Patents

Literature

53 results about "Cobalt-chrome" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cobalt-chrome or cobalt-chromium (CoCr) is a metal alloy of cobalt and chromium. Cobalt-chrome has a very high specific strength and is commonly used in gas turbines, dental implants, and orthopedic implants.

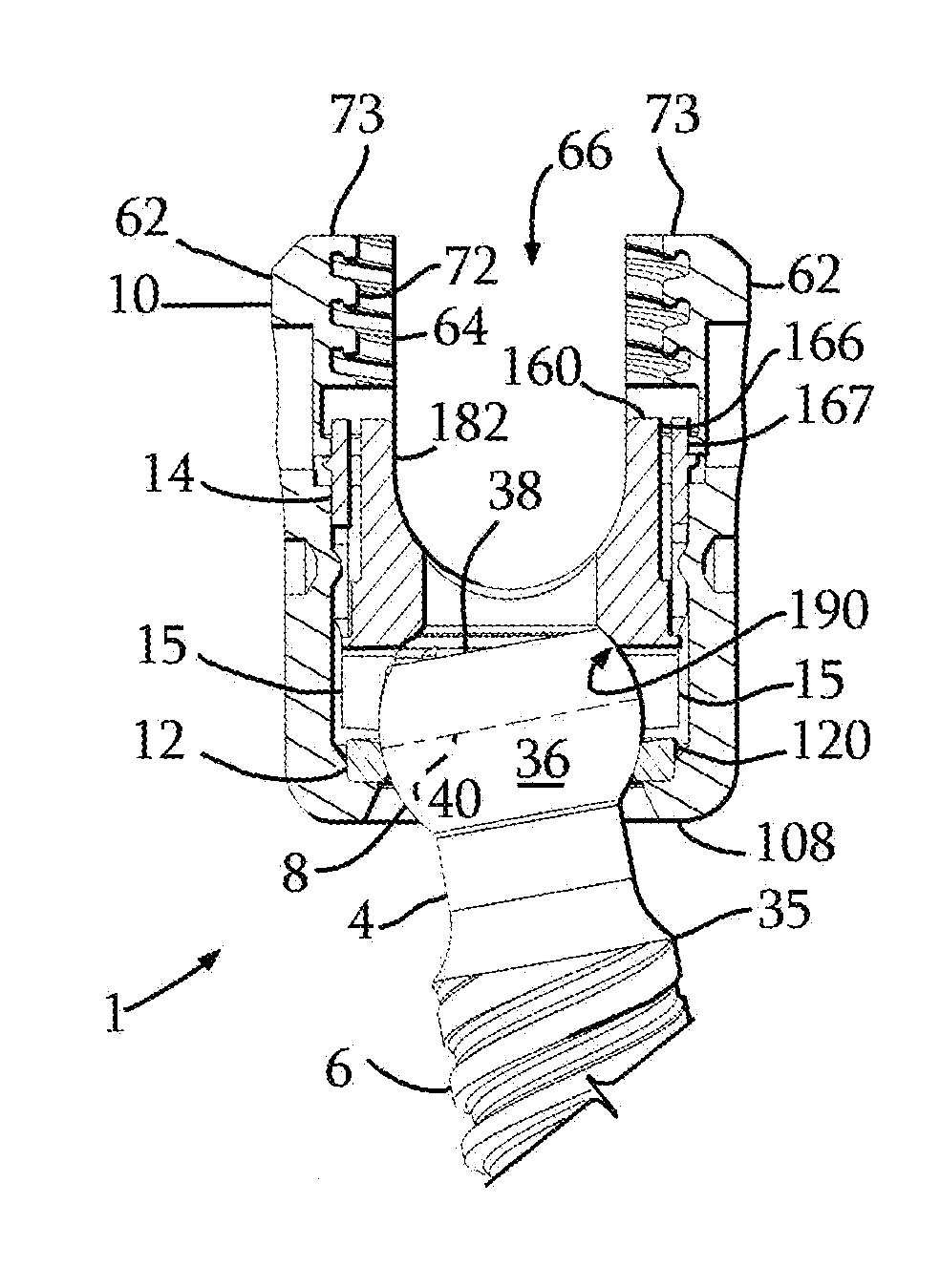

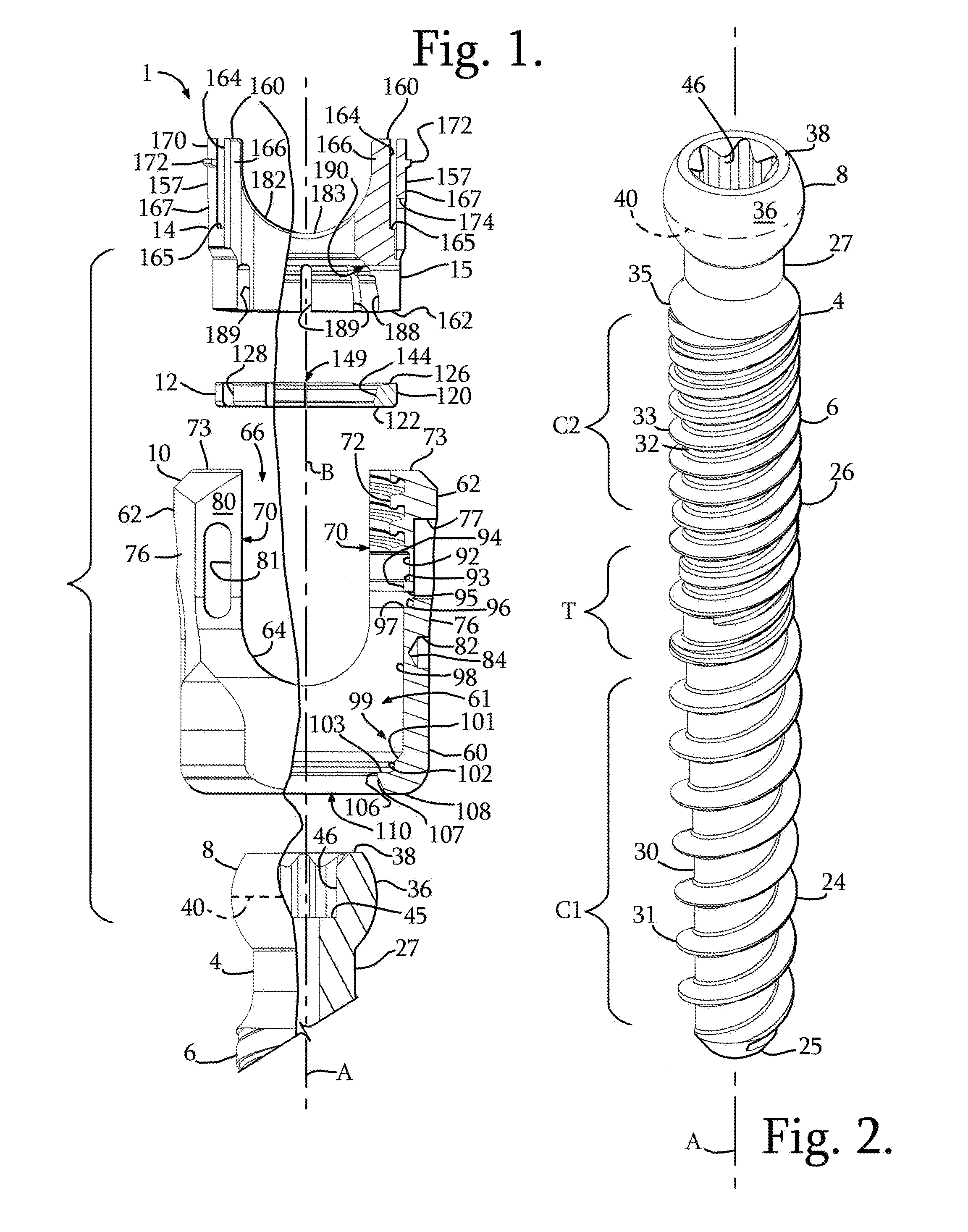

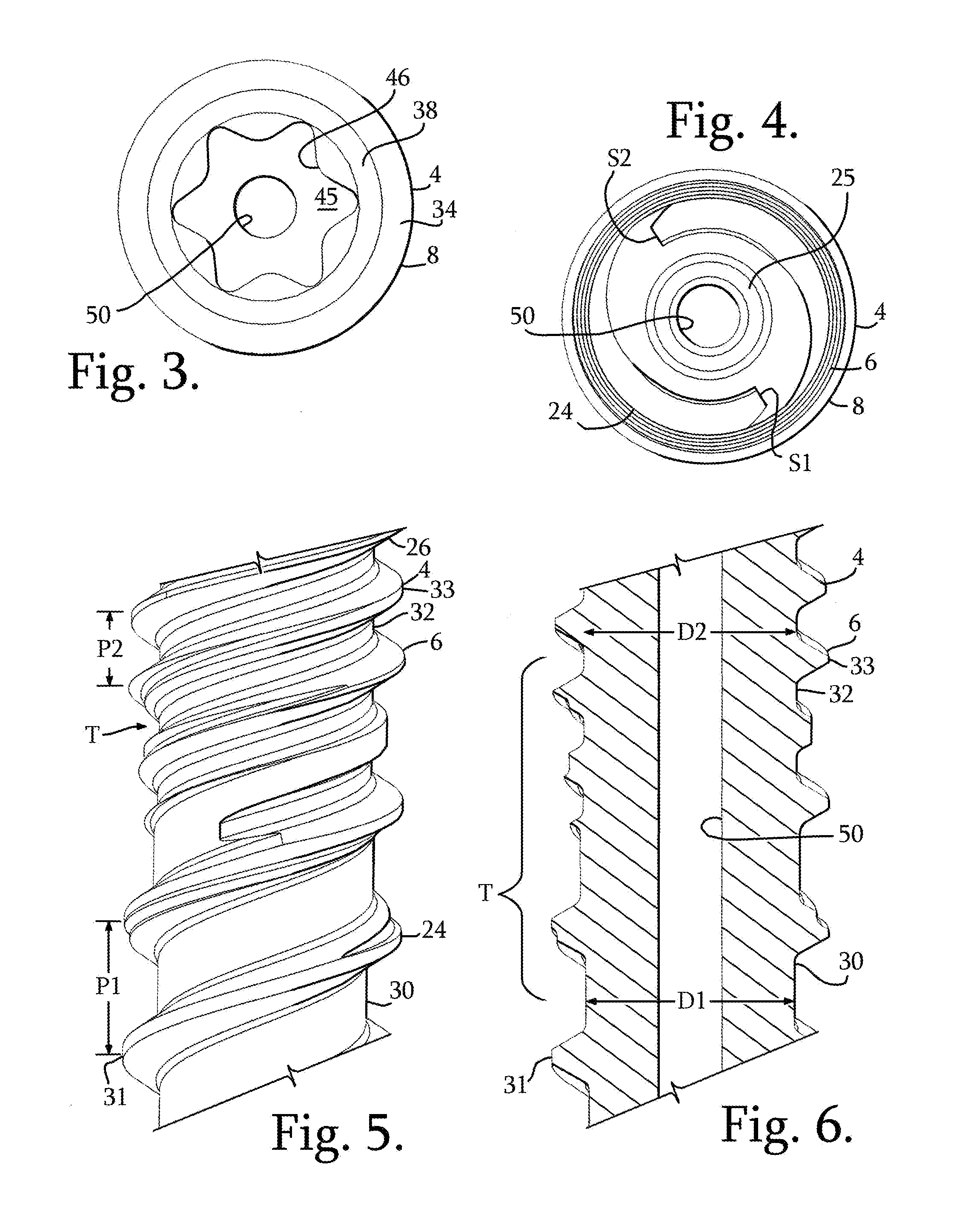

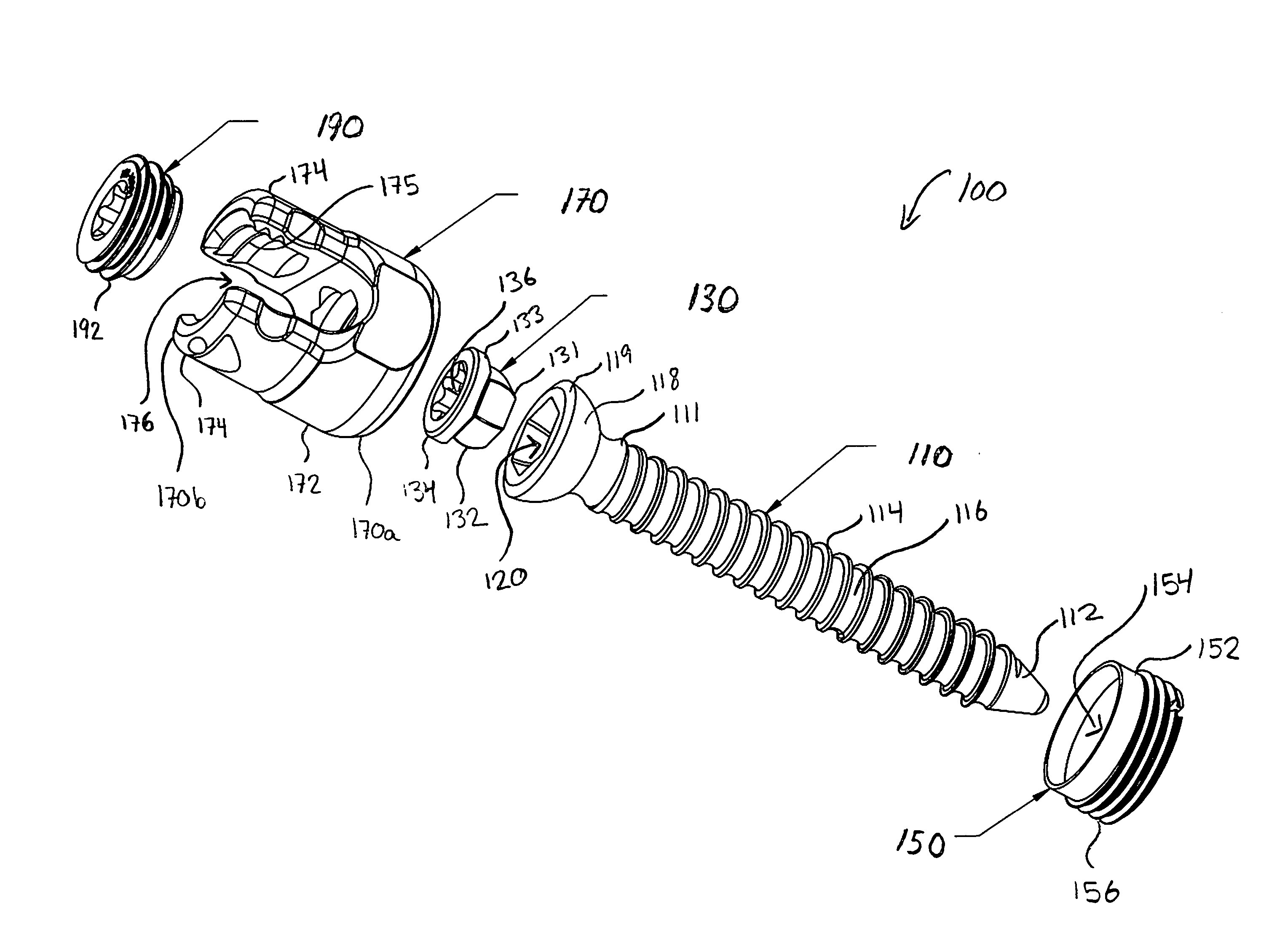

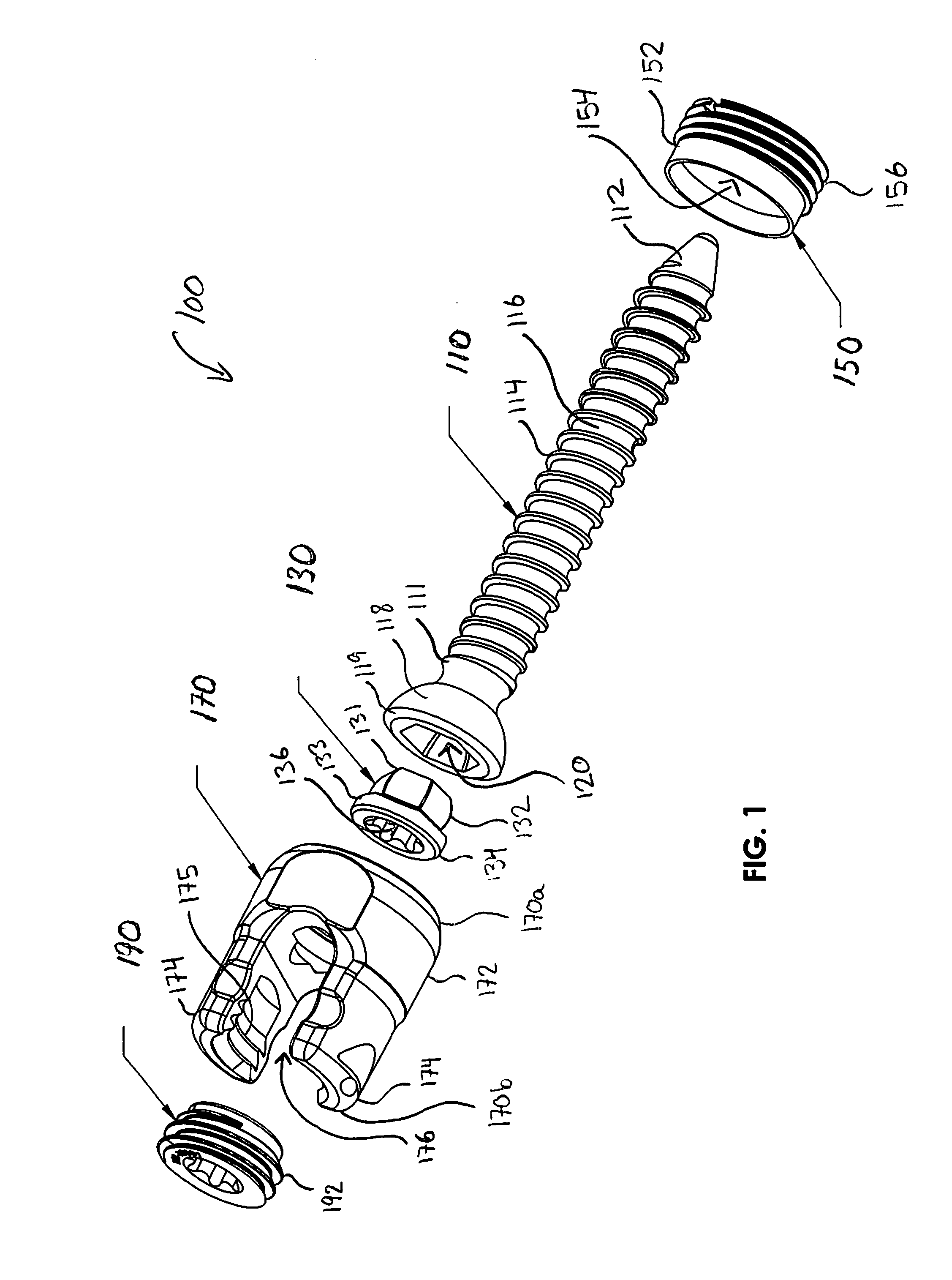

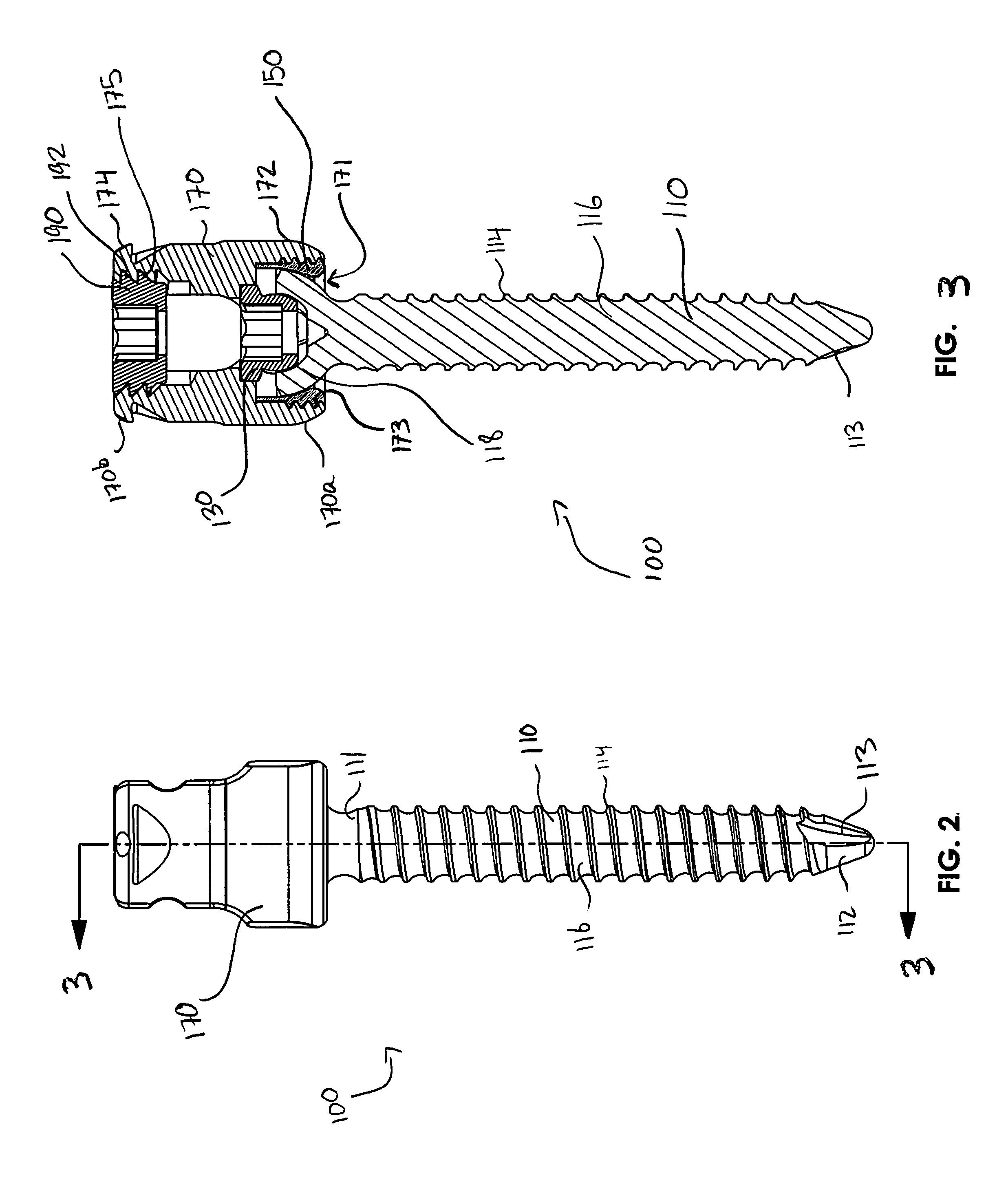

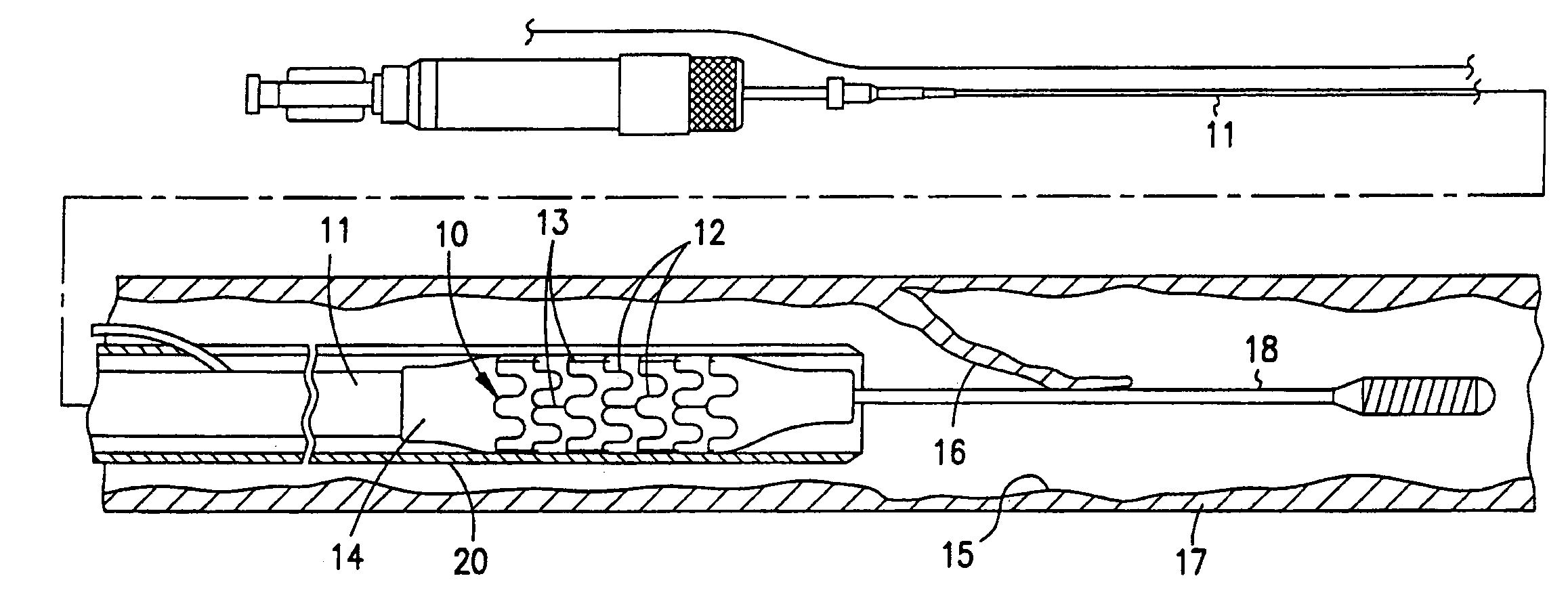

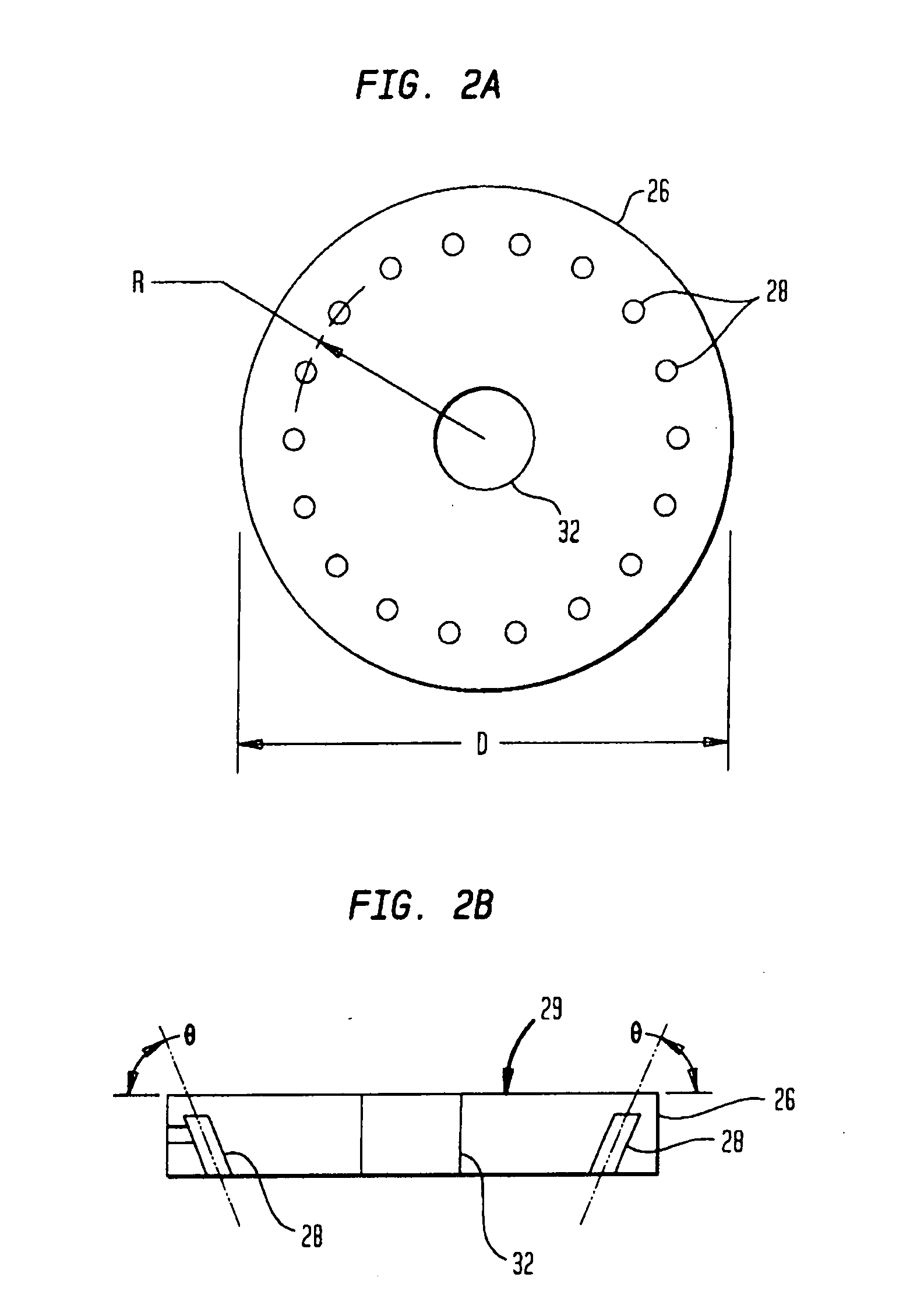

Polyaxial bone anchor with pop-on multi-thread shank, some with diametric interference fit inserts

InactiveUS20140121703A1Improved spinal correction techniqueInternal osteosythesisJoint implantsInterference fitCobalt-chrome

Polyaxial and uni-planar bone screw assemblies include a multi-threaded shank body having an integral upper portion receivable in a one piece receiver, the receiver having an upper channel for receiving a longitudinal connecting member and a lower cavity cooperating with a lower opening. A compression insert and open retaining ring located in the receiver may be made of cobalt-chrome and the compression insert may provide a diametric interference fit with the receiver. Receivers or inserts may include resilient arm portions. The open ring cooperates with the shank to provide for pop- or snap-on assembly of the shank with the receiver either prior to or after implantation of the shank into a vertebra.

