Patents

Literature

33results about How to "The deposition process is easy to control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing anti-attrition MoS2/C/Ti composite film by magnetron sputtering

InactiveCN101654771AReduce coefficient of frictionReduce the binding forceVacuum evaporation coatingSputtering coatingSputteringComposite film

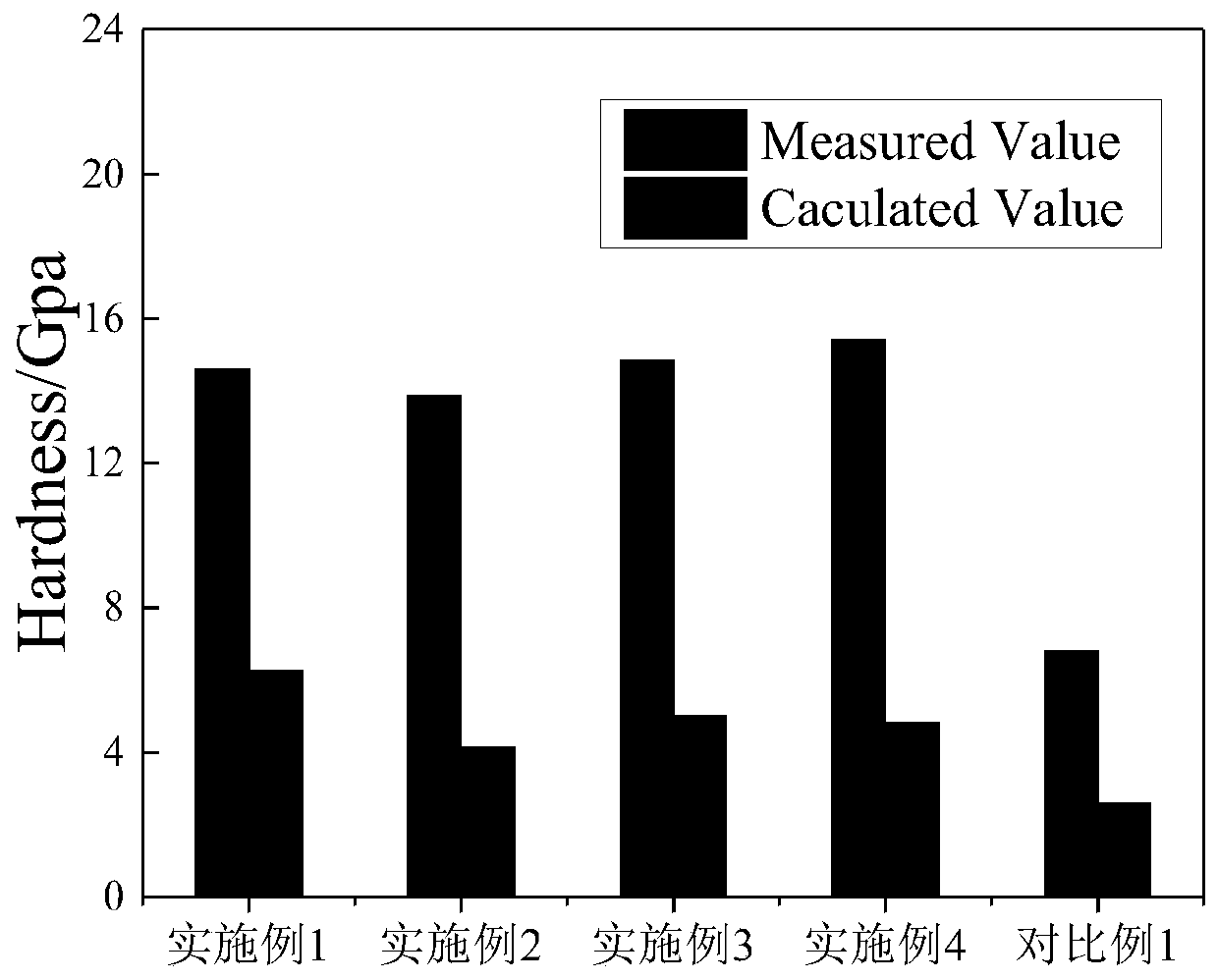

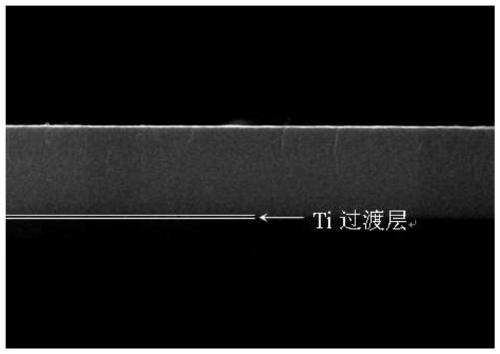

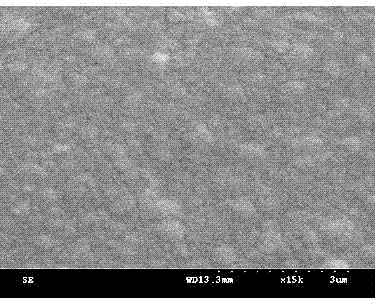

The invention discloses a method for preparing an anti-attrition MoS2 / C / Ti composite film by magnetron sputtering in the technical field of solid lubrication, comprising the following steps: firstly,polishing a substrate, then ultrasonically washing and drying the substrate, and then packing the substrate in a sputtering chamber; secondly, carrying out pure titanium sputtering and composite layersputtering in the sputtering chamber, then obtaining the anti-attrition composite film by magnetron sputtering when the sputtering chamber is naturally cooled to the room temperature. The invention has simple process and easily controlled precipitation process; the precipitated film can be directly used as an anti-attrition protection film on the surface of a mechanical part without thermal treatment; and the composite film has the nano hardness of 5.9GPa and the friction coefficient of 0.03.

Owner:SHANGHAI JIAO TONG UNIV +1

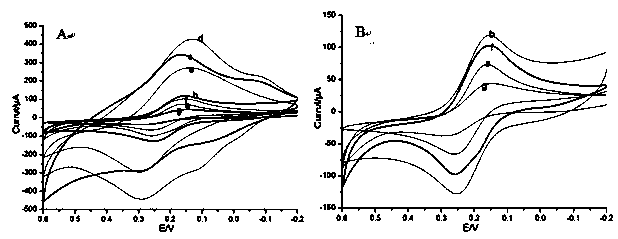

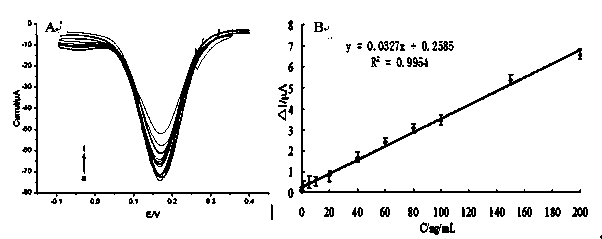

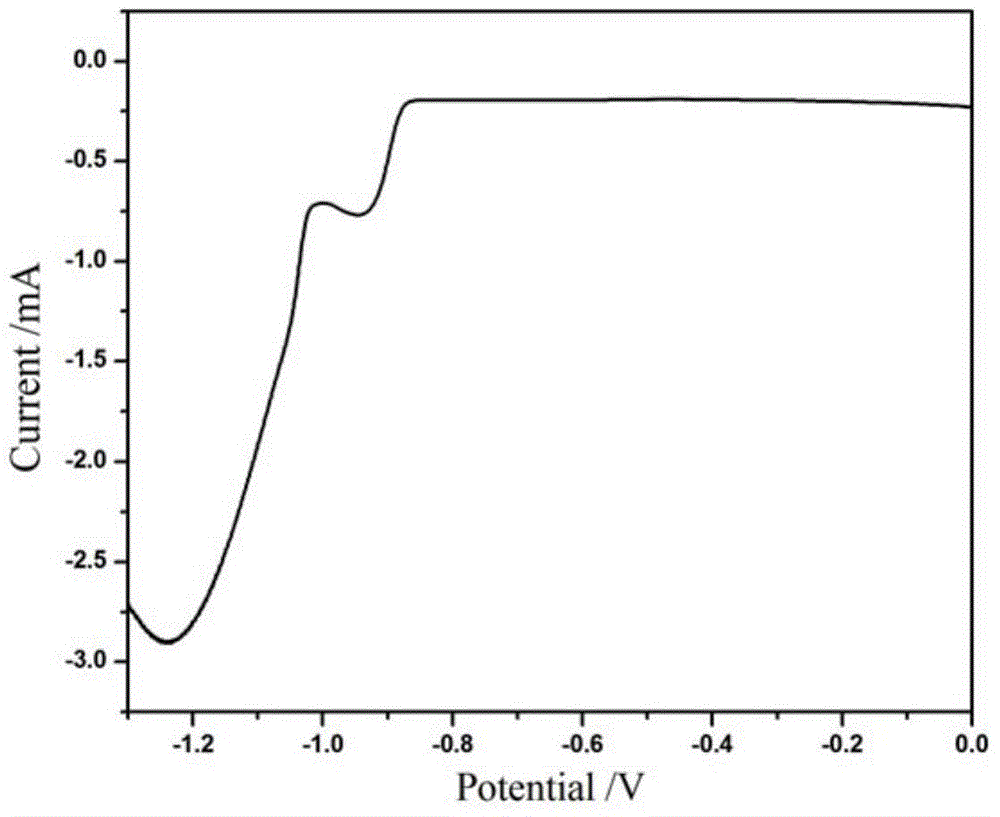

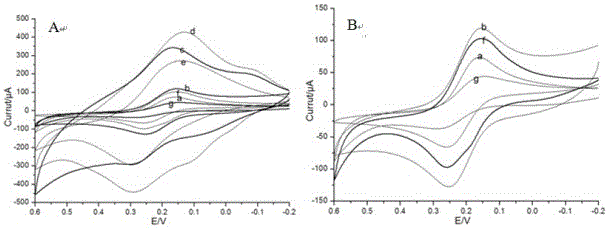

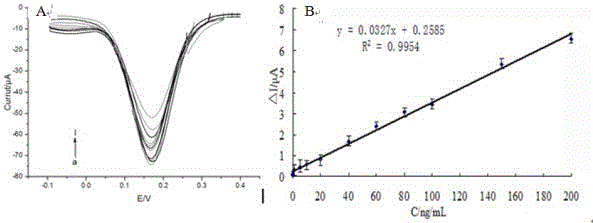

Preparation method of aptamer sensor for detecting antibiotic residue

InactiveCN103837588ALarge specific surface areaImprove stabilityMaterial electrochemical variablesCarbon nanotubeGraphene

The invention discloses a preparation method of an aptamer sensor for detecting antibiotic residue, belonging to the technical field of safety test of agricultural products. The method comprises the steps of carrying out electrochemical polymerization on a gold electrode and thionine to obtain electrically polymerized thionine electrode; after that, evenly dripping the prepared carbon nano tube-graphene nano-composition onto the surface of the electrically polymerized thionine electrode; drying in the air, and then soaking the electrode into antibiotic aptamer solution; washing, drying in the air, and closing by bull serum albumin (BSA) solution to obtain the antibiotic aptamer sensor. The prepared aptamer sensor has the advantages of not needing pretreatment, being high in analysis speed, simple in an operation system, high in accuracy, high in specificity, low in cost, rapid in response and the like, and has the limit of detection reaching up to 0.8nm, thus being suitable for rapidly detecting the antibiotic residue.

Owner:SHANDONG UNIV OF TECH

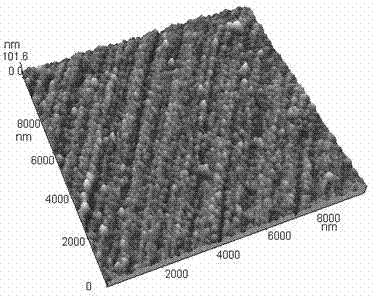

Method for preparing compound metal sulfide diamond composite membrane

InactiveCN101550535AReduce coefficient of frictionImprove wear resistanceVacuum evaporation coatingSputtering coatingMetallic sulfideHeat treated

A method for preparing compound metal sulfide diamond composite membrane belongs to the nanometer composite membrane technology field, comprises: polishing, washing and drying the substrate; sputtering the intermediate layer; letting in acetylene gas; and performing composite target sputtering process to metal sulfide. The method of the invention can obtain composite membrane with excellent wear-resisting performance and good wear resistance; and has the advantages of simple preparation technology and easily controlled deposition process. The membrane need no heat treatment after deposited, and can be directly used as wear-resisting protection film on mechanical component surface.

