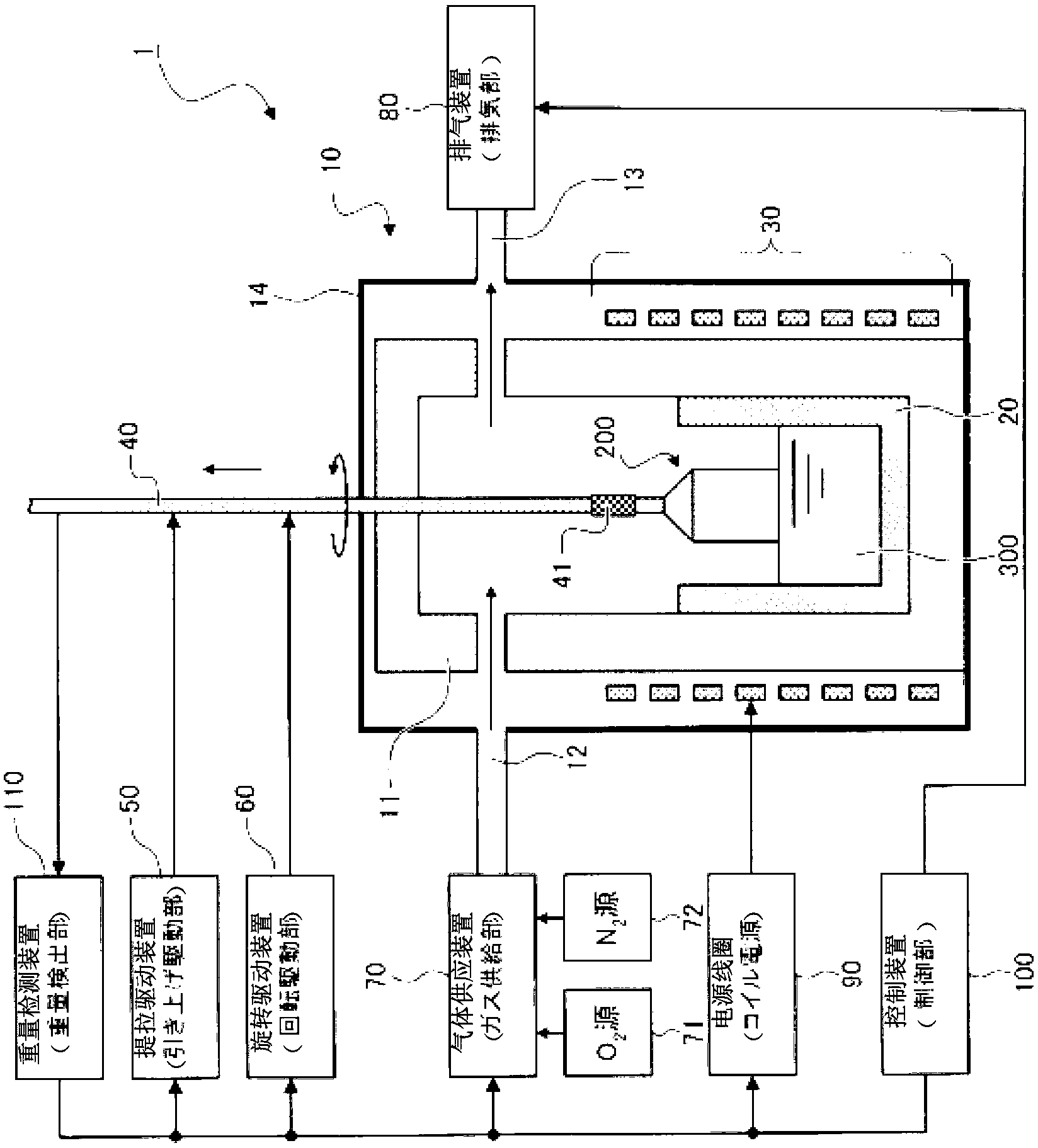

Improvement on structure of crystal growing furnace for pulling alumina single crystal and method for growing alumina single crystal

