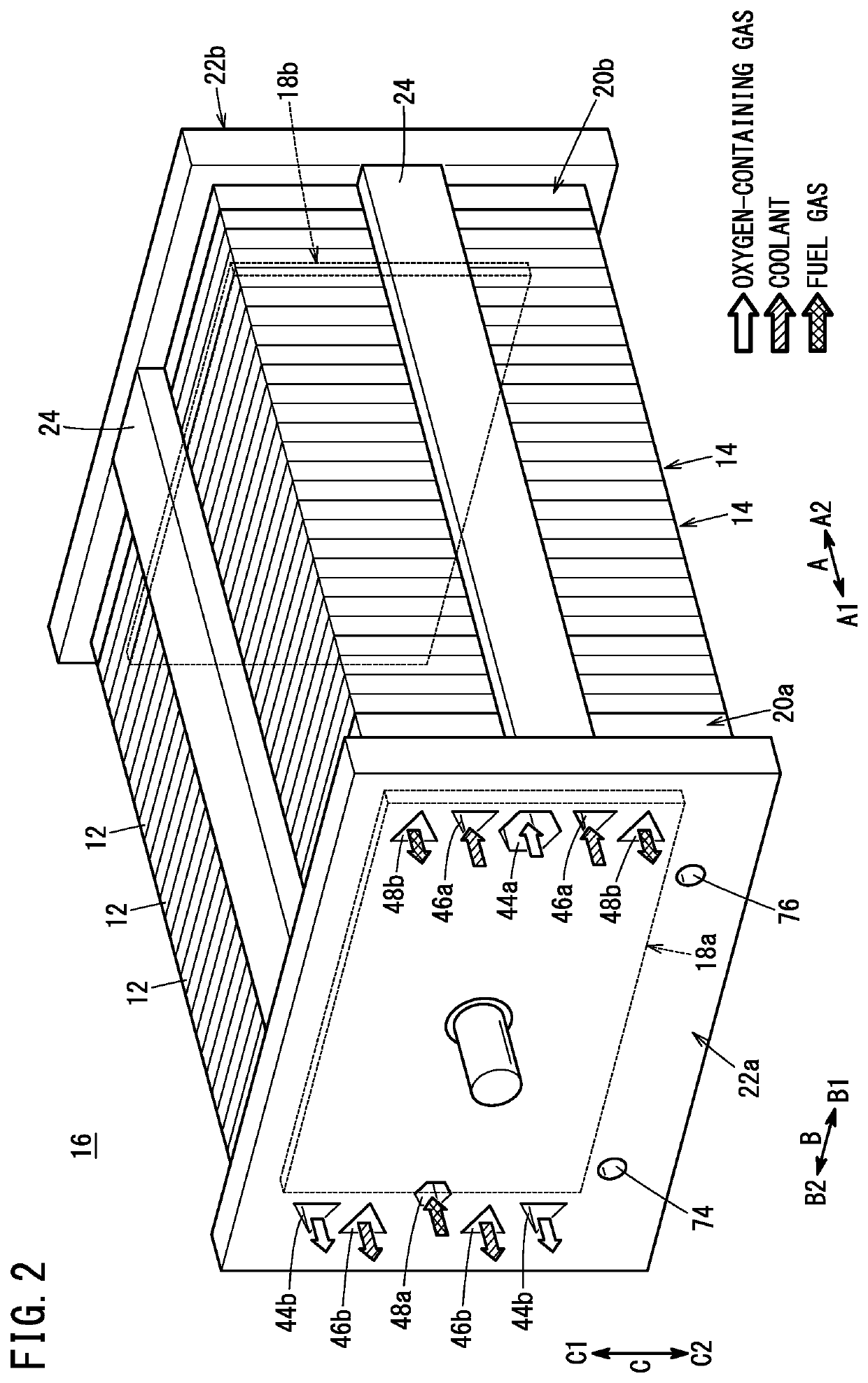

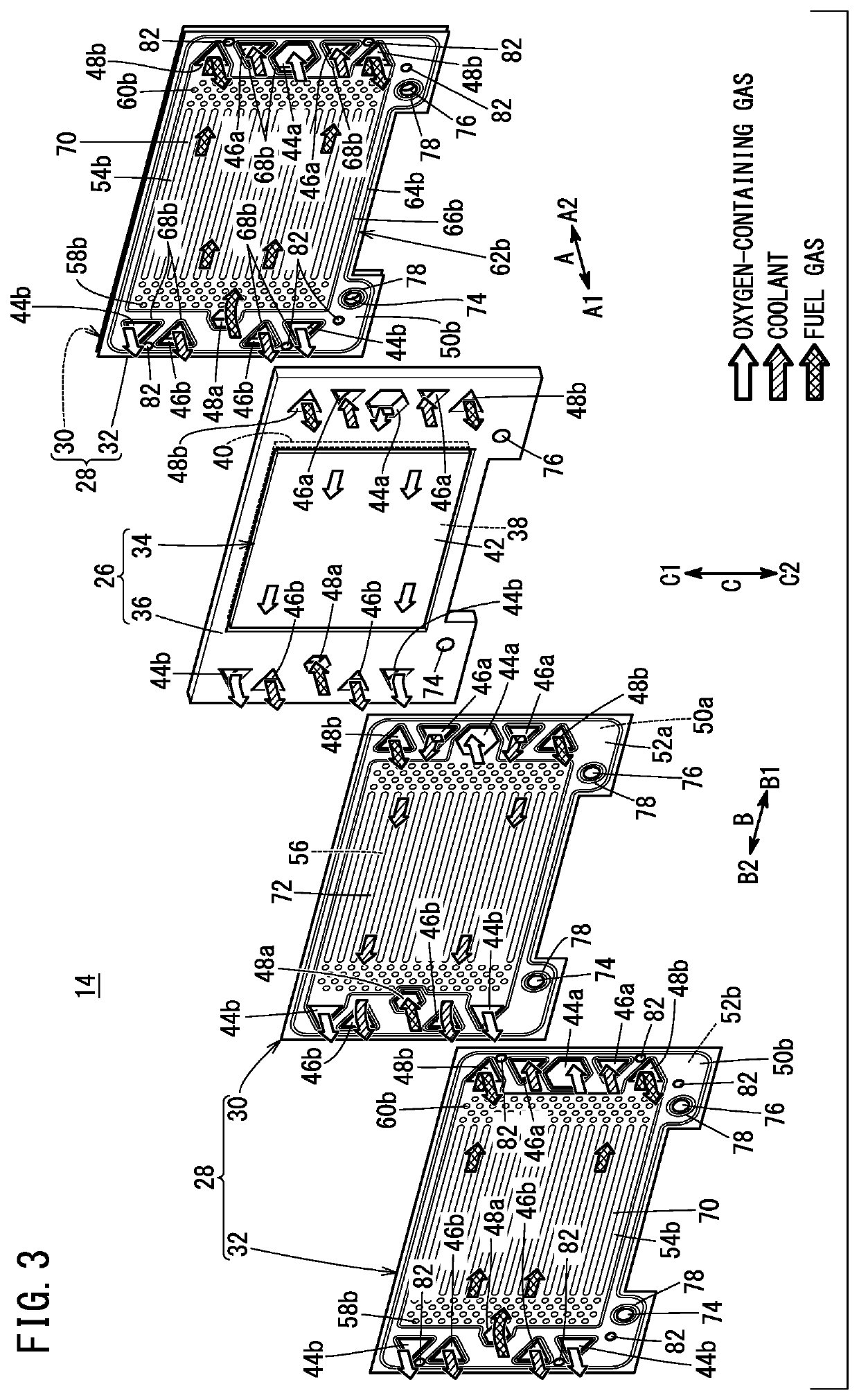

Manufacturing method and manufacturing apparatus for fuel cell unit

ActiveUS20220045341A1Reduce usageReduced strengthFinal product manufactureMotive system fuel cellsFuel cellsMechanical engineering

The manufacturing method for the fuel cell unit includes a stacking step and a laser irradiation step. In the stacking step, a stacked portion including, stacked together, a resin frame member of a resin frame equipped membrane electrode assembly and an outer peripheral portion of a separator is placed on a metal spacer. The resin frame member at a joining target portion of the stacked portion is placed so as to face a recess of the metal spacer. In the laser irradiation step, the separator at the joining target portion in a state where the resin frame member faces the recess is irradiated with a laser beam to thereby form a welded portion where the resin frame member and the separator are welded to each other.