Owner:SHANGHAI JIAO TONG UNIV +1

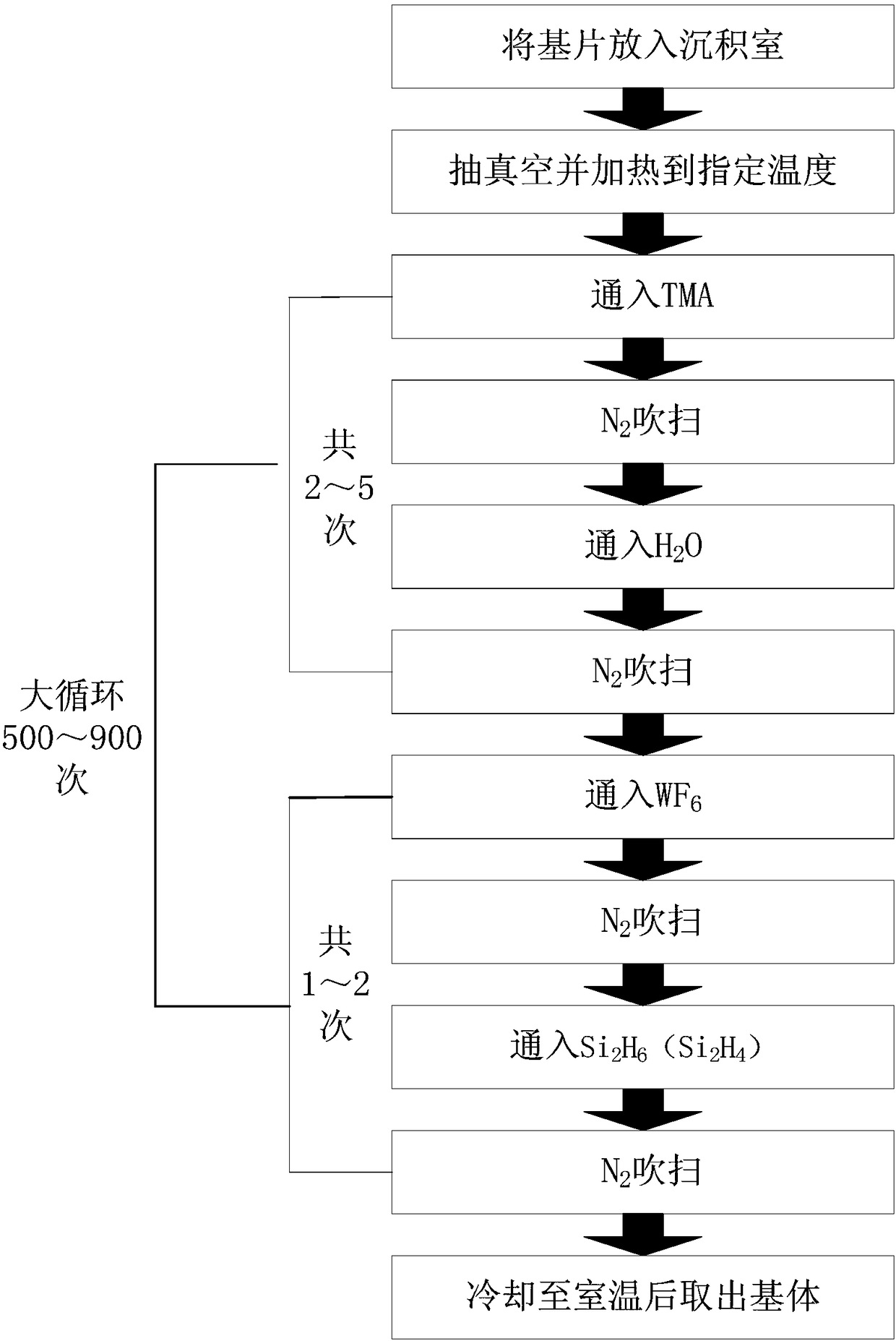

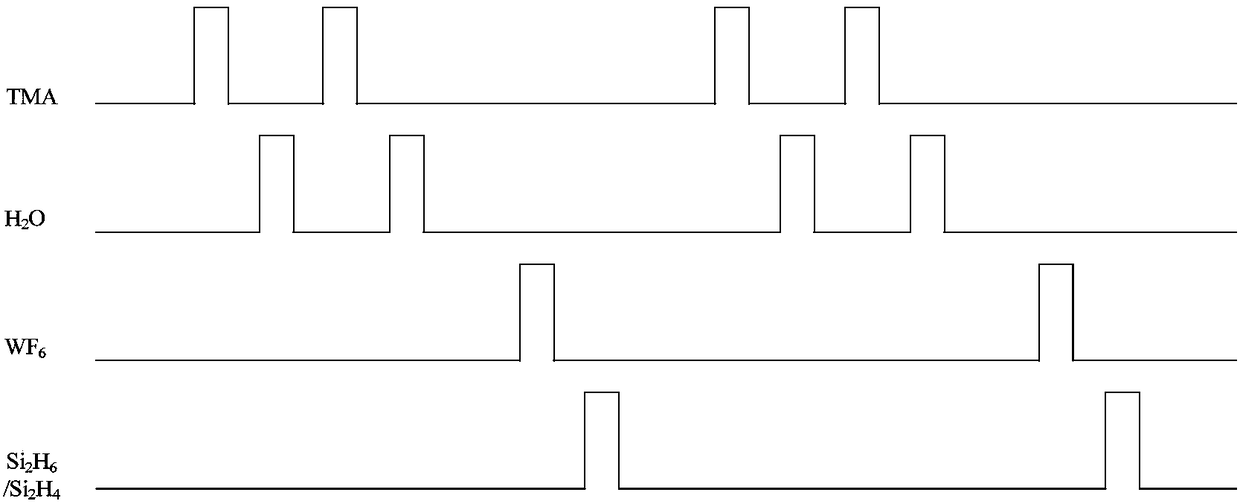

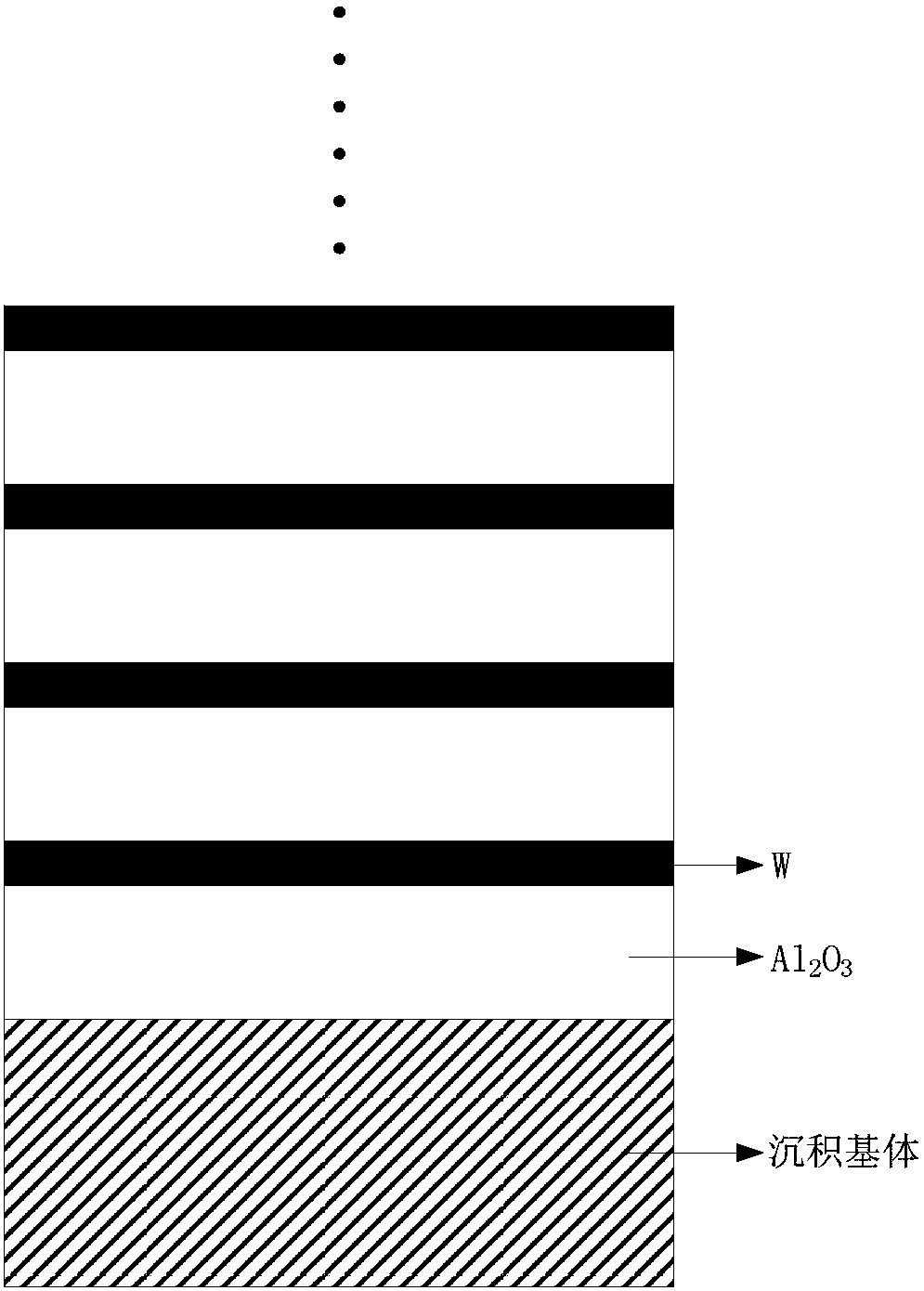

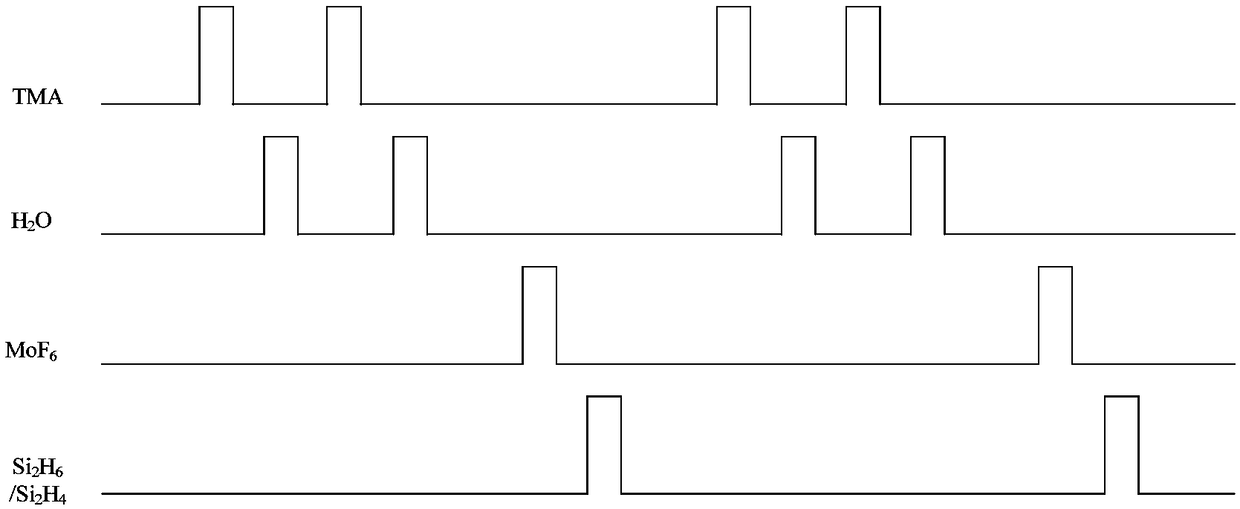

Method for preparing W-doped Al2O3 high-resistance membrane through atomic layer deposition

InactiveCN108588679AReduce surface roughnessFlat surfaceChemical vapor deposition coatingHigh resistanceOxygen

The invention relates to a method for preparing an W-doped Al2O3 high-resistance membrane through atomic layer deposition and aims at solving the problems that in the prior art,the thickness and the doping ratio of the membrane cannot be accurately controlled, and particularly defects exist when the accuracy of controlling the thickness of the membrane reaches an atom level and large-area uniformgrowth is realized at the same time. The method comprises the following steps of (1) putting a matrix into a deposition chamber; (2) vacuumizing the deposition chamber, heating the matrix; (3) performing Al2O3 deposition circulation for 2-5 times, wherein single Al2O3 deposition comprises the following steps of (3.1) introducing a precursor Al source into the deposition chamber, and purging the deposition chamber with the Al source at deposition chamber exposure set time; (3.2) introducing a precursor oxygen source to obtain a single layer Al2O3; and (3.3 ) purging the deposition chamber; (4)performing W deposition for 1-2 times, wherein the step of performing W deposition for 1-2 times comprises the following steps of (4.1) introducing a precursor W source into the deposition chamber, and purging the deposition chamber; (4.2) introducing a reducer to obtain a single-layer W metal element; and (4.3) purging the deposition chamber; and (5) sequentially conducting the step (3) and the step (4) repeatedly for many times to obtain the W-doped Al2O3 high-resistance membrane.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

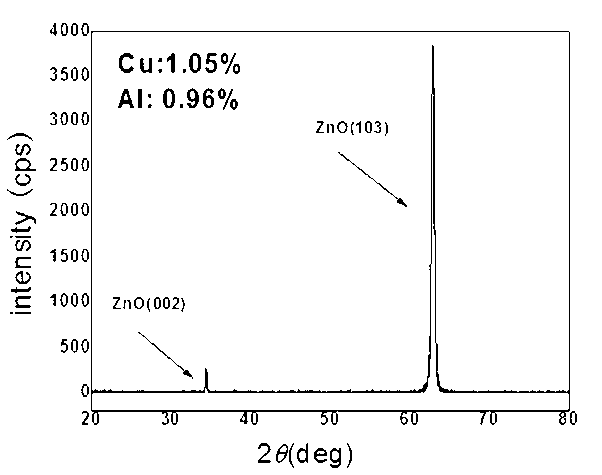

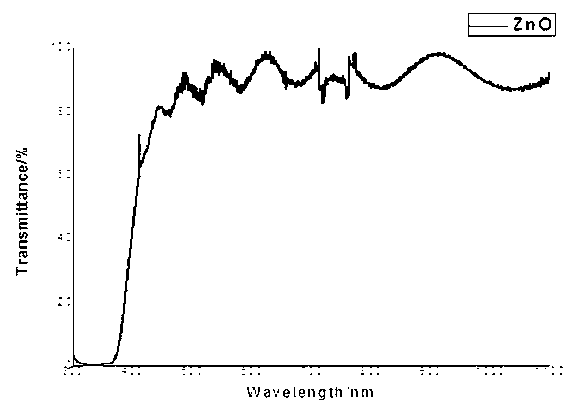

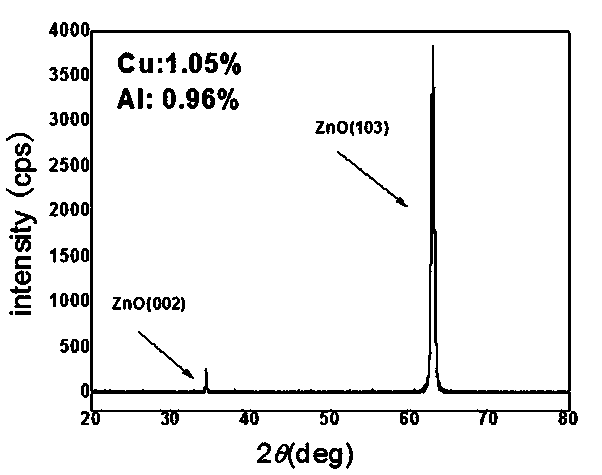

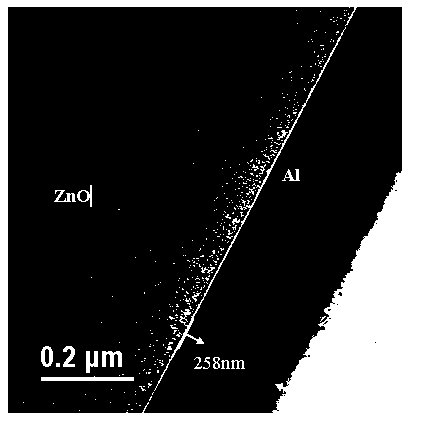

Deposition method of Cu/ZnO/Al photoelectric transparent conducting film

ActiveCN103014705AIncrease concentrationImprove conductivityFinal product manufactureSuperimposed coating processNitrogen gasOmega

The invention relates to a deposition method of a Cu / ZnO / Al photoelectric transparent conducting film, belonging to the field of transparent conducting materials. The method comprises the following steps: (1) sequentially carrying out ultrasonic cleaning on a substrate with acetone, ethanol and deionized water, blow-drying with nitrogen gas, and sending the substrate into a reaction chamber; (2) depositing a magnetron sputtering Al film; (3) preparing a middle-layer ZnO film by organic substance chemical vapor deposition; (4) depositing a magnetron sputtering Cu film; and (5) carrying out high-temperature annealing on the Cu / ZnO / Al multilayer-structure transparent conducting film at 100-400 DEG C for 30 minutes to obtain the Cu / Al-codoped ZnO photoelectric transparent conducting film. The preparation technique is simple, and the deposition process is easy to control. The transparent conducting film has the advantages of favorable uniformity, excellent photoelectric properties and low resistivity (down to 8.0*10<-4>Omega.cm), and the light transmittance is up to higher than 82%. The transparent conducting film can be used for manufacturing transparent electrodes of photoelectric devices, such as solar cells, light-emitting diodes, LCDs (liquid crystal displays), mobile phones and the like.

Owner:辽宁普天能源发电集团亿峰新能源科技有限公司

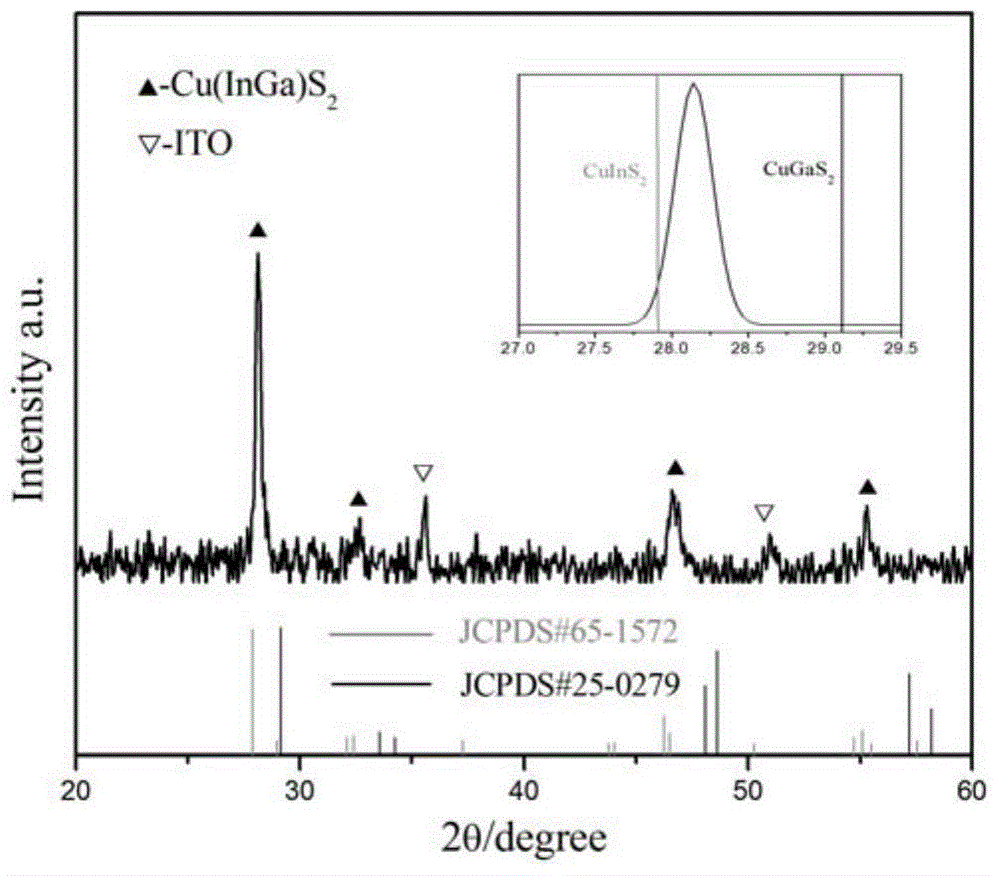

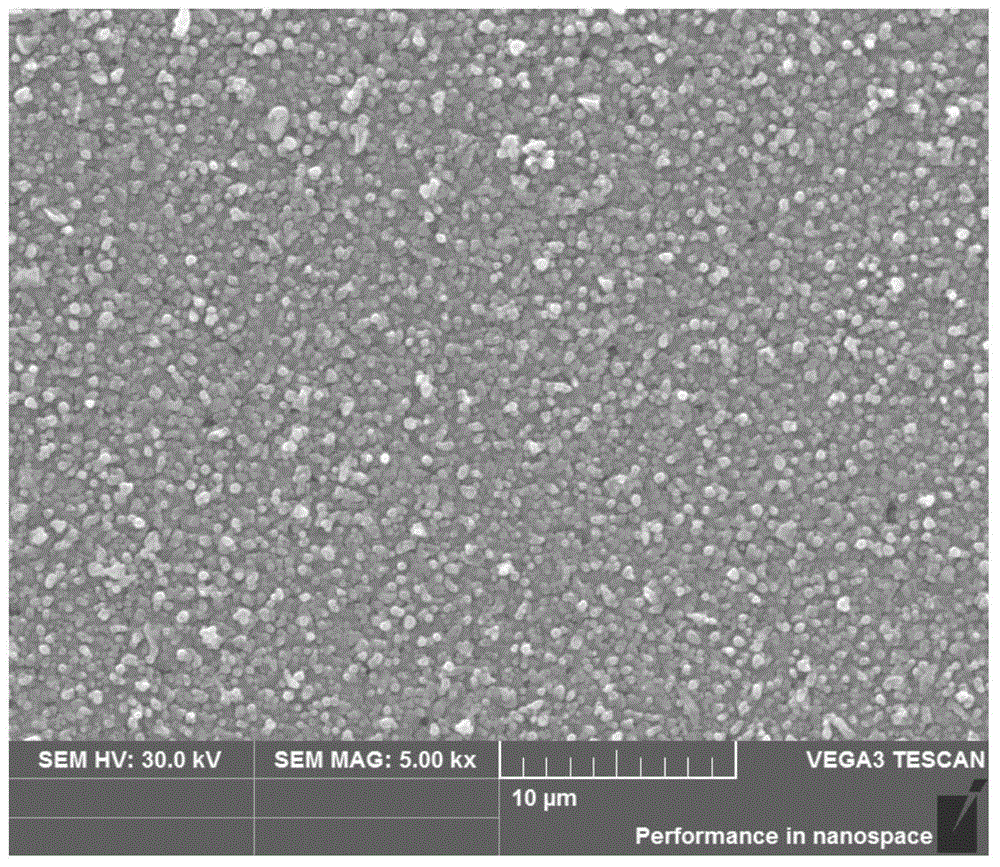

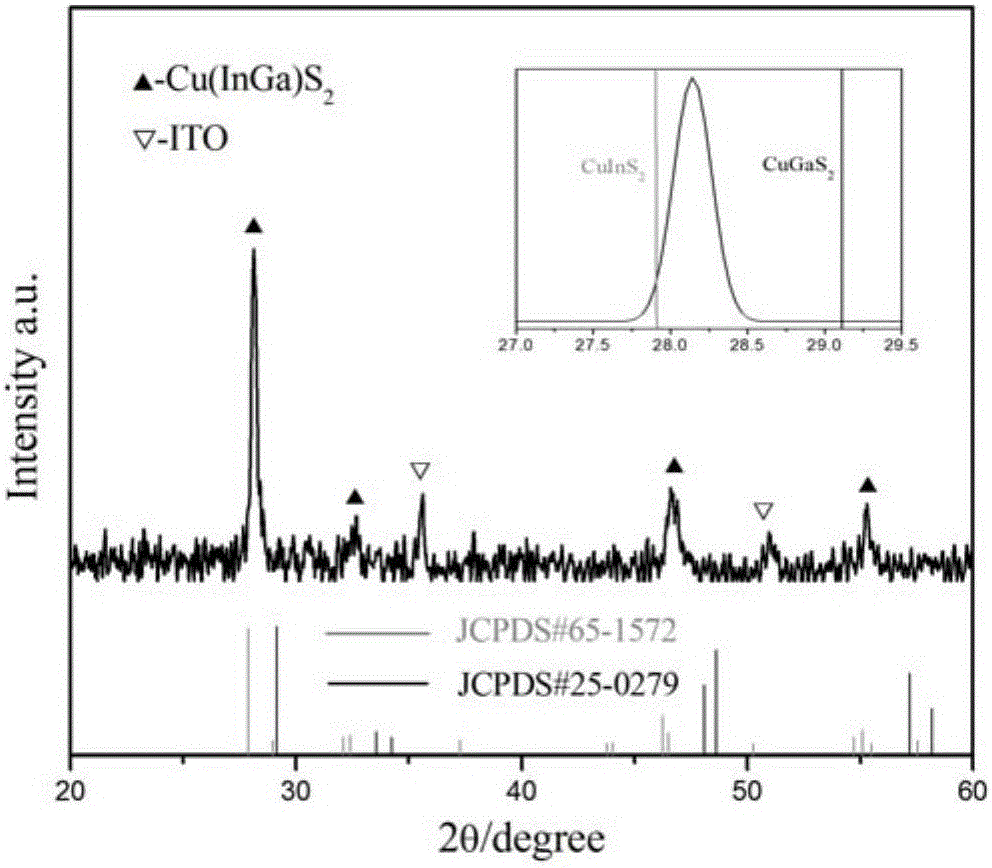

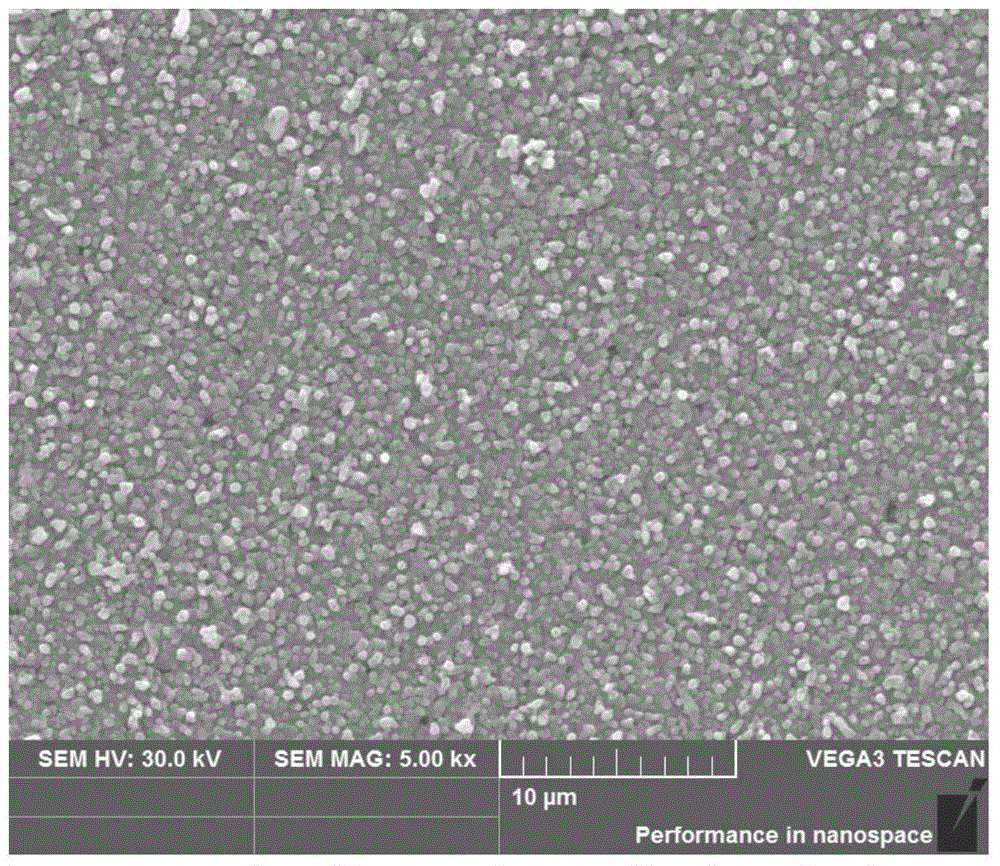

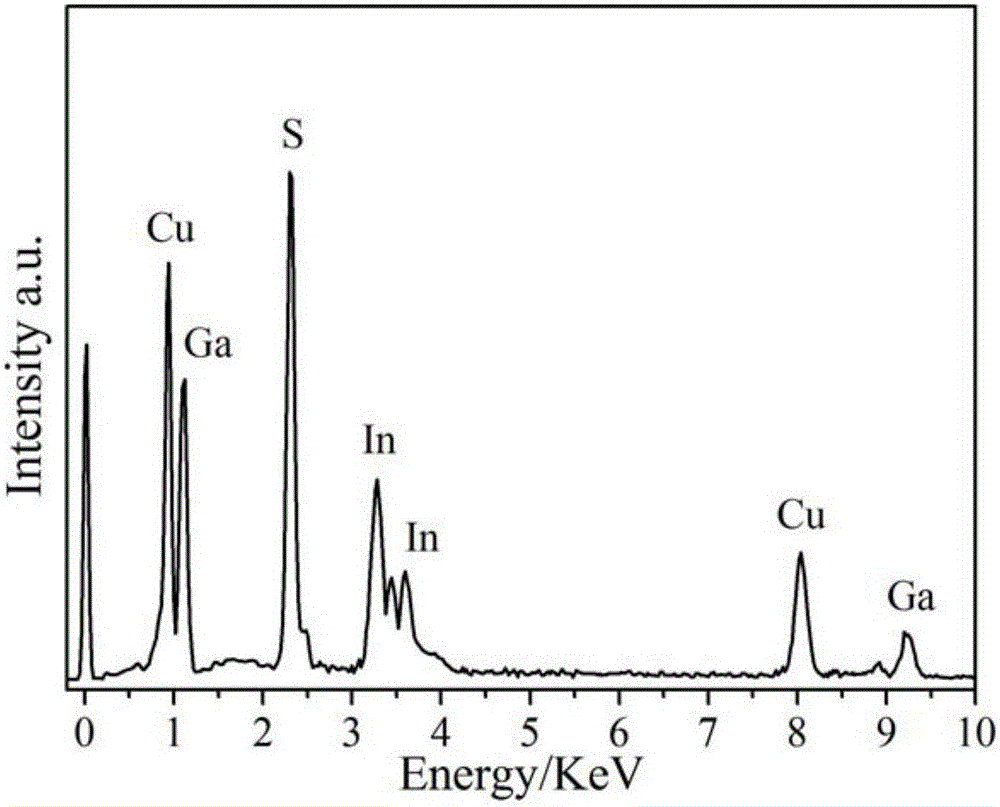

Sulfide annealing copper indium gallium sulfur solar cell thin film material preparation method after double-potential step method electrodeposition