Owner:JACKSON

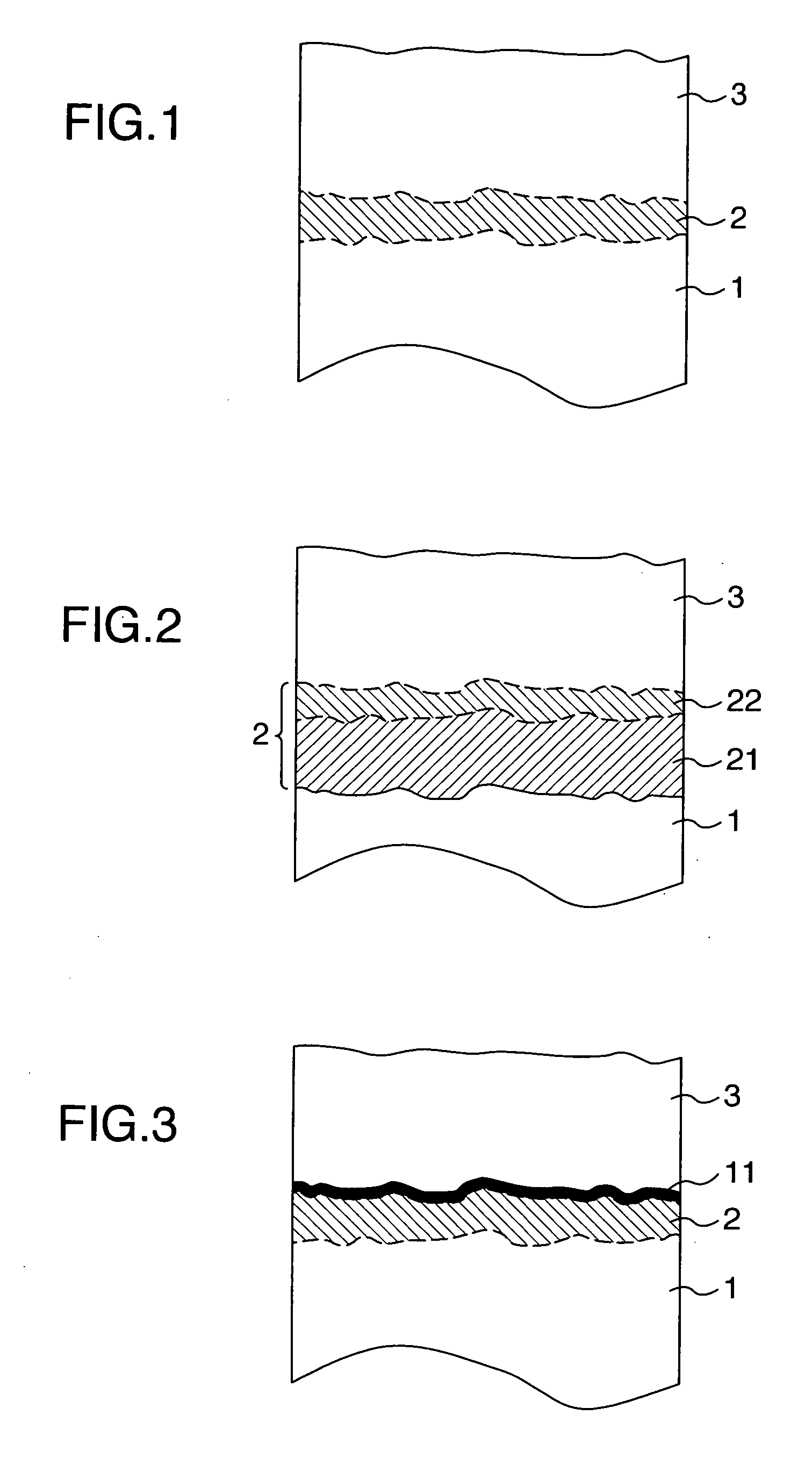

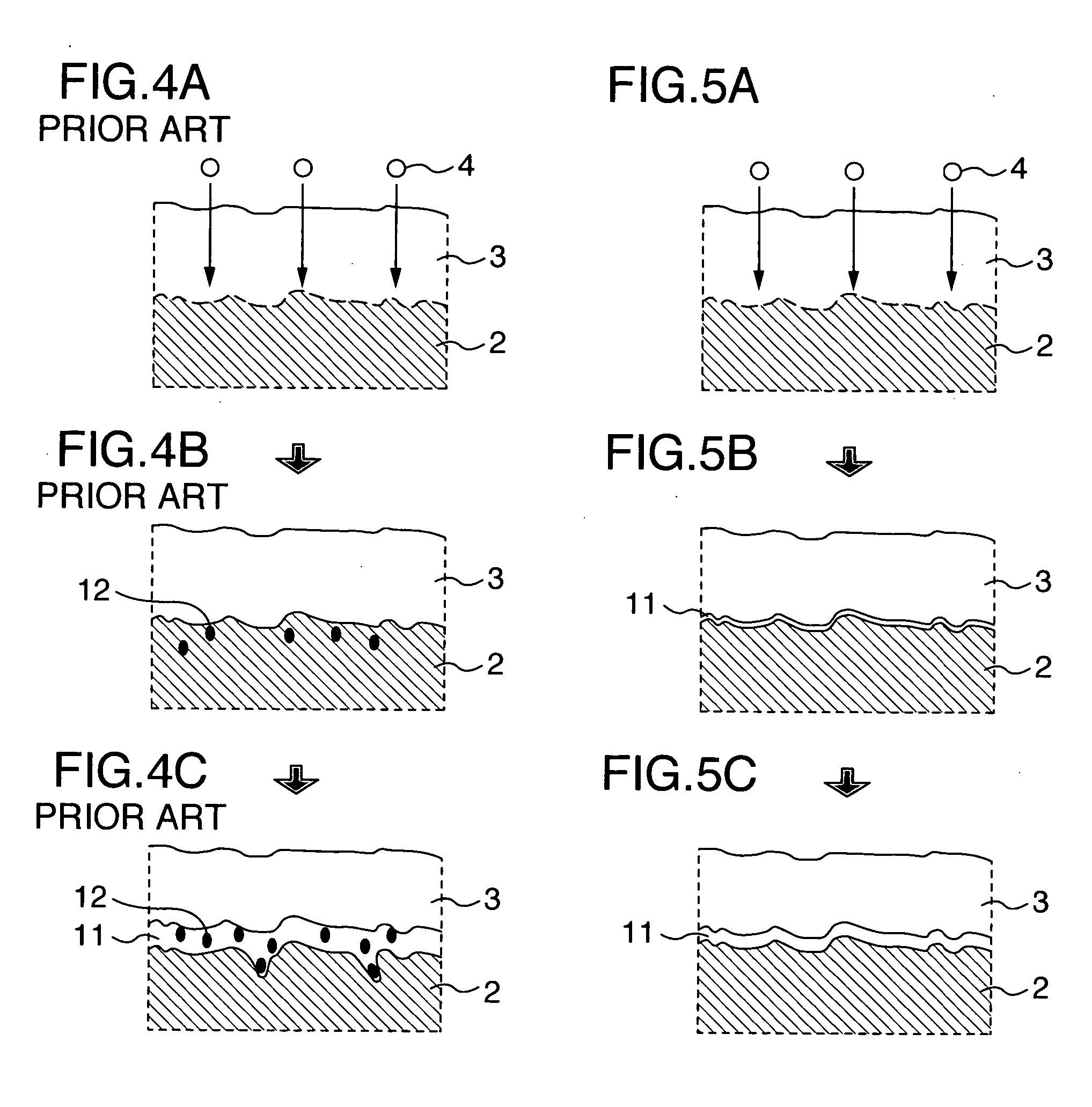

High temperature component with thermal barrier coating and gas turbine using the same

There is provided a high temperature component with a thermal barrier coating, which can be used as a high temperature component for a gas turbine, an aircraft gas turbine engine, or the like. A top coat is formed of a ceramic on a bond coat, the bond coat being formed on a heat resistant alloy substrate composed mainly of at least one element of nickel and cobalt, wherein the bond coat contains at least one of nickel and cobalt, chromium and aluminum, and further contains at least one selected from a group consisting of tantalum, cesium, tungsten, silicon, platinum, manganese and boron in a range of 0 to 20 wt %. The high temperature component according to the present invention has very high durability of a thermal-insulating ceramic layer, and is less susceptible to spalling damage.

Owner:CENTRAL RESEARCH INSTITUTE OF ELECTRIC POWER INDUSTRY +1

Bone screw assembly with non-uniform material

A bone anchor comprises a screw having a threaded shank portion and a head portion, and a housing assembly. At least the threaded shank portion is formed from a titanium or titanium alloy and at least a portion of the housing is formed from a stronger material such as cobalt chrome. The housing assembly has a passageway extending therethrough and a proximal end and a distal end. A saddle is defined within the proximal end of the housing assembly and is configured to retain a portion of a rod therein. The distal end of the housing assembly is configured for securely engaging the head portion of the screw such that the screw is at least one of rotatable and pivotable with respect to the housing.

Owner:K2M

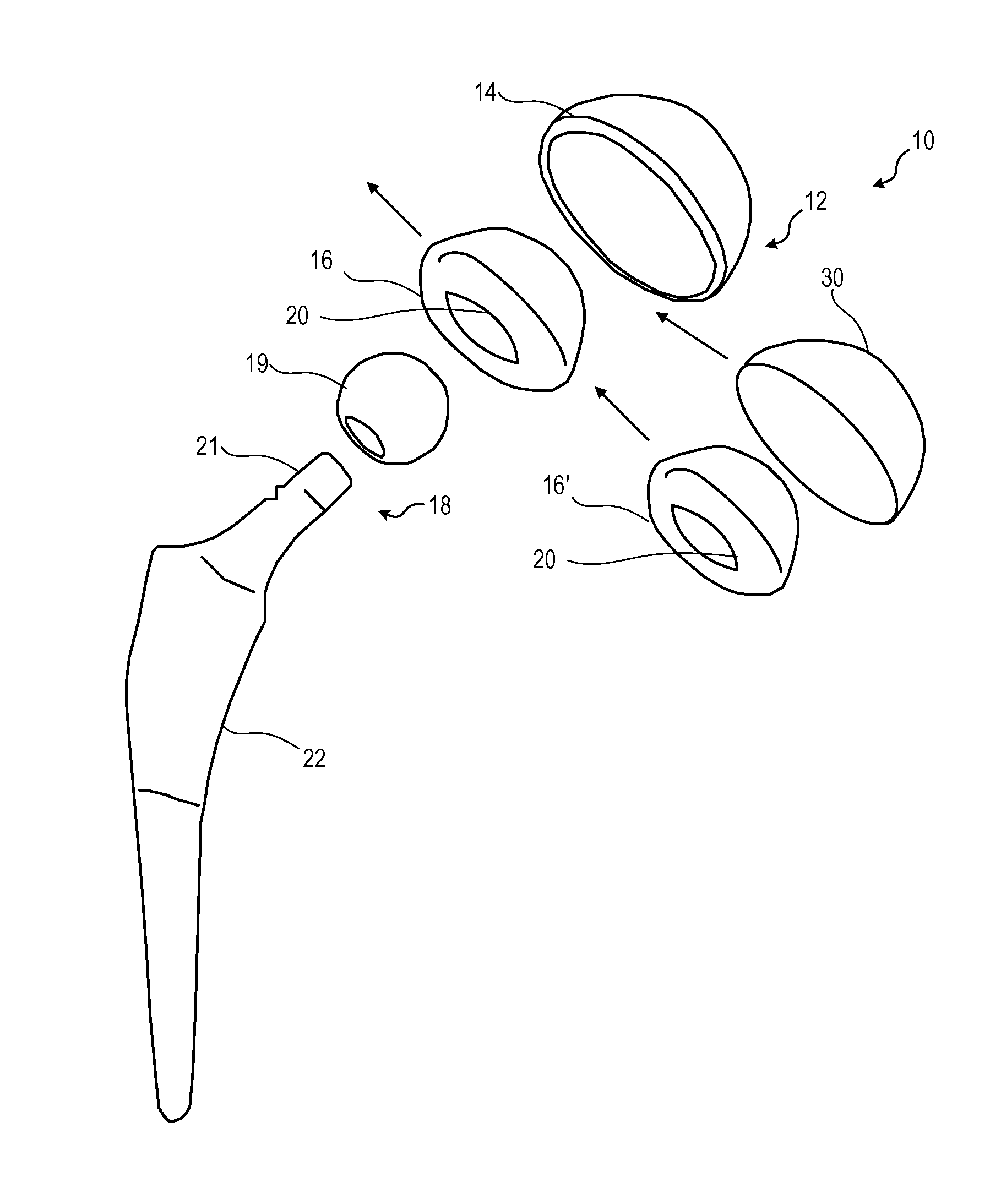

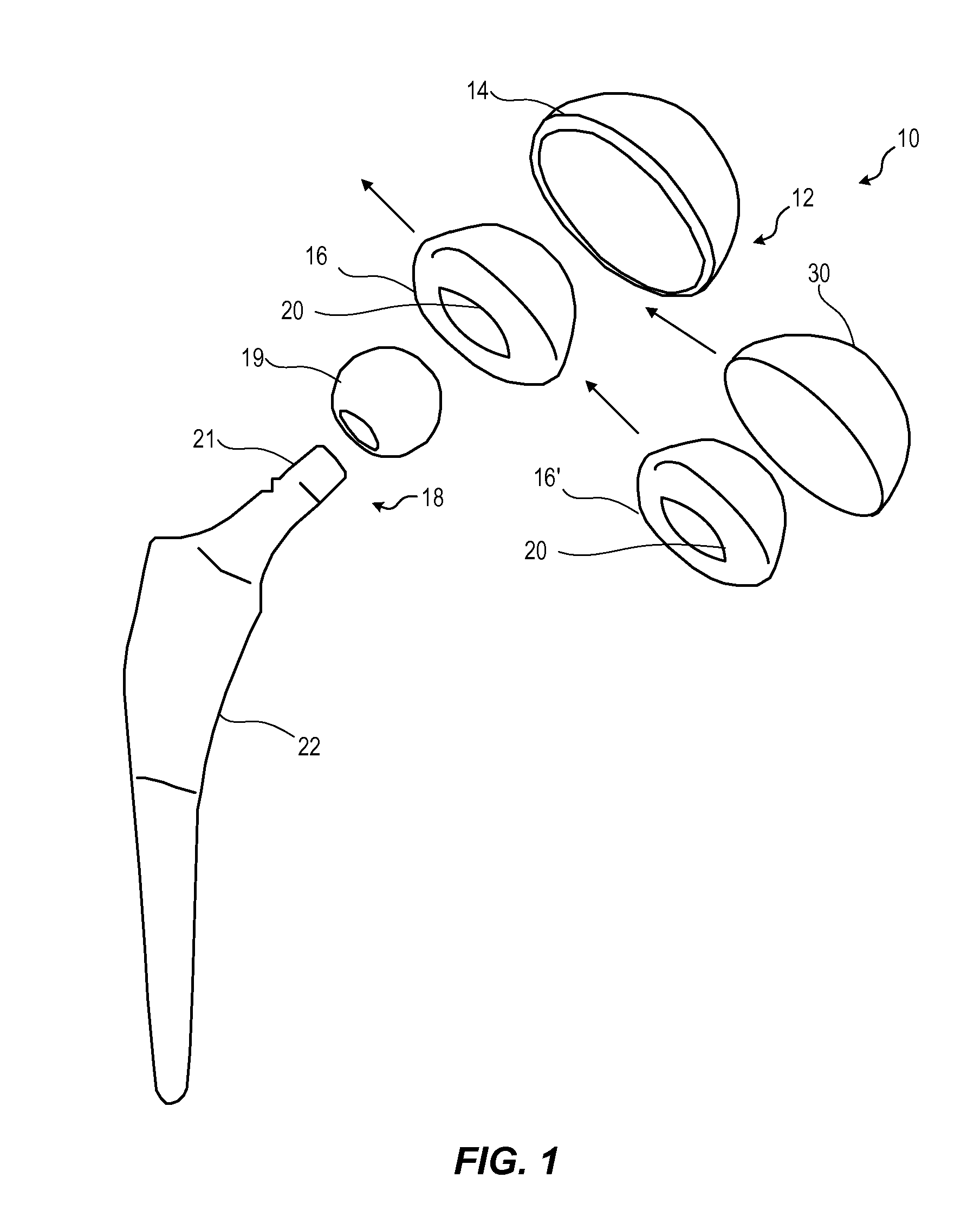

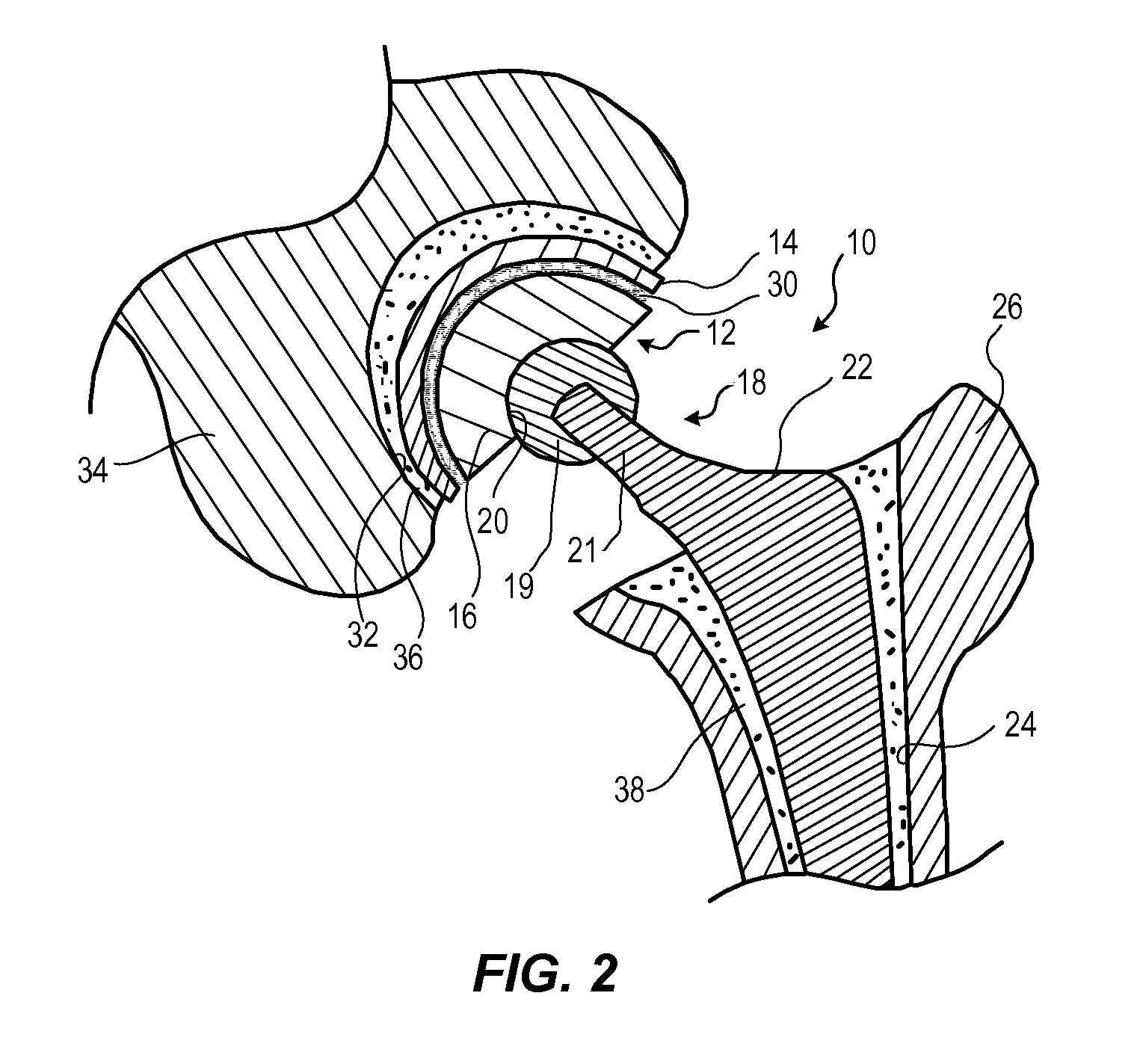

Inner acetabular liner for a dual mobility femoral head construct

A dual mobility femoral head construct has a secure acetabular shell received within an acetabular recess formed in a pelvis. An implantable prosthetic device is implantable after a failure of an originally installed articular head insert of an acetabular cup assembly. A hemispherical liner is formed from a cast cobalt-chromium alloy for thinness and elasticity. At least three spacers are annularly displaced about an outer diameter of the hemispherical liner to define a uniform cement thickness with the secure acetabular shell. Web shaped depressions are formed circumferentially in the outer diameter of the hemispherical liner to receive cement to resist lever out forces and to secure the cement bond with the secure acetabular shell. A replacement articular head insert is then received for dual mobility rotational movement in an inner diameter of the hemispherical liner. A femoral head implant is received for articulating movement in the articular head insert.