A structure improvement and crystal growth furnace technology, which is applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., can solve the problems of reducing the service life of the crucible, complex device structure, and deterioration of the crucible, so as to suppress the generation of bubbles, Excellent effect with little deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

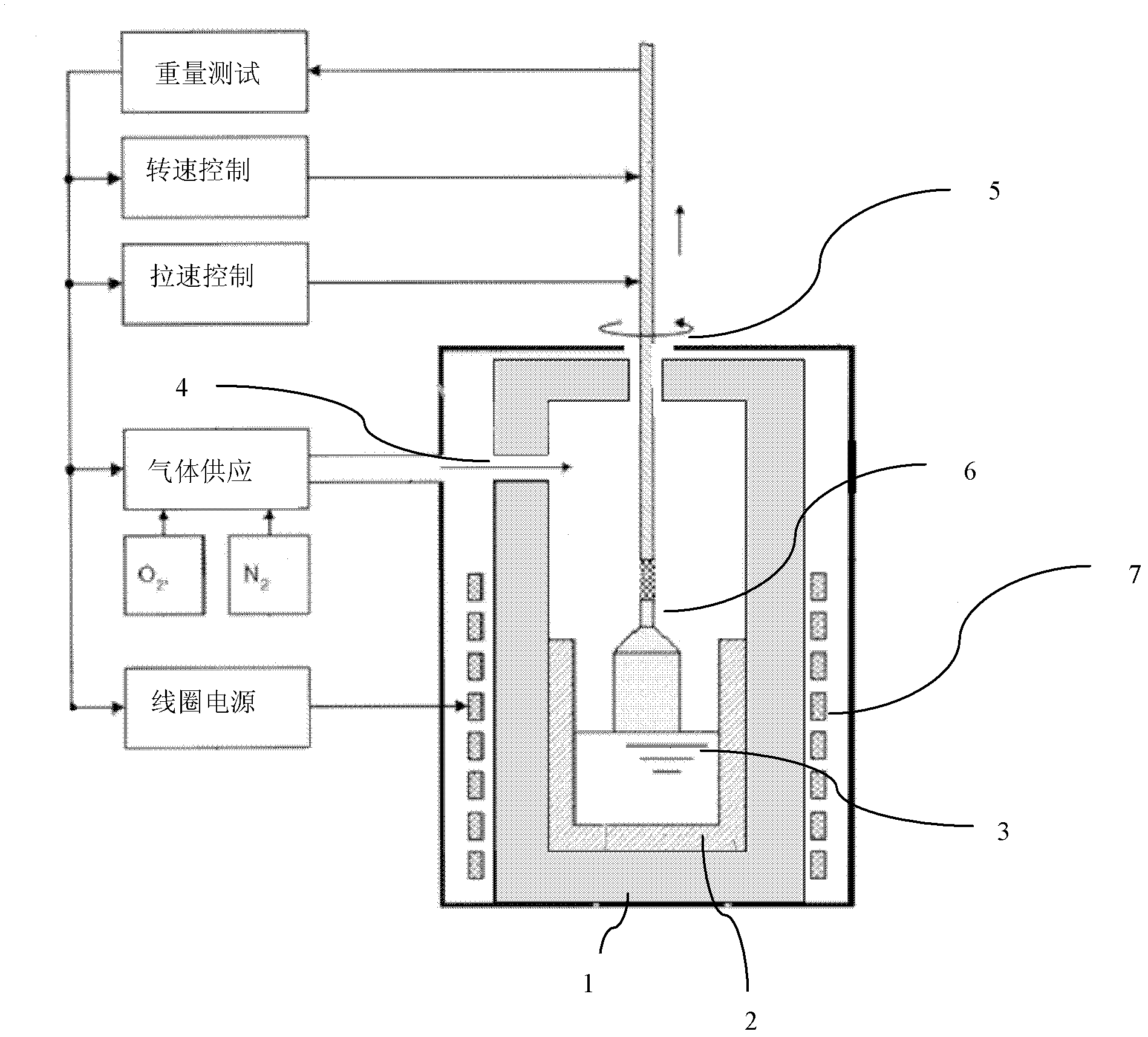

Method used

Image

Examples

Embodiment 7 and 8

[0051] The oxygen concentration in the crystal growth process affects the bubbles in the crystal. When the concentration is too low, such as lower than 0.1%, more bubbles will be generated.

