Patents

Literature

88 results about "Cobalt chromium alloy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cobalt-Chromium Alloy is a non-magnetic alloy which contains a variety of different metal components with the main elements being cobalt and chromium.

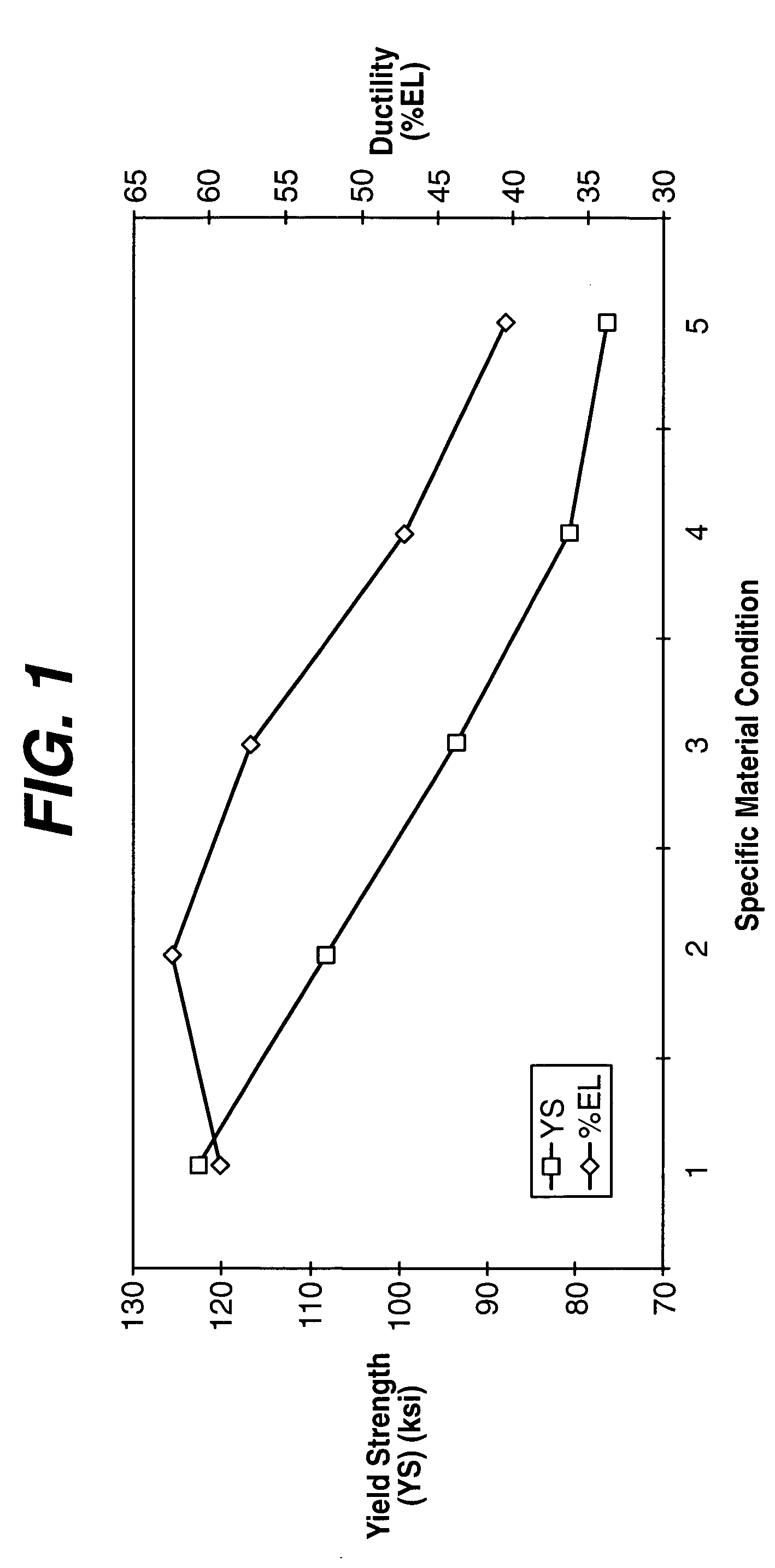

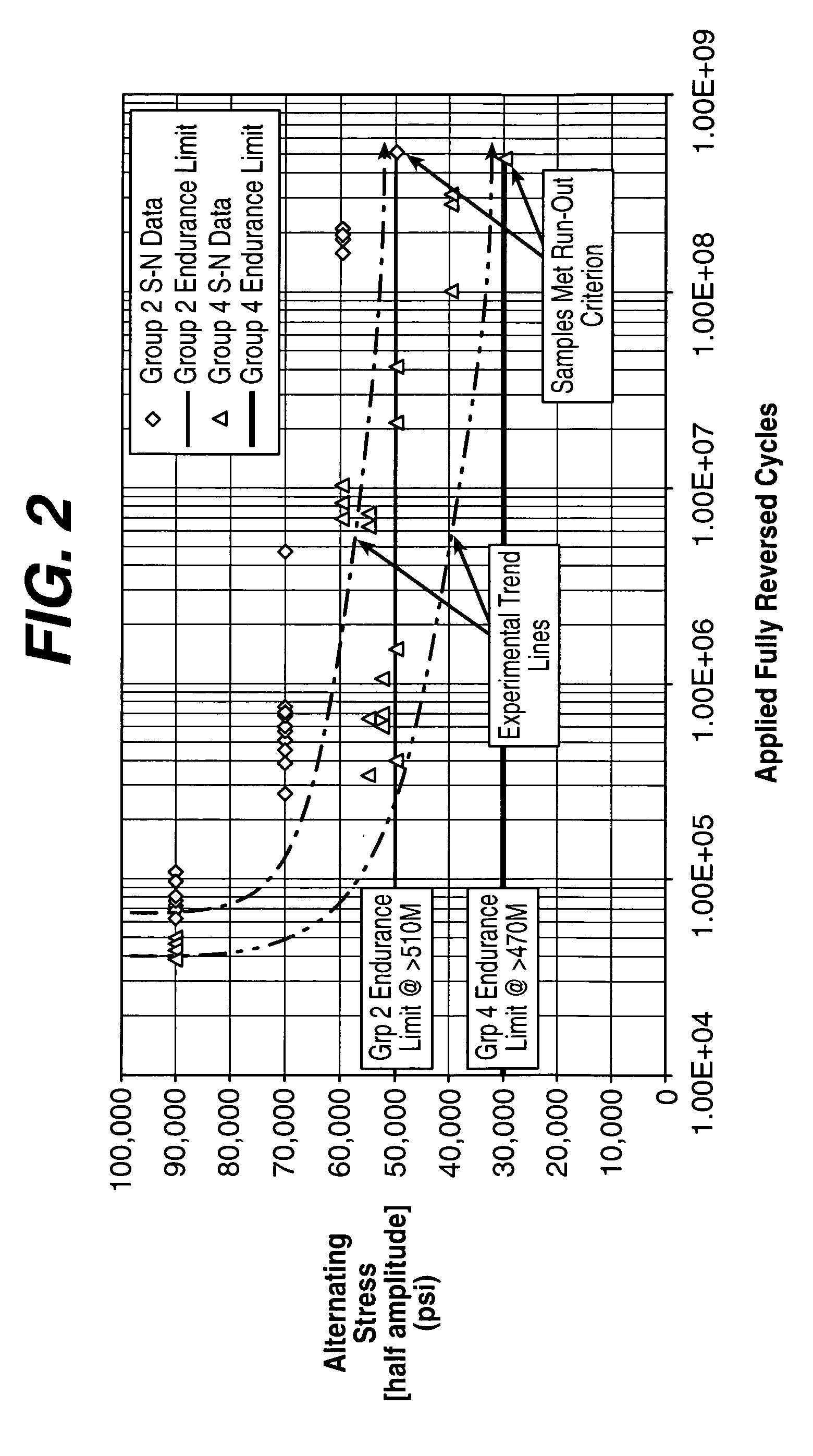

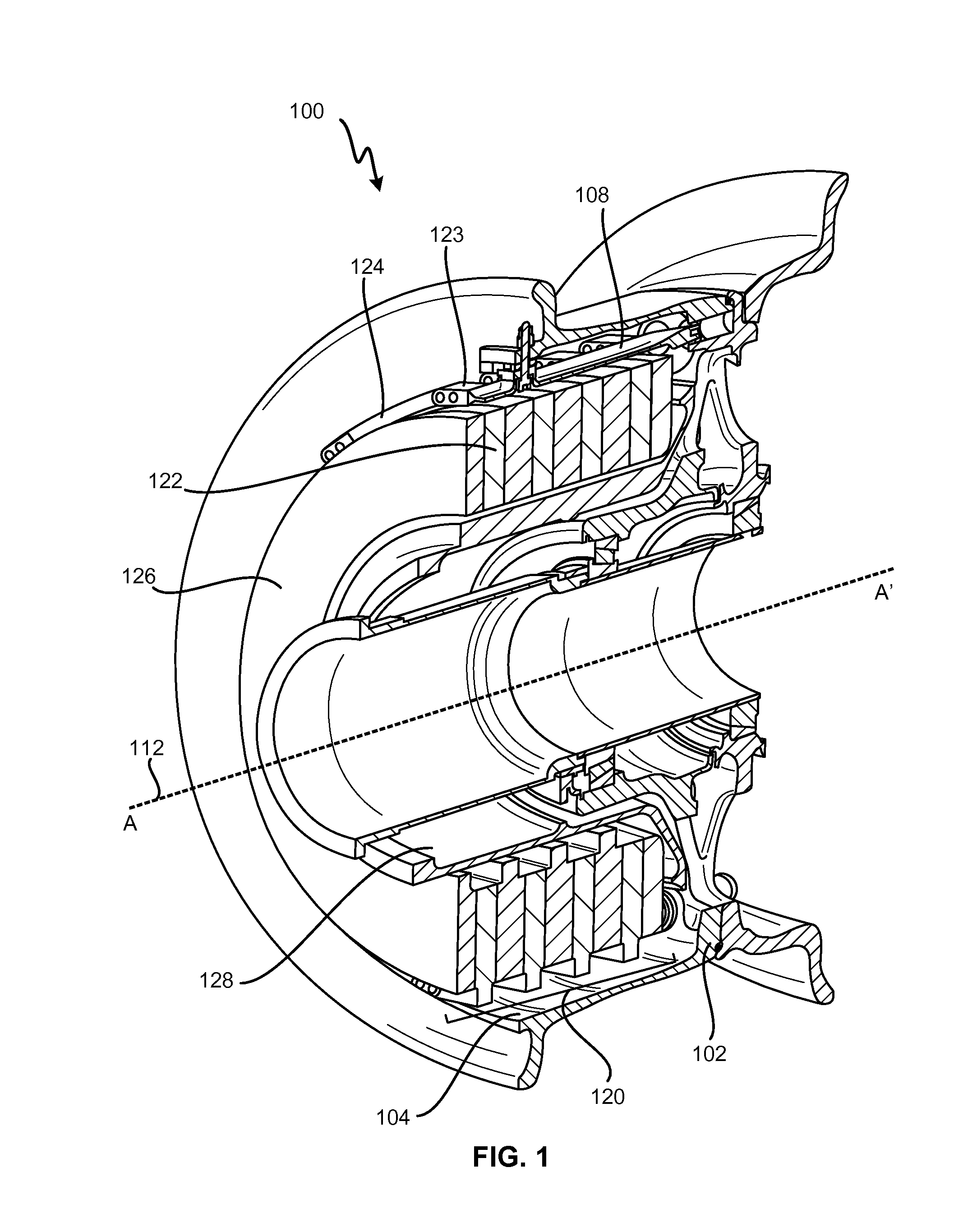

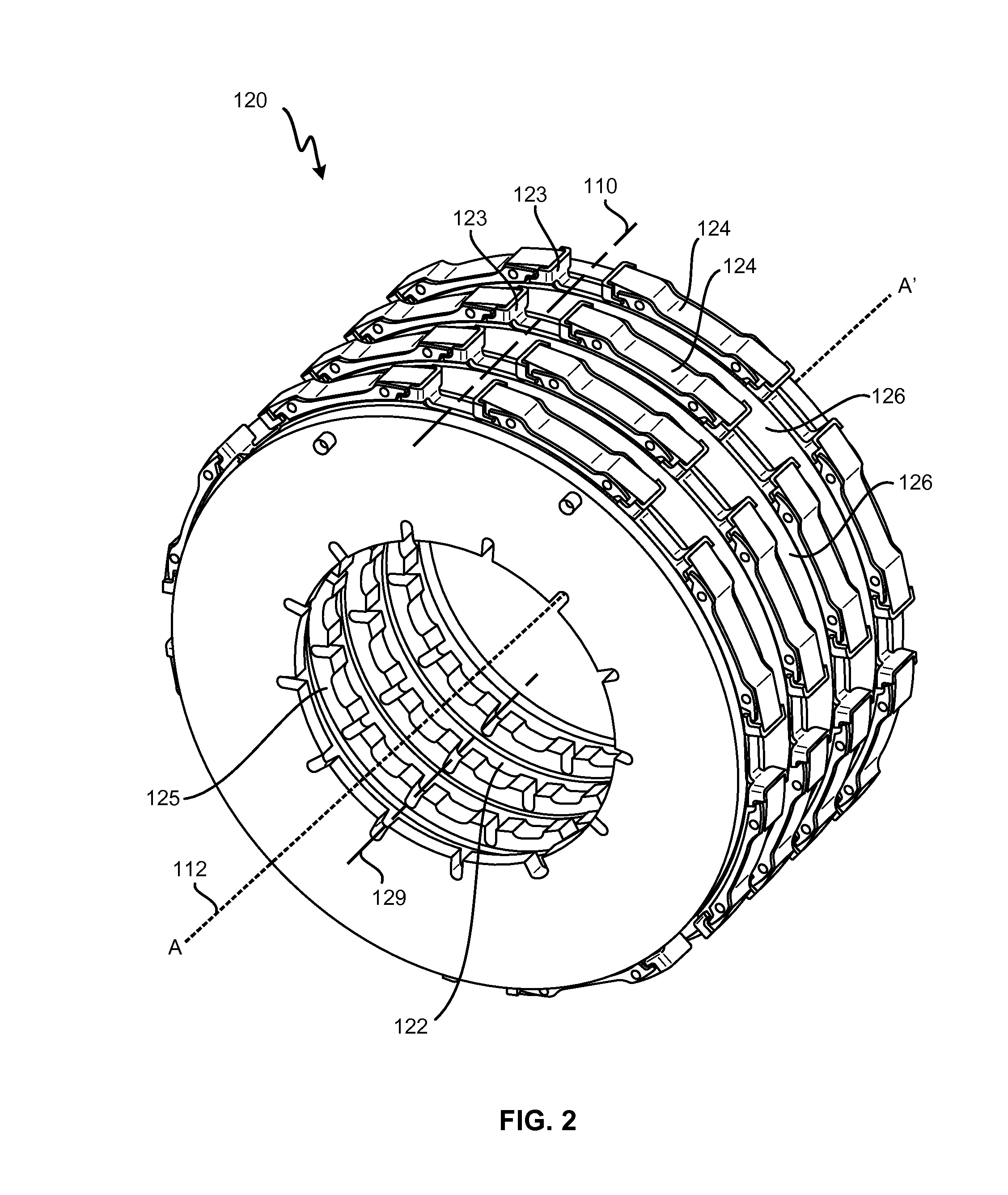

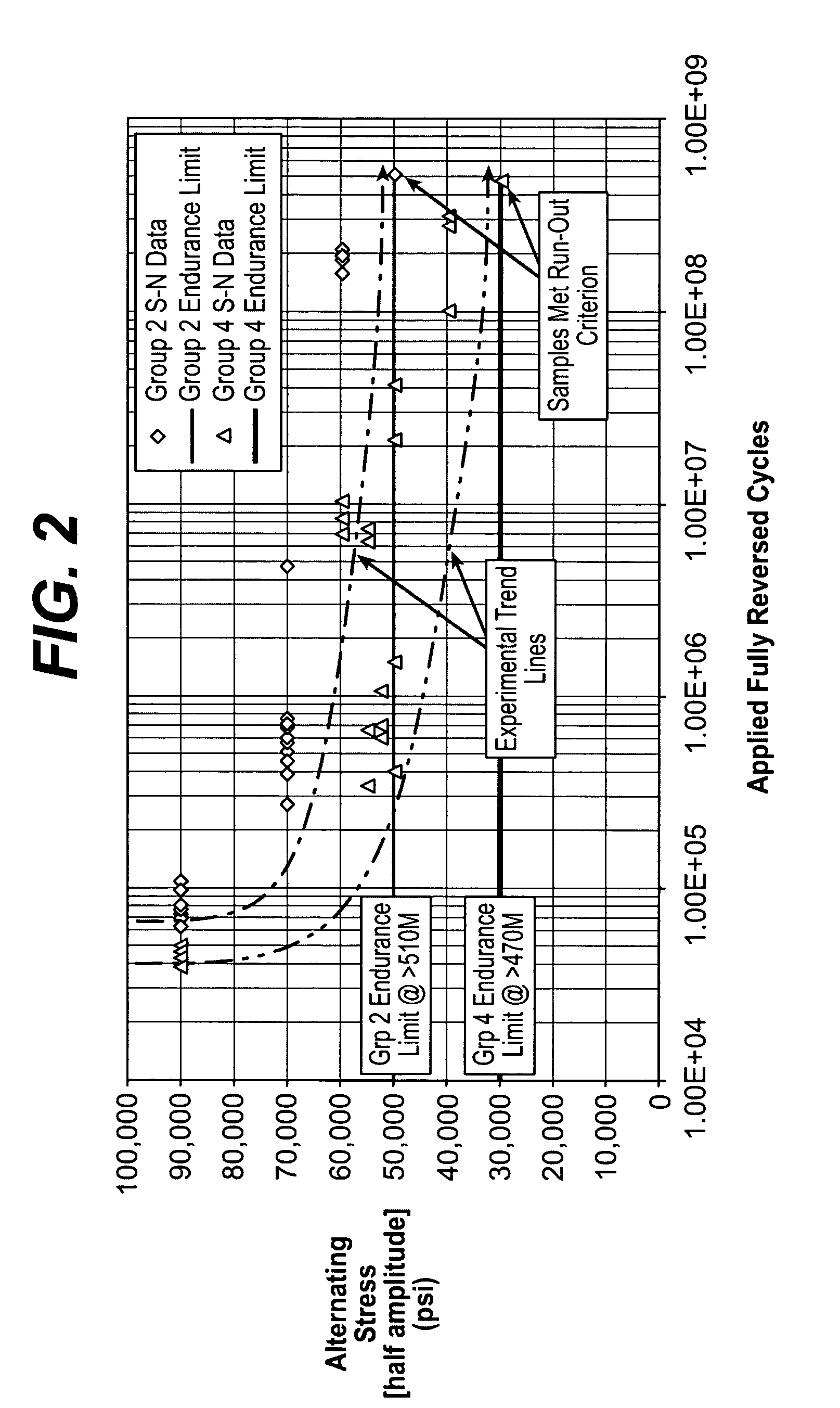

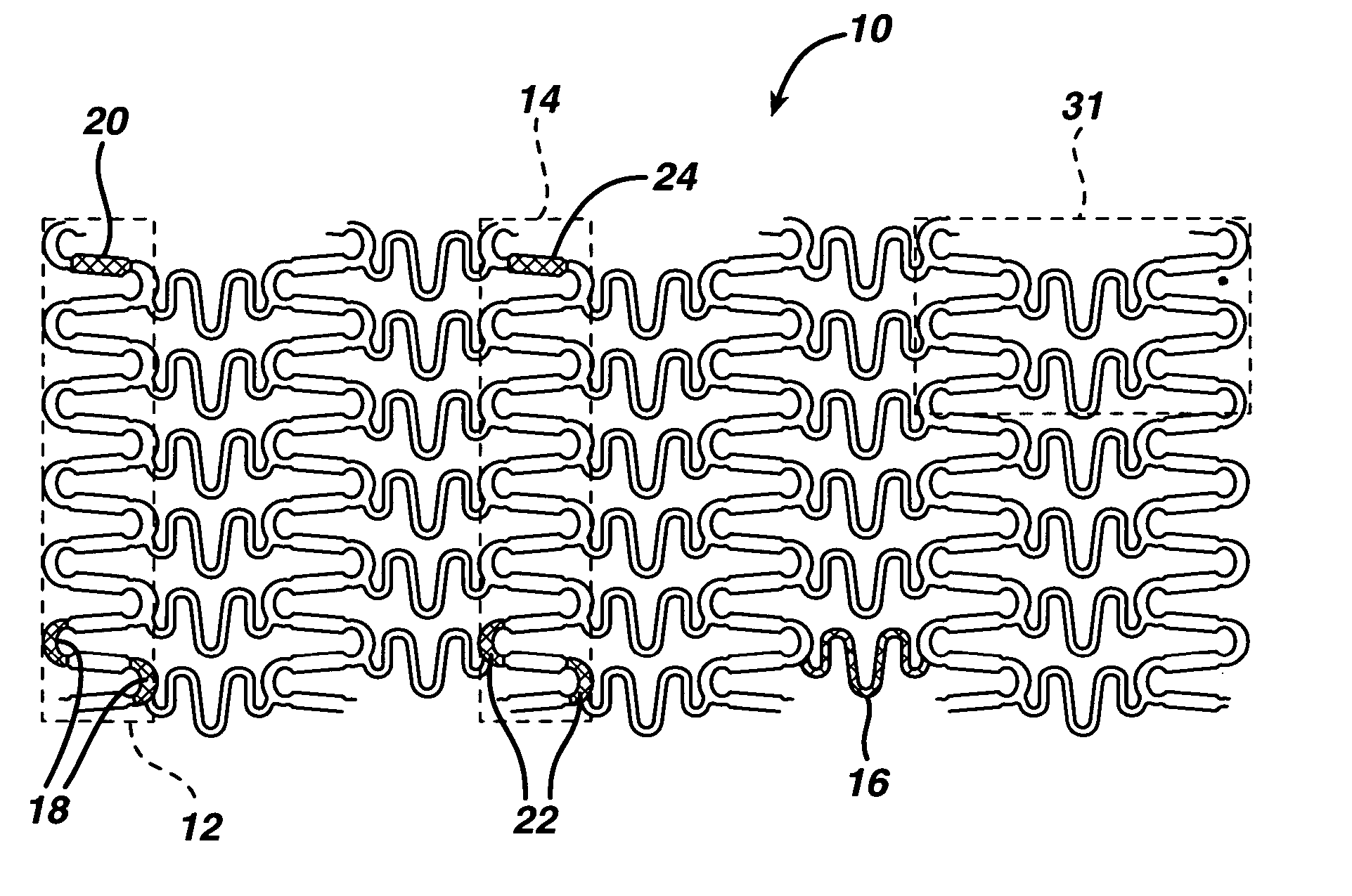

Material for high strength, controlled recoil stent

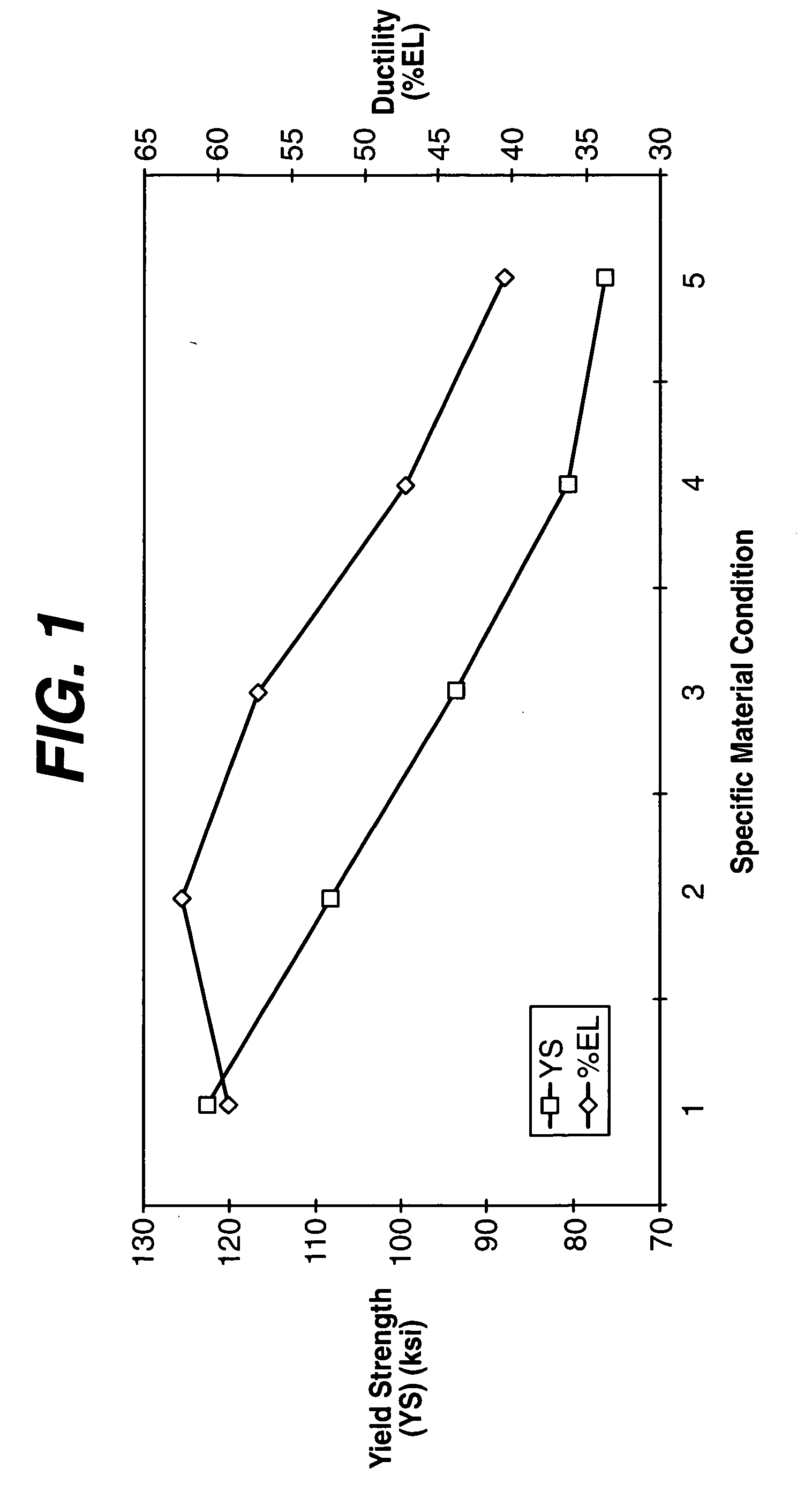

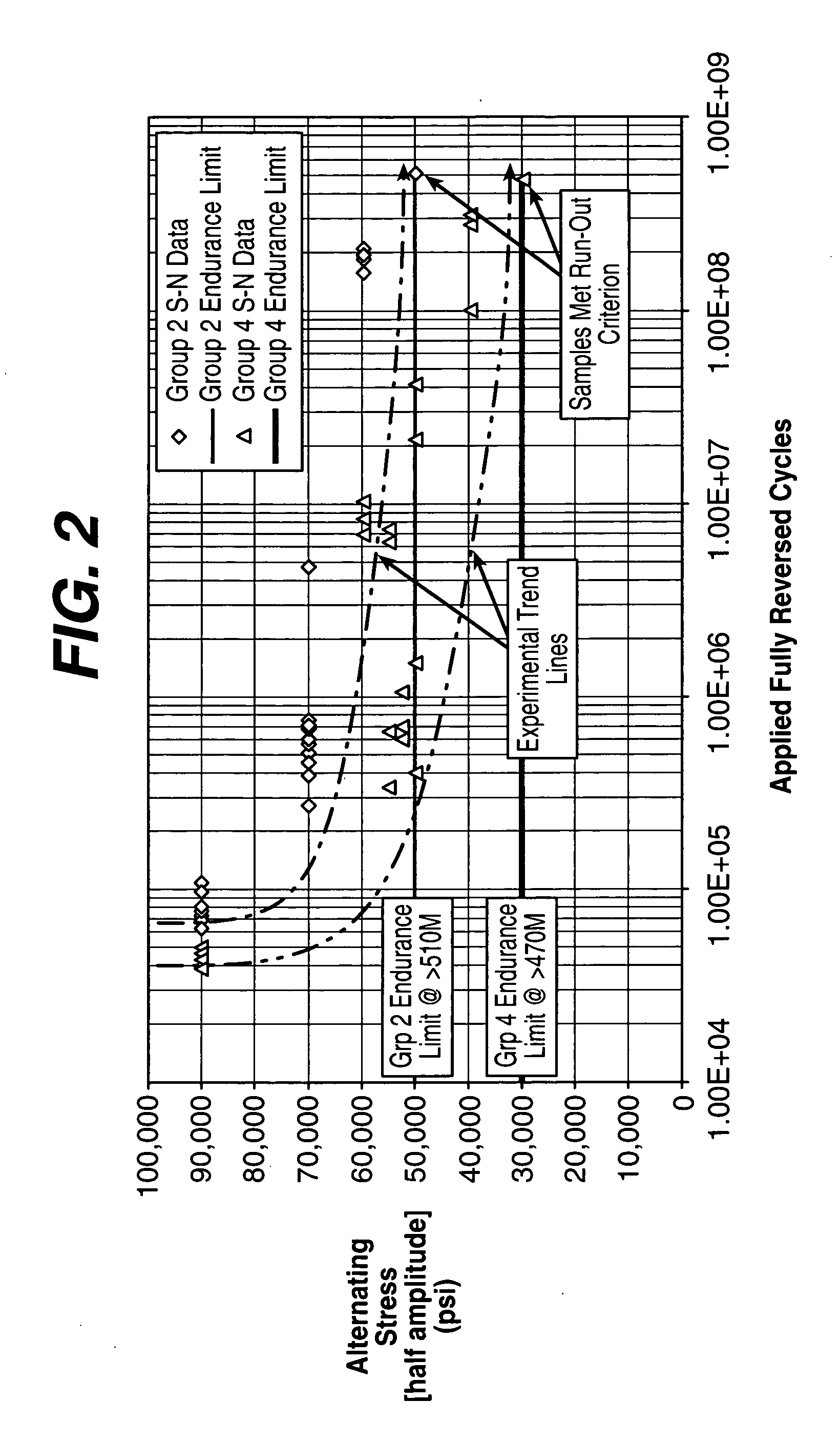

InactiveUS20060020325A1Simple and inexpensive to manufactureIncreased durabilityStentsSurgeryInsertion stentMetallic materials

