Low melting point glass composition excellent in water resistance

A low-melting glass and composition technology, which is applied in the direction of compression mold cup, dental prosthesis, dental prosthesis, etc., to achieve the effect of excellent acid resistance and low firing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0076] Preparation of the low-melting-point glass composition of the present invention can be carried out by those skilled in the art without limitation according to conventional general manufacturing methods of glass compositions. As a general production method, various inorganic compounds are blended to obtain the target glass composition, and the glass is melted at 1300 to 1500° C. in a glass melting furnace. This is a method in which a molten metal is made to flow in water and rapidly cooled (quenched) to obtain a glass frit.

[0077] In order to use the low-melting-point glass composition of the present invention as a dental pottery or a coloring material for dental ceramics, it is necessary to make the low-melting-point glass composition into a powder form. In order to prepare a low-melting glass composition powder, for example, there is a method of pulverizing the above-mentioned glass frit with a pulverizer such as a ball mill or a jet mill.

[0078] In this case, it ...

Embodiment 1~20、 comparative example 1~11

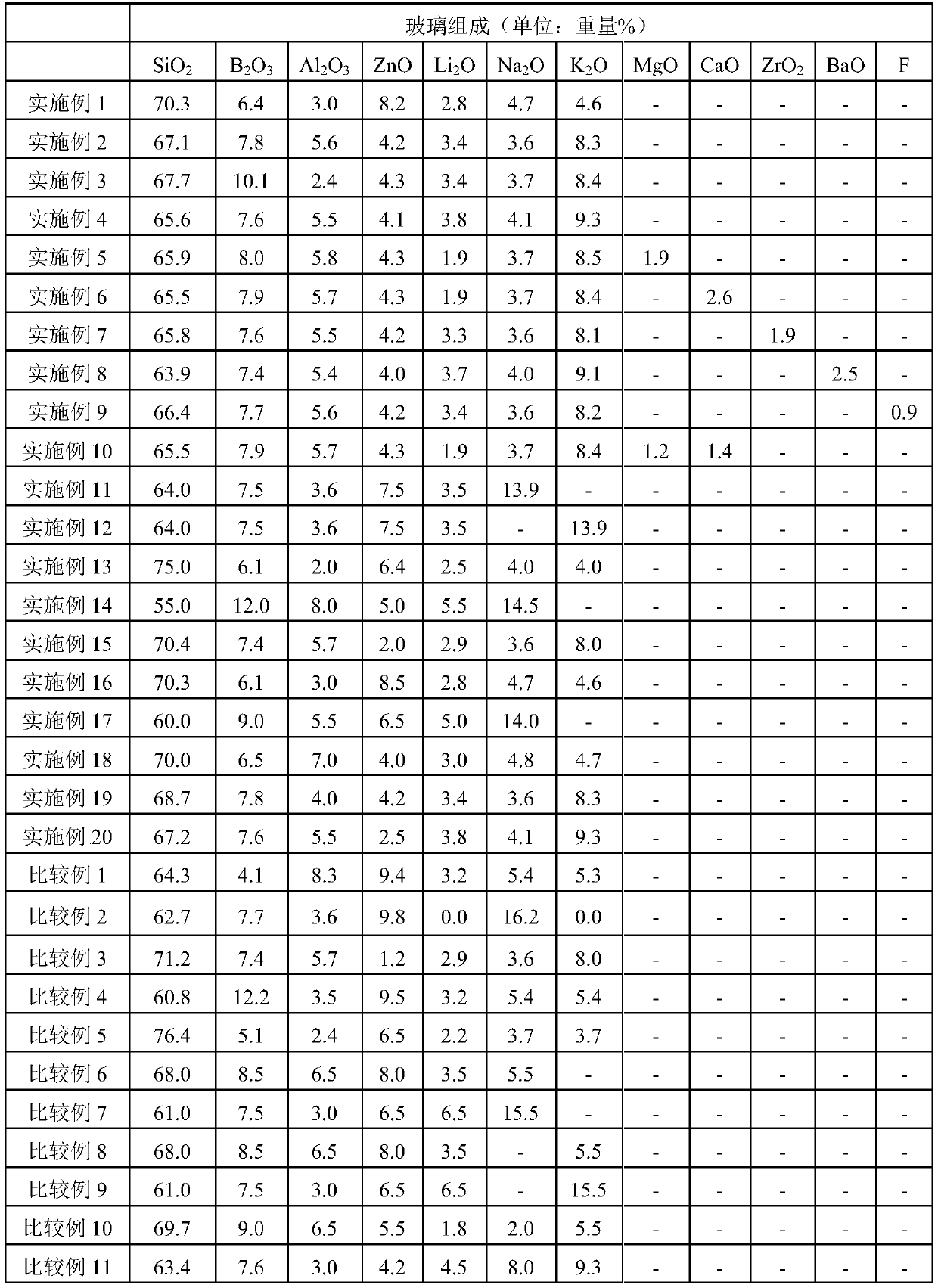

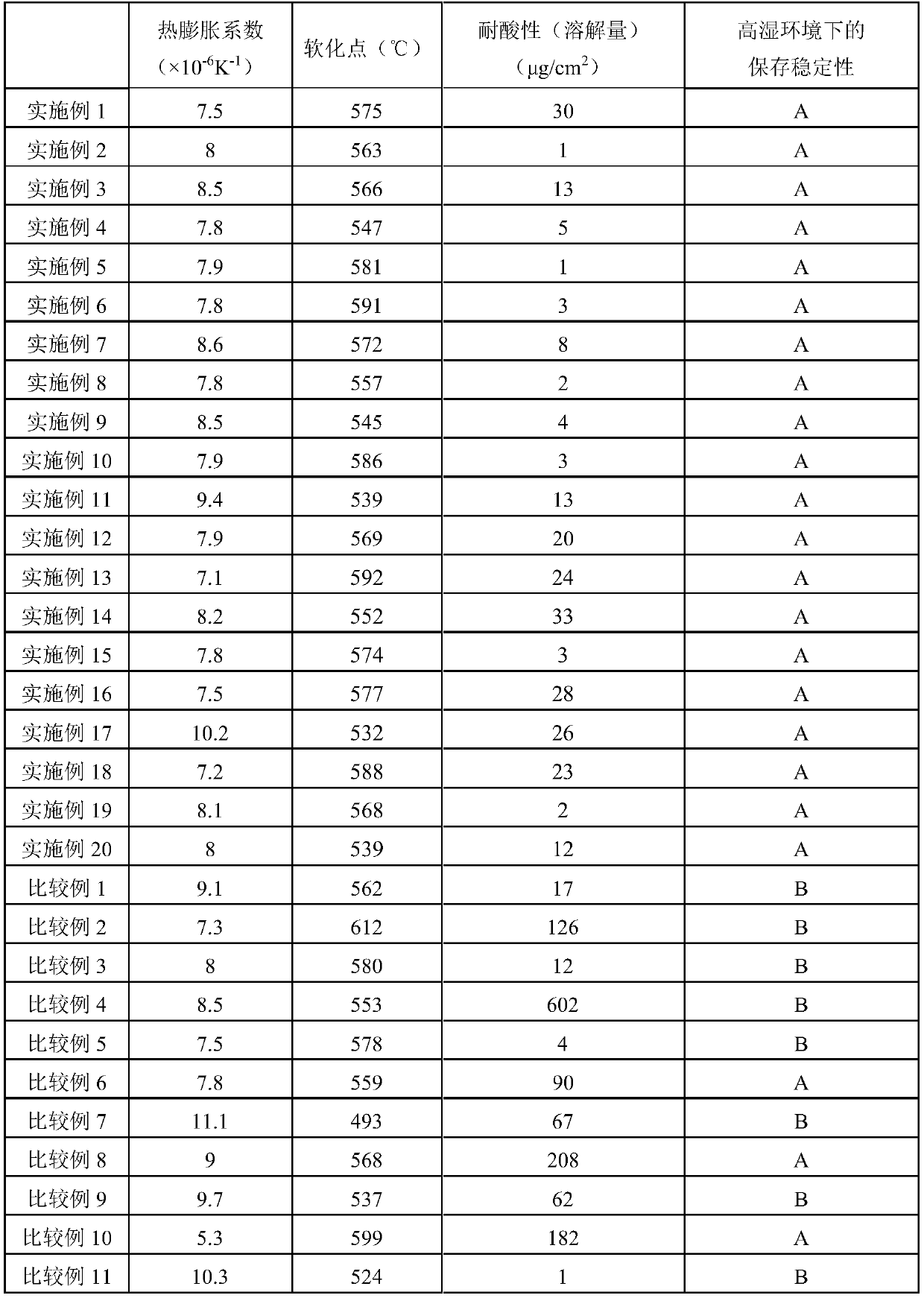

[0092] According to the glass composition described in Table 1, various inorganic compounds were prepared and melted, and the glass frits of Examples 1-20 and Comparative Examples 1-11 were manufactured (it shows it as weight%). The glass frits of Examples 1 to 20 and Comparative Examples 1 to 11 were pulverized to obtain glass frit powder having an average particle diameter of about 20 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com