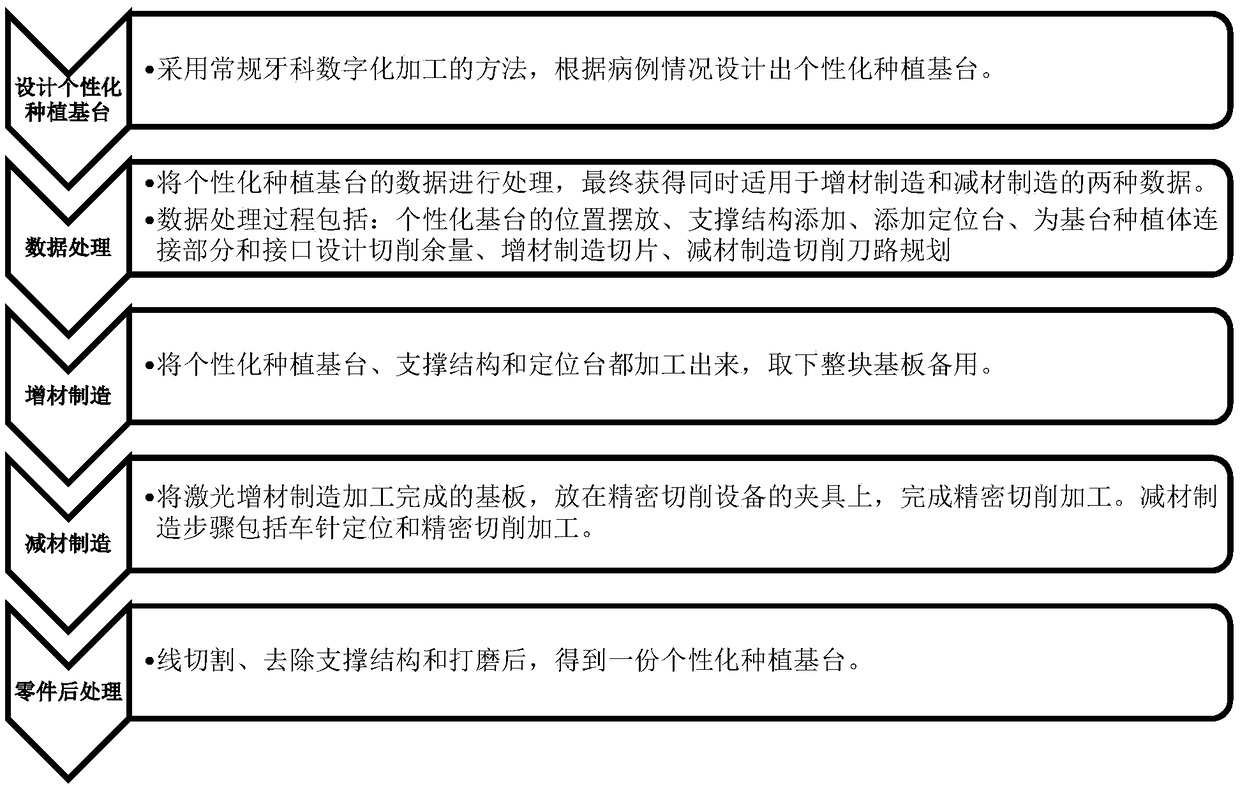

Additive and subtractive compound processing and molding method of individualized dental implanting abutment

A composite processing and forming method technology, applied in the field of additive manufacturing and additive manufacturing of dental implants, can solve the problems of low precision, large thermal stress, and affecting the accuracy of the interface, achieve high precision and mechanical properties, and be easy to cut and process , the effect of a wide range of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

