Interventional cardiac valve prosthesis based on polymer fiber composite material and preparation method of interventional cardiac valve prosthesis

A technology of artificial heart valves and polymer fibers, applied in heart valves, coatings, medical science, etc., to achieve good hydrodynamic performance, improve radial compliance, and reduce protein and platelet adhesion effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Raw materials and requirements: polyethylene terephthalate / polyamide 6 composite polymer fiber material, polyethylene glycol, acryloyl chloride, PBS solution, ethanol, ultrapure water (chemical reagents are all analytical grade).

[0036] PEGDA synthesis: Polyethylene glycol diacrylate (PEGDA) is prepared by reacting polyethylene glycol (PEG) with acryloyl chloride;

[0037] A nickel-titanium alloy thin-walled tube with an outer diameter of 7 mm and a wall thickness of 0.5 mm was laser-engraved, heat-treated, shaped, and polished to prepare a self-expanding stent with a bottom diameter of 23 mm;

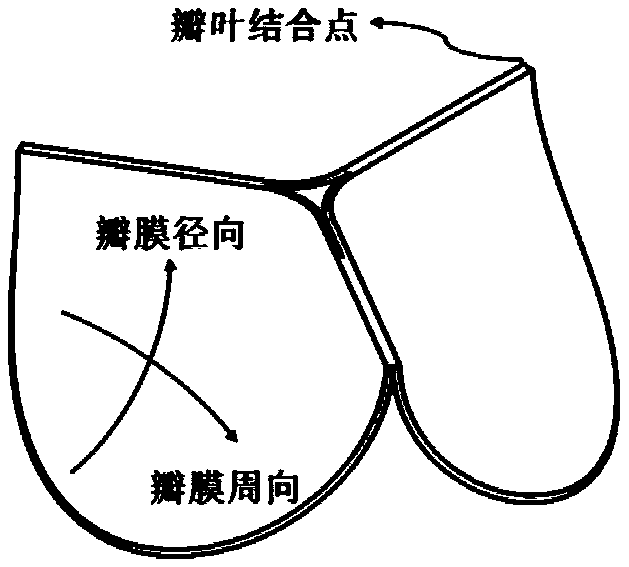

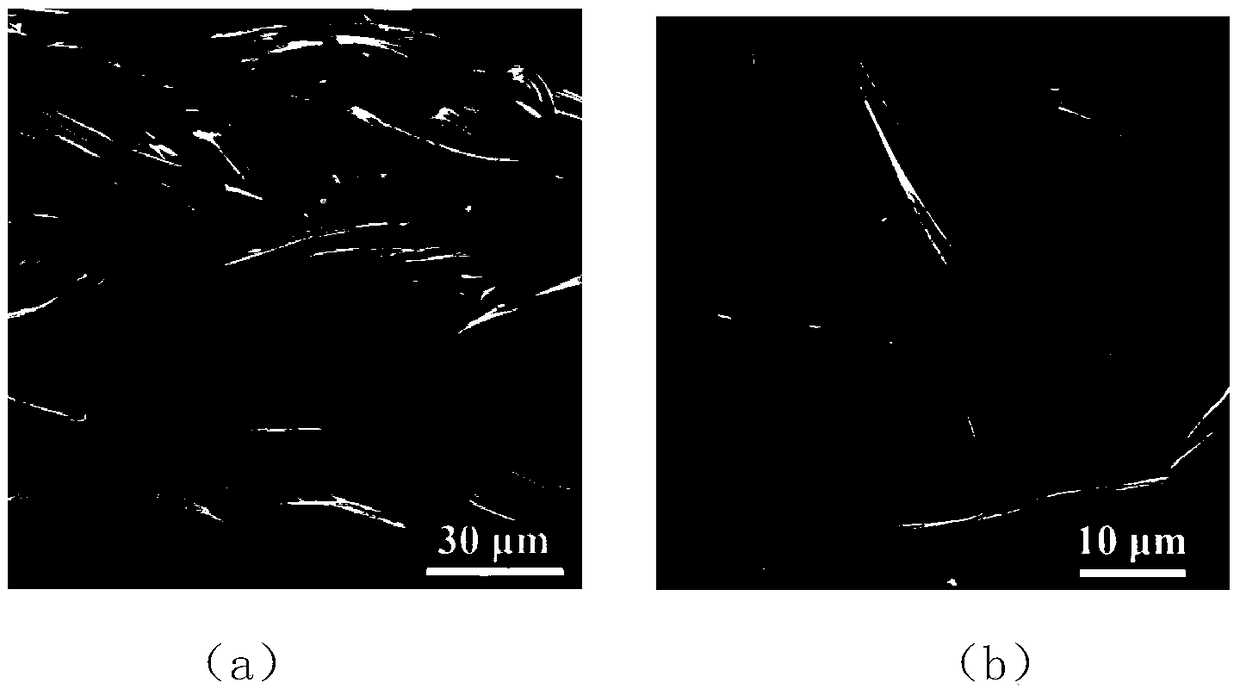

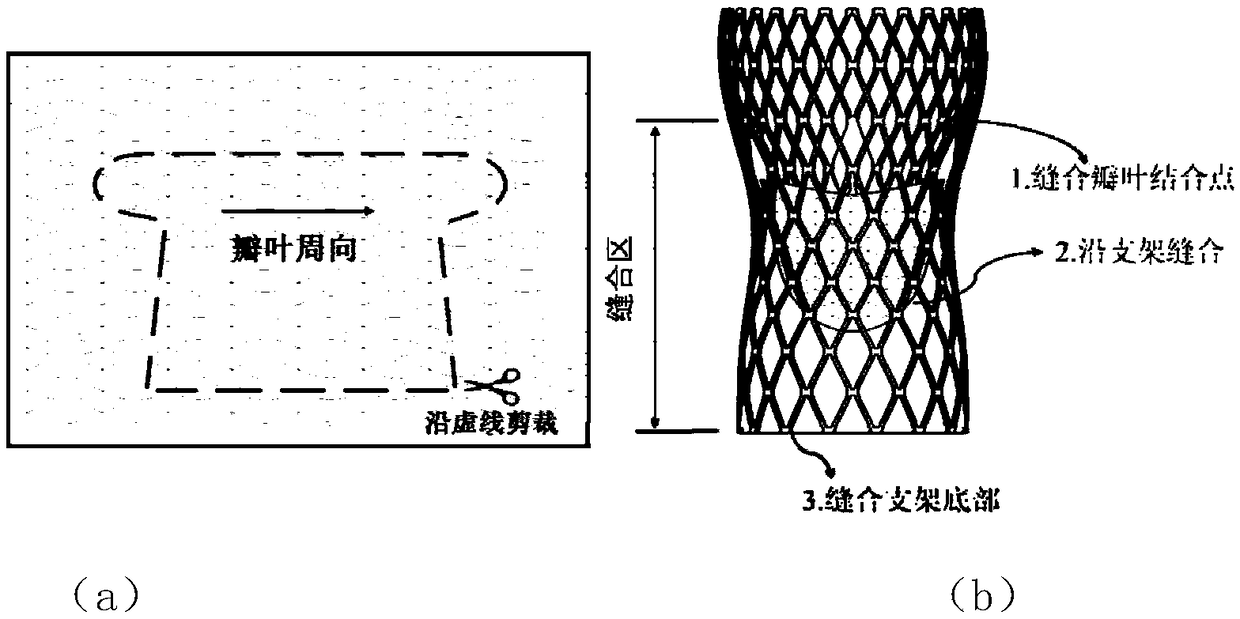

[0038] Cutting of polymer fiber material: According to the shape and size of the metal bracket, the polyethylene terephthalate / polyamide 6 composite polymer fiber cloth is cut into such image 3 (a) The shape shown; the polymer fiber cloth is made of directional weaving of polyethylene terephthalate / polyamide 6 composite polymer fiber bundles ( figure 2 (a)); the weaving met...

Embodiment 2

[0047] In this example, a self-expanding interventional valve prosthesis with a stent bottom diameter of 25 mm was prepared. A nickel-titanium alloy thin-walled tube with a diameter of 7 mm was laser-engraved, then heat-treated, shaped, and polished to prepare a self-expanding stent. The bottom diameter of the stent was 25 mm, and the rest were the same as in Example 1.

[0048] The various performance tests of the valve prosthesis prepared in this example are basically the same as those in Example 1.

Embodiment 3

[0050] In this example, a self-expanding interventional valve prosthesis with a diameter of 23 mm at the bottom of the stent was prepared using polyurethane fiber material. Cut the polyurethane fiber material into a suitable shape and sew it inside the metal bracket, and the rest are the same as in Example 1.

[0051] The various performance tests of the valve prosthesis prepared in this example are basically the same as those in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| storage modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com