ActiveCN105226117AReduced porosityIncrease plating ratePhotovoltaic energy generationSemiconductor devicesCopper indium gallium selenide solar cellsIon

The invention discloses a sulfide annealing copper indium gallium sulfur solar cell thin film material preparation method after double-potential step method electrodeposition. The method comprises the steps that copper and gallium metal salt is used as a main raw material; the main raw material is dissolved in an ionic liquid at a certain concentration; a copper gallium precursor thin film is prepared on ITO conductive glass through double-potential cycle step method electrodeposition; sulfide annealing is carried out on the precursor thin film; in the annealing process, indium in the ITO conductive layer diffuses into the thin film; and finally a copper indium gallium sulfur thin film is generated. Compared with a traditional constant potential deposition technology, the method provided by the invention has the advantages that by controlling double potential pulse potential, controllable preparation of the crystalline phase, the composition, the morphology and the like of the thin film can be realized; pore structures are reduced; the thin film morphology is improved; the plating rate is improved; and hydrogen evolution reaction does not produce any adverse effect on the thin film in the deposition process. Compared with a high-vacuum vapor phase method, the method provided by the invention has the advantages of good film quality, low cost, high controllability and the like.

Owner:XIANGTAN UNIV

Method for coating films on focusing mirrors

InactiveCN102409304AEliminates uneven thicknessUniform film thicknessVacuum evaporation coatingSputtering coatingVacuum chamberFilm-coated tablet

The invention discloses a method for coating films on focusing mirrors. The method comprises the following steps: 1. putting focusing mirrors to undergo film coating on a horizontal rotary table uniformly and selecting a target; 2. ensuring a marked position indication sign to be in an initial position before film coating; 3. sealing a vacuum chamber and starting a vacuum acquirement system; 4. filling a reacting gas; 5. keeping a baffle of a magnetron sputtering target closed and switching on a sputtering power supply to begin pre-sputtering; 6. setting the rotating speed of the rotary table while opening the baffle and starting the rotation of the rotary table to begin film coating timing at the moment; and 7. when the film coating time is achieved and the position indication sign returns to the initial position, immediately closing the baffle and then switching off the sputtering power supply and stopping the rotation of the rotary table to coating films on the focusing mirrors. The problem that the thickness of the films coated on the focusing mirrors is nonuniform is solved by using the method.

Owner:STARARC COATING TECH SUZHOU

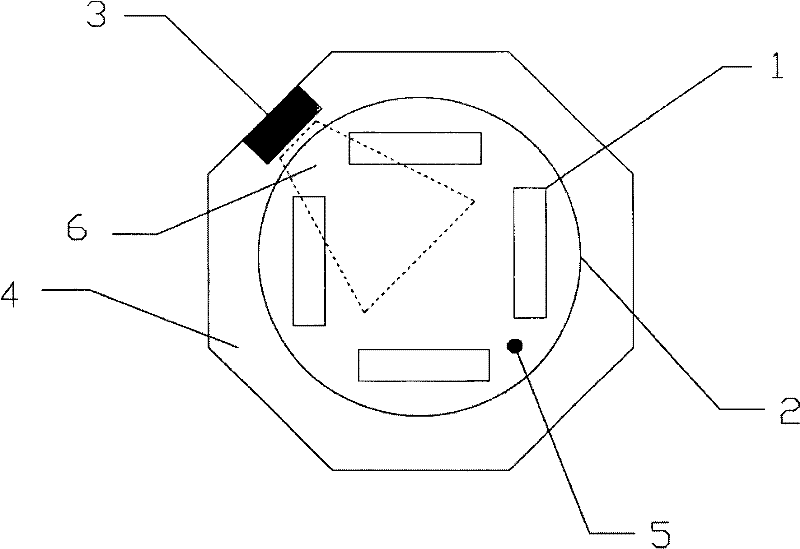

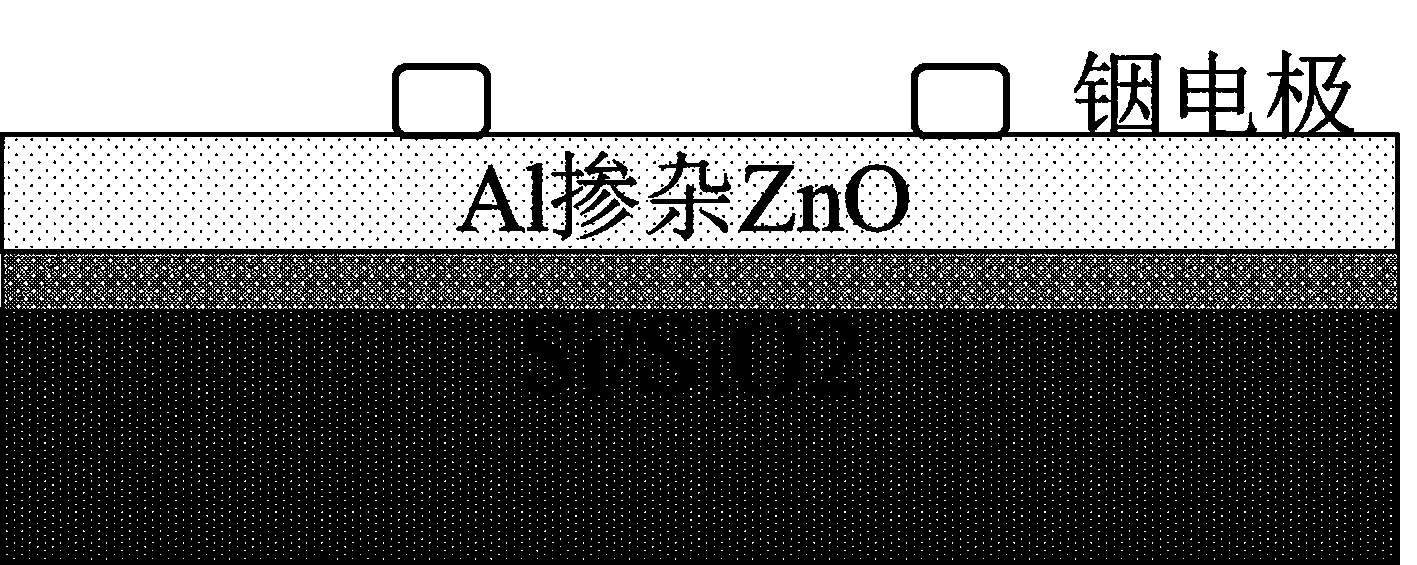

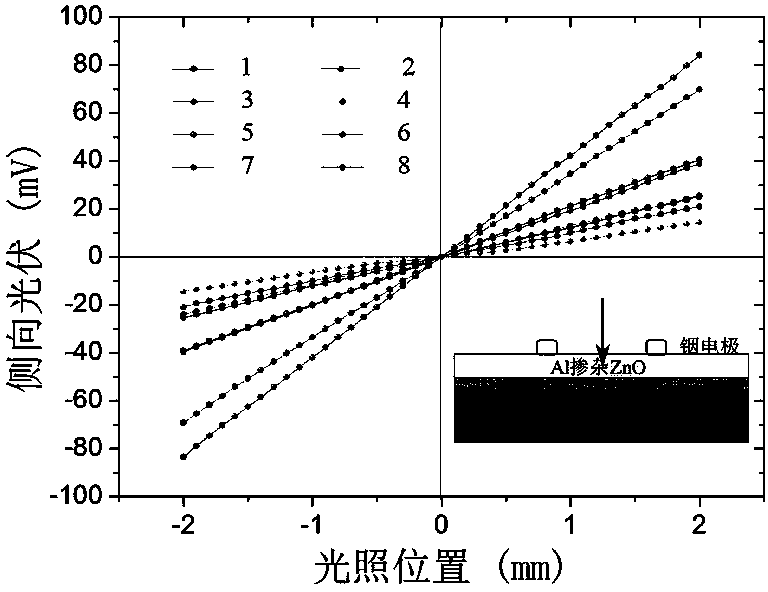

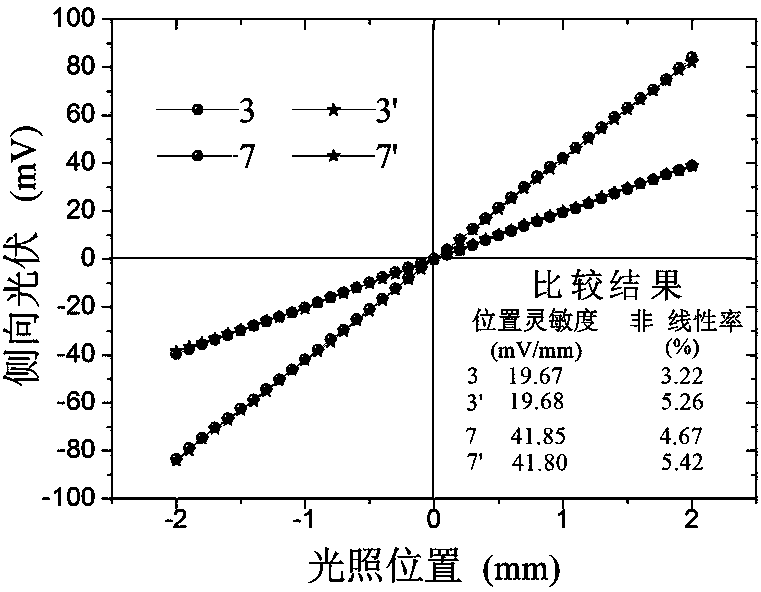

Anti-aging photoelectric displacement sensor

InactiveCN104022168AImprove anti-aging propertiesExcellent sensitivityFinal product manufactureUsing electrical meansIndiumManufacturing technology

The invention relates to an anti-aging photoelectric displacement sensor, which comprises a semiconductor substrate, an Al ZnO-doped film on the surface of the semiconductor substrate and two indium point electrodes on the surface of the film. The anti-aging photoelectric displacement sensor on the basis of lateral photovoltaic effects can be obtained by depositing the Al ZnO-doped film on the Si substrate through ultrasonic cleaning to replace a metal film layer in a metal- oxide-semiconductor structure. The nonlinear rate of the sensor can be controlled to be 3.22%, and the position sensitivity can reach 41.85mV / mm. As the Al ZnO-doped target material is directly used, the manufacturing technology is simple, and large-scale preparation in actual production can be realized.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

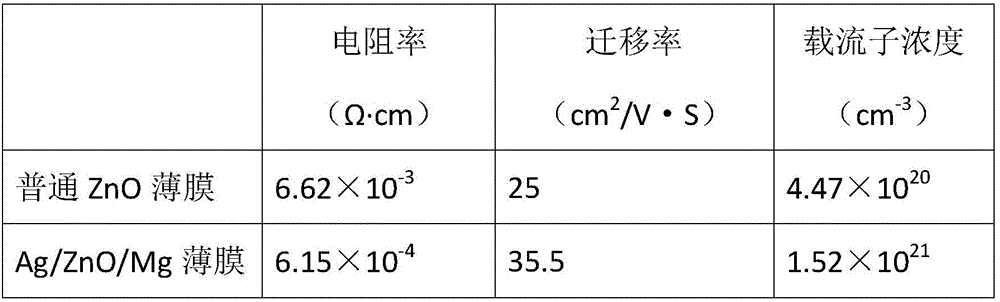

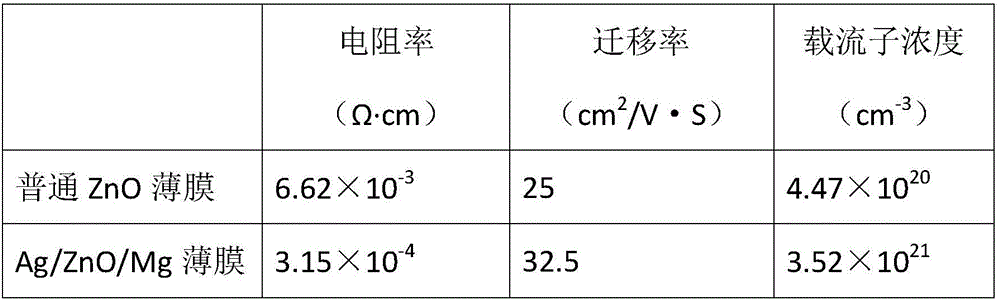

Depositing method for Ag/ZnO/Mg photoelectric transparent conducting thin film

InactiveCN106637204AIncrease concentrationImprove conductivityVacuum evaporation coatingSputtering coatingGas phaseSolar cell

The invention relates to a depositing method for an Ag / ZnO / Mg photoelectric transparent conducting thin film, and belongs to the field of transparent conducting materials. The depositing method is conducted according to the following steps that (1) a substrate is subjected to ultrasonic cleaning sequentially with acetone, ethyl alcohol and deionized water, then dried with nitrogen and put into a reaction chamber; (2) deposition of a magnetron sputtering Mg film is conducted; (3) a middle layer ZnO thin film is prepared through organic matter chemical vapor deposition; (4) deposition of a magnetron sputtering Ag film is conducted; and (5) the transparent conducting thin film of the Ag / ZnO / Mg multi-layer structure is subjected to high-temperature annealing, the annealing temperature is 200-600 DEG C, the annealing time is 20 min, and the ZnO photoelectric transparent conducting thin film jointly doped with Ag and Mg is obtained. The preparation process is simple, and the depositing process is easy to control. The prepared transparent conducting thin film is good in uniformity and excellent in photoelectric performance, the electrical resistivity can be as low as 7.0*10<-4> ohm.cm, and the light transmittance can reach 85% or above. The transparent conducting thin film can be used for manufacturing transparent electrodes of photoelectric devices such as solar cells, light emitting diodes, LCDs and mobile phones.

