Method for processing lactic acid bacteria fermentation rice-flour noodles

A technology of lactic acid bacteria fermentation and processing method, applied in the field of food processing, can solve the problems of lack of clear key control indicators of rice raw materials, inability to ensure the hygienic quality of finished rice noodles, unclear names of fermentation microorganisms, etc., so as to inhibit harmful bacteria pollution and shorten production cycle. , the effect of preventing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

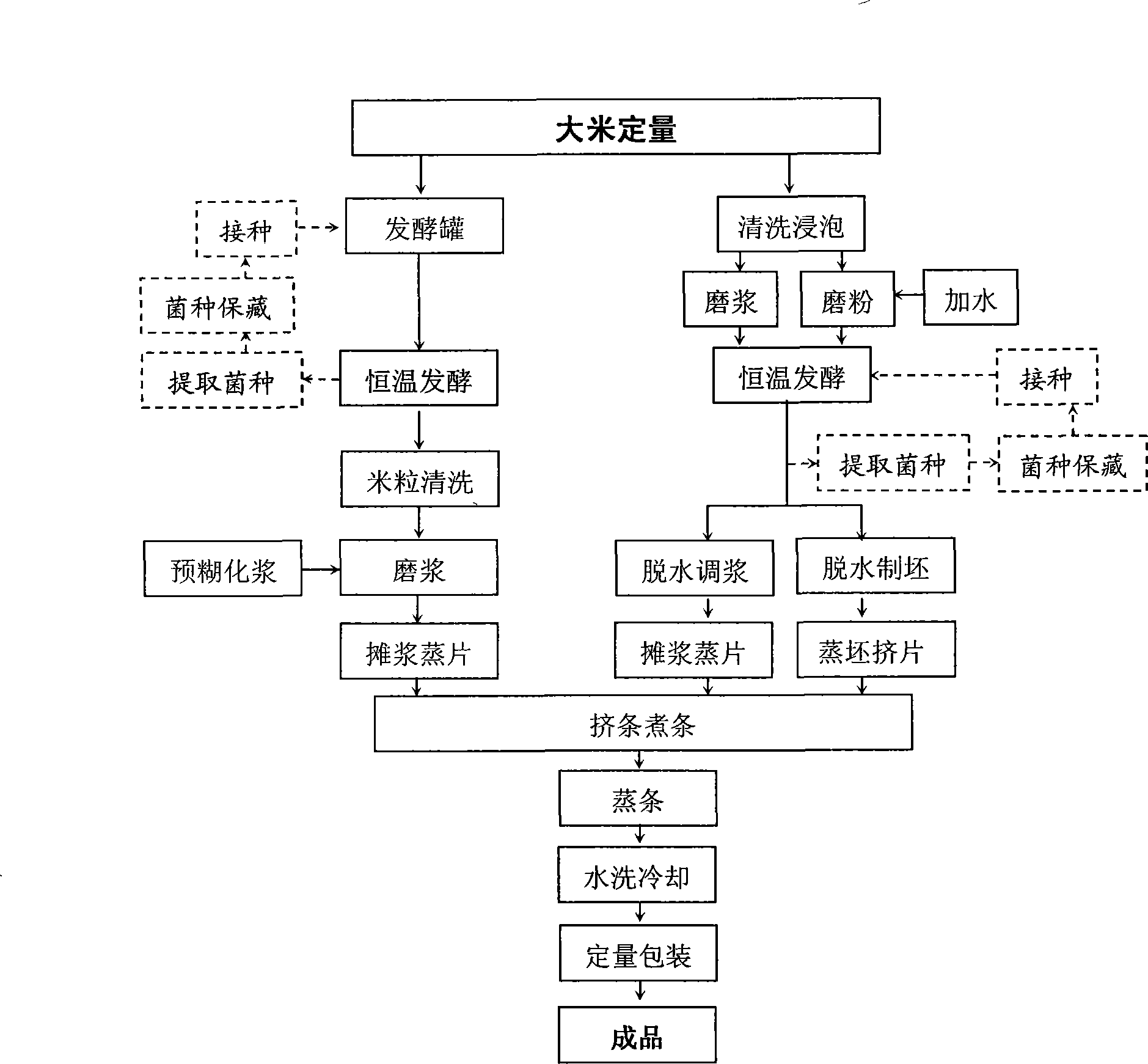

[0027] Embodiment 1: rice grain lactic acid bacteria fermentation method

[0028] Lactobacillus plantarum, Lactobacillus cellobiosus, Lactobacillus curvatus, Lactobacillus fermentum, Lactobacillusacidophilus, Lactobacillus delbruckii. Seed Preservation Management Center), activated with MRS liquid medium to make seed liquid. The seed liquid is expanded and cultivated in 5% to 15% skim milk (no antibiotics are required), and it is made to contain 10 bacteria. 9 ~10 11 The cfu / ml lactic acid bacteria suspension is ready for use. It is also possible to expand the seed solution in the lactic acid bacteria proliferation factor composed of 2% to 4% wort juice, 5% to 7% carrot juice, 1% to 2% peptone water, and 1% to 3% potato juice to cultivate.

[0029] Put the indica rice (amylose content greater than 20%) that has been stored for more than half a year in a fermentation tank or a fermentation tank, and add 2 times the volume of lactic acid bacteria containing 10 6 ~10 9 cfu / ...

Embodiment 2

[0030] Embodiment 2: Rice Milk Lactic Acid Bacteria Fermentation Production Method

[0031] Wash the indica rice raw material with an amylose content greater than 20% for 10 to 15 minutes, let it stand for 2 to 5 hours, add 1 to 2 times of water to refine, and require the particle size to reach more than 100 mesh sieve. Gained rice milk is placed in a fermenter, and lactic acid bacteria are added to make the rice milk contain lactic acid bacteria with a count of 10 6 ~10 9 cfu / ml (the preparation method of the lactic acid bacteria strain is the same as in Example 1), stir evenly, and leave to ferment at 30-50° C. for 8-12 hours. The fermented rice milk is dehydrated by pressure filtration, and the powder base is adjusted to 60% to 65% rice milk by adding water, spread on a canvas conveyor belt to form a 2.0mm thick slurry layer, and steamed at 100°C for 6 minutes to form powder flakes. Gained powder sheet enters screw extruder again and is extruded into the vermicelli of dia...

Embodiment 3

[0032] Embodiment 3: Utilize the fermented liquid in the production process to extract bacterial classification and carry out production

[0033] The fermented liquid in the constant temperature fermentation stage in Example 1 or 2 is collected, add 5%~15% skimmed milk powder (not to have antibiotics) and other lactic acid bacteria proliferation factors, cultivate at 30~50°C to make the number of bacteria reach 10 9 ~10 11 cfu / ml, the obtained strains are directly used for production inoculation; or the bacterial suspension is centrifuged, and the supernatant is discarded, and the obtained precipitated strains can be dried and stored for a long time.

[0034] In this embodiment, only the strain source is different, and other processes are the same as in embodiment 1 or embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com