Owner:HONDA MOTOR CO LTD

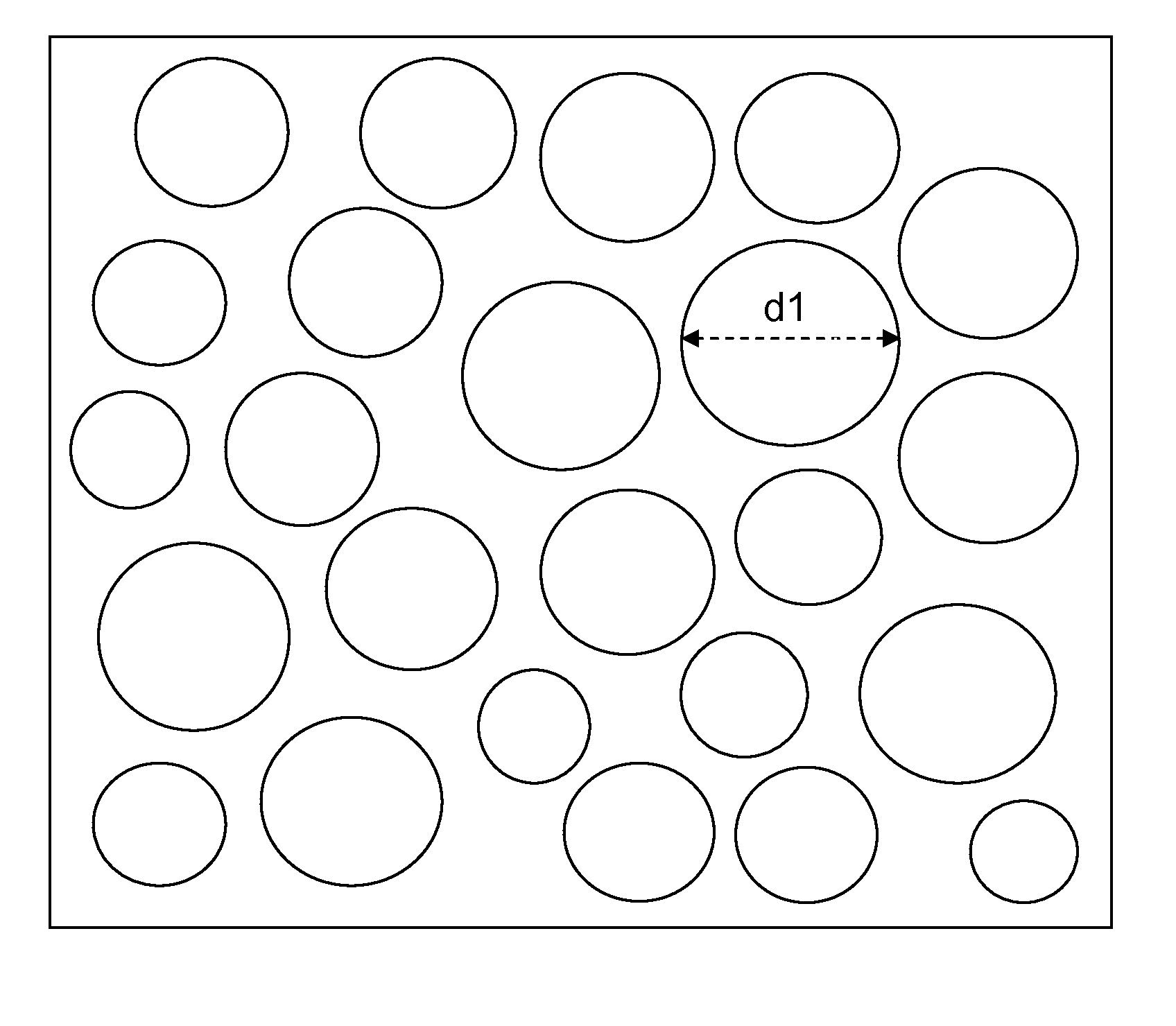

Encapsulant sheet for solar cell module and solar cell module including same

ActiveUS8263854B2Avoid cell damageSuppress the generation of air bubblesPV power plantsOrnamental structuresEngineeringSolar battery

An encapsulant sheet for solar cell modules comprising a transparent soft resin film having a plurality of hemispherical concave parts of varying sizes formed on one or both surfaces of the transparent soft resin film, can disperse pressure generated in the process of combining the encapsulant sheet and a solar battery cell to prevent damage to the solar battery cell and suppress bubble generation by allowing air to escape easily.

Owner:SKC ECO SOLUTIONS CO LTD

Air-drying polyester (METH)acrylate resin composition, structure, and method for applying the resin composition

InactiveUS20120108700A1Maintain good propertiesSuppress generationPolyester coatingsMethacrylatePolyester

An object of the present invention is to provide an air-drying polyester (meth)acrylate resin composition in a curing system of a ketone peroxide curing agent and a cobalt-based curing accelerator, the resin composition being used as a topcoat in the field of civil engineering and construction, and having such good properties as, when coated or stacked, being capable of forming a cured coating film with no bubbles remaining therein due to non-bubbling properties of suppressing the generation of bubbles in the course of the curing reaction and being free from problems related to room-temperature curability such as a retarded gelation time, even after being stored for about one month; a structure coated with the resin composition; and a method for applying the resin composition.

Owner:DAINIPPON INK & CHEM INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com