Owner:CHOUDHURY SAMBHU +3

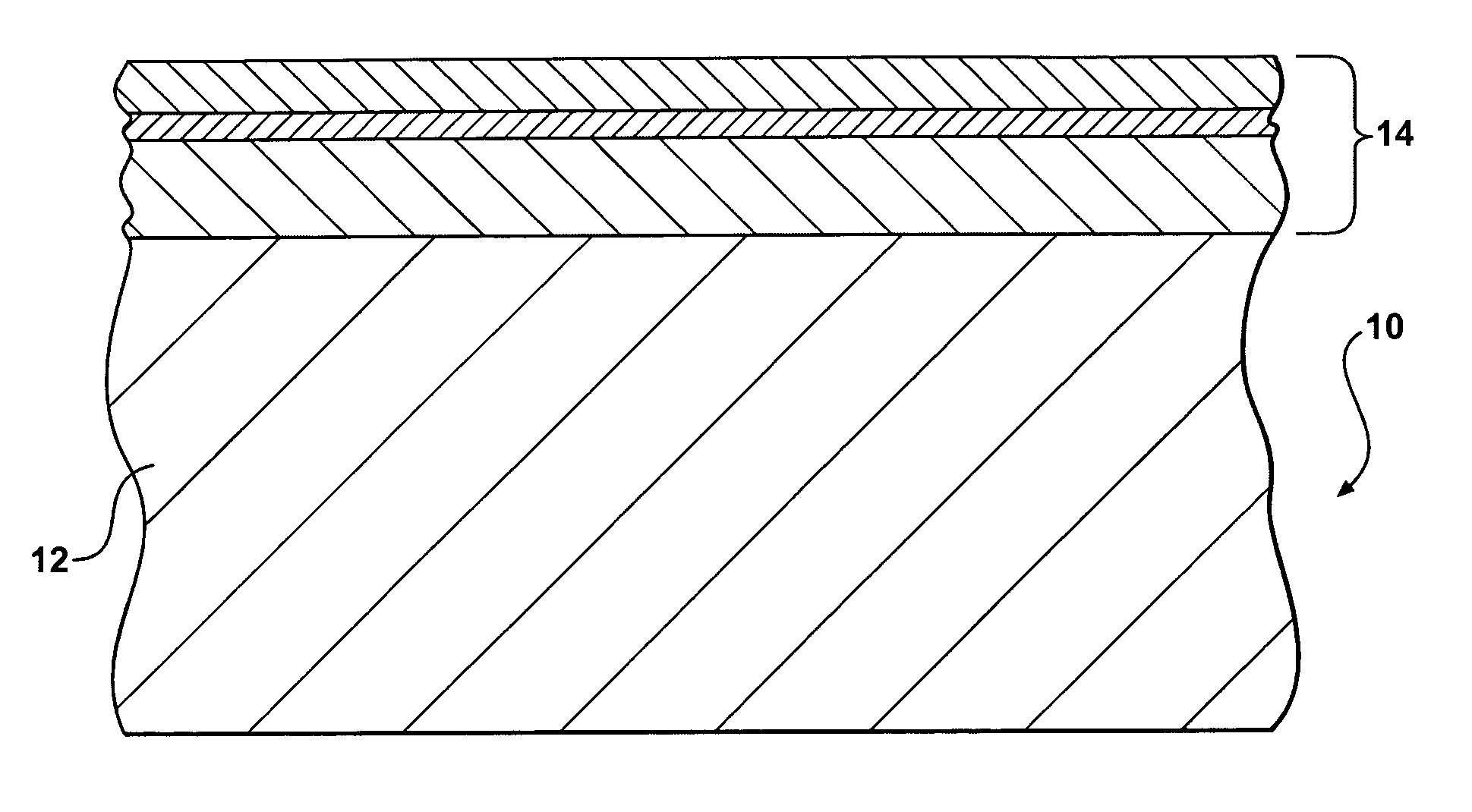

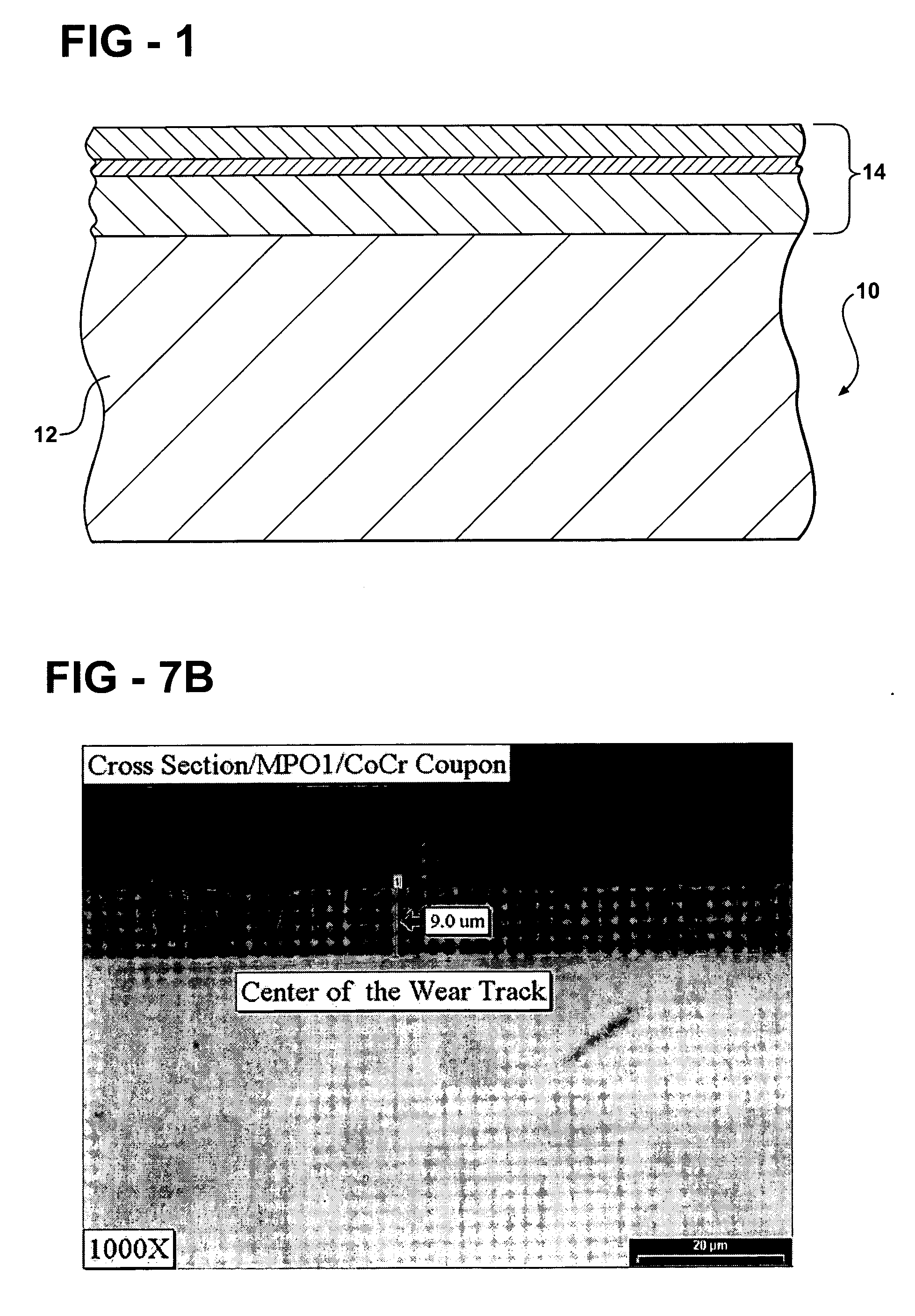

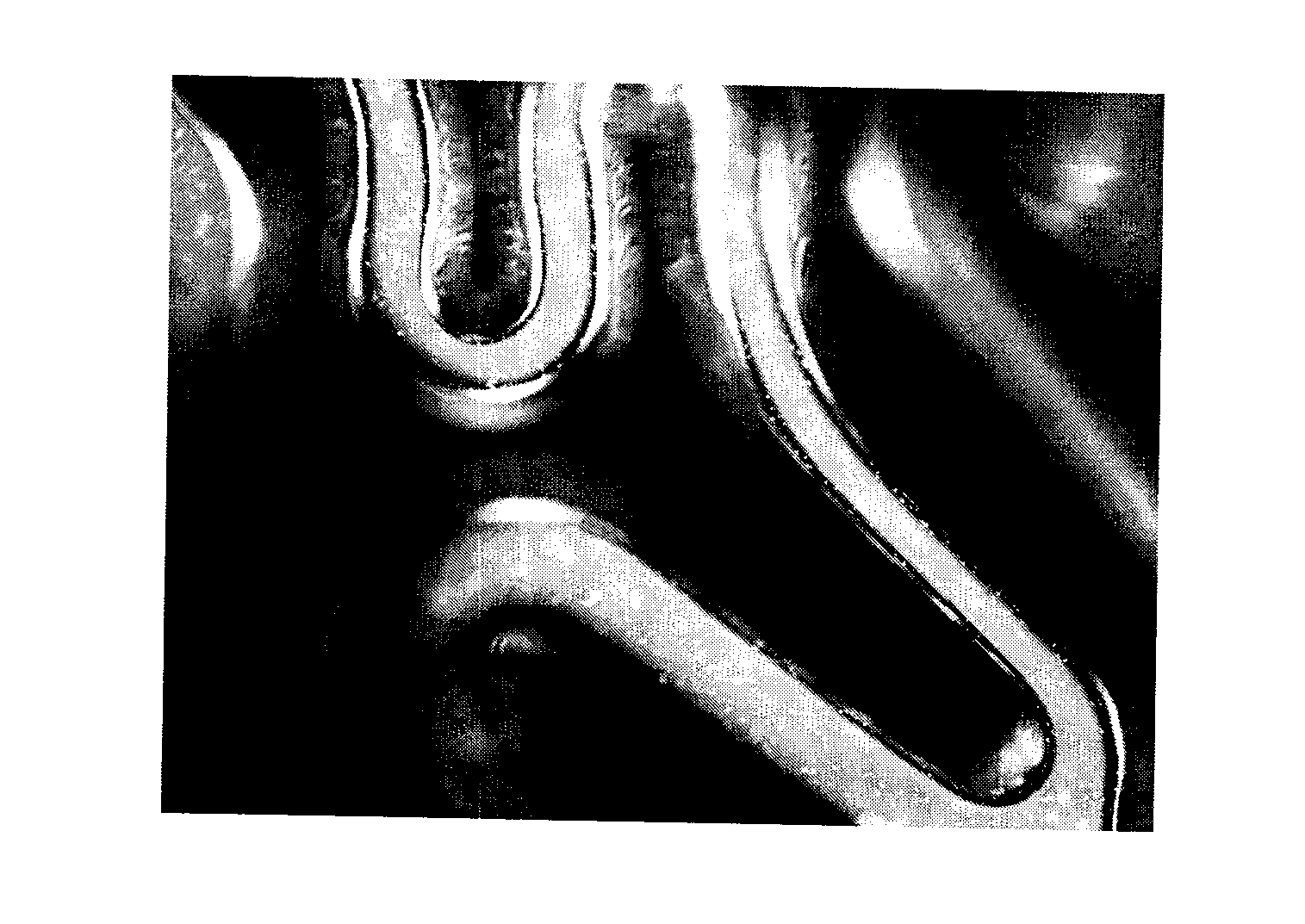

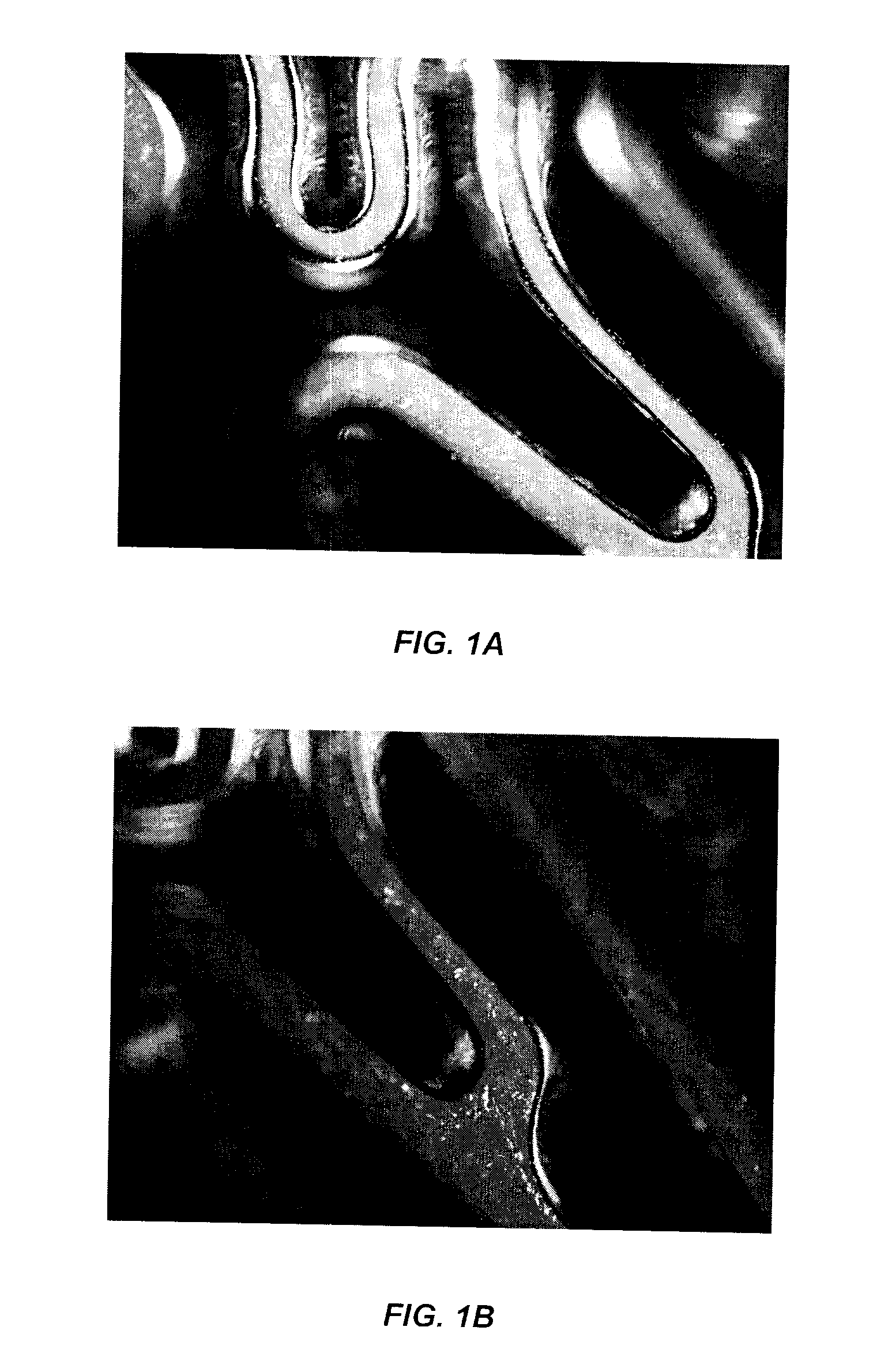

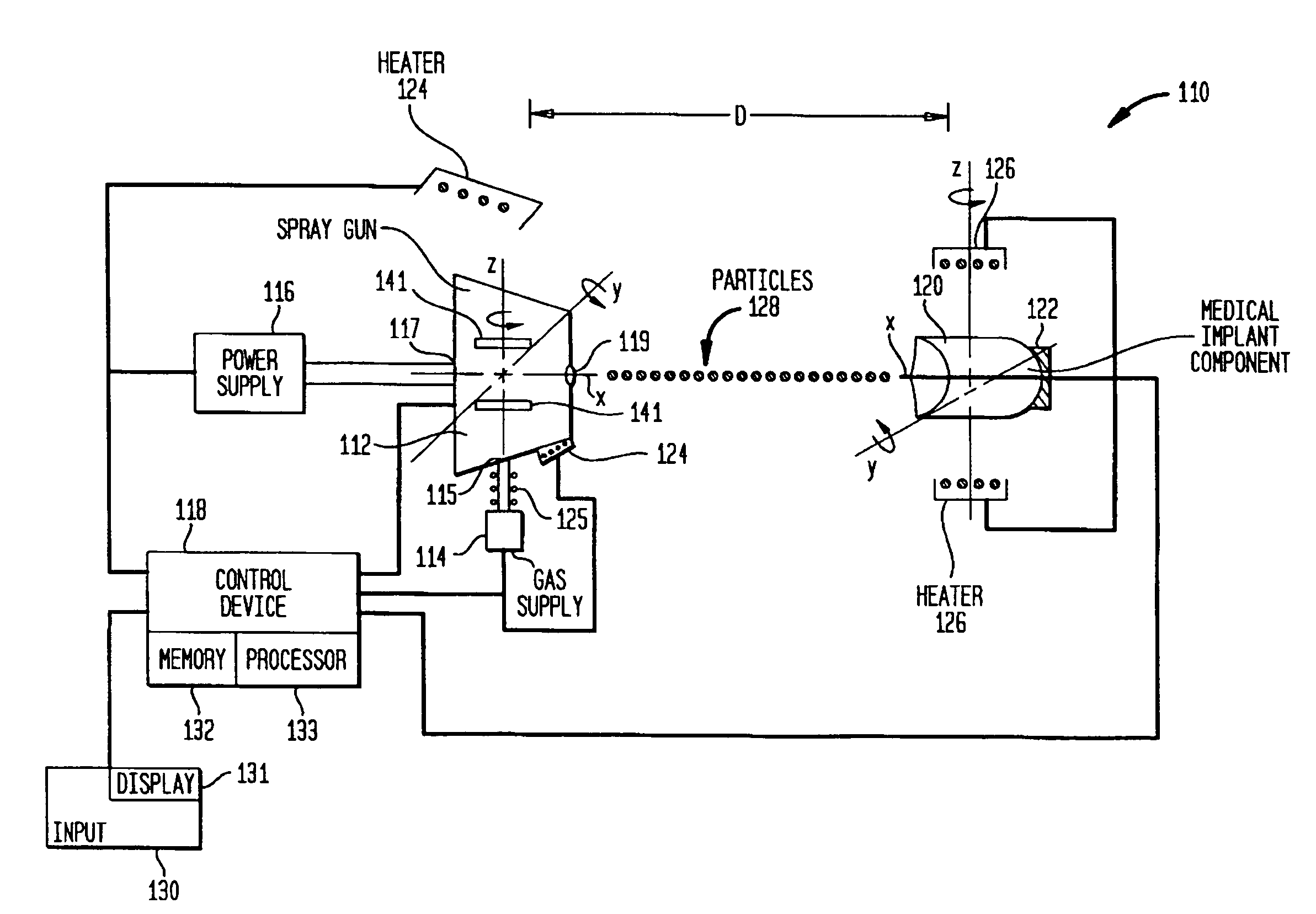

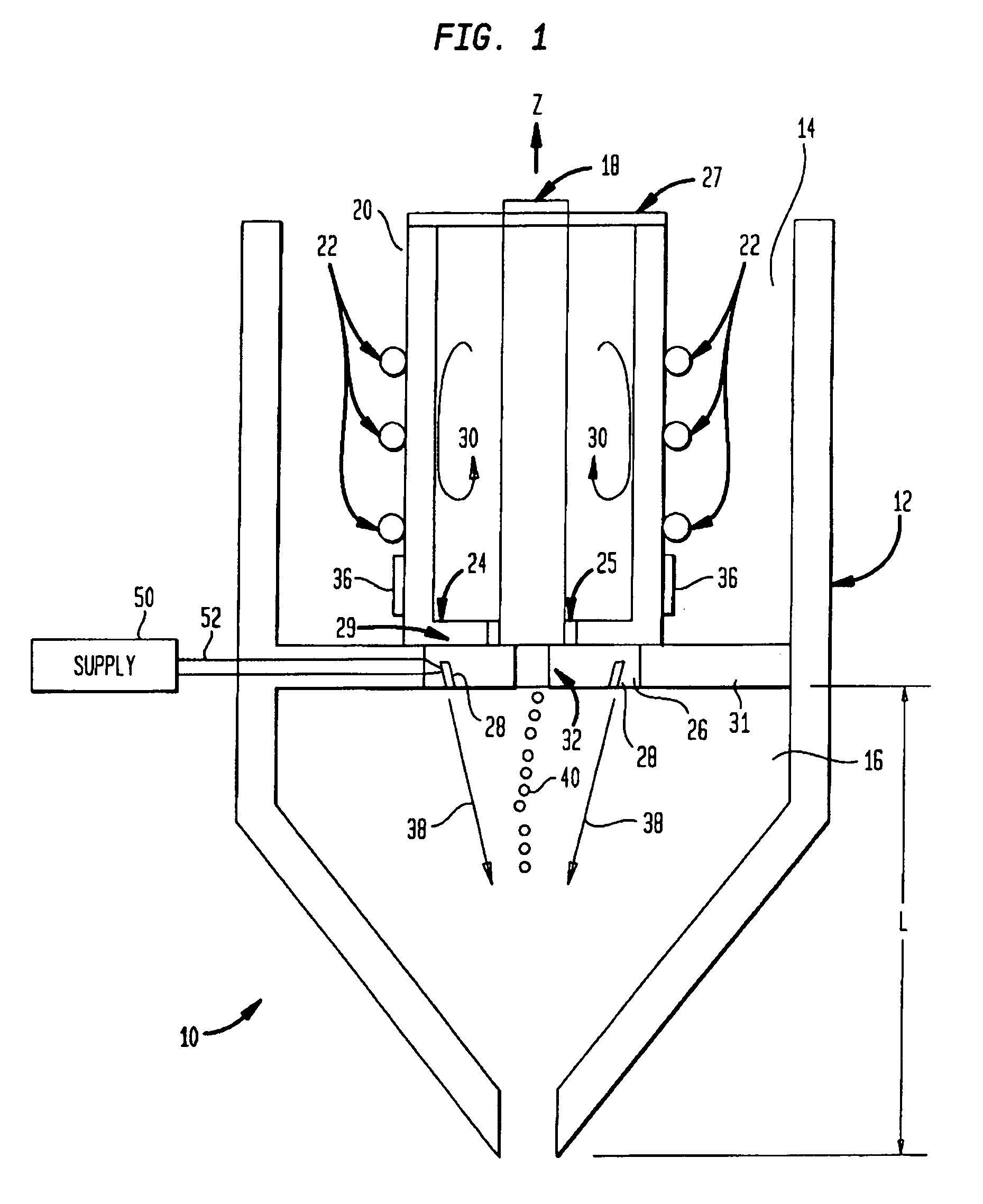

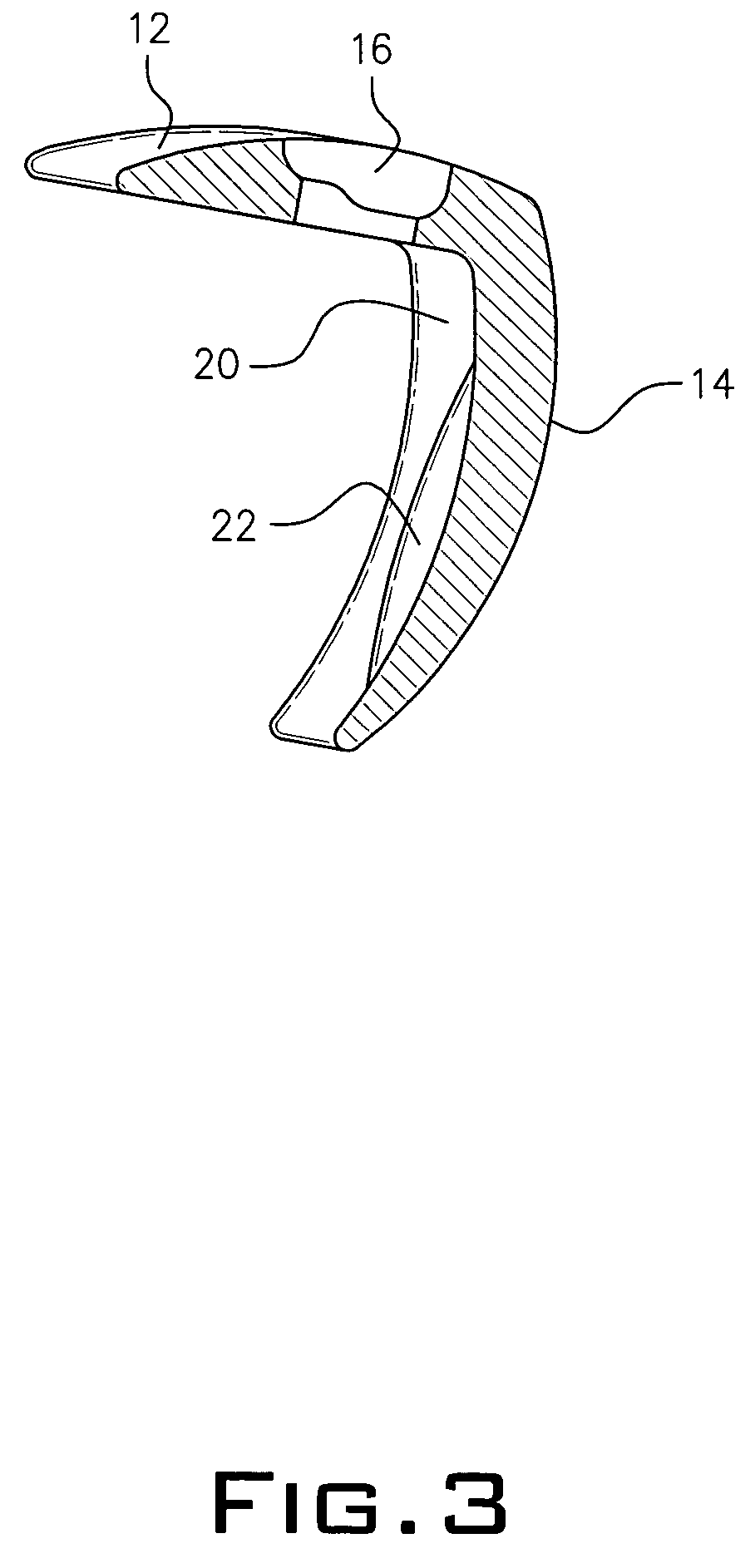

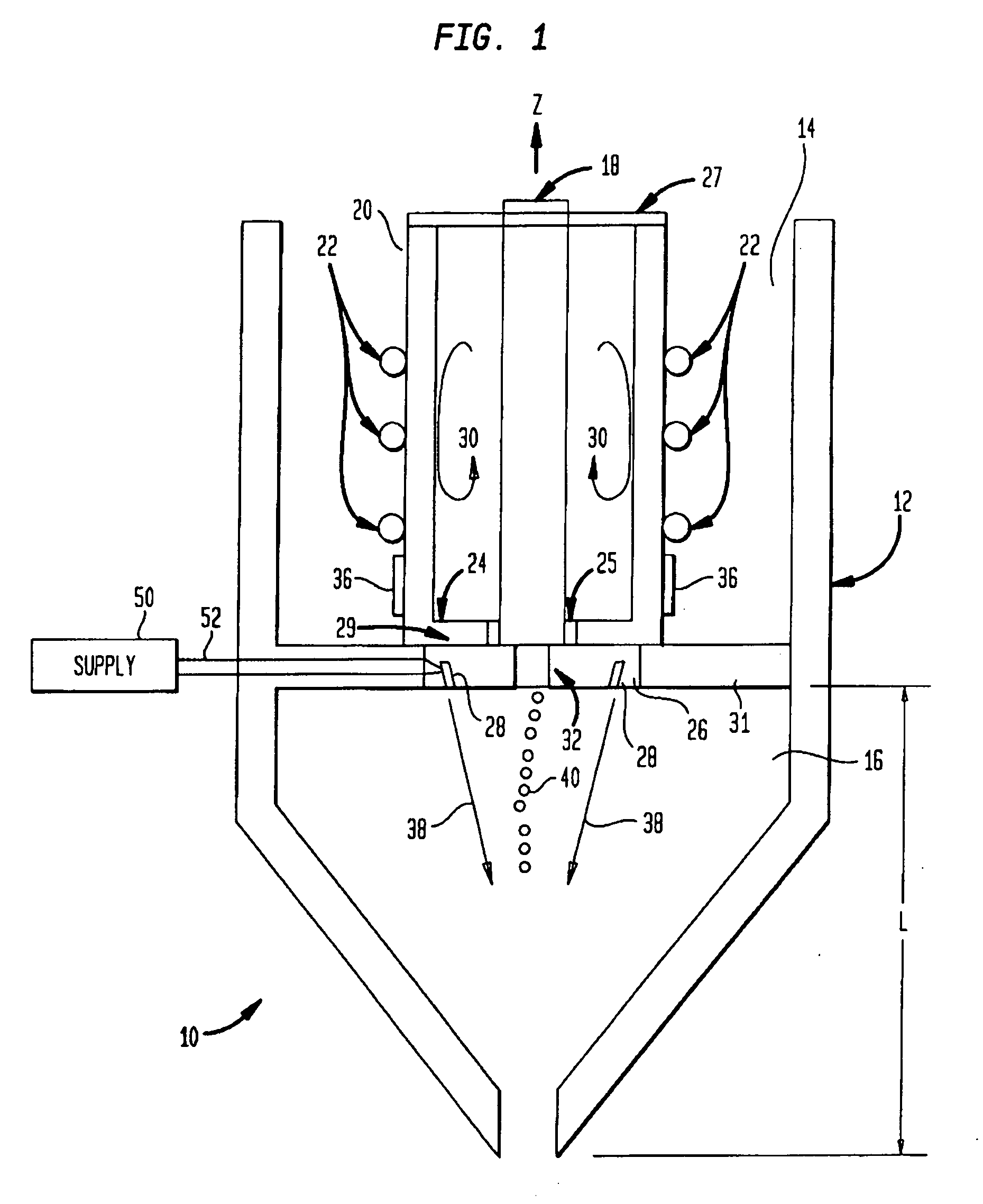

Method for fabricating a medical component from a material having a high carbide phase and such medical component

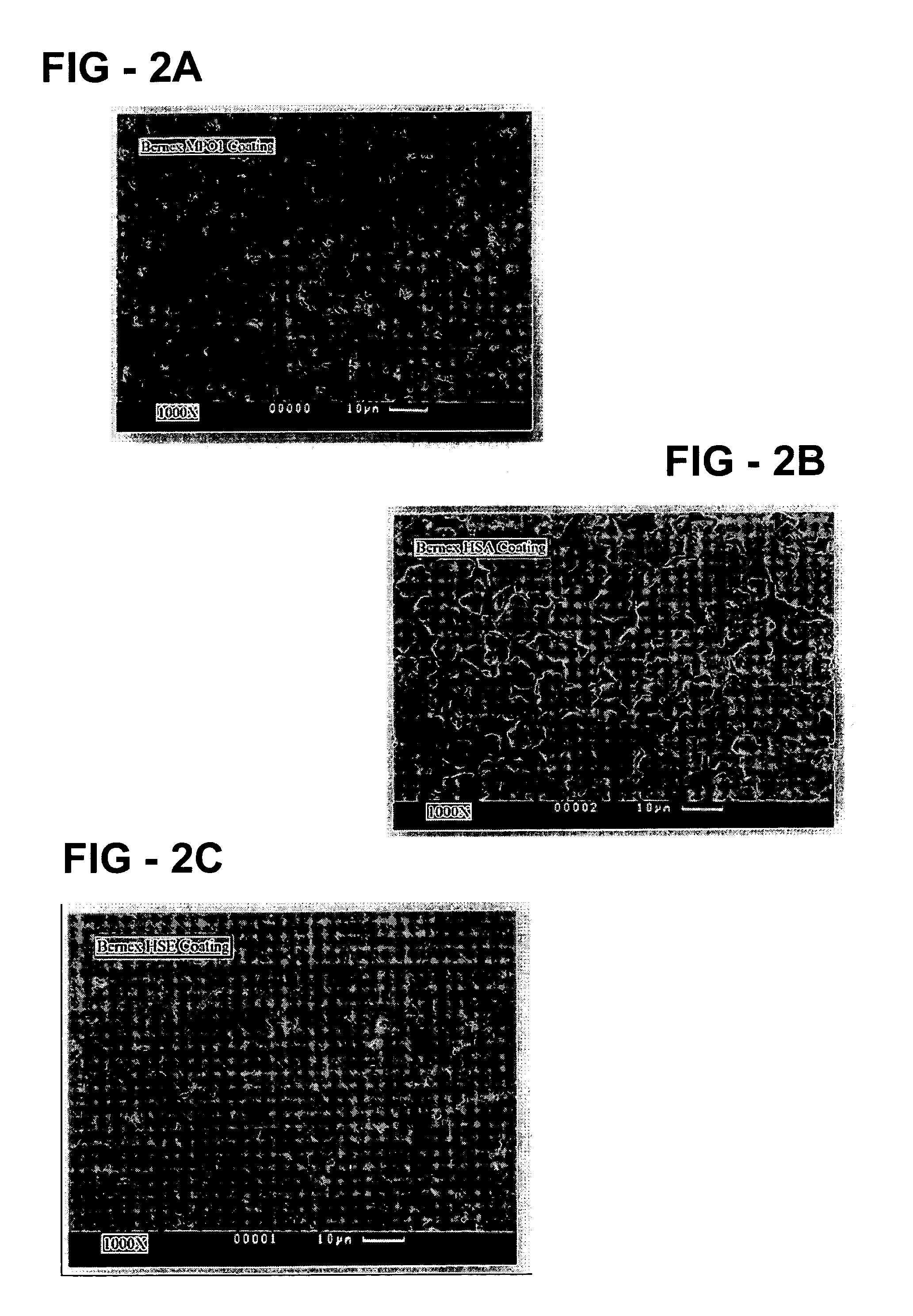

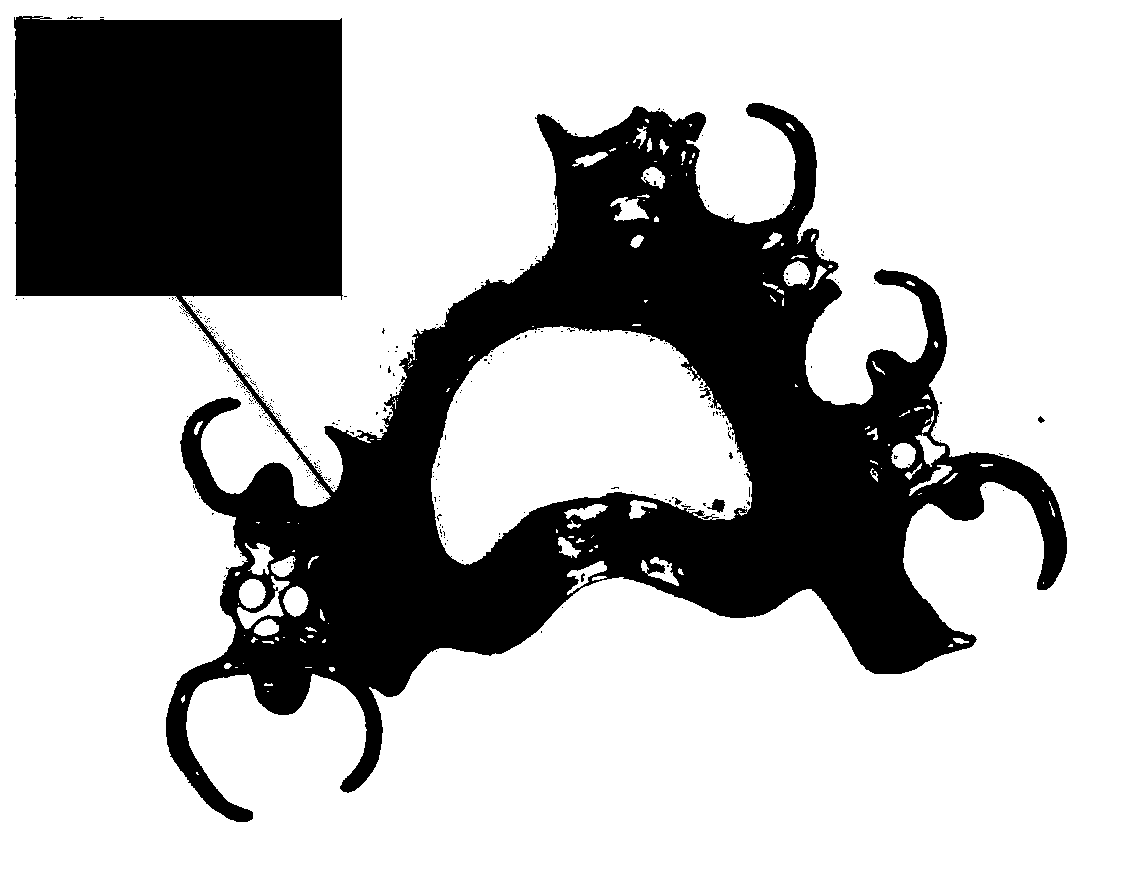

ActiveUS20080241570A1Molten spray coatingSemiconductor/solid-state device detailsCobalt-chromeCarbide

A method of fabricating a medical implant component. The method may comprise producing a substrate from a first material in which the substrate has a bearing portion, and causing particles of a second material to be formed onto at least the bearing portion of the substrate. The second material may be formed from a biocompatible material and a carbide source, in which the carbide source is 6.17% or more of the second material by weight. The particles of the second material may be formed onto at least the bearing portion of the substrate by a predetermined spraying technique, a CVD process, a PVD process, or a carburization process. The biocompatible material may be cobalt chrome and the carbide source may be graphite.