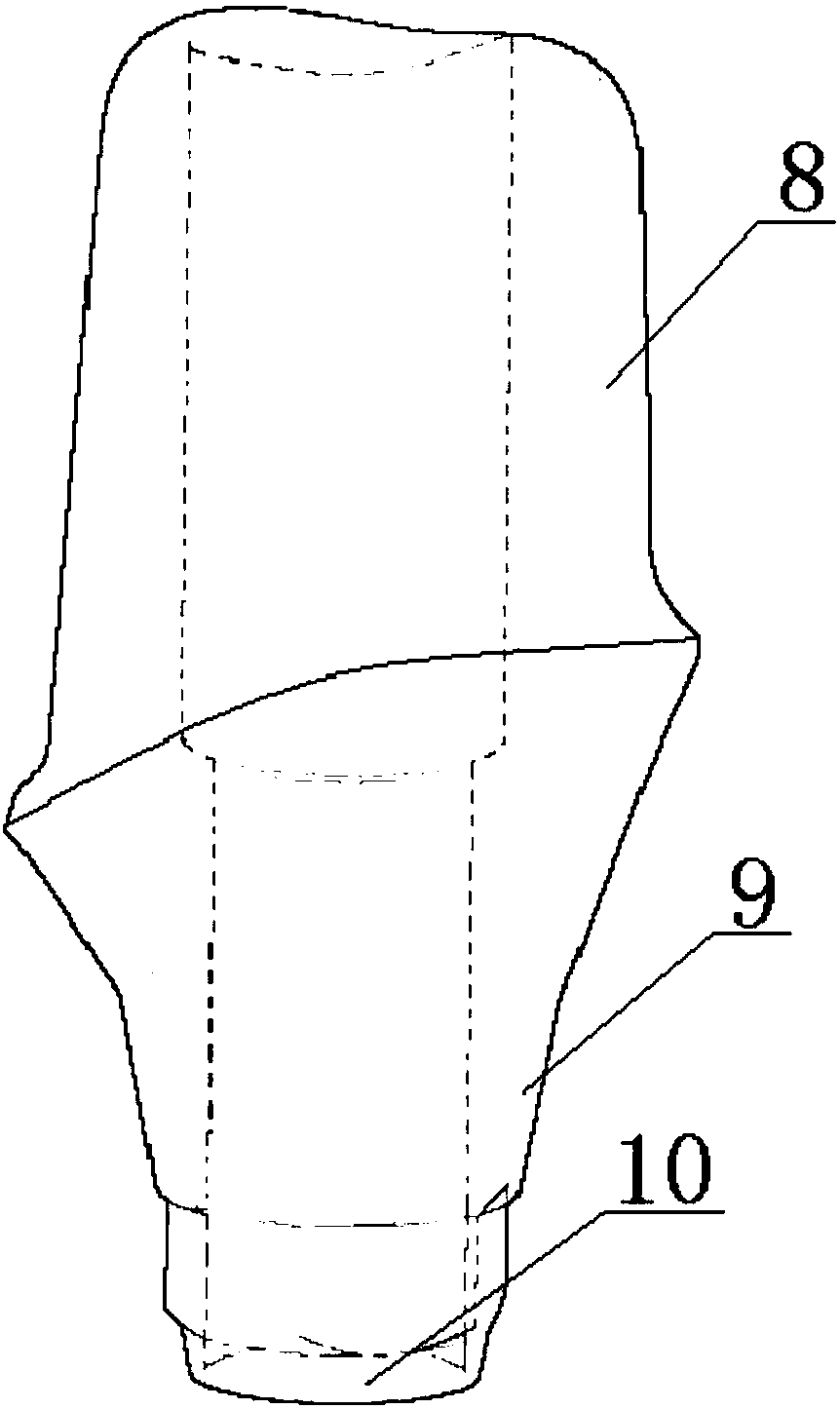

[0074] There are many types of additive manufacturing, such as laser three-dimensional printing technology based on polymer polymerization, polymer printing technology, micro three-dimensional printing, etc., selective laser sintering technology based on sintering and melting, laser selection Melting technology, electron beam melting technology and so on. Combined with the selection of corresponding materials, it can be used to print personalized implant abutments. However, as a preferred method, the present invention uses laser selective melting technology for additive manufacturing, and adopts a checkerboard partition scanning strategy. The specific embodiments are as follows:

