A kind of glass powder for all-ceramic dental porcelain and preparation method thereof

The technology of glass powder and porcelain teeth is applied in the field of glass powder for porcelain enamel for all-ceramic teeth and its preparation. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

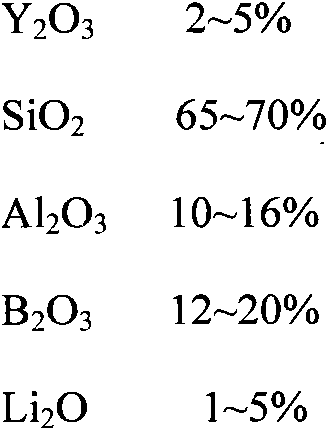

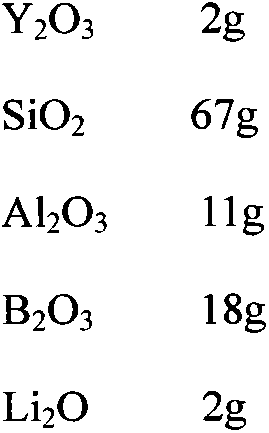

[0022] (1) Prepare materials according to the following quality, and fully mix them uniformly:

[0023]

[0024] (2) Place the homogeneously mixed raw materials in step (1) in a frit furnace at room temperature, raise the temperature to 650° C., and keep it warm for 20 minutes, then heat it to 1400° C., and keep it warm for 120 minutes, so that the raw materials are fully fused into molten glass;

[0025] (3) Pour the glass liquid obtained in step (2) into deionized water for water quenching, and the glass liquid forms small glass particles through rapid cooling;

[0026] (4) heat preservation at 100~150° C. for 30 minutes, and dry the glass frit after water quenching;

[0027] (5) Filter out the glass particles obtained in step (4) and grind them with a planetary ball mill to a glass powder with a particle size of 3-5 μm to obtain glass powder for all-ceramic teeth;

[0028] (6) After testing, the softening point of the glass powder is 581°C, and the coefficient of therma...

Embodiment 2

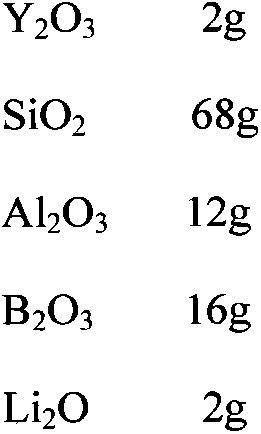

[0030] (1) Prepare materials according to the following quality, and fully mix them uniformly:

[0031]

[0032] (2) Place the homogeneously mixed raw materials in step (1) in a frit furnace at room temperature, raise the temperature to 650°C and keep it warm for 20 minutes, then heat it to 1420°C and keep it warm for 120 minutes, so that the raw materials are fully melted into molten glass;

[0033] (3) Pour the glass liquid obtained in step (2) into deionized water for water quenching, and the glass liquid forms small glass particles through rapid cooling;

[0034] (4) heat preservation at 100~150° C. for 30 minutes, and dry the glass frit after water quenching;

[0035] (5) Filter out the glass particles obtained in step (4) and grind them with a planetary ball mill to a glass powder with a particle size of 3-5 μm to obtain glass powder for all-ceramic teeth;

[0036] (6) After testing, the softening point of the glass powder is 587°C, and the coefficient of thermal exp...

Embodiment 3

[0038] (1) Prepare materials according to the following quality, and fully mix them uniformly:

[0039]

[0040] (2) Place the homogeneously mixed raw materials in step (1) in a room temperature frit furnace, raise the temperature to 650°C, and then keep it warm for 20 minutes, then heat it to 1450°C, and keep it warm for 150 minutes, so that the raw materials are fully melted into molten glass;

[0041] (3) Pour the glass liquid obtained in step (2) into deionized water for water quenching, and the glass liquid forms small glass particles through rapid cooling;

[0042] (4) heat preservation at 100~150° C. for 30 minutes, and dry the glass frit after water quenching;

[0043] (5) Filter out the glass particles obtained in step (4) and grind them with a planetary ball mill to a glass powder with a particle size of 3-5 μm to obtain glass powder for all-ceramic teeth;

[0044] (6) After testing, the softening point of the glass powder is 595°C, and the coefficient of thermal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com