Owner:HOWMEDICA OSTEONICS CORP

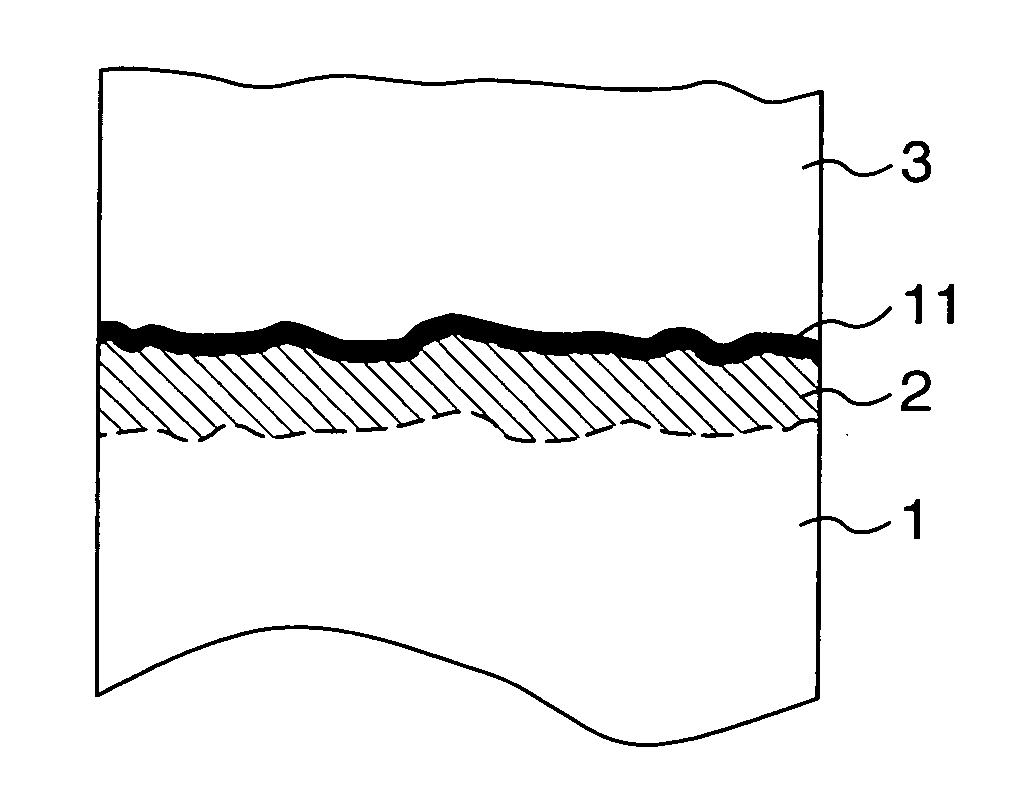

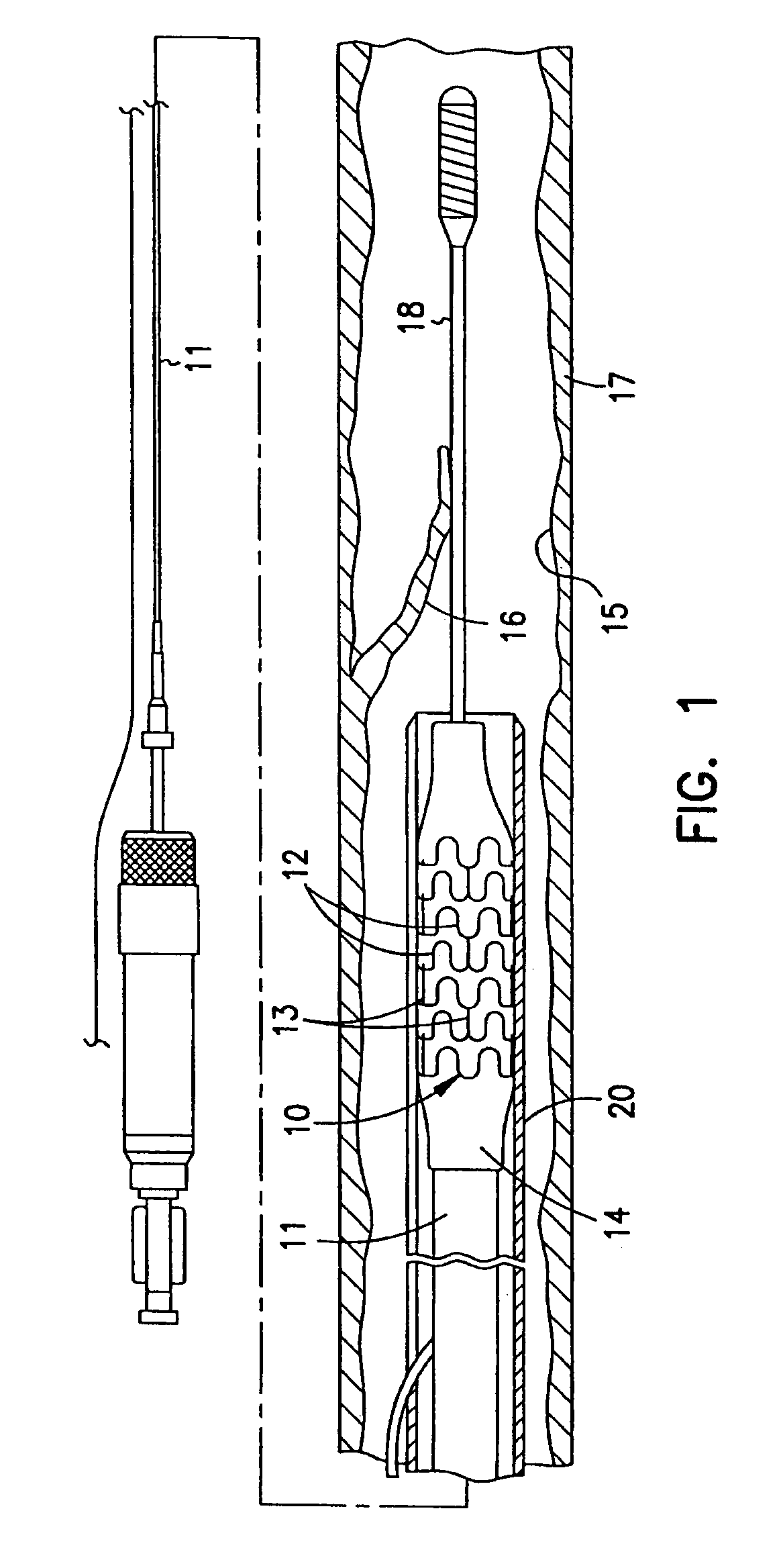

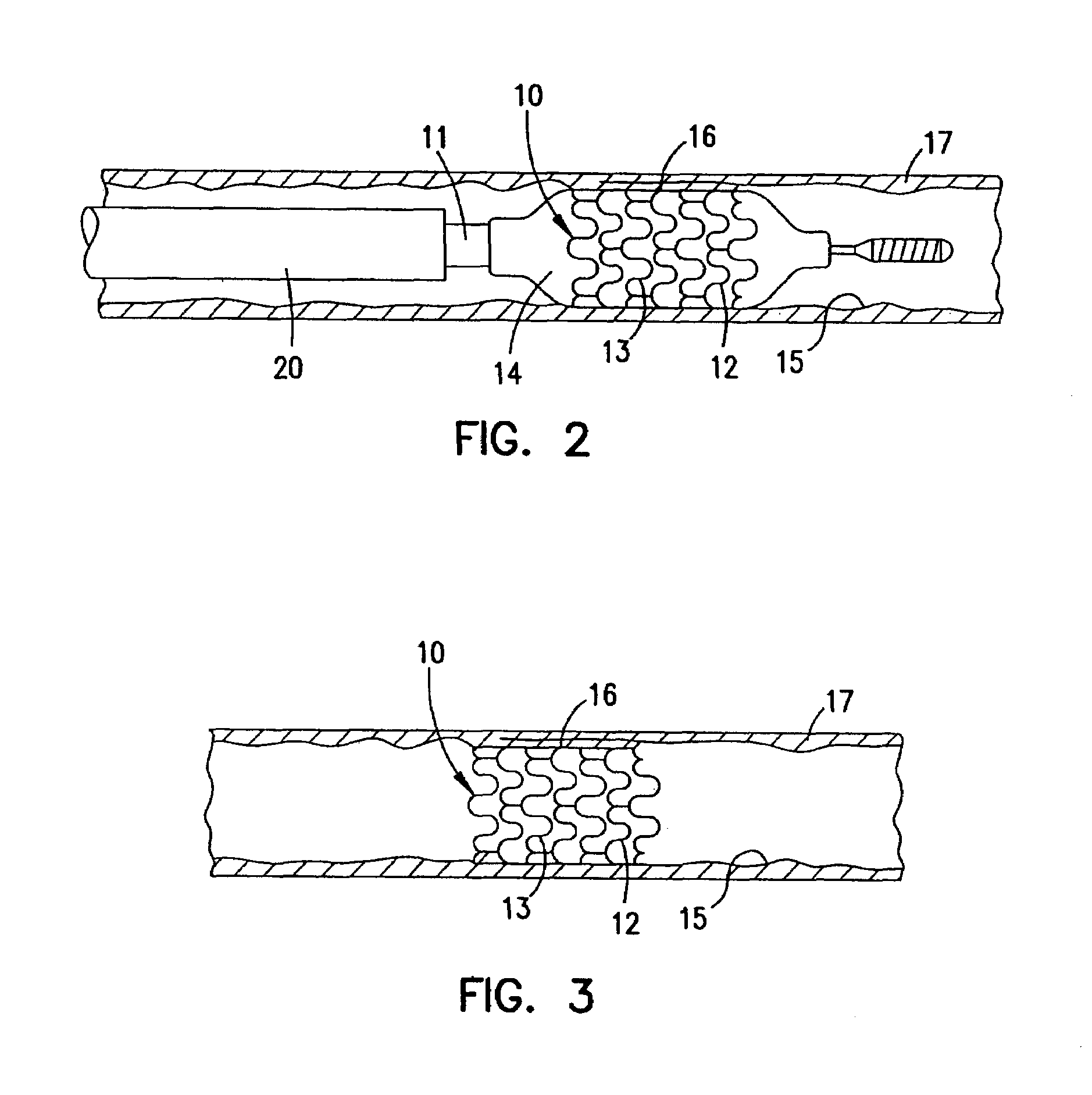

Dual layer diffusion bonded chemical vapor coating for medical implants

Coatings for use in artificial joints and other implanted medical devices. The coatings comprise a dual layer structure vapor deposited atop a medical grade substrate, such as cobalt chromium. The dual layer structure comprises a first ceramic layer vapor deposited atop at least a portion of the substrate and a second ceramic layer deposited atop the first ceramic layer. The first ceramic layer is formed of a material which has particularly good adhesion to the substrate, and the second ceramic layer from a material exhibiting particularly high hardness and good wear characteristics. The vapor deposition process is controlled so as to form a graded interface between the two ceramic layers to form a dual layer coating which resists delamination, adheres well to the substrate, and exhibits good wear characteristics in situ.

Owner:IONBOND

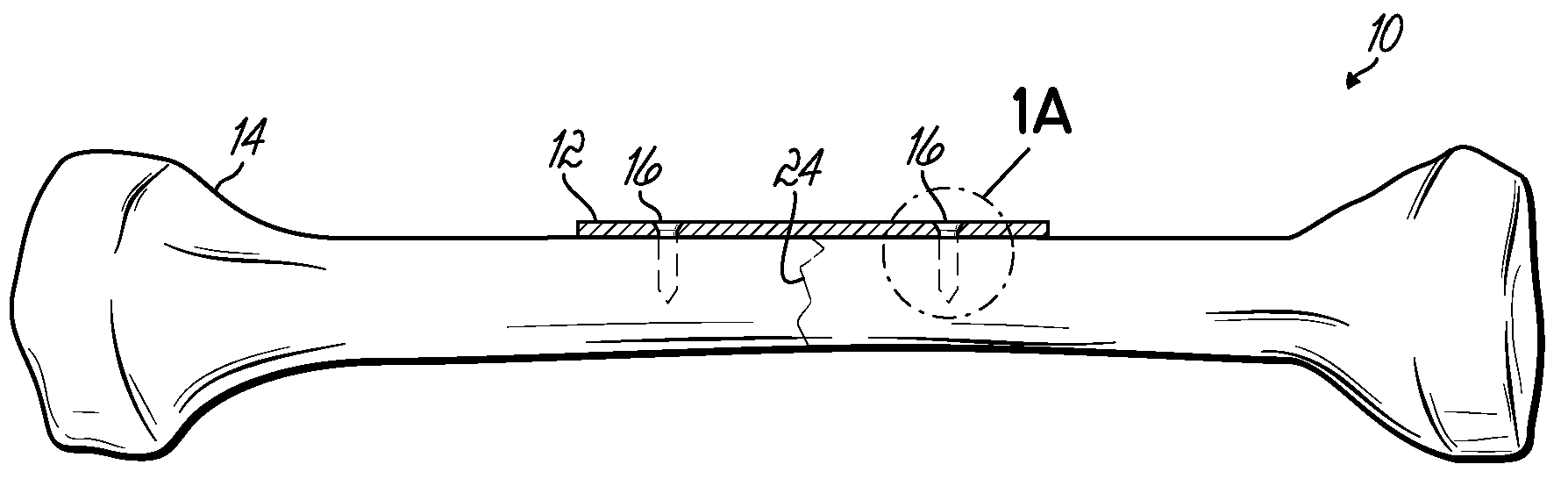

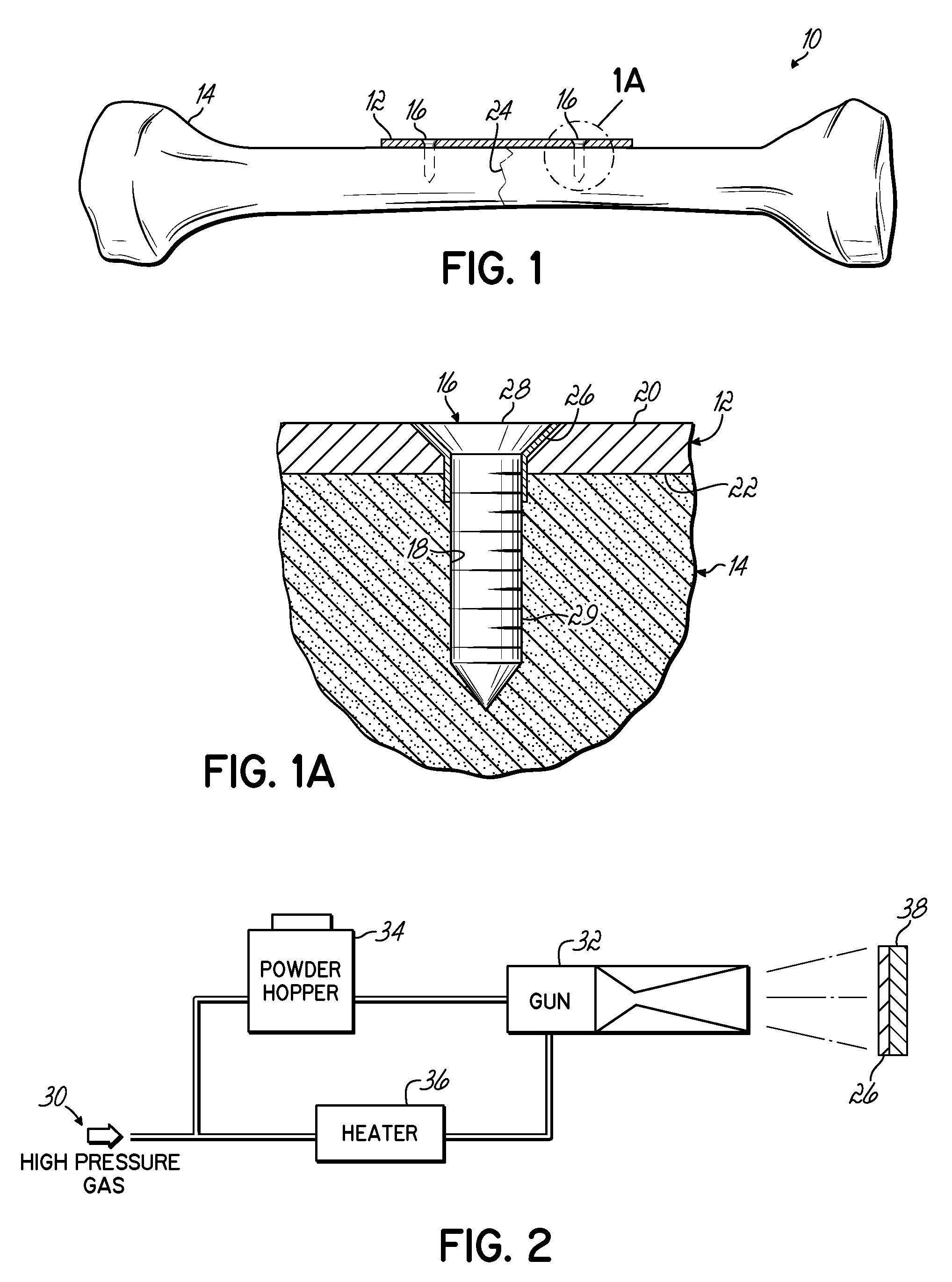

Bone fracture fixation system

InactiveUS20090198286A1Avoid bondingAvoid corrosionSuture equipmentsLigamentsMetallic materialsCobalt-chrome

A bone fracture fixation system comprising a metallic bone plate having a first composition comprising titanium or a titanium alloy and an opening for receiving a metallic fastener that has a second composition comprising titanium, a titanium alloy, or a stainless steel, and is sized to be received in the opening, and a cold-sprayed metallic coating either within the opening or on the metallic fastener is provided. The cold-sprayed metallic coating comprises a biocompatible metallic material having a third composition different than the first and second compositions. When the metallic fastener is inserted into the opening to stabilize a bone fracture, the cold-sprayed metallic coating may substantially prevent bonding or one or more types of corrosion between the metallic fastener and the metallic bone plate. In another embodiment, the cold-sprayed metallic coating comprises at least one of a cobalt-chrome alloy, gold, a gold alloy, silver or a silver alloy.

Owner:ZIMMER INC

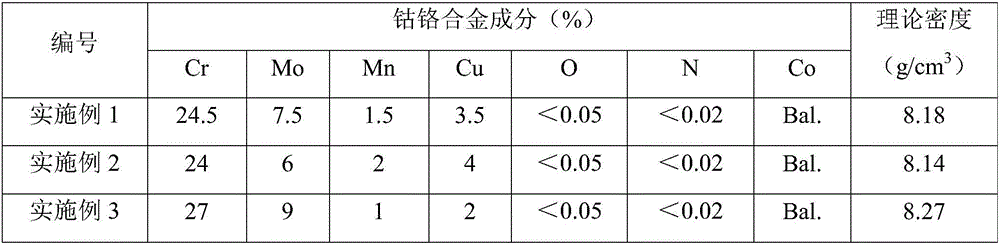

Cobalt-chromium alloy powder and preparation method and application thereof

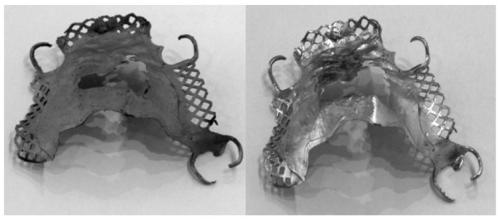

ActiveCN106381419AGood biocompatibilityLow densityImpression capsAdditive manufacturing apparatusManufacturing technologyBiocompatibility Testing

The invention relates to cobalt-chromium alloy powder and a preparation method and application thereof, and belongs to the technical field of material increase manufacturing in the department of dentistry. The cobalt-chromium alloy powder special for material increase manufacturing in the department of dentistry is provided. The cobalt-chromium alloy powder comprises, by weight, 24%-27% of Cr, 6%-9% of Mo, 2%-4% of Cu, 1%-2% of Mn, 0-0.05% of O, 0-0.02% of N and the balance Co. According to the cobalt-chromium alloy powder, the specific ingredients and matching are adopted, so that the alloy density is decreased, and the low-weight purpose of final products is realized; the toxicity caused by beryllium, cadmium and nickel in final cobalt-chromium alloy in the department of dentistry is completely removed while the usability is guaranteed, and biocompatibility of the cobalt-chromium alloy is greatly enhanced; and moreover, the powder prepared through the preparation method has the advantages of being good in degree of sphericity, small in number of hollow sphere particles, good in mobility and the like, thereby being capable of completely meeting the requirement for the powder by metal material increase manufacturing.

Owner:OPTIMAL MATERIAL TECH CO LTD

Cobalt chrome alloy containing rare earth La for dental ceramic stent

InactiveCN1827814AHigh wearing safetyHigh strengthImpression capsDentistry preparationsCobaltInduction furnace

The invention relates the stove enamel support cobalt chromium alloy containing rare earth La used for teeth. The method uses the electrolysis Co, metal Cr, metal Mo, metal La, metal W, electrolysis Mn, and crystal Si as raw materials, getting the cast ingot by melting them in electric induction furnace. The chemical compositions are following: Cr 15.0-30.0wt%,Mo 4.0-9.0wt%, La 0.03-0.30wt%, Mn 0-2.0wt%, Si 0-3.0wt%, W 0-10.0wt%,C 0-0.2wt% and Co. The alloy can be made with the casting machine, stove enamel furnace, and porcelain. The alloy binding ability is improved because of the rare earth La. The test indicates: alloy bonding strength is 75MPa, strength for extension (ªÊb ) is 800MPa, yield strength (ªÊ0.2) is 680MPa, elongation (ª€5) is 18%, diamond pyramid hardness (HV) is 300-400, coefficient of thermal expansion (ª‡RT-500Deg.C) is 13.4-14.5ª–m / m / Deg.C, and casting shrinkage is 1.8-2.1%. The binding ring and bar, which are cast by cobalt chromium alloy, has the advantages of high intensity and good rebound elasticity. The invention is the ideal material.