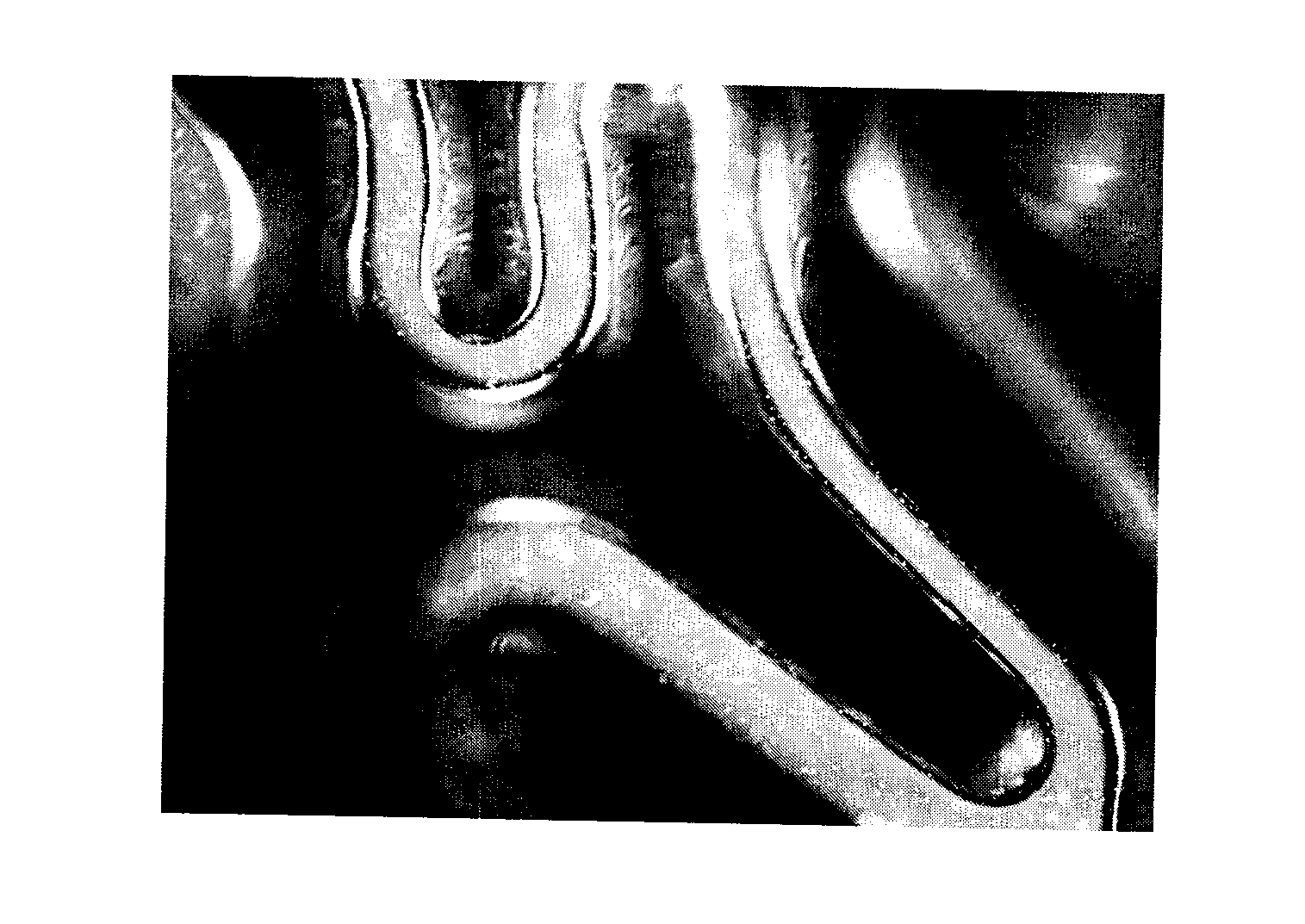

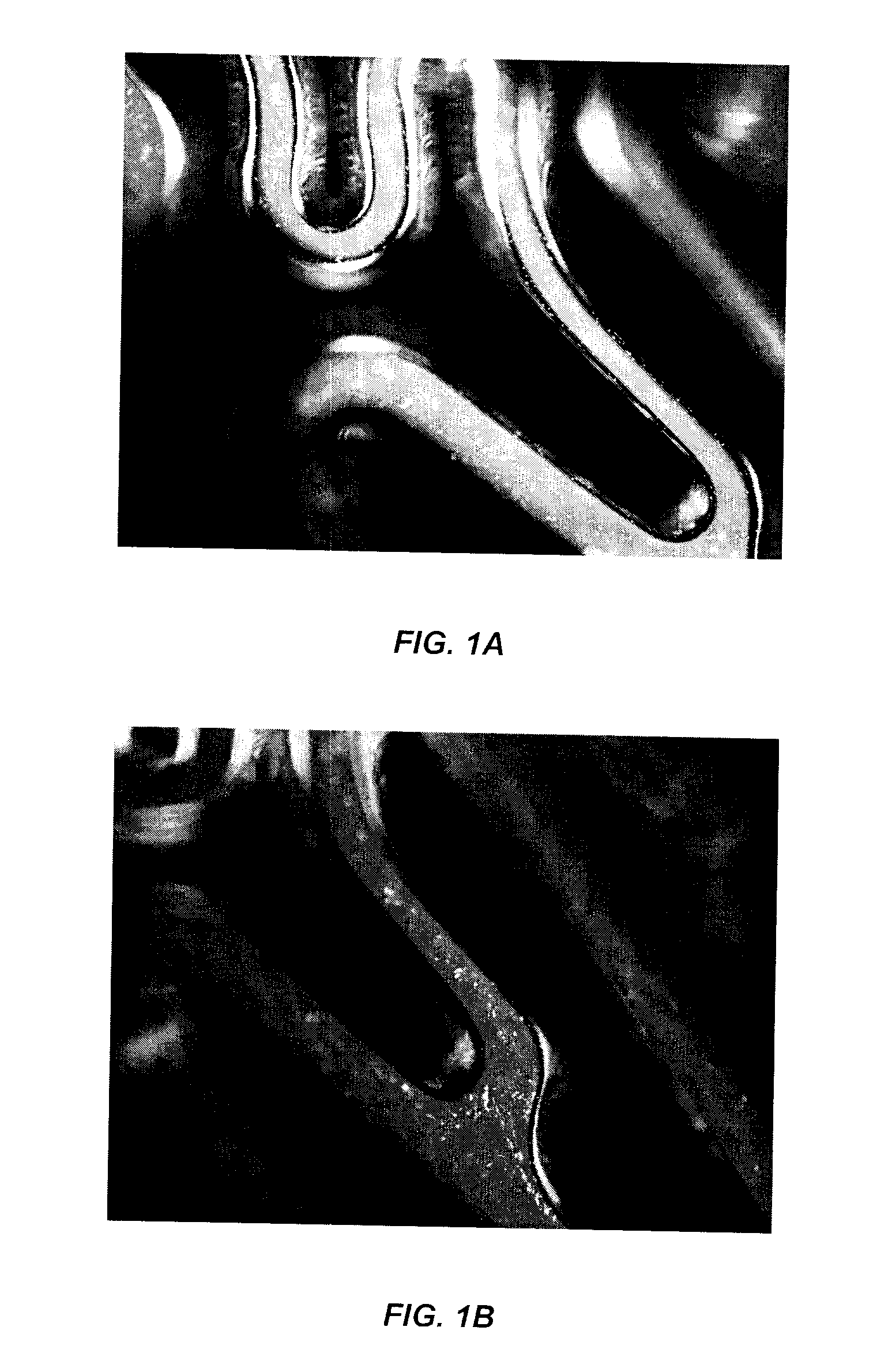

A biocompatible metallic material may be configured into any number of implantable medical devices including intraluminal stents. The intraluminal stents may be specifically configured to optimize the number of discrete equiaxed grains that comprise the wall dimension so as to provide the intended user with a high strength, controlled recoil device as a function of expanded inside diameter. One biocompatible metallic material may comprise a Cobalt-Chromium alloy having substantially reduced Iron and / or Silicon content.