Owner:梁结平

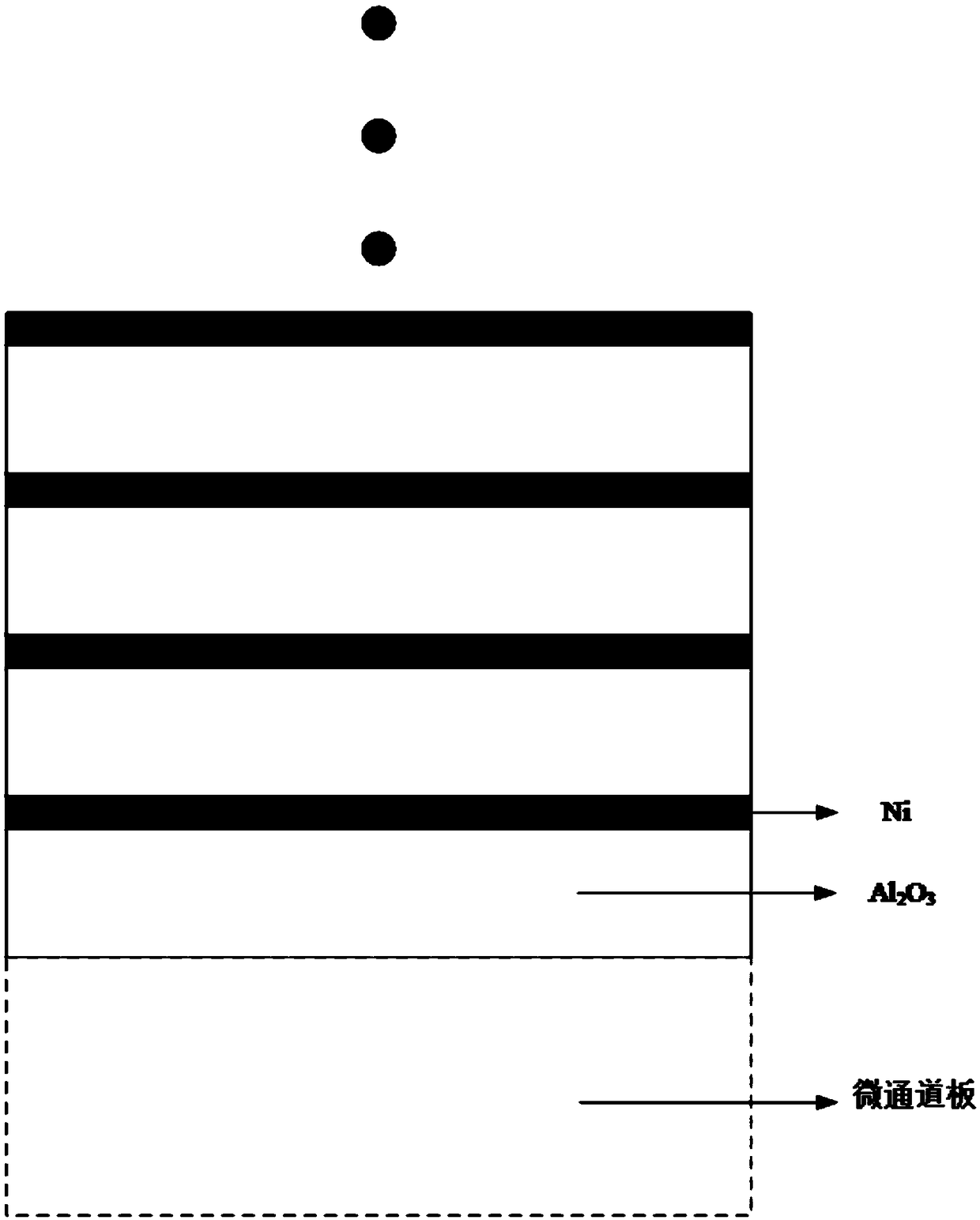

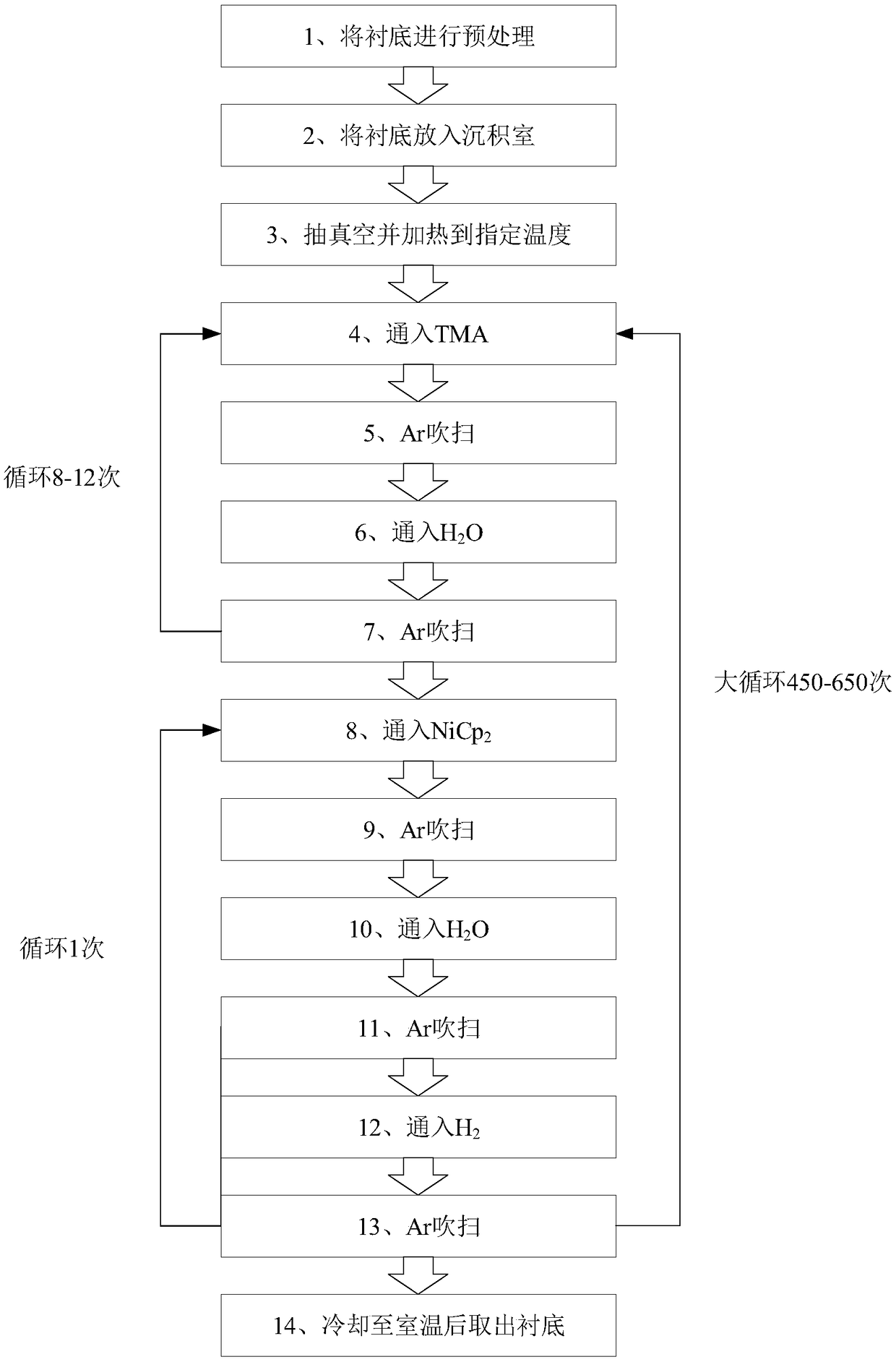

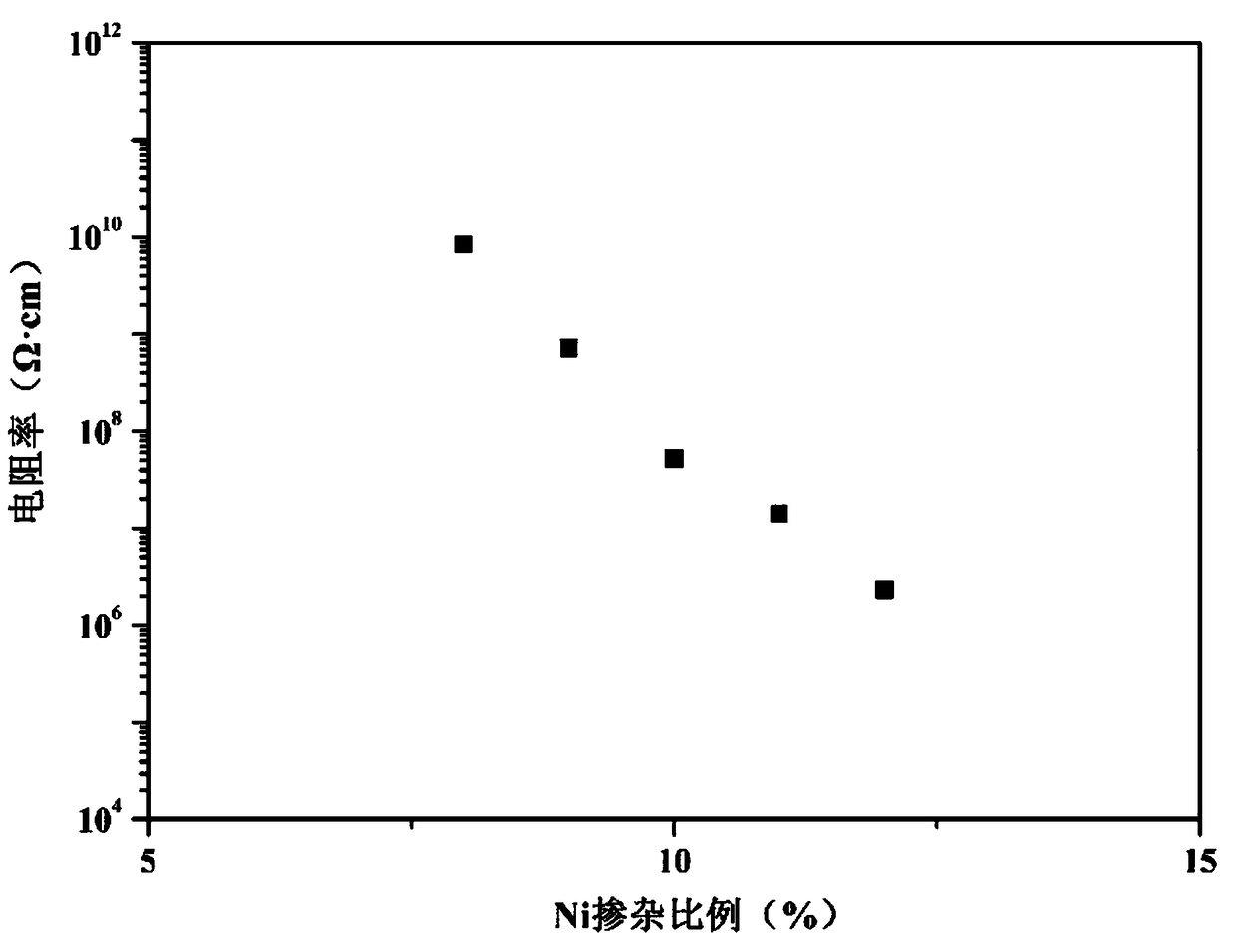

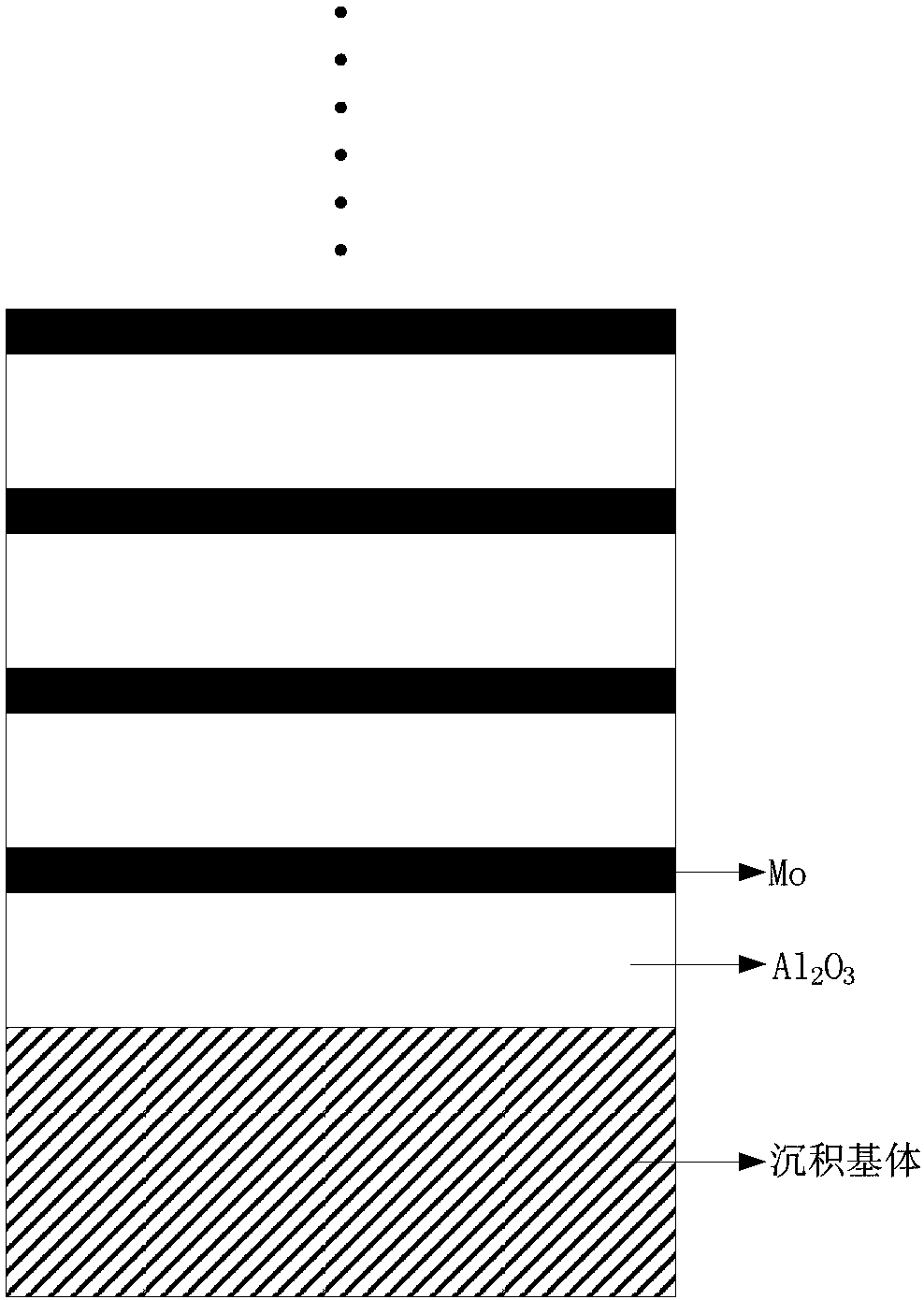

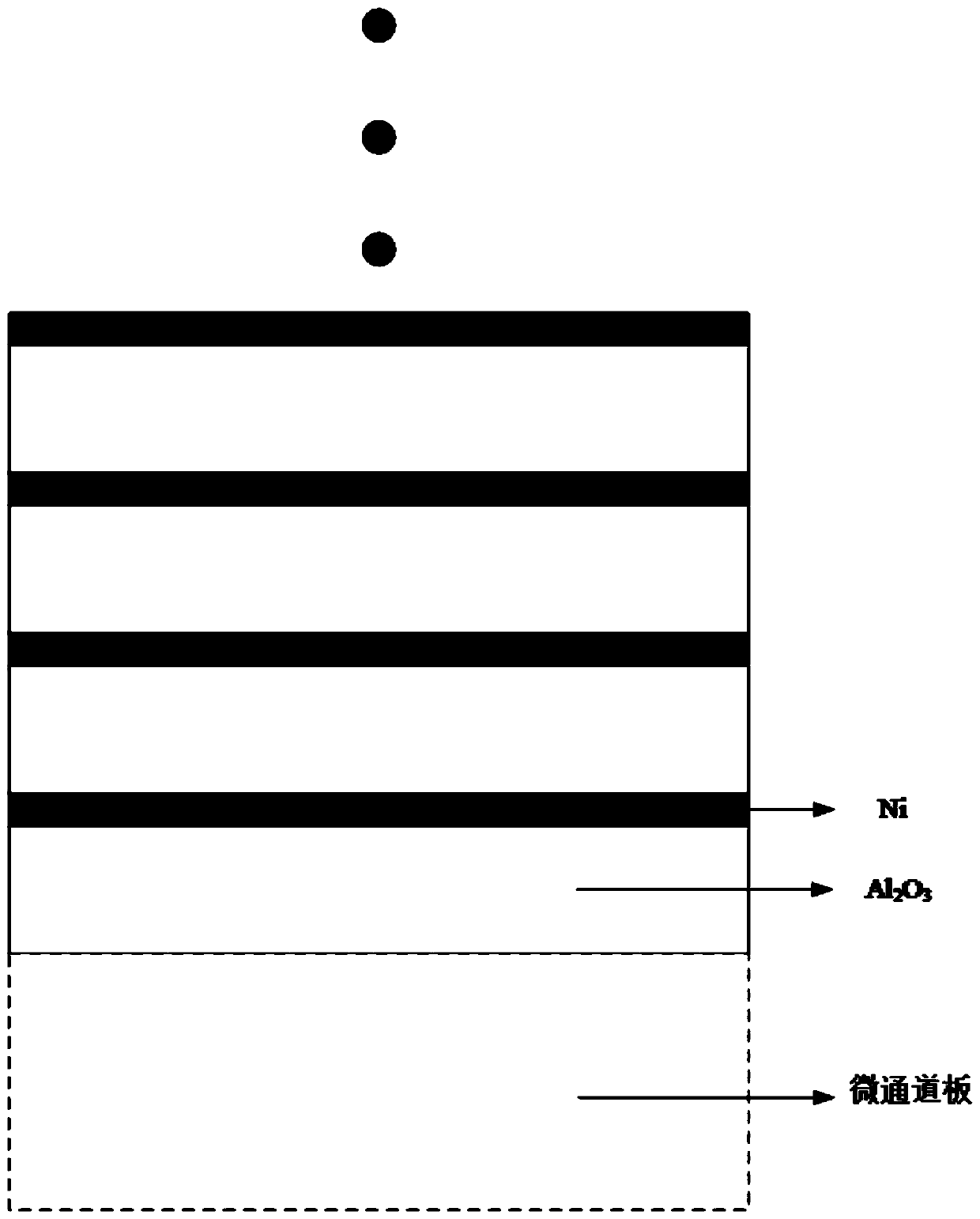

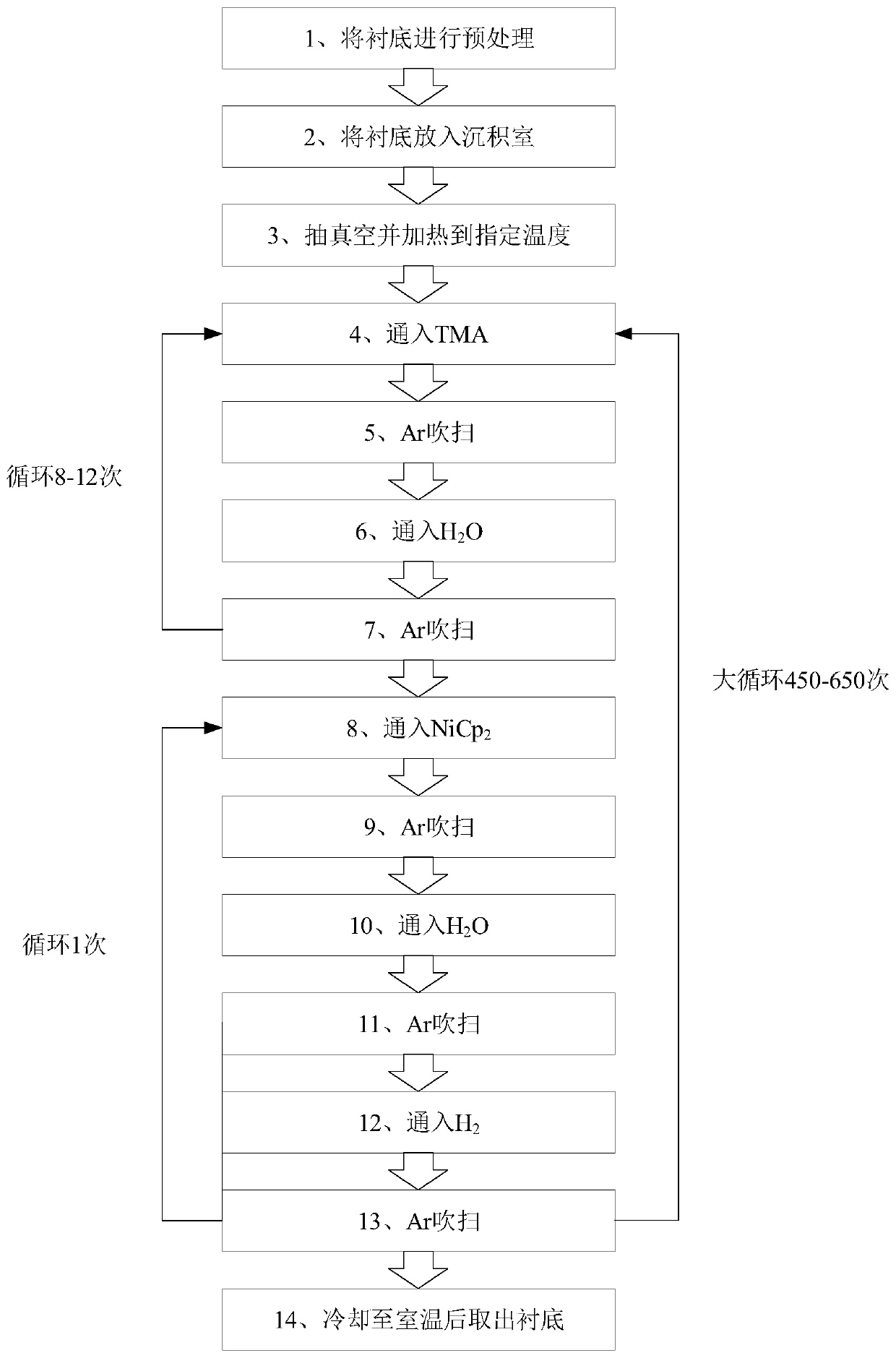

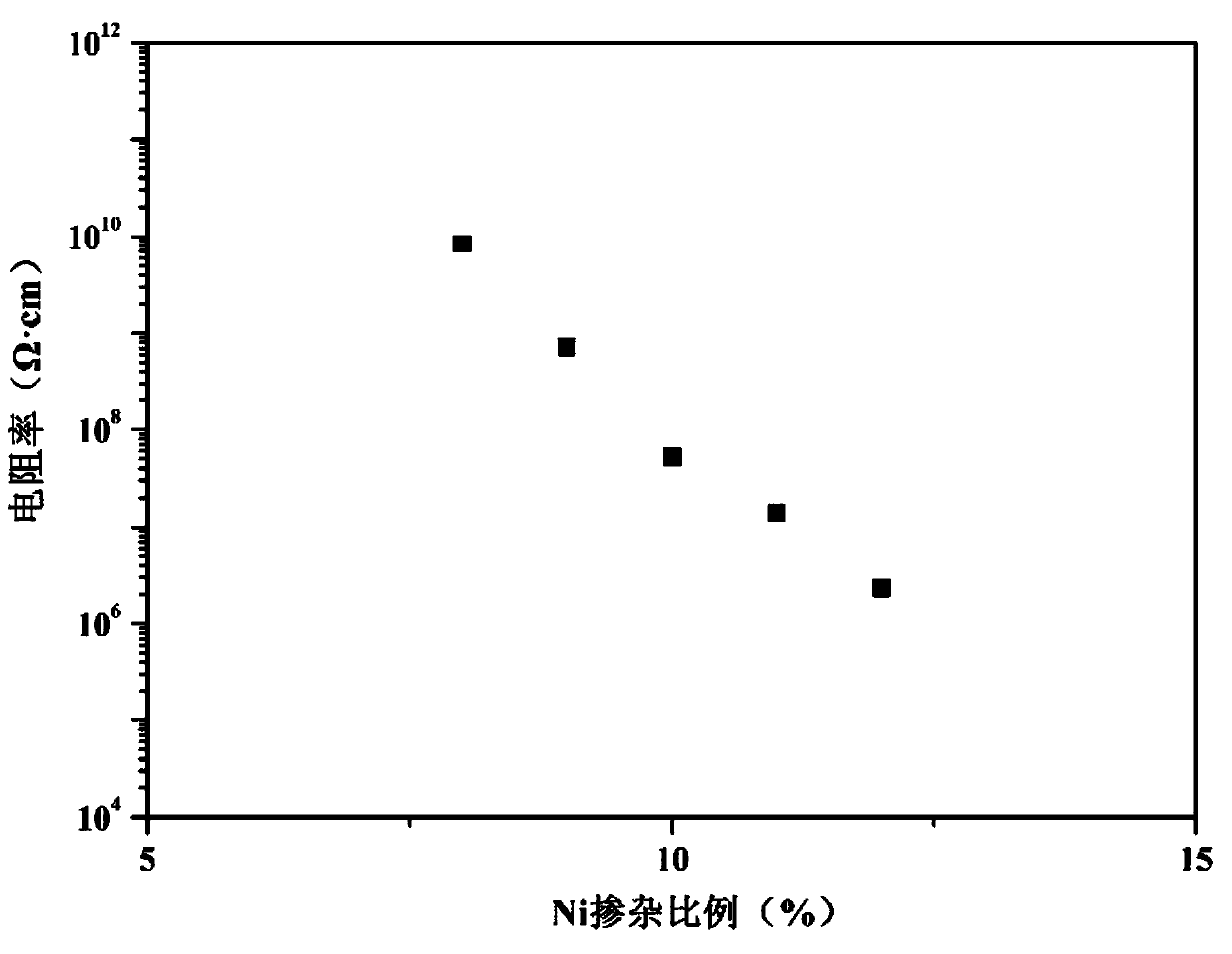

Micro-channel plate and method for preparing Ni-doped Al2O3 high-resistance film on inner wall of micro-channel plate