Owner:SICHUAN UNIV

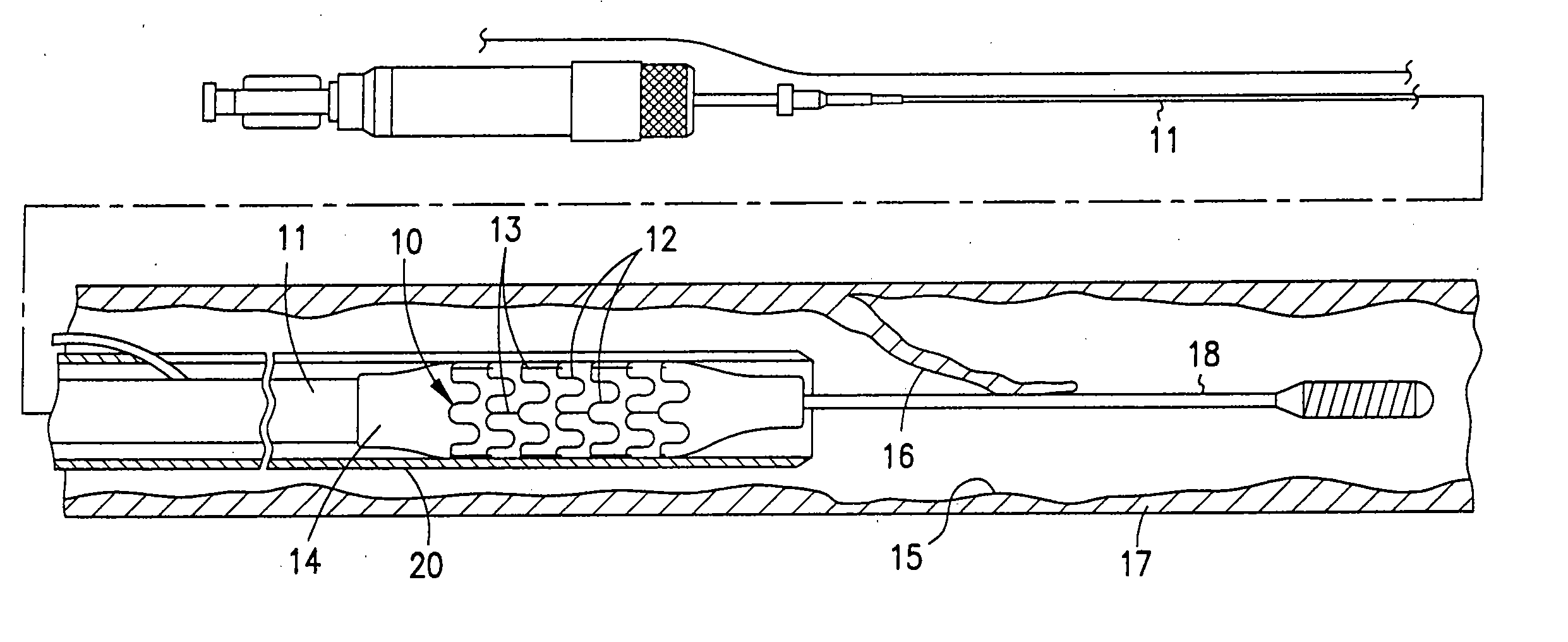

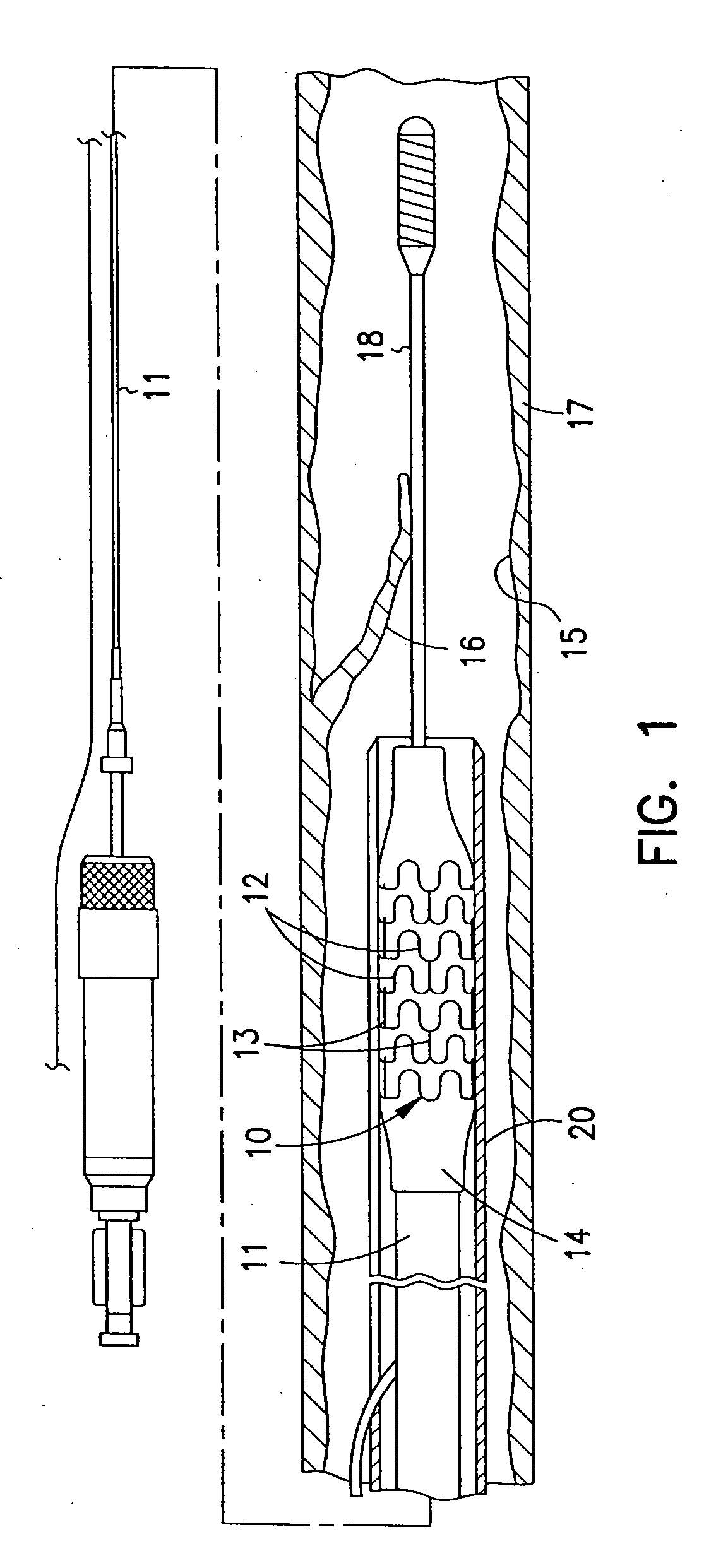

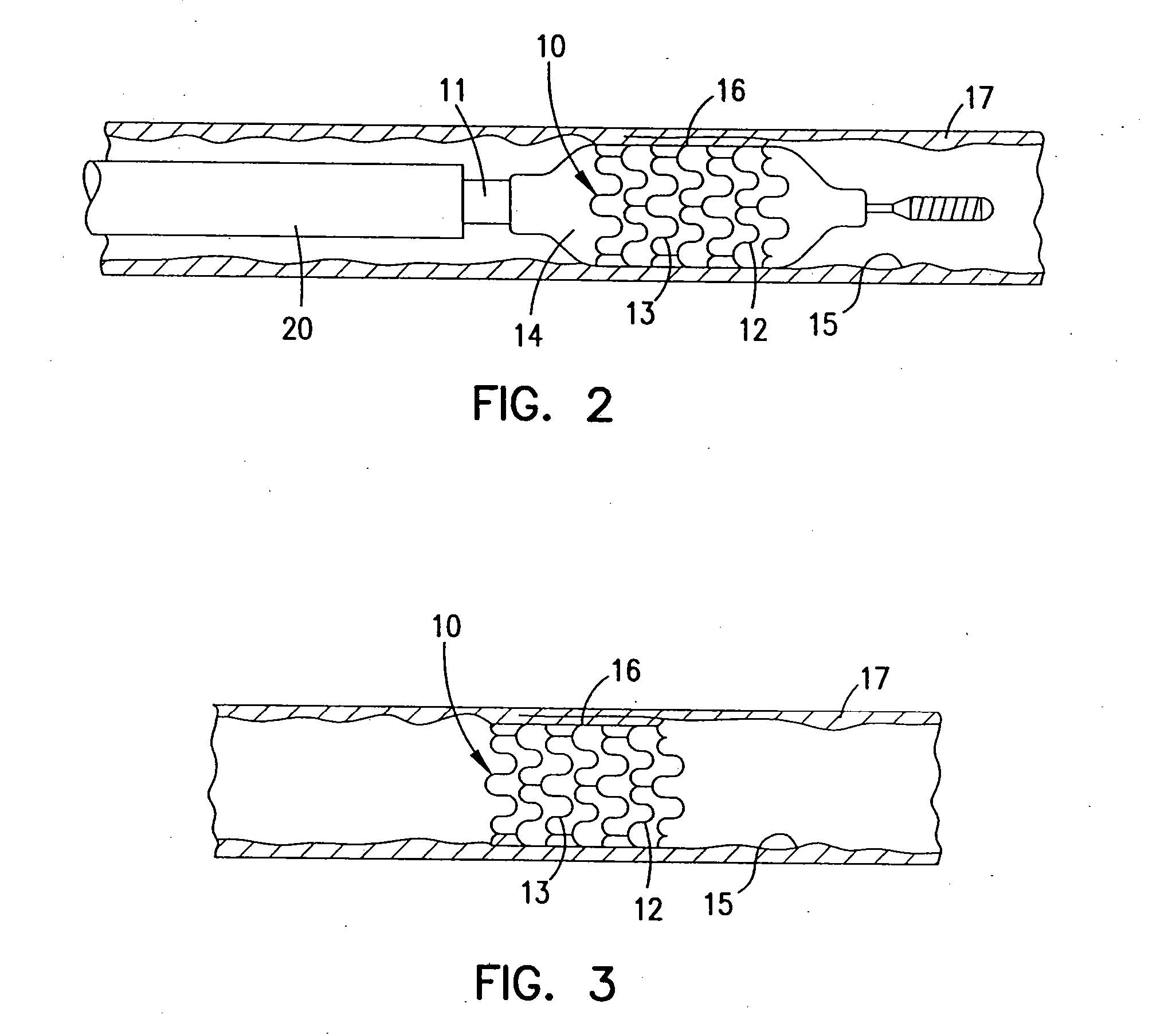

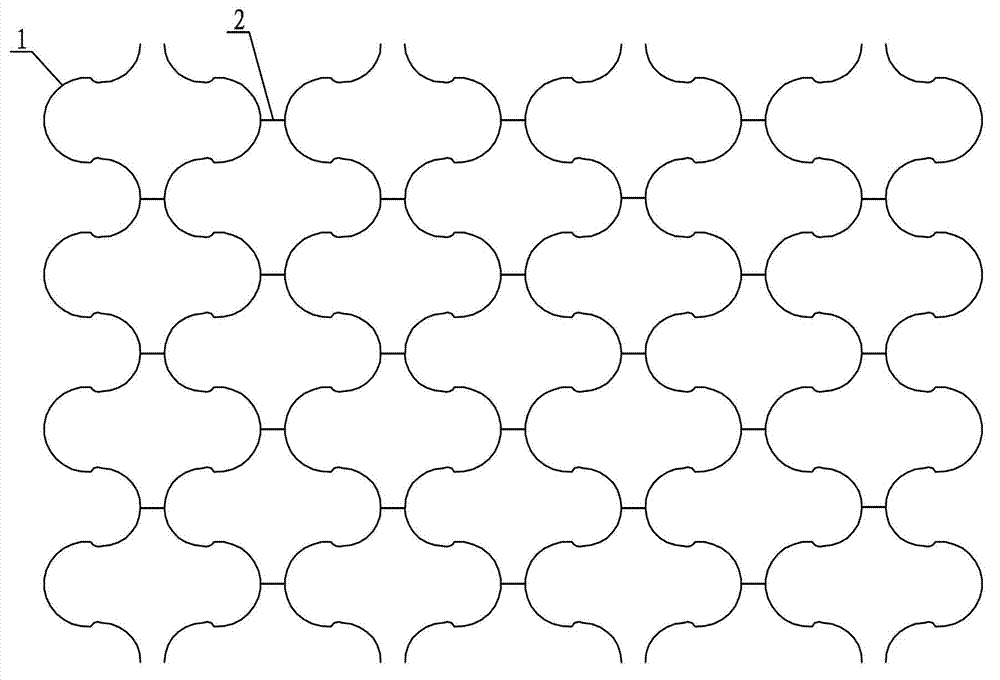

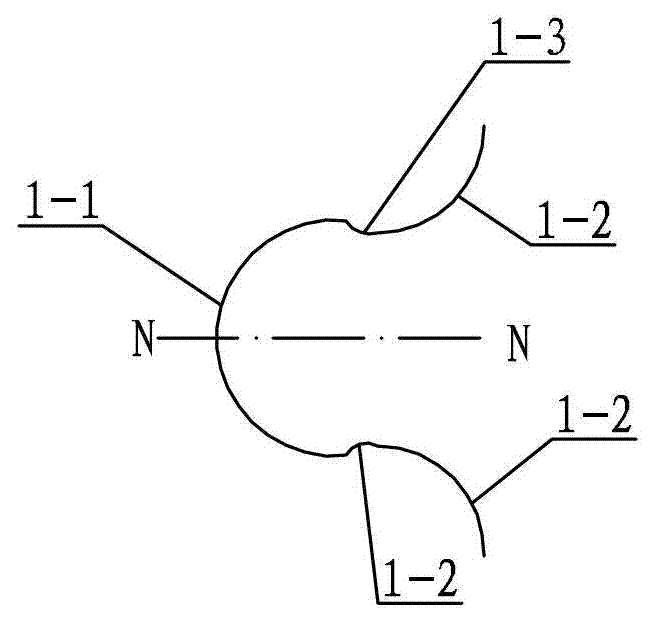

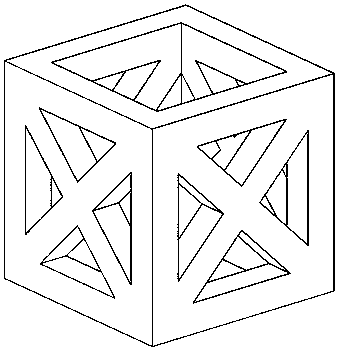

Magnesium alloy coronary support frame

ActiveCN103110465ADoes not cause toxic reactionsImprove the quality of lifeStentsSurgeryCoronary heart diseaseToxic reaction

The invention provides a magnesium alloy coronary support frame and relates to a metal coronary artery support frame. The problems that metal preparation which is not degradable of stainless steel, cobalt chrome alloy, platinum iridium alloy, chromel alloy, tantalum and the like are adopted by the prior support frame, toxic reaction is caused due to the fact that the support frame is implanted in a blood vessel as a foreign material are solved. The support frame is carved into a net shape round pipe structure by the magnesium alloy through a laser. The net shape round pipe structure is composed of a plurality of subject units and a plurality of straight line connecting bodies. Each subject unit is composed of a half circular ring, two quarters of round rings and two arcs. The two quarters of the round rings are arranged symmetrically at two ends of the half circular ring. The quarters of the round rings are connected with the half circular ring through the arcs. The plurality of the subject units are uniformly arranged along the axial direction and the circumference direction of a net pipe. Every adjacent two subject units are arranged symmetrically relative to a straight line connecting body in the plurality of the subject units arranged along the circumference direction. Arc top ends of every adjacent two half circular rings are connected with one straight line connecting body. The magnesium alloy coronary support frame is used for clinical curing coronary disease.

Owner:JIANGYIN BIODEGRADE MEDICAL TECH CO LTD

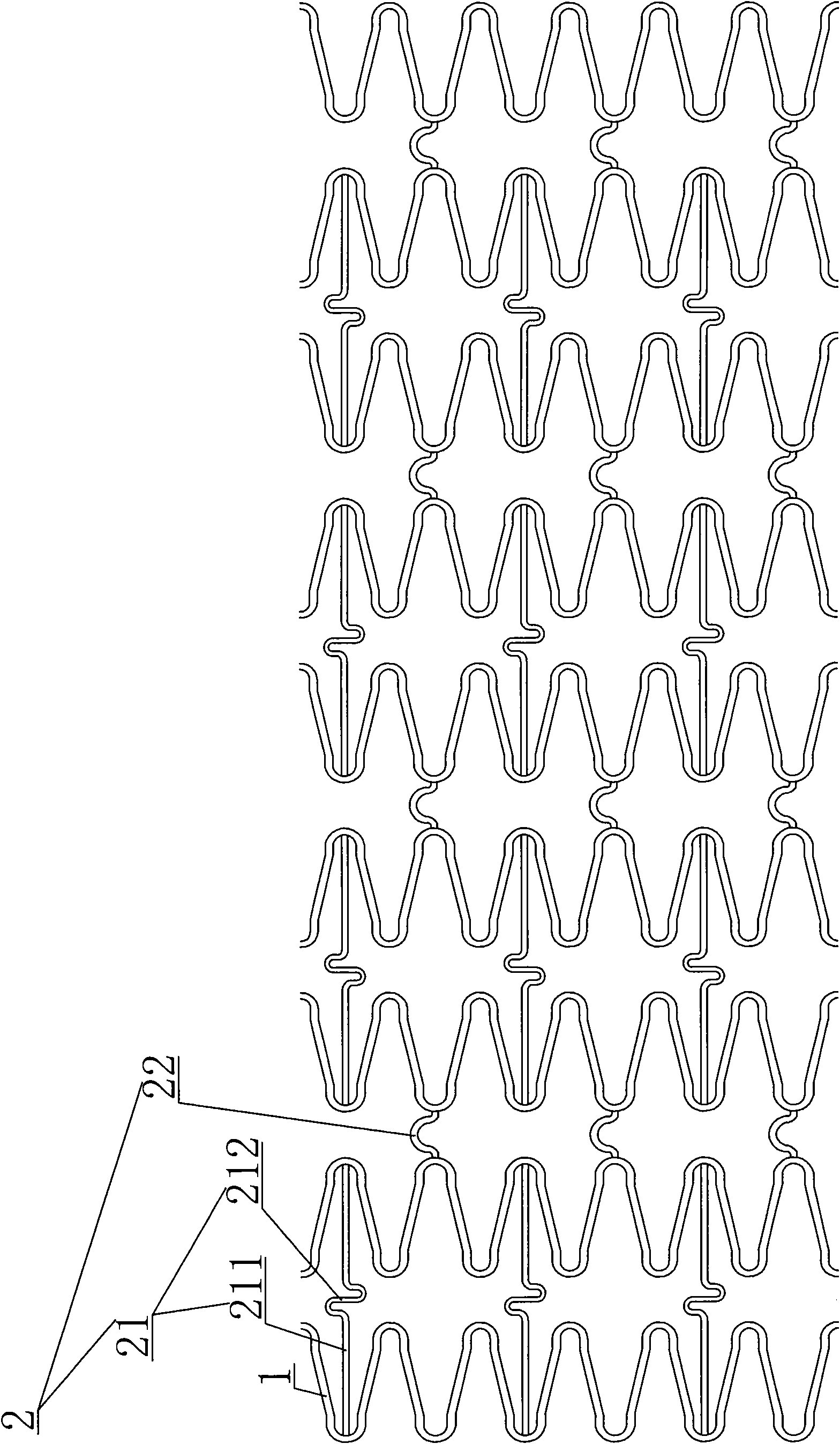

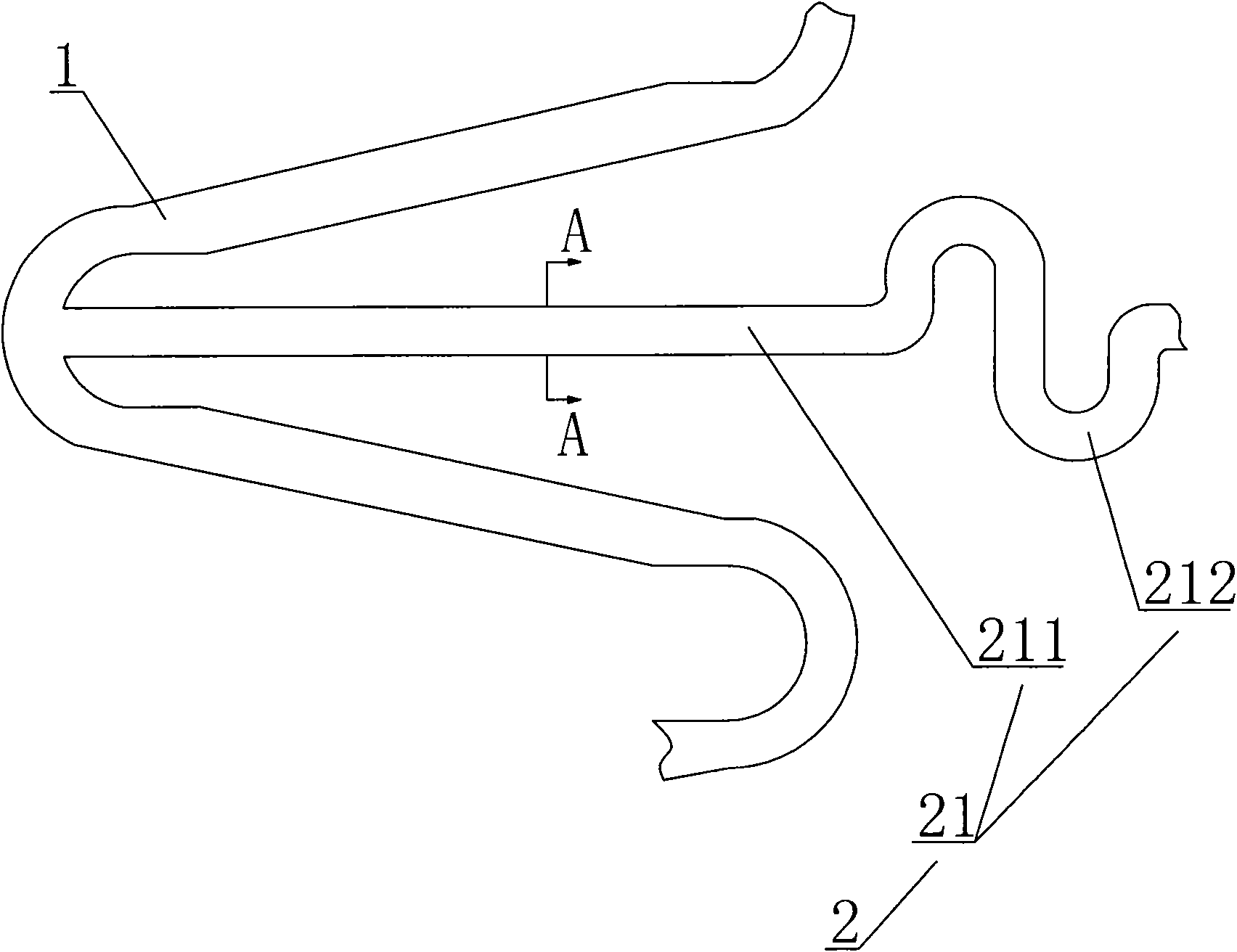

Intracranial sirolimus medicament-release blood vessel stent and preparation method thereof

InactiveCN101601616AReduce bending pressureReduce rebound rateStentsMedical devicesPercent Diameter StenosisUnit structure

The invention relates to an intracranial sirolimus medicament-release blood vessel stent. The blood vessel stent has an integral net tubular structure which is formed by a cobalt-chromium alloy L605 tube through laser engraving and cutting and electrochemical polishing treatment; the net tubular structure comprises a plurality of support rods with sine waveform unit structures and connecting rods connected among the support rods; and the blood vessel stent is integrally coated with a sirolimus medicament-release layer. A preparation method for the blood vessel stent comprises the following steps: preparing the cobalt-chromium alloy L605 tube into the blood vessel stent of the net tubular structure through laser engraving and cutting and electrochemical polishing treatment; pre-treating the surface of the blood vessel stent of the net tubular structure; preparing sirolimus medicament coating solution; compositely spraying the sirolimus medicament solution to the surface of the blood vessel stent; and drying the sirolimus medicament-release blood vessel stent. The blood vessel stent has low nominal pressure, can effectively inhibit the neointimal formation of the blood vessel and the proliferation and migration of smooth muscle cells (SMC), and also can effectively solve the problem of intracranial arterial blood vessel restenosis.

Owner:万瑞飞鸿(北京)医疗器材有限公司

Preparation method of antibacterial cobalt chromium alloy porcelain artificial tooth

ActiveCN103060618AQuickly vaporize and eliminateEasy feedingImpression capsFoundry mouldsSand blastingCobalt-chrome

The invention discloses a preparation method of an antibacterial cobalt chromium alloy porcelain artificial tooth. Cobalt chromium alloy consists of Cr, Mo, W, Mn, Nb, Si, Ag, Cu, Ce and Co. The preparation method comprises the following steps: (1) manufacturing a lost foam pattern, then coating a coating on the surface, putting into a sand box after the coating is dried, filling sand and compacting, and putting into a pouring table with a vibration device; (2) putting ingot metal, intermediate alloy and other raw materials into an induction furnace for melting according to the mixture ratio, testing and adjusting ingredients after solution is uniform, then adjusting the pouring temperature, ensuring that the pouring temperature is about 30-40 DEG C higher than that of an alloy melting point and preparing to pour; (3) starting the vibration device, so that the vibration frequency is about 140-160 Hz, and the amplitude of vibration is about 4-6 mm and then pouring the solution in the step (2); and (4) sand-blasting, ultrasonic cleaning and conventional porcelain-baking after cooling and cleaning. The prepared artificial tooth has the advantages of excellent performance and good antibacterial effect.