Owner:CORDIS CORP

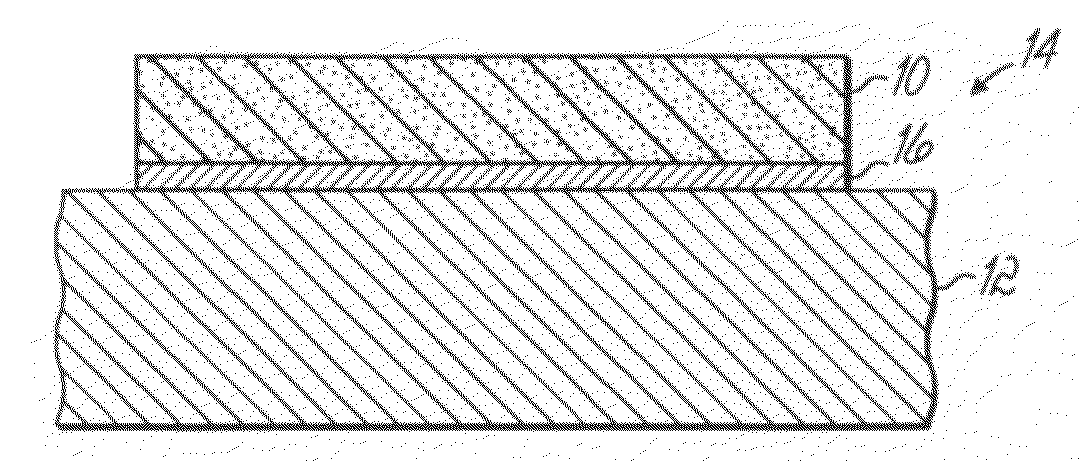

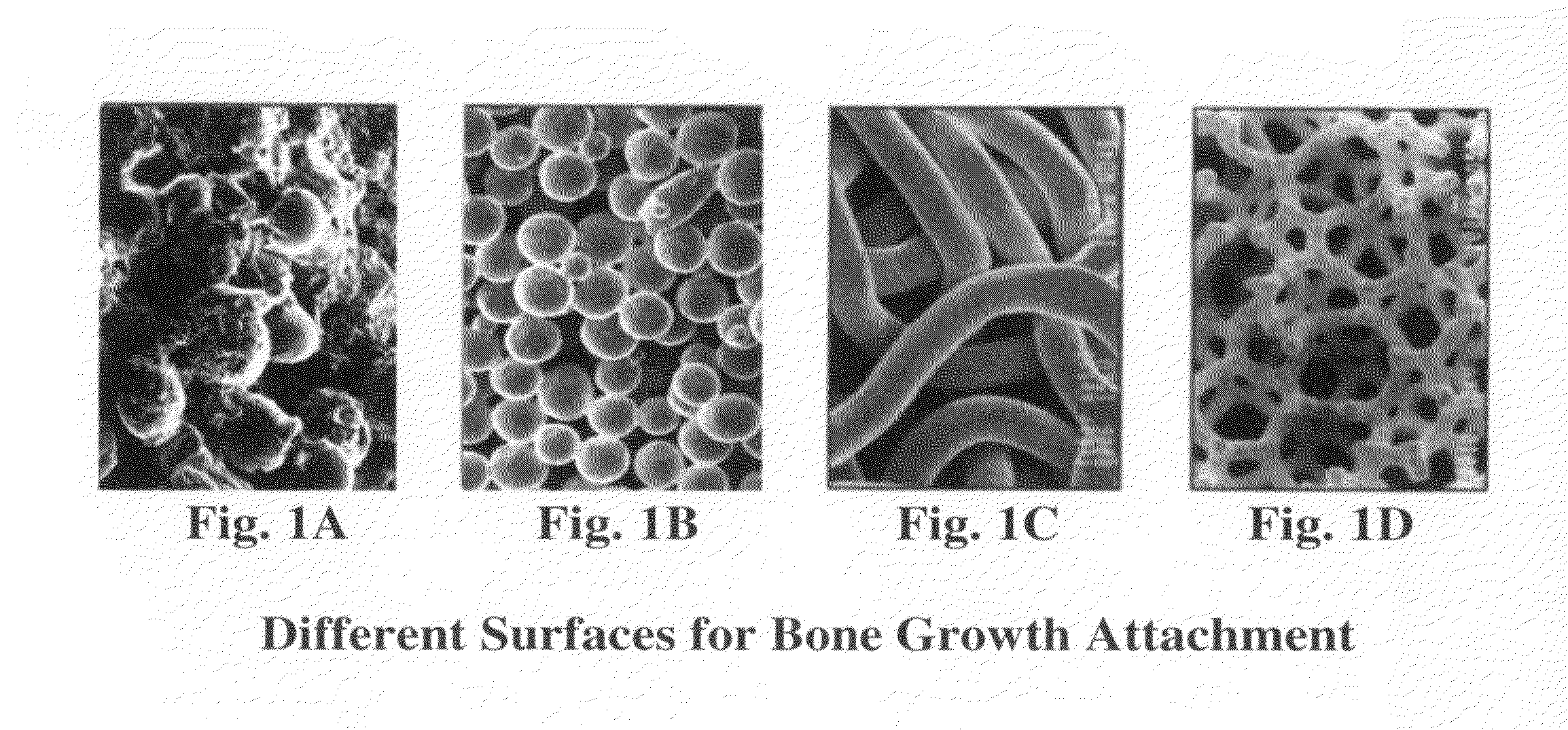

Method for bonding a tantalum structure to a cobalt-alloy substrate

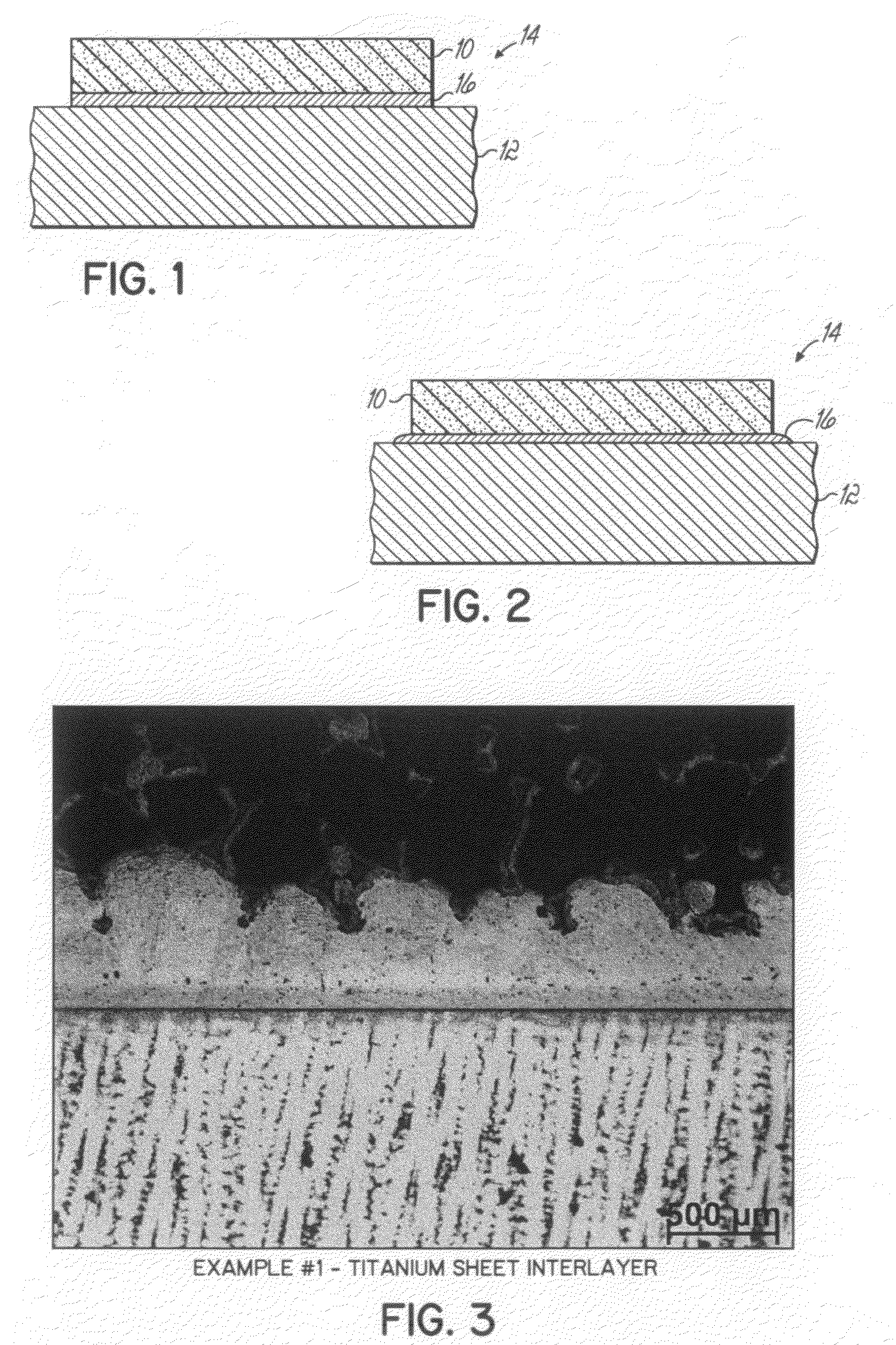

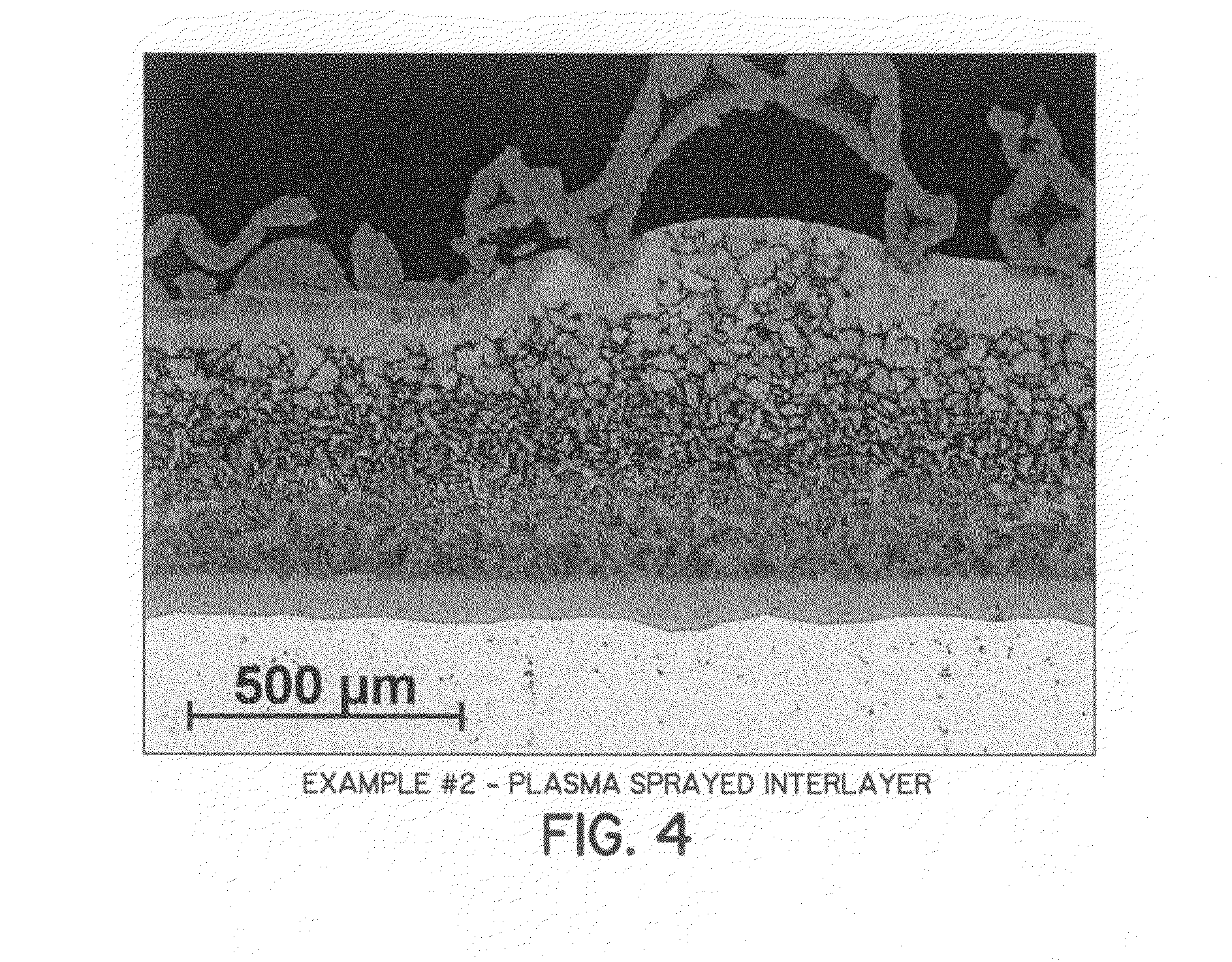

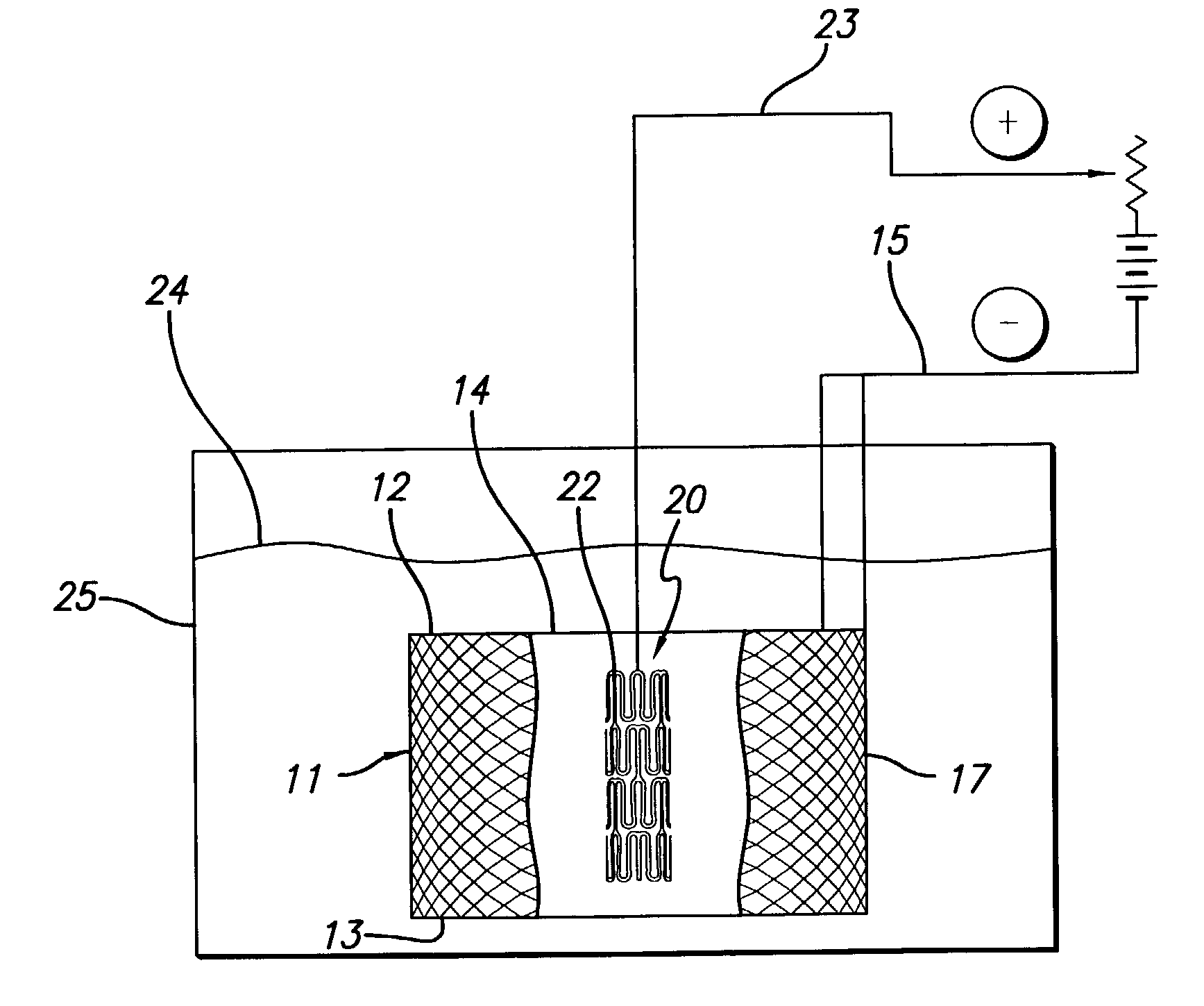

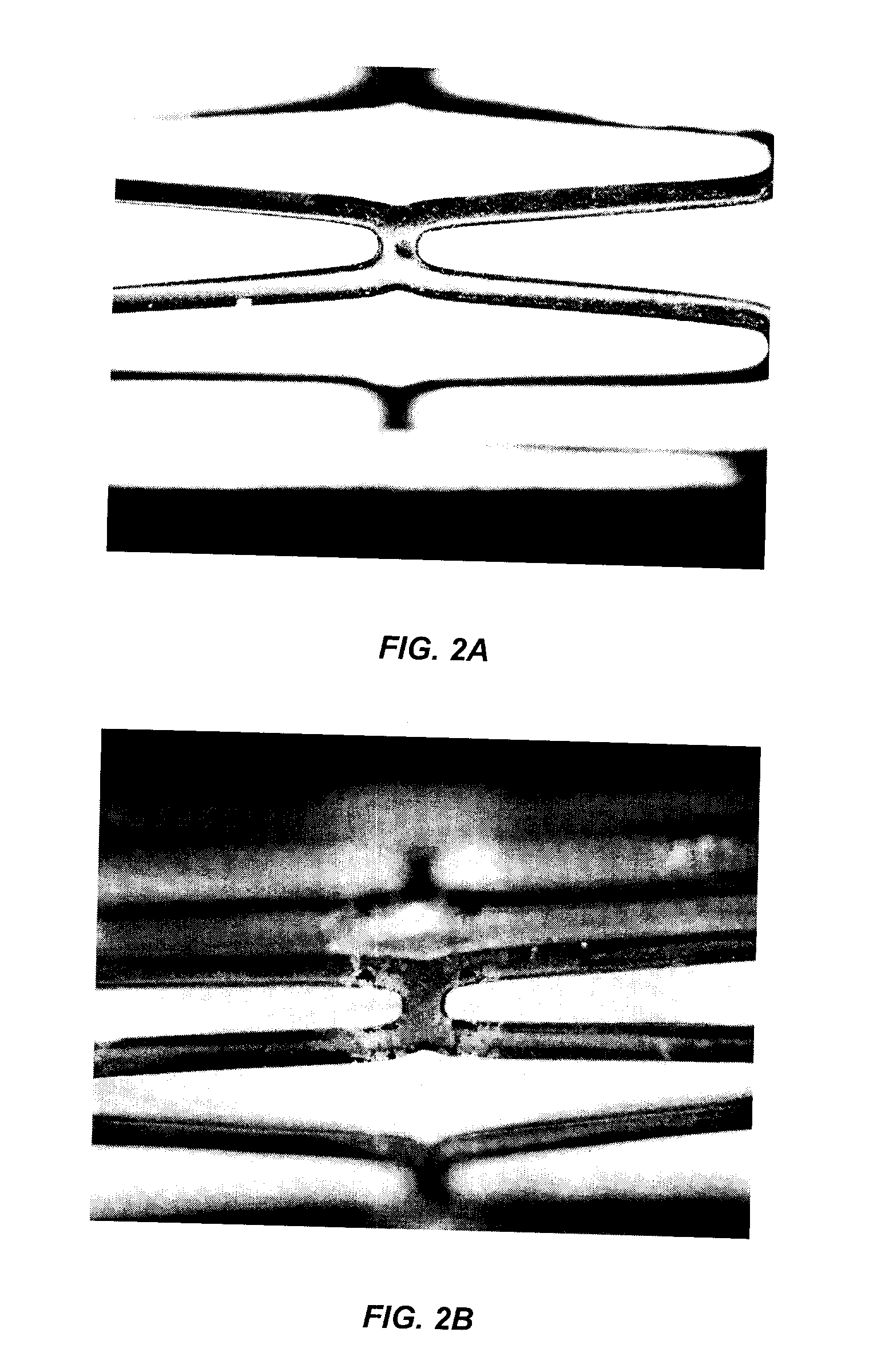

A method for bonding a porous tantalum structure to a substrate is provided. The method comprises providing a substrate comprising cobalt or a cobalt-chromium alloy; an interlayer consisting essentially of at least one of hafnium, manganese, niobium, palladium, zirconium, titanium, or alloys or combinations thereof; and a porous tantalum structure. Heat and pressure are applied to the substrate, the interlayer, and the porous tantalum structure to achieve solid-state diffusion between the substrate and the interlayer and between the interlayer and the porous tantalum structure.

Owner:ZIMMER INC

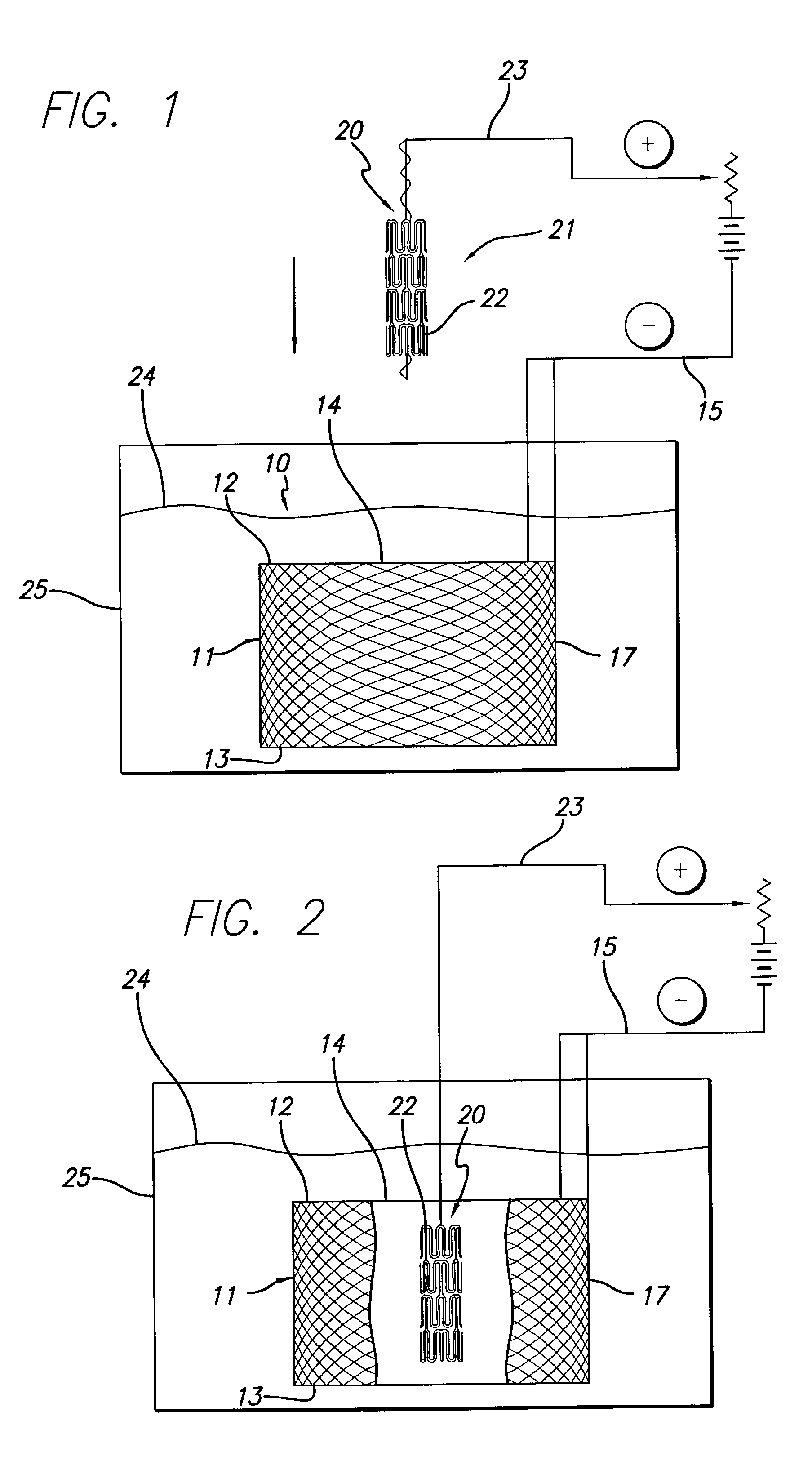

Process for electropolishing a device made from cobalt-chromium

ActiveUS7357854B1Reduce weightHigh densityStentsPolycrystalline material growthElectrolysisBiocompatibility Testing

The invention is directed to an electropolishing solution for products or devices made from at least in part a cobalt-chromium alloy. The invention is particularly suitable for medical devices or intravascular stents made at least in part of cobalt-chromium. More particularly, the electropolishing process of the invention is particularly suited for use on implantable medical devices, such as stents, due to the biocompatibility of cobalt-chromium alloys. The invention is directed to an improved stent formed from a cobalt-chromium alloy, that possesses an ultrasmooth shiny surface. This invention is also directed to a method of electropolishing such a stent using an acidic electrolytic solution comprising a mixture of 6 parts of about 98% sulfuric acid (H2SO4), 1 part of about 37% hydrochloric acid (HCl) and 1 part by of about 85% concentrated phosphoric acid (H3PO4) to produce an exceptionally smooth surface.

Owner:ABBOTT CARDIOVASCULAR

Manufacture of fine-grained material for use in medical devices

Medical devices are manufactured from fine grained materials, processed from of a variety of metals and alloys, such as stainless steel, cobalt-chromium and nickel-titanium alloys. A fine grained metal or alloy is formed from a specimen rapidly heated to its recrystallization temperature, and then subjected to high temperature, multi-axial deformation, for example, by heavy cross-forging or swaging. The deformed specimen may be cooled and reheated to a second recrystallization temperature. The metal or alloy in the specimen is then allowed to recrystallize, such that the grain size is controlled by quenching the specimen to room temperature. A desired medical device is then configured from the fine grained material. Decreasing the average grain size of a substrate material and increasing the number of grains across a thickness of a strut or similar component of the medical device increases the strength of the device and imparts other beneficial properties into the device.

Owner:ABBOTT CARDIOVASCULAR

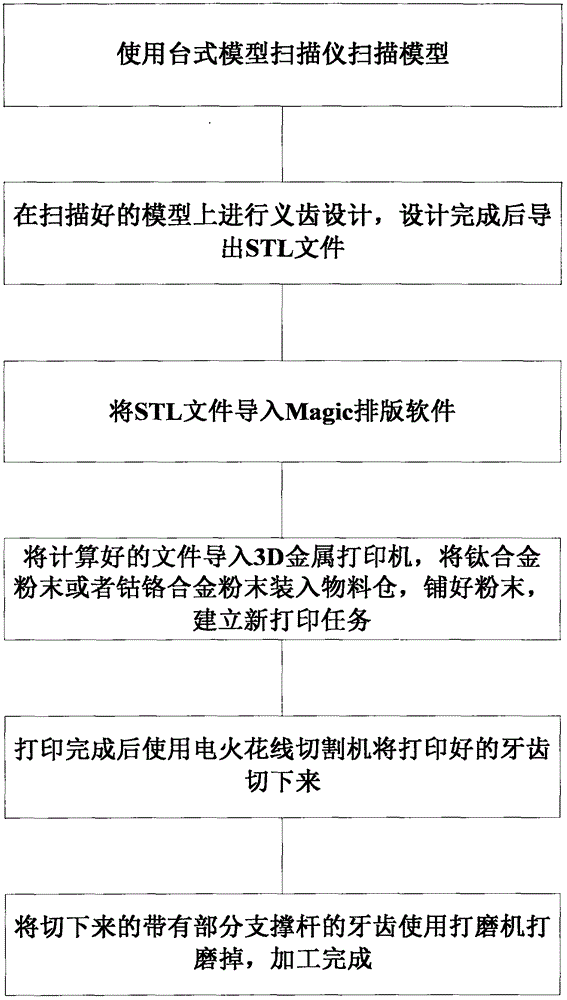

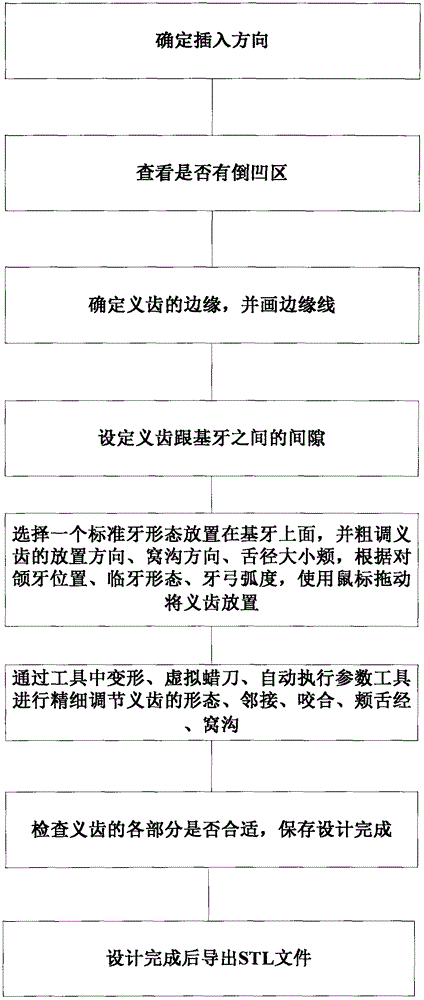

Manufacturing method of false tooth based on 3D (three dimensional) printing

ActiveCN105030357AIn line with the concept of environmental protection developmentThere will be no problems of deformation and incomplete castingArtificial teethSanderElectric discharge

The invention provides a manufacturing method of a false tooth based on 3D (three dimensional) printing. The method comprises the steps of scanning a model by using a desktop model scanner; designing the false tooth on a scanned model, exporting a STL file when the design is finished; importing the exported STL file into a Magic publishing software, overturning the imported tooth crown by 180 degrees along the direction of a Y axis by a location moving tool, and moving 1.5 mm along the positive direction of a Z axis; then, checking whether the file is damaged through a checking tool, inserting a support rod through a part tool, performing split layer treatment on the file through a platform tool, and calculating the file; importing the calculated file into a 3D metal printer, putting titanium alloy powder or cobalt-chromium alloy powder into a stock bin, spreading the powder, and creating a new print job; using a wire cut electric discharge machine to cut off a printed tooth after the printing is completed; polishing off the part of a cut-off false tooth with the support rod by using a sander, and the processing is completed.

Owner:SHANDONG MAIER DENTAL MATERIALS CO LTD

Cobalt-chromium alloy artery stent with full-biodegradation medicine coating, stent system and preparation method thereof

ActiveCN101745153AImprove flexibilityShorten repair timeStentsSurgeryPercent Diameter StenosisCvd risk

The invention provides a cobalt-chromium alloy artery stent with full-biodegradation medicine coating; the full-biodegradation coating of the stent has good stent flexibility, pathological change permeability and radial bearing force; the invention further provides a preparation method of the stent; multi-level coating applying technology, metallic support surface inert gas processing process and the like are adopted, the firmness of the stent surface coating, the toughness and tensile strength thereof are greatly improved, thereby being beneficial to keeping the integrity of the coating; in addition, the invention provides a cobalt-chromium alloy artery stent with full-biodegradation medicine coating, which is prepared by radial grading squeezing process, the damage of the coating can be avoided to the greatest extent, the retention force between the stent and a conveying system is greatly improved, the possibility that the stent is migrated in the conveying process is avoided, the clinical using risk is reduced, and the problems of coronary artery stenosis and restenosis are effectively solved.