ActiveCN109182998ASimple processControllable deposition processChemical vapor deposition coatingEngineeringMicrochannel plate detector

The invention relates to a micro-channel plate and a method for preparing a Ni-doped Al2O3 high-resistance film on an inner wall of the micro-channel plate. The Ni-doped Al2O3 high-resistance film isacquired by depositing different component materials on the inner wall of the micro-channel plate through an atomic layer deposition method; when depositing, the deposition times of Al2O3 and Ni are controlled in a great circulation so as to control a Ni-doped ratio, thus the resistivity of the film can be precisely controlled with the range of 106-1010 omega.cm; and the thickness of the film is controlled by controlling the circulation times of the great circulation. The resistivity of the prepared film is basically kept constant in a high temperature working environment or after high temperature annealing; and the technical problem of unstable performance of the micro-channel plate caused by great change of the resistivity of the surface film of the existing micro-channel plate under high temperature conditions is solved.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

Method for improving oxidation resistance of carbon fibers

InactiveCN106436272AEvenly distributedGood shape retentionCarbon fibresUltrasonic/sonic fibre treatmentFiberEcological environment

The invention relates to a method for improving the oxidation resistance of carbon fibers, belonging to the technical field of composite materials. According to the method, aluminum-base functional nano-particles are bonded to the surfaces of the carbon fibers through chemical bonds by virtue of an atomic layer deposition technique so as to form uniform and dense nanometer functional films on the surfaces of the carbon fibers, and the aluminum-base functional nano-films formed on the surfaces of the carbon fibers are uniformly distributed, good in shape maintenance property and controllable in thickness and have relatively good lasting stability, so that the thermal oxidation performance and mechanical stability of the carbon fibers can be effectively improved. An operation method adopted in the improvement of the oxidation resistance of the carbon fibers is simple, a sedimentation process is easy to control, the cost and the energy consumption are low, and the ecological environment is not polluted, so that the method is applicable to the industrial production.

Owner:WUHAN TEXTILE UNIV

Method for preparing compound metal sulfide diamond composite membrane

InactiveCN101550535BReduce coefficient of frictionImprove wear resistanceVacuum evaporation coatingSputtering coatingMetallic sulfideHeat treated

A method for preparing compound metal sulfide diamond composite membrane belongs to the nanometer composite membrane technology field, comprises: polishing, washing and drying the substrate; sputtering the intermediate layer; letting in acetylene gas; and performing composite target sputtering process to metal sulfide. The method of the invention can obtain composite membrane with excellent wear-resisting performance and good wear resistance; and has the advantages of simple preparation technology and easily controlled deposition process. The membrane need no heat treatment after deposited, and can be directly used as wear-resisting protection film on mechanical component surface.