Owner:GUANGZHOU NALIAN MATERIAL TECH CO LTD

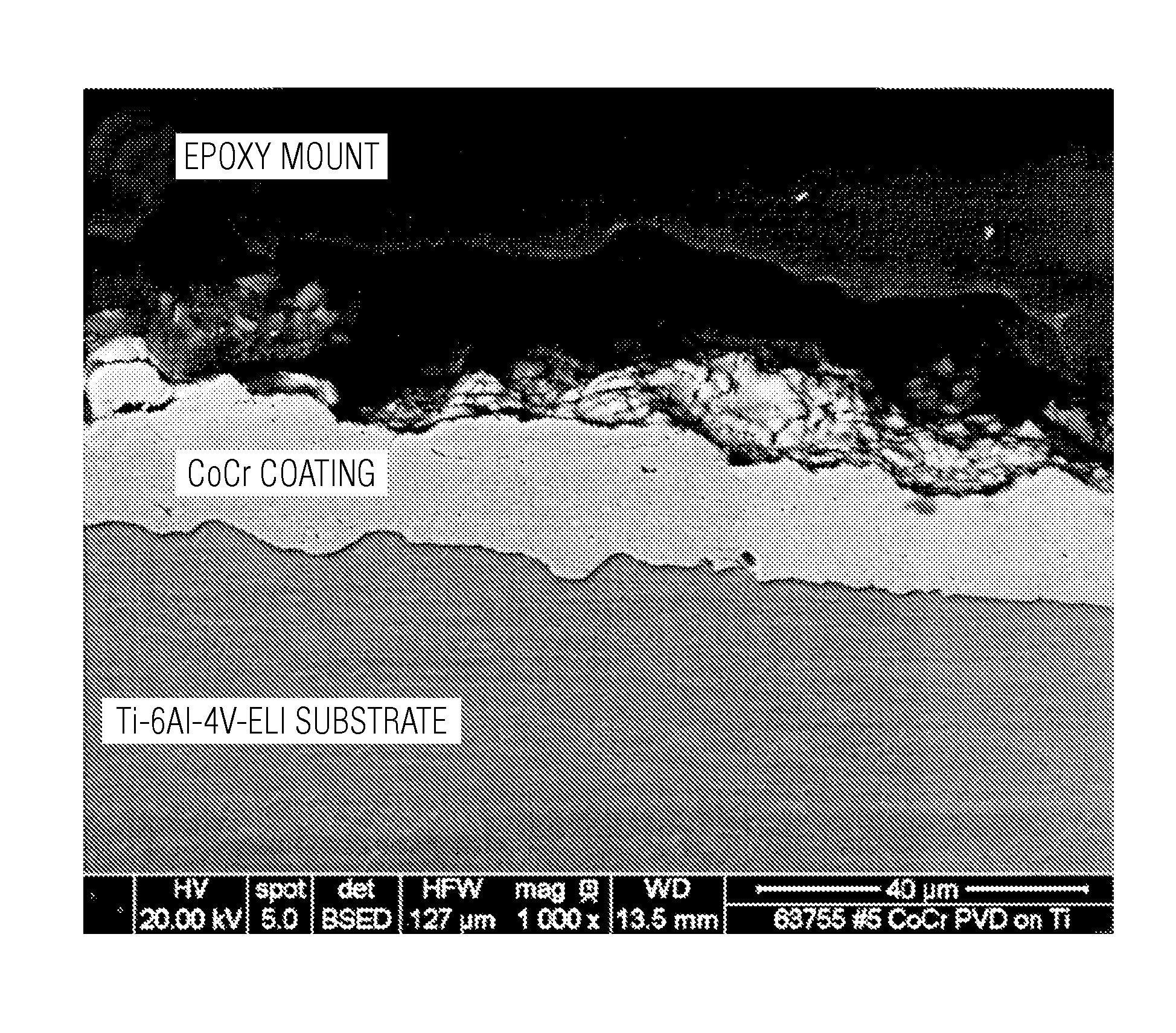

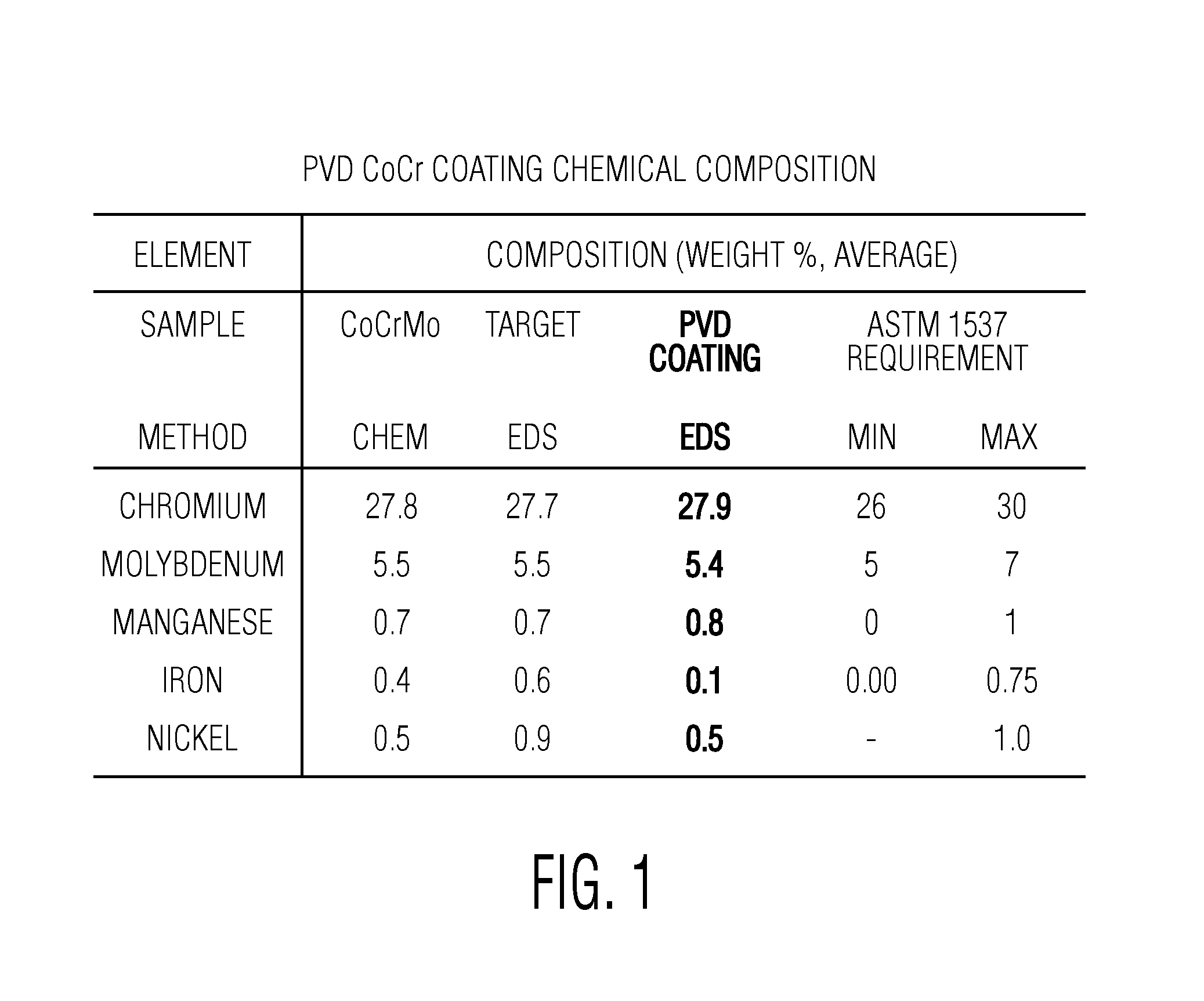

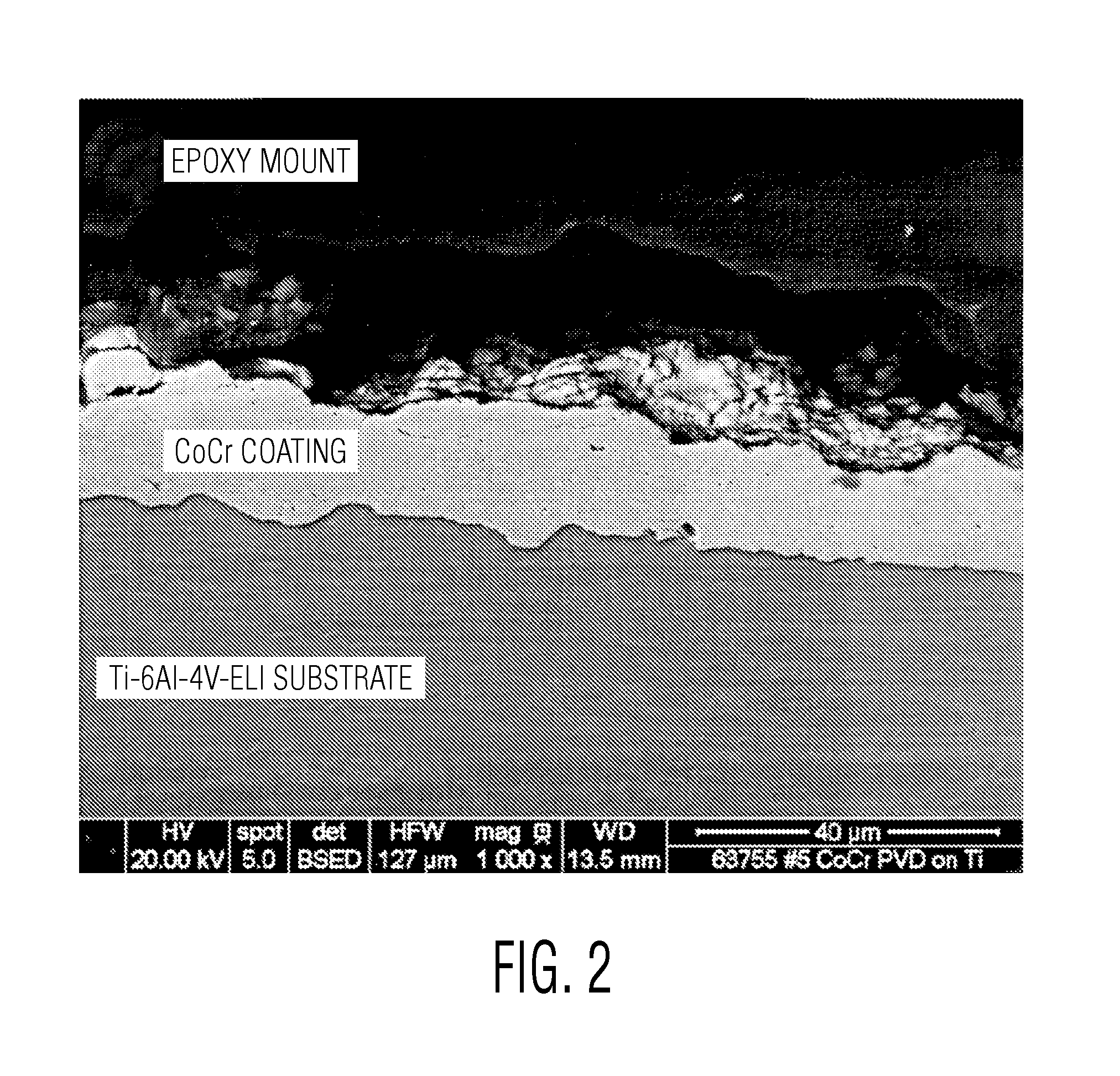

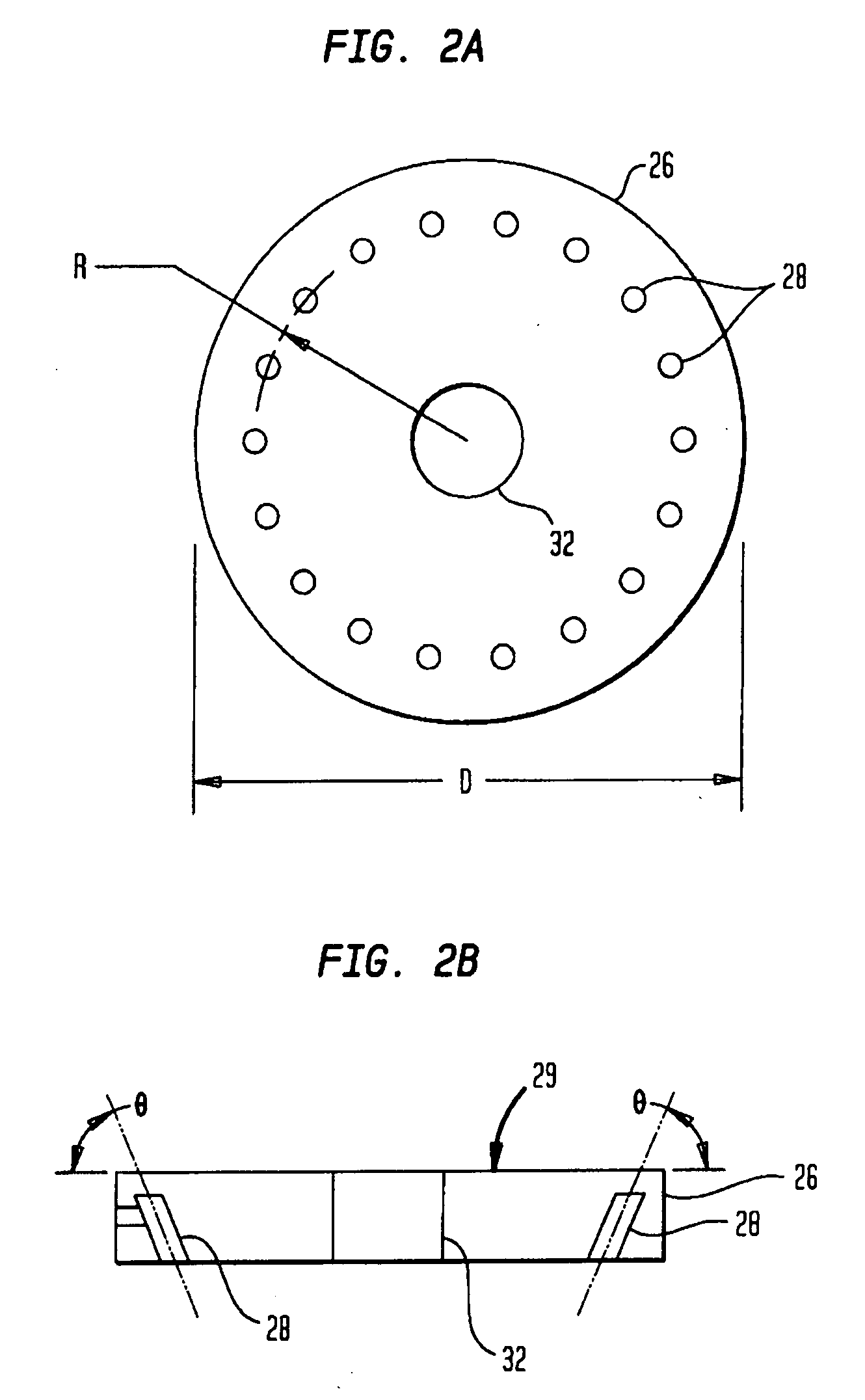

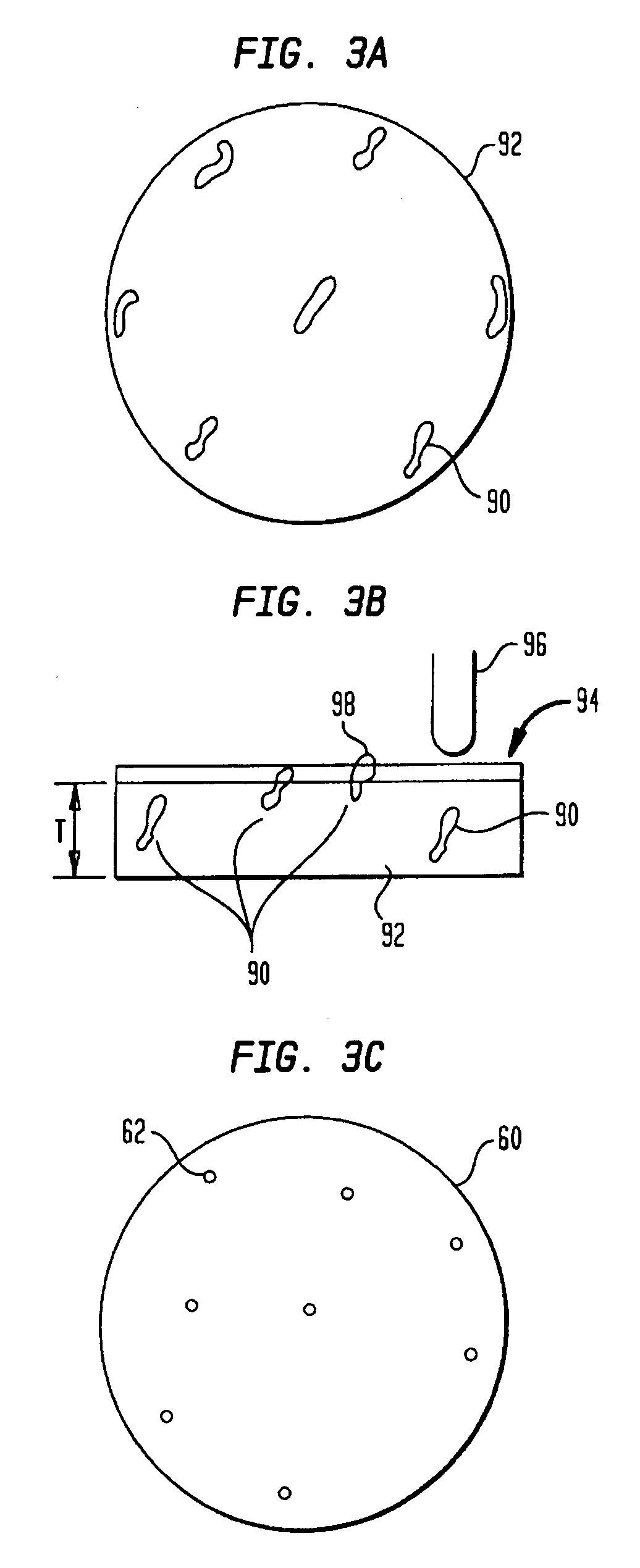

Cobalt chrome coated titanium implant

ActiveUS9370605B2Third body wear resistanceHigh hardnessVacuum evaporation coatingSputtering coatingCobalt-chromeProsthetic joint component

Owner:HOWMEDICA OSTEONICS CORP

Polishing solution for cobalt-chromium metal electrolyte plasma polishing

The invention discloses a polishing solution for cobalt-chromium metal electrolyte plasma polishing. The polishing solution comprises the following preparation raw materials of, in parts by weight, 5-15 parts of sulfate, 0.1-2 parts of organic acid and 150-300 parts of water. The polishing solution for cobalt-chromium metal electrolyte plasma polishing is specially used for the development of cobalt-chromium metal workpieces, and processing operation does not influence the application performance of a to-be-polished metal accessory in a specific field; after being polished, the workpieces arebright and glossy, and the surfaces of the workpieces is smooth and sand-free; and the processing efficiency is improved, and the damage such as burning black and notches of the workpieces are avoided.

Owner:广州市雷傲科技有限公司

Method for manufacturing cobalt-chrome artificial tooth

InactiveCN106308953ARapid productionInhibit sheddingTooth crownsArtificial teethNumerical controlWax

The invention relates to the field of tooth mold manufacturing, in particular to a method for manufacturing a cobalt-chrome artificial tooth. The method for manufacturing the cobalt-chrome artificial tooth comprises the steps that S1, an artificial tooth crude base wax mold is manufactured; S2, an alloy mixture is added to the artificial tooth crude base wax mold for calcination and casting, and an artificial tooth crude base is formed; S3, the formed artificial tooth crude base is subjected to numerical control cutting, and an artificial tooth mold rudiment is formed; S4, the base crown top of the artificial tooth mold is cut, and the thickness of the occlusion position is made to be larger than that of the cut end finger-shaped structure in the middle of the crown top; S5, a protection coating is sintered outside the positions, except for the occlusion position, of the tooth mold base crown; S6, the sintered tooth mold is dyed and glazed. According to the method for manufacturing the cobalt-chrome artificial tooth, the artificial tooth crude base is cut through a numerical control device, production can be fast carried out, the size and shape of the artificial tooth can be adjusted at any time in the production process, and the method is convenient to use and practical.

Owner:李洁

Process for producing tungsten carbide cobalt chrome metal composite powder

Owner:GUANGDONG XIANGLU TUNGSTEN

Calcium phosphate coated stents comprising cobalt chromium alloy

InactiveUS20100217377A1Electrolytic inorganic material coatingSurgeryCalcium biphosphateSurface finish

Disclosed herein are medical devices, such as stents, coated with calcium phosphate and processes for making the same. The stent can comprise a cobalt chromium alloy that has been treated to improve surface adhesion to the calcium phosphate and / or improve surface finish properties. A pharmaceutically active agent can be present in the calcium phosphate coating.

Owner:MIV SCI HLDG

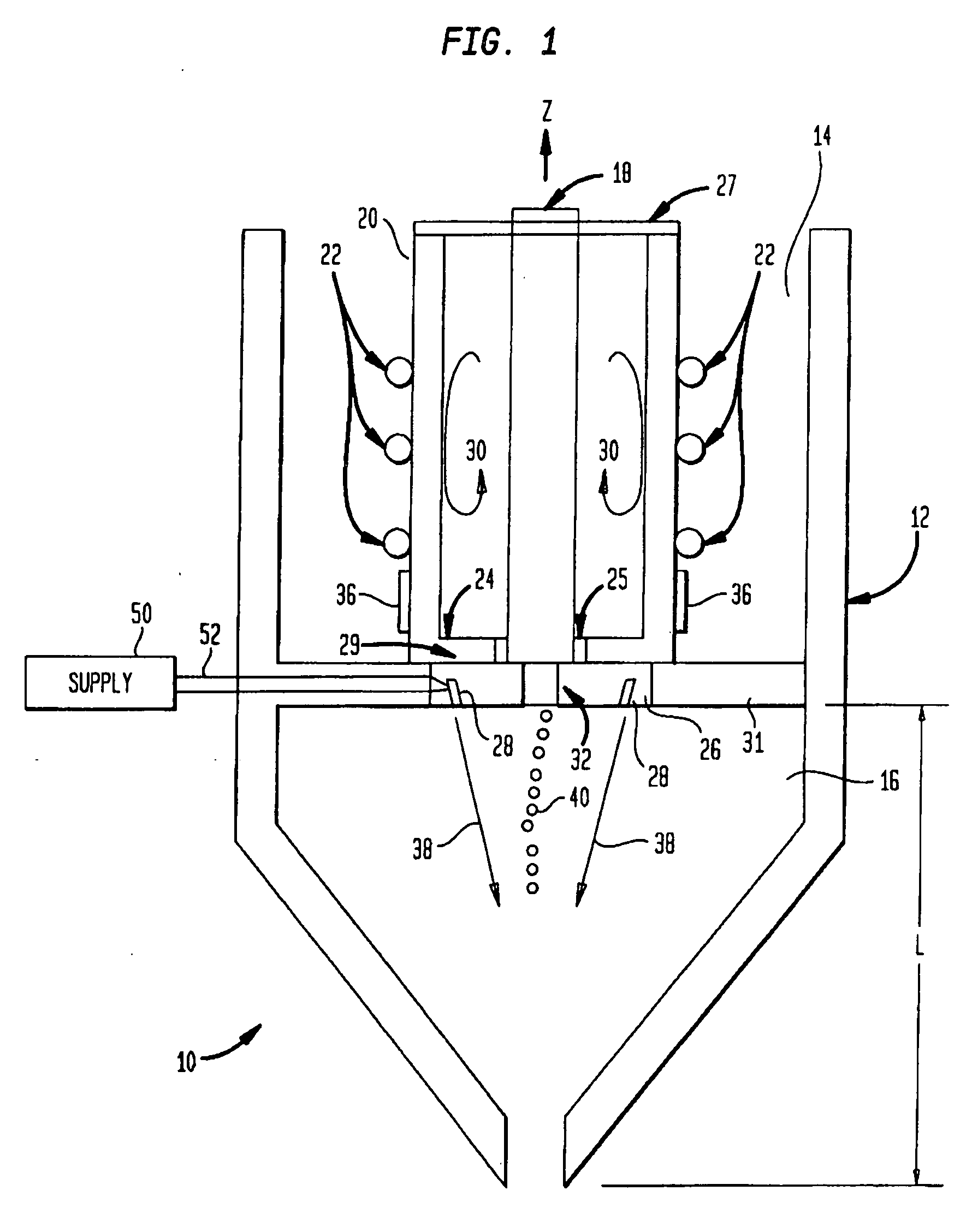

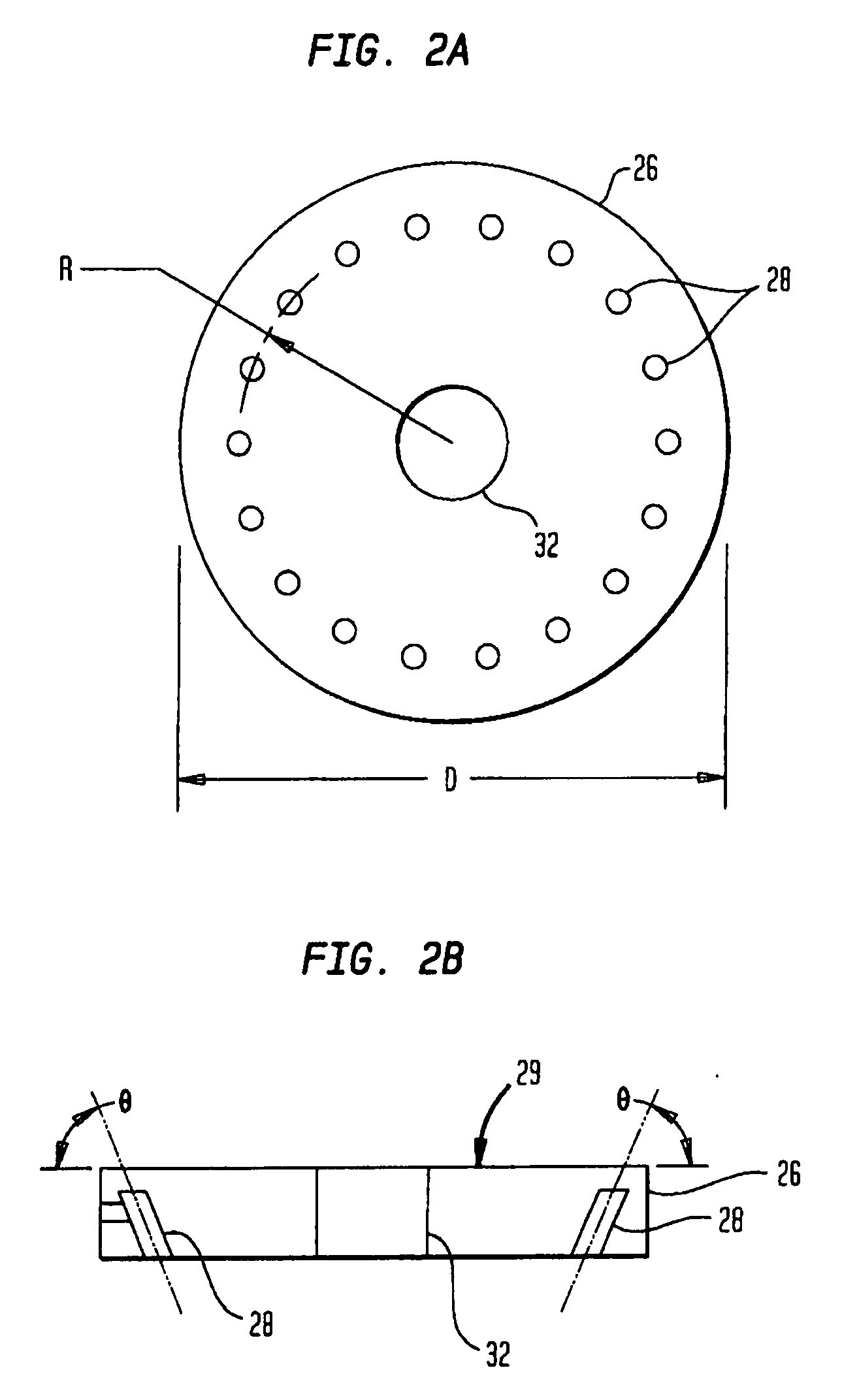

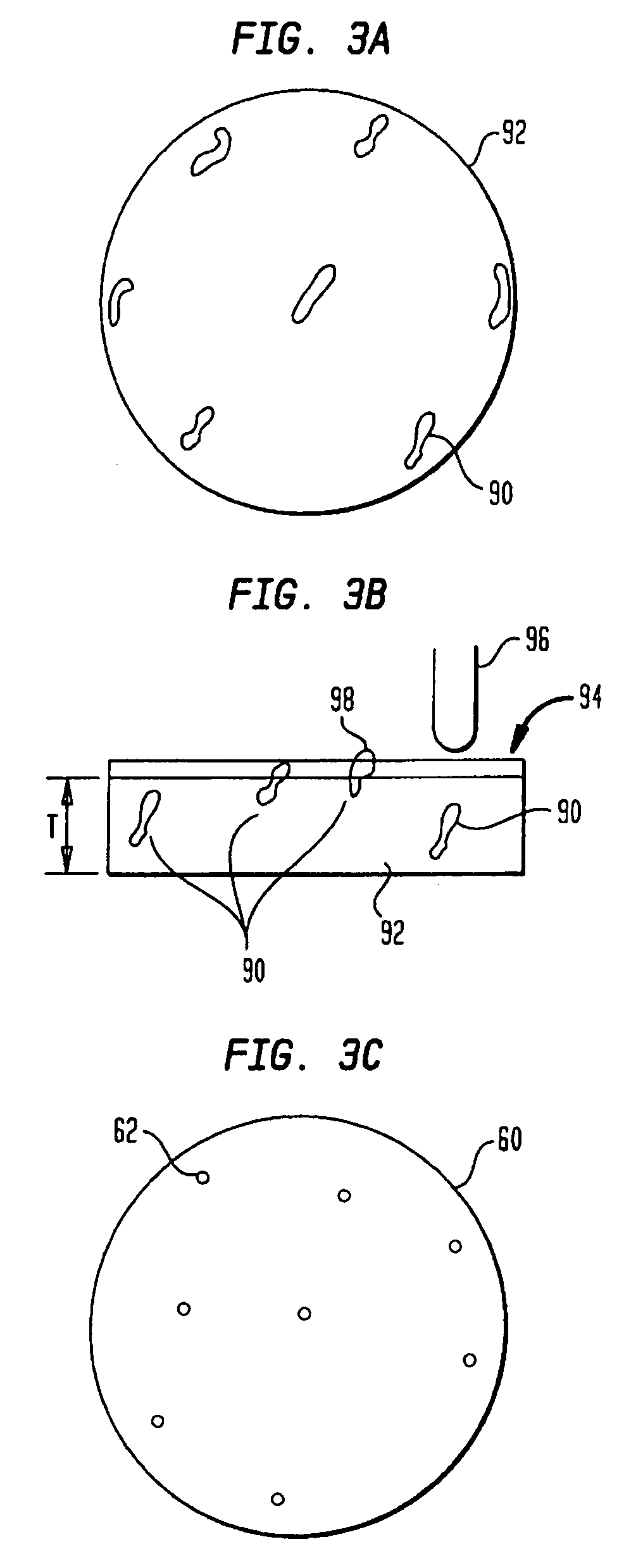

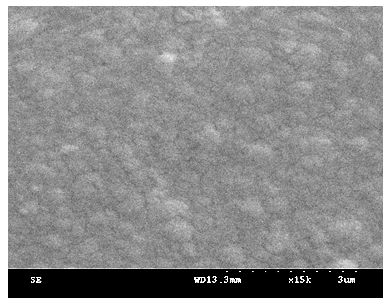

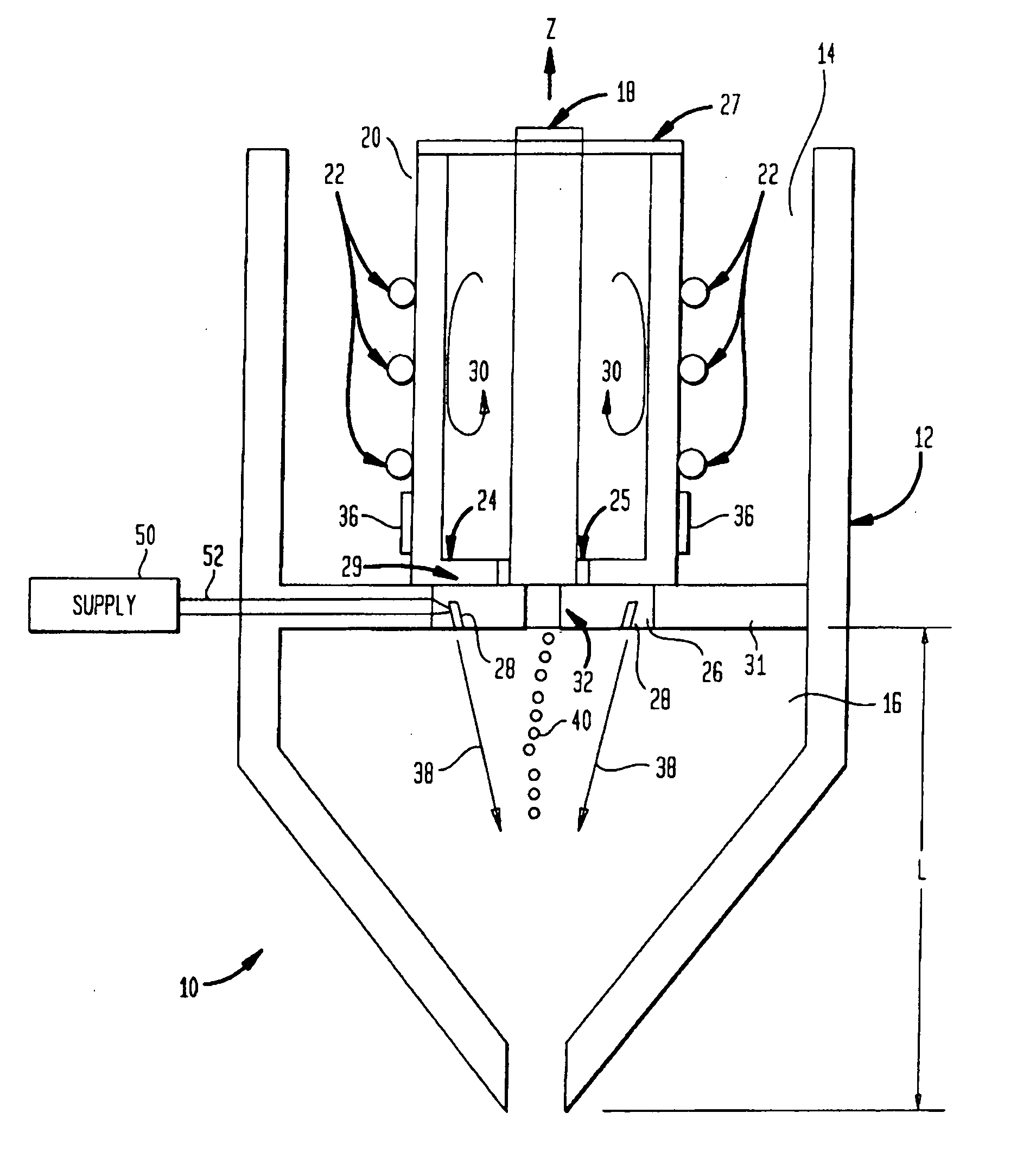

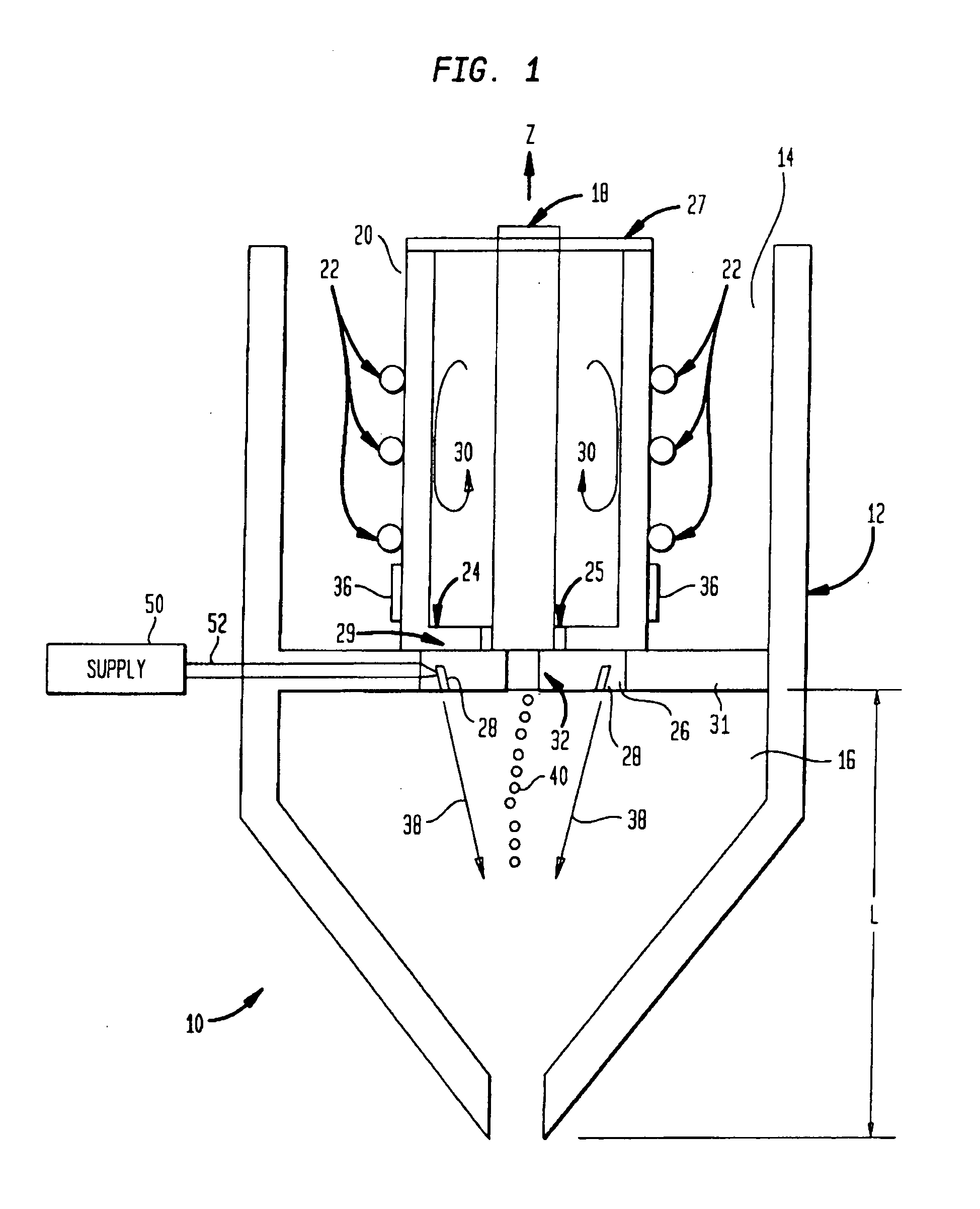

Method for fabricating a medical component from a material having a high carbide phase

A method of fabricating a medical implant component. The method may comprise producing a substrate from a first material in which the substrate has a bearing portion, and spraying particles of a second material by use of a thermal type spraying process onto at least the bearing portion of the substrate. The second material may be formed from a biocompatible material and a carbide source, in which the carbide source is 6.17% or more of the second material by weight. The biocompatible material may be cobalt chrome and the carbide source may be graphite. The thermal type spraying process may be a plasma spraying process or a high velocity oxygen fuel spraying process.

