Liquid cyclone

A liquid cyclone, the main body technology, applied in the direction of the cyclone device, the liquid degassing, the device in which the axial direction of the cyclone can be reversed, etc. Mix-in prevention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

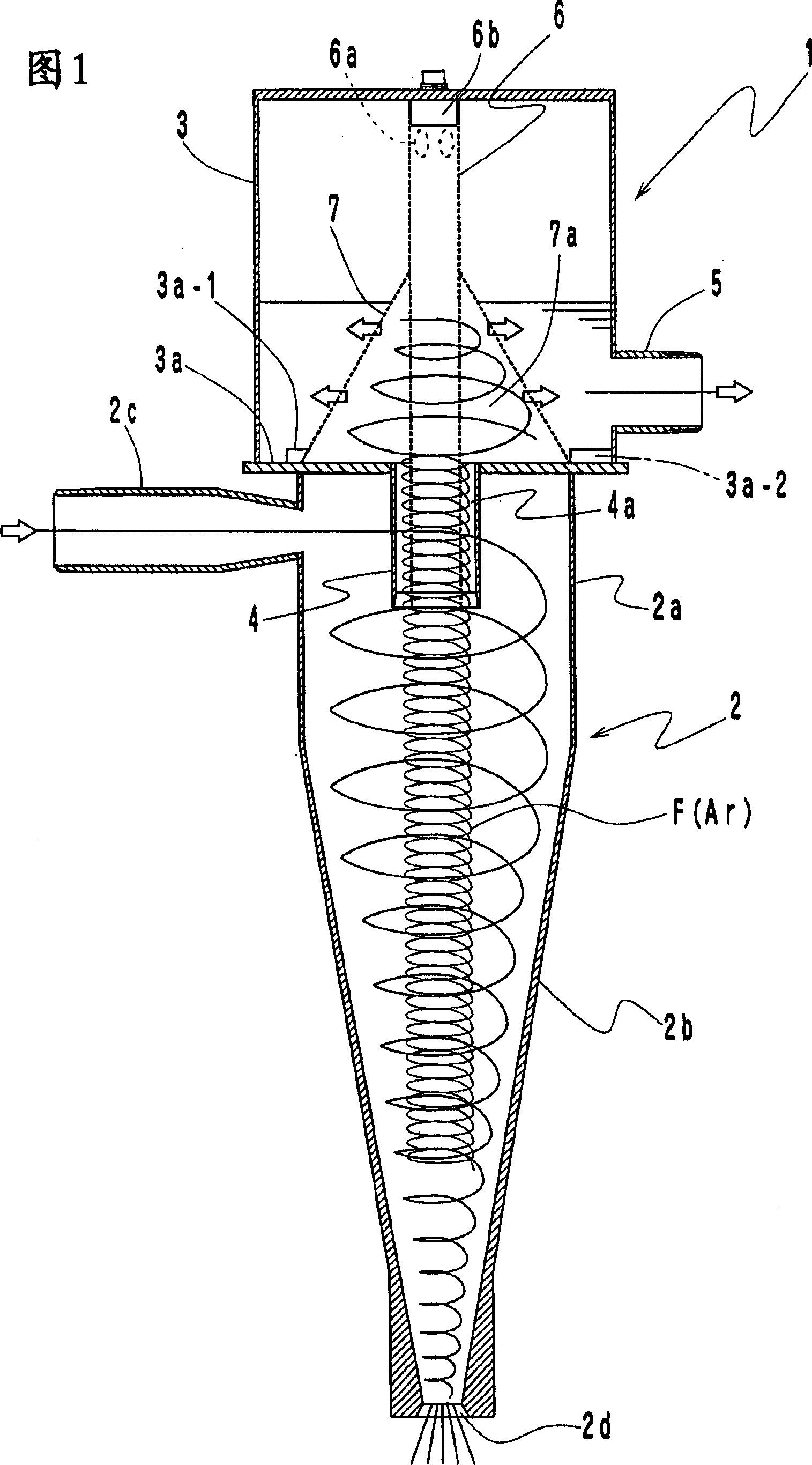

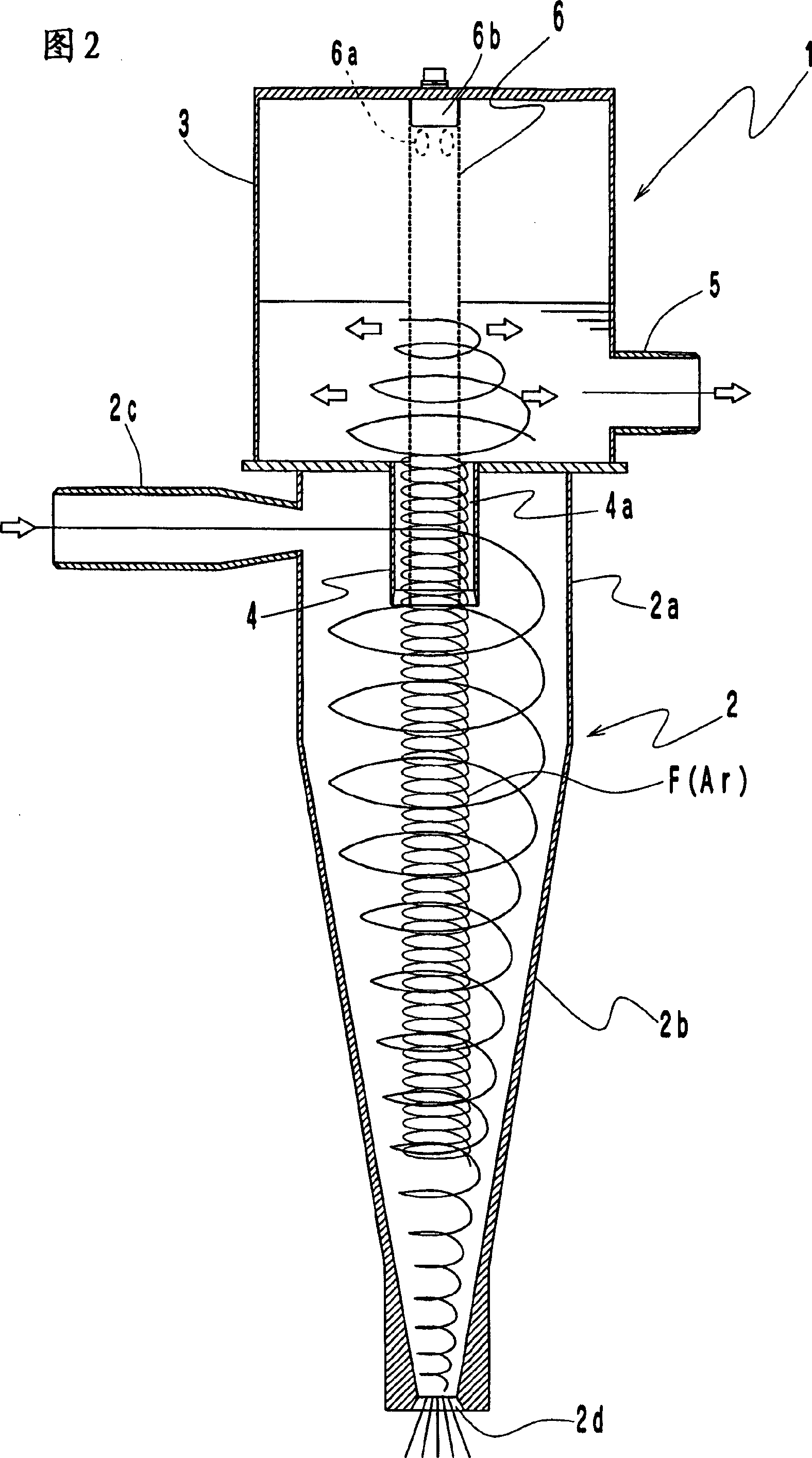

[0035] Fig. 1 shows a first embodiment of the liquid cyclone of the present invention.

[0036] In this liquid cyclone 1, a cylindrical body 6 having a net-shaped peripheral surface is inserted from the upper case 3 with a gap in the inner peripheral portion of the outlet pipe 4 connected to the upper case 3, and, The outflow damper 7 a is formed by a mesh-like umbrella 7 surrounding the inner protrusion of the upper casing 3 of the aforementioned cylindrical body 6 .

[0037] The cylindrical body 6 may be formed by rolling a mesh-like (metal mesh, etc.) plate into a cylindrical shape, or a porous plate (punched metal, etc.) or a cylindrical body formed with slits or the like may be used. In addition, the upper end of the cylinder 6 is mounted on the pin 6b, and the lower end is inserted into the inside of the outlet pipe 4. The pin 6b is fixed on the upper surface of the upper casing 3 and concentric with the outlet pipe 4 by a fixing mechanism such as a bolt.

[0038] At th...

