Method for preparing high-hardness diamond film on surface of medical CoCrMo alloy

A diamond film, high hardness technology, applied in metal material coating process, gaseous chemical plating, coating and other directions, can solve problems such as artificial joint replacement failure, achieve easy control of deposition process, improve wear resistance, and improve interface The effect of bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

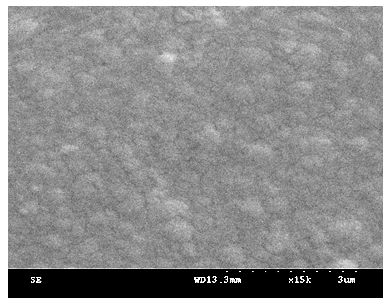

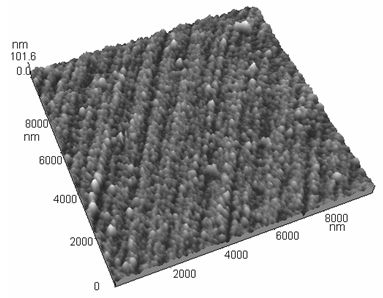

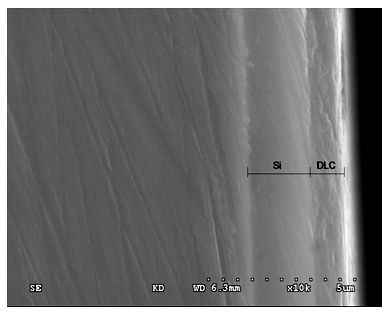

[0024] Embodiment one: the medical CoCrMo (cobalt chromium molybdenum) alloy surface is first used 180 # , 400 # , 800 # , 1200 # Grinding with water sandpaper in turn, polishing treatment reduces the surface roughness of CoCrMo (cobalt chromium molybdenum) alloy to less than 15nm, then immerses it in alcohol solvent and ultrasonically cleans it for 10 minutes to remove the dirt on the alloy surface, and then puts it in a drying oven at 60°C Dry for 10 hours and set aside. The dried medical CoCrMo (cobalt chromium molybdenum) alloy is put into the chemical vapor deposition reaction chamber, and the reaction chamber is evacuated (pressure is lower than 10 -4 Pa), then pass into H 2 (hydrogen), control its flow rate to 60sccm, reaction pressure to 20Pa, radio frequency power to 100W, and sputter cleaning time to 5min. After the sputtering is completed, the H in the reaction chamber is pumped out 2 (hydrogen) (atmospheric pressure lower than 10 -4 Pa), SiH was introduced i...

Embodiment 2

[0026] Embodiment two: the medical CoCrMo (cobalt chromium molybdenum) alloy surface is first used 180 # , 400 # , 800 # , 1200 # Grinding with water sandpaper in turn, polishing treatment reduces the surface roughness of CoCrMo (cobalt chromium molybdenum) alloy to less than 15nm, then immerses it in alcohol solvent and ultrasonically cleans it for 15min to remove the dirt on the alloy surface, and then puts it in a drying oven at 60°C Dry for 10 hours and set aside. The dried medical CoCrMo (cobalt chromium molybdenum) alloy is put into the chemical vapor deposition reaction chamber, and the reaction chamber is evacuated (pressure is lower than 10 -4 Pa), then pass into H 2 (hydrogen), control its flow rate to 60sccm, reaction pressure to 20Pa, radio frequency power to 100W, and sputter cleaning time to 5min. After the sputtering is completed, the H in the reaction chamber is pumped out 2 (hydrogen) (atmospheric pressure lower than 10 -4 Pa), SiH was introduced into t...

Embodiment 3

[0028] Embodiment three: the medical CoCrMo (cobalt chromium molybdenum) alloy surface is first used 180 # , 400 # , 800 # , 1200 # Grinding with water sandpaper in turn, polishing treatment reduces the surface roughness of CoCrMo (cobalt chromium molybdenum) alloy to less than 15nm, then immerses it in alcohol solvent and ultrasonically cleans it for 20 minutes to remove the dirt on the alloy surface, and then puts it in a drying oven at 60°C Dry for 10 hours and set aside. The dried medical CoCrMo (cobalt chromium molybdenum) alloy is put into the chemical vapor deposition reaction chamber, and the reaction chamber is evacuated (pressure is lower than 10 -4 Pa), then pass into H 2 (hydrogen), control its flow rate to 60sccm, reaction pressure to 20Pa, radio frequency power to 100W, and sputter cleaning time to 5min. After the sputtering is completed, the H in the reaction chamber is pumped out 2 (hydrogen) (atmospheric pressure lower than 10 -4 Pa), SiH was introduced...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com