Owner:HOWMEDICA OSTEONICS CORP

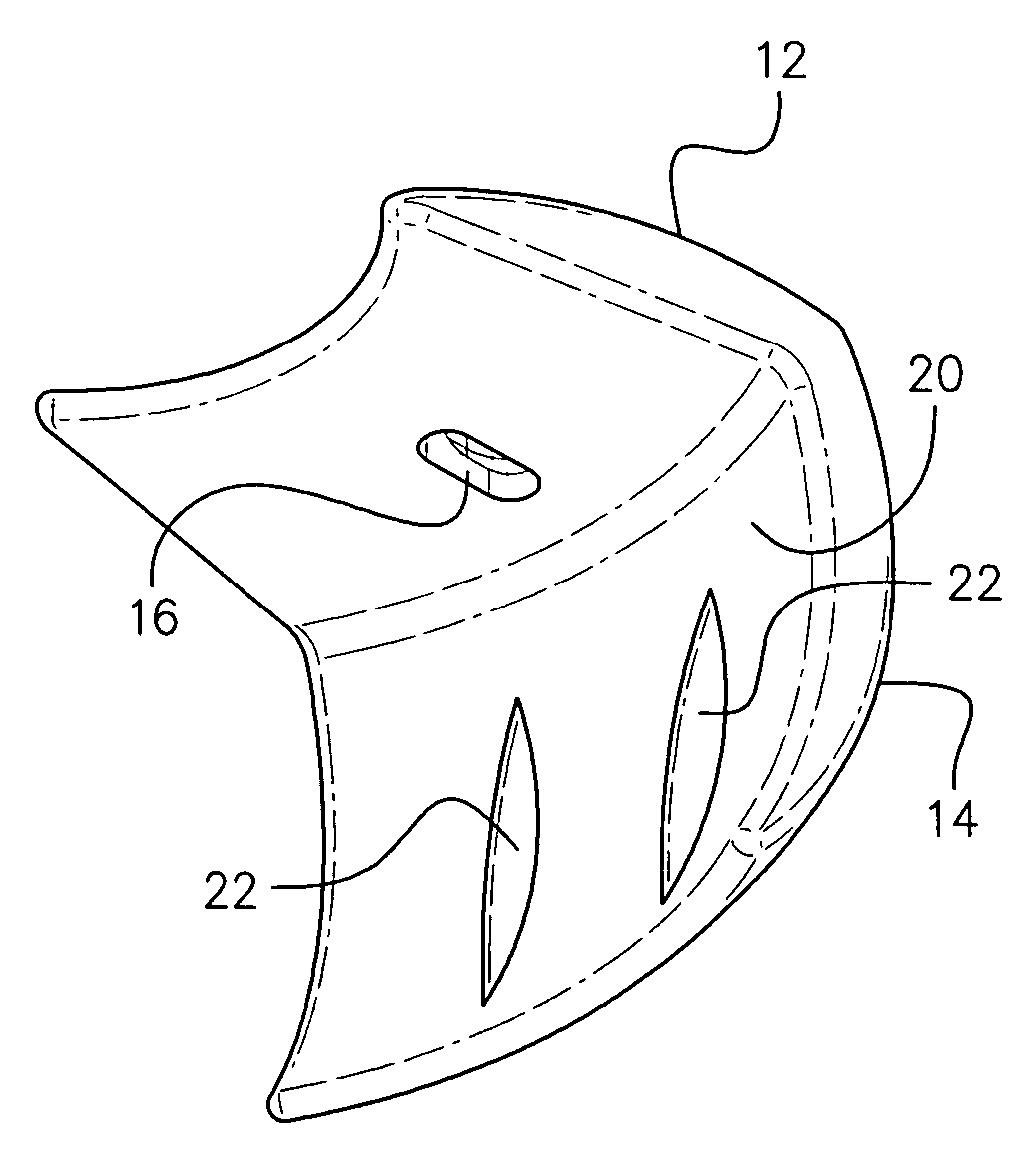

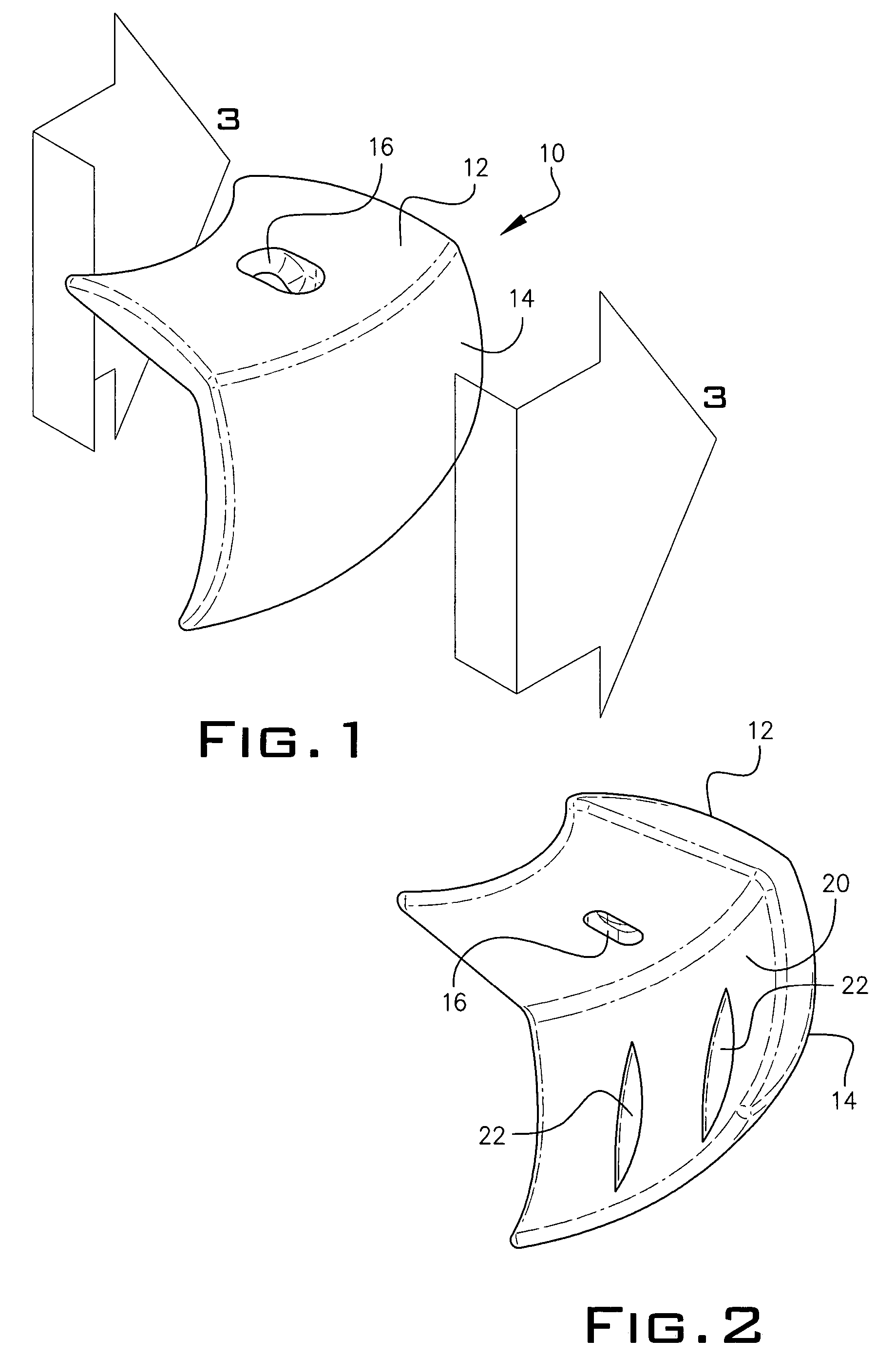

Metallic prosthetic implant for use in minimally invasive acromio-clavicular shoulder joint hemi-arthroplasty

InactiveUS20060111786A1Minimally invasiveLess traumaticJoint implantsShoulder jointsHemi arthroplastyCobalt-chrome

A biocompatible metallic implant apparatus shaped to fit a natural contour of a shoulder joint, the implant having a cobalt-chrome convex outer surface, a porous concave inner surface and blades on the inner surface for insertion into bone. A locking screw through the implant adheres the implant to the shoulder joint.

Owner:MINSURG INT

Method for fabricating a medical component from a material having a high carbide phase

A method of fabricating a medical implant component. The method may comprise producing a substrate from a first material in which the substrate has a bearing portion, and spraying particles of a second material by use of a thermal type spraying process onto at least the bearing portion of the substrate. The second material may be formed from a biocompatible material and a carbide source, in which the carbide source is 6.17% or more of the second material by weight. The biocompatible material may be cobalt chrome and the carbide source may be graphite. The thermal type spraying process may be a plasma spraying process or a high velocity oxygen fuel spraying process.

Owner:HOWMEDICA OSTEONICS CORP

Process for producing tungsten carbide cobalt chrome metal composite powder

The invention discloses a process for producing tungsten carbide cobalt chrome metal composite powder, comprising the following production steps: pre-preparing ammonium tungstate solution, cobalt nitrate solution and chromium nitrate solution; controlling the pH value by heating after controlling the concentration of ammonia in the ammonium tungstate solution; respectively adding the cobalt nitrate solution and chromium nitrate solution, and then stopping heating; adopting vacuum filtration to the solution for solid-liquid separation after cooling; obtaining a coprecipitation crystal; using ammonium nitrate solution to wash and soak the crystal and then draining and baking the crystal to implement calcination; using hydrogen to reduce the calcinated metal oxide to be metal reduction powder; and then using carbon dioxide gas to lead the metal reduction powder to be insulated from the air; adding carbon to the metal reduction powder for ball milling after low-temperature cooling; implementing low-temperature carbonization to the metal reduction powder which is added with the carbon; and finally obtaining the finished product by grinding, crushing and sieving. The process for producing tungsten carbide cobalt chrome metal composite powder has high product purity, high combined carbon content, good uniformity, normal distribution, complete particle size development, good main chemical component uniformity, and excellent use performance.

Owner:GUANGDONG XIANGLU TUNGSTEN

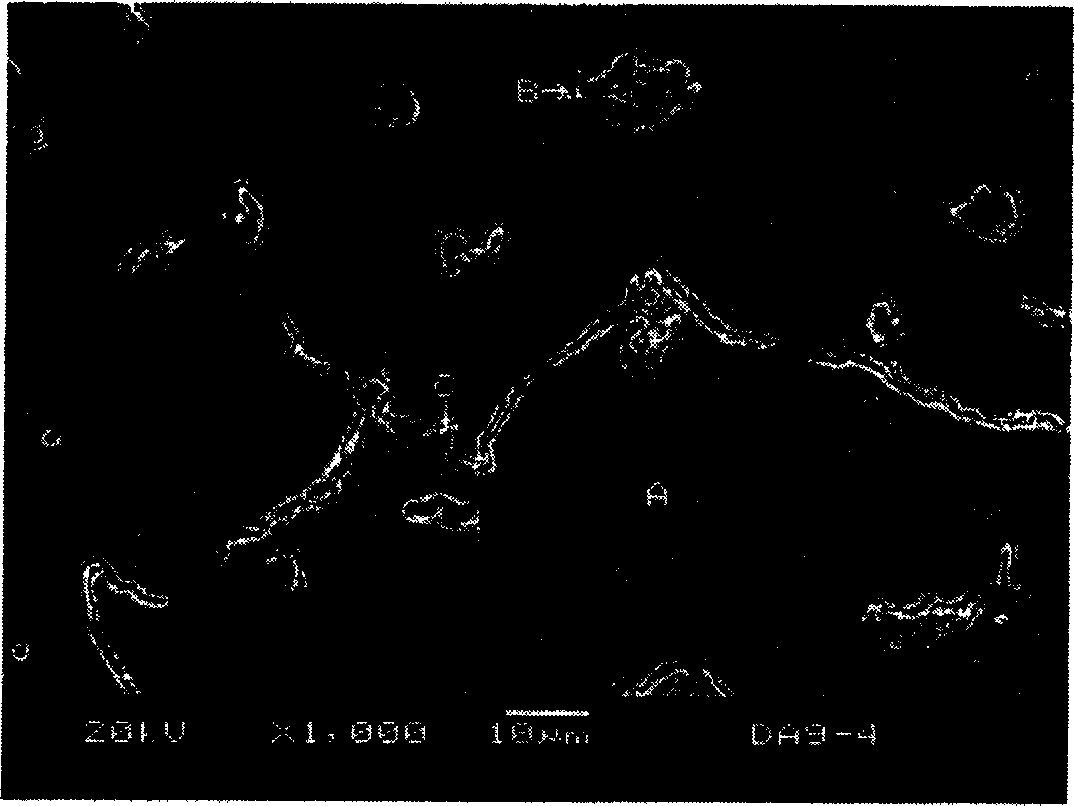

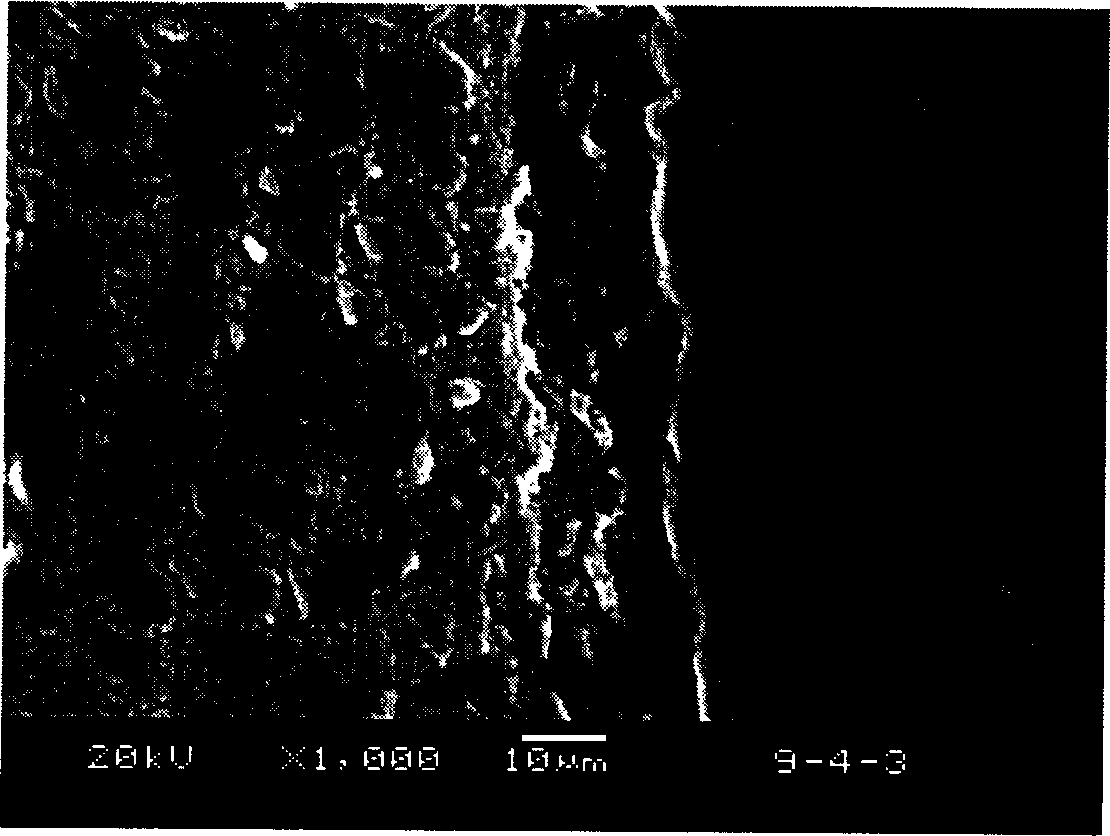

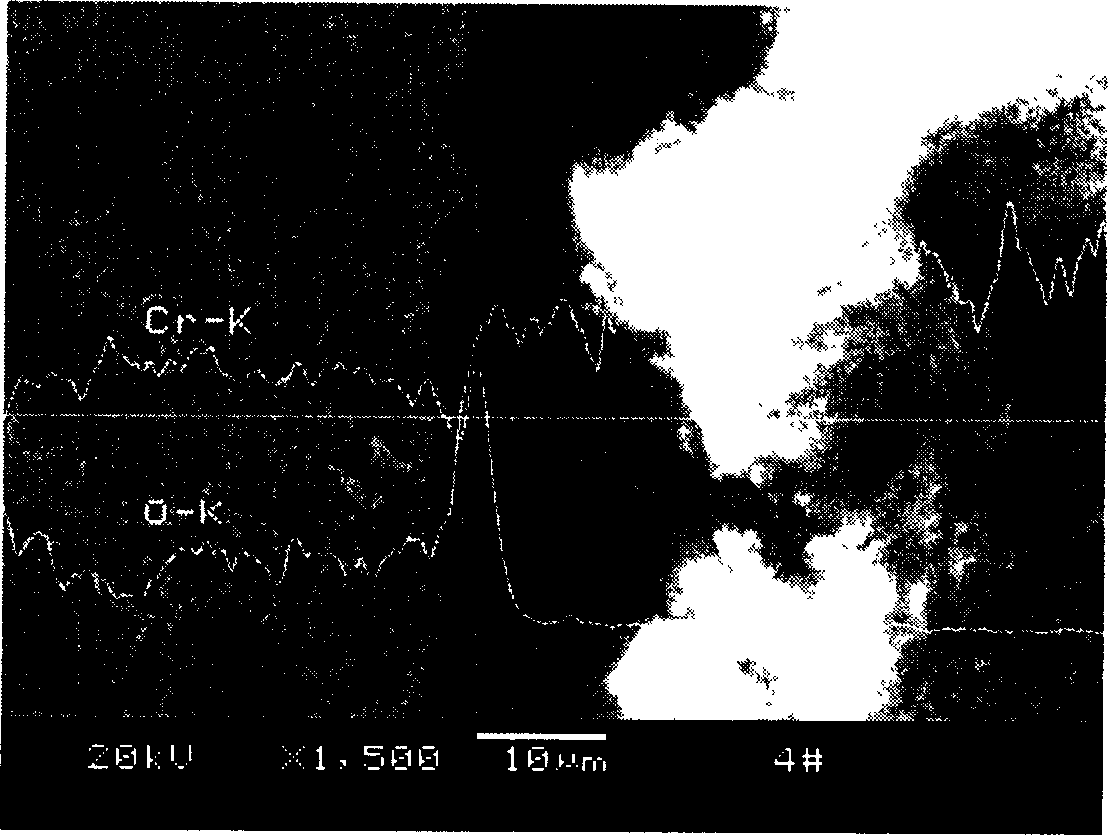

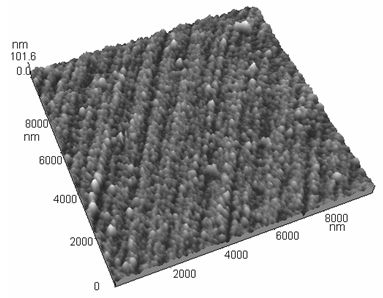

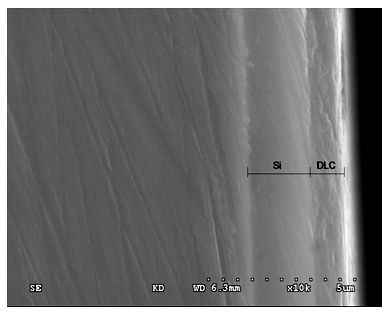

Method for preparing high-hardness diamond film on surface of medical CoCrMo alloy

InactiveCN101967626AHigh hardnessImprove stabilityChemical vapor deposition coatingSputter cleaningPolymer science

The invention discloses a method for preparing a high-hardness diamond film on the surface of medical cobalt-chrome-molybdenum (CoCrMo) alloy. The method comprises the following steps of: performing sputter-cleaning on polished and cleaned CoCrMo alloy by using hydrogen (H2) gas; depositing a silicon (Si) film transition layer on the surface of the CoCrMo alloy by taking silicane (SiH4) and hydrogen (H2) as a gas source by the conventional radio frequency plasma-enhanced chemical vapor deposition; and preparing a diamond like carbon (DLC) film on the Si film transition layer by taking methane (CH4) and hydrogen (H2) as a gas source by the conventional radio frequency plasma-enhanced chemical vapor deposition. Film bases prepared by the method are combined in a saw-toothed mode, good combination performance is represented between the film bases, and the defect of low boundary bearing capacity caused by low combination performance is overcome; meanwhile, the sp3C bond content of prepared DLC film is high, the DLC film with high hardness can be obtained and the wear resistance of the DLC film is effectively improved. In addition, the method has the advantages of simple process and low cost and has great application potential in the technical field of surface modification of a biomaterial.