Owner:万瑞飞鸿(北京)医疗器材有限公司

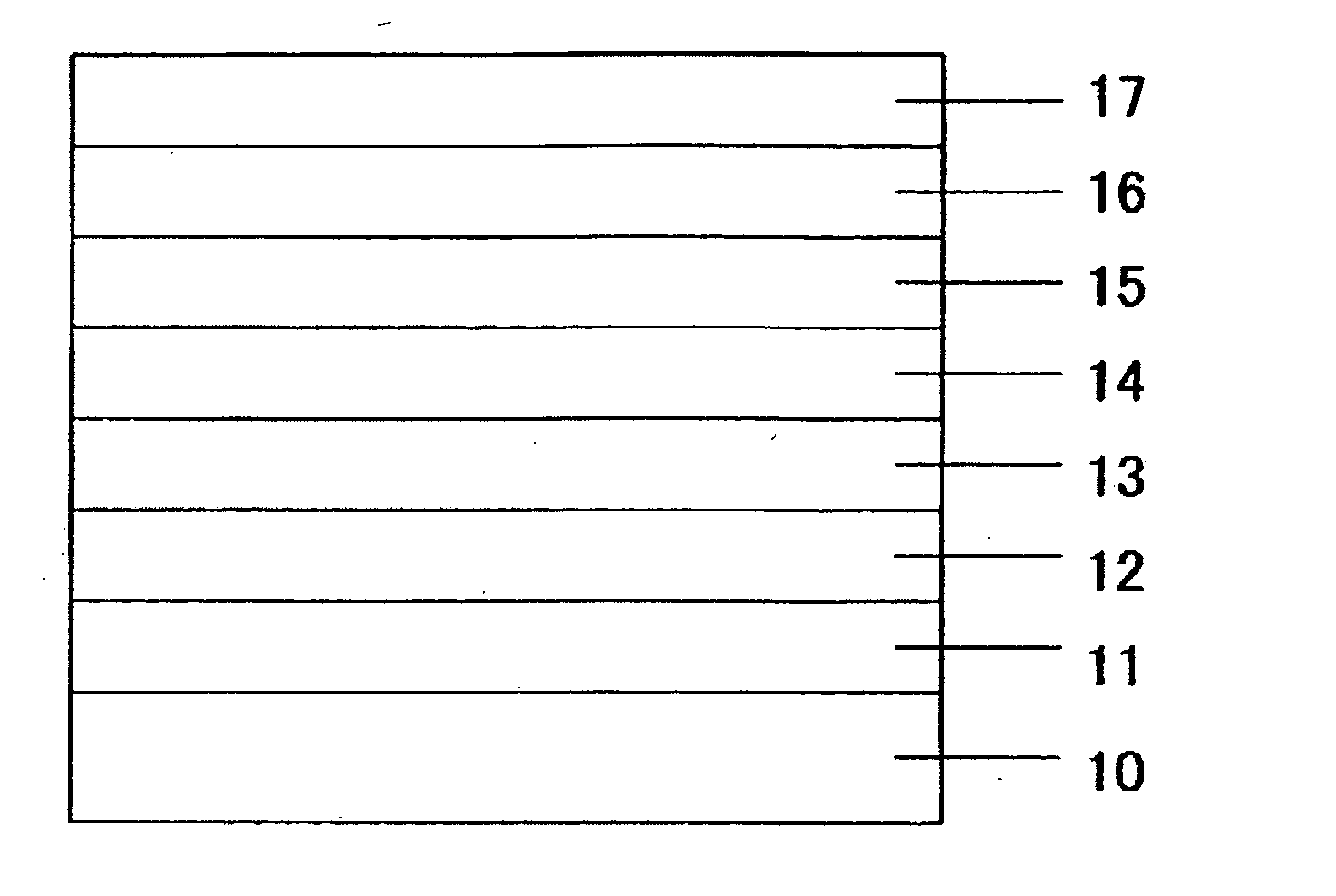

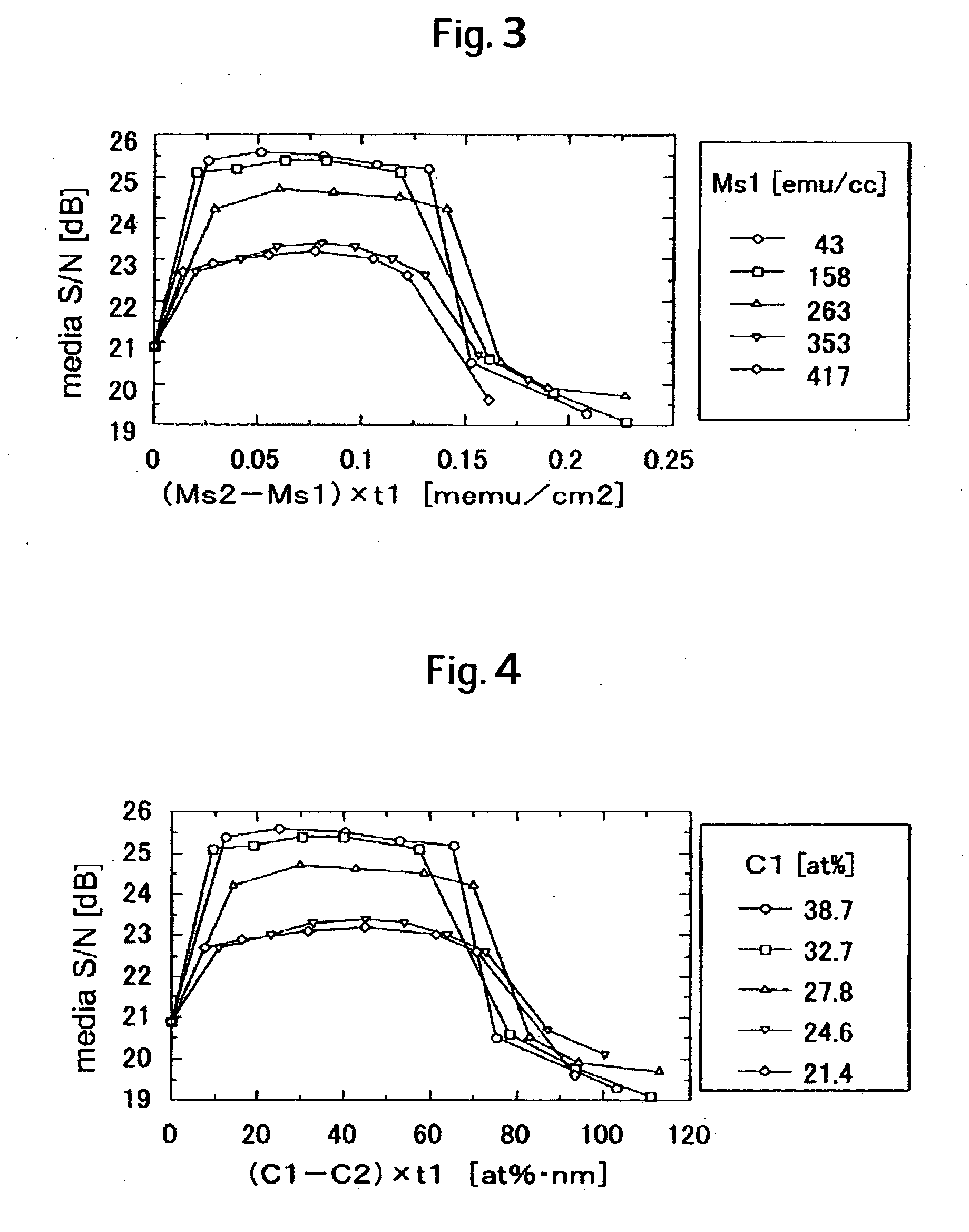

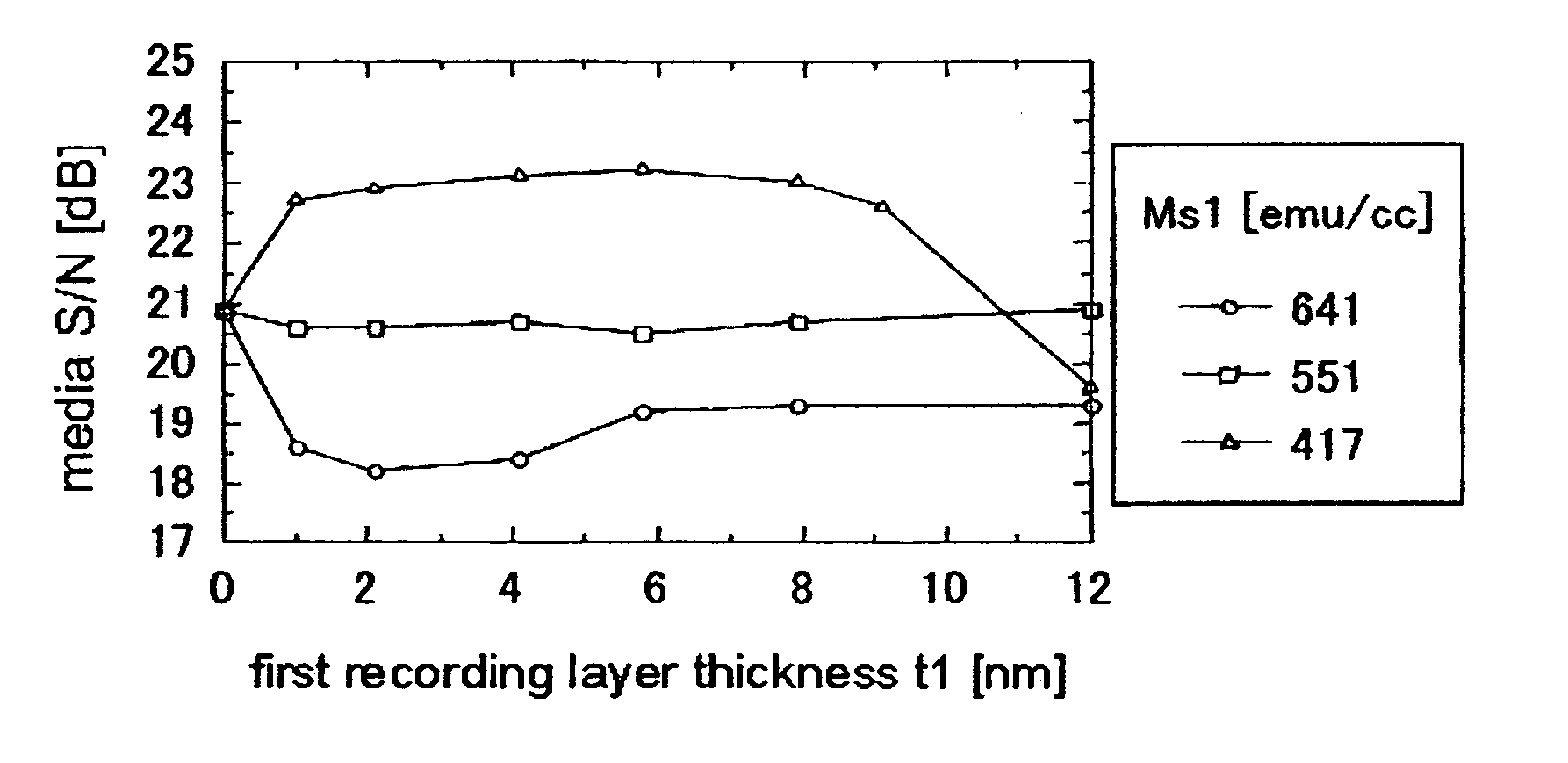

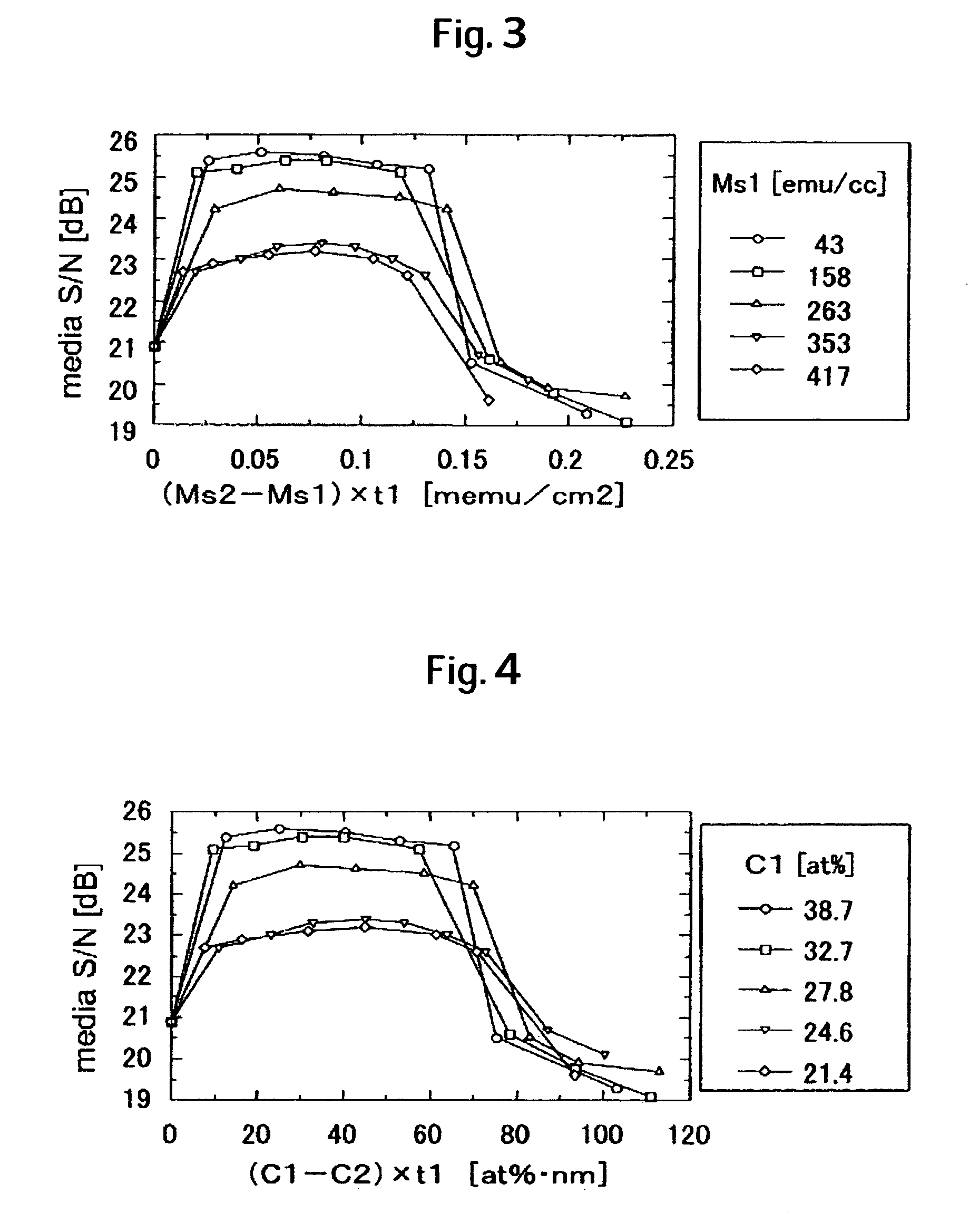

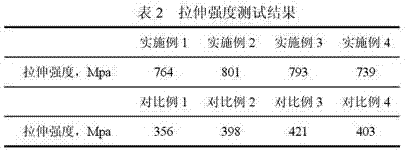

Perpendicular magnetic recording medium and magnetic storage apparatus using the same

ActiveUS20070188924A1Reduce noiseImprove recording densityRecord information storageDisk carriersLow noiseMagnetic storage

Embodiments in accordance with the present invention provide a perpendicular recording medium with low noise and high recording density by reducing the effects from noise generated from the vicinity of the interface with the intermediate layer of the recording layer, in a perpendicular recording medium utilizing a granular recording layer containing oxygen or oxide additive in a cobalt-chromium alloy formed on an intermediate layer with a ruthenium or ruthenium alloy layer. A first recording layer and a second recording layer are formed in order on an intermediate layer of ruthenium or ruthenium alloy. The first recording layer and the second recording layer are comprised of cobalt as the main material in a granular structure containing chromium and oxygen. The saturation magnetization of the first recording layer is lower than the saturation magnetization of the second recording layer. When a first recording layer saturation magnetization is set as Ms1 (emu per cubic centimeter), a second recording layer saturation magnetization is set as Ms2 (emu per cubic centimeter), and the first recording layer film thickness is set to t1 (nm), then (Ms2−Ms1)×t1 will be larger than 0 (memu per square centimeter) and smaller than 0.15 (memu per square centimeter).

Owner:WESTERN DIGITAL TECH INC

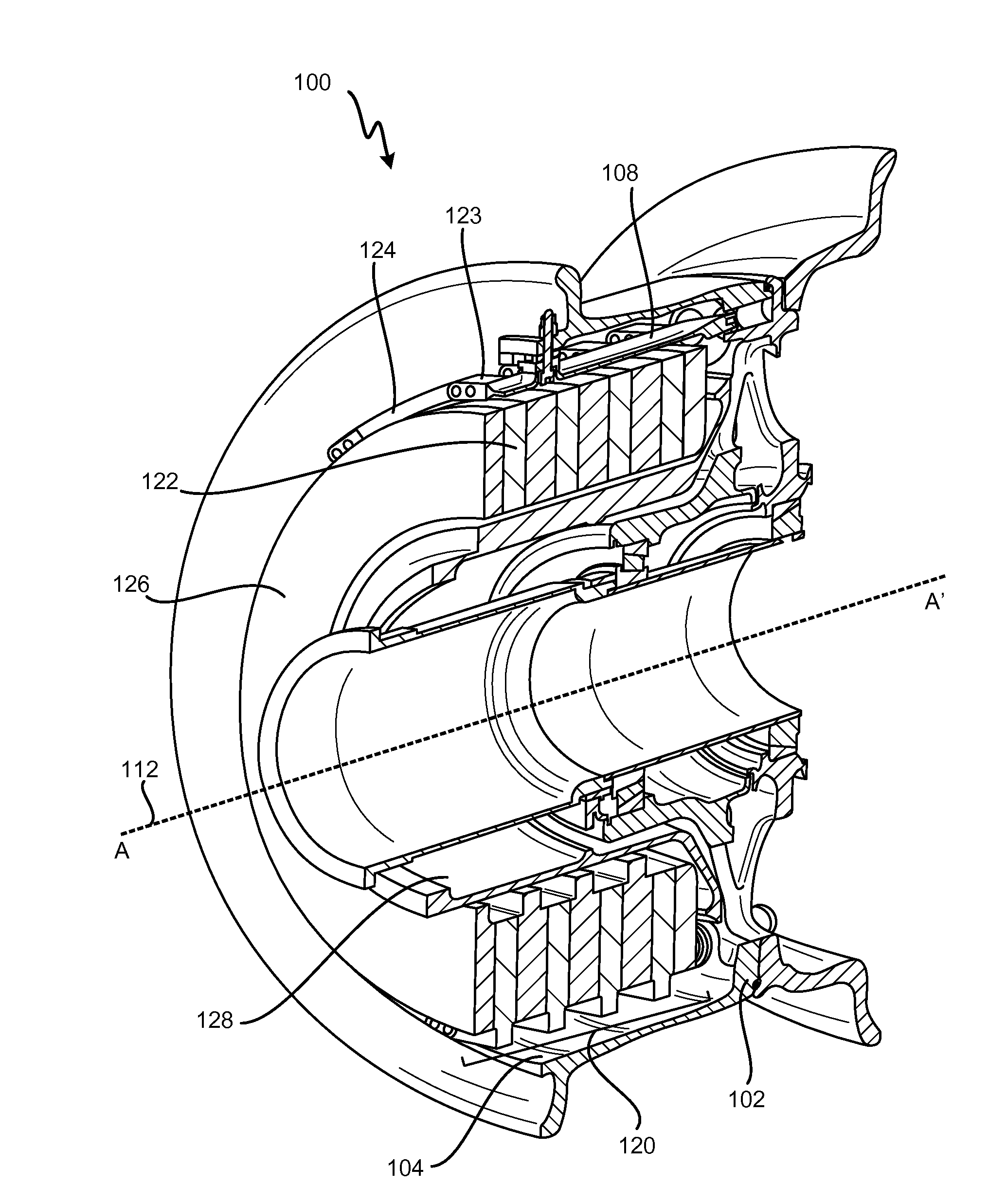

Aircraft brake rotor clip repair methods

InactiveUS20160279710A1Additive manufacturing apparatusAxially engaging brakesCobalt chromium alloyAdditive layer manufacturing

The present disclosure provides methods related to repair of aircraft brake assembly components using additive manufacturing processes. In various embodiments, methods for modifying a brake assembly component may comprise measuring an actual dimension of the brake assembly component, determining a desired dimension of the brake assembly component, comparing the desired dimension to the actual dimension to define a modification specification, and using an additive manufacturing process to alter the brake assembly component. In various embodiments, methods for modifying a brake assembly component may comprise applying a cobalt-chromium alloy to the brake assembly component until the desired dimension is achieved.

Owner:THE BF GOODRICH CO

Cobalt-nickel-chromium biocompatible alloy for implantable medical devices

InactiveUS20050276718A1Simple and inexpensive to manufactureIncreased durabilityStentsSurgeryResonanceSolid solution

A biocompatible solid-solution alloy may be formed into any number of implantable medical devices. The solid-solution alloy comprises a combination of elements in specific ratios that make it magnetic resonance imaging compatible while retaining the characteristics required for implantable medical devices. The biocompatible solid-solution alloy is a cobalt-chromium alloy having substantially reduced iron and / or Silicon content.

Owner:CORDIS CORP

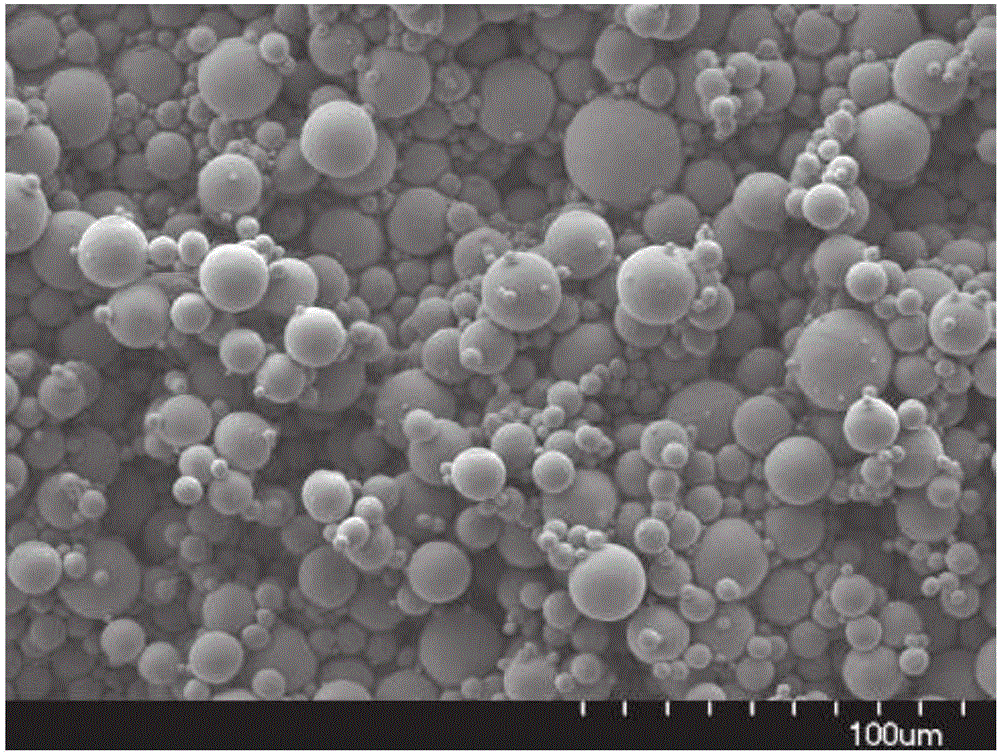

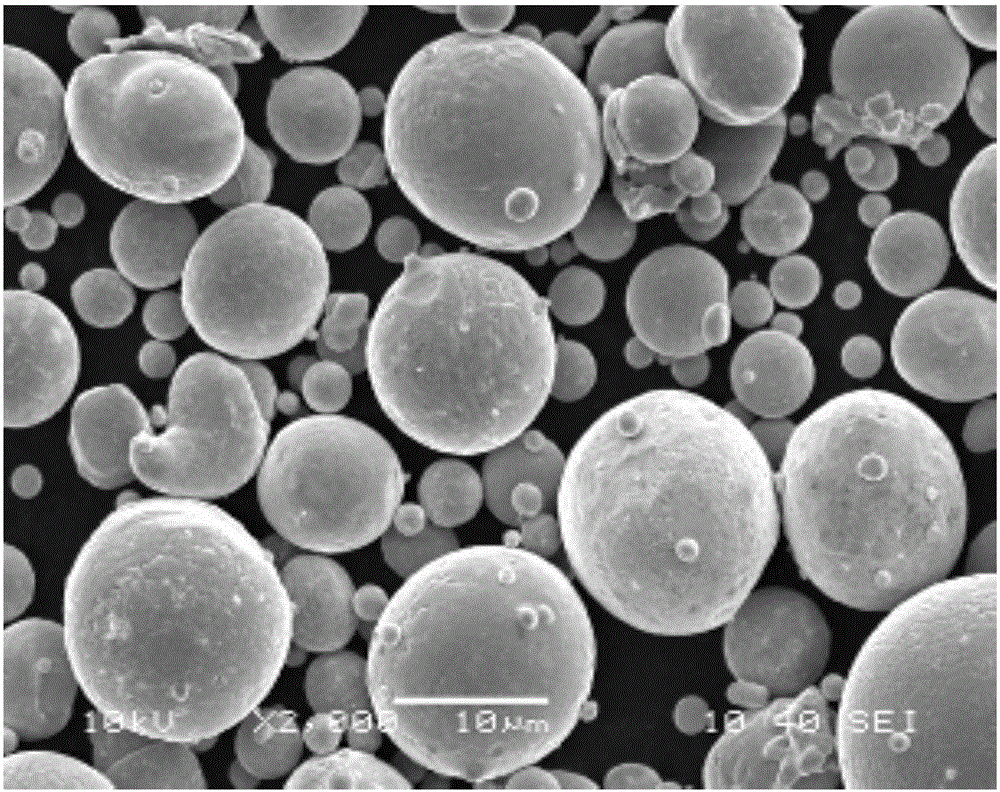

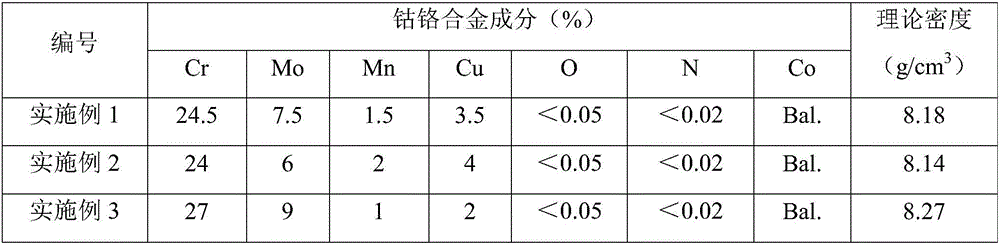

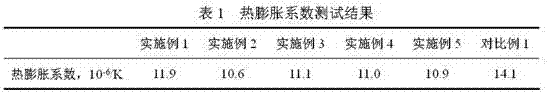

Cobalt-chromium alloy powder and preparation method and application thereof

ActiveCN106381419AGood biocompatibilityLow densityImpression capsAdditive manufacturing apparatusManufacturing technologyBiocompatibility Testing

The invention relates to cobalt-chromium alloy powder and a preparation method and application thereof, and belongs to the technical field of material increase manufacturing in the department of dentistry. The cobalt-chromium alloy powder special for material increase manufacturing in the department of dentistry is provided. The cobalt-chromium alloy powder comprises, by weight, 24%-27% of Cr, 6%-9% of Mo, 2%-4% of Cu, 1%-2% of Mn, 0-0.05% of O, 0-0.02% of N and the balance Co. According to the cobalt-chromium alloy powder, the specific ingredients and matching are adopted, so that the alloy density is decreased, and the low-weight purpose of final products is realized; the toxicity caused by beryllium, cadmium and nickel in final cobalt-chromium alloy in the department of dentistry is completely removed while the usability is guaranteed, and biocompatibility of the cobalt-chromium alloy is greatly enhanced; and moreover, the powder prepared through the preparation method has the advantages of being good in degree of sphericity, small in number of hollow sphere particles, good in mobility and the like, thereby being capable of completely meeting the requirement for the powder by metal material increase manufacturing.

Owner:OPTIMAL MATERIAL TECH CO LTD

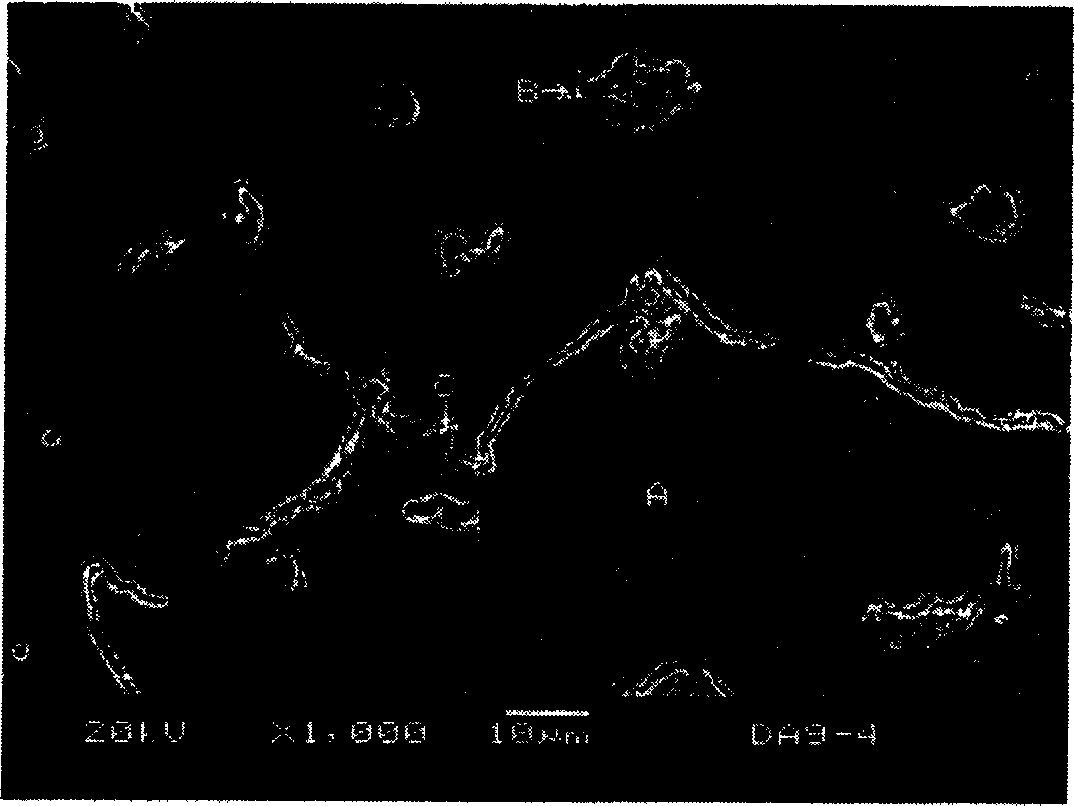

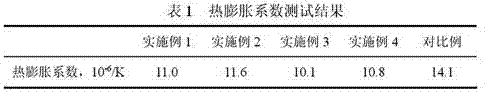

Cobalt chrome alloy containing rare earth La for dental ceramic stent

InactiveCN1827814AHigh wearing safetyHigh strengthImpression capsDentistry preparationsCobaltInduction furnace

The invention relates the stove enamel support cobalt chromium alloy containing rare earth La used for teeth. The method uses the electrolysis Co, metal Cr, metal Mo, metal La, metal W, electrolysis Mn, and crystal Si as raw materials, getting the cast ingot by melting them in electric induction furnace. The chemical compositions are following: Cr 15.0-30.0wt%,Mo 4.0-9.0wt%, La 0.03-0.30wt%, Mn 0-2.0wt%, Si 0-3.0wt%, W 0-10.0wt%,C 0-0.2wt% and Co. The alloy can be made with the casting machine, stove enamel furnace, and porcelain. The alloy binding ability is improved because of the rare earth La. The test indicates: alloy bonding strength is 75MPa, strength for extension (ªÊb ) is 800MPa, yield strength (ªÊ0.2) is 680MPa, elongation (ª€5) is 18%, diamond pyramid hardness (HV) is 300-400, coefficient of thermal expansion (ª‡RT-500Deg.C) is 13.4-14.5ª–m / m / Deg.C, and casting shrinkage is 1.8-2.1%. The binding ring and bar, which are cast by cobalt chromium alloy, has the advantages of high intensity and good rebound elasticity. The invention is the ideal material.

Owner:SICHUAN UNIV

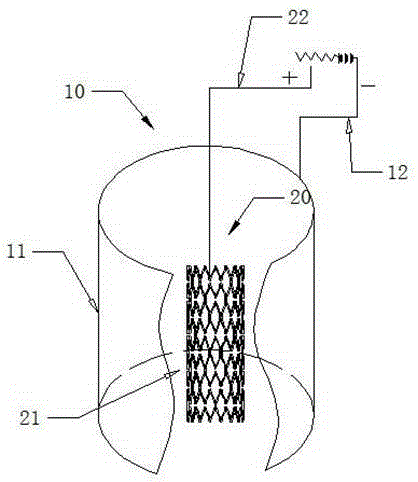

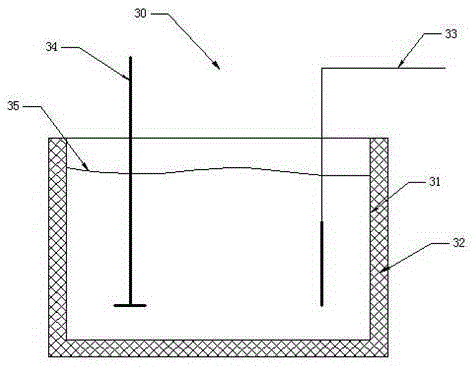

Electrochemical polishing device and method for support

InactiveCN105386117AImprove uniformityImprove the problem of large amount of removalElectrolysis componentsNitinol stentElectrochemistry

The invention provides an electrochemical polishing device and method for a support. The device and method are mainly suitable for electrochemical polishing of the medical metal support. The electrochemical polishing device for the support is characterized by comprising a metal anode, a metal cathode of a cylindrical structure, an electrochemical polishing tank and the like, and in the electrochemical polishing process, the current can be evenly distributed to all the portions of the support. The device is suitable for electrochemical polishing of the metal support such as a nickel-titanium alloy support, a cobalt-chromium alloy support, a stainless steel alloy support and a titanium alloy support and is used for improving the phenomena that pits and protrusions are generated on the inner surface of a support and the inner surface is not smooth and bright in the electrochemical polishing process, and the electrochemical polishing effect of the inner surface of the support is improved, so that both the inner surface and the outer surface of the support can achieve the good mirror surface effect. By the adoption of the device and method, the problem that the removing amount of the head end of the support is large can be solved as well, the polishing evenness of the support is improved, and therefore the metal surface of the support is smooth and bright.

Owner:LEO MEDICAL

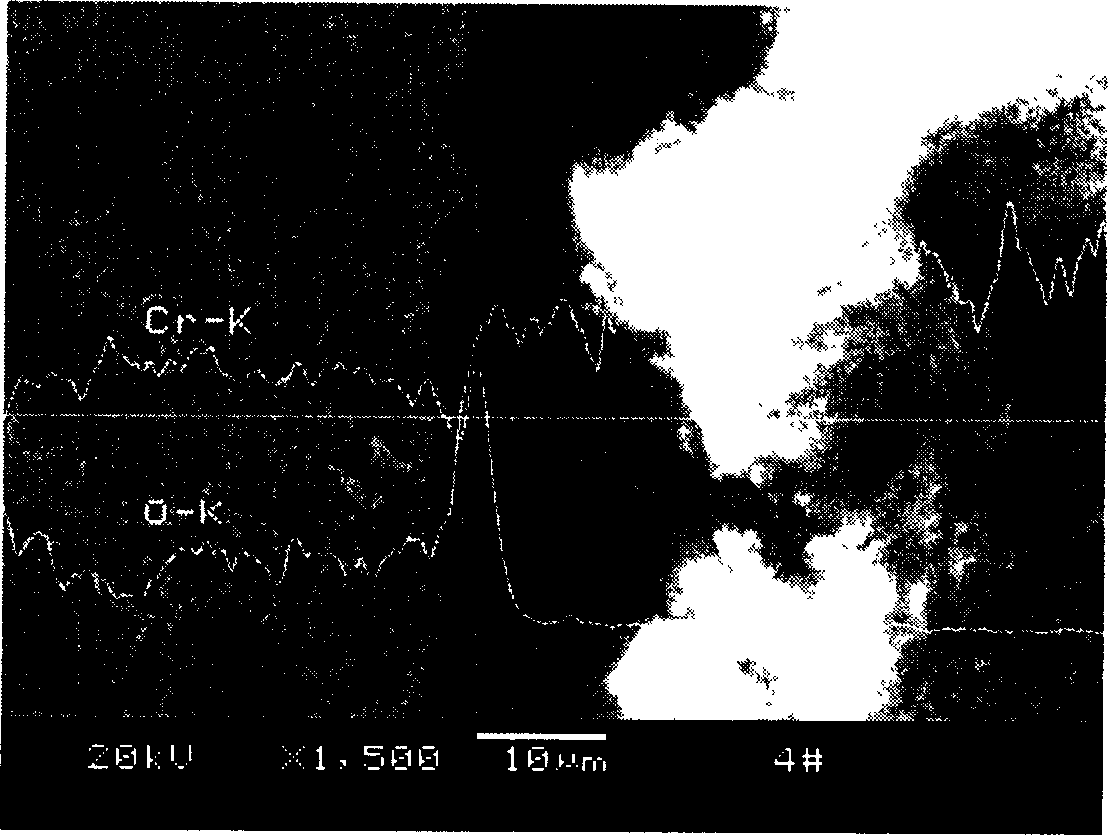

Preparation method of salt-mist-corrosion-resistant hard-surface coating material used for thermal spraying

ActiveCN103073940AOvercoming the problem of insufficient corrosion resistanceEvenly distributedMolten spray coatingChromium carbideThermal spraying

The invention provides a preparation method of a salt-mist-corrosion-resistant hard-surface coating material used for thermal spraying. As the preparation method takes prealloyed cobalt-chromium alloy powder having a small particle size and tungsten carbide as raw materials to prepare cobalt-chromium tungsten carbide composite powder, so that the corrosion resistance of the material is improved. With the method, the problems that chromium is not uniformly distributed or exists in a form of chromium carbide in the former composite powder binding phase, and the corrosion resistance is weak are solved; the prealloyed CoCr powder is taken as a binding phase; Cr is uniformly distributed; a complete oxidation film can be formed on the surface of the binding phase; and the corrosion resistance of the material is improved.