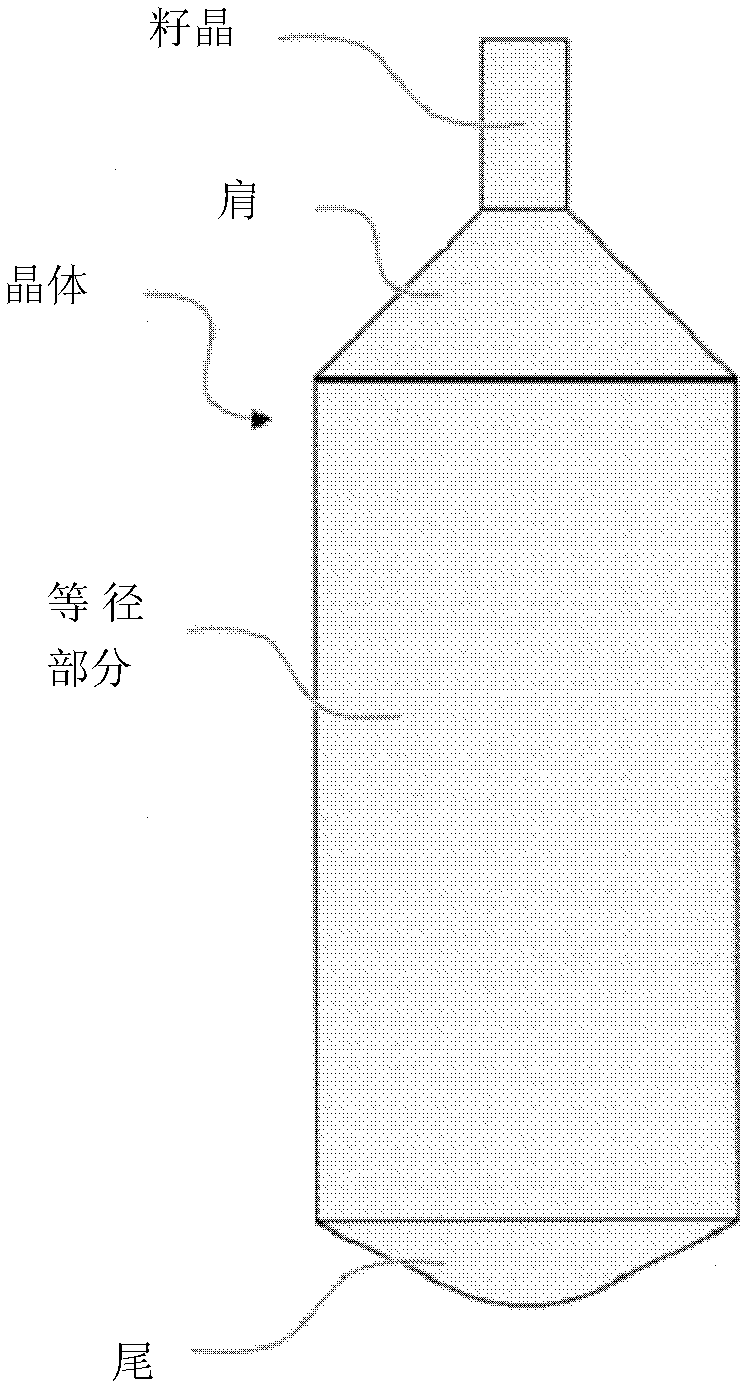

[0052] The rotation speed will also affect the quality of the crystal ingot. When the rotation speed and the pulling speed are too high, the crystal quality will be deteriorated. The best rotation speed for drawing c-plane white gemstones in the present invention is 0.5-3rpm, and the pulling speed is 0.5-2mm / hour.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com