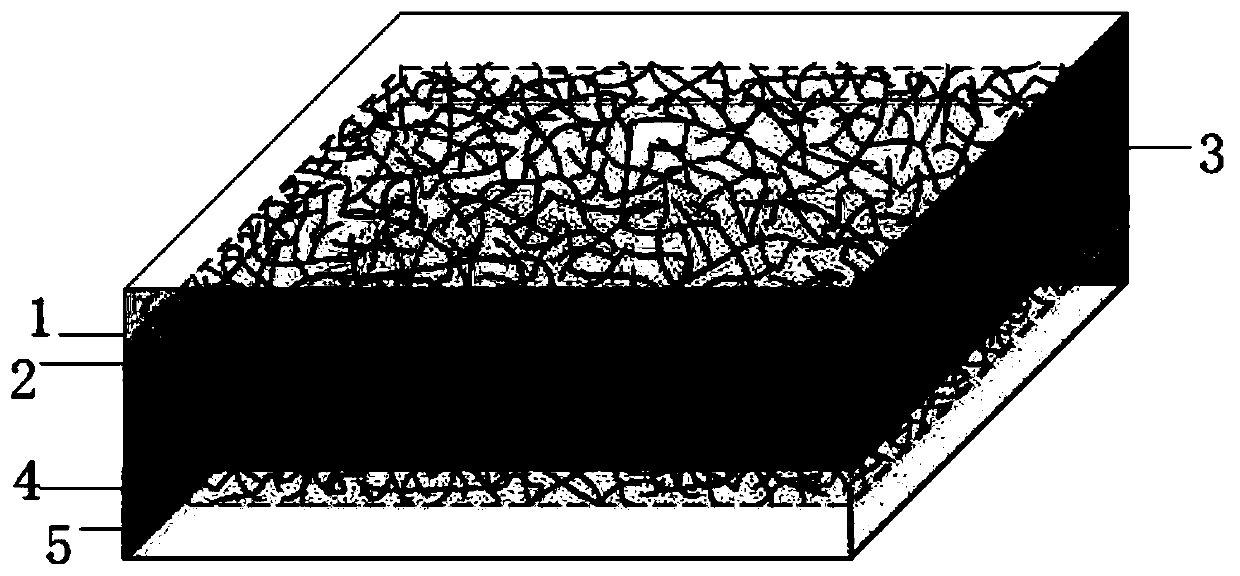

Flexible capacitive sensor fabricated by employing silver nanowire flexible electrode and fabrication method of flexible capacitive sensor

A technology of silver nanowires and flexible electrodes, which is applied in the field of capacitive sensor research, can solve the problems of increasing the sensitivity of capacitive sensors, poor adhesion and flexibility alone, high conductive filling materials, etc., and achieves good biocompatibility characteristics and wide pressure detection range. , the effect of high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

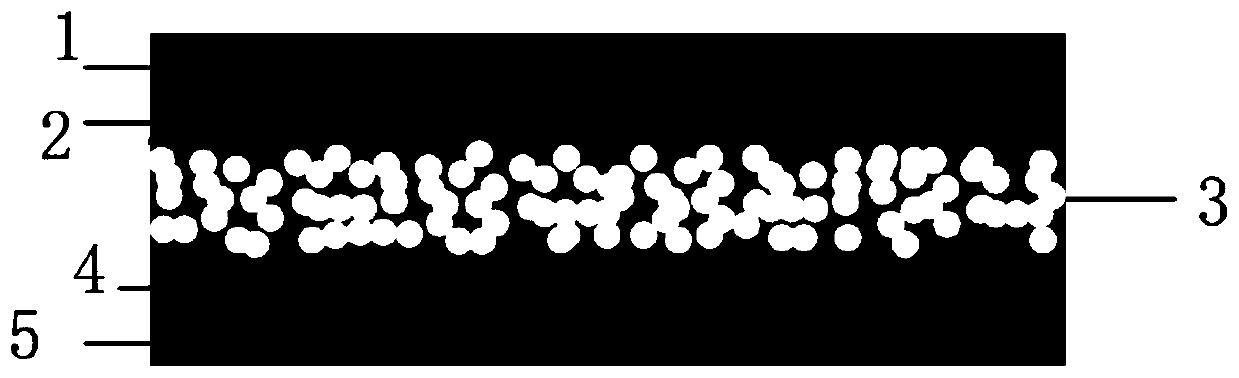

[0053] (1) According to the ratio of flexible polymer and curing agent mass ratio of 10:1, mix and stir evenly to obtain PDMS prepolymer solution, let it stand for 15 minutes for degassing treatment, use rod coating method, use glass rod to dip PDMS and concrete Apply the solution on the silicon wafer and coat the PDMS film with uniform thickness on the silicon wafer, let it stand for 40 minutes to remove air bubbles, and cure at 80°C for 40 minutes to obtain the PDMS film, cut off the PDMS with the required electrode shape (1mm×1mm) with a knife, and obtain the corresponding electrode Shaped grooves serve as templates for electrode fabrication.

[0054] (2) Put the template with the silicon wafer on the hot stage, set the temperature of the hot stage to 50°C, and drop the silver nanowire solution in the template, heat and evaporate the solvent to obtain an electrode pattern with uniform distribution of silver wires; transfer the silicon wafer to On the table at room temperatu...

Embodiment 2

[0059] (1) According to the mass ratio of flexible polymer and curing agent of 10:1, mix and stir evenly to obtain the PDMS prepolymer solution, let it stand for 15 minutes for degassing treatment, use a glass rod to dip the PDMS prepolymer, and coat the silicon wafer with A PDMS film with uniform thickness was left to stand for 40 minutes to remove air bubbles, then cured at 80°C for 40 minutes to obtain a PDMS film, and the PDMS with the required electrode shape (1mm×1mm) was cut off with a knife to obtain a groove corresponding to the electrode shape as an electrode template.

[0060] (2) Put the silicon wafer template on the hot stage, set the temperature of the hot stage to 60°C, then drop the silver nanowire solution into the template, heat and evaporate the solvent to obtain an electrode pattern with uniform distribution of silver wires; transfer the silicon wafer to room temperature On the table, remove the PDMS template prepared in the first step, drop the PDMS prepoly...

Embodiment 3

[0065] (1) According to the mass ratio of flexible polymer and curing agent of 10:1, mix and stir evenly to obtain PDMS prepolymer solution, vacuumize (vacuum degree -80kpa to -100kpa) for 10 minutes for degassing treatment, use glass rod to dip PDMS Prepolymer, coating a PDMS film with uniform thickness on the silicon wafer, vacuum treatment for 15 minutes to remove air bubbles, and then curing at 80°C for 40 minutes to obtain a PDMS film, and cut off the PDMS with the required electrode shape (1mm×2mm) with a knife to obtain The groove corresponding to the shape of the electrode is used as a template for making the electrode.

[0066] (2) Put the silicon wafer template on the hot stage, set the temperature of the hot stage to 70°C, then drop the silver nanowire solution into the template, heat and evaporate the solvent to obtain an electrode pattern with uniform distribution of silver wires; transfer the silicon wafer to room temperature On the table, remove the PDMS templat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com