Owner:BGRIMM ADVANCED MATERIALS SCI & TECH +1

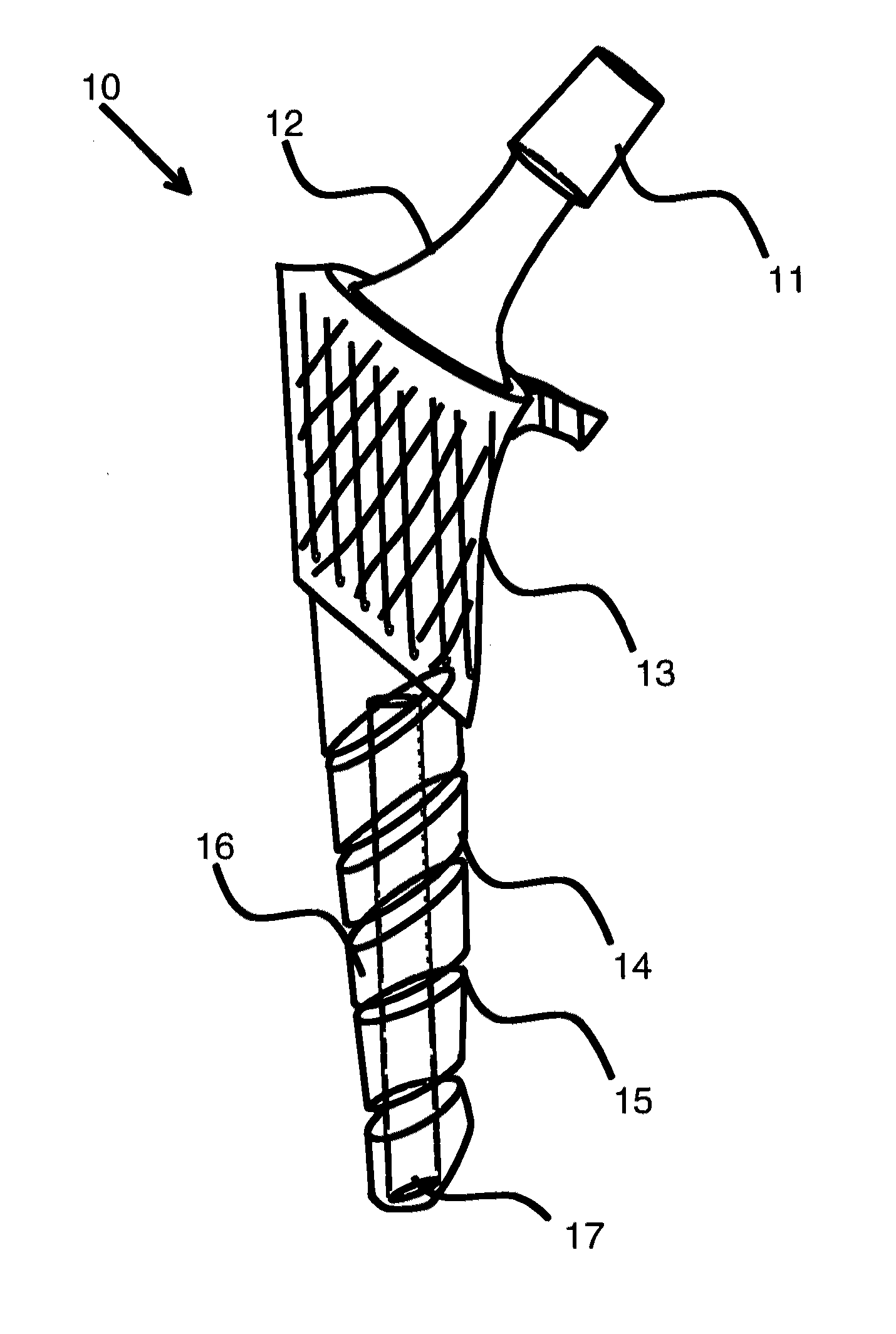

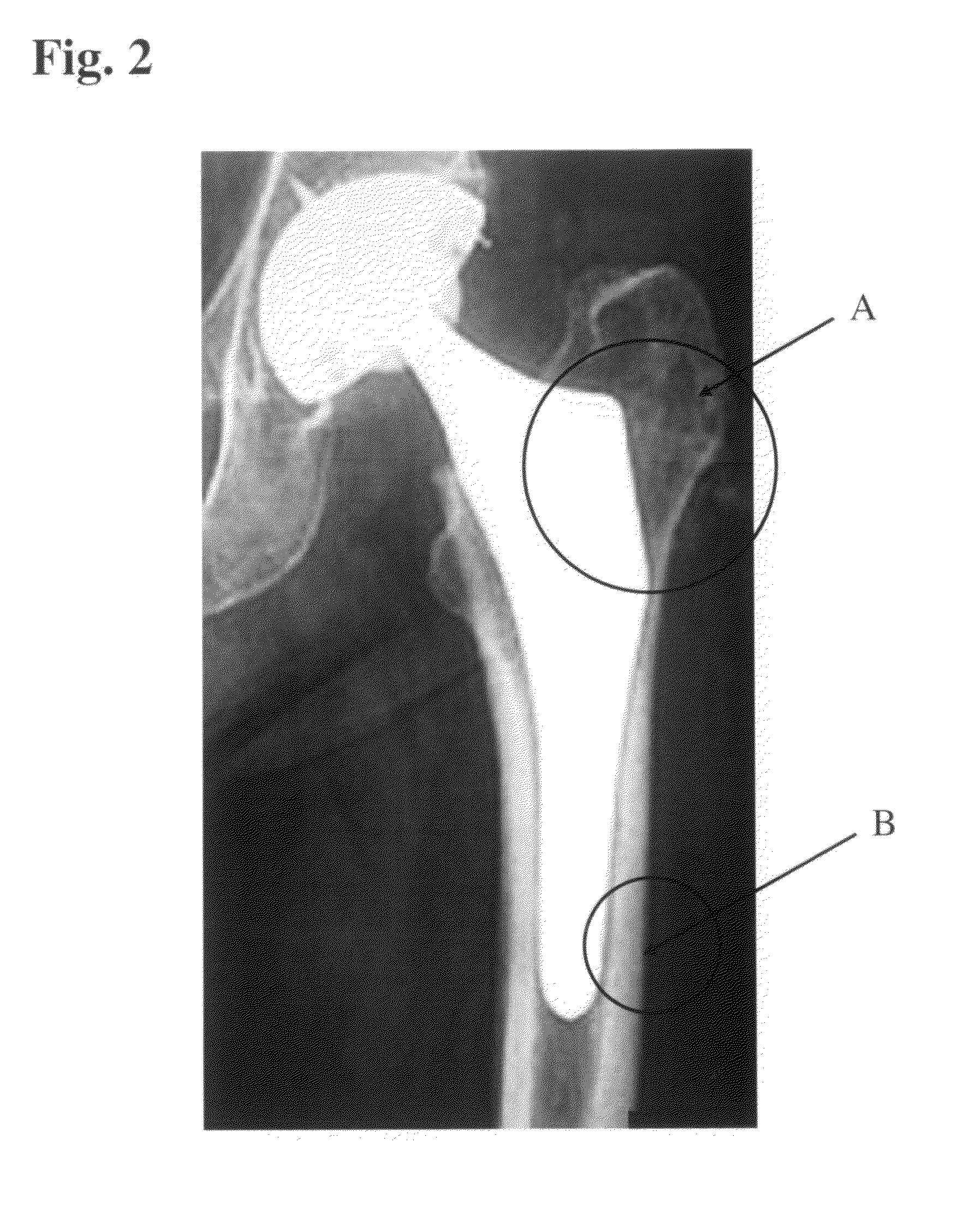

Load bearing implants

ActiveUS20120245700A1Minimizing excessive loadingPreventing of wear debrisInternal osteosythesisJoint implantsThighNatural bone

A bio-compatible femoral stem is made from a bio-compatible titanium alloy or cobalt-chromium alloy, each of which have an elastic modulus far greater than that of natural bone. When the implant heals within a bone cavity, the implant essentially carries substantially the entire load. Transfer of load to the surrounding bone tissue is lost or resorbed due to lack of use after implant healing. Flexing a stiff implant applies a very large load at the implant distal end. The bone cortex is thereby allowed to thicken due to excessive load, causing thigh pain long after implant healing. The femoral implant has a bone ingrowth coating on the proximal end, allowing firm attachment of the implant in the bone cavity. The distal end has a central aperture and a helical machined groove that permits flexing of the distal portion of the femoral implant stem. This flexing is occurs in a manner similar to surrounding bone tissue, preventing thigh pain.

Owner:SIDEBOTHAM CHRISTOPHER G

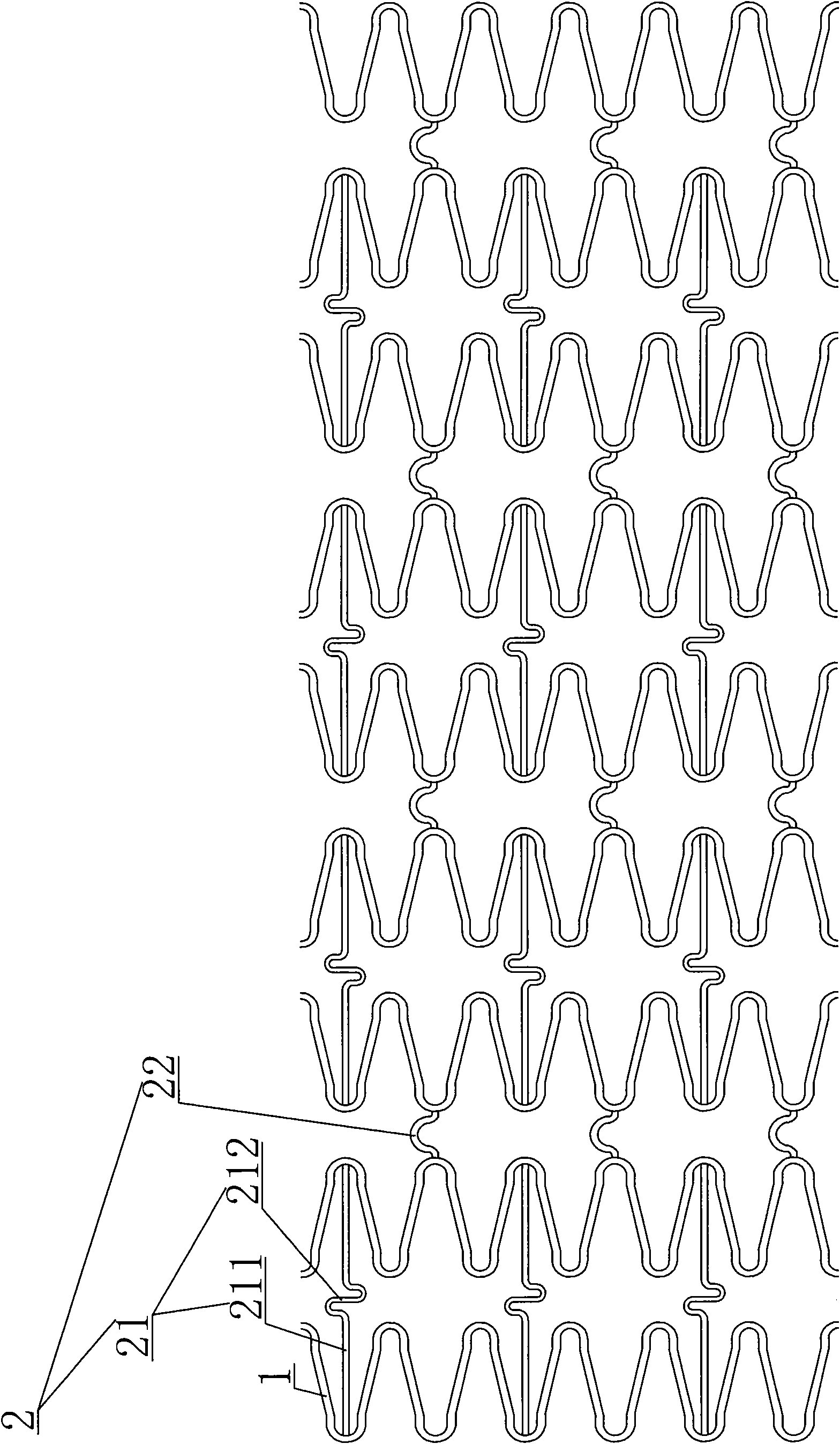

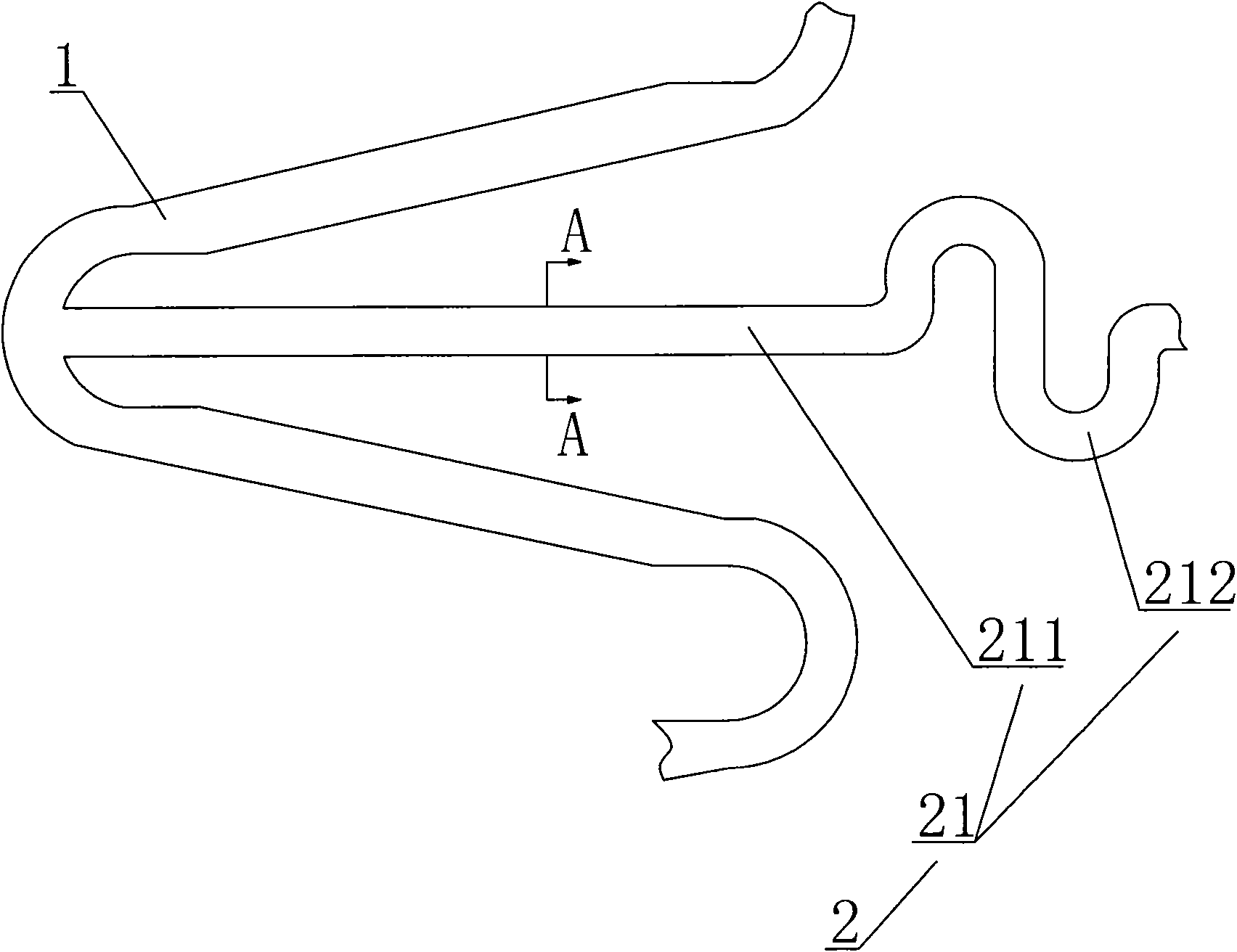

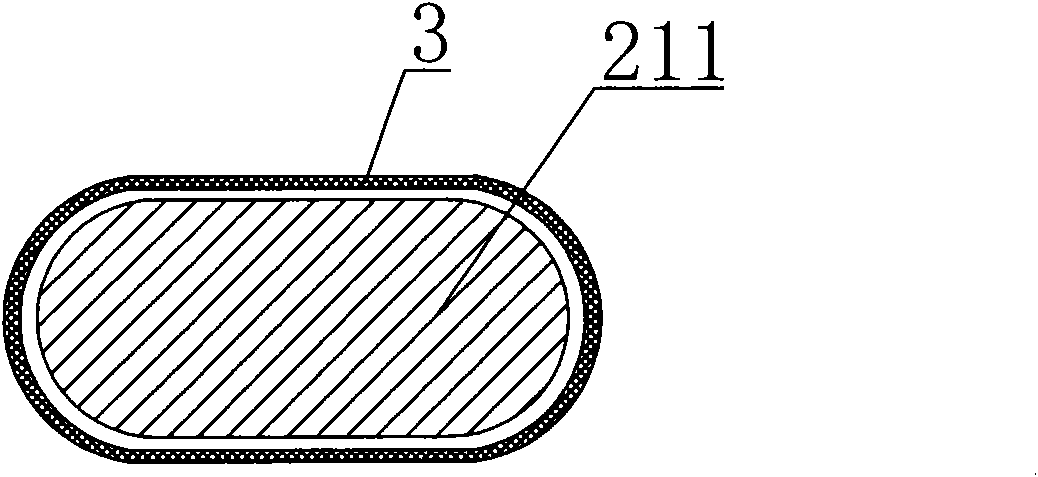

Intracranial sirolimus medicament-release blood vessel stent and preparation method thereof

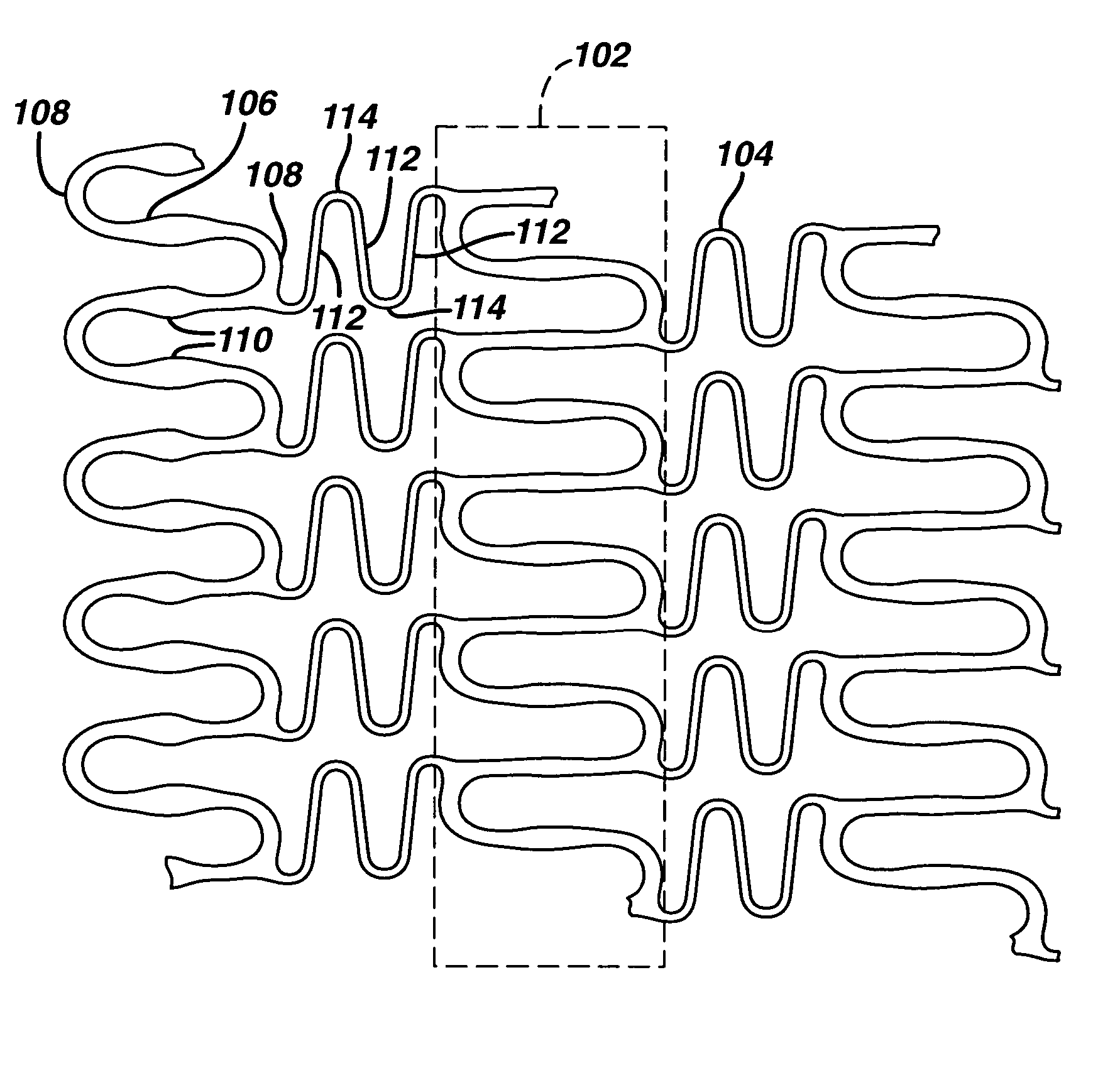

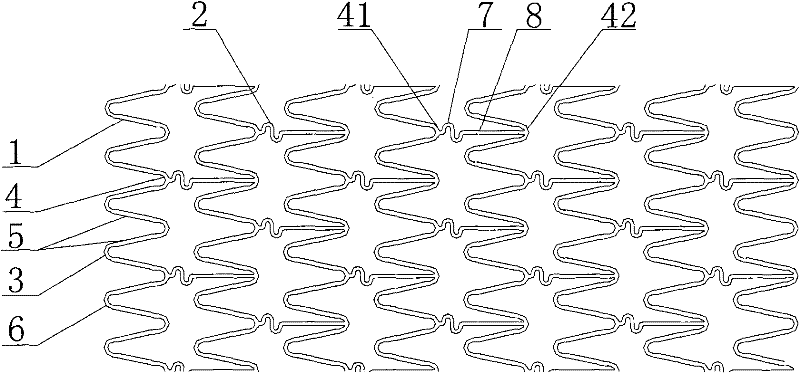

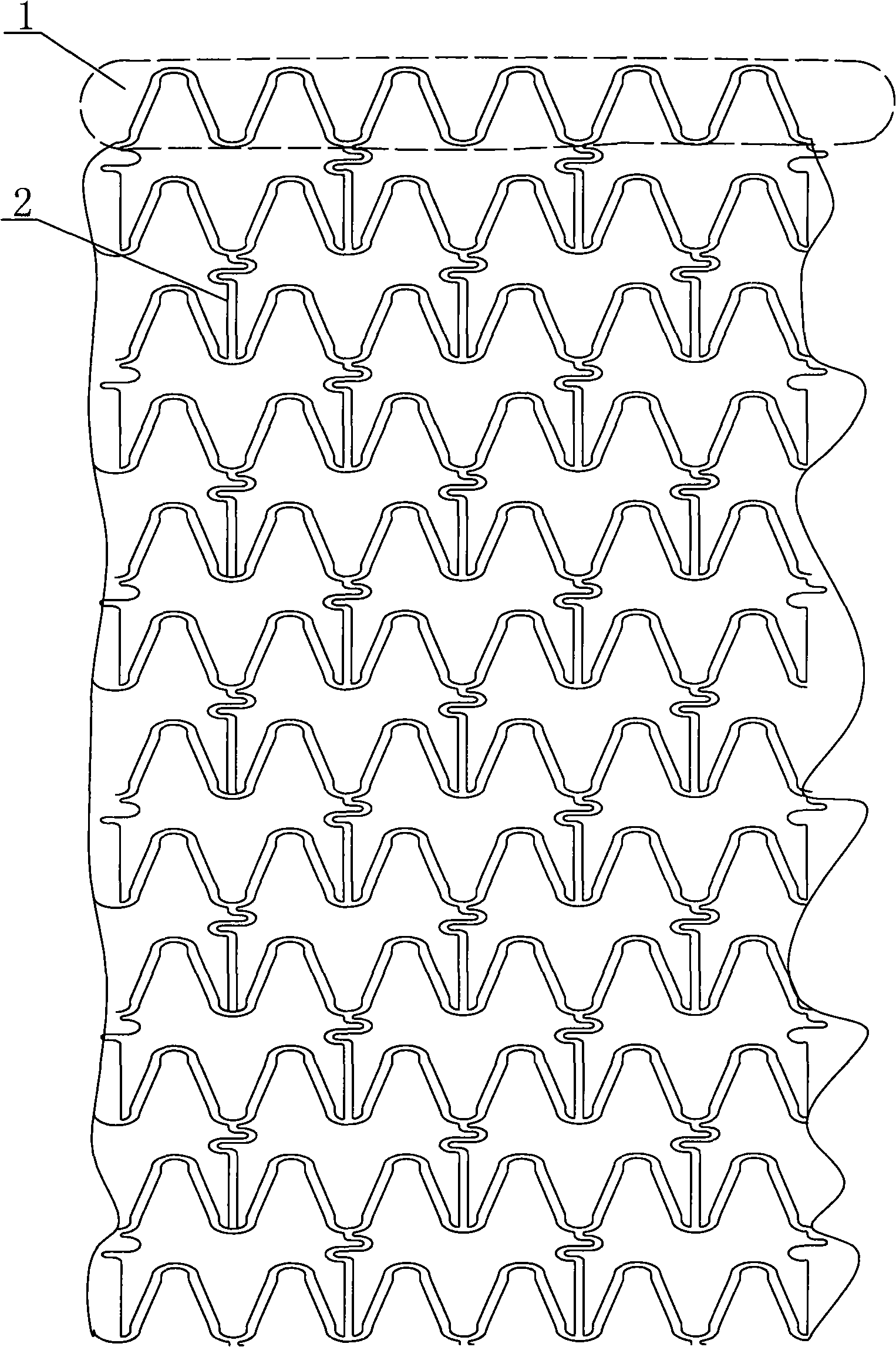

InactiveCN101601616AReduce bending pressureReduce rebound rateStentsMedical devicesPercent Diameter StenosisUnit structure

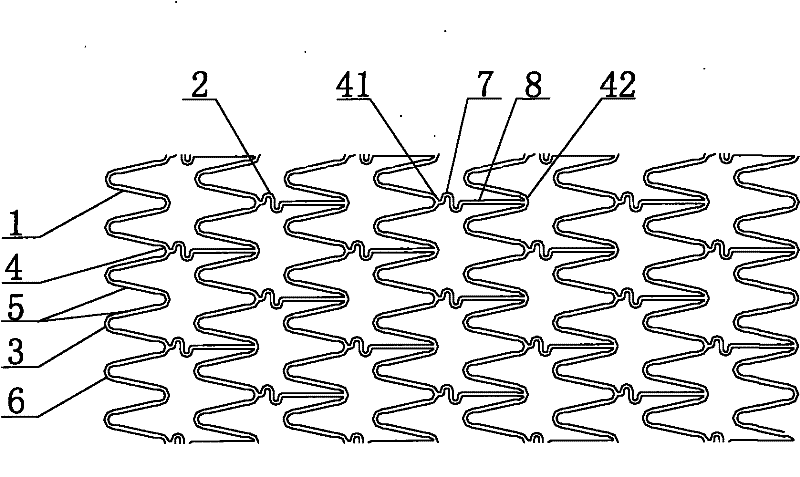

The invention relates to an intracranial sirolimus medicament-release blood vessel stent. The blood vessel stent has an integral net tubular structure which is formed by a cobalt-chromium alloy L605 tube through laser engraving and cutting and electrochemical polishing treatment; the net tubular structure comprises a plurality of support rods with sine waveform unit structures and connecting rods connected among the support rods; and the blood vessel stent is integrally coated with a sirolimus medicament-release layer. A preparation method for the blood vessel stent comprises the following steps: preparing the cobalt-chromium alloy L605 tube into the blood vessel stent of the net tubular structure through laser engraving and cutting and electrochemical polishing treatment; pre-treating the surface of the blood vessel stent of the net tubular structure; preparing sirolimus medicament coating solution; compositely spraying the sirolimus medicament solution to the surface of the blood vessel stent; and drying the sirolimus medicament-release blood vessel stent. The blood vessel stent has low nominal pressure, can effectively inhibit the neointimal formation of the blood vessel and the proliferation and migration of smooth muscle cells (SMC), and also can effectively solve the problem of intracranial arterial blood vessel restenosis.