Owner:SHANGHAI JIAOTONG UNIV +1

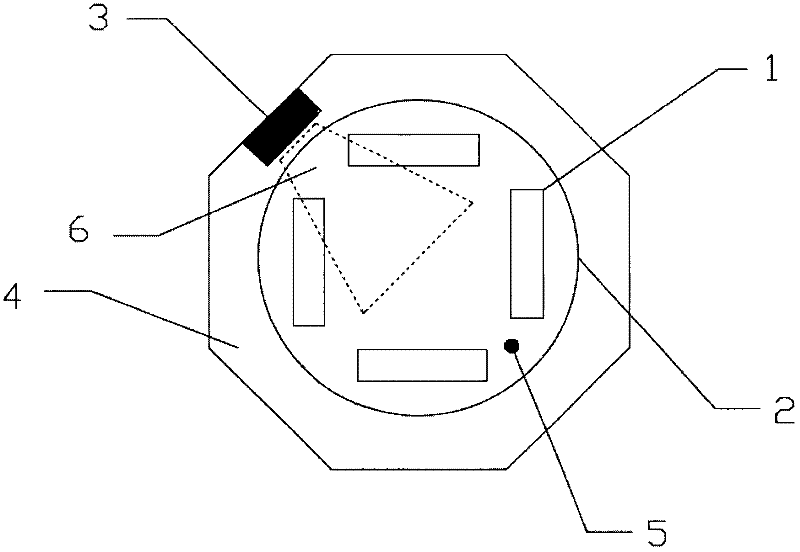

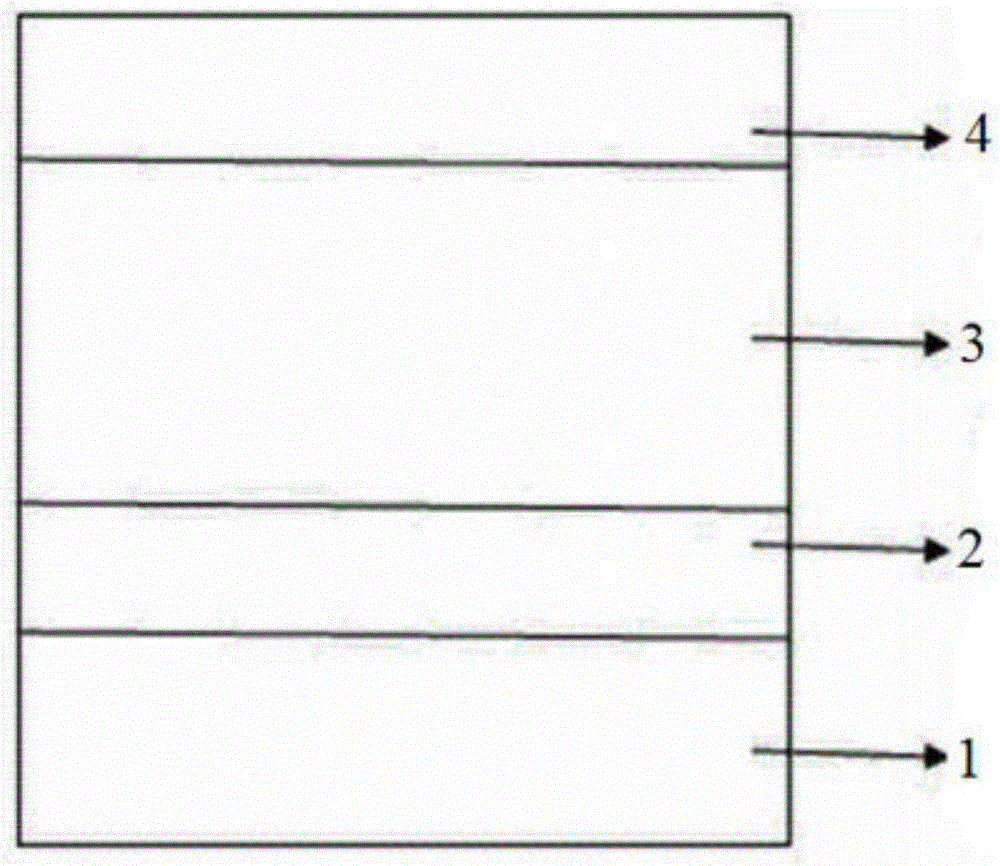

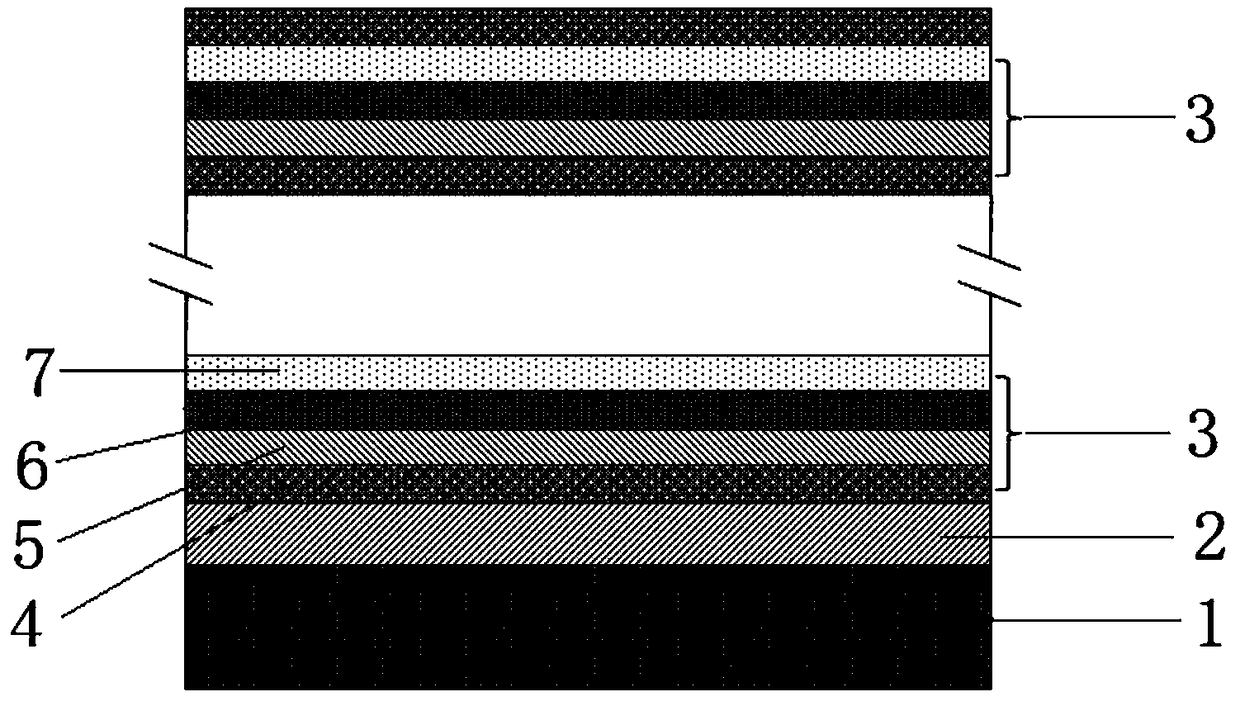

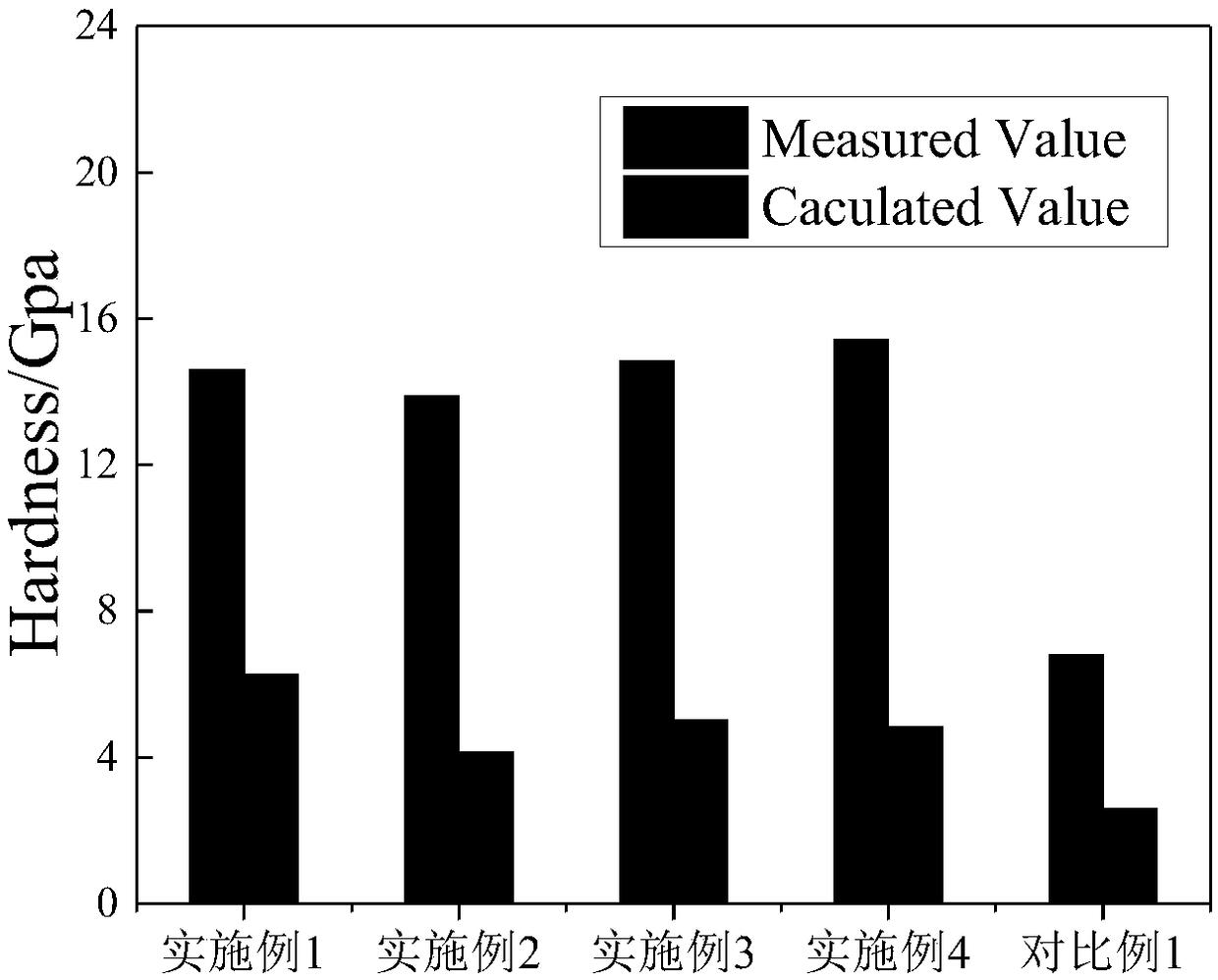

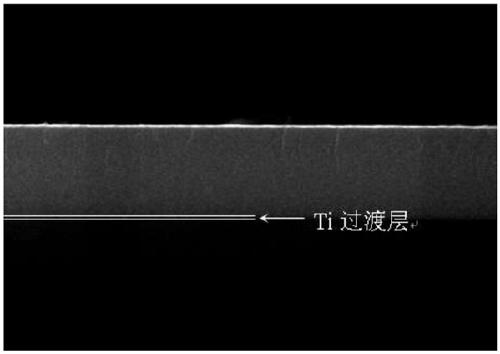

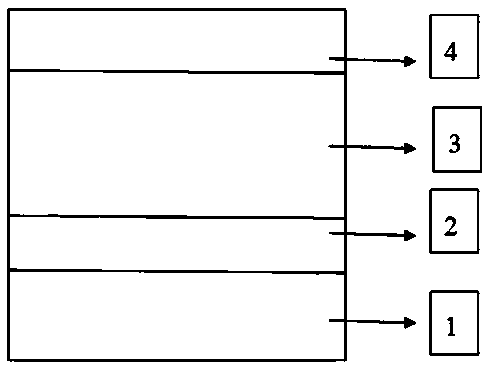

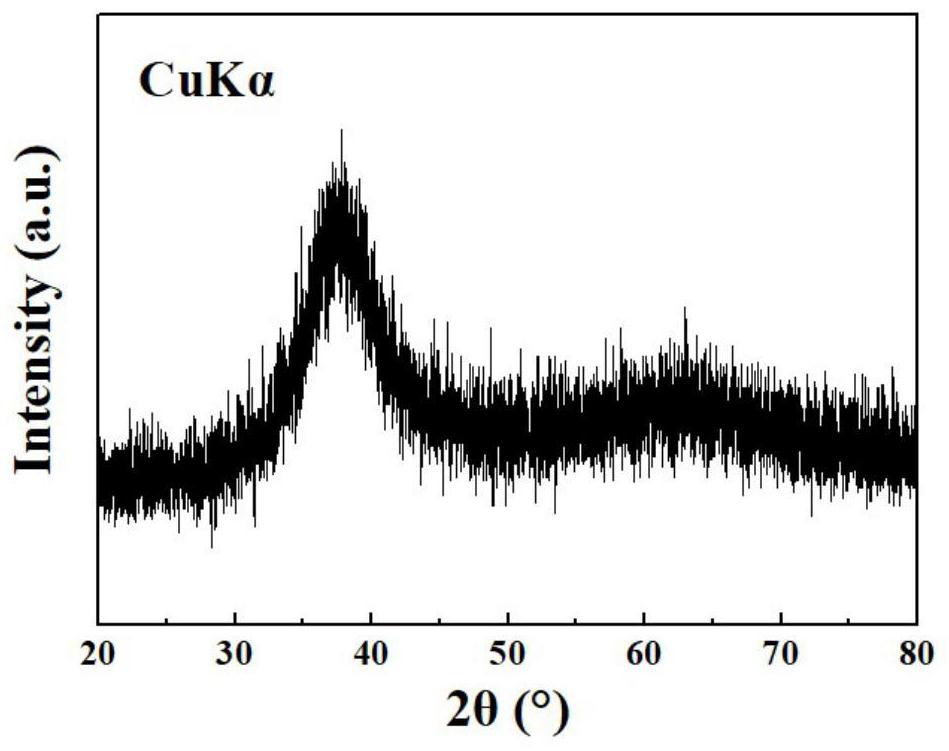

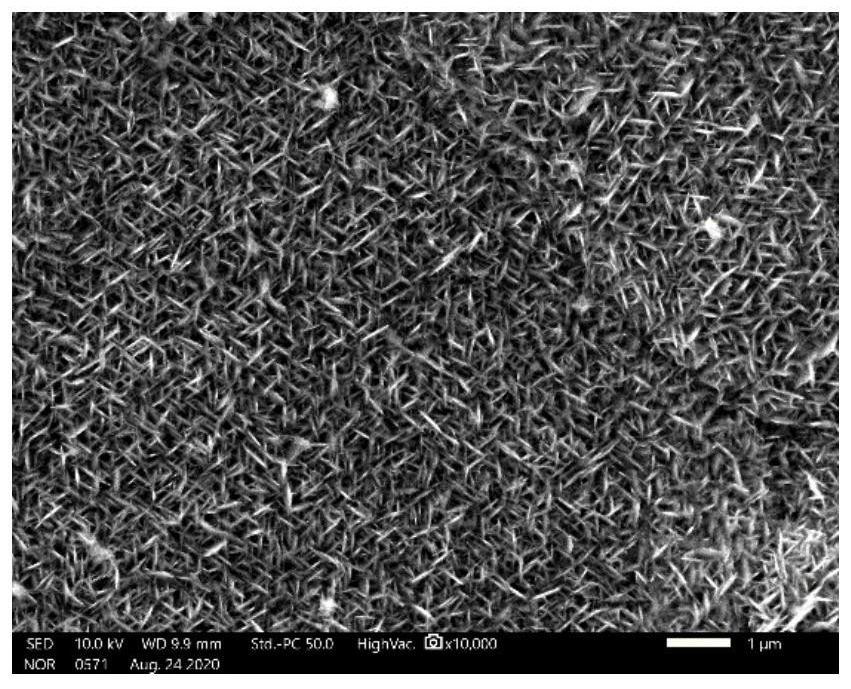

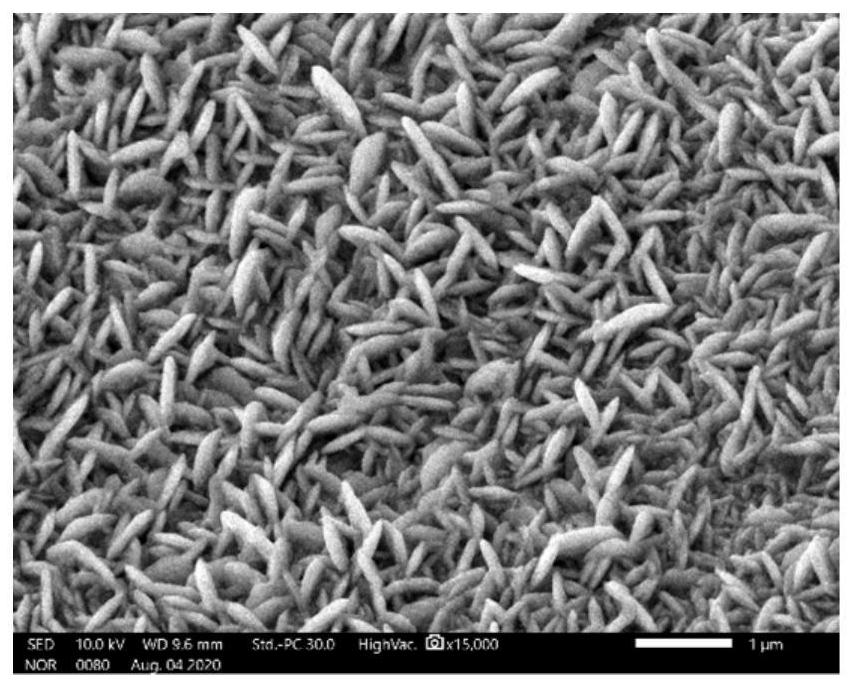

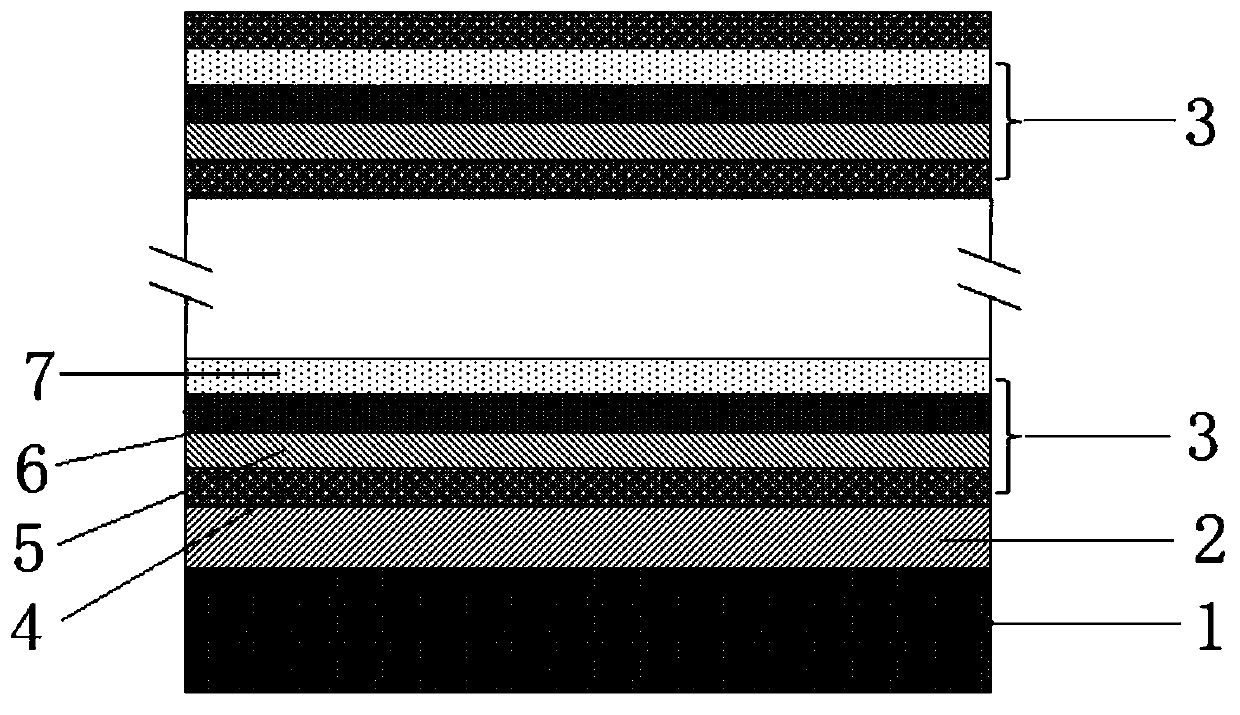

WSx/Me/a-C/Me nanometer multi-layer structure solid lubricating film and preparation method thereof

ActiveCN108977765ASignificant interface strengthening effectSignificant strengthening effectVacuum evaporation coatingSputtering coatingLubricationPollution

The invention relates to the technical field of material frictional wear and solid lubrication, in particular to a WSx / Me / a-C / Me nanometer multi-layer structure solid lubricating film and a preparation method thereof. The solid lubricating film comprises a matrix (1), a metal transition layer (2) and a nanometer multi-layer film (3); the nanometer multi-layer film is of a layered structure formedby a plurality of nanometer composite units; each nanometer composite unit comprises a WSx layer (4), a metal layer (5), an amorphous carbon film layer (6) and a metal sublayer (7); and the materialsof the metal layer and the metal sublayer are identical or different. The solid lubricating film provided by the invention has excellent oxidation resistance, is relatively low in friction coefficient, excellent in carrying capacity and wear resistance, relatively good in combination state with the matrix, long in service life, simple in preparation technology, liable to control deposition process, low in cost and safe in preparation process without pollution, can be applied to lubrication protective films on the surfaces of components and parts in the machinery field and has a wide application prospect.

Owner:ZHEJIANG UNIV OF TECH

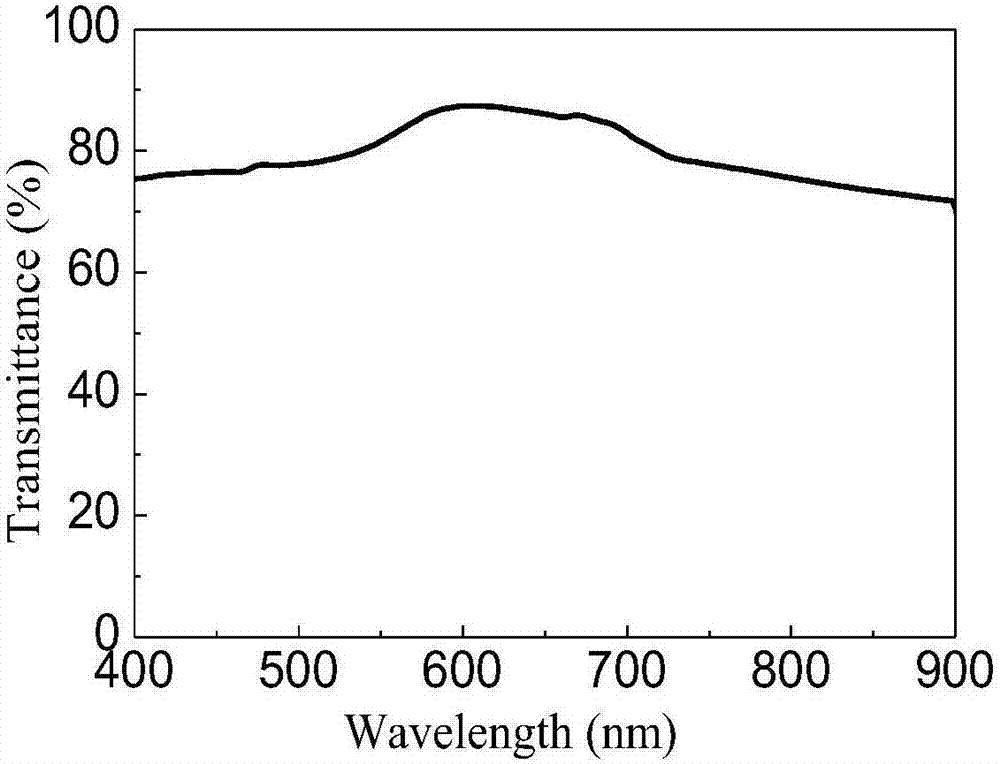

Method for preparing transparent copper thin film conductive electrode through replacement reaction via atomic layer deposition technology

InactiveCN106868470AImprove uniformityImprove photoelectric performanceChemical vapor deposition coatingPhotovoltaic energy generationTectorial membraneTime range

The invention belongs to the technical field of transparent conductive electrode preparing, and relates to a method for preparing a transparent copper thin film conductive electrode through a replacement reaction via an atomic layer deposition technology. The method comprises the steps that firstly, a transparent substrate is subjected to cleaning treatment and then blow-dried through nitrogen; then, two separated protective films are pasted on the surface of the same side of the transparent substrate, the two protective films are symmetrically located at the positions, close to the edge, of the surface of the substrate, a graphical transparent substrate is obtained, and then the graphical transparent substrate is fed into a reaction chamber of atomic layer deposition equipment to carry out growth of a transparent copper thin film; and finally, the transparent substrate and the transparent copper thin film growing on the transparent substrate in a deposition manner are subjected to high-temperature annealing, the annealing temperature ranges from 200 DEG C to 300 DEG C, the annealing time ranges from 20 min to 30 min, and the graphical uniform transparent copper thin film conductive electrode is obtained on the transparent substrate. The transparent copper thin film conductive electrode prepared through the method is good in uniformity and excellent in photoelectric property and can be used for manufacturing solar cells, light-emitting diodes, LCDs, mobile phones and other photoelectric devices.

Owner:JILIN UNIV

Method for preparing Mo-doped Al2O3 high-resistance film by atomic layer deposition

InactiveCN108588680AReduce surface roughnessFlat surfaceChemical vapor deposition coatingHigh resistanceAtomic layer deposition

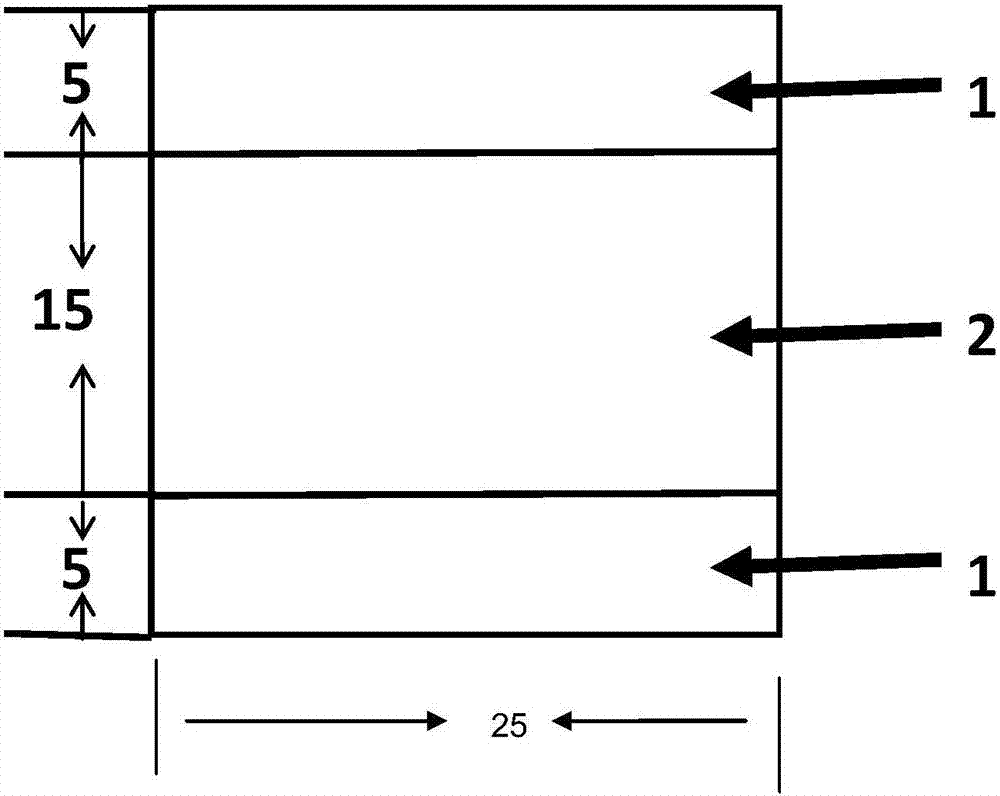

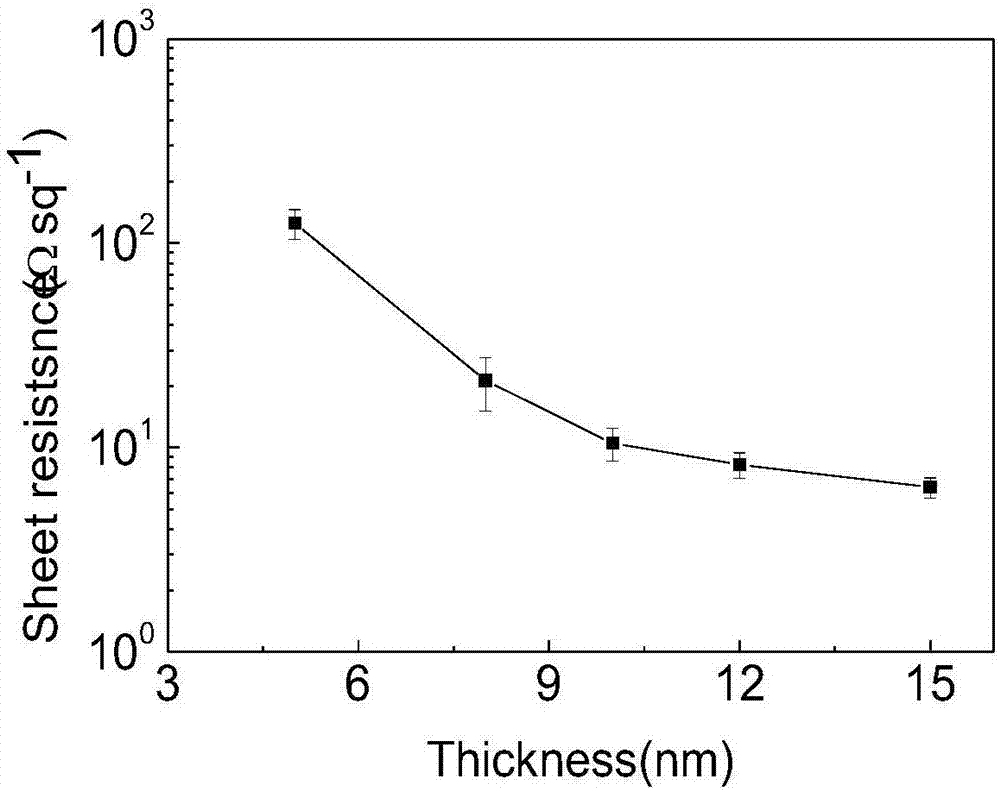

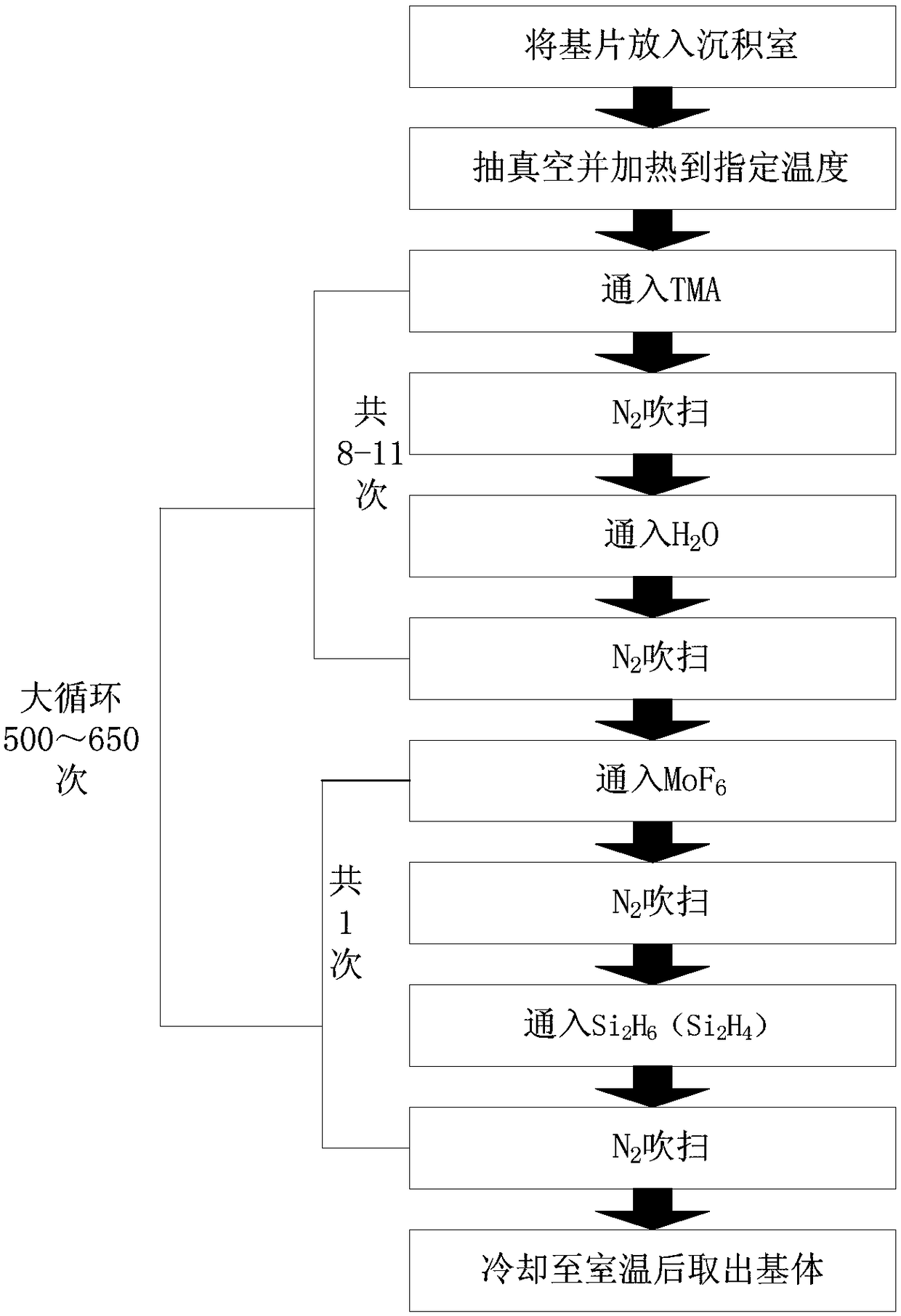

The invention relates to a method for preparing a Mo-doped Al2O3 high-resistance film by atomic layer deposition, and solves the problems of incapability of precisely controlling the film thickness and the mixing ratio, in particular existence of defects on the aspects of control of the film thickness precision reaching the atomic grade and synchronous realization of large-area uniform growth in the prior art. The method comprises the following steps: 1) a basal body is put in a deposition chamber; 2) the deposition chamber is vacuumized; and the basal body is heated; 3) 8-11 times of Al2O3 deposition circulation are performed; and single Al2O3 deposition comprises the following steps: 3.1) a precursor Al source is introduced into the deposition chamber; the Al source is exposed in the deposition chamber by set time; and the deposition chamber is purged; 3.2) a precursor oxygen source is introduced to obtain single-layer Al2O3; and 3.3) the deposition chamber is purged; 4) once Mo deposition is performed: 4.1) a precursor Mo source is introduced in the deposition chamber; and the deposition chamber is purged; 4.2) a reducing agent is introduced to obtain single-layer Mo metal simple substances; and 4.3) the deposition chamber is purged; and 5) the steps 3) and 4) are repeated by multiple times in sequence to obtain the Mo-doped Al2O3 high-resistance film.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

Method for preparing anti-attrition MoS2/C/Ti composite film by magnetron sputtering

InactiveCN101654771BReduce coefficient of frictionReduce the binding forceVacuum evaporation coatingSputtering coatingSputteringComposite film

The invention discloses a method for preparing an anti-attrition MoS2 / C / Ti composite film by magnetron sputtering in the technical field of solid lubrication, comprising the following steps: firstly, polishing a substrate, then ultrasonically washing and drying the substrate, and then packing the substrate in a sputtering chamber; secondly, carrying out pure titanium sputtering and composite layer sputtering in the sputtering chamber, then obtaining the anti-attrition composite film by magnetron sputtering when the sputtering chamber is naturally cooled to the room temperature. The invention has simple process and easily controlled precipitation process; the precipitated film can be directly used as an anti-attrition protection film on the surface of a mechanical part without thermal treatment; and the composite film has the nano hardness of 5.9GPa and the friction coefficient of 0.03.