Embodiment 2

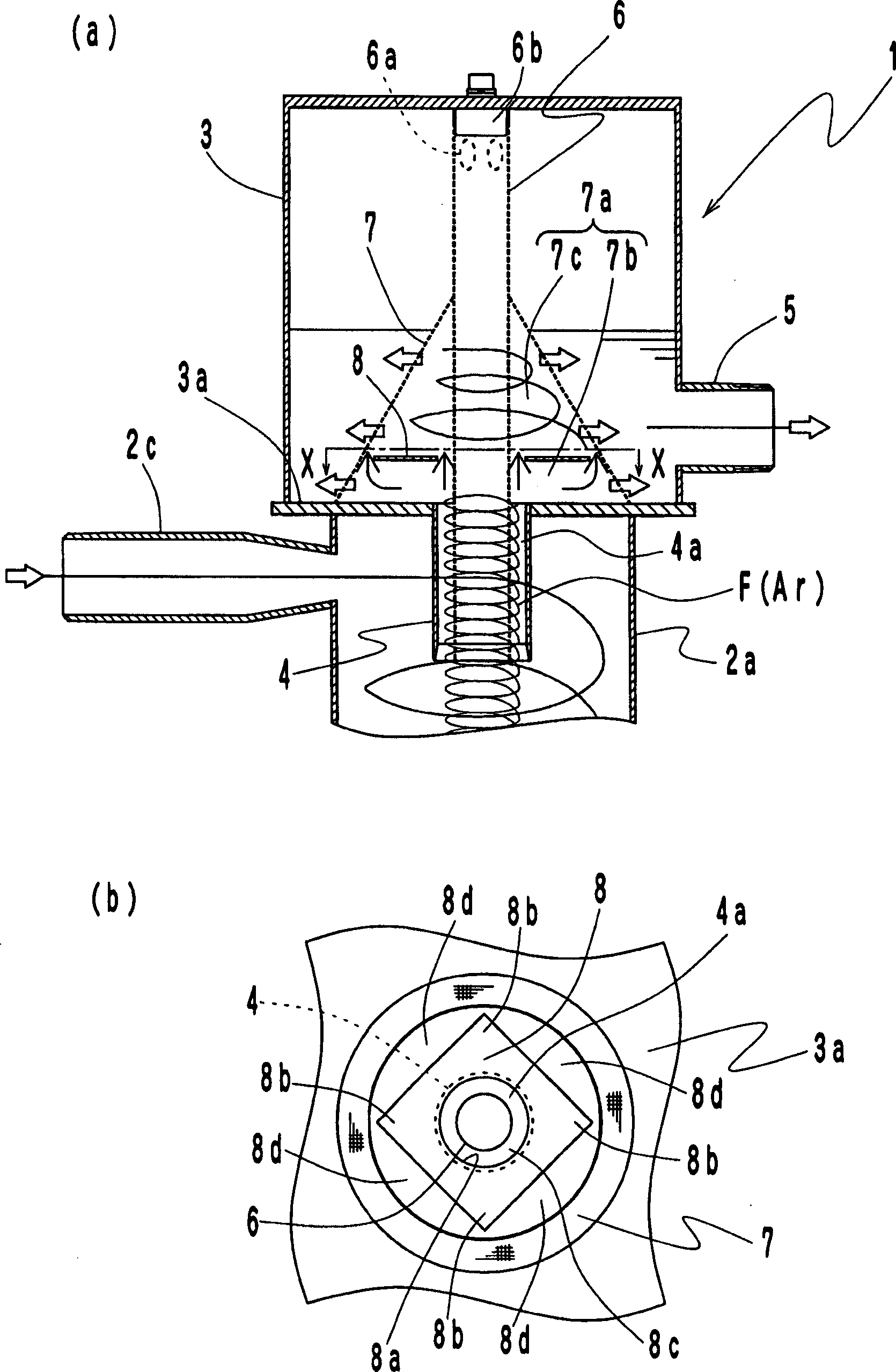

[0051] image 3 A second embodiment of the liquid cyclone of the present invention is shown.

[0052] This liquid cyclone 1 is constituted by the same structure as that of Embodiment 1, and furthermore, a suppressing plate 8 is arranged inside the outflow damping part 7a to suppress the swirling flow F from the outlet pipe 4 from flowing into the outflow damping part 7a. Rise of cleaning solution.

[0053] The shape and material of the restraining plate 8 are not particularly limited. In addition to using a non-porous plate, a mesh-shaped plate, a perforated plate, or a square shape with slits or the like can be used similarly to the cylinder body 6 or the umbrella body 7. plate, round plate. Moreover, in addition to image 3 (b) In addition to the structure in which the center is pierced with a square plate with a hole 8a through which the cylinder body 6 passes, and is fixed on the appropriate part of the inner peripheral surface of the umbrella-shaped body 7, it can also b...

Embodiment 3

[0059] 7 to 8 show a third embodiment of the liquid cyclone of the present invention.

[0060] In this liquid cyclone 1, a gas-liquid separation plate 60 is arranged on the outlet pipe 4 of the lower surface 3a of the upper housing 3, the minimum diameter of the gas-liquid separation plate 60 is greater than the diameter of the outlet pipe 4, and the cross section is the direction and The gas and liquid rising along the outlet pipe 4 have a vortex shape in which the direction of swirl is opposite.

[0061] The gas-liquid separation plate 60 can use a porous plate (punched metal, etc.) or a plate-shaped body formed with slits, etc., in addition to being formed by rolling a mesh-like (metal mesh, etc.) plate into a spiral shape. Furthermore, a plurality of through-holes 60a are opened to allow passage of the cleaning liquid among the gas swirling and rising in the outlet pipe 4 and the liquid.

[0062] In addition, the upper end of the gas-liquid separation plate 60 is set as a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com