Method for preparing 3D printing cobalt-based ceramic composite powder for dental department

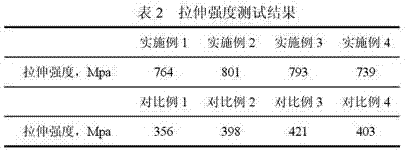

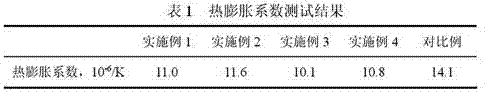

A ceramic composite and 3D printing technology, applied in medical science, metal processing equipment, transportation and packaging, etc., can solve the problems of low interface bonding strength, reduced tensile properties, low density of ceramic components, etc., and achieve good interface wettability. , the effect of tensile strength improvement, low thermal expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Weigh 25.4 g of aluminum isopropoxide (purity >98%) and add it to 500 mL of deionized water, then add 30.7 g of citric acid, heat up to 60 ° C and stir for 1 h, adjust the pH value of the system to 7 with nitric acid or ammonia water, and make the system Transparent without precipitation, then add 2 g of ethylene glycol, and ultrasonically vibrate for 1 hour to obtain aluminum sol.

[0029] Add 100 g of medical cobalt-chromium alloy powder with a particle size of 20-55 μm to the above-mentioned aluminum sol, and ultrasonically vibrate for 30 minutes at 70° C. to obtain a fully dispersed cobalt-chromium alloy gel.

[0030] The above gel was placed in a blast drying oven and dried at 150° C. for 10 h to obtain a fine-grained AlOOH-coated cobalt-chromium alloy precursor.

[0031] The obtained precursor was transferred to a muffle furnace at 450°C for calcination for 4 hours to obtain Al 2 o 3 Cobalt-based ceramic composite powder raw material coated with cobalt-chromium ...

Embodiment 2

[0036] Weigh 15.7 g of aluminum isopropoxide (purity >98%) and add it to 500 mL of deionized water, then add 21.3 g of citric acid, heat up to 80 ° C and stir for 1.2 h for hydrolysis reaction, and adjust the pH value of the system to 7 with nitric acid or ammonia water to make The system was transparent without precipitation, and then 2 g of ethylene glycol was added and ultrasonically oscillated for 1 hour to obtain an aluminum sol.

[0037] Add 100 g of medical cobalt-chromium alloy powder with a particle size of 20-55 μm to the above-mentioned aluminum sol, and ultrasonically vibrate for 30 minutes at 70° C. to obtain a fully dispersed cobalt-chromium alloy gel.

[0038] The above-mentioned gel was placed in a forced air drying oven, and dried at 80°C for 15 hours to obtain a fine-grained AlOOH-coated cobalt-chromium alloy precursor.

[0039] The obtained precursor was transferred to a muffle furnace at 460°C for calcination for 4 hours to obtain Al 2 o 3 Cobalt-based ce...

Embodiment 3

[0044] Weigh 11.3 g of aluminum isopropoxide (purity >98%) and add it to 500 mL of deionized water, then add 16.4 g of citric acid, heat up to 80 ° C and stir for 0.8 h for hydrolysis reaction, and adjust the pH value of the system to 7 with nitric acid or ammonia water to make The system was transparent without precipitation, and then 2 g of ethylene glycol was added and ultrasonically oscillated for 1 hour to obtain an aluminum sol.

[0045] Add 100 g of medical cobalt-chromium alloy powder with a particle size of 20-55 μm to the above-mentioned aluminum sol, and ultrasonically vibrate for 30 minutes at 80° C. to obtain a fully dispersed cobalt-chromium alloy gel.

[0046] The above gel was placed in a blast drying oven and dried at 80° C. for 13 hours to obtain a fine-grained AlOOH-coated cobalt-chromium alloy precursor.

[0047] The obtained precursor was transferred to a muffle furnace at 460°C for calcination for 4 hours to obtain Al 2 o 3 Cobalt-based ceramic composit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com