Owner:SHANGHAI JIAO TONG UNIV +1

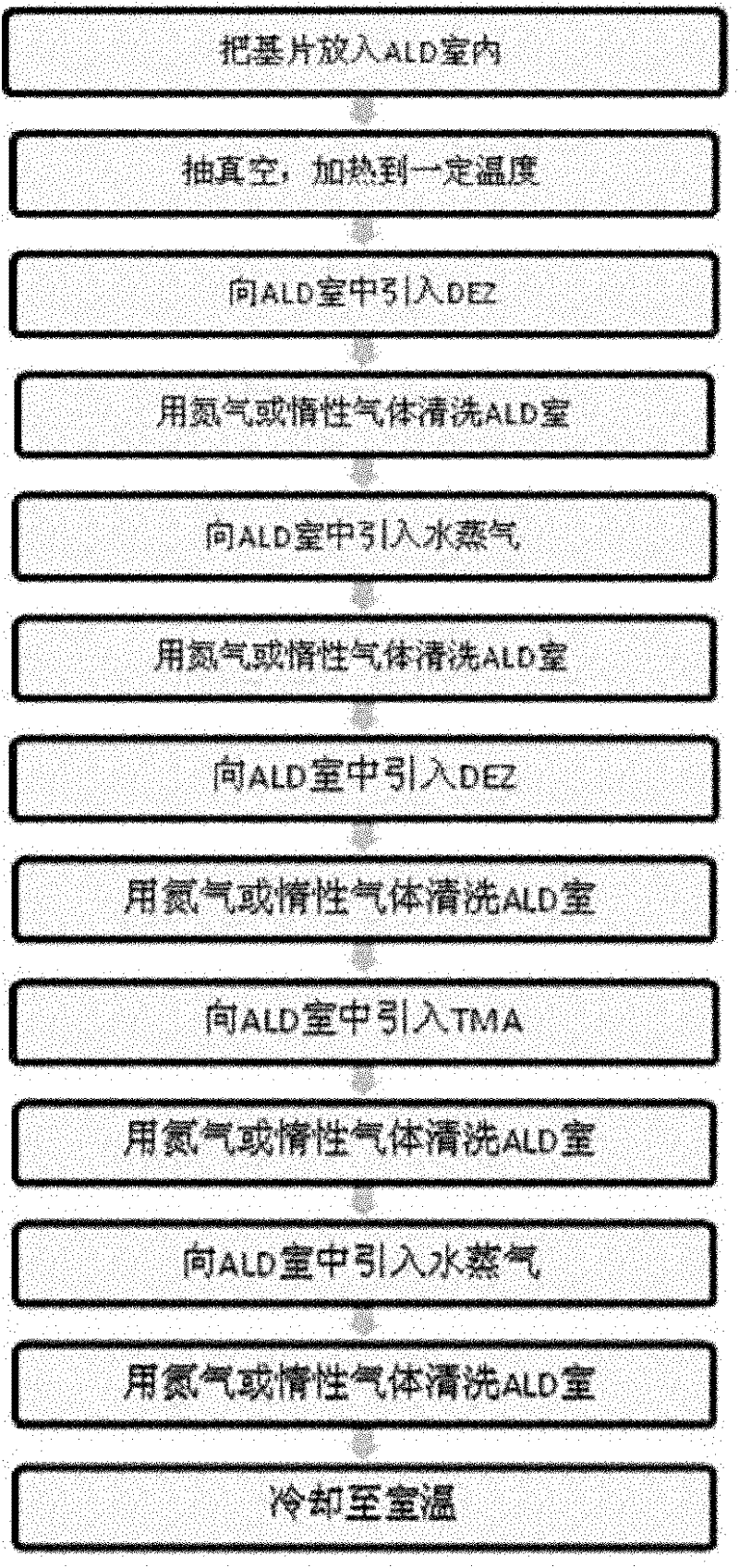

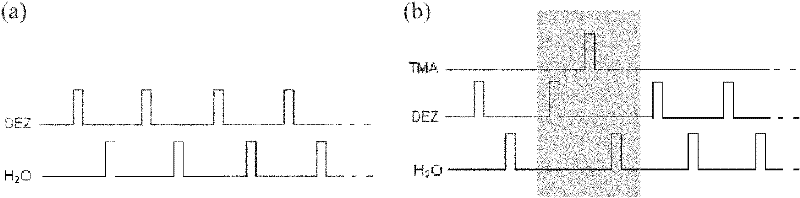

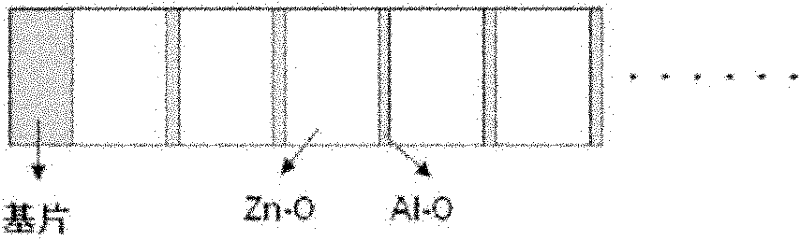

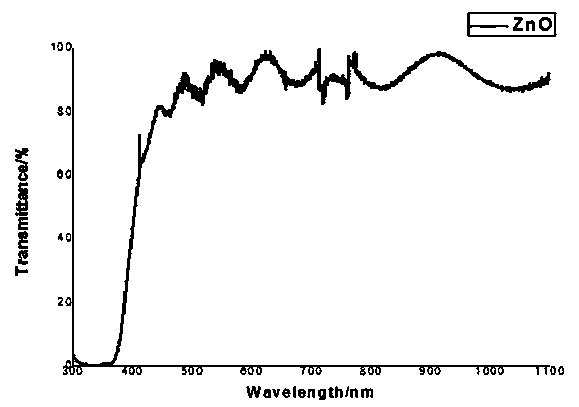

Method for preparing Al-doped ZnO transparent conductive film by atomic layer deposition

InactiveCN102051594BImprove uniformityImprove conductivityChemical vapor deposition coatingTransmittanceAtomic layer deposition

The invention discloses a method for preparing an Al-doped ZnO transparent conductive film by atomic layer deposition in the technical field of photoelectric materials. The method comprises the following steps of: heating a substrate, and then performing multiple groups of composite depositions to obtain the Al-doped ZnO transparent conductive film by atomic layer deposition, wherein each group of composite deposition consists of multiple ZnO depositions and Al-doped deposition. The transparent conductive film prepared by the method has excellent uniformity, good electric conductivity, low resistivity reaching 7.2*10<-4>cm and high visible light transmittance reaching over 90 percent.

Owner:SHANGHAI JIAO TONG UNIV +1

Manufacturing technology of foam metal plate for radiator fin

InactiveCN107541756AQuality improvementEasy to adjust pressureElectroforming processesMetal formingManufacturing technology

The invention discloses a manufacturing technology of a foam metal plate for a radiator fin. The manufacturing technology includes the steps that thermoplastic conducting plastics are made into the foam plate, and the foam plate is bent into the fin; the foam plate serves as a cathode, metal forming the foam metal plate serves as an anode, and the cathode and the anode are soaked into a solution containing metal positive ions of the foam metal plate; the cathode and the anode are connected with a power source, and the power source is connected with a voltage regulation circuit; the voltage size is changed in real time according to the required foam metal deposition speed, and the metal can be deposited; and the thermoplastic conducting plastics in the foam plate are removed through sintering. The manufacturing technology is flexible and ingenious, and the deposition technology and a conducting plastic skeleton are combined; and moreover, the voltage regulating circuit is used for leading the deposition speed, the obtained foam metal plate is in a fin form, and using is made convenient.

Owner:太仓市华天冲压五金制品厂

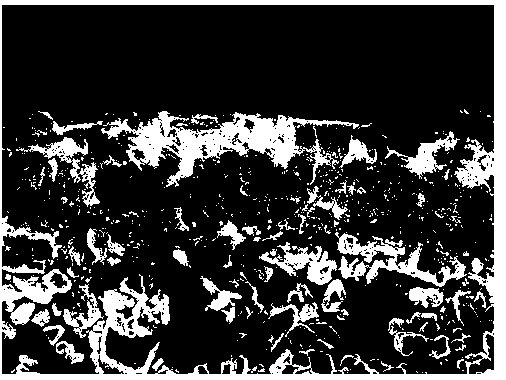

A method for preparing copper-indium-gallium-sulfur solar cell thin film material after electrodeposition by bipotential step method

ActiveCN105226117BGood lookingShape is easy to controlPhotovoltaic energy generationSemiconductor devicesThin film morphologyIndium

The invention discloses a sulfide annealing copper indium gallium sulfur solar cell thin film material preparation method after double-potential step method electrodeposition. The method comprises the steps that copper and gallium metal salt is used as a main raw material; the main raw material is dissolved in an ionic liquid at a certain concentration; a copper gallium precursor thin film is prepared on ITO conductive glass through double-potential cycle step method electrodeposition; sulfide annealing is carried out on the precursor thin film; in the annealing process, indium in the ITO conductive layer diffuses into the thin film; and finally a copper indium gallium sulfur thin film is generated. Compared with a traditional constant potential deposition technology, the method provided by the invention has the advantages that by controlling double potential pulse potential, controllable preparation of the crystalline phase, the composition, the morphology and the like of the thin film can be realized; pore structures are reduced; the thin film morphology is improved; the plating rate is improved; and hydrogen evolution reaction does not produce any adverse effect on the thin film in the deposition process. Compared with a high-vacuum vapor phase method, the method provided by the invention has the advantages of good film quality, low cost, high controllability and the like.

Owner:XIANGTAN UNIV

Method of preparing antifriction I1F-WS2/IF-MoS2 composite film by magnetic controlled sputtering

InactiveCN100387750CImprove carrying capacityImprove wear resistanceVacuum evaporation coatingSputtering coatingHigh resistanceComposite film

A process for preparing an antifriction IF-WS2 / IF-MoS2 film features that under the proper technological parameters, the IF-WS2 and IF-MoS2 are used for co-sputtering to obtain said antifriction film. Its advantages are low friction coefficient, high resistance to moisture, oxidizing and wearing, and high adhesion to substrate.

Owner:SHANGHAI JIAOTONG UNIV

Deposition method of Cu/ZnO/Al photoelectric transparent conducting film

ActiveCN103014705BIncrease concentrationImprove conductivityFinal product manufactureSuperimposed coating processNitrogen gasOmega

The invention relates to a deposition method of a Cu / ZnO / Al photoelectric transparent conducting film, belonging to the field of transparent conducting materials. The method comprises the following steps: (1) sequentially carrying out ultrasonic cleaning on a substrate with acetone, ethanol and deionized water, blow-drying with nitrogen gas, and sending the substrate into a reaction chamber; (2) depositing a magnetron sputtering Al film; (3) preparing a middle-layer ZnO film by organic substance chemical vapor deposition; (4) depositing a magnetron sputtering Cu film; and (5) carrying out high-temperature annealing on the Cu / ZnO / Al multilayer-structure transparent conducting film at 100-400 DEG C for 30 minutes to obtain the Cu / Al-codoped ZnO photoelectric transparent conducting film. The preparation technique is simple, and the deposition process is easy to control. The transparent conducting film has the advantages of favorable uniformity, excellent photoelectric properties and low resistivity (down to 8.0*10<-4>Omega.cm), and the light transmittance is up to higher than 82%. The transparent conducting film can be used for manufacturing transparent electrodes of photoelectric devices, such as solar cells, light-emitting diodes, LCDs (liquid crystal displays), mobile phones and the like.

Owner:辽宁普天能源发电集团亿峰新能源科技有限公司

A preparation method of an aptamer sensor for detecting antibiotic residues

InactiveCN103837588BLarge specific surface areaImprove stabilityMaterial electrochemical variablesCarbon nanotubePhysical chemistry

The invention discloses a preparation method of an aptamer sensor for detecting antibiotic residue, belonging to the technical field of safety test of agricultural products. The method comprises the steps of carrying out electrochemical polymerization on a gold electrode and thionine to obtain electrically polymerized thionine electrode; after that, evenly dripping the prepared carbon nano tube-graphene nano-composition onto the surface of the electrically polymerized thionine electrode; drying in the air, and then soaking the electrode into antibiotic aptamer solution; washing, drying in the air, and closing by bull serum albumin (BSA) solution to obtain the antibiotic aptamer sensor. The prepared aptamer sensor has the advantages of not needing pretreatment, being high in analysis speed, simple in an operation system, high in accuracy, high in specificity, low in cost, rapid in response and the like, and has the limit of detection reaching up to 0.8nm, thus being suitable for rapidly detecting the antibiotic residue.

Owner:SHANDONG UNIV OF TECH

Method for preparing ZnO/Al film on solar cell without introduced electrode

ActiveCN103022255AQuality improvementImprove conductivityFinal product manufactureSemiconductor devicesMetallic electrodeSolar cell

The invention belongs to the field of novel transparent conducting materials and particularly relates to a method for preparing ZnO / Al film on a solar cell without an introduced electrode. The solar cell without the introduced electrode is used as a substrate, cleaned before being sent into a magnetron sputtering reaction chamber, pure Al is used as target for magnetron sputtering to obtain an Al film 20-300 nanometers in thickness, the substrate is then placed in a vapor deposition chamber, oxygen and with argon with Zn(CH2CH3)2 are fed into the vapor deposition chamber, a ZnO film 50-600 nanometers in thickness is obtained after deposition, and at last, under oxygen atmosphere, annealing treatment is performed to the substrate with the ZnO film and the Al film at 400-600 DEG C to obtain the ZnO / Al film. The method has the advantages that the preparation process is simple, the deposition is easy to control, the prepared transparent conducting film has good uniformity and excellent photoelectric performance, the transparent conducting film is used as back electrode of the solar cell to replace the traditional aluminum electrodes, and conversion efficiency of the solar cell is further improved.