Owner:万瑞飞鸿(北京)医疗器材有限公司

Preparation method of antibacterial cobalt chromium alloy porcelain artificial tooth

ActiveCN103060618AQuickly vaporize and eliminateEasy feedingImpression capsFoundry mouldsSand blastingCobalt-chrome

The invention discloses a preparation method of an antibacterial cobalt chromium alloy porcelain artificial tooth. Cobalt chromium alloy consists of Cr, Mo, W, Mn, Nb, Si, Ag, Cu, Ce and Co. The preparation method comprises the following steps: (1) manufacturing a lost foam pattern, then coating a coating on the surface, putting into a sand box after the coating is dried, filling sand and compacting, and putting into a pouring table with a vibration device; (2) putting ingot metal, intermediate alloy and other raw materials into an induction furnace for melting according to the mixture ratio, testing and adjusting ingredients after solution is uniform, then adjusting the pouring temperature, ensuring that the pouring temperature is about 30-40 DEG C higher than that of an alloy melting point and preparing to pour; (3) starting the vibration device, so that the vibration frequency is about 140-160 Hz, and the amplitude of vibration is about 4-6 mm and then pouring the solution in the step (2); and (4) sand-blasting, ultrasonic cleaning and conventional porcelain-baking after cooling and cleaning. The prepared artificial tooth has the advantages of excellent performance and good antibacterial effect.

Owner:GUANGZHOU NALIAN MATERIAL TECH CO LTD

Preparation method for cobalt-based composite ceramic powder for dentistry 3D printing

InactiveCN107252894AWell mixedImprove the bonding strength of the interfaceAdditive manufacturing apparatusTransportation and packagingCeramic compositeComposite ceramic

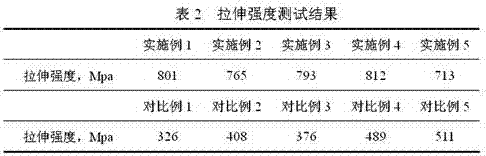

The invention discloses a preparation method for cobalt-based composite ceramic powder for dentistry 3D printing. Medical cobalt-chromium alloy powder is mixed with ceramic powder with the mass ratio of the cobalt-chromium alloy powder to the ceramic powder being 100:(0.5-10), and the cobalt-chromium alloy powder and the ceramic powder are subjected to ball milling in a ball mill, then sprayed into an argon plasma torch through carrier gas and subjected to radio frequency plasma spheroidization through argon plasmas generated by a radio frequency plasma generator with the power being 55-65 KW and the frequency being 3-4 MHz to obtain the spheroidized cobalt-based ceramic composite powder. In the laser melting process of the cobalt-based composite ceramic powder prepared by the method, the interface bonding strength of a ceramic phase and a metal matrix is high, wettability is good, and a prepared 3D printing formed part is low in thermal expansion coefficient and good in tensile property.

Owner:ZHONGBEI UNIV

Stents with low strut thickness and variable strut geometry

InactiveCN103249380AReduced radial strengthIncrease flexibilityStentsProsthesisCobalt chromium alloyOpen cell

Owner:MERIL LIFE SCI PVT

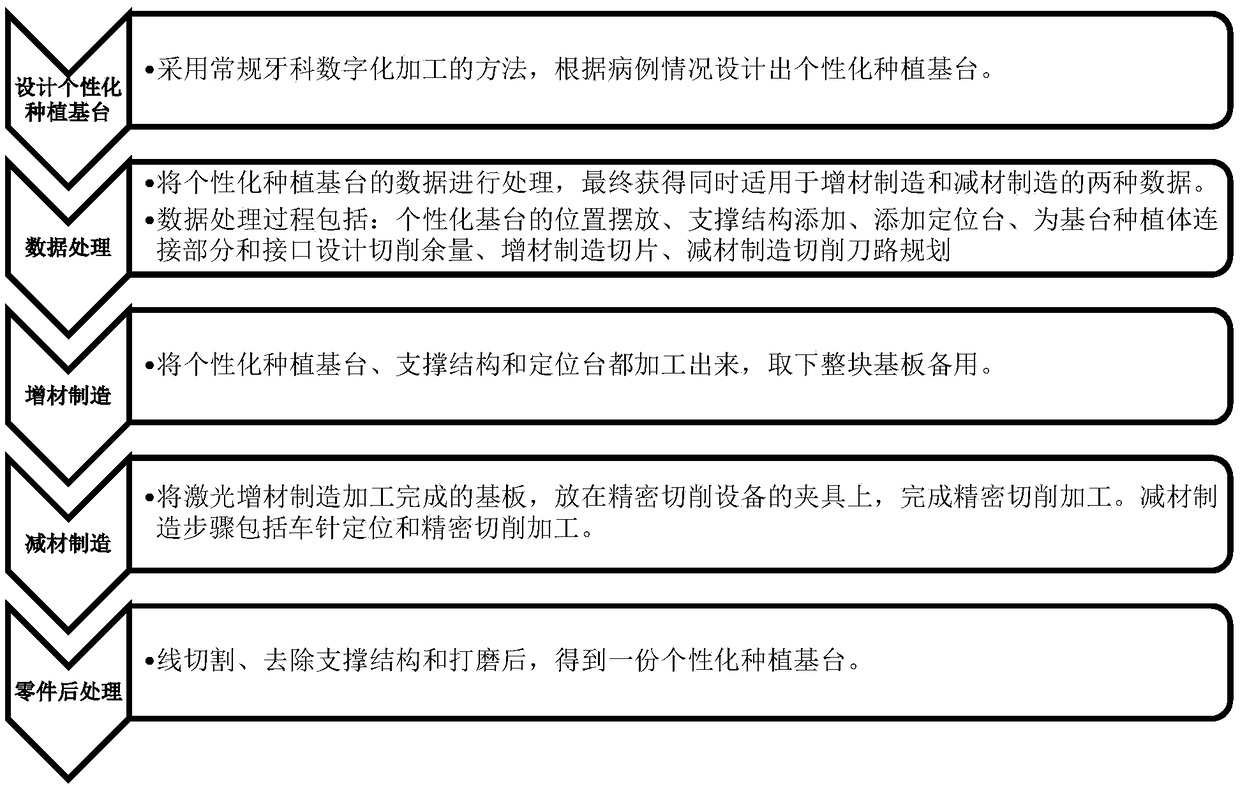

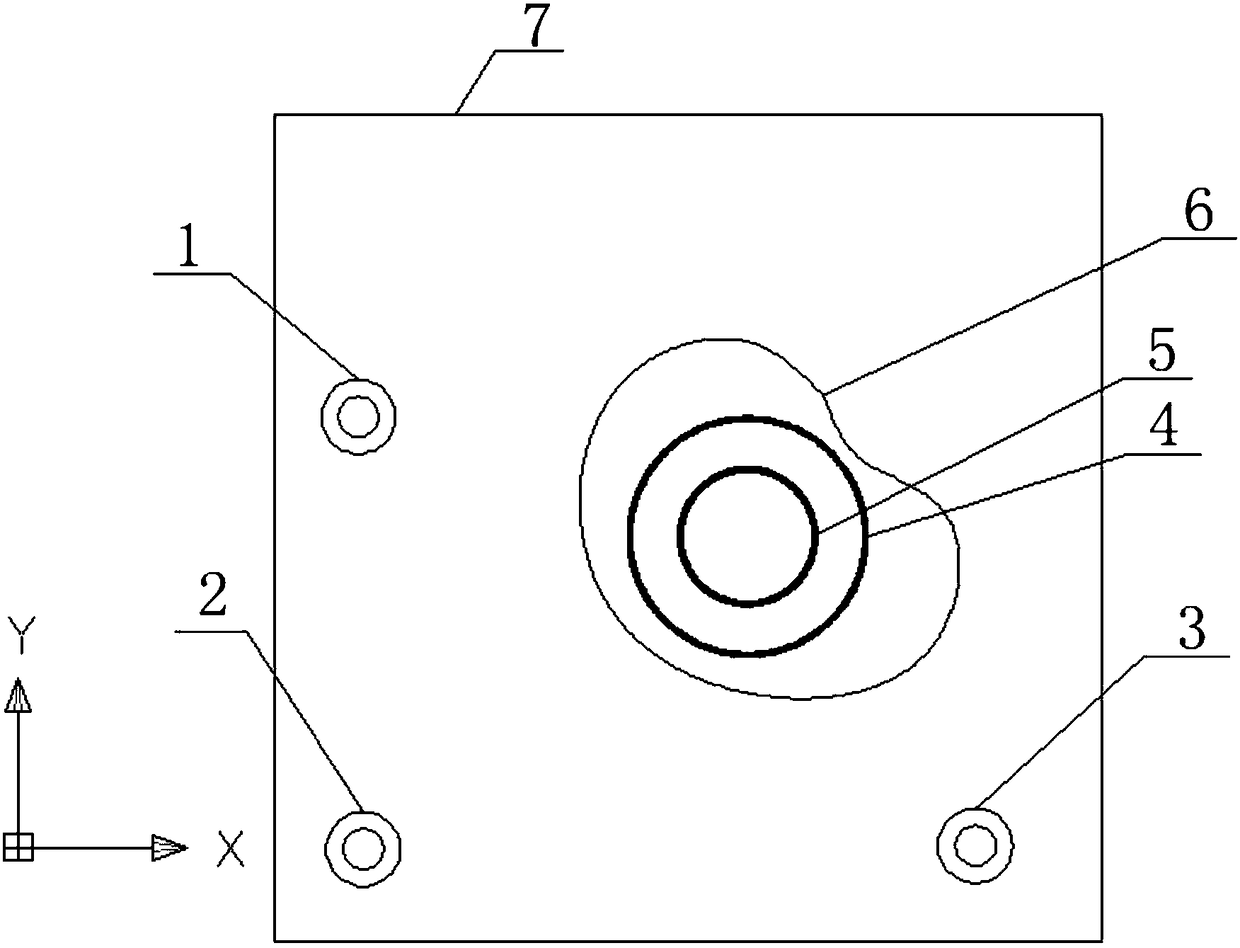

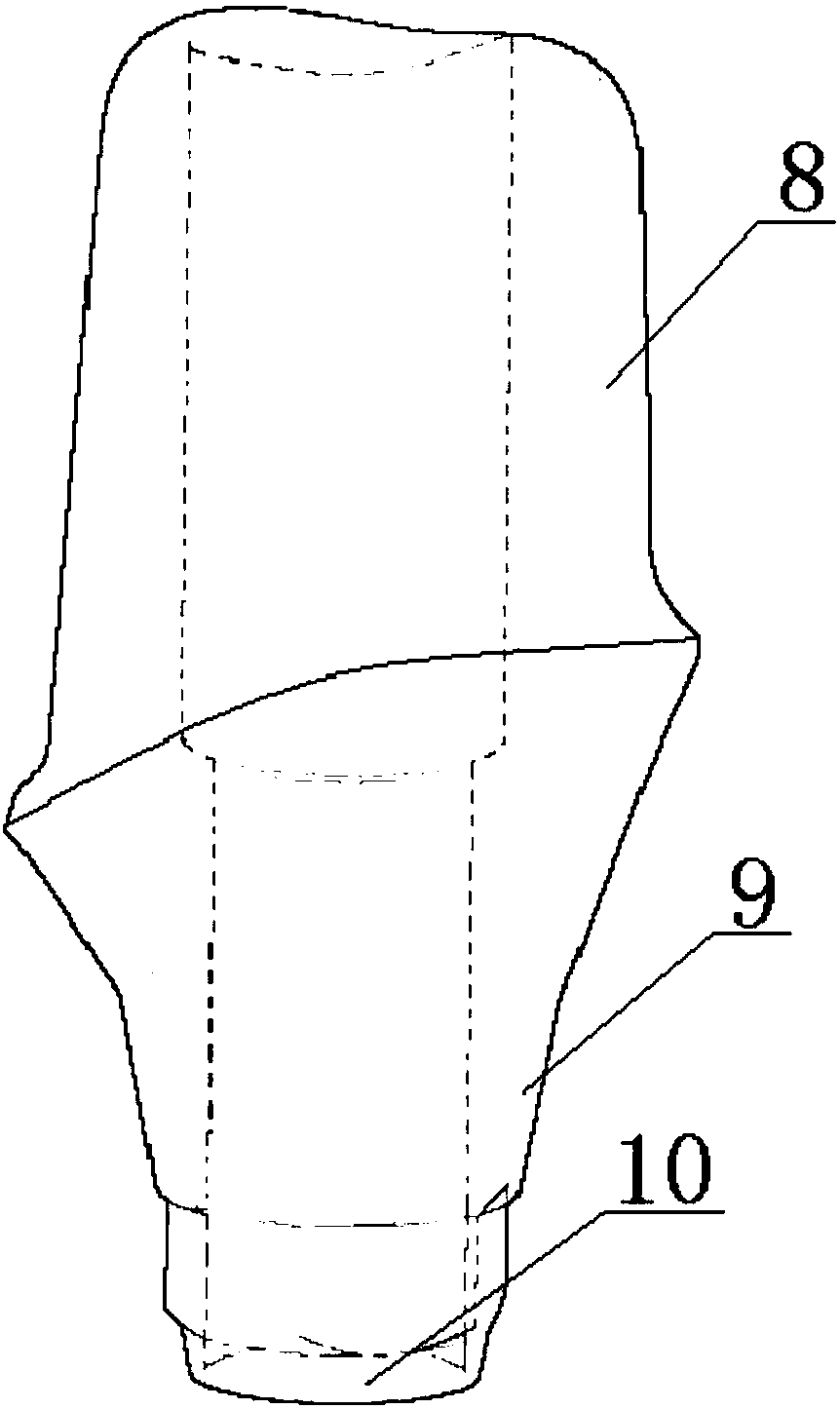

Additive and subtractive compound processing and molding method of individualized dental implanting abutment

ActiveCN108309477ASave materialHigh precisionDental implantsAdditive manufacturing apparatusWork in processTitanium

The invention relates to the field of additive manufacturing, in particular relates to additive manufacturing dental implanting field and discloses an additive and subtractive compound processing andmolding method of an individualized dental implanting abutment. The additive and subtractive compound processing and molding method of the individualized dental implanting abutment comprises the following steps: designing an individualized implant abutment: designing the individualized implant abutment according to conditions of illness cases; carrying out data processing: designing chipping allowance for a part needing to be subjected to cutting processing on the individualized implant abutment; carrying out slicing treatment needed by the additive manufacturing on the abutment and planning acutting cutter path for carrying out the cutting processing on the abutment; carrying out the additive manufacturing: processing an abutment semi-finished product through the additive manufacturing;carrying out subtractive manufacturing: carrying out cutting processing on the abutment semi-finished product to manufacture the individualized implant abutment. The processing and molding method provided by the invention combines advantages of additive manufacturing and subtractive manufacturing manners and high efficiency and high precision of the individualized implant abutment are realized; the additive and subtractive compound processing and molding method is applicable to a cobalt-chromium alloy, titanium, a titanium alloy and the like, and a selectable material range is wider.

Owner:CHENGDU TIANQI ADDITIVE MFG CO LTD

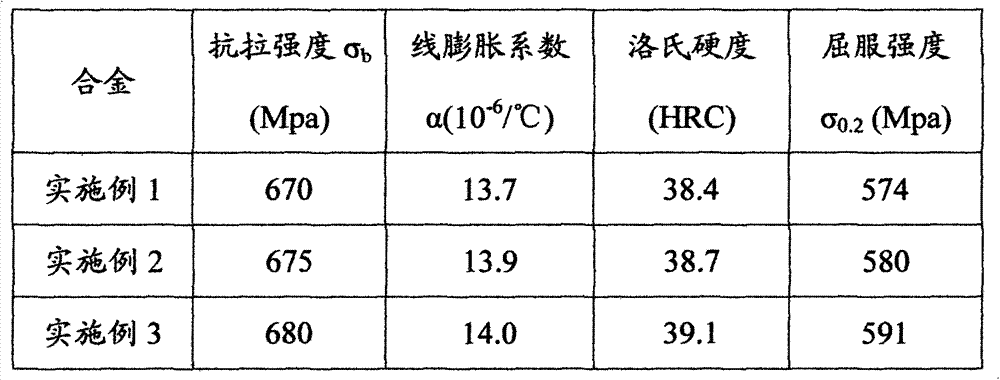

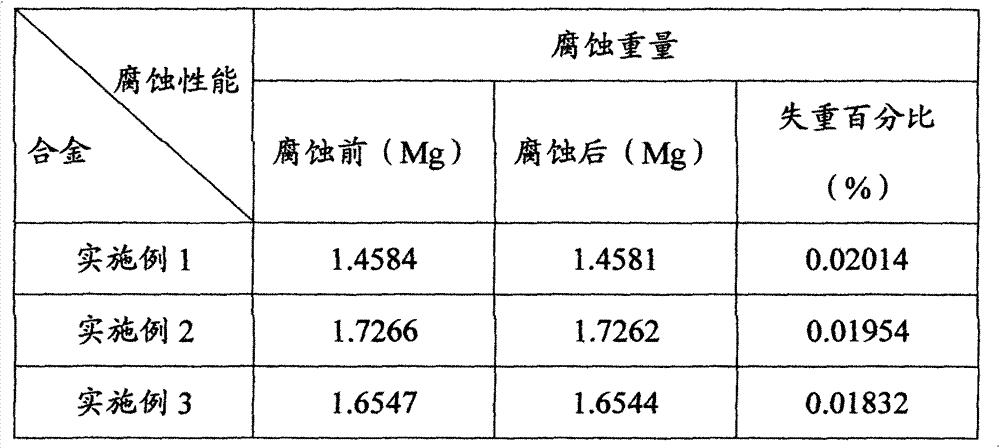

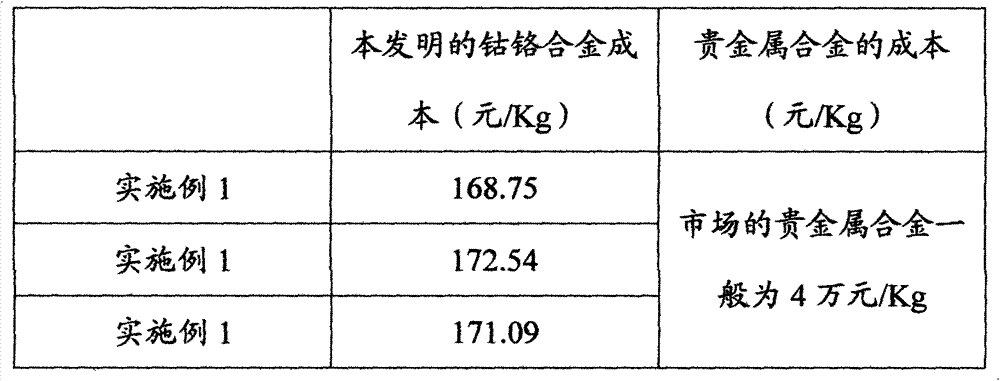

Alloy material for false tooth

InactiveCN103114226AHigh hardnessHigh strengthImpression capsDentistry preparationsHardnessUltimate tensile strength

The invention relates to an alloy material for a false tooth. The alloy material comprises the following components in percentage by weight: 58.00-63.00% of Co, 22.00-26% of Cr, 6.00-10.00% of W, 2.30-2.80% of Mo, 0.80-1.10% of Nb, 0.80-1.10% of Mn, 0.80-1.10% of Si and 0.80-1.10% of Fe. According to the alloy material for the false tooth, cobalt-chromium alloy is used, noble material which is high in using price is not used, Be element which is harmful to a human body is abandoned, and the cobalt-chromium alloy prepared from Co, Cr, W, Mo, Nb, Mn, Si and Fe low in price and safe and nontoxic is low in cost, safe and nontoxic, strong in corrosion resistance, high in strength of extension, low in coefficient of linear expansion, large in hardness and yield strength. The alloy material for the false tooth provided by the invention is an excellent material for making ceramic teeth.

