Novel manufacturing process of 3D printing movable false tooth support frame

A technology of 3D printing and removable dentures, applied in the field of 3D printing, can solve the problems of high labor and material costs, high rework rate of removable denture brackets, and many materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

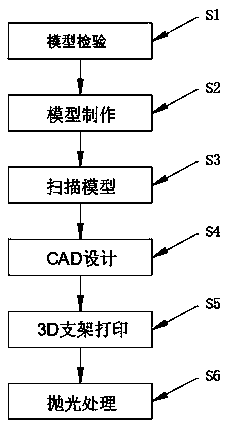

[0026] see Figure 1-2 , the present invention provides a technical solution: a manufacturing process of a novel 3D printed movable denture bracket, comprising the following steps:

[0027] Step S1: Model inspection, check whether the model is intact, whether the accessories are complete, whether the occlusal space is sufficient, whether there is a good common seating path, etc., to ensure that the model meets the production requirements;

[0028] Step S2: Model making, clean the silicone tray with water and dry it with an air gun, adjust the plaster with a vacuum mixer, pour the plaster into the tray, wait for 30 minutes until the plaster is completely solidified, and use a plaster finisher on the bottom of the plaster model Shuhei;

[0029] Step S3: Scan the model, fix the upper and lower bites with wax, put the model into the 3shape scanning chamber, start the scanning program to scan the model;

[0030] Step S4: CAD design, CAD designers design the bracket on the oral sc...

Embodiment 2

[0041] see Figure 1-2 , the present invention provides a technical solution: a manufacturing process of a novel 3D printed movable denture bracket, comprising the following steps:

[0042] Step S1: Model inspection, check whether the model is intact, whether the accessories are complete, whether the edges of the silicone impression and plaster model are clear, whether the occlusal space is sufficient, whether there is a good joint in place, etc., to ensure that the model meets the production requirements;

[0043] Step S2: Model making, after receiving the plaster model and closing the mold;

[0044] Step S3: Scan the model, fix the upper and lower bites with wax, put the model into the 3shape scanning chamber, start the scanning program to scan the model;

[0045] Step S4: CAD design, the CAD designer designs the bracket based on the oral scan data, designs on the model according to the design drawing provided by the doctor and the observation line, and designs the bracket ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com