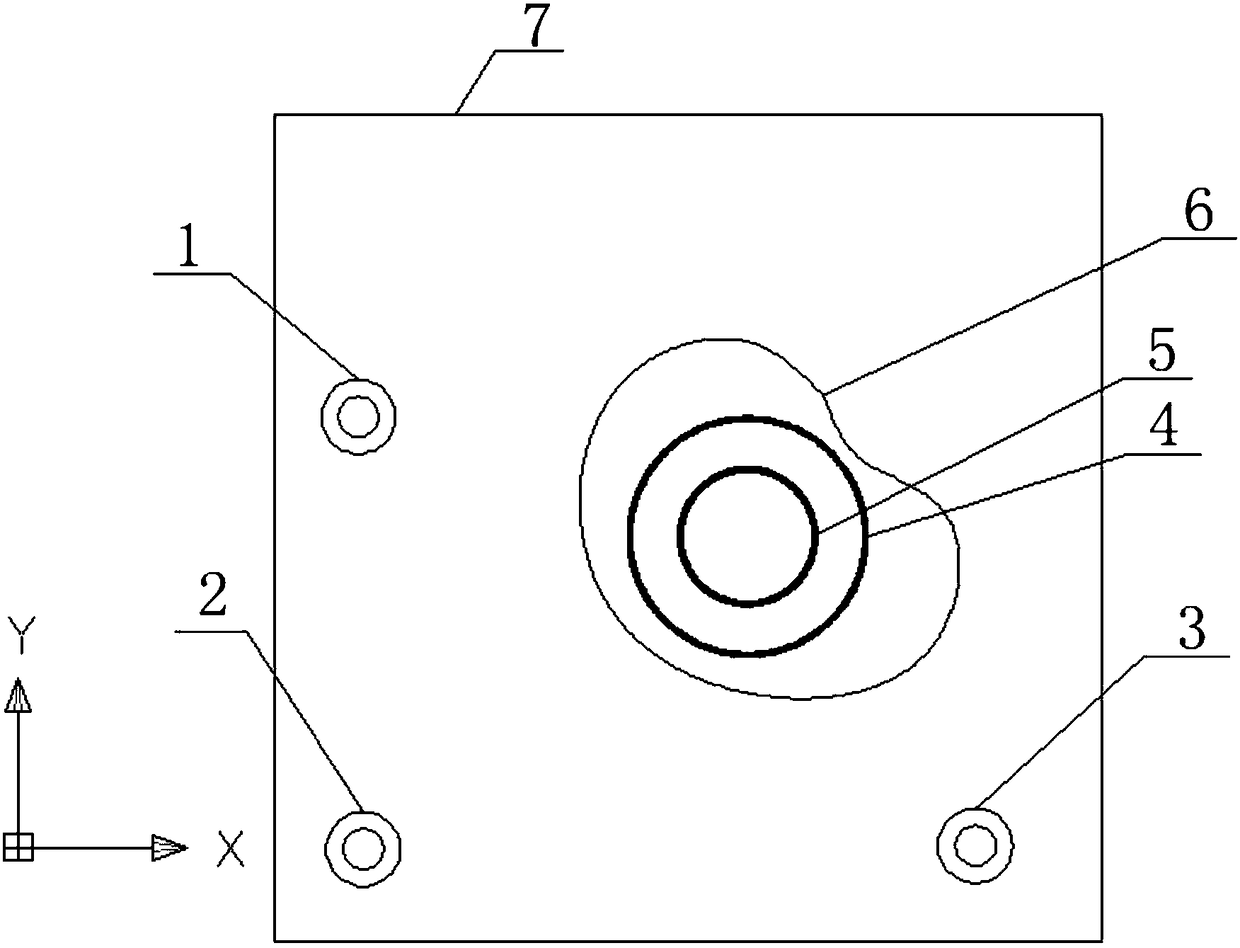

[0075] During data processing, after the semi-finished abutment 6 is designed, the semi-finished abutment 6 is subjected to slice design for additive manufacturing, and the thickness of each layer is 0.02-0.03mm.

[0076] During additive manufacturing, the metal 3D printing equipment that uses laser...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com