Owner:AI JIA DENTAL LAB

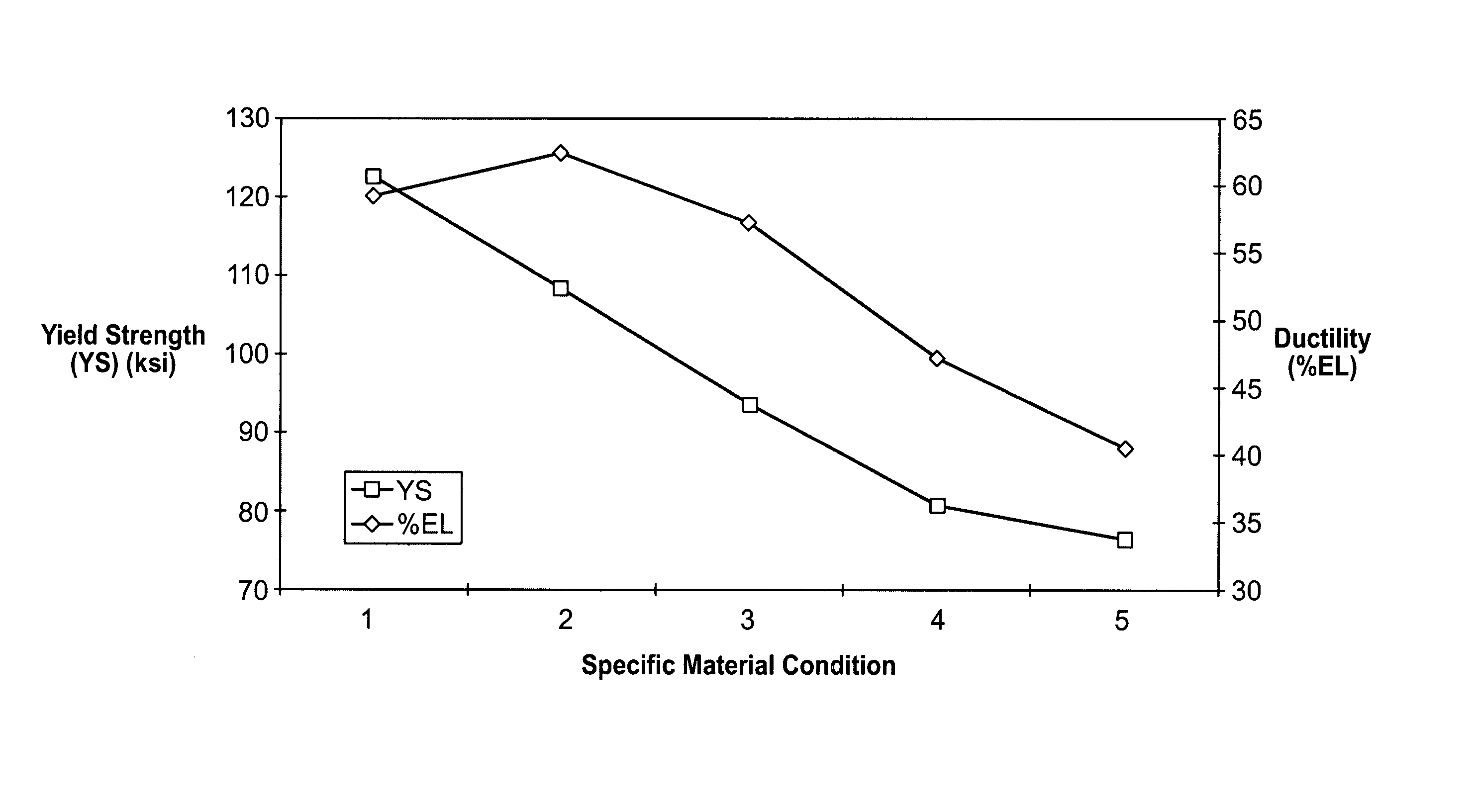

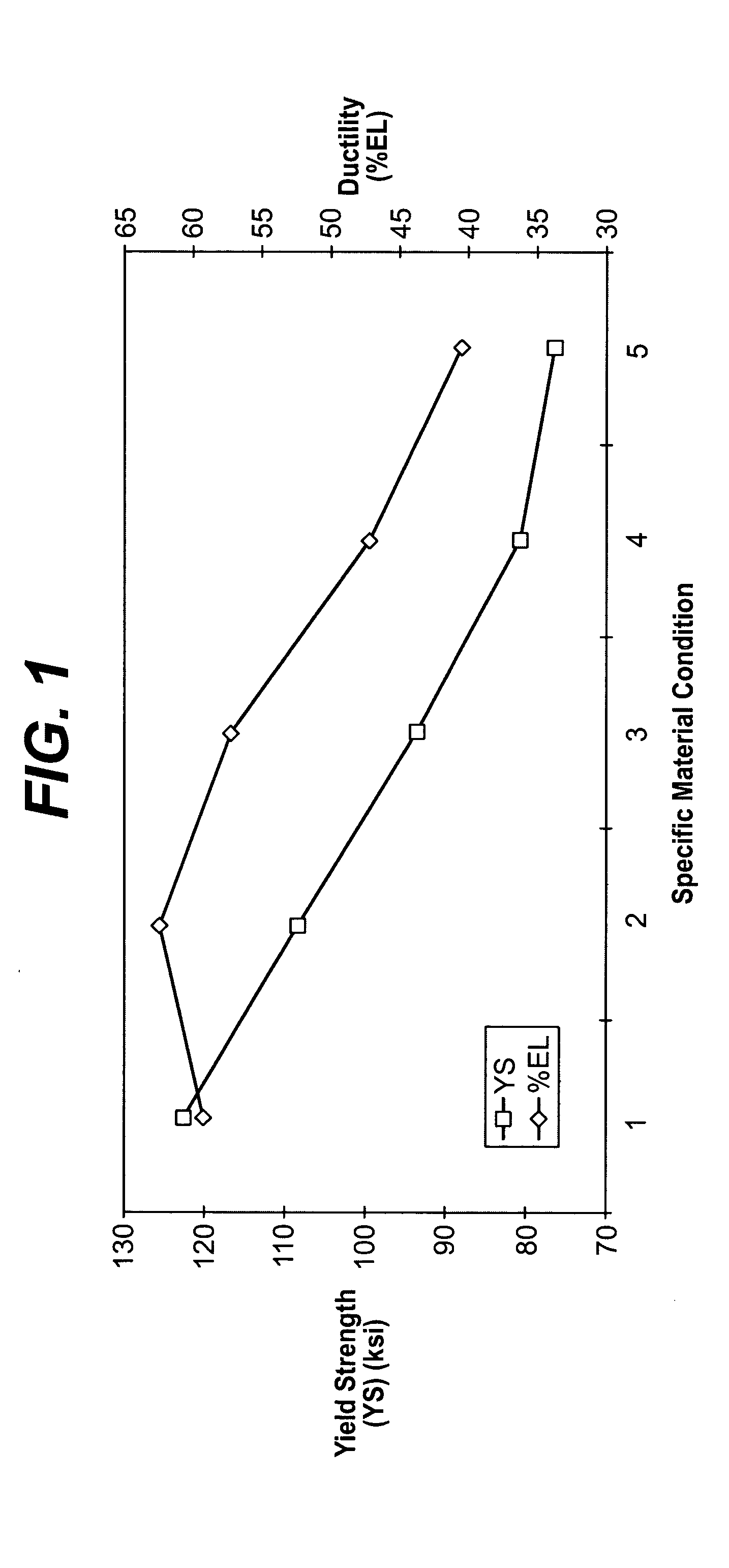

Magnetic resonance imaging compatibility alloy for implantable medical devices

ActiveUS20060004435A1Improve ductilityImprove toughnessSurgeryDiagnostic recording/measuringProton magnetic resonanceResonance

A biocompatible solid-solution alloy may be formed into any number of implantable medical devices. The solid-solution alloy comprises a combination of elements in specific ratios that make it magnetic resonance imaging compatible while retaining the characteristics required for implantable medical devices. The biocompatible solid-solution alloy is a cobalt-chromium alloy having substantially reduced iron, silicon, phosphorus and sulfur content.

Owner:CARDINAL HEALTH SWITZERLAND 515 GMBH

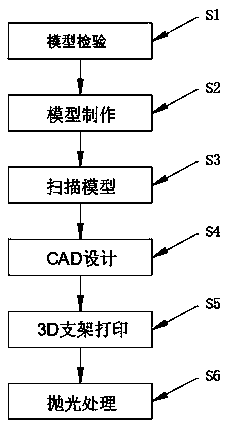

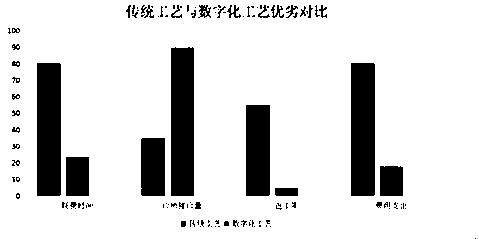

Novel manufacturing process of 3D printing movable false tooth support frame

ActiveCN109394364AImprove comfortImprove satisfactionDental prosthetics3D printingCobalt chromium alloyWax

The invention discloses a novel manufacturing process of a 3D printing movable false tooth support frame. The process comprises the following steps of model inspection: checking whether a model is complete or not; making the model: cleaning a silica rubber tray by water, performing blowing drying by an air gun, and filling gypsum into the tray; model scanning: performing fixation by wax and performing vertical engaging, then, putting the model into a 3 shape scanning cabin, and starting the scanning procedure to perform model scanning; CAD design: performing support frame design on oral cavityscanning data by a CAD design person; 3D support frame printing: a 3D printing center person checks that the designed support frame has a reasonable layout angle and no deformation, and puts printingmaterial titanium powder or cobalt chromium powder into a printing cabin for printing; post treatment: performing sintering stress release after the printing is completed, wherein the stress releasetemperature is 830 DEG C for pure titanium, and is 1,050 DEG C for cobalt chromium alloy, and after the cooling, eliminating an oxide layer on the surface of a casting by a sand blasting machine. Themanufacturing process has the advantages that the material cost and the labor cost are reduced; the rework rate is greatly reduced, so that the movable false tooth support frame is more precise.

Owner:SHANDONG MAIER DENTAL MATERIALS CO LTD

Calcium phosphate coated stents comprising cobalt chromium alloy

InactiveUS20100217377A1Electrolytic inorganic material coatingSurgeryCalcium biphosphateSurface finish

Disclosed herein are medical devices, such as stents, coated with calcium phosphate and processes for making the same. The stent can comprise a cobalt chromium alloy that has been treated to improve surface adhesion to the calcium phosphate and / or improve surface finish properties. A pharmaceutically active agent can be present in the calcium phosphate coating.

Owner:MIV SCI HLDG

Artery medicine elution bracket

InactiveCN101314059AImprove flexibilitySafe for clinical useStentsSurgeryCurve shapeCobalt chromium alloy

The present invention discloses an artery medicament elution bracket, which is a net-shaped hollow tubular body made by processing a cobalt-chromium alloy with laser engraving and electro-polishing cochrome. The bracket comprises more than one annular-wave-shaped supporting bar and connecting rods which are alternately and spirally connected between the supporting bars. The shape of the connecting rod is an array of waves formed by more than one connected sinusoidal waveform unit, and curve-shaped connected bend angles with different radiuses are positioned at the fold positions of wave crests and the wave troughs of the sinusoidal waveform unit. The shape of the connecting rod is an S-shaped sinusoid section connected with a straight line section. The surface of the bracket is covered by a medicament coating. The fold positioned at the wave crests and the wave troughs of the sinusoidal waveform unit adopt curve-shaped bend angles with unequal radiuses so that the blend pressure of the support bars is reduced, the rebound degree is reduced, and the bracket abscission incidence rate due to the insufficient retentivity is reduced. After being pressed and held, the bracket has a passing outer diameter of between 1 and 1.08mm. The possibility and the operability of the bracket are apparently improved.

Owner:万瑞飞鸿(北京)医疗器材有限公司

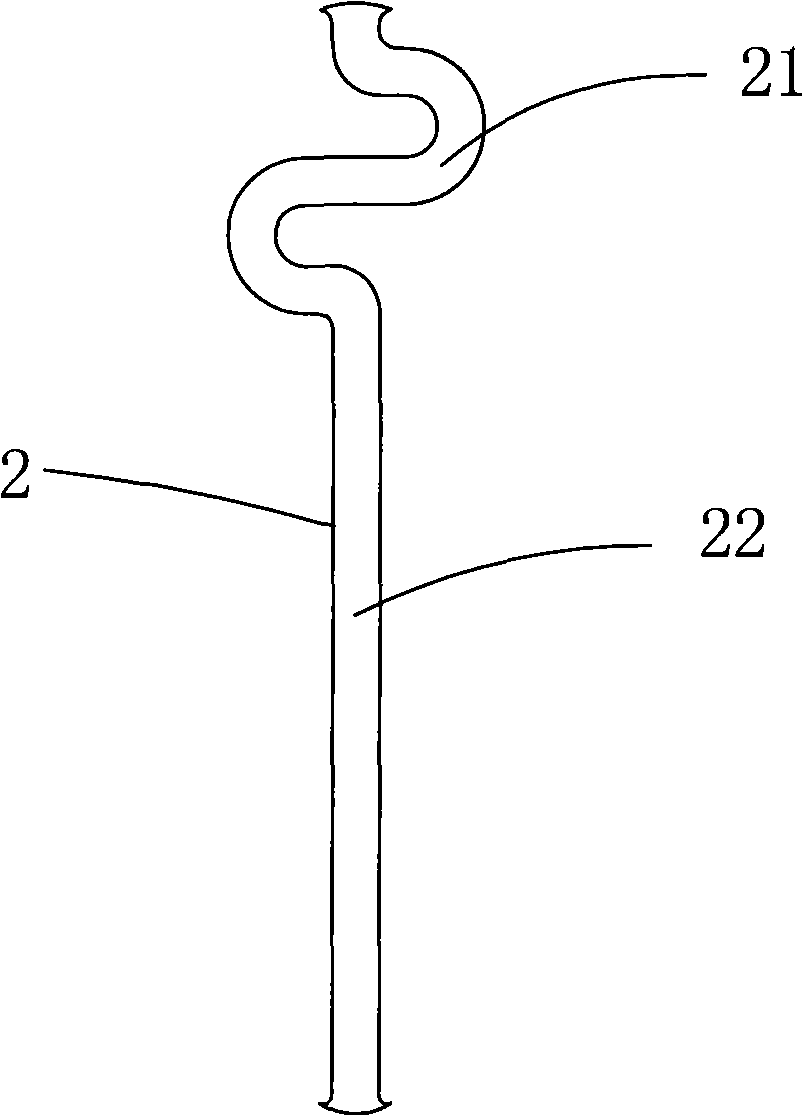

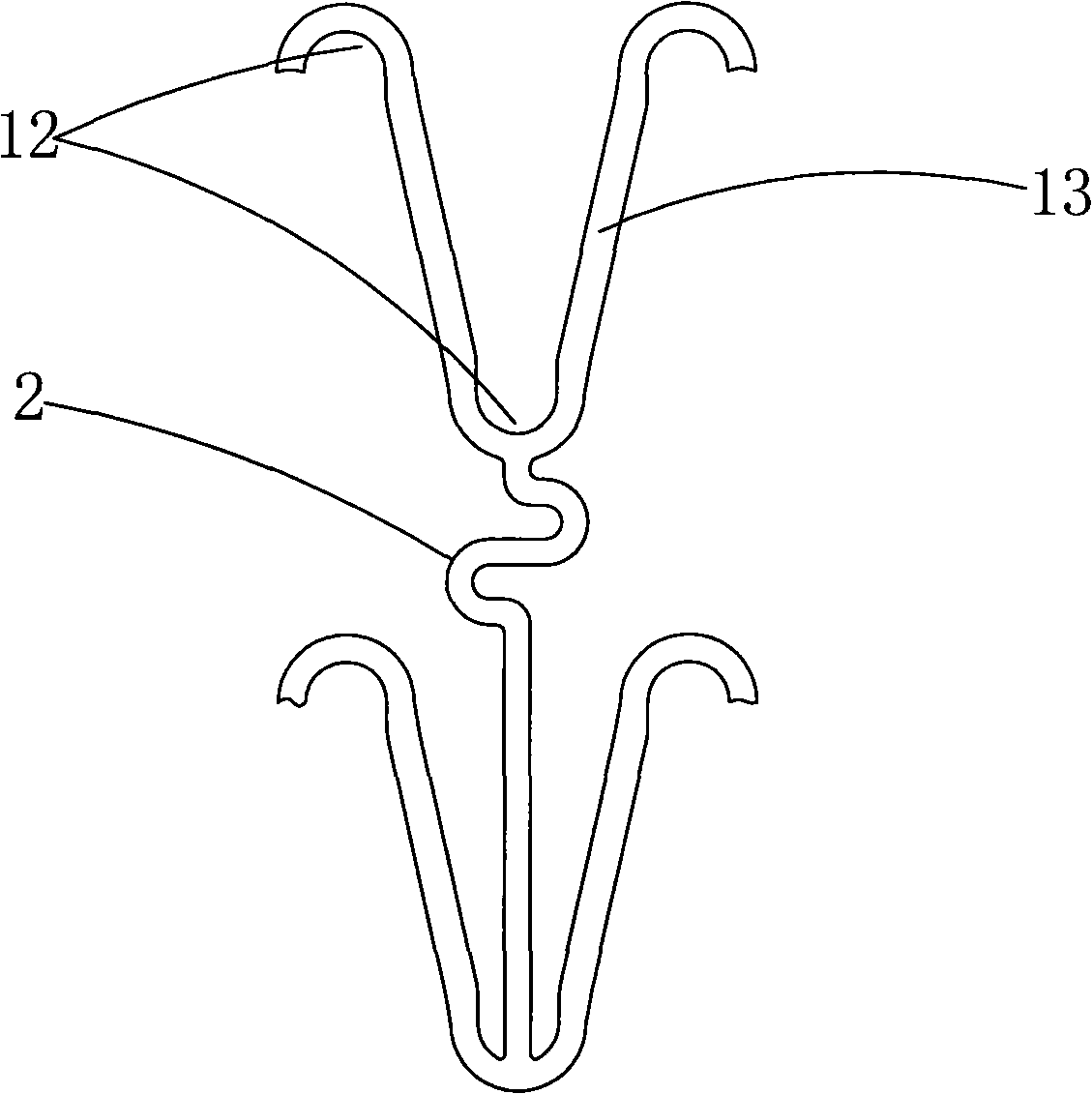

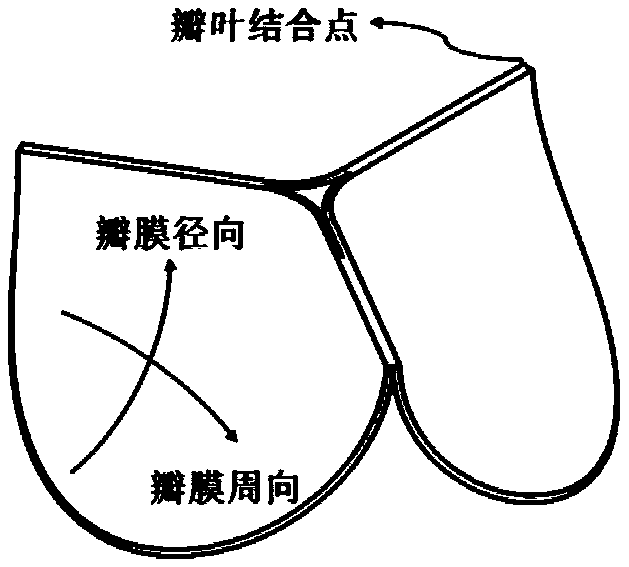

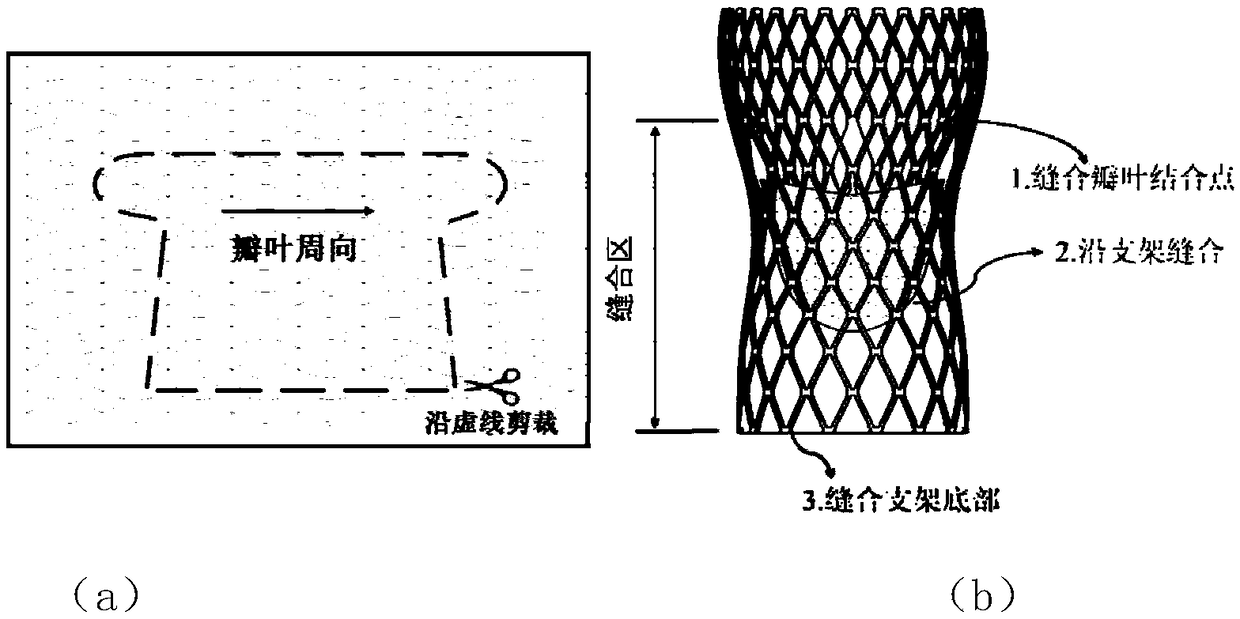

Interventional cardiac valve prosthesis based on polymer fiber composite material and preparation method of interventional cardiac valve prosthesis

InactiveCN108904877AEasy to acceptHigh strengthHeart valvesTissue regenerationPolyesterTitanium alloy

The invention prepares an interventional cardiac valve prosthesis based on anisotropic polymer fiber composite material valve leaflets. Anisotropic polymer fiber cloth is seamed in a metal stent, so that a self-expanded (such as nickle-titanium alloy stent material) or self-expanded (such as cobalt-chromium alloy stent material) interventional valve stent prosthesis is prepared; and photo-crosslinking or chemical crosslinking polyethylene glycol hydrogel covers the surface of the polymer fiber material. The interventional cardiac valve prosthesis provided by the invention, which is prepared from polymer fiber cloth having anisotropic mechanical performance, such as polyester, polyurethane, polytetrafluoroethylene or a composite material thereof, can simulate a stress distribution state ofa human body aortic valve under a blood flow effect, so that mechanical performance, which is similar to that of human body valve, can be achieved, and subsequently, the fatigue resistance of the valve leaflets can be improved. In addition, by combining the polyethylene glycol hydrogel on the surface, the integration of the valve leaflet material is guaranteed, and moreover, an anti-fouling function is achieved; platelet adhesion and protein adsorption can be relieved; and good bio-compatibility can be achieved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