Owner:SHENYANG INST OF ENG

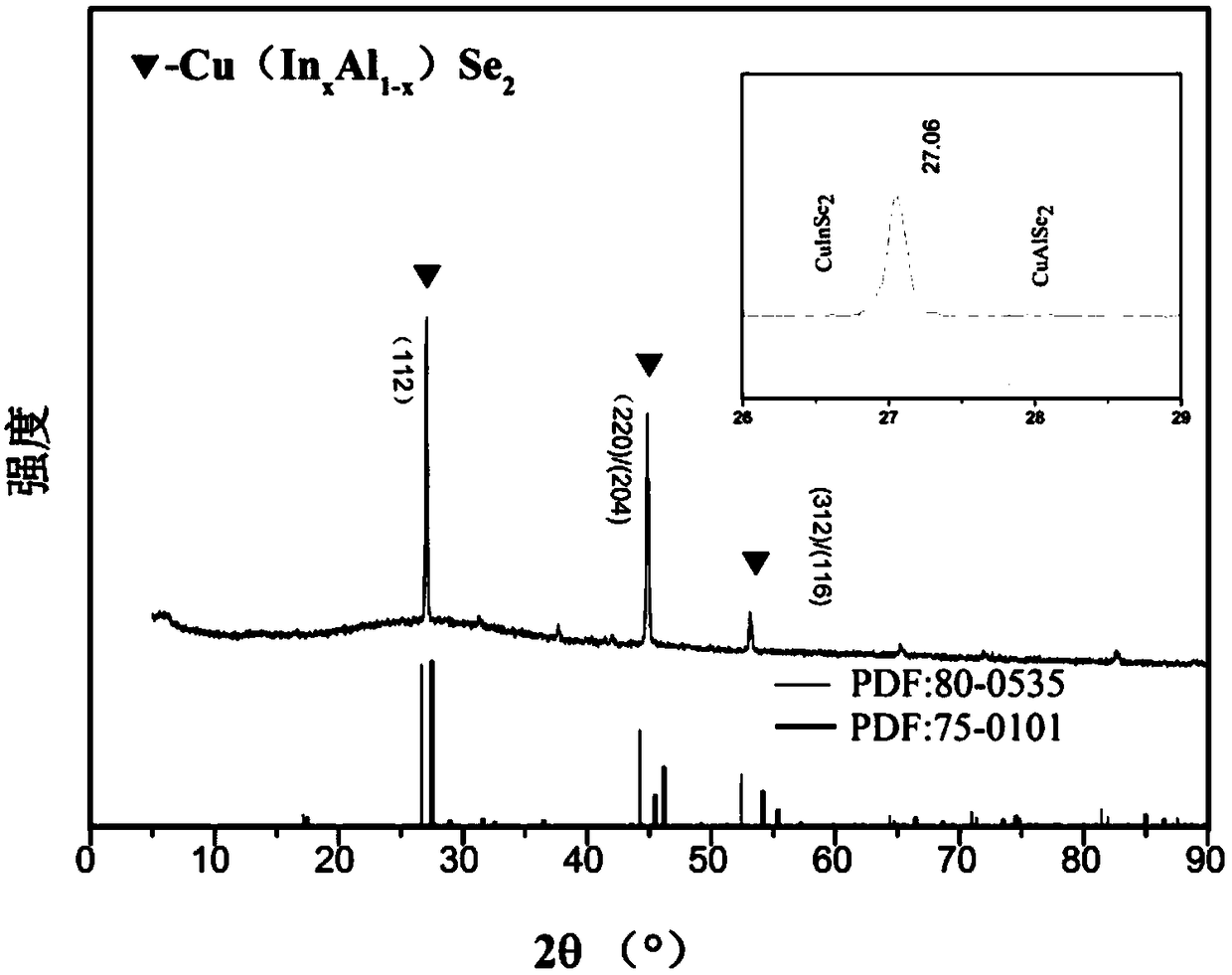

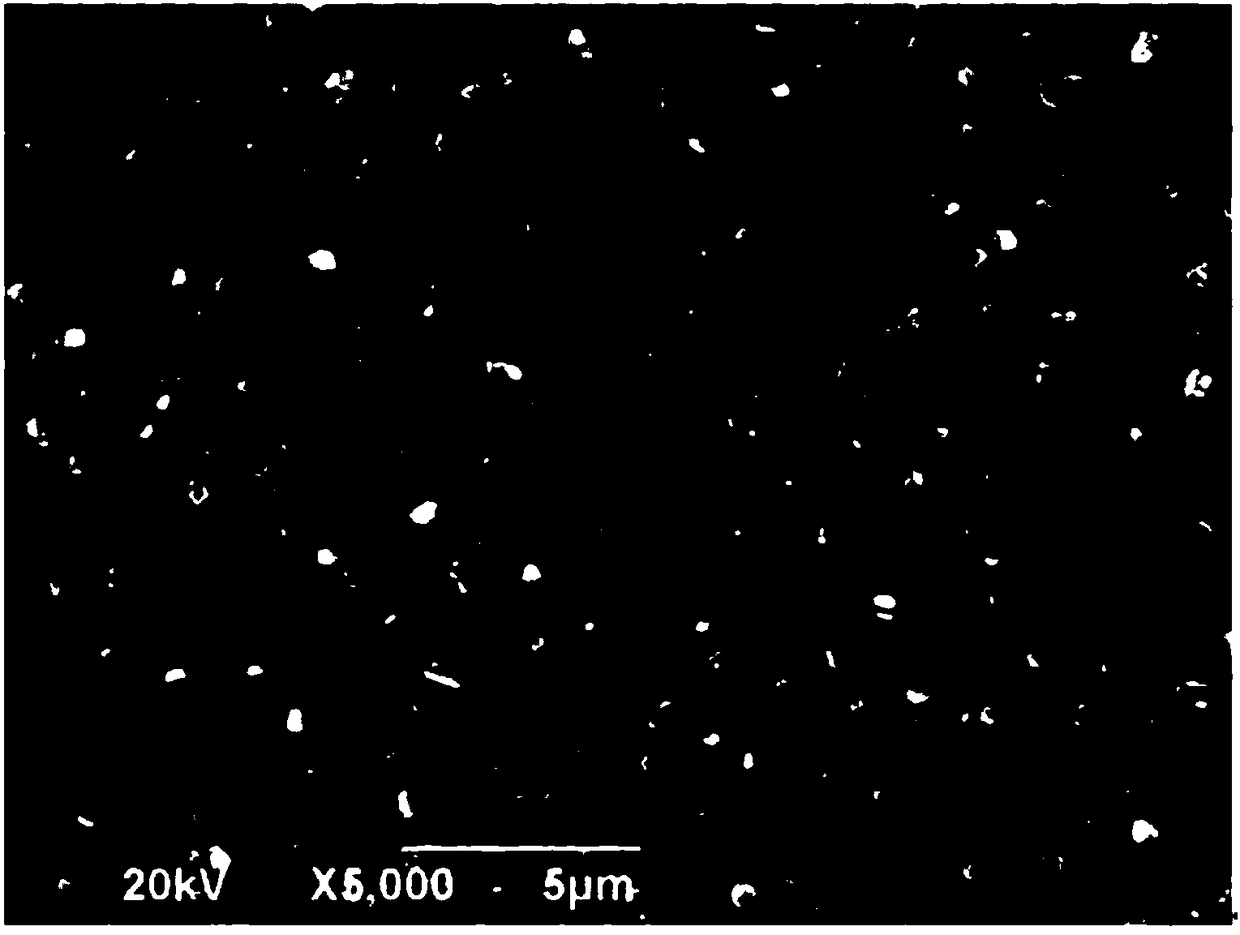

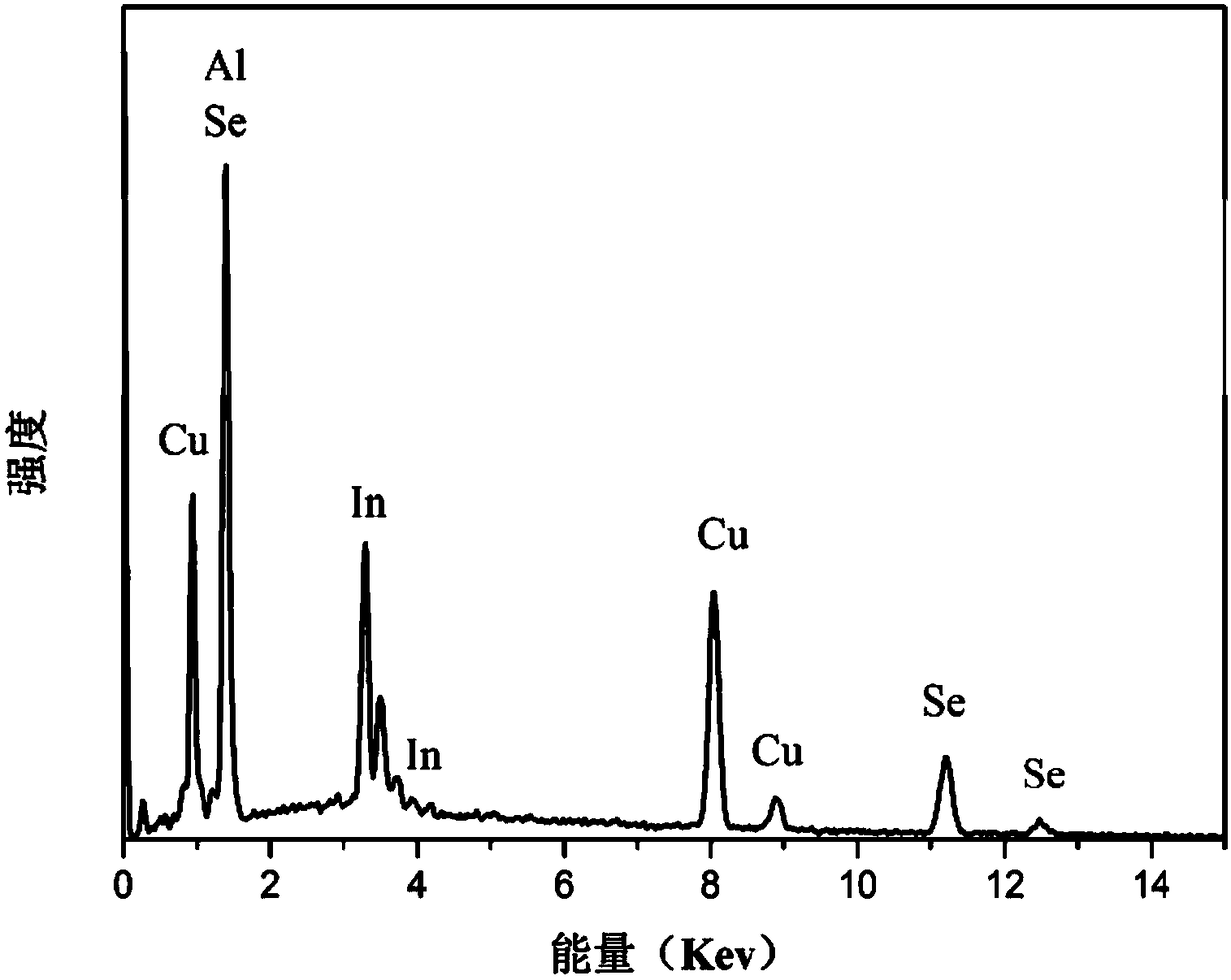

Method of preparing copper indium aluminum selenium solar cell film materials through selenized annealing after layered electrodeposition

ActiveCN108538934AEliminate the effects of hydrogen evolutionHigh purityPhotovoltaic energy generationSemiconductor devicesFilm materialIndium

The invention discloses a method of preparing copper indium aluminum selenium solar cell film materials through selenized annealing after layered electrodeposition. In order to overcome the hydrogen evolution phenomenon in an aqueous solution, caused by electrodeposition of aluminum, the method of preparing copper indium aluminum selenium solar cell film materials through selenized annealing afterlayered electrodeposition deposits an aluminum thin film by means of a fuse salt electrodeposition method, then dissolves the copper metal salt in deionized water, electrodeposits copper on the aluminized film, dissolves indium metal salt in the deionized water, electrodeposits indium on the aluminized / copper-plated film, and then selenizes and anneals the precursor film to obtain a copper indiumaluminum selenium film. The method of preparing copper indium aluminum selenium solar cell film materials through selenized annealing after layered electrodeposition can realize controllable preparation of film compositions, crystal structure, morphology, and the like by means of layered control of the deposition current density and time of each layer of film. Compared with an electrodeposition method in one-step aqueous solution, the film prepared by the method of preparing copper indium aluminum selenium solar cell film materials through selenized annealing after layered electrodeposition has higher purity and does not have CuxSey or InxSey binary phase. Compared with a high vacuum method, the method of preparing copper indium aluminum selenium solar cell film materials through selenized annealing after layered electrodeposition has high controllability, simple preparation process, high utilization rate of raw materials, low cost, and high repeatability, and is easy to achieve preparation of films with large area and high quality.

Owner:XIANGTAN UNIV

A kind of lead silicate glass microchannel plate and the method for preparing Ni-doped Al2O3 high-resistance film on the inner wall of microchannel plate

ActiveCN109182998BImprove performanceStrong adhesionChemical vapor deposition coatingHigh resistanceWorking environment

The invention relates to a micro-channel plate and a method for preparing a Ni-doped Al2O3 high-resistance film on an inner wall of the micro-channel plate. The Ni-doped Al2O3 high-resistance film isacquired by depositing different component materials on the inner wall of the micro-channel plate through an atomic layer deposition method; when depositing, the deposition times of Al2O3 and Ni are controlled in a great circulation so as to control a Ni-doped ratio, thus the resistivity of the film can be precisely controlled with the range of 106-1010 omega.cm; and the thickness of the film is controlled by controlling the circulation times of the great circulation. The resistivity of the prepared film is basically kept constant in a high temperature working environment or after high temperature annealing; and the technical problem of unstable performance of the micro-channel plate caused by great change of the resistivity of the surface film of the existing micro-channel plate under high temperature conditions is solved.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

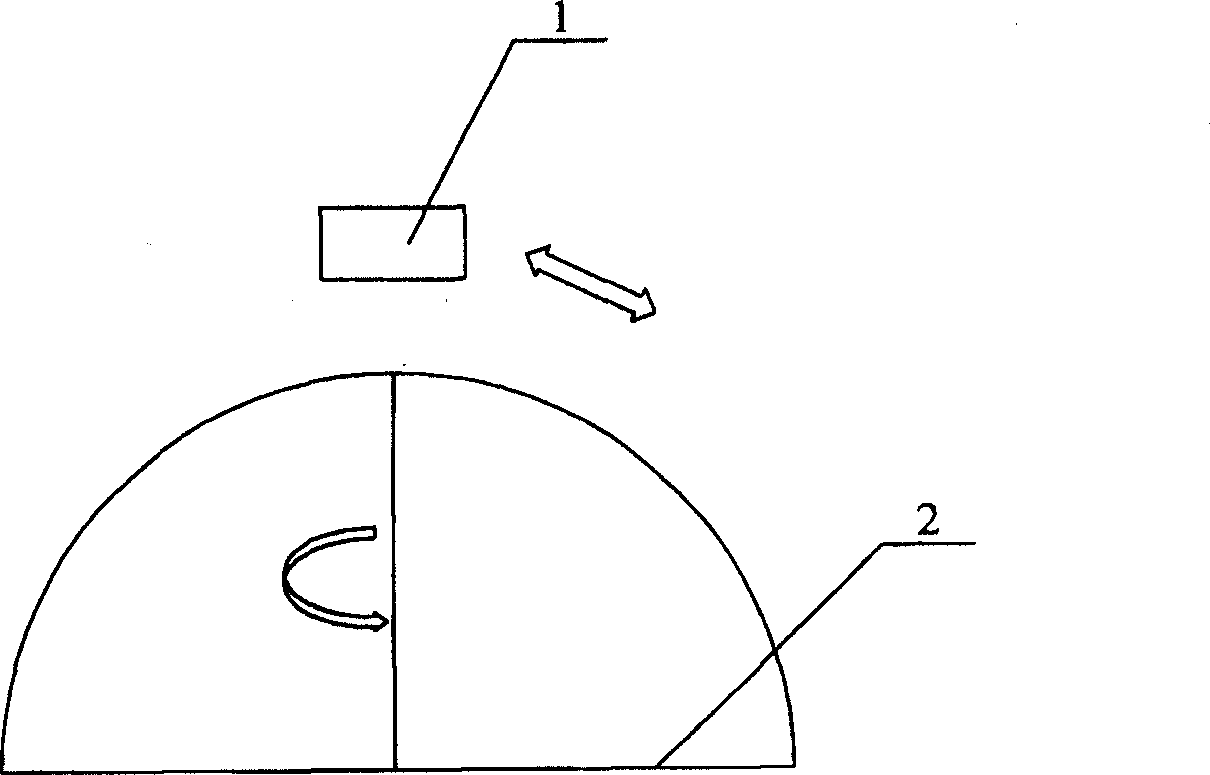

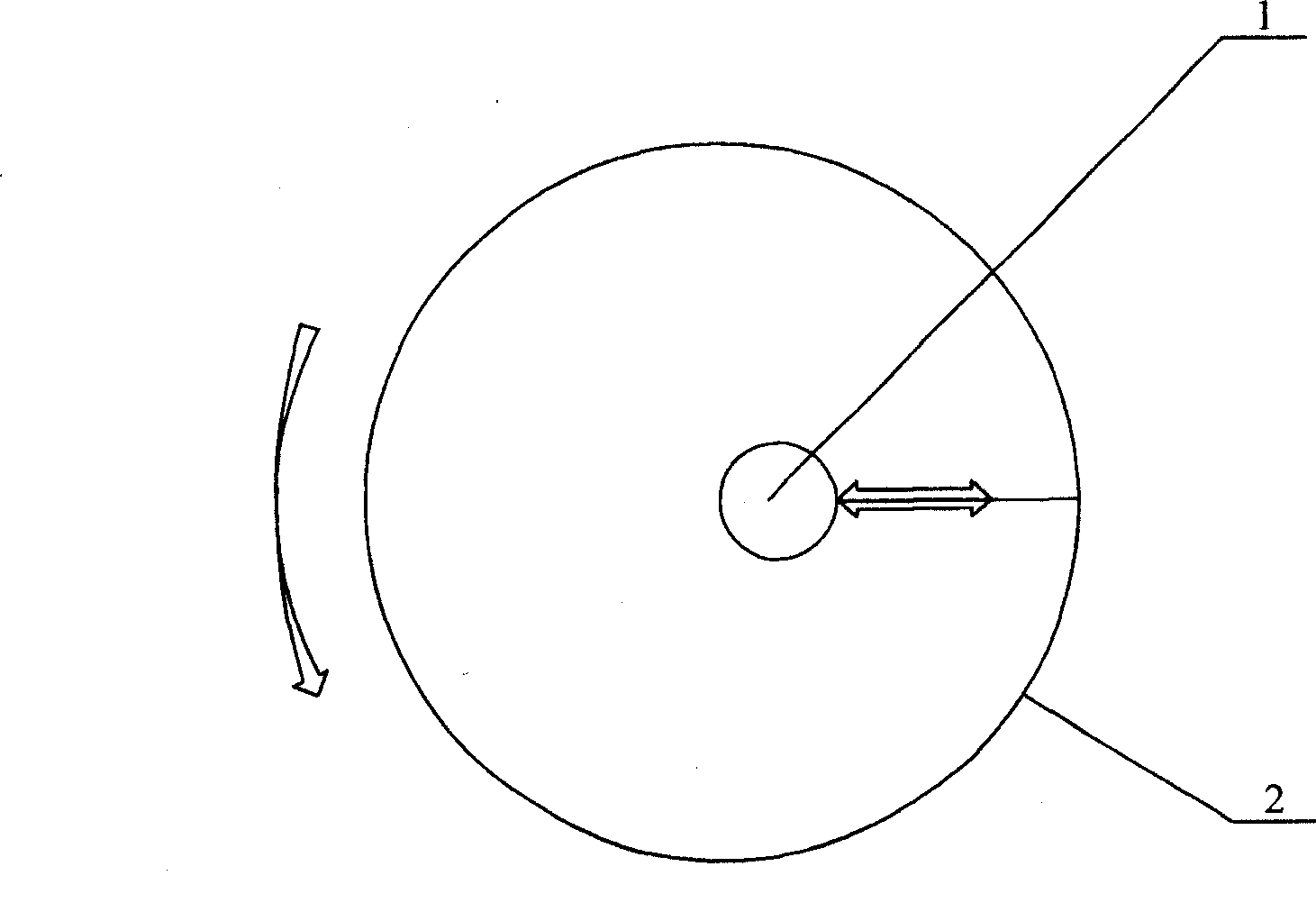

Method for preparing magnetron sputtering hemisphere film

InactiveCN100480419CFixedUniform natureVacuum evaporation coatingSputtering coatingWorking temperatureEngineering

Owner:HARBIN INST OF TECH

Method for preparing nano material by electrodeposition based on corrosion of amorphous alloy anode material

PendingCN114192749AEasy to controlAvoid poor electrode conductivityCellsMaterial nanotechnologyGalvanic depositionCorrosion

The invention discloses a method for preparing a nano-structure material by electrodeposition based on corrosion of an amorphous alloy anode material, and the preparation method comprises the following steps: proportioning metal elementary substances according to a target alloy ZraAlbCocMd, and smelting to obtain a master alloy; wherein a is larger than or equal to 55 at.% and smaller than or equal to 56 at.%, b is larger than or equal to 13 at.% and smaller than or equal to 20 at.%, c is larger than or equal to 20 at.% and smaller than or equal to 28 at.%, d is larger than or equal to 0 at.% and smaller than or equal to 5 at.%, and M is any one of Nb, Cu, Ag and Ni metal elements; the obtained mother alloy is treated through a single-roller melt-spinning quenching method, so that a ZraAlbCocMd amorphous alloy strip is obtained; and in a standard three-electrode system, the obtained ZraAlbCocMd amorphous alloy strip is used as a working electrode, a target deposition substrate is used as a counter electrode, the ZraAlbCocMd amorphous alloy strip is corroded through a constant potential polarization method, and the required nano-structure material is deposited on the counter electrode. The method provided by the invention is more beneficial to reaction stability, the deposition process is easier to control, and a uniform nano-structure material can be directly deposited on the substrate.

Owner:NANJING UNIV OF SCI & TECH

a ws x /me/a-c/me nanometer multilayer structure solid lubricating film and preparation method thereof

ActiveCN108977765BImprove antioxidant capacityLow friction factorVacuum evaporation coatingSputtering coatingOxidation resistantDeposition process

The invention relates to the technical field of material frictional wear and solid lubrication, in particular to a WSx / Me / a-C / Me nanometer multi-layer structure solid lubricating film and a preparation method thereof. The solid lubricating film comprises a matrix (1), a metal transition layer (2) and a nanometer multi-layer film (3); the nanometer multi-layer film is of a layered structure formedby a plurality of nanometer composite units; each nanometer composite unit comprises a WSx layer (4), a metal layer (5), an amorphous carbon film layer (6) and a metal sublayer (7); and the materialsof the metal layer and the metal sublayer are identical or different. The solid lubricating film provided by the invention has excellent oxidation resistance, is relatively low in friction coefficient, excellent in carrying capacity and wear resistance, relatively good in combination state with the matrix, long in service life, simple in preparation technology, liable to control deposition process, low in cost and safe in preparation process without pollution, can be applied to lubrication protective films on the surfaces of components and parts in the machinery field and has a wide application prospect.

Owner:ZHEJIANG UNIV OF TECH

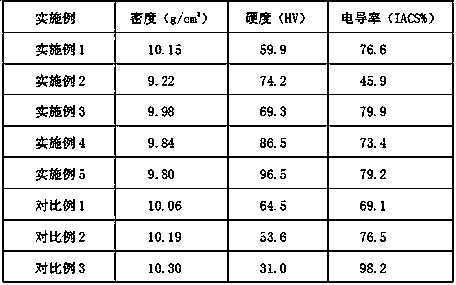

A kind of preparation method of nickel-plated graphene/silver-nickel electric contact material

The invention relates to a preparation method of a nickel-plated graphene / silver-nickel electrical contact material. The preparation method comprises the following steps: performing direct-current magnetron sputtering and nickel plating of graphene, ball-milling and mixing nickel-plated graphene, silver powder and nickel powder, cold pressing and forming, sintering, and processing and forming, wherein the material comprises 0.1-5.0 wt% of nickel-plated graphene, 10-40 wt% of nickel powder and the rest of silver powder ball-milled mixed powder. A nickel-plated graphene reinforcing body is added into the silver powder and the nickel powder, such that the hardness, the abrasive resistance and the melting-welding resistance of silver are improved while the electrical conductivity and the thermal conductivity of the electrical contact material prepared by the invention are not decreased.

Owner:UNIV OF JINAN

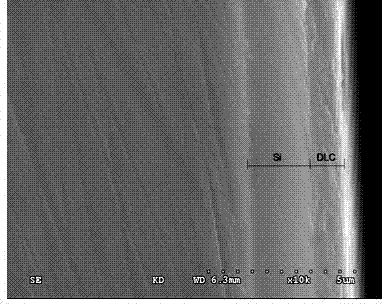

Method for preparing high-hardness diamond film on surface of medical CoCrMo alloy

InactiveCN101967626BHigh hardnessImprove stabilityChemical vapor deposition coatingSputter cleaningPolymer science

The invention discloses a method for preparing a high-hardness diamond film on the surface of medical cobalt-chrome-molybdenum (CoCrMo) alloy. The method comprises the following steps of: performing sputter-cleaning on polished and cleaned CoCrMo alloy by using hydrogen (H2) gas; depositing a silicon (Si) film transition layer on the surface of the CoCrMo alloy by taking silicane (SiH4) and hydrogen (H2) as a gas source by the conventional radio frequency plasma-enhanced chemical vapor deposition; and preparing a diamond like carbon (DLC) film on the Si film transition layer by taking methane(CH4) and hydrogen (H2) as a gas source by the conventional radio frequency plasma-enhanced chemical vapor deposition. Film bases prepared by the method are combined in a saw-toothed mode, good combination performance is represented between the film bases, and the defect of low boundary bearing capacity caused by low combination performance is overcome; meanwhile, the sp3C bond content of prepared DLC film is high, the DLC film with high hardness can be obtained and the wear resistance of the DLC film is effectively improved. In addition, the method has the advantages of simple process and low cost and has great application potential in the technical field of surface modification of a biomaterial.

Owner:CHINA UNIV OF MINING & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com