Owner:CHINA UNIV OF MINING & TECH

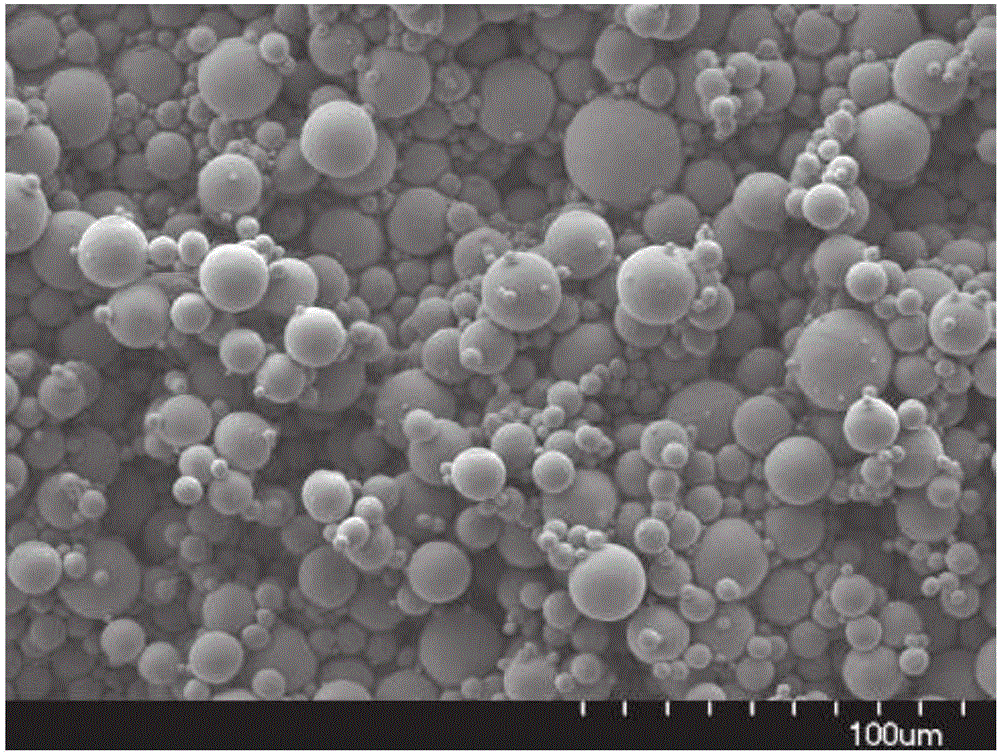

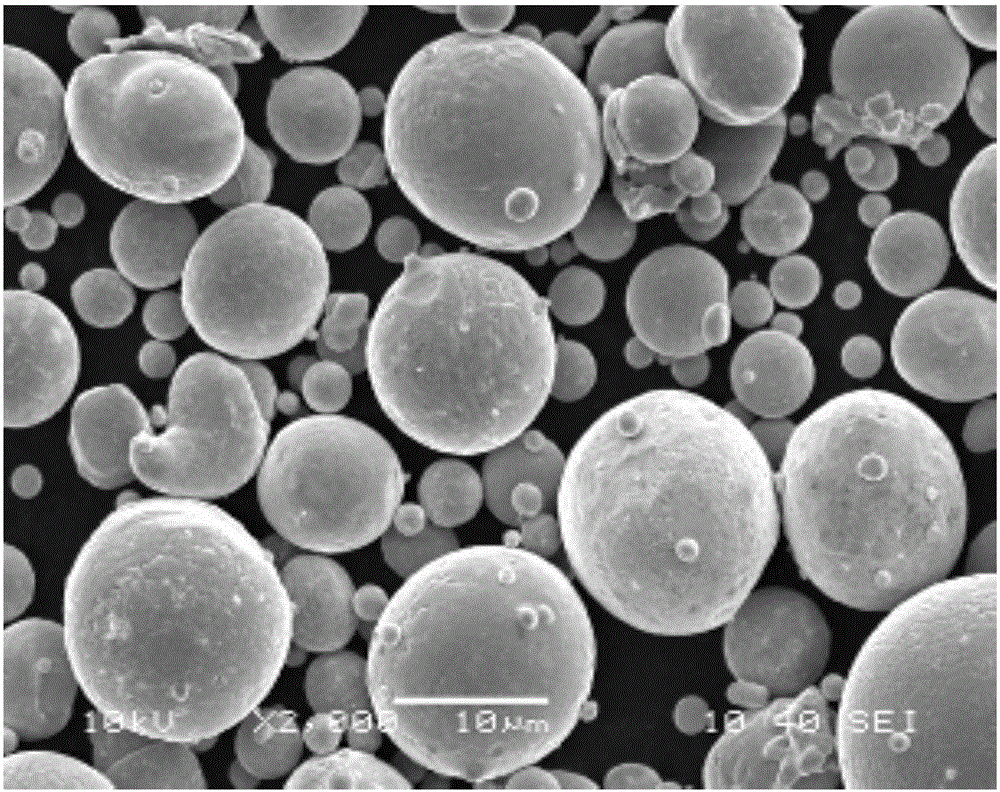

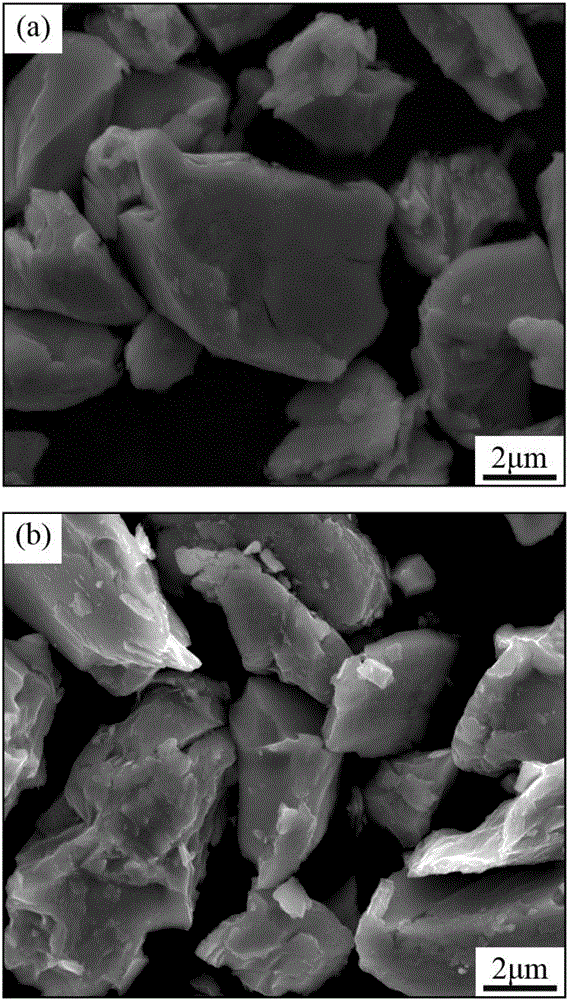

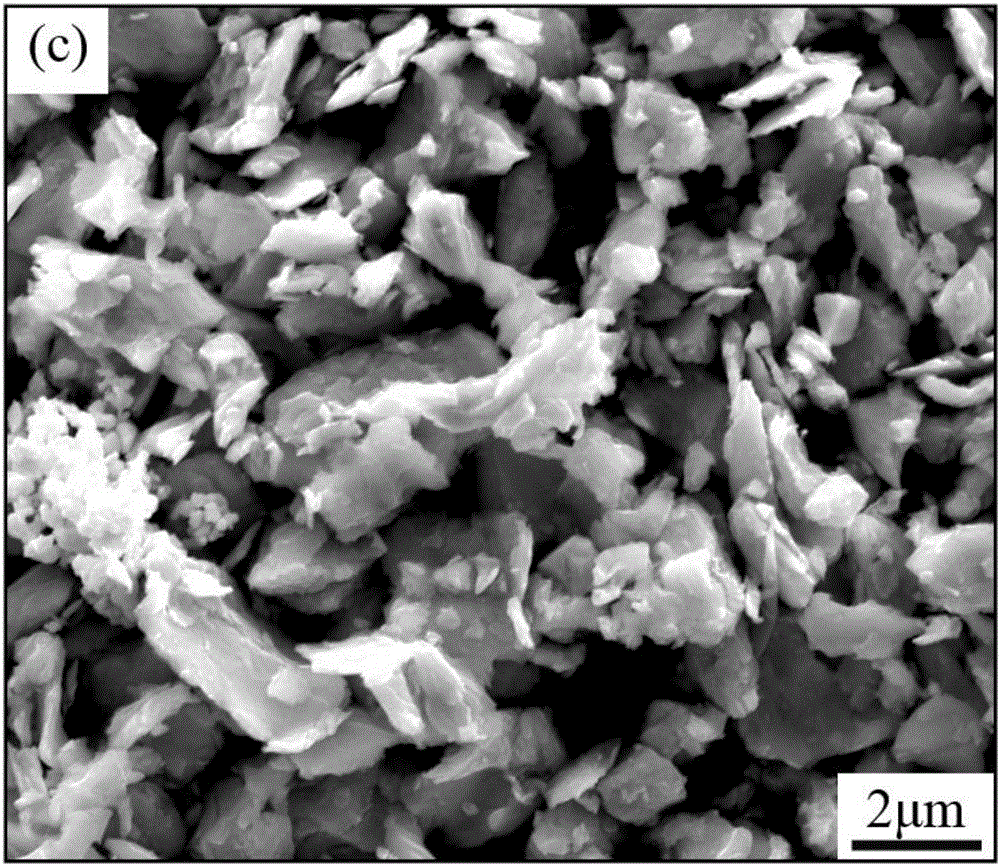

Method for preparing spherical cobalt-chromium-molybdenum alloy powder for micron-level additive material manufacturing

InactiveCN108856699AMorphological rulesHigh nodularityAdditive manufacturing apparatusTransportation and packagingCobalt-chromeAdditive layer manufacturing

The invention provides a method for preparing spherized cobalt-chromium-molybdenum alloy powder for micron-level additive material manufacturing. The adopted raw material is irregular cobalt-chromium-molybdenum alloy powder prepared through water atomization, and the micron-level spherical cobalt-chromium-molybdenum alloy powder with the irregular shape, the high nodularity larger than or equal to90%, the high sphericity degree and the high stacking density can be obtained through adjusted experiment parameter spheroidizing, and the spherical cobalt-chromium-molybdenum alloy powder can be directly used for additive material manufacturing due to good mobility.

Owner:LONGYAN ZIJIN INNOVATION RES INST

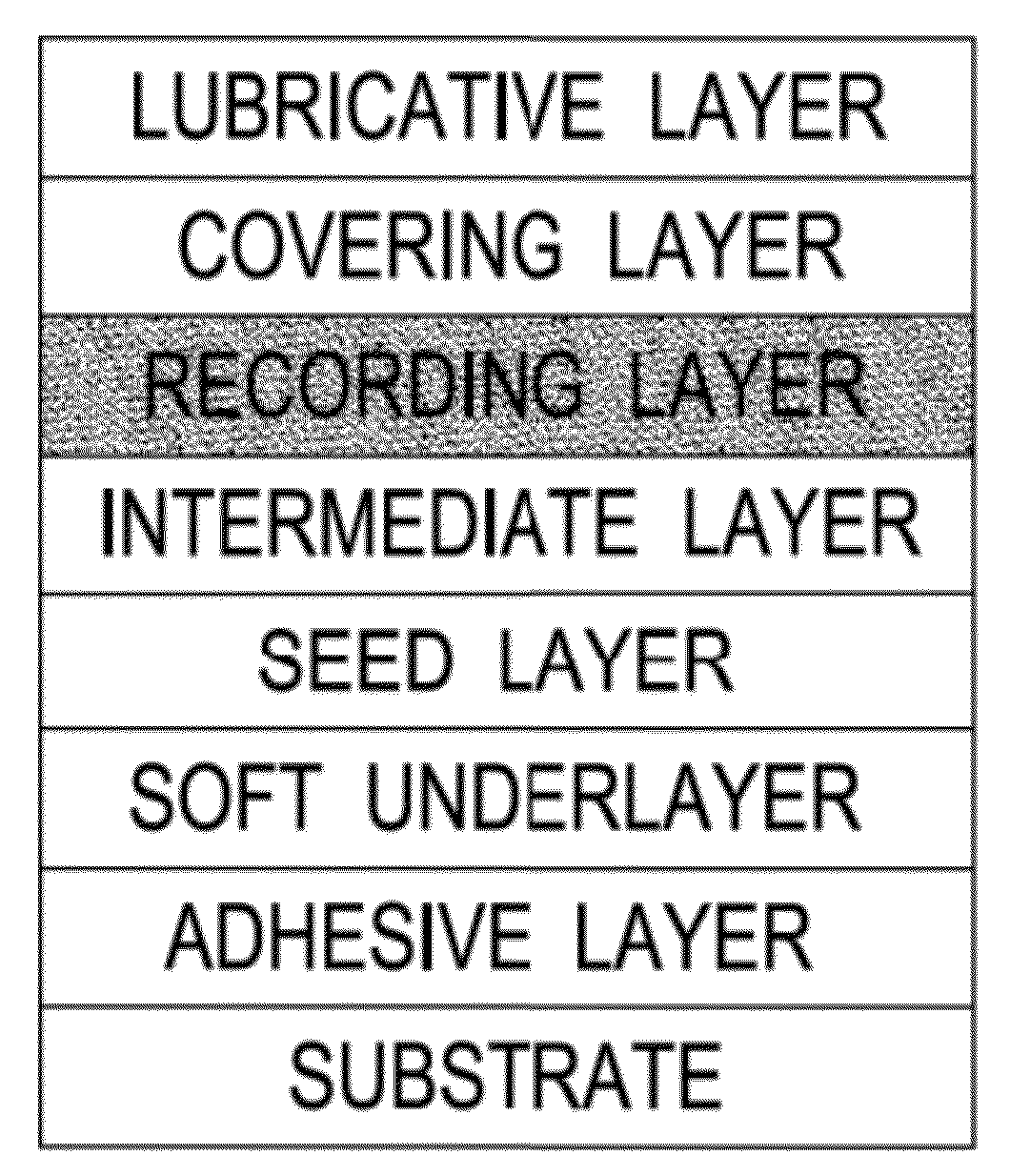

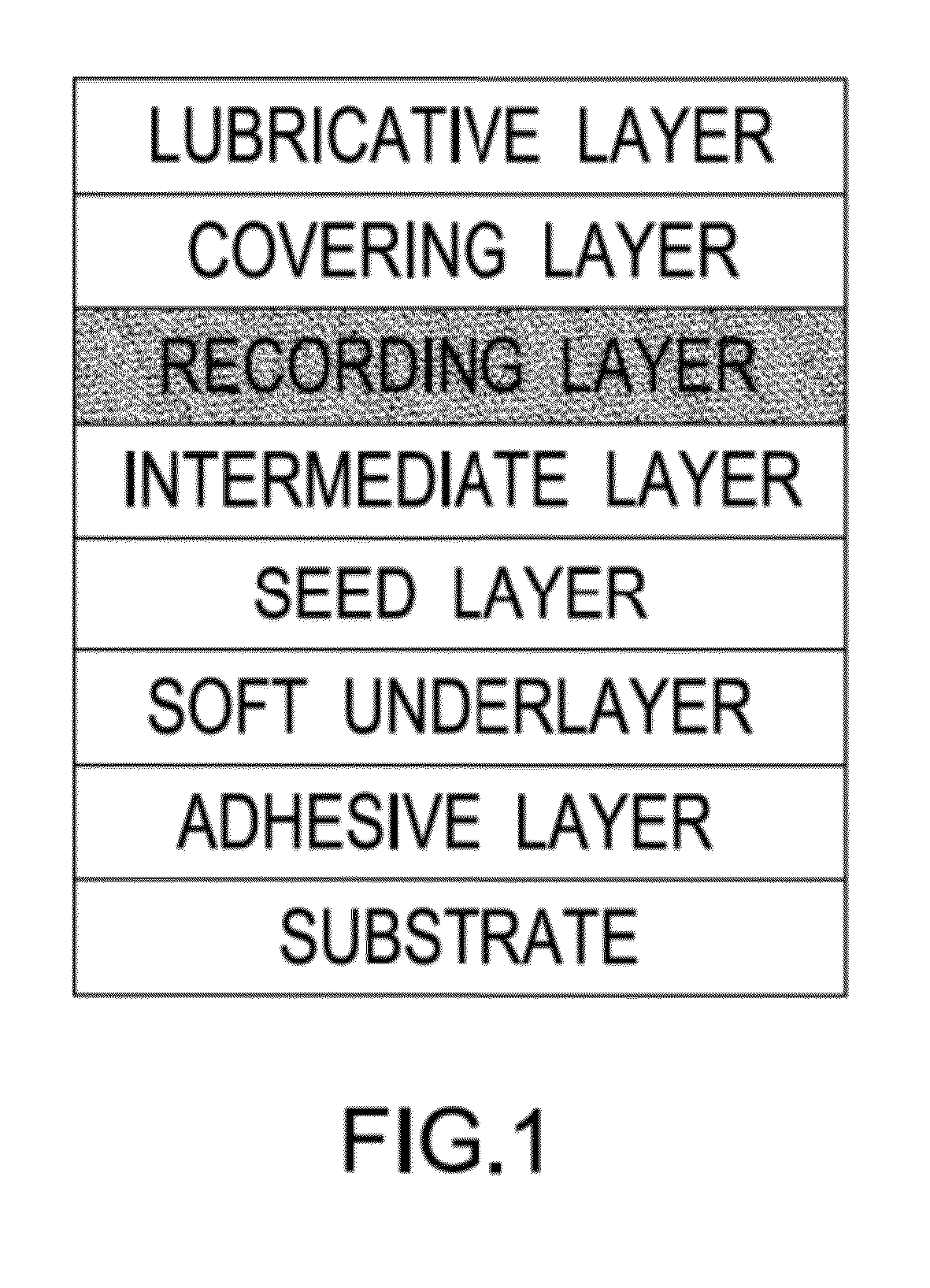

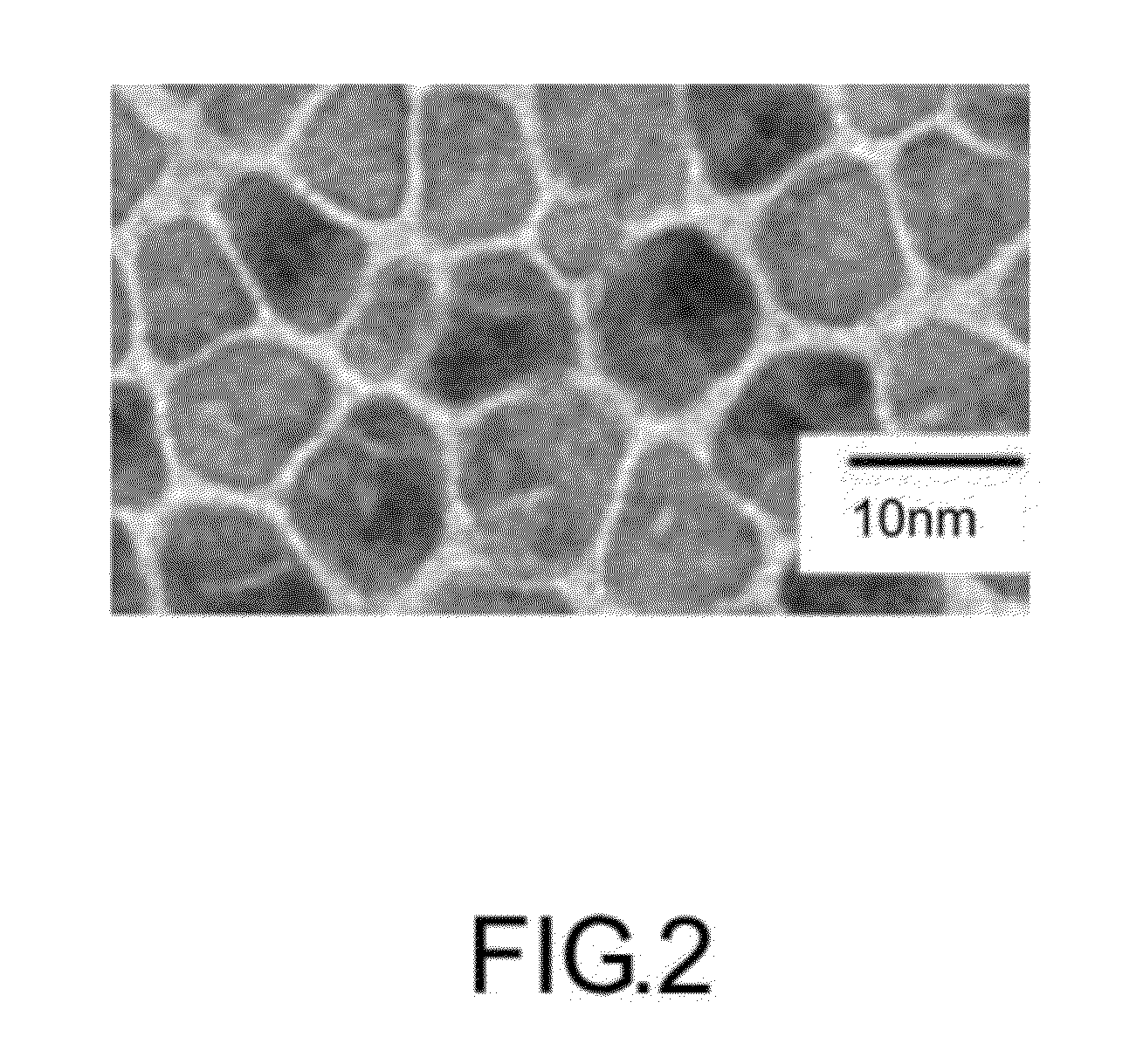

Sputtering Targets And Recording Materials Of Hard Disk Formed From The Sputtering Target

InactiveUS20120114975A1Increased areal recording densityEfficient implementationCellsVacuum evaporation coatingPlatinumCobalt-chrome

Disclosed is a sputtering target and its application to the recording material of hard disks wherein the sputtering target comprises cobalt-platinum (CoPt), cobalt-chrome-platinum (CoCrPt) or cobalt-chrome-platinum-boron (CoCrPtB) and a combination of oxides. A recording material is formed by the sputtering target through the sputtering process as a high areal recording density hard disk, which essentially has silica oxide (SiO2) and Cr2O3, wherein the amount of silica oxide (SiO2) ranges from 4 to 8 atomic % and the amount of chromium oxide (Cr2O3) ranges from 0.8 atomic % to 5 atomic %. The present invention is characterized by Cr2O3 as an oxygen supplier during sputtering process to donate oxygen to the oxygen defects. The sputtering target containing the combination of oxides is used to form a recording material applied as a recording layer of magnetic recording medium of hard disks, resulting in enhancement of the areal recording density of medium storage.

Owner:SOLAR APPLIED MATERIALS TECHNOLOGY CORPORATION

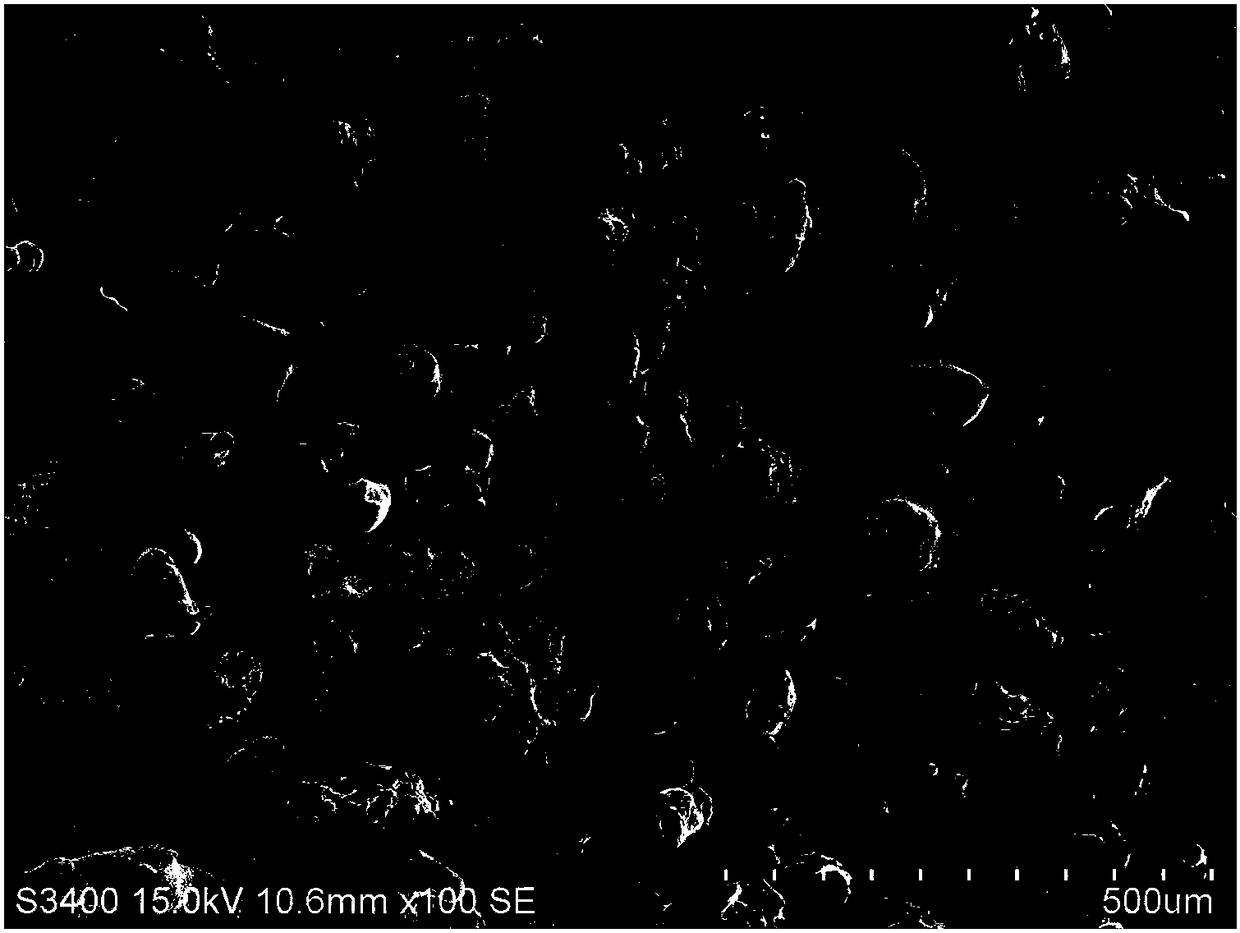

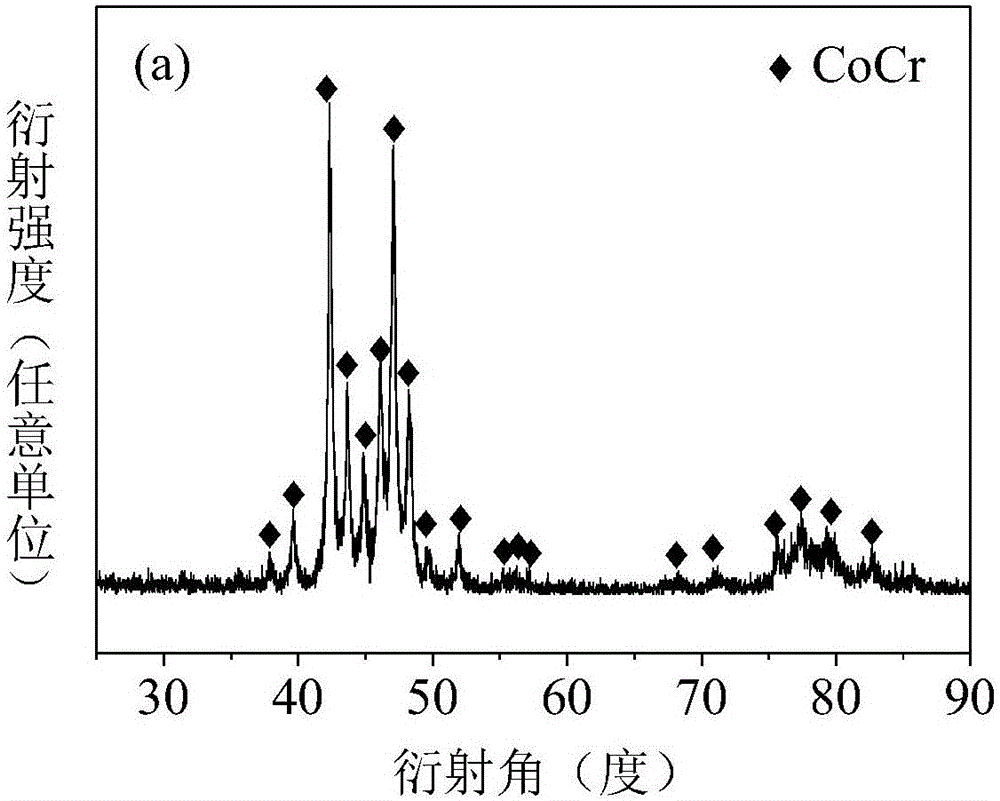

Preparation method of wear-resistant and abrasion-resistant WC-CoCr coating

ActiveCN106544616AReduce wear rateLow wear resistanceMolten spray coatingThermal sprayingWear resistant

The invention discloses a preparation method of a wear-resistant and abrasion-resistant WC-CoCr coating and belongs to the technical field of preparation of metal ceramic coatings. The preparation method comprises the following steps that cobalt ingots and chrome ingots are mixed in proportion and put in an induction suspended smelting furnace to be fused and mixed with argon as protective gas, so that a cobalt-chrome intermetallic compound cast ingot is obtained; the cobalt-chrome intermetallic compound cast ingot is broken through ball grinding, and CoCr intermetallic compound sheets with the average thickness being 0.2-0.8 microns are obtained; WC powder with the average grain size being smaller than 500 nm and the CoCr intermetallic compound sheets are mixed through wet grinding and sufficiently dried, and then WC-CoCr powder is obtained; and with the WC-CoCr powder as a raw material, thermal spraying feed powder is obtained through aggregation granulation and airflow grading treatment, and the powder is sprayed with a supersonic speed flame spraying process. The WC-CoCr coating with high wear resistance and corrosion resistance can be obtained by adoption of the method.

Owner:BEIJING UNIV OF TECH

Method for processing and preparing medical small-diameter thin-wall cobalt-chromium pipe

The invention discloses a method for processing and preparing a medical small-diameter thin-wall cobalt-chromium pipe. The method comprises the following steps: 1, preparing a cobalt-chromium alloy ingot by adopting a vacuum induction melting method, and carrying out cogging and forging so as to obtain a cobalt-chromium ingot bar; 2, after cutting off the cobalt-chromium alloy bar according to a fixed length, carrying out excircle turning and drill hole machining in sequence so as to obtain a cobalt-chromium pipe blank; 3, carrying out incircle grinding on the cobalt-chromium pipe blank, and then carrying out multi-pass cold rotary forging; and 4, carrying out multi-pass drawing on the cobalt-chromium pipe blank subjected to multi-pass cold rotary forging, so as to obtain the cobalt-chromium pipe. According to the method disclosed by the invention, the conventional rolling process is replaced by cold rotary forging, so that the processing plasticity of the cobalt-chromium alloy pipe blank can be improved, the processing hardening phenomenon can be reduced, and the processing and forming can be facilitated; then, the quantity of annealing passes during processing can be reduced andthe processing efficiency can be improved; meanwhile, the surface quality of the cobalt-chromium pipe can be improved, and then the size of the cobalt-chromium pipe can be further reduced; and accordingly, the small-diameter thin-wall cobalt-chromium pipe for medical purposes can be acquired.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Method for fabricating a biocompatible material having a high carbide phase and such material

A method of fabricating a material having a high concentration of a carbide constituent. The method may comprise adding a carbide source to a biocompatible material in which a weight of the carbide source is at least approximately 10% of the total weight, heating the carbide source and the biocompatible material to a predetermined temperature to melt the biocompatible material and allow the carbide source to go into solution to form a molten homogeneous solution, and impinging the molten homogeneous solution with a high pressure fluid to form spray atomized powder having carbide particles. The size of a particle of carbide in the atomized powder may be approximately 900 nanometers or less. The biocompatible material may be cobalt chrome, the carbide source may be graphite, and the fluid may be a gas or a liquid.

Owner:HOWMEDICA OSTEONICS CORP

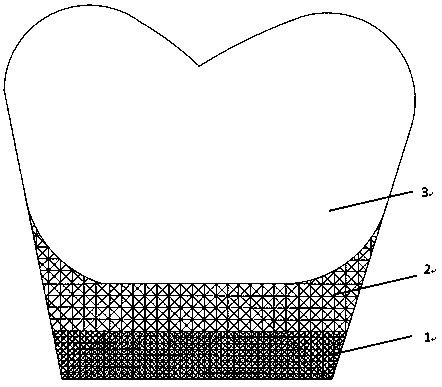

Method for 3D printing of rapidly renewable cobalt-chromium alloy coated tooth

PendingCN109464205AFast preparationHigh precisionImpression capsArtificial teethCarbon nanotubeBiocompatibility Testing

The invention discloses a method for 3D printing of a rapidly renewable cobalt-chromium alloy coated tooth. Laser scanning is adopted to assist manufacturing of an individual false tooth model, by using a 3D printing technique, zirconium dioxide powder is mixed with a small amount of graphene and carbon nanotube powder to make a false tooth main body, cobalt-chromium alloy powder is mixed with a small amount of the graphene and the carbon nanotube powder to make a false tooth base which is small and large gradually, and coating treatment is carried out on the false tooth base. The problems that a pure metal material is not attractive in appearance, a pure ceramic material is too crispy and long in recovery period after implanting can be overcome, people can feel that a false tooth and gingiva grow together, and an individual false tooth which is high in precision, good in wearing resistance, good in acid-alkali resistance, high in mechanical strength and good in biocompatibility can befinally manufactured.

Owner:SHANDONG JIANZHU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com