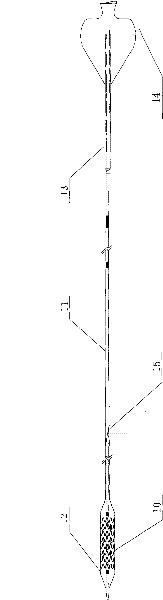

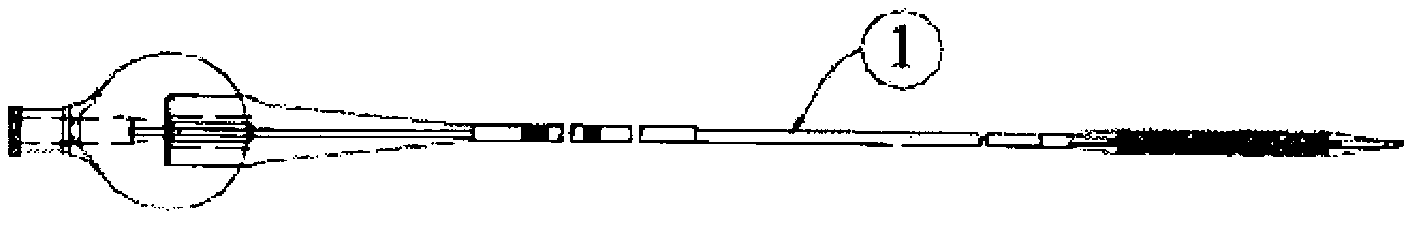

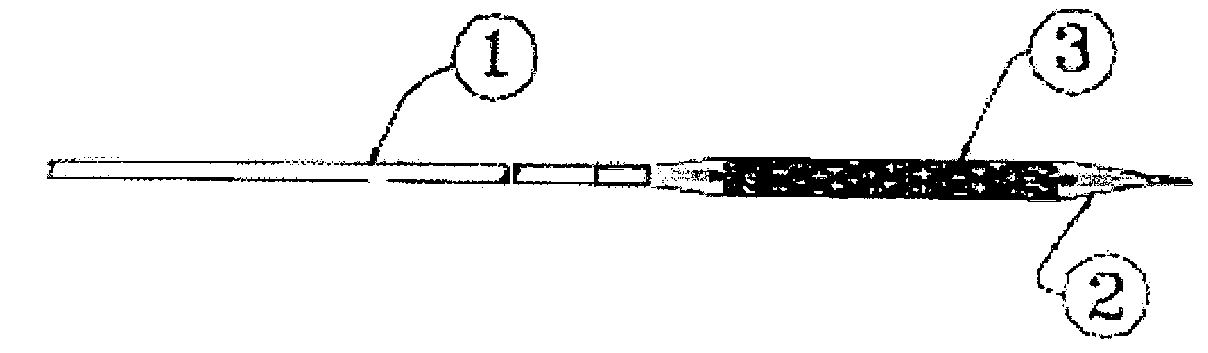

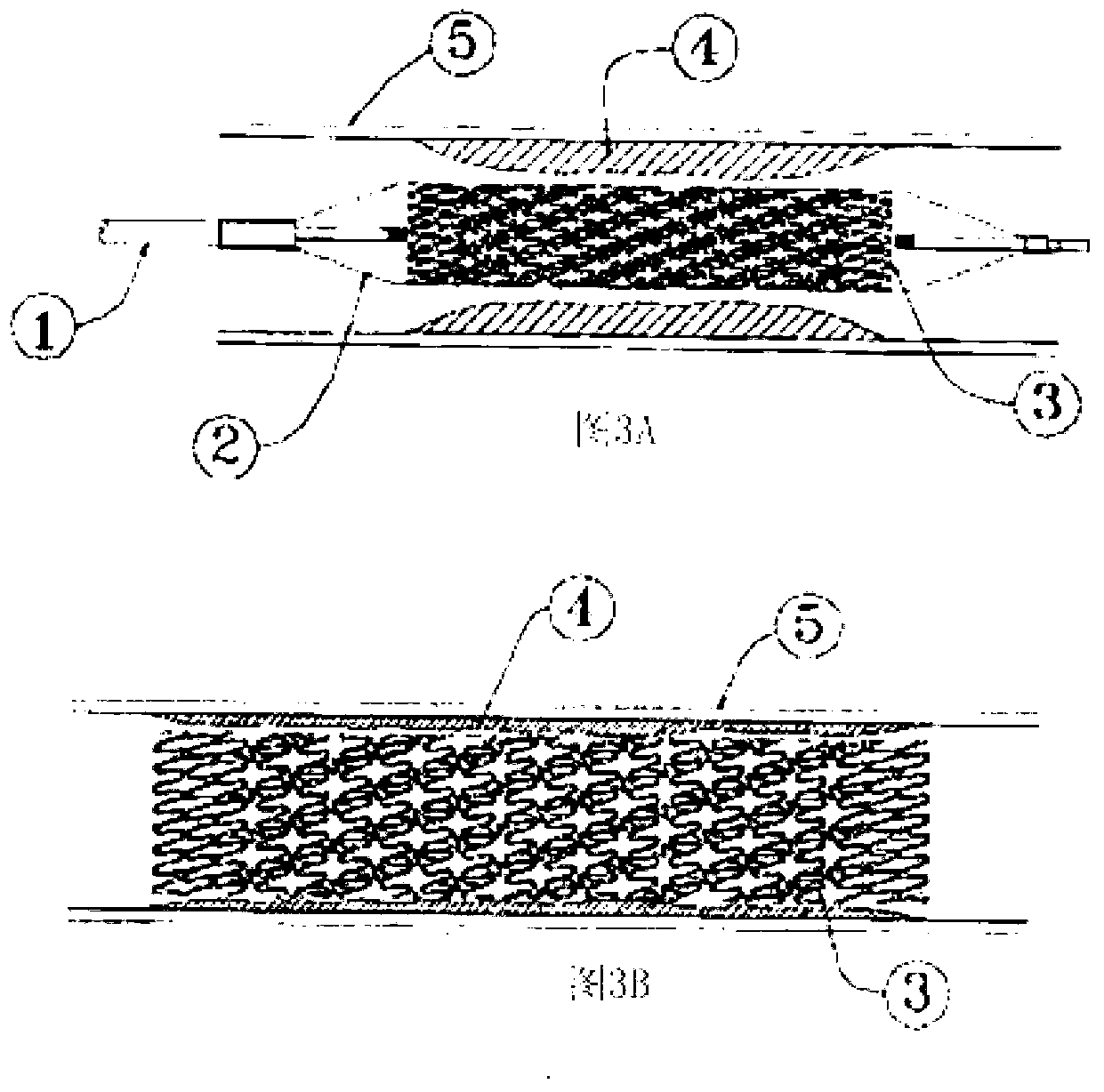

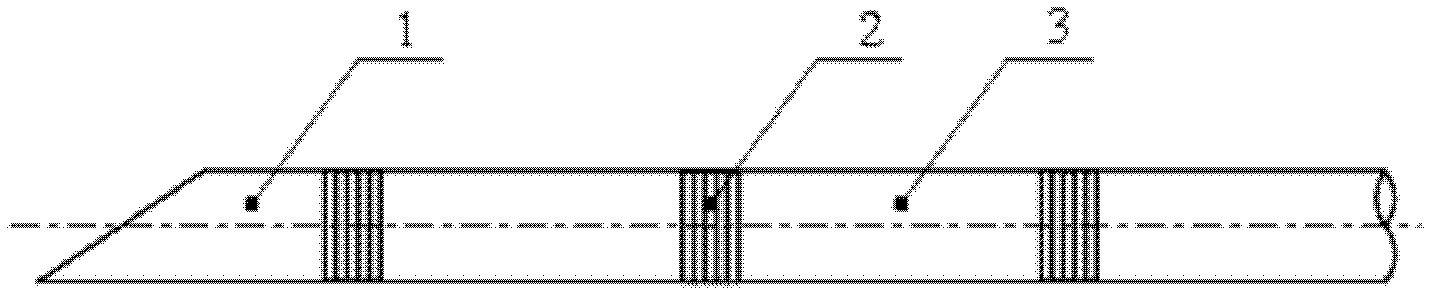

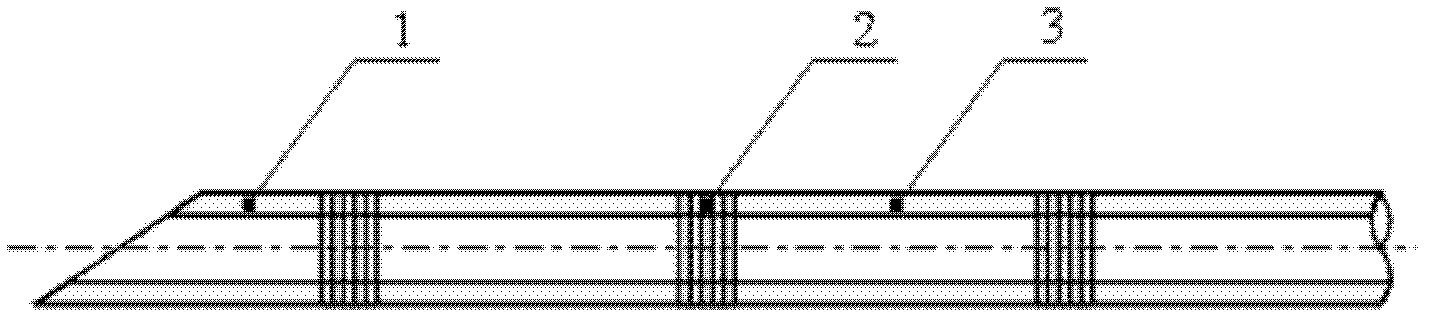

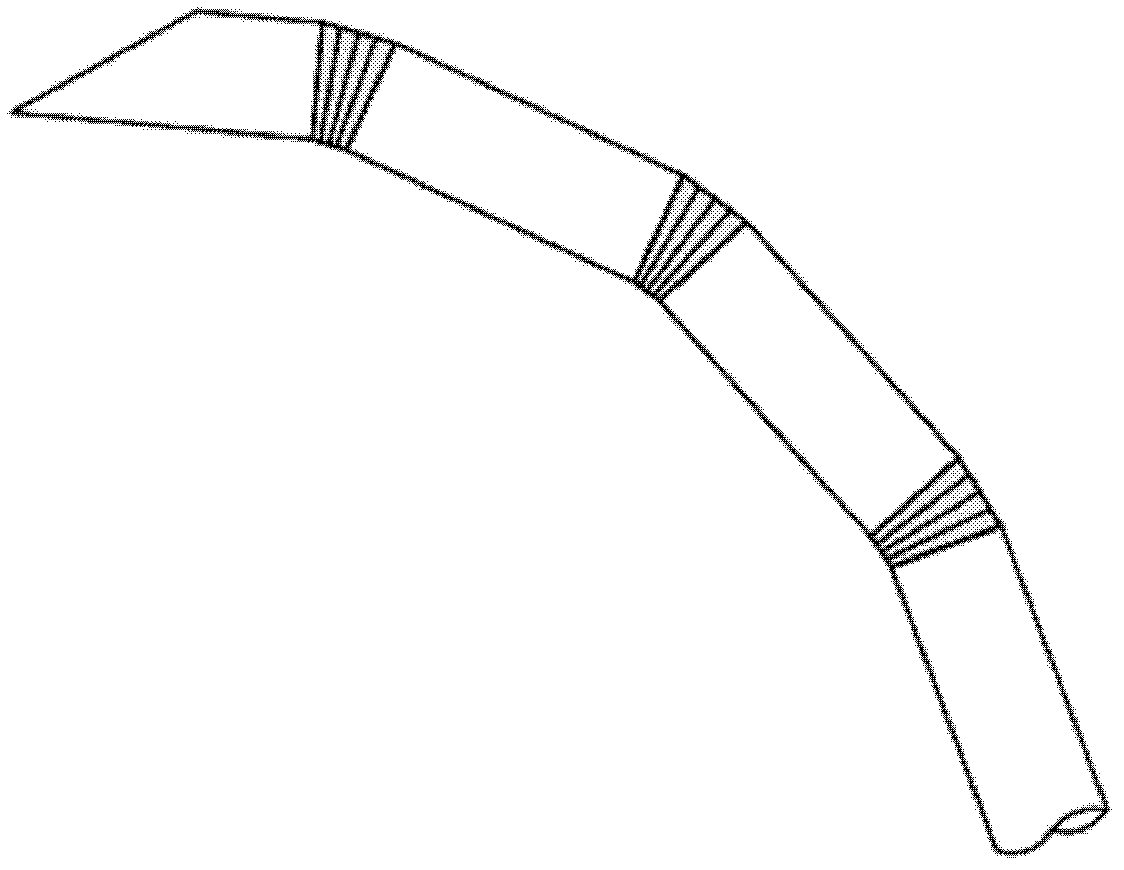

Passive homing type articulated puncture needle

InactiveCN102499738AAvoid performance damageEasy to controlDiagnosticsSurgical needlesEngineeringSurgical department

The invention relates to a passive homing type articulated puncture needle, which comprises a head section and needle sections. A wedged tip is formed at the front end of the head section, the needle sections are coaxially mounted at the back of the head section, the head section and the needle sections are made of stainless steel materials, the head section and the needle sections coaxially mounted at the back of the head section are connected by a flexible articulation, and the needle sections are also connected coaxially by flexible articulations. The flexible articulations are coils made of cobalt-chromium alloy by laser melting, two ends of each flexible articulation made of cobalt-chromium alloy are coaxially fixedly mounted with the needle sections and the head section in a jointing manner, the head section and the needle section can be bent, but flexibility of the head section and the needle sections is smaller than that of the flexible articulations. The passive homing type articulated puncture needle is capable of realizing accurately homing and controlling puncture path and position of the puncture needle when the puncture needle is used for non-straight puncture in thehuman body to reach the focus where the other types of puncture needles are hard to reach, so that the applicable range of minimally invasive surgery is expanded, Iatrogenic injury is reduced and patients are benefited.

Owner:TIANJIN UNIV OF SCI & TECH

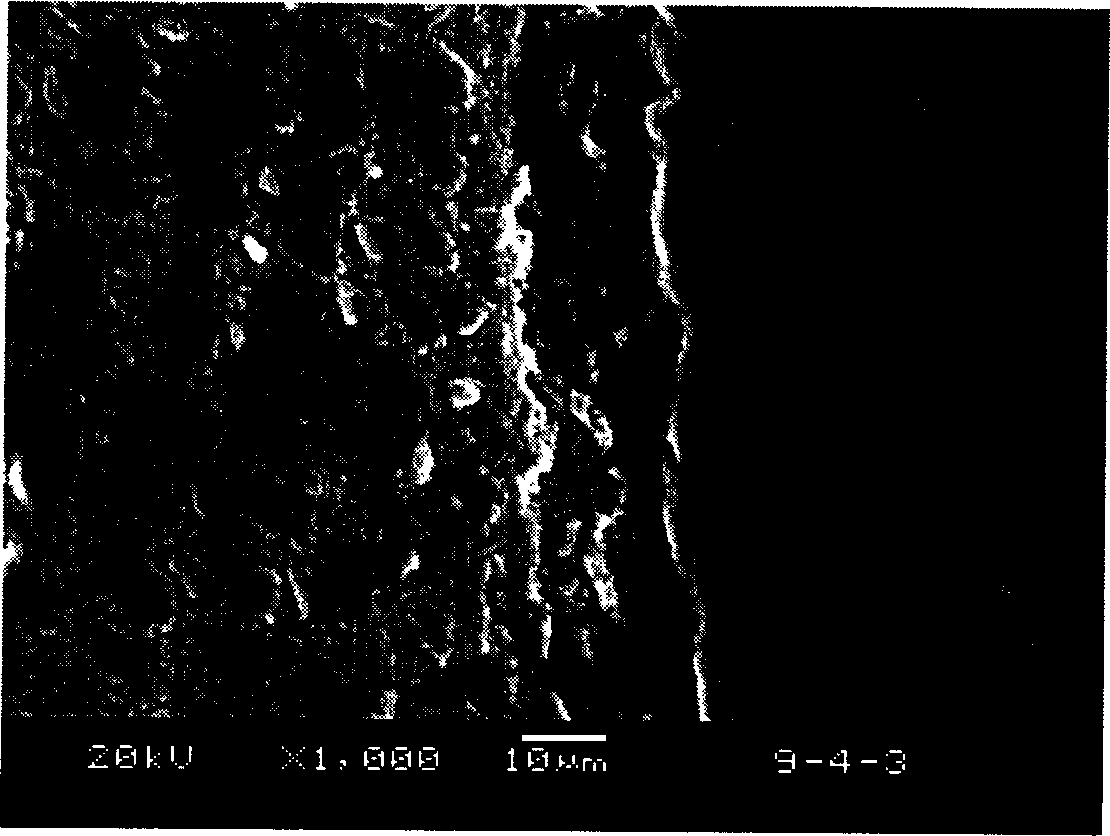

Electrophoresis deposition-laser cladding composite processing method for cobalt-chromium baked porcelain false tooth

ActiveCN106149030ANo emissionsEasy to produceElectrophoretic coatingsMetallic material coating processesElectrophoresisCobalt

The invention discloses an electrophoresis deposition-laser cladding composite processing method for a cobalt-chromium baked porcelain false tooth. The method includes the steps that electrophoresis is firstly adopted for depositing a porcelain layer on the surface of a dentistry cobalt-chromium alloy substrate material, and then laser cladding is adopted for cladding the porcelain layer; and the cobalt-chromium baked porcelain false tooth is manufactured. According to the method, the defects that processing of the baked porcelain false tooth excessively depends on manual coating, and repeatability is poor can be overcome, and the method is widely applied to the processing process of the cobalt-chromium baked porcelain false tooth.

Owner:CHINA UNIV OF MINING & TECH

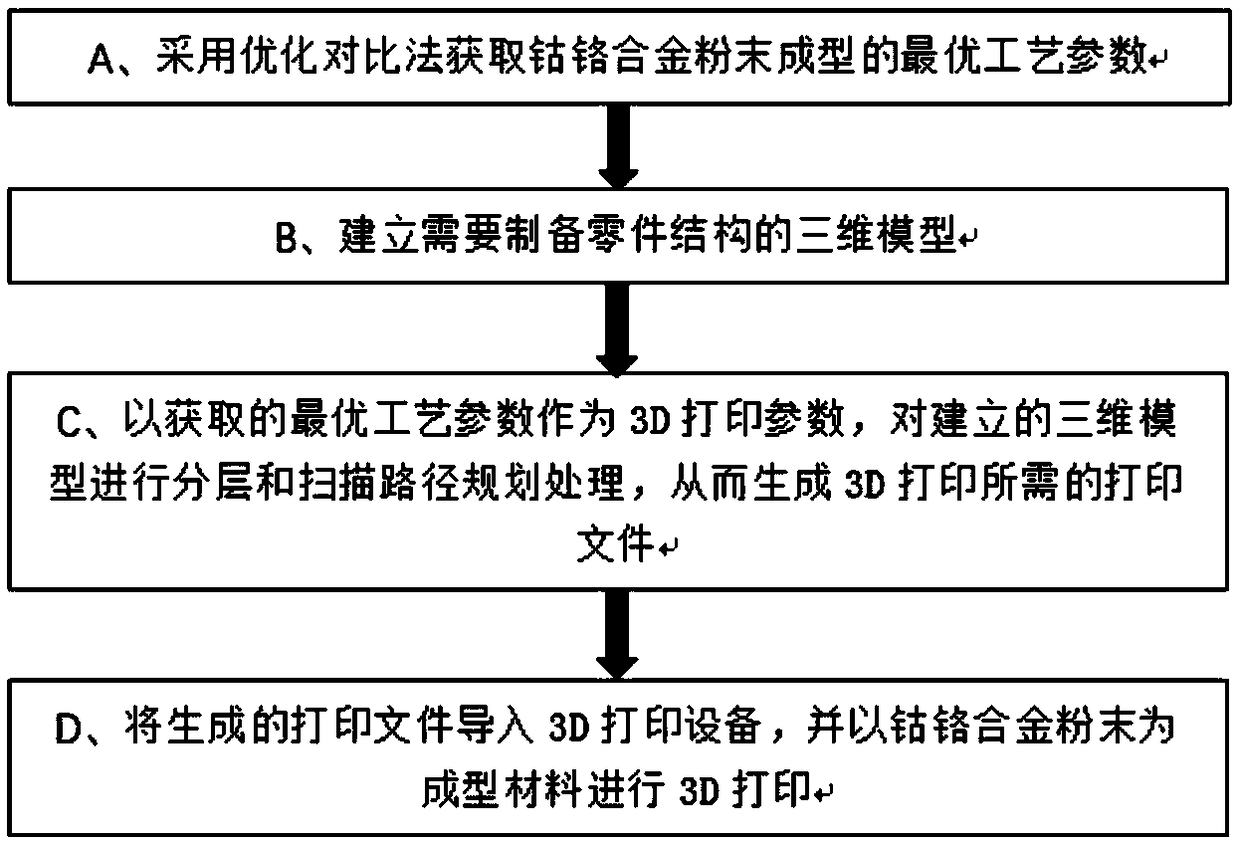

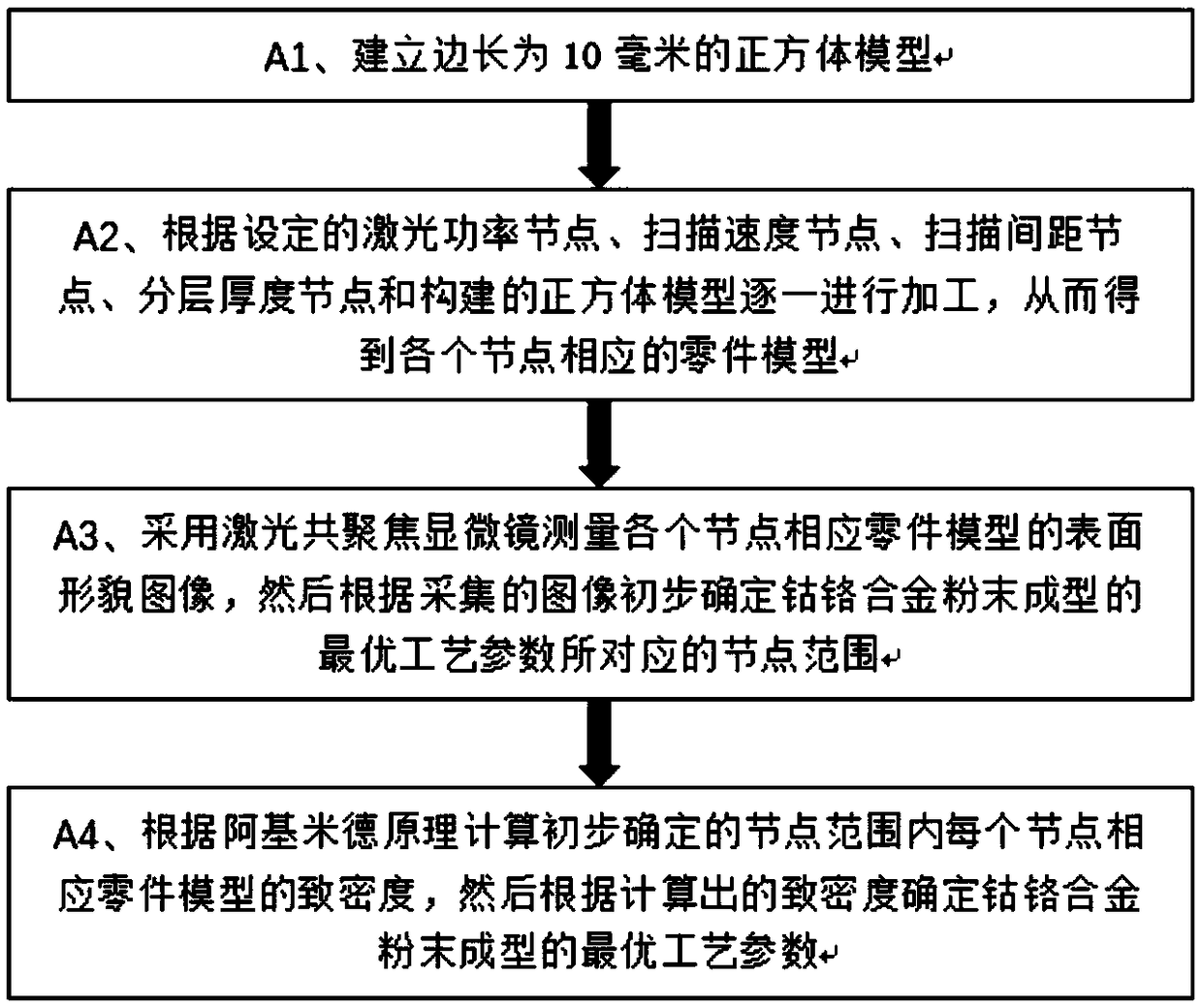

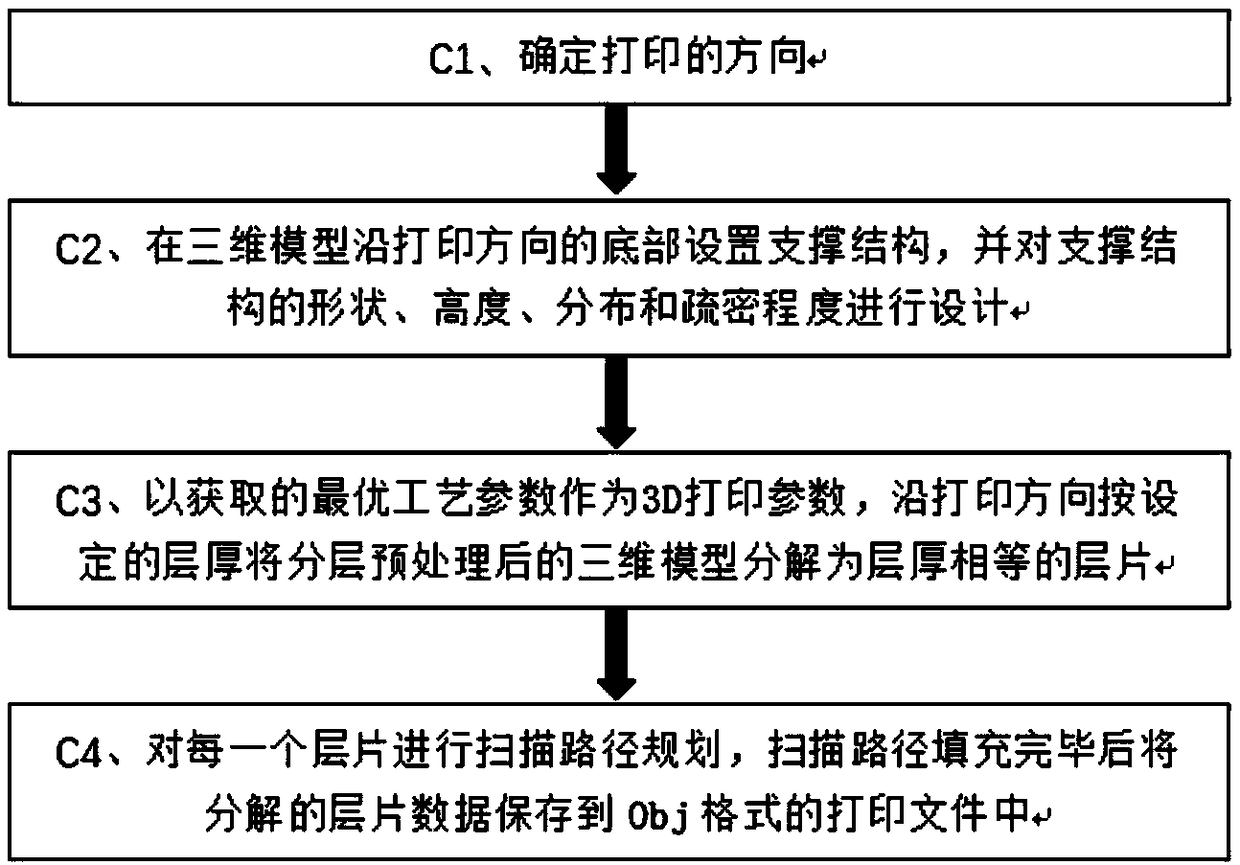

Cobalt-chromium alloy powder forming method based on selective laser melting

InactiveCN108772562AMade preciselyHigh precisionAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingSelective laser sintering

The invention discloses a cobalt-chromium alloy powder forming method based on selective laser melting. The method comprises following steps: using optimized contrast method to obtain the optimal process parameters for cobalt-chromium alloy powder molding; then, establishing 3D models of part structures that need to be prepared; then, using the obtained optimal process parameters as 3D printing parameters, performing layering and scanned path planning processing on the established 3D model to generate print files required for 3D printing; then importing the generated print files into a 3D printing device, and the cobalt-chromium powder is used as the molding material for 3D printing. The invention is based on the selective laser melting technology, and can accurately manufacture metal parts of various complicated structures according to actual requirements. The optimal process parameters of cobalt-chromium powder molding are obtained by optimized contrast method, and different optimalprocess parameters can be set according to the actual mechanical properties required, with high flexibility and good dynamic performance.

Owner:SHANGHAI UNIV

Perpendicular magnetic recording medium and magnetic storage apparatus using the same

ActiveUS7701667B2Reduce noiseImprove recording densityRecord information storageDisk carriersLow noiseMagnetic storage

Embodiments in accordance with the present invention provide a perpendicular recording medium with low noise and high recording density by reducing the effects from noise generated from the vicinity of the interface with the intermediate layer of the recording layer, in a perpendicular recording medium utilizing a granular recording layer containing oxygen or oxide additive in a cobalt-chromium alloy formed on an intermediate layer with a ruthenium or ruthenium alloy layer. A first recording layer and a second recording layer are formed in order on an intermediate layer of ruthenium or ruthenium alloy. The first recording layer and the second recording layer are comprised of cobalt as the main material in a granular structure containing chromium and oxygen. The saturation magnetization of the first recording layer is lower than the saturation magnetization of the second recording layer. When a first recording layer saturation magnetization is set as Ms1(emu per cubic centimeter), a second recording layer saturation magnetization is set as Ms2(emu per cubic centimeter), and the first recording layer film thickness is set to t1 (nm), then (Ms2−Ms1)×t1 will be larger than 0 (memu per square centimeter) and smaller than 0.15 (memu per square centimeter).

Owner:WESTERN DIGITAL TECH INC

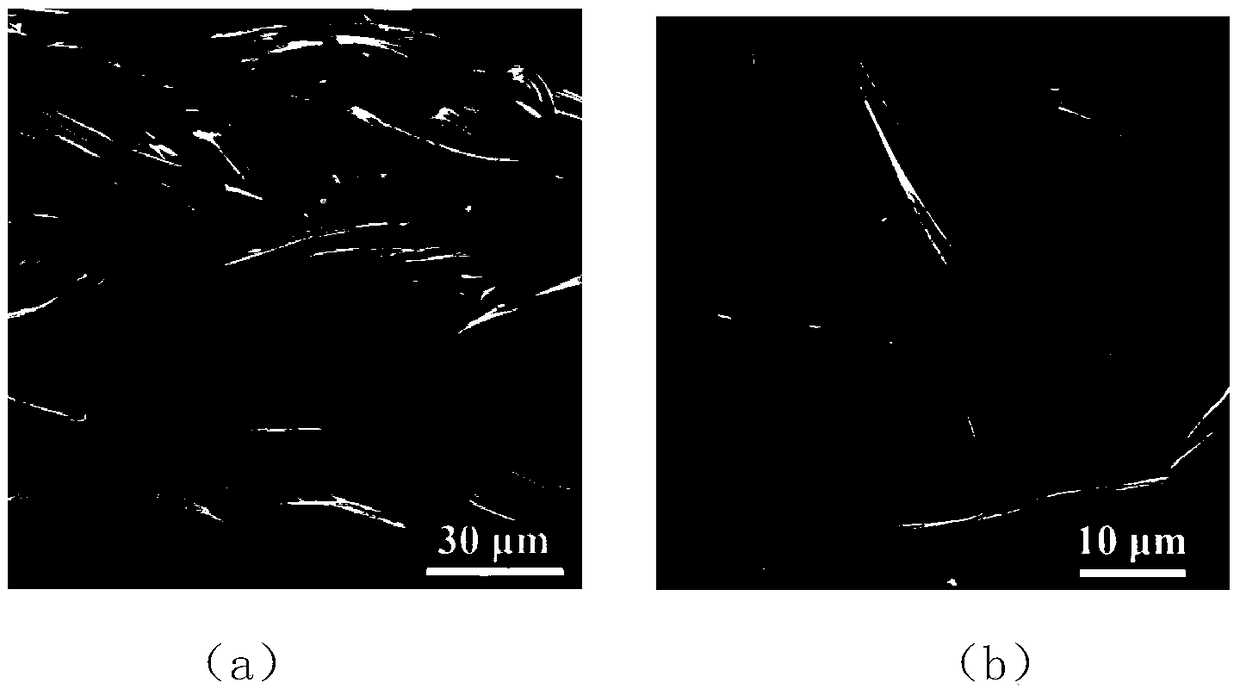

Method for preparing 3D printing cobalt-based ceramic composite powder for dental department

ActiveCN107309423ASmall particle sizeHigh bonding strengthAdditive manufacturing apparatusTransportation and packagingCeramic compositeThermal expansion

The invention discloses a method for preparing 3D printing cobalt-based ceramic composite powder for a dental department. The method comprises the steps that medical cobalt-chromium alloy powder is added to aluminum sol according to the requirement that the mass ratio of Al2O3 to a medical cobalt-chromium alloy is (0.05-0.2): 1, and the mixture is dispersed uniformly, so that gel is obtained; then, the gel is dried, so that an AlOOH-clad cobalt-chromium alloy precursor is obtained; the precursor is calcinated at the temperature of 400-500 DEG C, so that a cobalt-based ceramic composite powder raw material of an Al2O3-clad cobalt-chromium alloy is obtained; and after ball milling and vacuum drying are conducted on the obtained cobalt-based ceramic composite powder raw material, screening is conducted, so that the cobalt-based ceramic composite powder with the particle diameter ranging from 20 microns to 55 microns is obtained. By means of the composite powder prepared through the method, in the 3D printing laser fusion process, a ceramic phase is high in bonding strength when being bonded with a metallic matrix interface and good in wettability; and a prepared 3D printing molding part is low in thermal expansion coefficient and good in tensile property.

Owner:ZHONGBEI UNIV

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com